Preparation method of membrane electrode and preparation method of membrane electrode anode catalytic layer

A membrane electrode and catalytic layer technology, applied in the field of proton exchange membrane fuel cells, can solve the problems of deviation from the life curve, increase the cost and plasticity of fuel cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

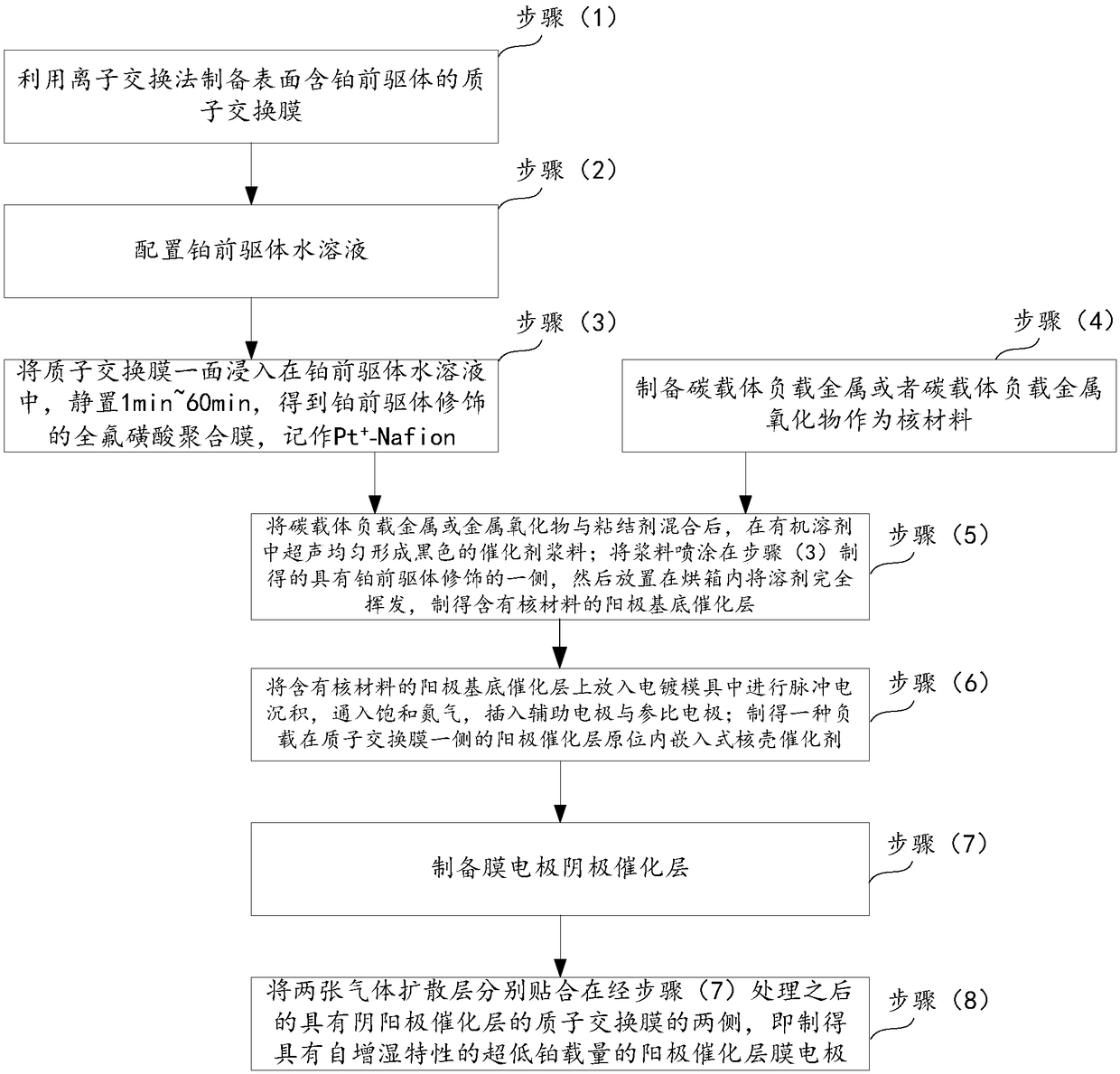

[0089] see figure 1 , figure 1 Disclosed in one embodiment of the present invention, the flow process of the preparation method of membrane electrode (may be aimed at proton exchange membrane fuel cell membrane electrode), please refer to figure 1 , in one embodiment of the present invention, the preparation method of membrane electrode comprises the following steps:

[0090] (1) Prepare the proton exchange membrane with platinum precursor on the surface by ion exchange method: first cut the proton exchange membrane into a size of 2.5×2.5cm, soak it in dilute sulfuric acid and hydrogen peroxide in turn, and then rinse it with distilled water; the proton exchange membrane is Perfluorosulfonic polymer membrane;

[0091] (2) configuring an aqueous solution of a platinum precursor of 5 mmol / L to 100 mmol / L, the platinum precursor being platinum dichlorotetramine;

[0092] (3) Immerse one side of the proton exchange membrane treated in step (1) in the solution obtained in step (...

