Patents

Literature

35results about How to "Change the coefficient of friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

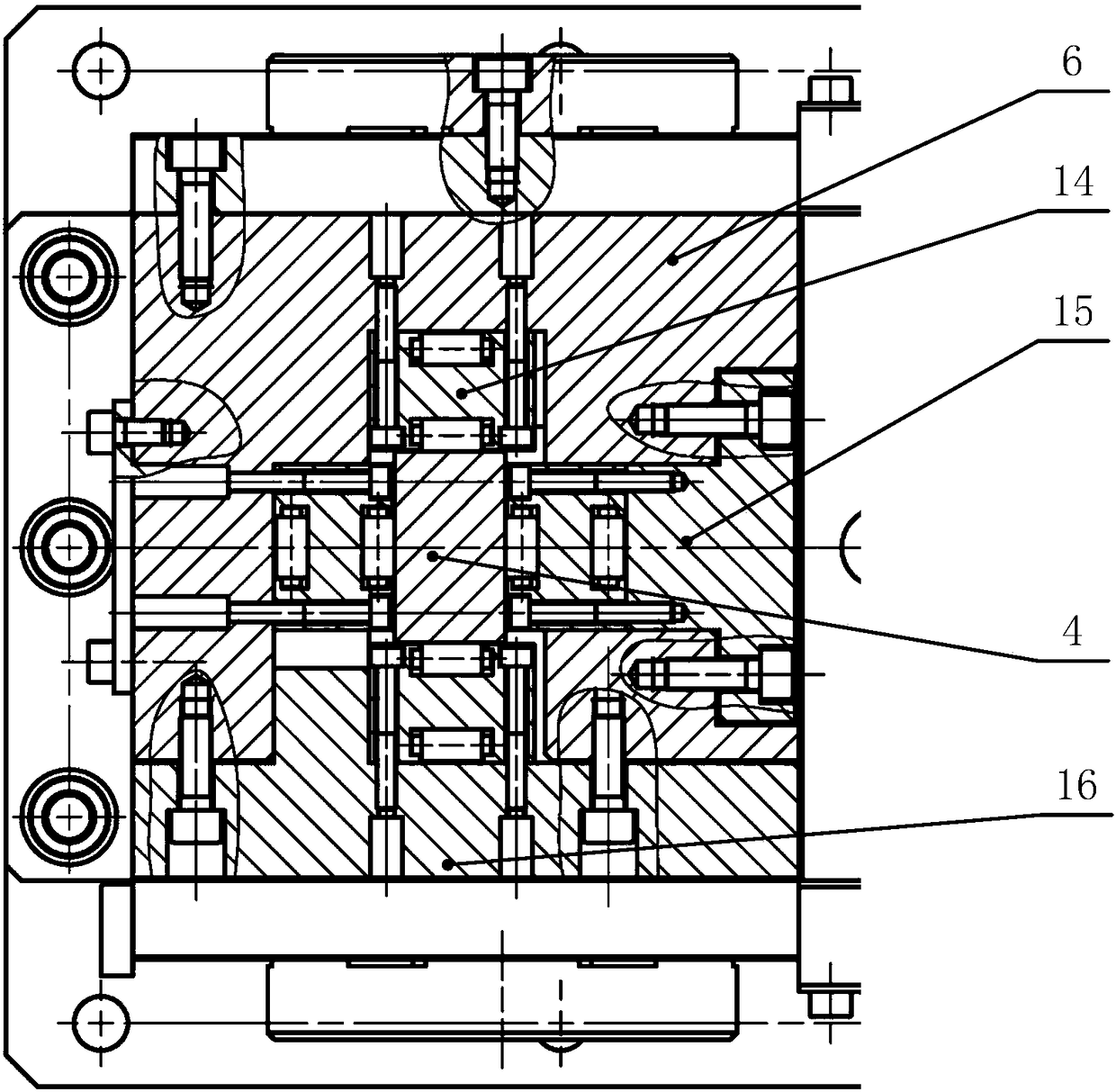

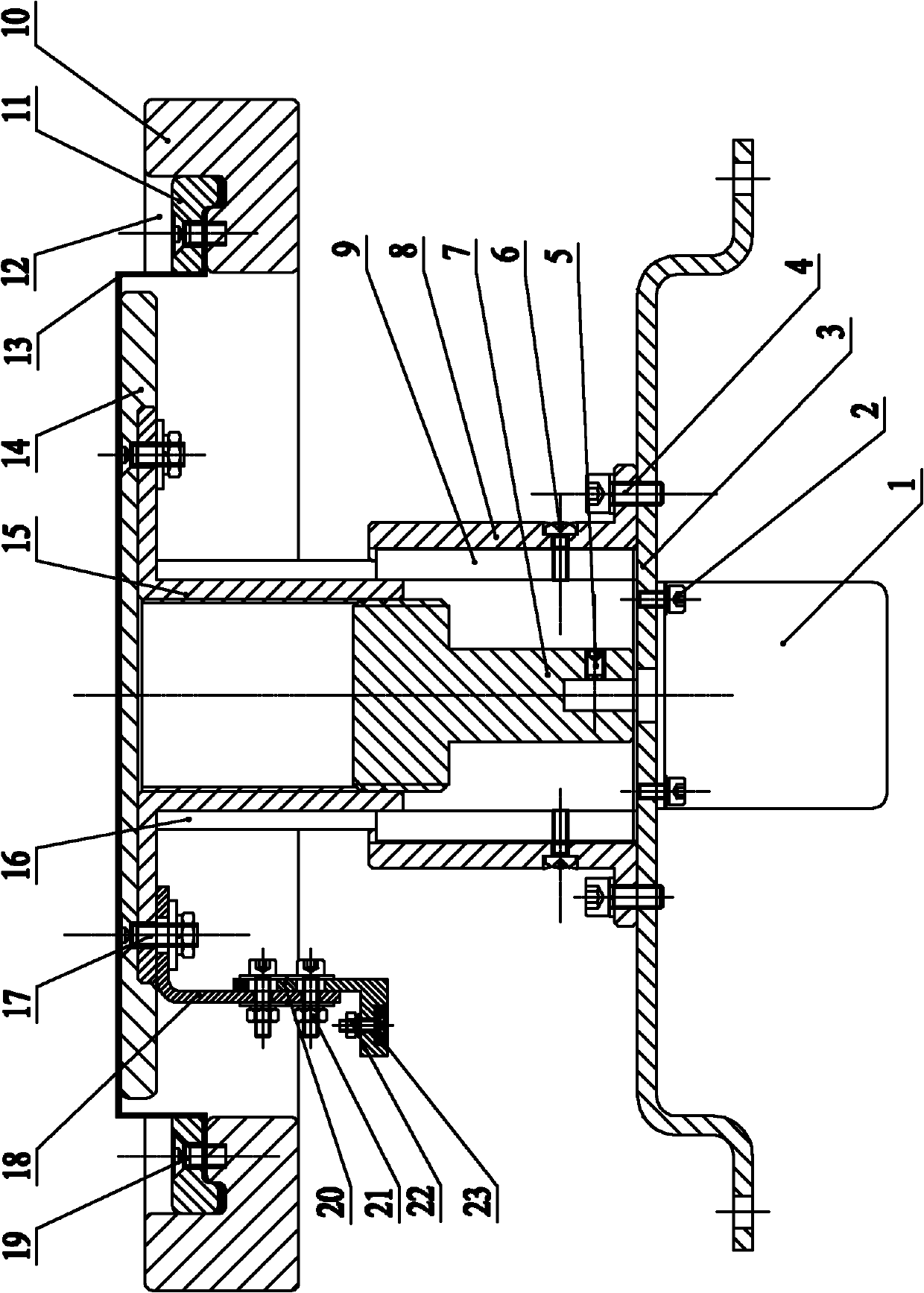

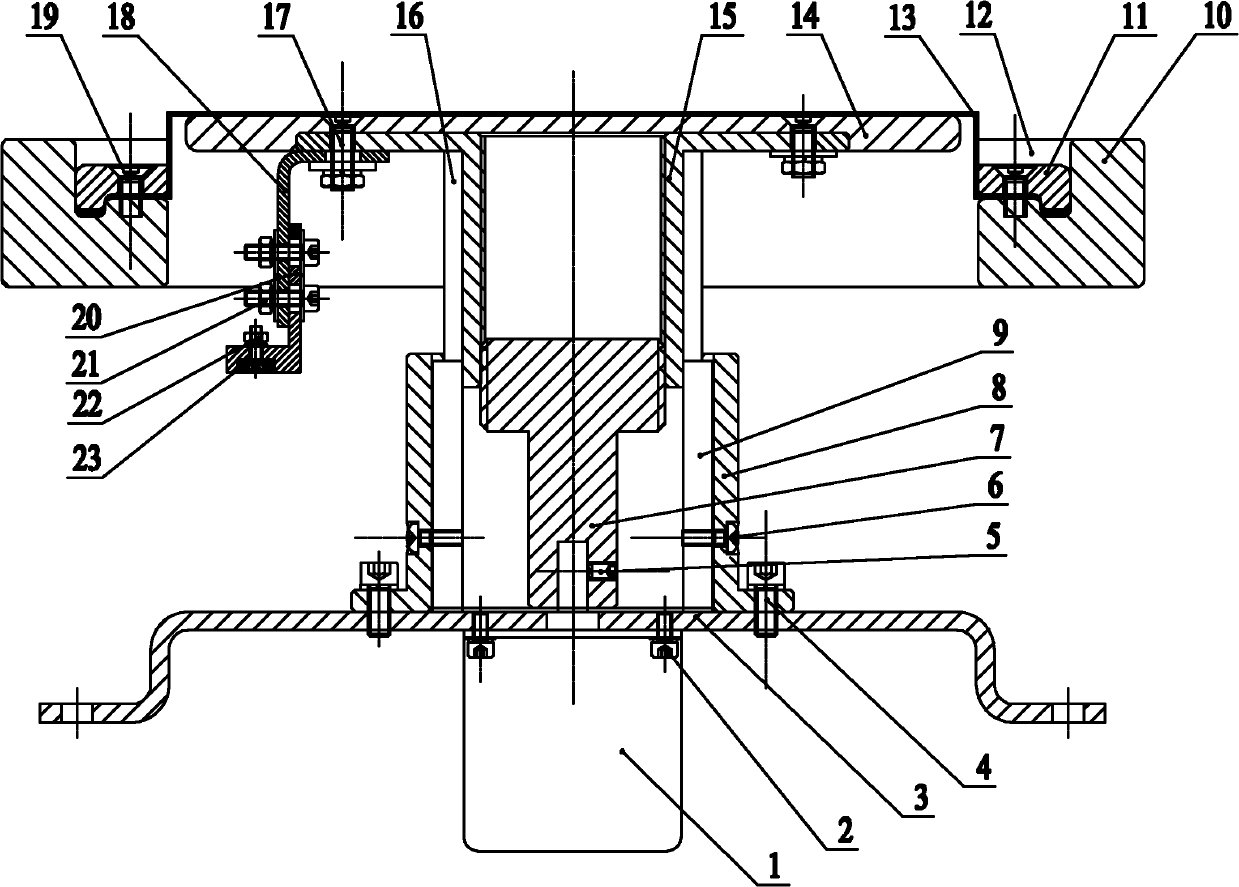

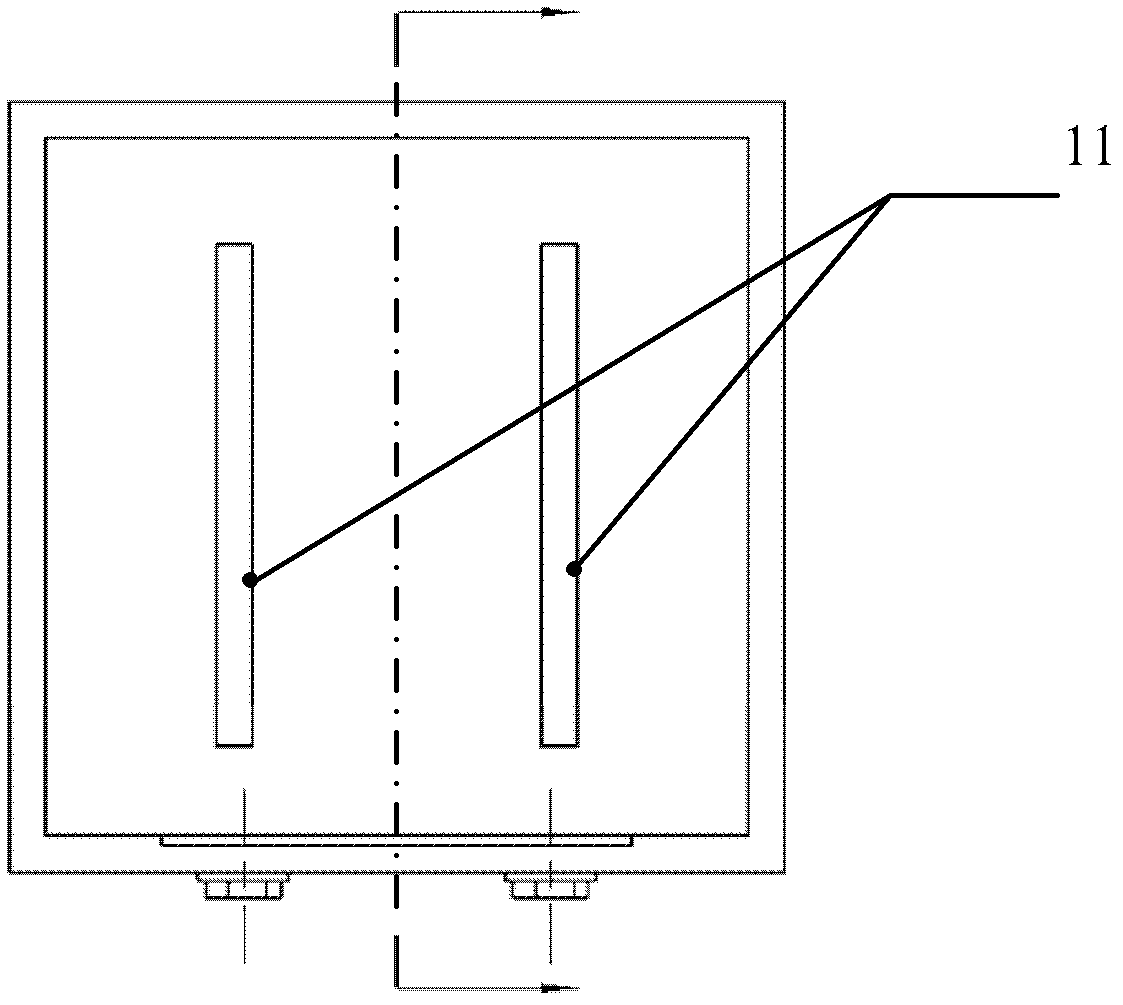

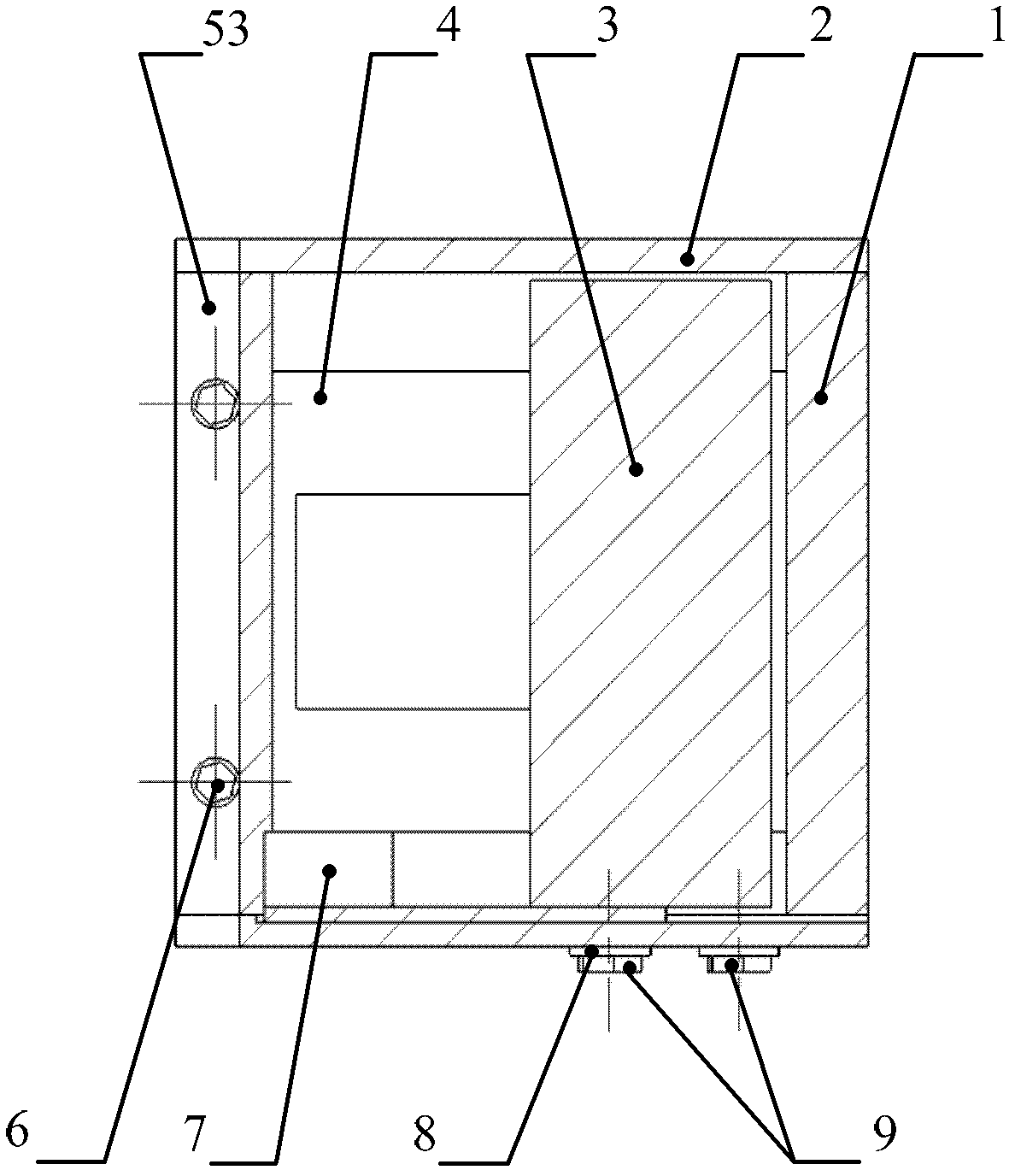

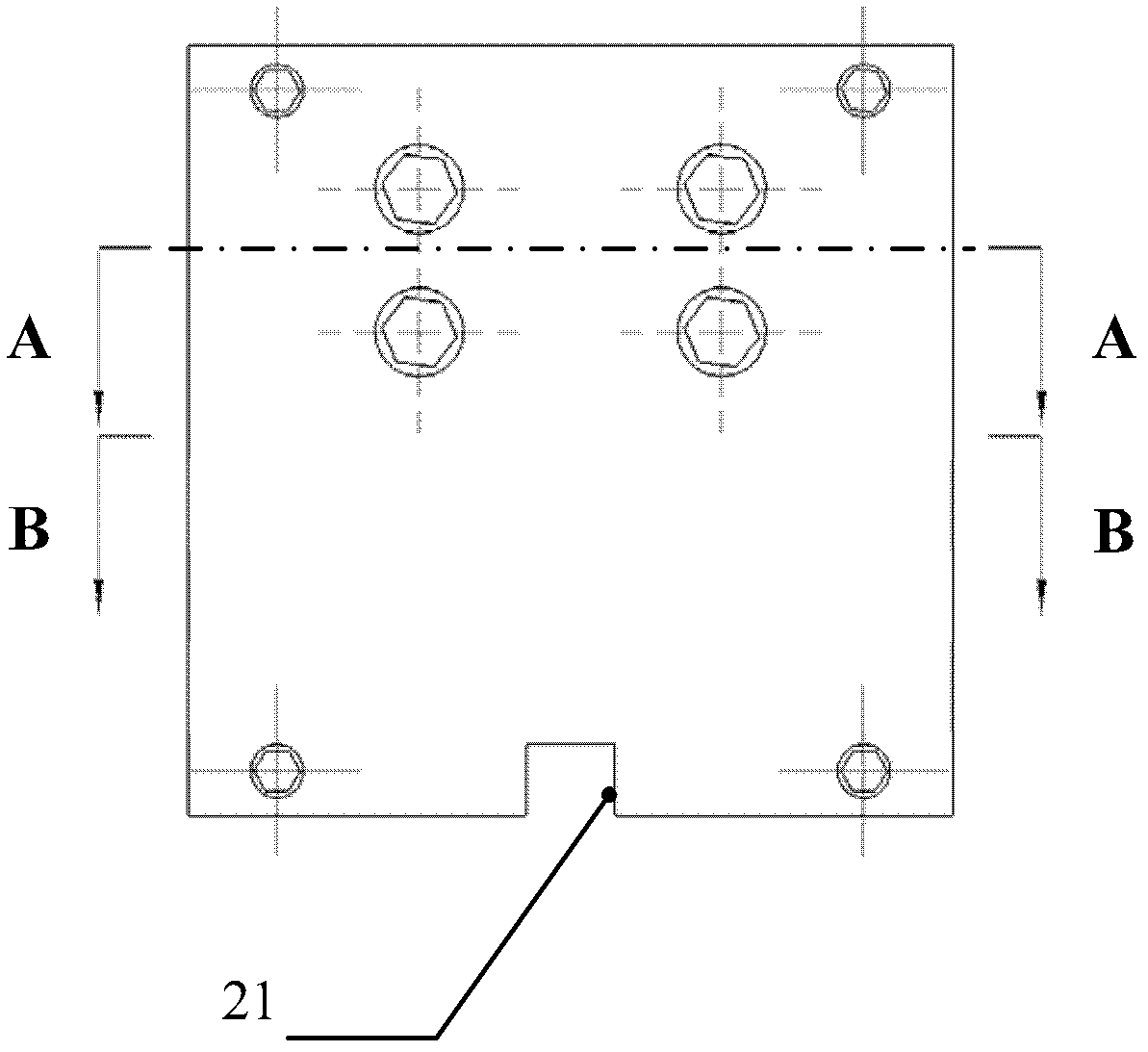

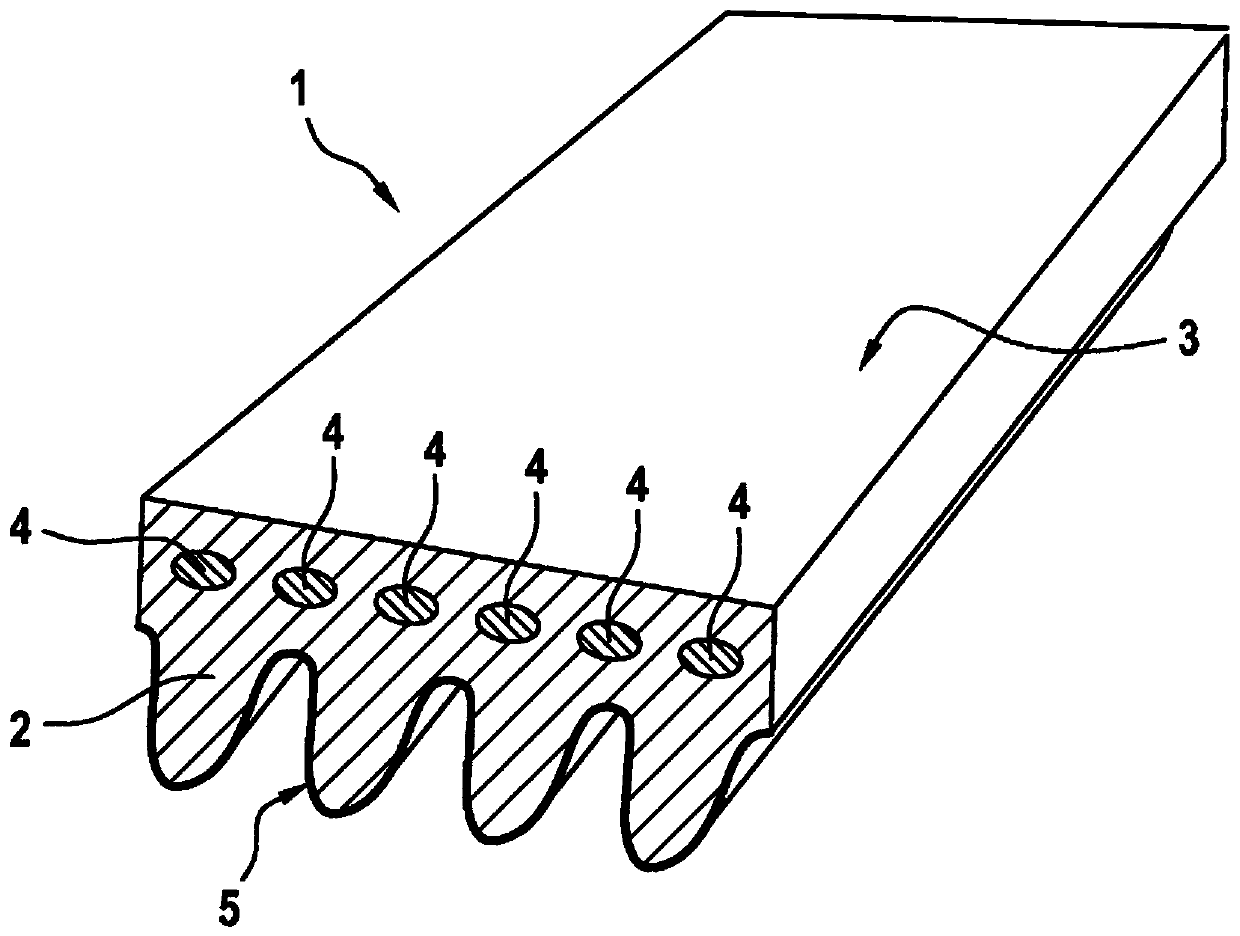

