Tiny particle conveying device and method based on hollow melt-embedded core capillary optical fiber

A technology for tiny particles and conveying devices, applied in the optical field, can solve the problems of single method and inflexible operation, and achieve the effect of strong operability and small device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

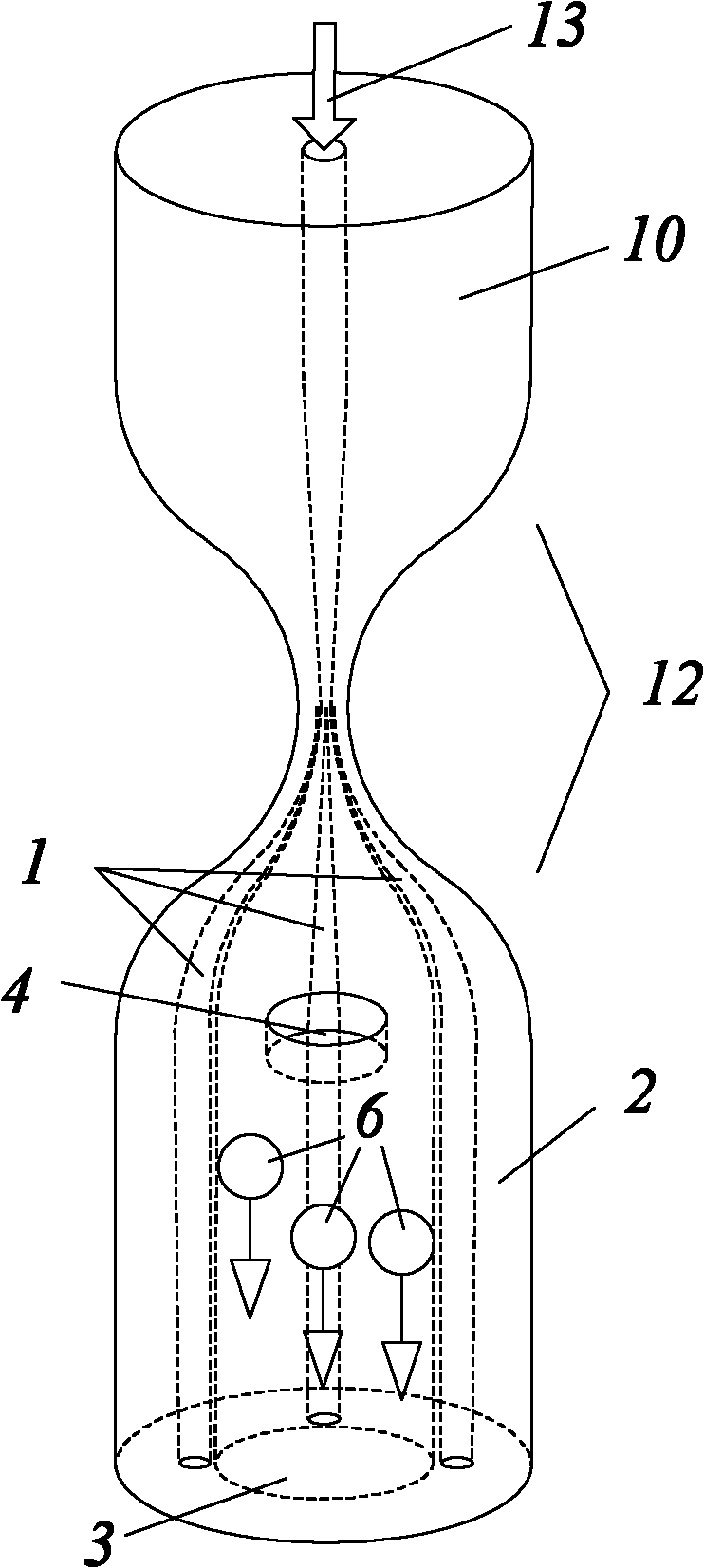

[0032] 1. Coupling connection: Take a section of single-core hollow fused-core capillary optical fiber, remove and cut the coating layer of the optical fiber at one end, and then align and weld it with the single-mode optical fiber 10 with light source pigtail; Figure 6 The shown solder joint 11 is heated to a softened state, then tapered, and the optical power is monitored until the optical power coupled to the single-core hollow fused-core capillary fiber reaches the maximum;

