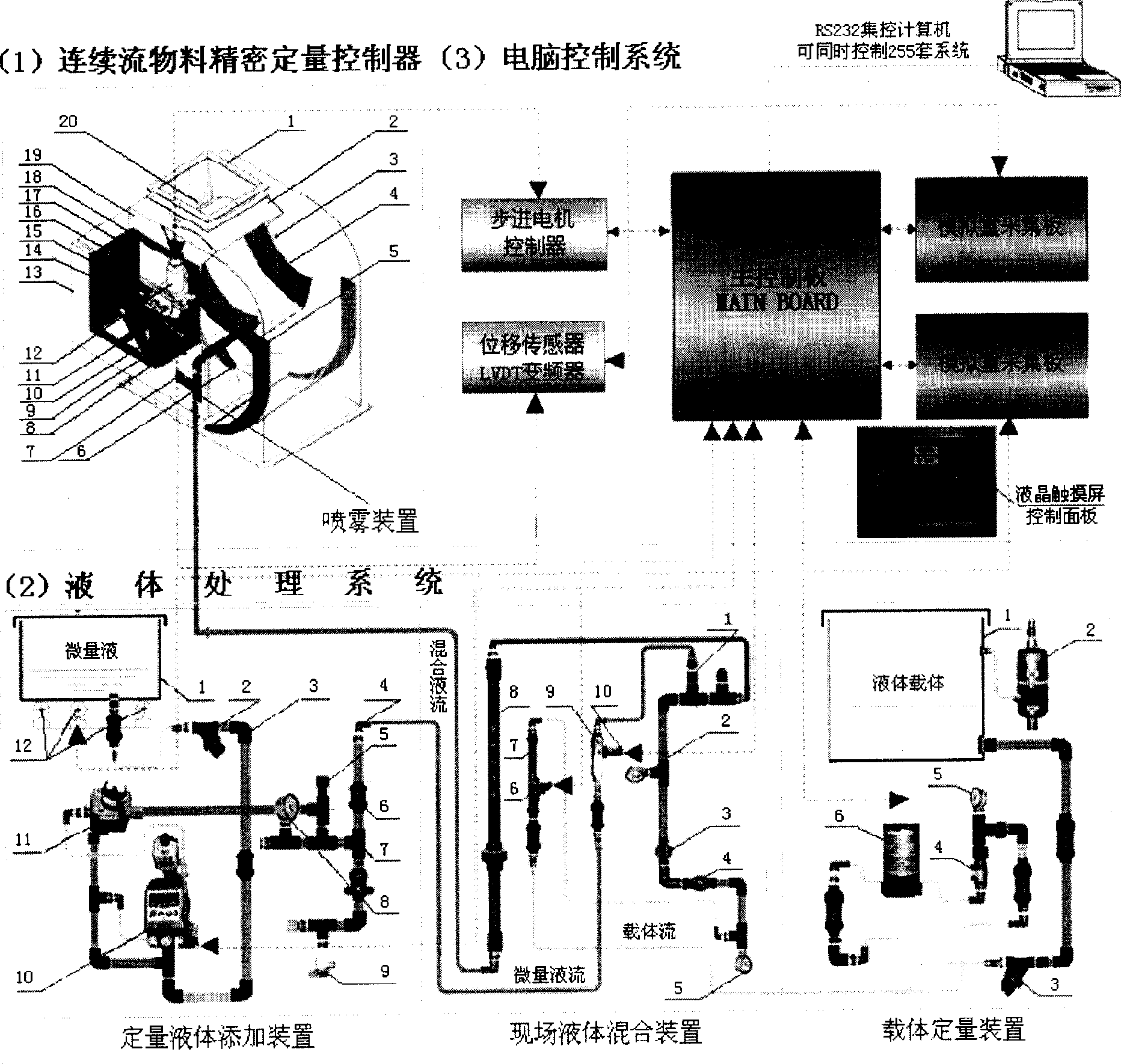

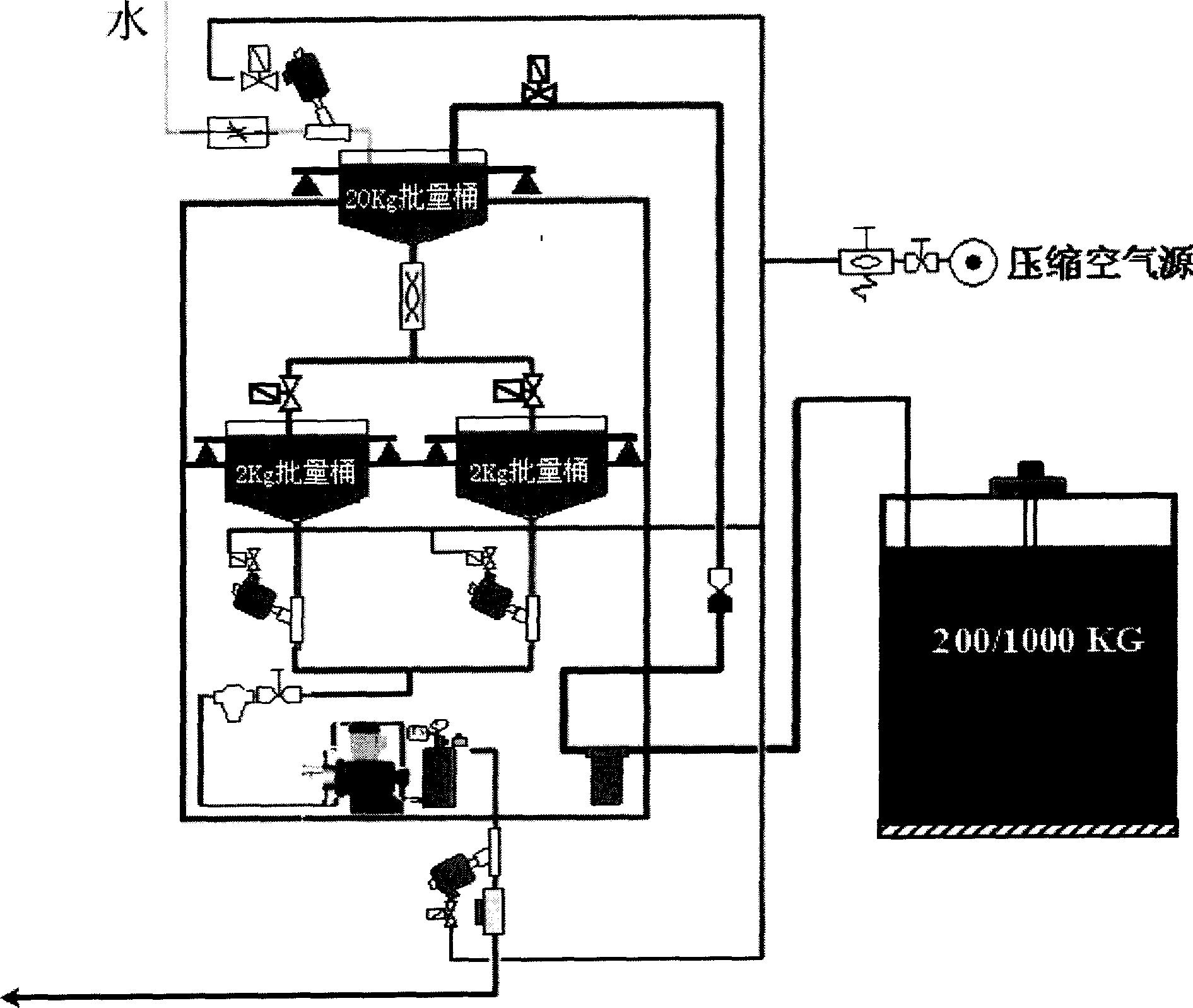

Proportionate dosing post pelleting liquid application (PPLA) system

A dynamic and liquid technology, applied in the direction of liquid injection devices, injection devices, mixer accessories, etc., can solve the problems of low reading pulse frequency, inaccurate measurement, pulse signal distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] Energy conversion mechanism: After the potential energy of the small particle material 20 under the action of gravity passes through the energy absorbing chute 4, the displacement generated by the impulse is transmitted by the long axis 3, and is converted into an elastic energy conversion device - a horizontal square balance frame. The potential energy produces a linearly scaled horizontal displacement, and the equivalent value of the horizontal displacement is transmitted to the flow detection mechanism and can be measured by the precision displacement sensor LVDT.

[0039] Flow detection mechanism: the displacement output by the energy conversion mechanism is transmitted to the precision displacement sensor (LVDT) 10 fixed by the displacement sensor holder 9 by the equivalent value of the displacement transmission bracket 11 and measured in real time. The measured displacement value is passed through A in the form of current. The / D conversion board is composed of con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com