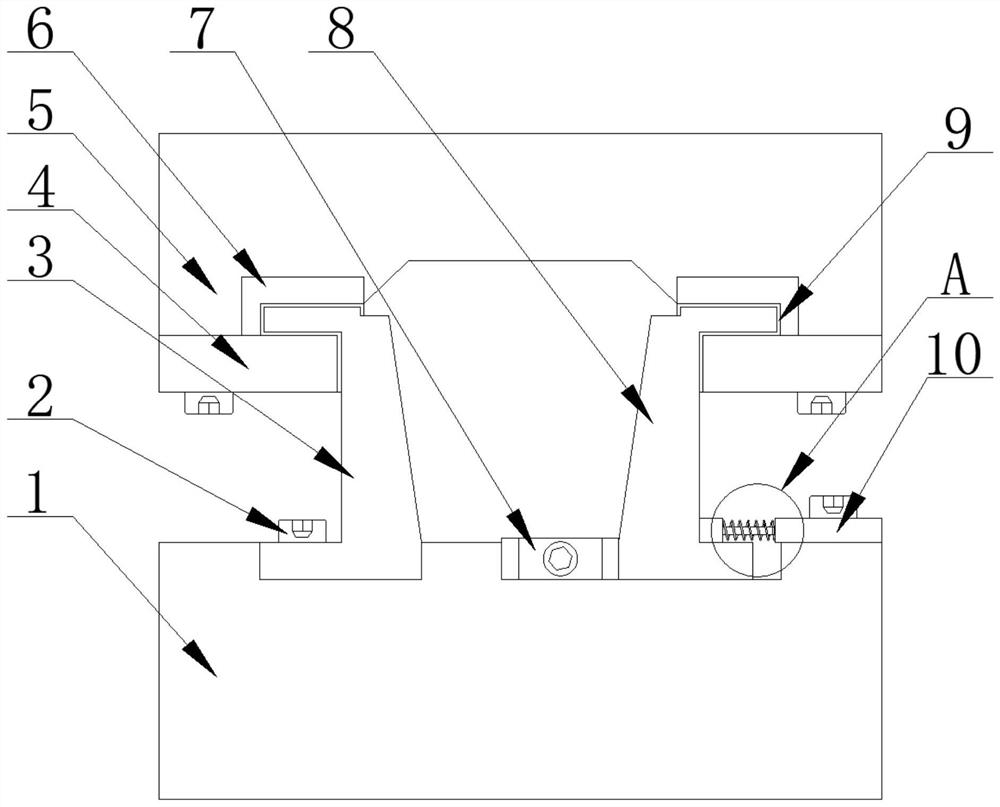

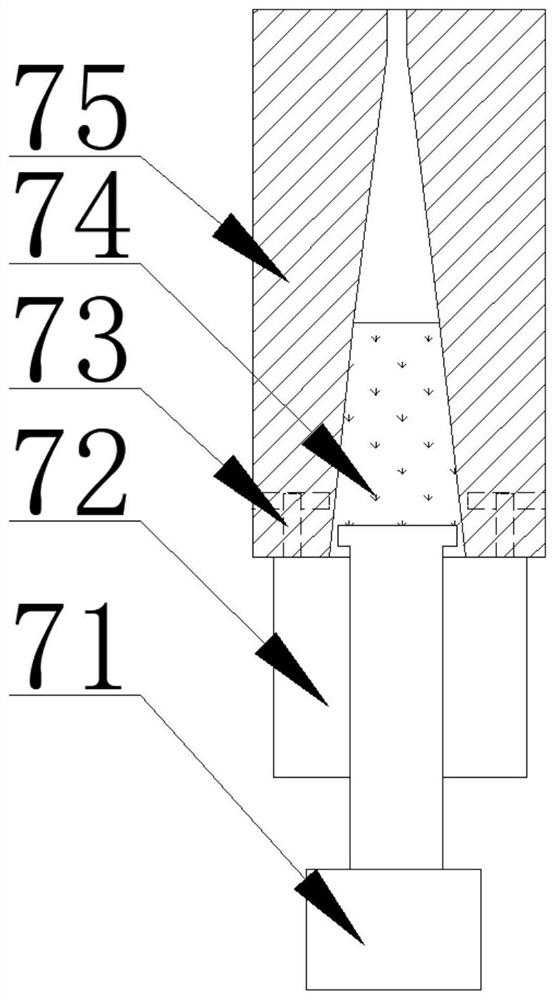

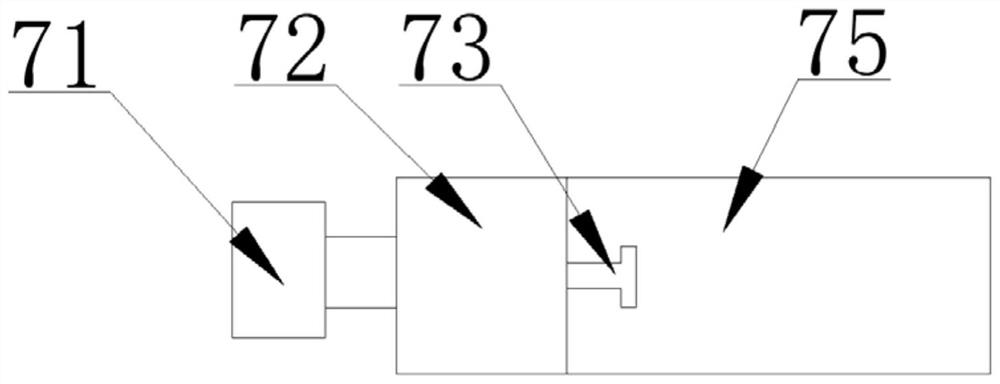

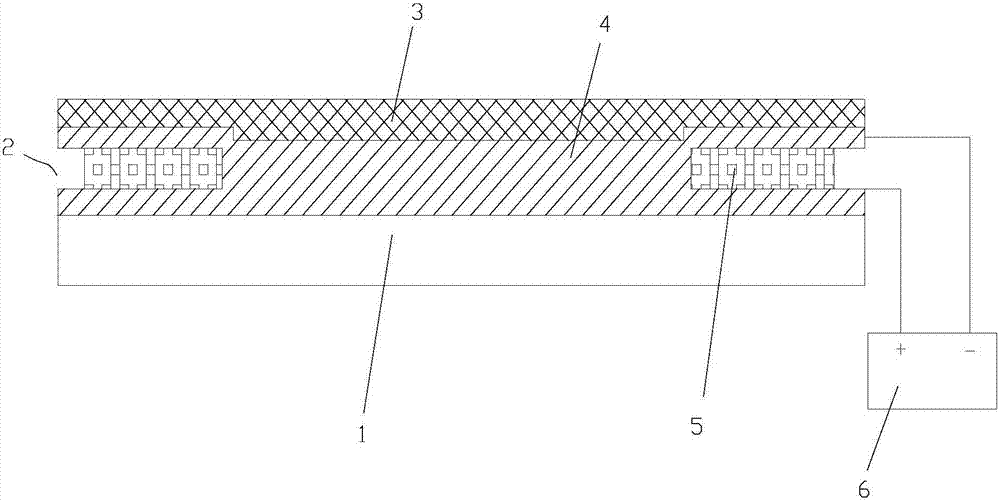

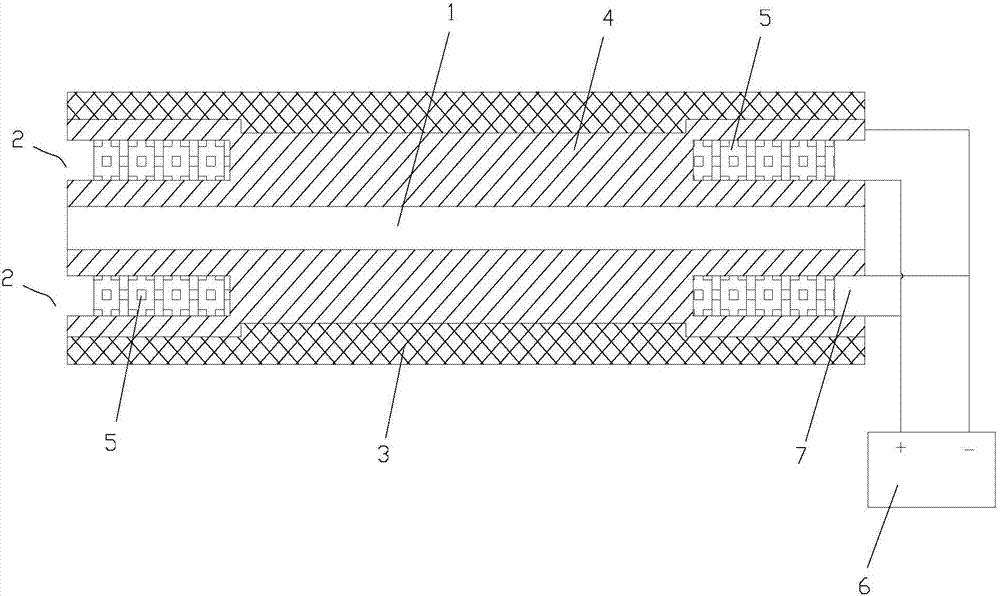

Stiffness/damping adjustable double-cantilever beam sealed passive damper

InactiveCN102418769AChange the coefficient of frictionWith stiffnessNon-rotating vibration suppressionNumerical controlCantilevered beam

