Moulding method for slag pot structure

A slag pot and molding technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of low precision, unsightly appearance, and high cost, and achieve the effects of high precision, less man-hours, and fewer connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] (1) The slag tank adopts an inverted shape (the dome is upward), scrape out the ground level, place a shaft scraper on the ground level, and use the scraper shape method to scrape out the inner cavity contour.

[0016] (2) Form an isolation layer on the surface of the scraped inner cavity contour by brushing paint, padding waste paper, etc., to prevent sand from sticking.

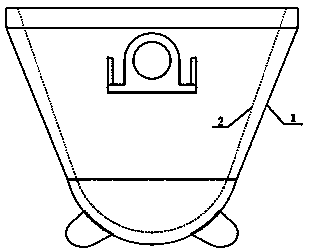

[0017] (3) Continue to use the scraper to scrape out the outline of the outer surface of the slag tank (excluding lifting lugs) outside the isolation layer on the inner cavity outline surface, that is, figure 1 , so that both sides 1 and 2 are scraped out with a scraper.

[0018] (4) Also form an isolation layer on the outer contour by brushing paint, padding waste paper, etc.

[0019] (5) Lower the sand core forming the trunnion seat on the periphery, lower the lifting lug (the lifting lug of this slag tank is a forging), and place a sand box on the periphery, place runners, risers, etc. according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com