Integrated circuit packaging method with postpositional embedded core flow and package structure

A technology of integrated circuits and packaging methods, which is applied in the direction of circuits, electrical components, and electric solid devices, and can solve the problems of reduced compactness of integrated circuits, increased manufacturing process steps, and reduced production yields, so as to improve the heat dissipation performance of chips and simplify The production process and the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] This embodiment provides an integrated circuit packaging method and its corresponding packaging structure after the buried core process.

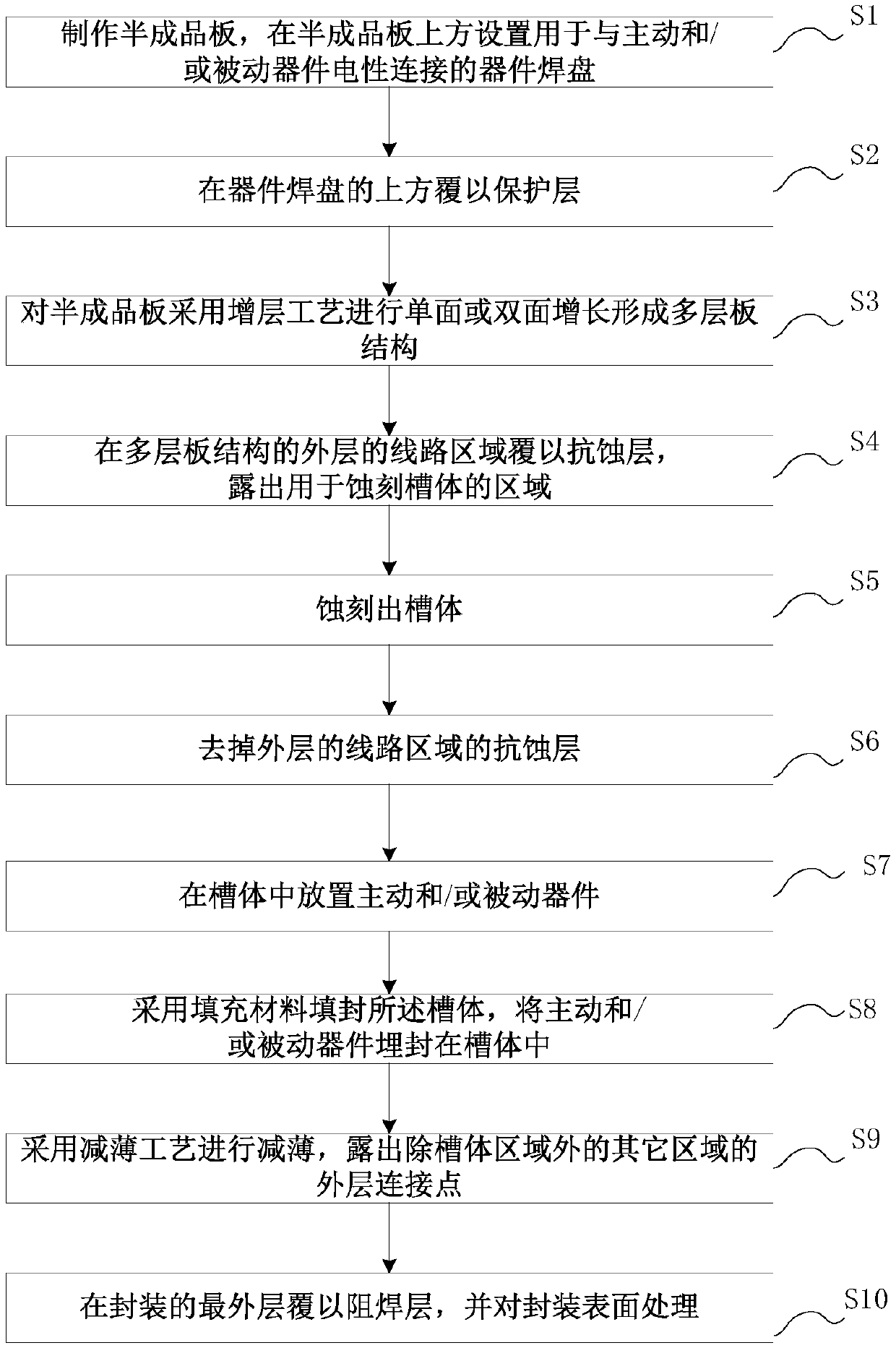

[0076] In this example, if figure 1 As shown, a post-buried integrated circuit packaging method includes the following steps:

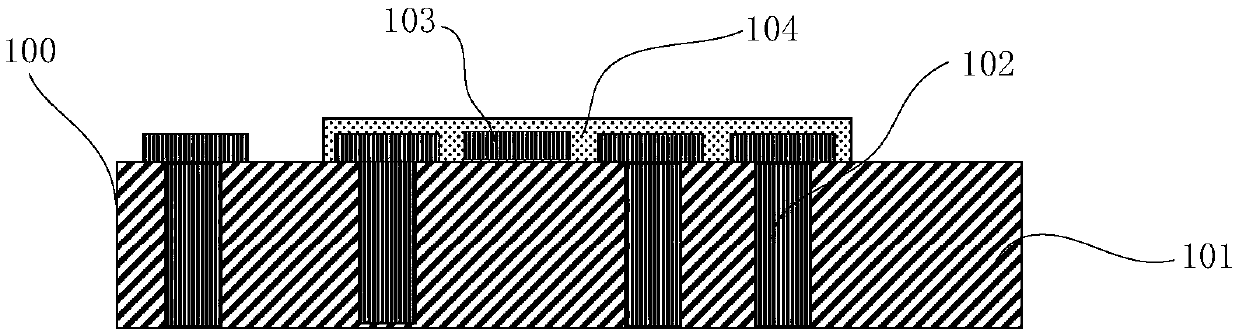

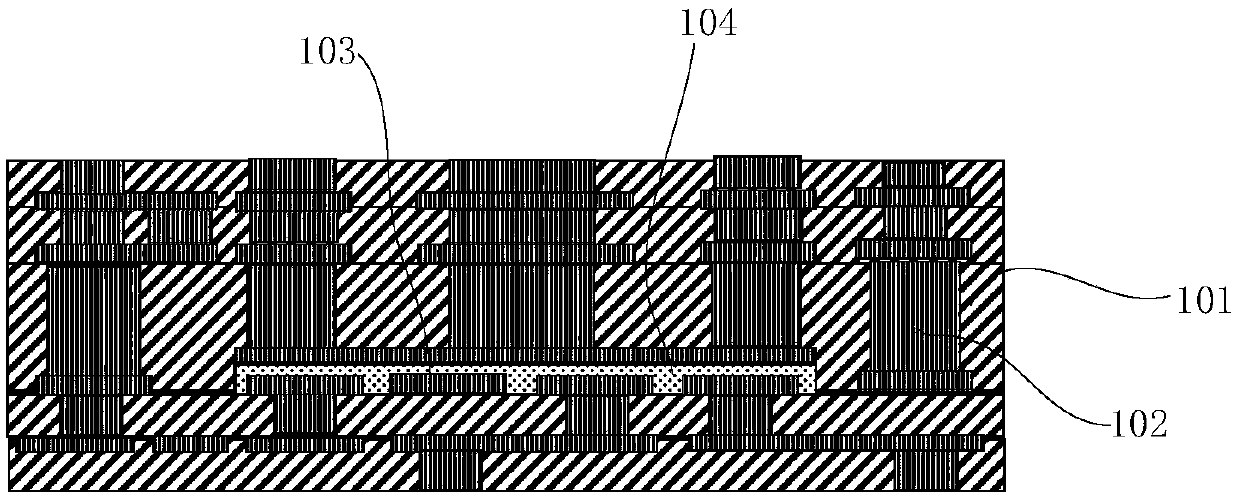

[0077] S1 , making a semi-finished board 100 , and disposing device pads 103 for electrically connecting active and / or passive devices 200 on the semi-finished board 100 . In the packaging method of the present invention, the semi-finished board 100 is first produced. The semi-finished board 100 is generally a packaging structure located under the active and / or passive device 200. The semi-finished board 100 can be a single-layer board structure or a multi-layer board structure. Such as figure 2 As shown, the semi-finished board 100 of this embodiment is a single-layer board structure, including a packaging material 101, and the packaging material 101 is provided with conductive copper pillars 102 (electr...

Embodiment 2

[0112] This embodiment provides an integrated circuit packaging method and a corresponding packaging structure after the component embedding process.

[0113] In this example, if Figure 10 As shown, the integrated circuit packaging method after the component embedding process includes the following steps:

[0114]P1 , making a semi-finished board 100 , and disposing device pads 103 for electrically connecting active and / or passive devices 200 on the semi-finished board 100 . In the packaging method of the present invention, the semi-finished board 100 is first produced. The semi-finished board 100 is generally a packaging structure located under the active and / or passive device 200. The semi-finished board 100 can be a single-layer board structure or a multi-layer board structure. Such as Figure 11 As shown, the semi-finished board 100 of this embodiment is a single-layer board structure, including a packaging material 101, and the packaging material 101 is provided with c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com