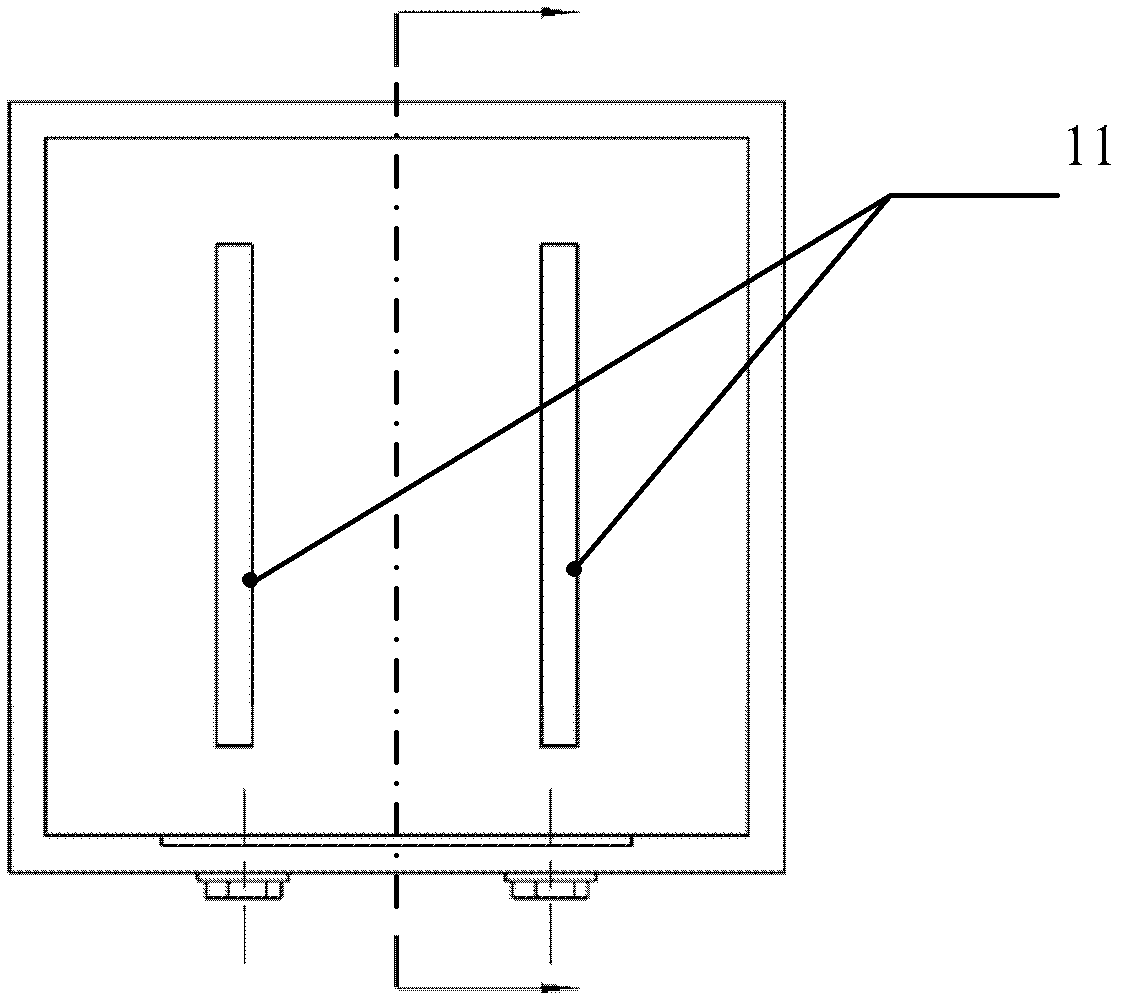

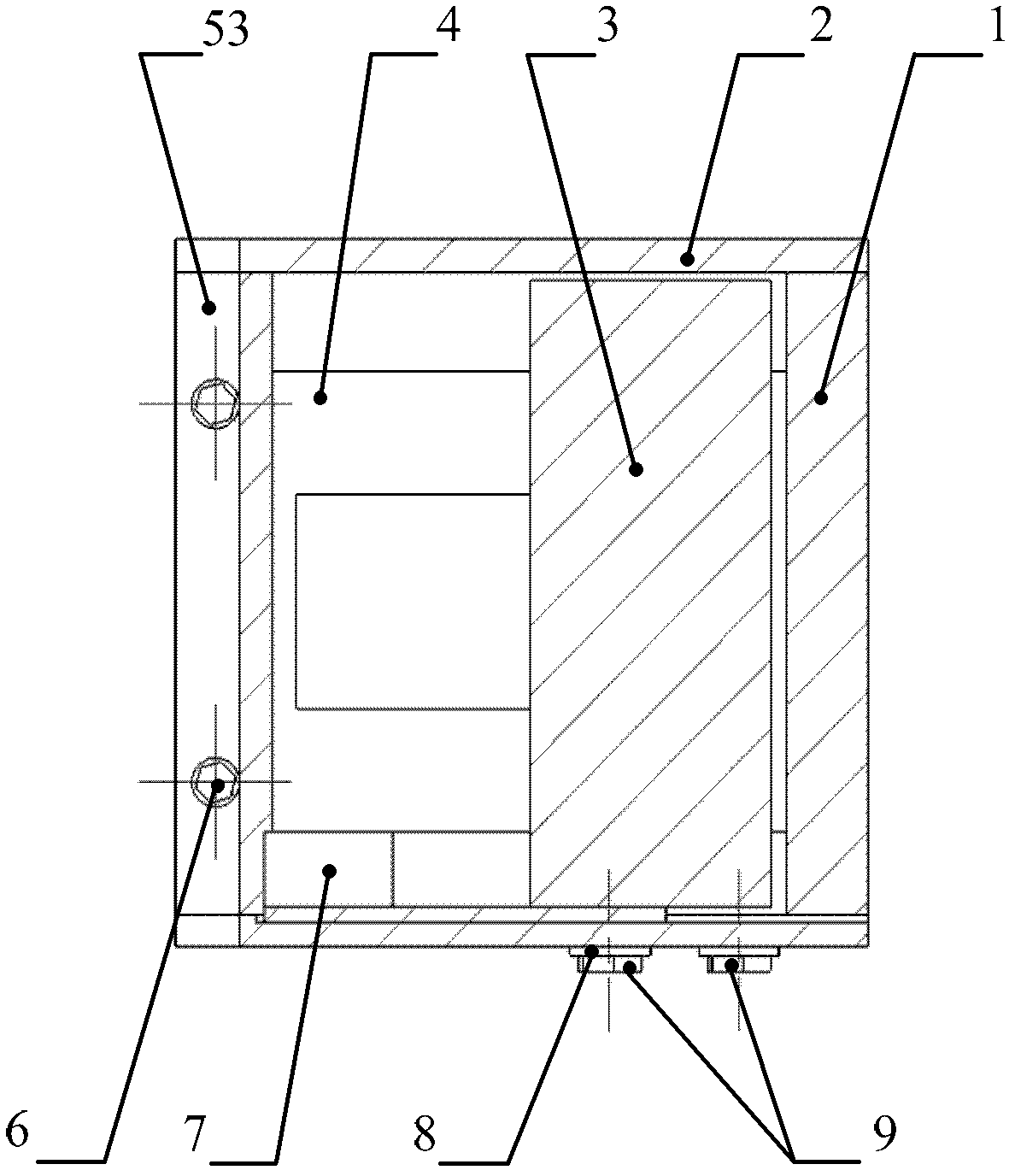

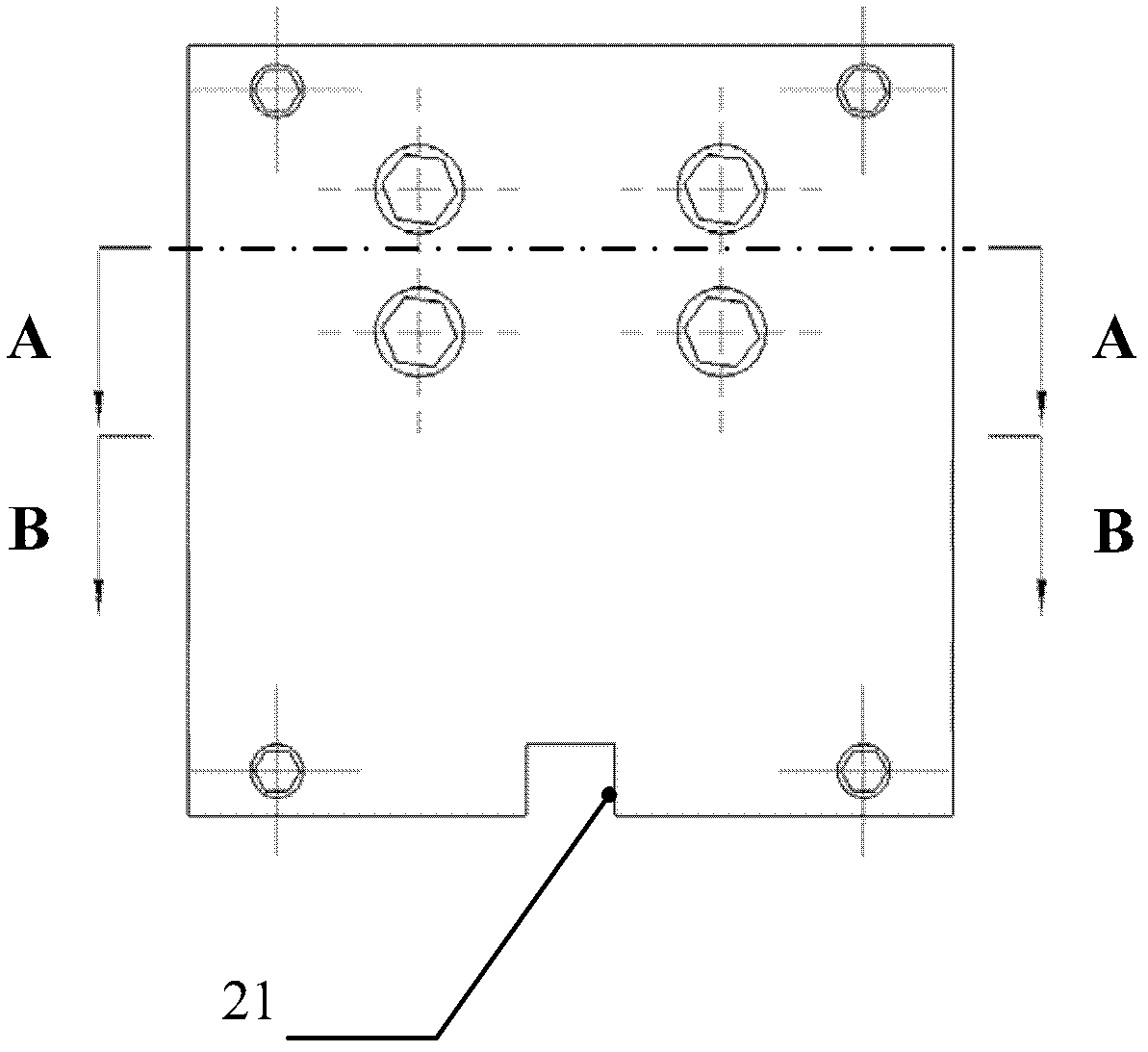

The invention relates to a numerical control machine tool and workpiece passive vibration damping device which can be applied to the field of machining and has the obvious single-degree-of-freedom vibration characteristic. The device comprises a shell, a base, cantilever beams, a mass block, a screw, a nut, a gasket, a friction plate, a threaded hole and the like and is of a box-like sealed structure. The device is characterized in that main mode motion which is strictly vertical to the direction of the cantilever beams is realized, and the vibration characteristic is derived from first-orderbending vibration of the two cantilever beams. The stiffness and damping of the device are adjustable, and the adjustment can be realized by adjusting the position of the mass block in the device andthe pretightening force of the friction plate, thereby having a wider vibration suppression frequency range. The device is suitable for the characteristics that the dynamic property of a workpiece ora machine tool changes during the machining and a damper is required to be capable of adjusting parameters. The device can be mounted on a numerical control lathe, a milling machine or the workpiece for vibration damping. The device is simple in structure, convenient to implement and lower in cost, has no environmental pollution, and can be used for effectively reducing the vibration during cutting machining and realizing high-efficient and high-quality machining of parts.

Owner:BEIHANG UNIV

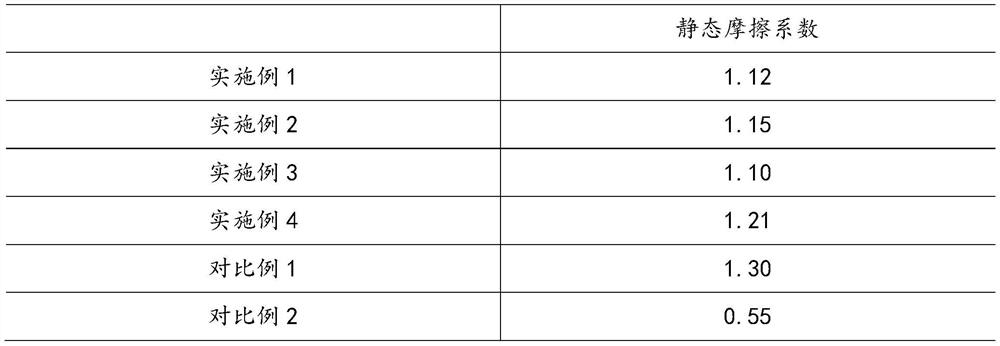

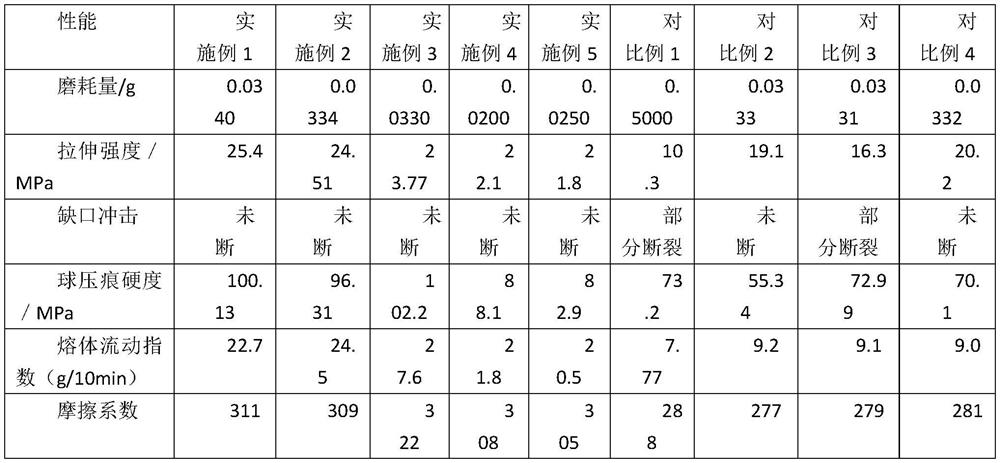

Modified polytrifluorochloroethylene and molding process thereof

The invention relates to a modified polytrifluorochloroethylene and a molding process thereof. The modified polytrifluorochloroethylene is prepared from polytrifluorochloroethylene and a modifier, wherein the modifier is a mixture of more than one, in an arbitrary ratio, selected from the group consisting of p-polyphenylene, graphite, carbon fiber, glass fiber, ceramic powder, polybenzoate, pigment, molybdenum disulfide and aluminum powder. The molding process for the modified polytrifluorochloroethylene is to subject polytrifluorochloroethylene and the modifier to drying, mixing, molding and cooling. The invention has the following beneficial effects: after addition of the modifier, the prepared modified polytrifluorochloroethylene has improved hardness, dimensional stability, high temperature resistance, wear resistance, thermal conductivity and creep resistance and altered friction coefficient; meanwhile, cost of polytrifluorochloroethylene is reduced, and the application scope of the modified polytrifluorochloroethylene is widened.