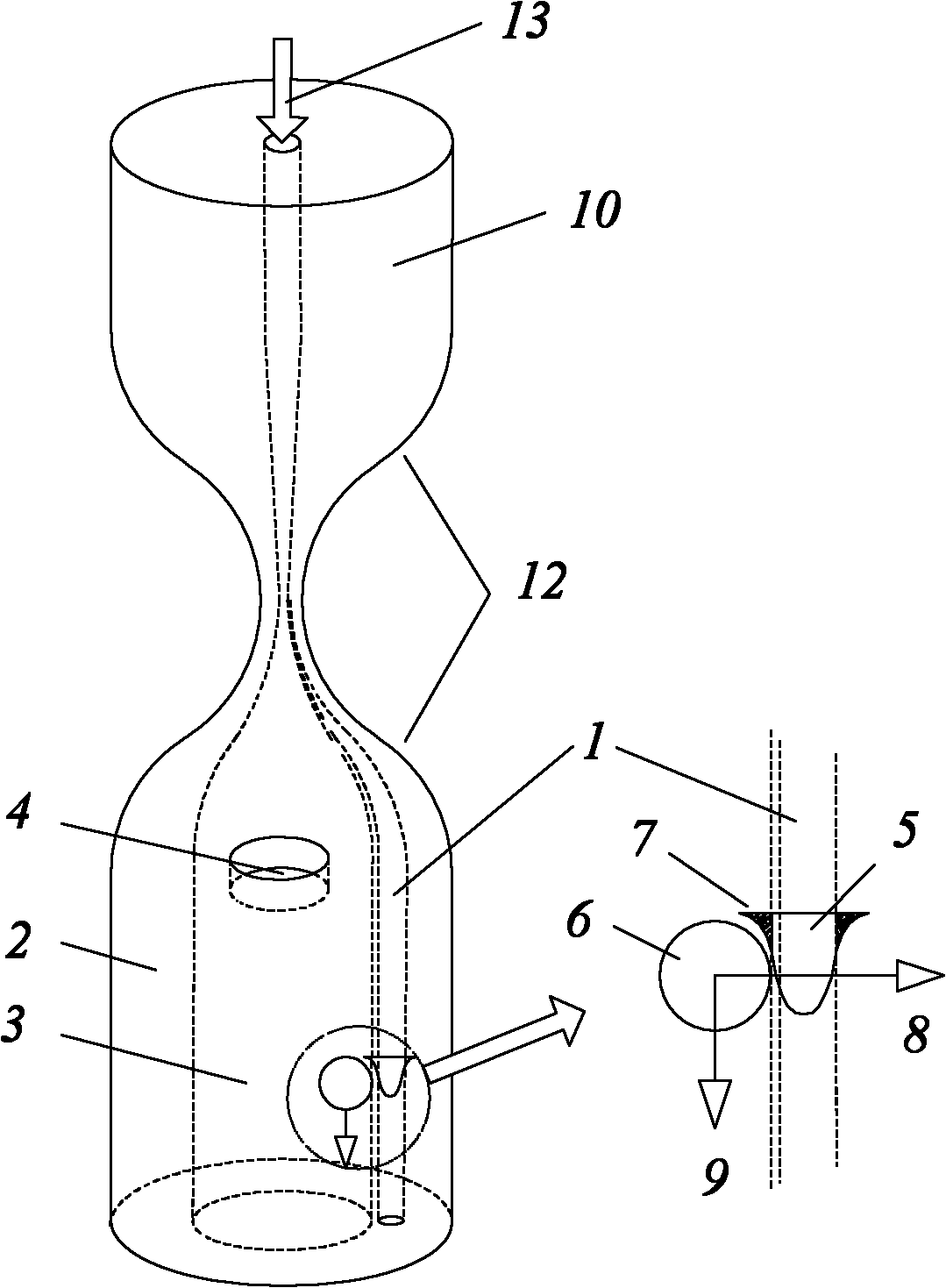

[0033] 2. Encapsulation protection: adjust the quartz tube with an inner diameter larger than the standard optical fiber or single-core hollow fused capillary single-core optical fiber to figure 1 Shown at the cone coupling zone 12, then at both ends of the quartz tube with CO 2 The laser is heated, welded and sealed, or encapsulated and cured with epoxy resin, and then secondly coated to complete the overall protection;

[0034]3. Small hole processing: In the middle of the single-core hollow fused...

Embodiment 2

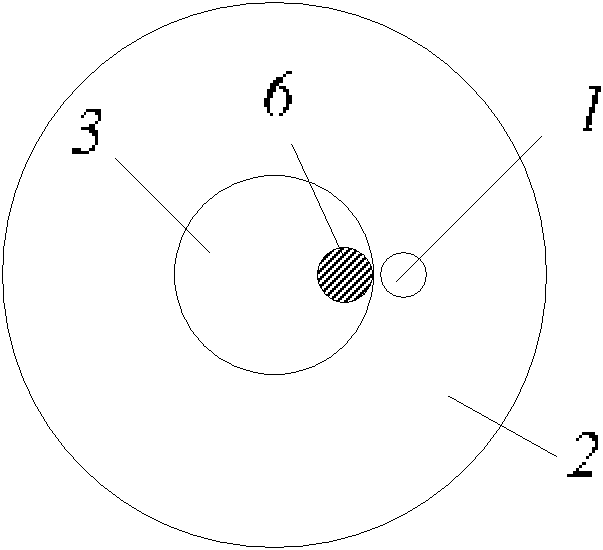

[0037] In the first embodiment, the single-core hollow fused-core fiber can also be replaced by a hollow fused-core capillary fiber whose core geometric distribution is circular distribution, triangular distribution, quadrilateral distribution or other polygonal distribution, such as image 3 , Figure 4 and Figure 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com