Embodiment 1

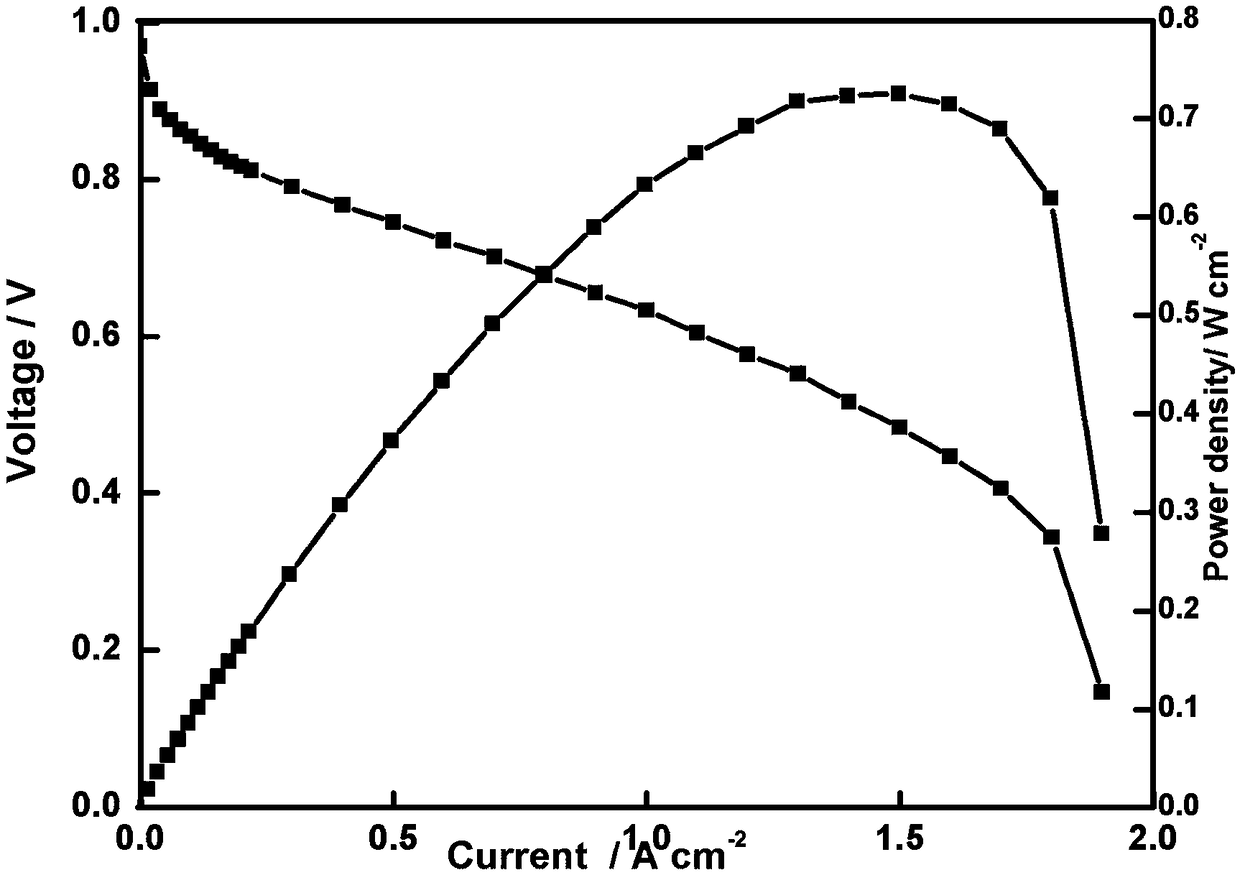

[0129] Example 1: Ru@Pt / C catalyst embedded in the anode catalyst layer

[0130] (1) Preparation of Pt by ion exchange + -Nafion

[0131] (A) Take a Nafion212 proton exchange membrane of 2.5cm×2.5cm, put it into a hydrogen peroxide solution with a concentration of 5% and treat it at 80°C for 3 hours, rinse it with deionized water, and place it in a 0.5M sulfuric acid solution Continue to treat at 80°C for 3 hours, and finally rinse with deionization, and put it into a beaker for storage until use.

[0132] (B) Gently spread the Nafion membrane treated in step (A) on the surface of the 5mM dichlorotetramine platinum solution, make one side of the membrane fully contact the solution, and after standing for 5min, take out the Nafion membrane and clean it to obtain Pt + -Nafion.

[0133] (2) Preparation of Ru / C substrate catalyst layer

[0134] (A) Toner XC-72R pretreatment:

[0135] Add 10g Vulcan XC-72R carbon powder into a 1L beaker, then add 600mL acetone, stir at room te...

Embodiment 2

[0157] Example 2: Pd@Pt / C catalyst embedded in the anode catalyst layer

[0158] Preparation method is except that following points are different, other is with embodiment 1

[0159] (1) Adopt palladium chloride instead of ruthenium trichloride.

[0160] (2) Palladium chloride needs to be dissolved with concentrated hydrochloric acid.

[0161] (3) The hydrogen reduction temperature is 120°C for 3 hours.

[0162] (4) The performance test and characterization of the membrane electrode are the same as the step (7) of Example 1. The single-cell discharge performance of this electrode meter is very excellent. Under the conditions of 100% humidification of the cathode and anode respectively, and the battery temperature is 70°C, the current density at 0.7V voltage can reach 700mAcm -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com