Owner:WENZHOU OUKE FLUORINE GASKETS CO LTD

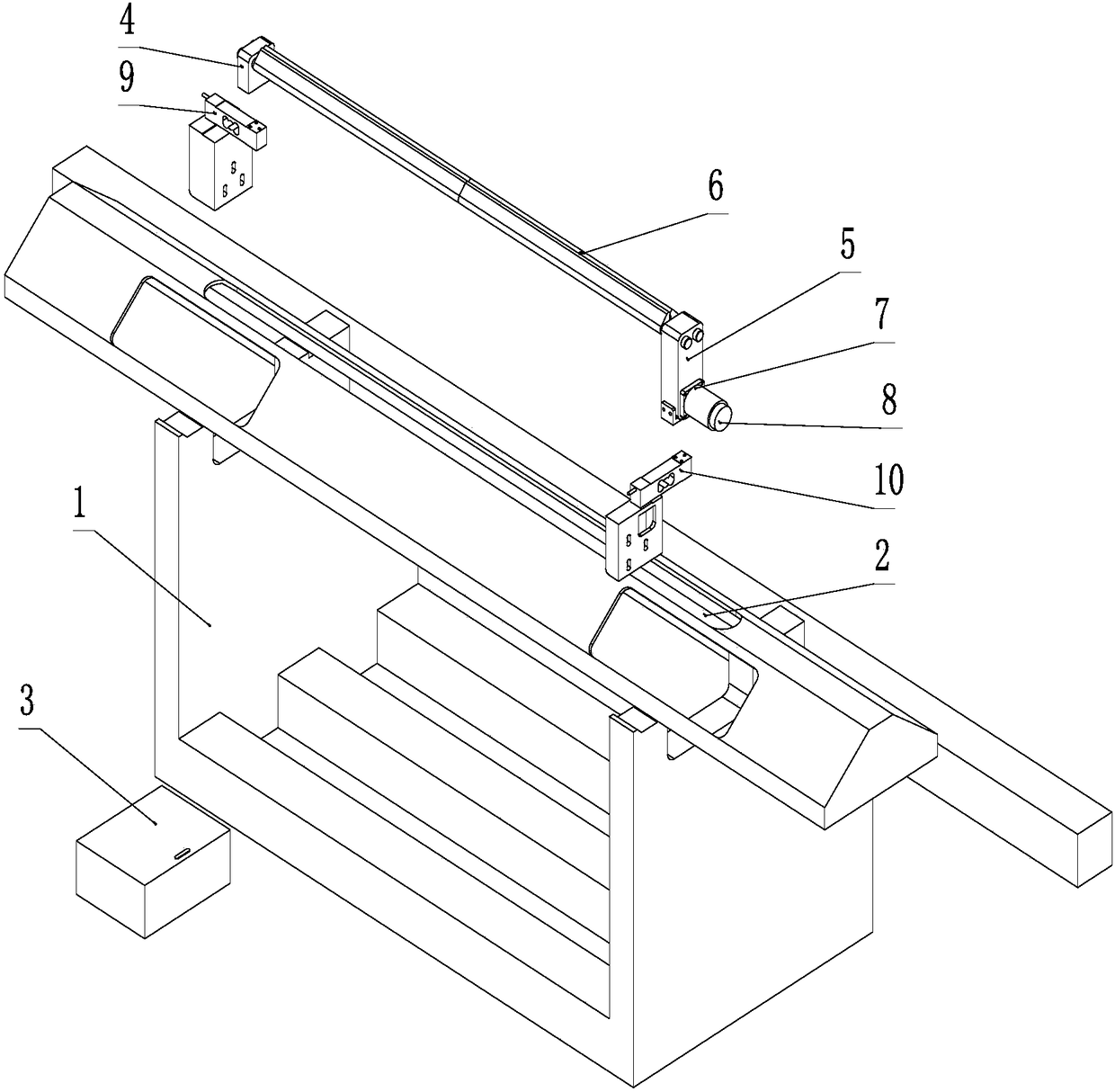

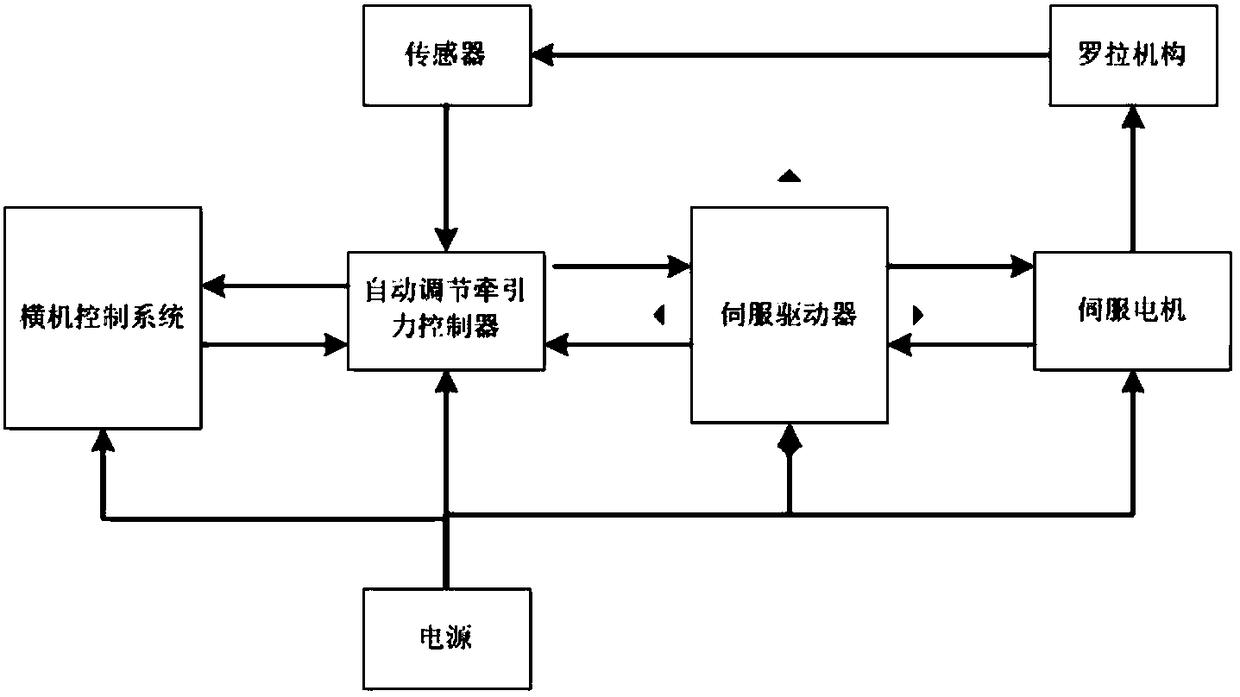

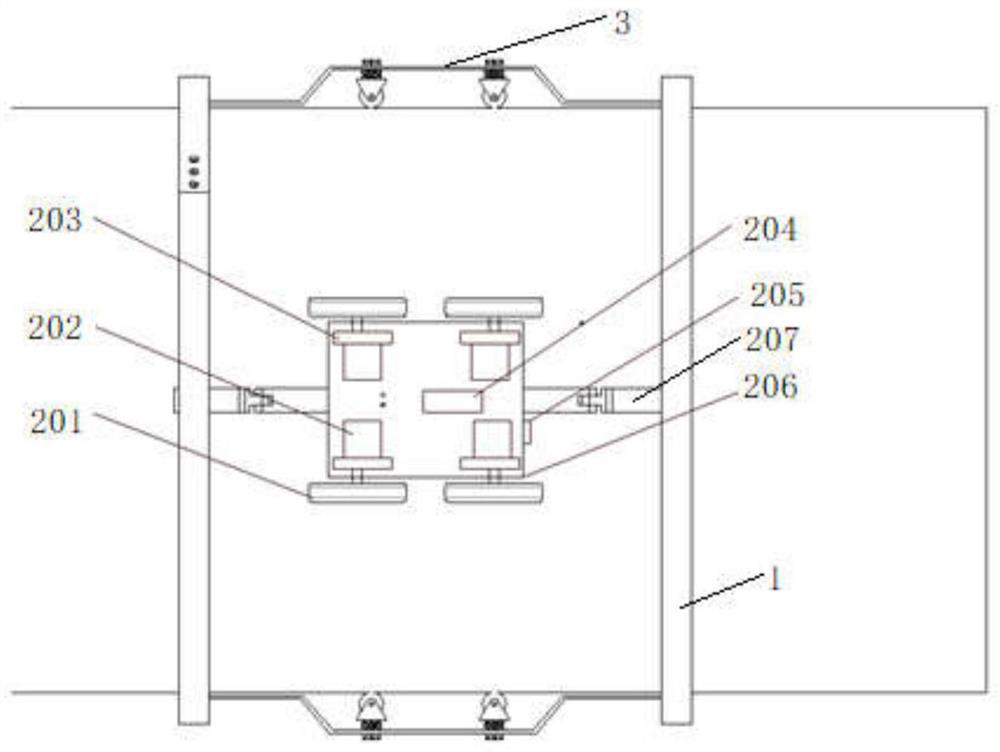

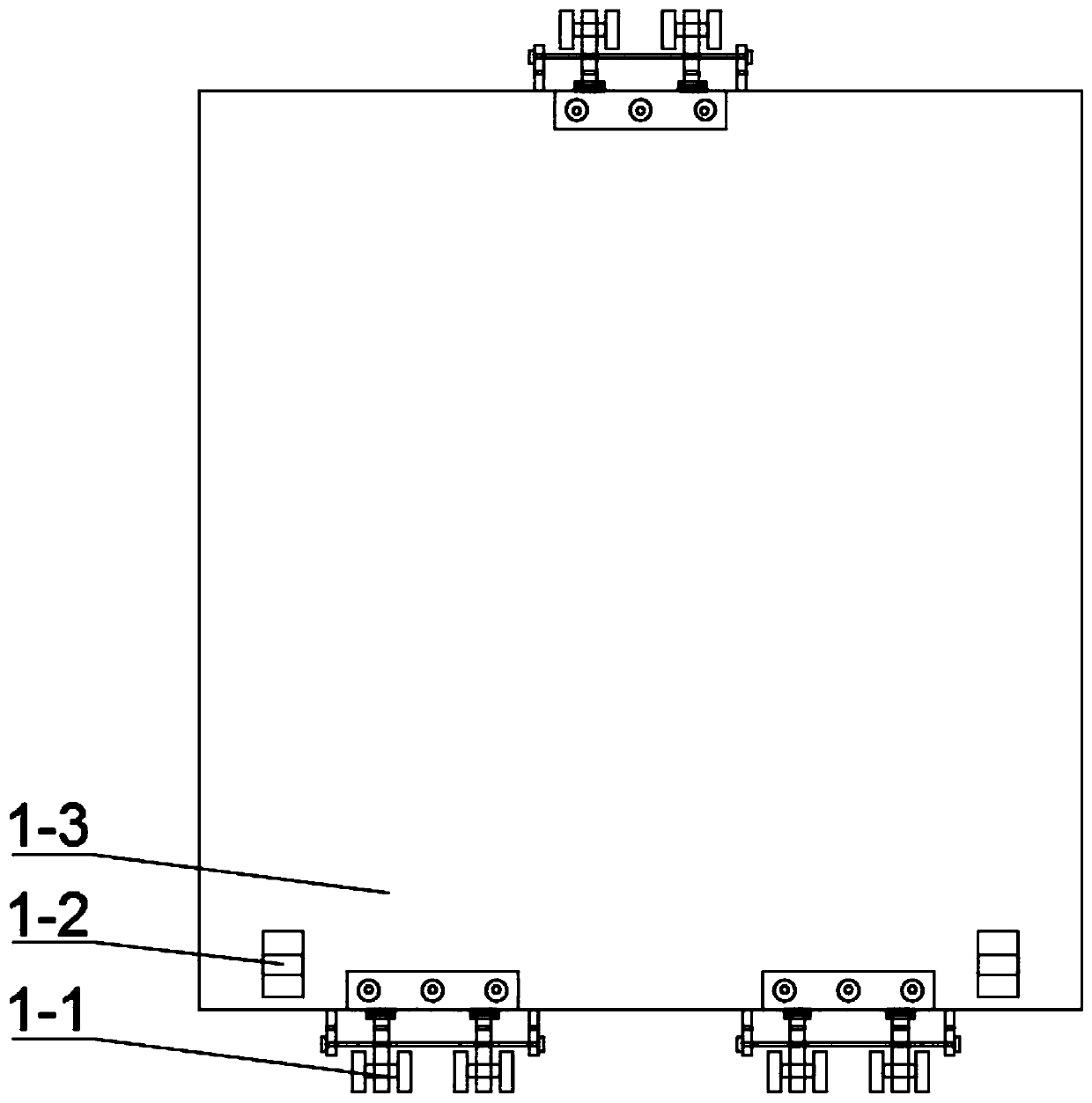

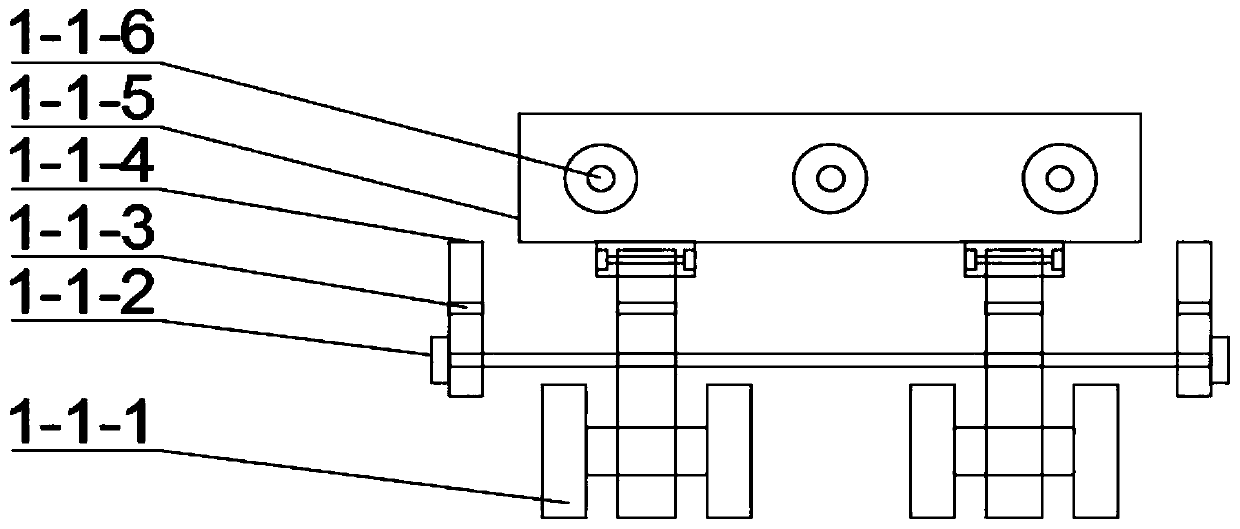

Automatic regulating device for roller traction force of flat knitting machine

PendingCN108385264AChange speedChange the coefficient of frictionWeft knittingMachine controlControl system

The invention discloses an automatic regulating device for roller traction force of a flat knitting machine. The automatic regulating device for the roller traction force of the flat knitting machineis characterized in that the automatic regulating device comprises a flat knitting machine frame and a roller mechanism which is used for towing fabric; the flat knitting machine frame is opened withan accommodating cavity for accommodating the roller mechanism, and the flat knitting machine frame also comprises an automatic regulating traction force controller connected with a flat knitting machine control system; both sides of the roller mechanism are connected to the flat knitting machine frame via a force measuring device; the force measuring device can take samples of traction force dataof the roller mechanism and provide feedback for the automatic regulating traction force controller; the roller mechanism is in drive connection with a servo drive mechanism; the automatic regulatingtraction force controller is in control connection with the servo drive mechanism; the automatic regulating traction force controller can perform speed control of the servo drive mechanism through the feedback of the traction force data provided by the force measuring device. Compared with the prior art, the automatic regulating device for the roller traction force of the flat knitting machine has the advantages of not only adjusting the traction force of the roller mechanism in real time but also maintaining constant traction force during the weaving process, guaranteeing the pieces of clothmore complete and beautiful with the pieces of cloth pulled slowly and evenly, and improving production efficiency.

Owner:ZHEJIANG HENGQIANG TECH

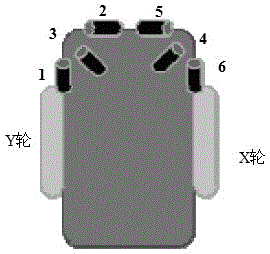

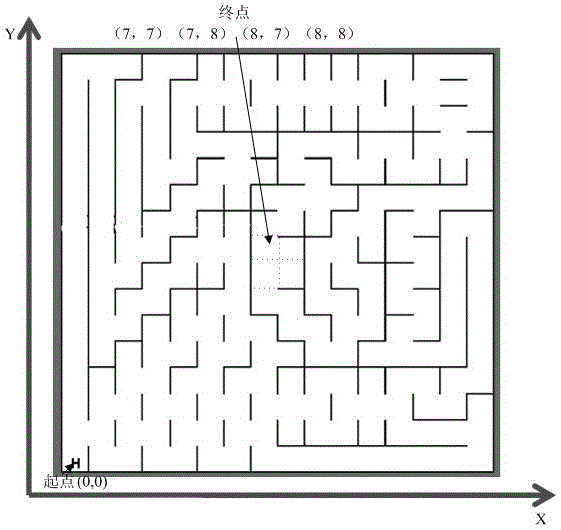

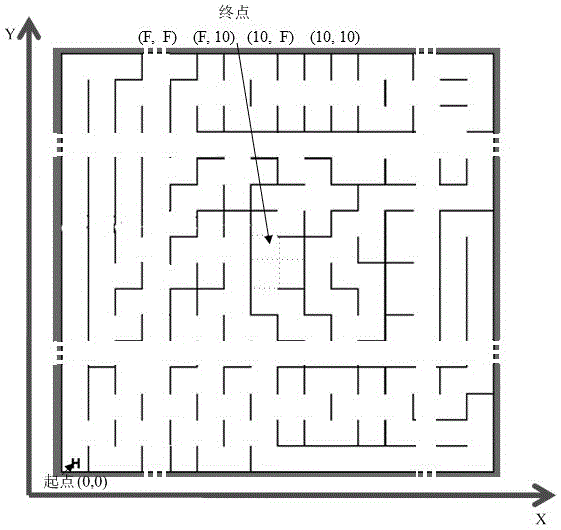

Single-core low-speed two-wheeled picomouse sprint controller

InactiveCN105116898AAvoid excessive agingAvoid shockPosition/course control in two dimensionsLow speedGyroscope

The invention discloses a single-core low-speed two-wheeled picomouse sprint controller, comprising an STM32F4 controller, an L6207D chip, a cell, a first sensor, a second sensor, a third sensor, a fourth sensor, a gyroscope, a first motor, a second motor, a third motor, a current sensor and a vacuum apparatus. The STM32F4 controller and the L6207D chip are in signal connection; the signal emission direction of two sensors is the same with a wheel running direction, and the signal emission direction of the other two sensors and the wheel running direction form a certain angle; the gyroscope and the STM32F4 controller are in signal emission; two motors among the three motors are respectively in corresponding connection with two wheels of a two-wheeled picomouse, and the other motor is in connection with the vacuum apparatus. The controller increases an operation speed, constantly monitors and calculates running states of the picomouse, automatically regulates the ground adsorption capability of the vacuum apparatus, and completely avoids the skidding of the picomouse when sprinting with a high speed in a complex labyrinth.

Owner:TONGLING UNIV

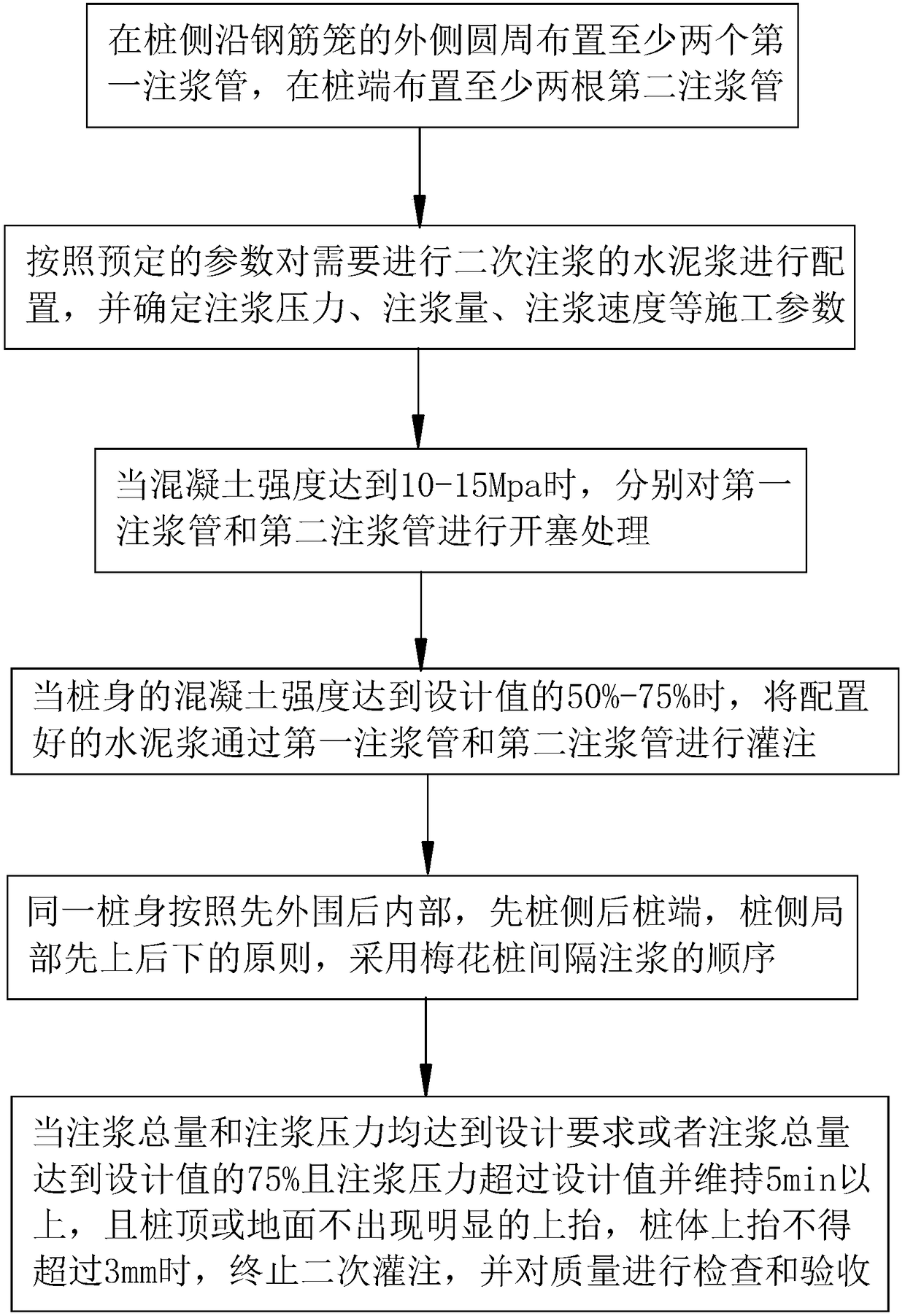

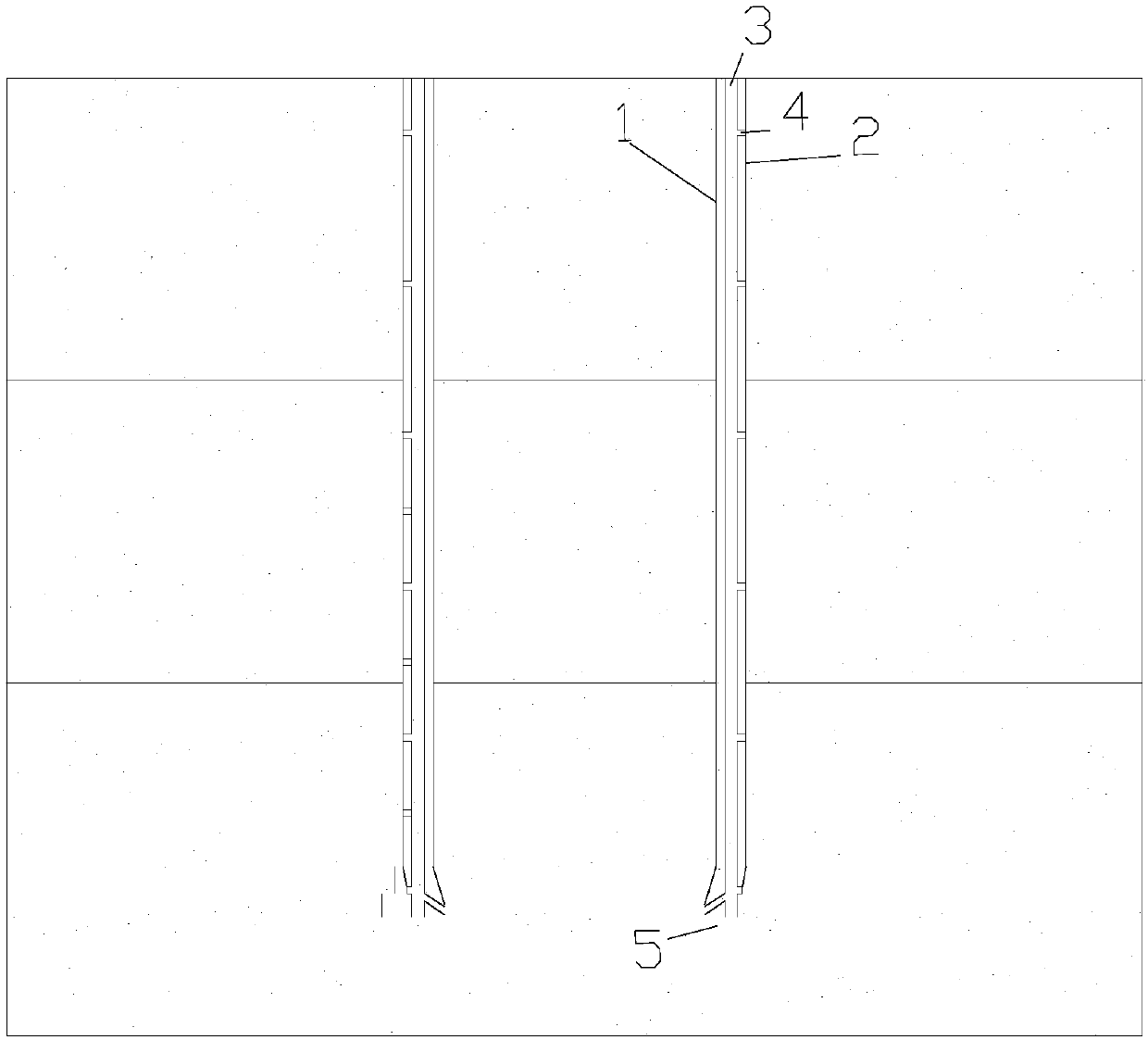

Cast-in-place pile post-grouting construction technology

InactiveCN108130903AImprove carrying capacityImprovement and surrounding pile conditionsBulkheads/pilesRebarCement slurry

The invention provides a cast-in-place pile post-grouting construction technology. The technology comprises the following steps that at least two first grouting pipes are circumferentially arranged onthe pile side along the outer side of a reinforcement cage, at least two second grouting pipes are arranged at a pile end, and the first grouting pipes and the second grouting pipes are connected with a grouting device separately; cement slurry needing to be grouted is prepared; when the concrete strength reaches 10-15 Mpa, a grout pump is adopted for opening the first grouting pipes and the second grouting pipe; when the concrete strength reaches 50%-75% of a design value, the prepared cement slurry is subjected to secondary grouting through the first grouting pipes and the second grouting pipes; the quality of secondary grouting is inspected and accepted. According to the post-grouting construction technology, the pile end supporting layer and the pile side condition can be effectivelyimproved, the pile end resistance and pile side frictional resistance are improved, the load transmitting property is improved, the single pile bearing capacity is greatly increased, the settling volume is reduced, it is guaranteed that the grouting process is performed smoothly, and the grouting quality is improved.

Owner:THE GUANGDONG NO 3 WATER CONSERVANCY & HYDRO ELECTRIC ENG BOARD CO LTD

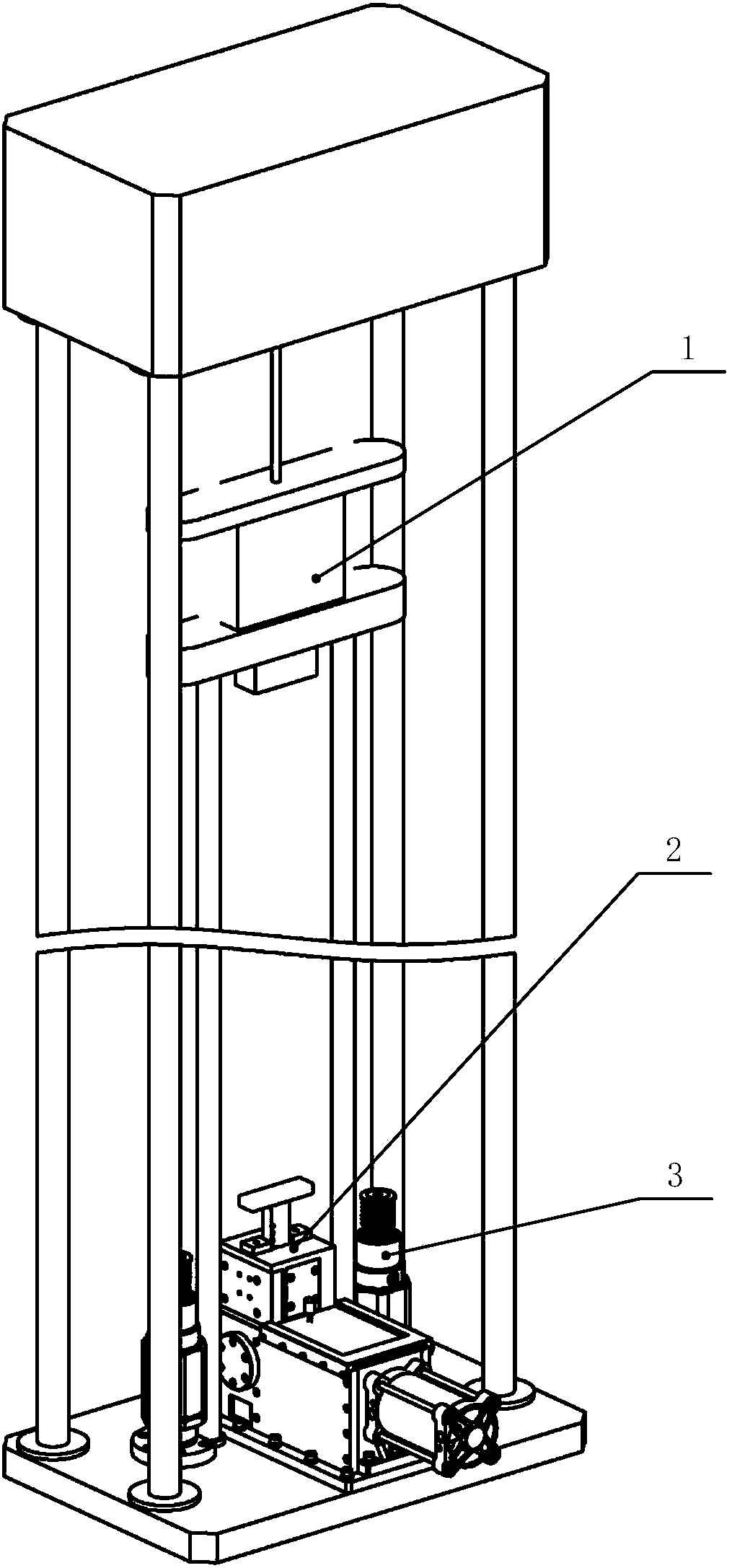

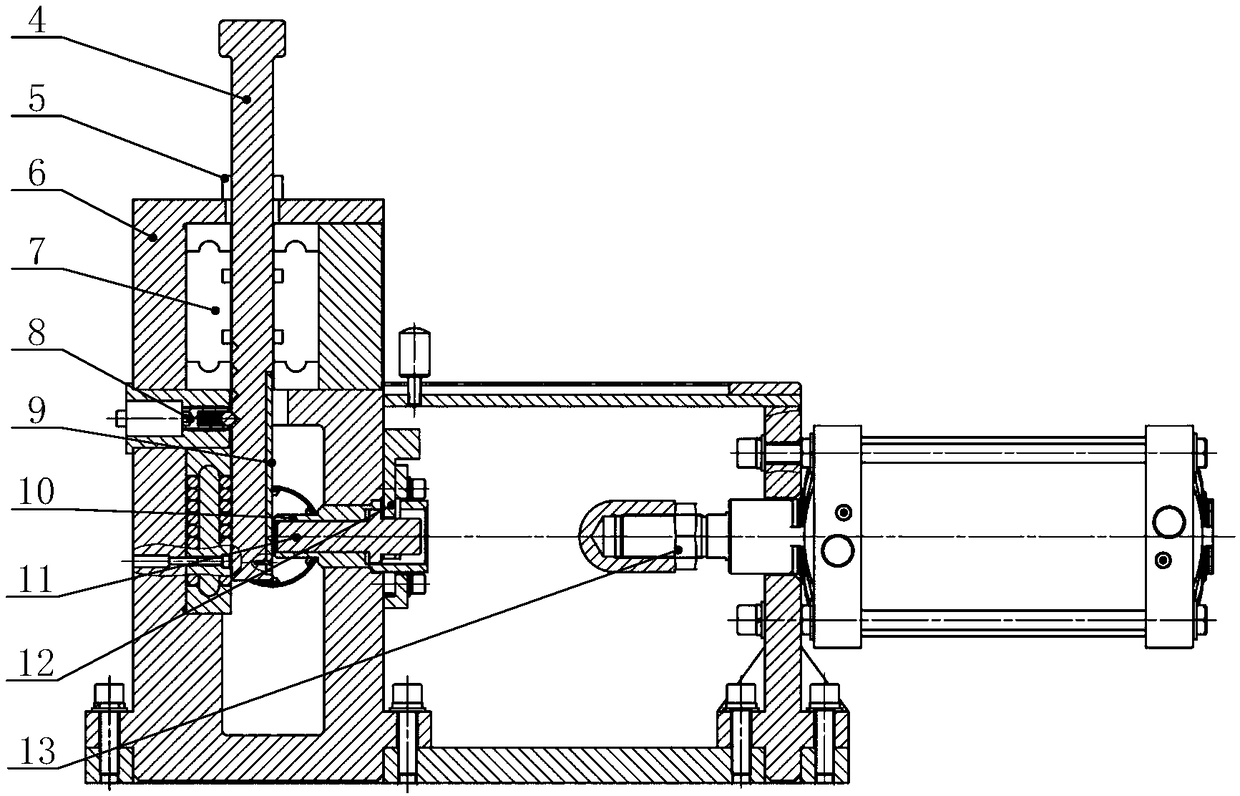

Drop hammer type high-energy insensitive explosive friction sensitivity tester

ActiveCN108226028AImprove stabilityImprove reliabilityUsing mechanical meansMaterial analysisFriction sensitivityControl system

The invention discloses a drop hammer type high-energy insensitive explosive friction sensitivity tester. The tester comprises a fully-automatic drop hammer assembly, a friction factor loading assembly positioned below the fully-automatic drop hammer assembly, and a drop hammer buffer assembly arranged beside the friction factor loading assembly, the friction factor loading assembly includes a slide plate, the slide plate is connected with a pedestal through a slide plate buffer gasket, a slide plate guiding unit in the pedestal is connected with the slide plate, a friction target plate is fixedly arranged at one side of the slide plate, the other side of the slide plate is connected with a slide plate height positioning device, an explosive tablet cover and a contact force loading guide shaft are arranged at on the other side of the friction target plate, the contact force loading guide shaft is connected with the explosive tablet cover, the contact force loading guide shaft is limited by a baffle plate, a cylinder is arranged outside the baffle, and the cylinder is connected with a cylinder pressure control system. The tester has the advantages of stable and reliable action process, large impact energy and high energy precision, and meets the energy demand of the high-energy insensitive explosive friction sensitivity test.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Self-lubricating running board

InactiveCN1456374AHas complete self-lubricating propertiesChange the coefficient of frictionSynthetic resin layered productsMovement coordination devicesDiluentEngineering

A self-lubricating running board used for the plate-type running appliance is prepared through adhering an elastic layer on hard substrate, proportionally mixing resin, trigger, promoter, diluent, lubricant, and pigment paste, stirring, spreading on the elastic layer, die pressing, and solidifying at 5-38 deg.c for 8-16 min.

Owner:吴小凤

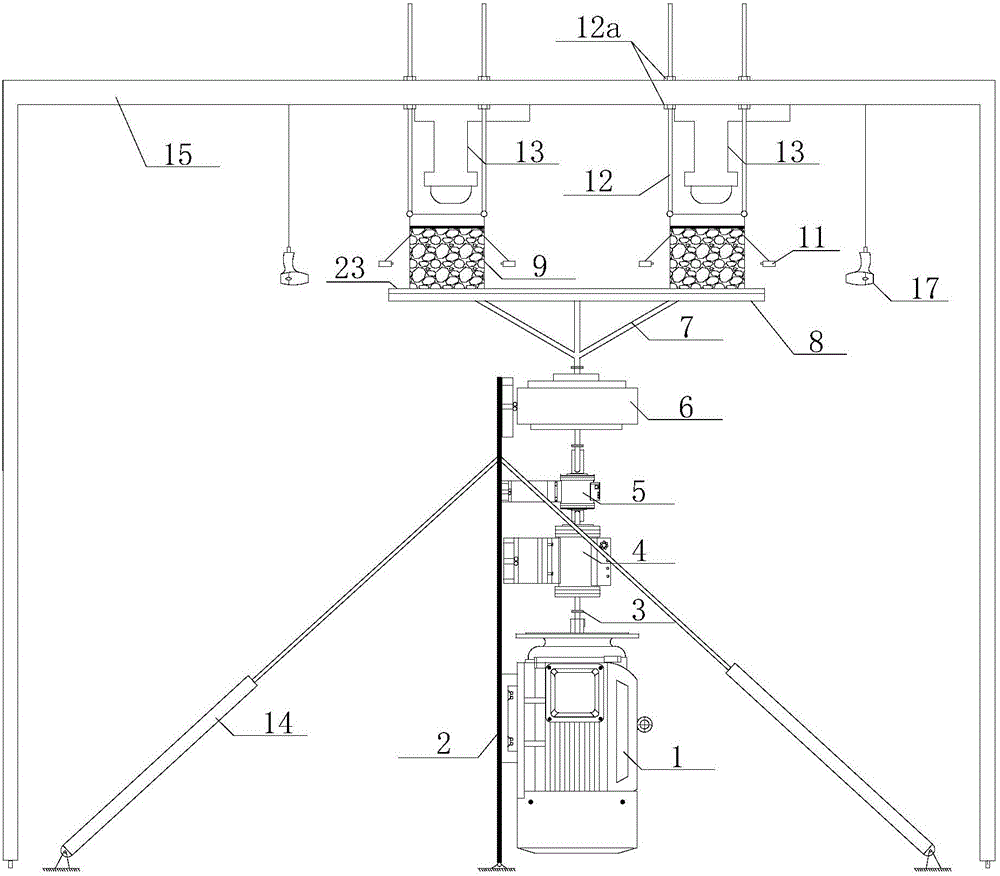

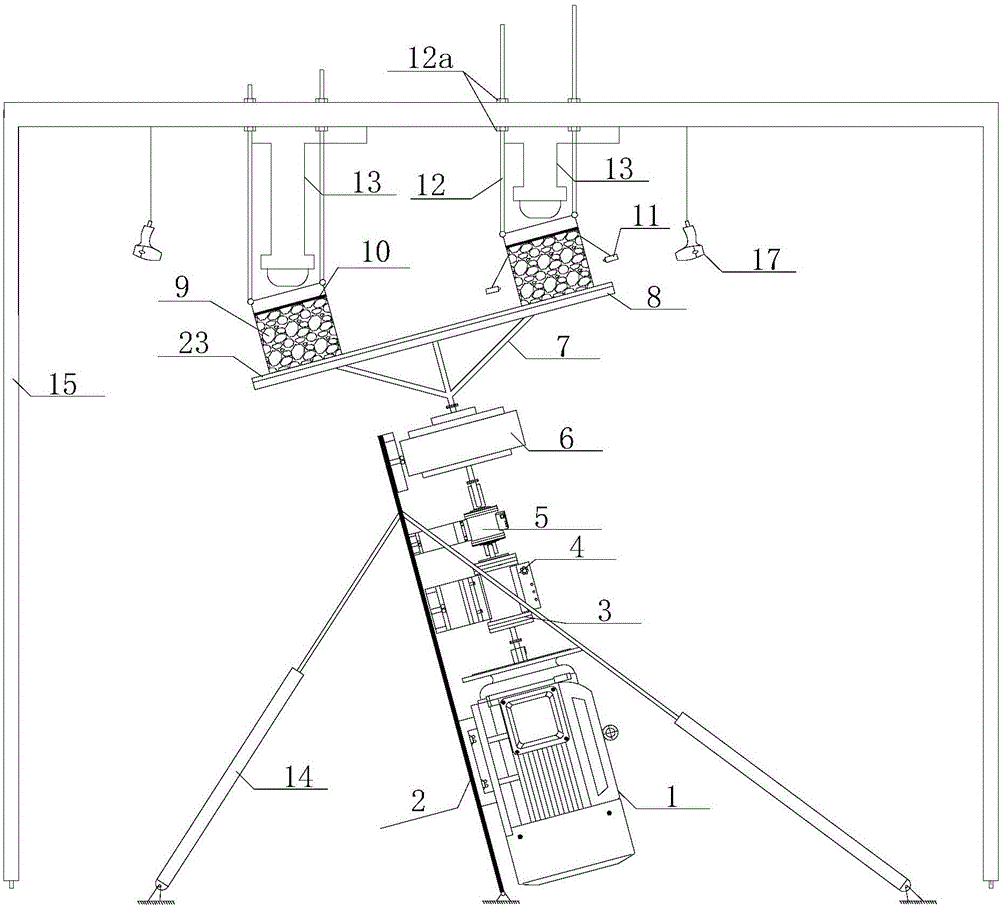

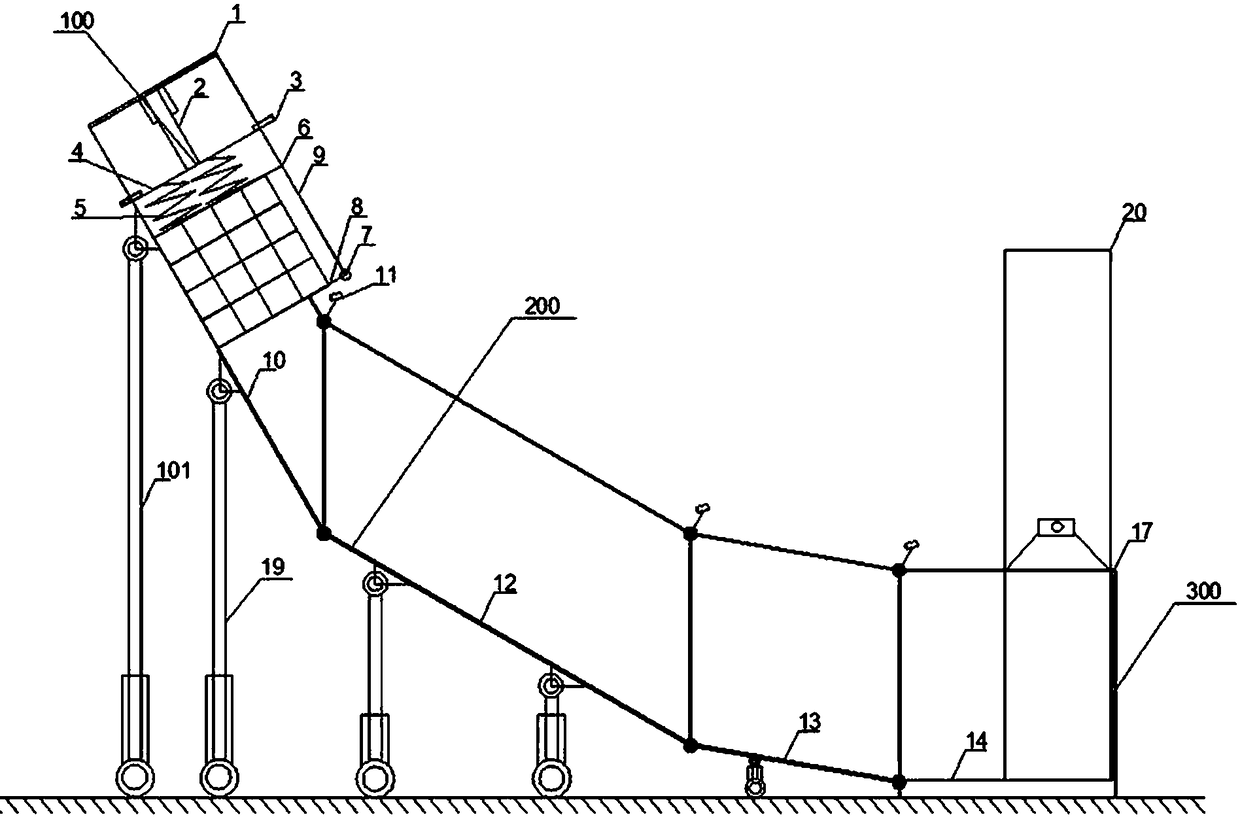

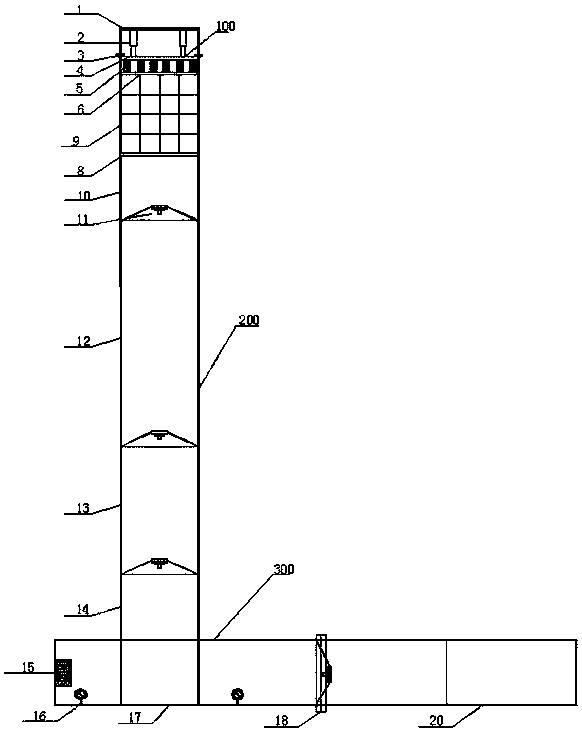

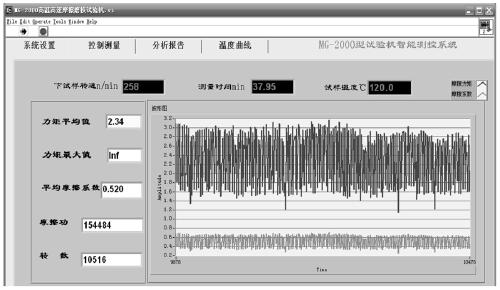

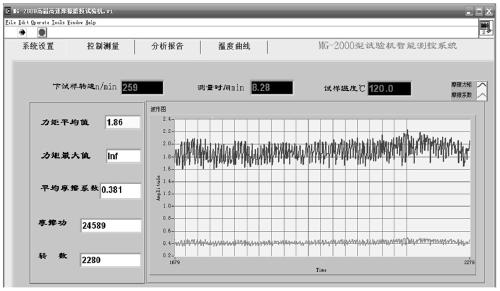

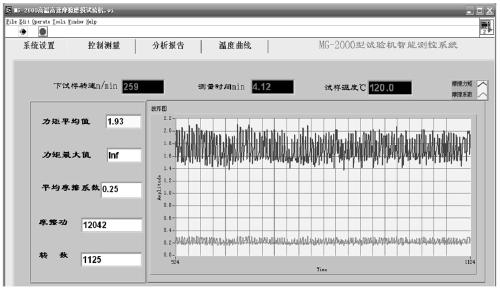

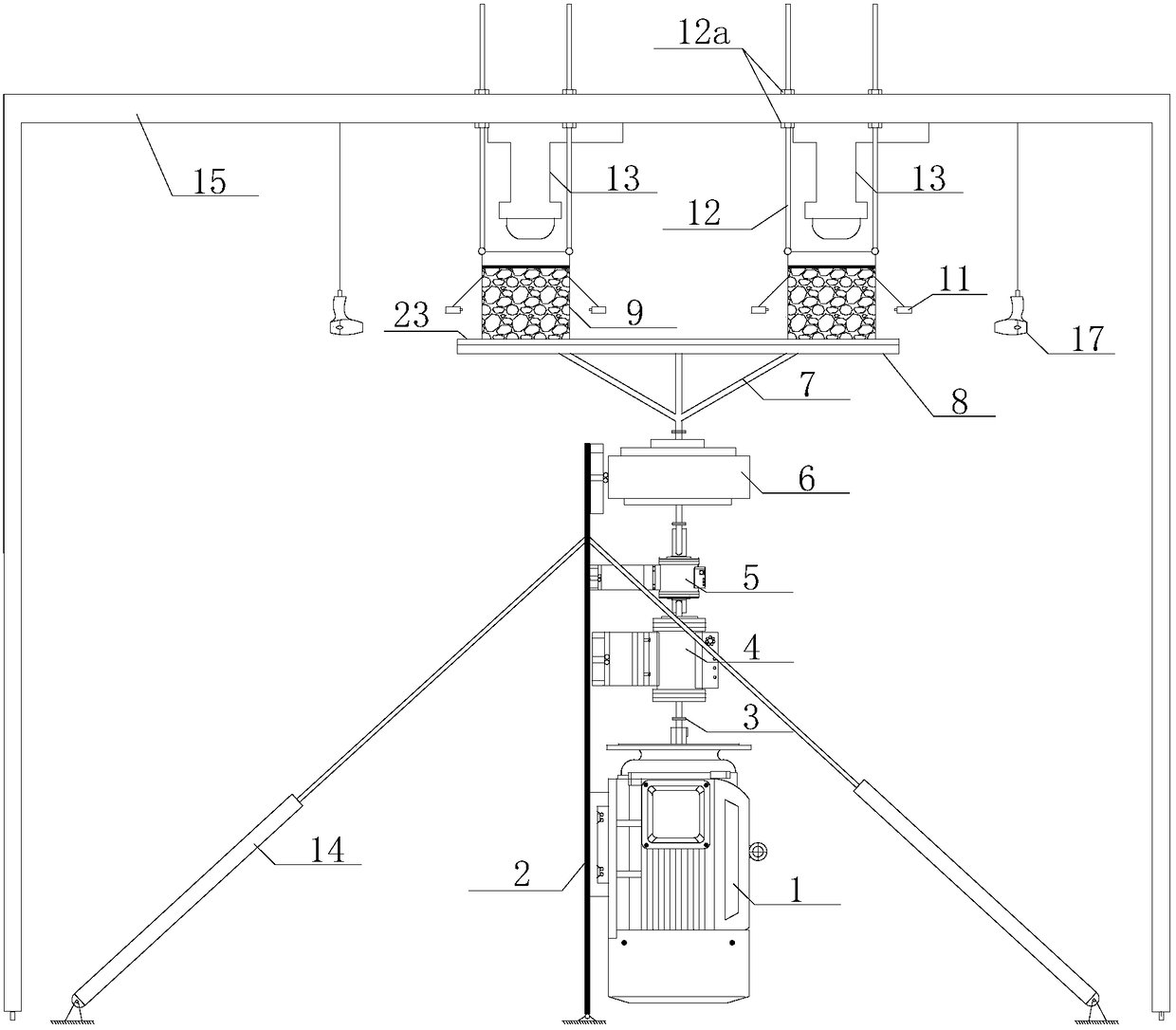

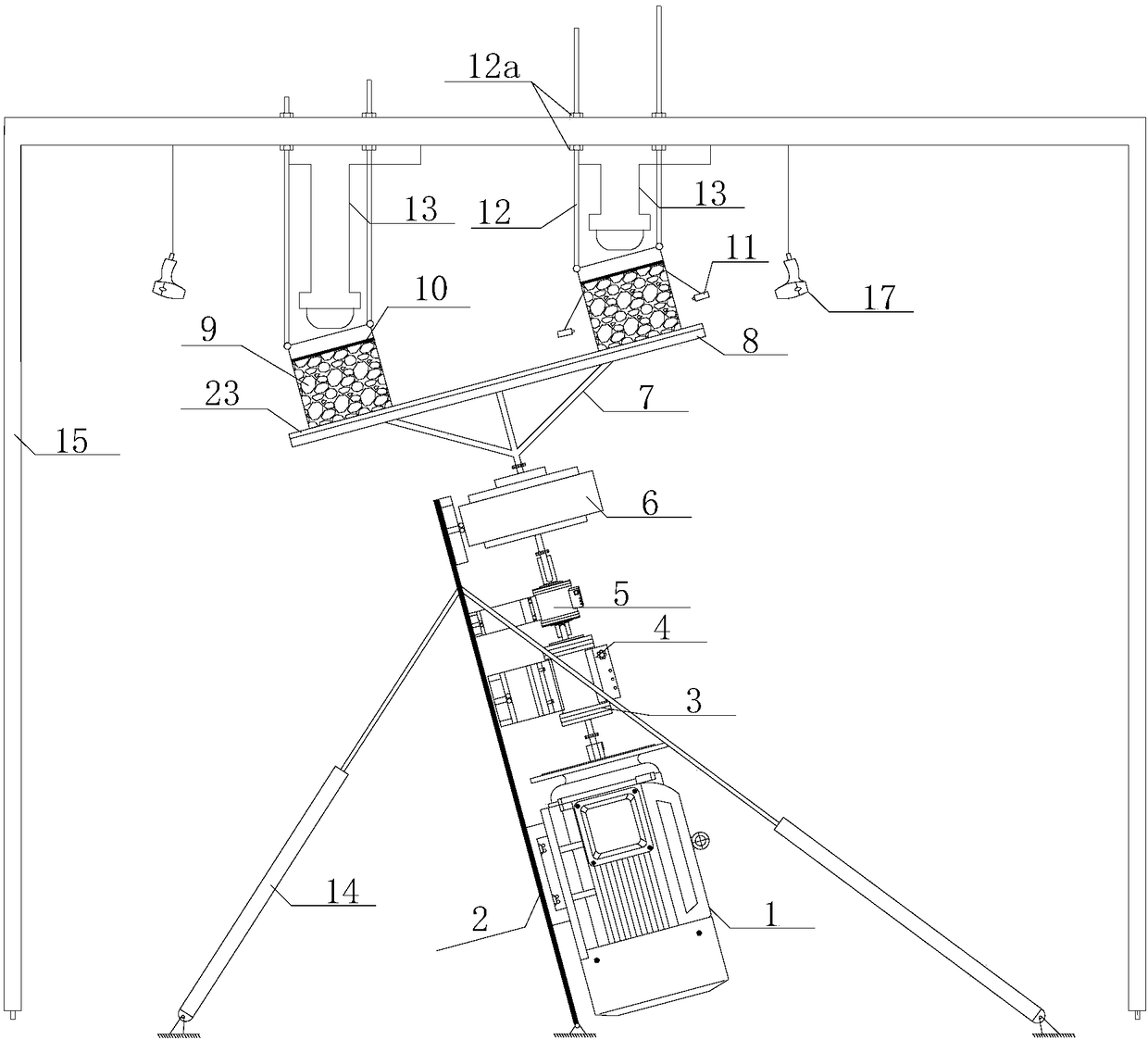

Adjustable multifunctional high-speed debris flow friction test device and test method thereof

InactiveCN105973798AAdjust relative speedUncovering Friction Fracture PhenomenaUsing mechanical meansMaterial analysisCircular discReduction drive

The invention discloses an adjustable multifunctional high-speed debris flow friction test device and a test method thereof. The adjustable multifunctional high-speed debris flow friction test device is characterized in that the bottom of a vertical steel plate is hinged with the ground; the upper part of the steel plate is hinged with the top end of a telescopic connecting rod; a motor, a speed reducer, a torque sensor and a bearing are sequentially fixed from bottom to top of the working surface of the steel plate; a motor shaft is connected with the lower end of a spindle through a speed reducer and the torque sensor; the upper end of the spindle is connected with the lower part of a bracket through bearings; a disc is fixed at the upper part of the bracket; two square, bottomless, coverless and transparent model boxes are symmetrically arranged at the upper part of the disc; four corners at the tops of the model boxes are hinged with the lower ends of upper connecting rods; upper ends of upper connecting rods penetrate through a transverse through groove in a gantry transverse beam upwards; pressure bearing steel covers are embedded inside the two model boxes; jacks are fixed on the gantry transverse beam; top rods of the jacks are aligned to the middle parts of the pressure bearing steel covers; high-speed cameras are mounted on side surfaces of the model boxes through camera connecting rods.

Owner:SOUTHWEST JIAOTONG UNIV

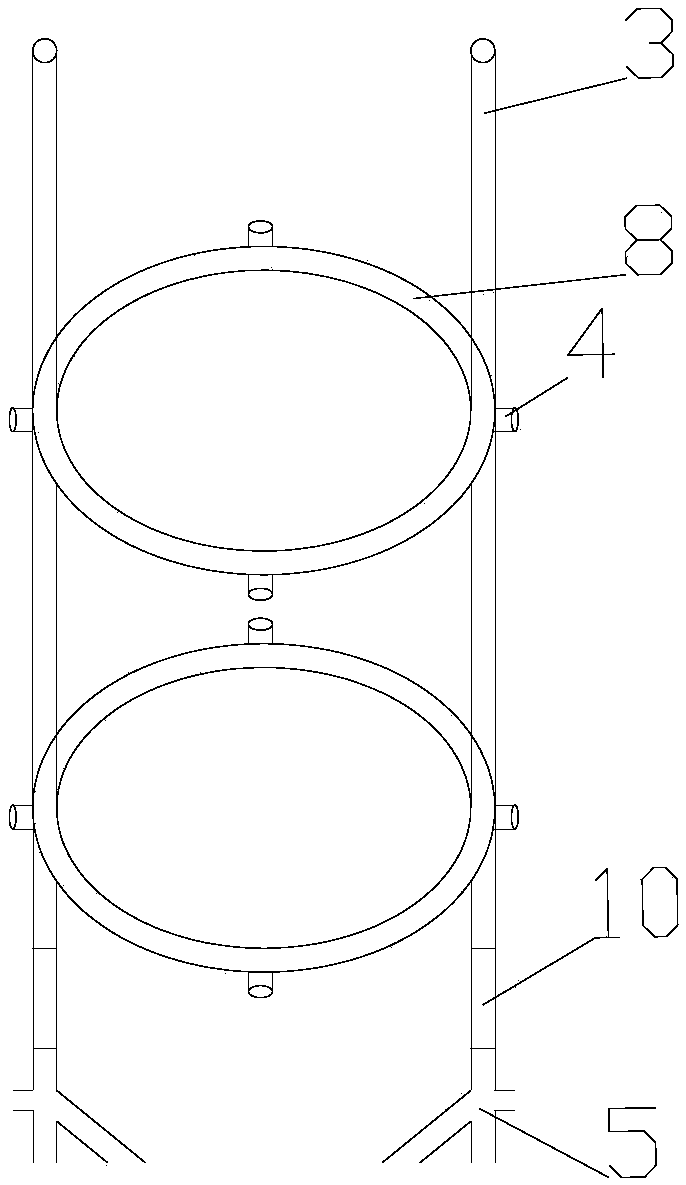

Post-grouting cast-in-place thin-wall pipe pile with grouting pipeline being reserved and construction method

The invention relates to a post-grouting cast-in-place thin-wall pipe pile with a grouting pipeline being reserved. The post-grouting cast-in-place thin-wall pipe pile comprises a reinforcement cage and a post-grouting device. The post-grouting device comprises grouting pipes, pile side one-way grout outlets, pile end one-way root-type grout outlets, pile side ring-type grouting pipes, grouting pipe pile side connectors and pile end grouting pipes. The grouting pipes are fixed to the two sides of the reinforcement cage. The pile side ring-type grouting pipes are fixed to the outer circle of the reinforcement cage. The pile side one-way grout outlets are distributed in the circle of each pile side ring-type grouting pipe at equal intervals. The two sides of each pile side ring-type groutingpipe are connected with the corresponding grouting pipe pile side connectors. The upper ends and the lower ends of the grouting pipe pile side connectors are connected with the grouting pipes. The pile end grouting pipes are arranged at the bottoms of the corresponding grouting pipes. The pile end one-way root-type grout outlets are formed in the lower ends of the pile end grouting pipes. The post-grouting cast-in-place thin-wall pipe pile has the beneficial effects that by adoption of the grouting technology, hole bottom dregs can be effectively removed, and the pile end resistance of the thin-wall pipe piles is increased.

Owner:ZHEJIANG UNIV CITY COLLEGE

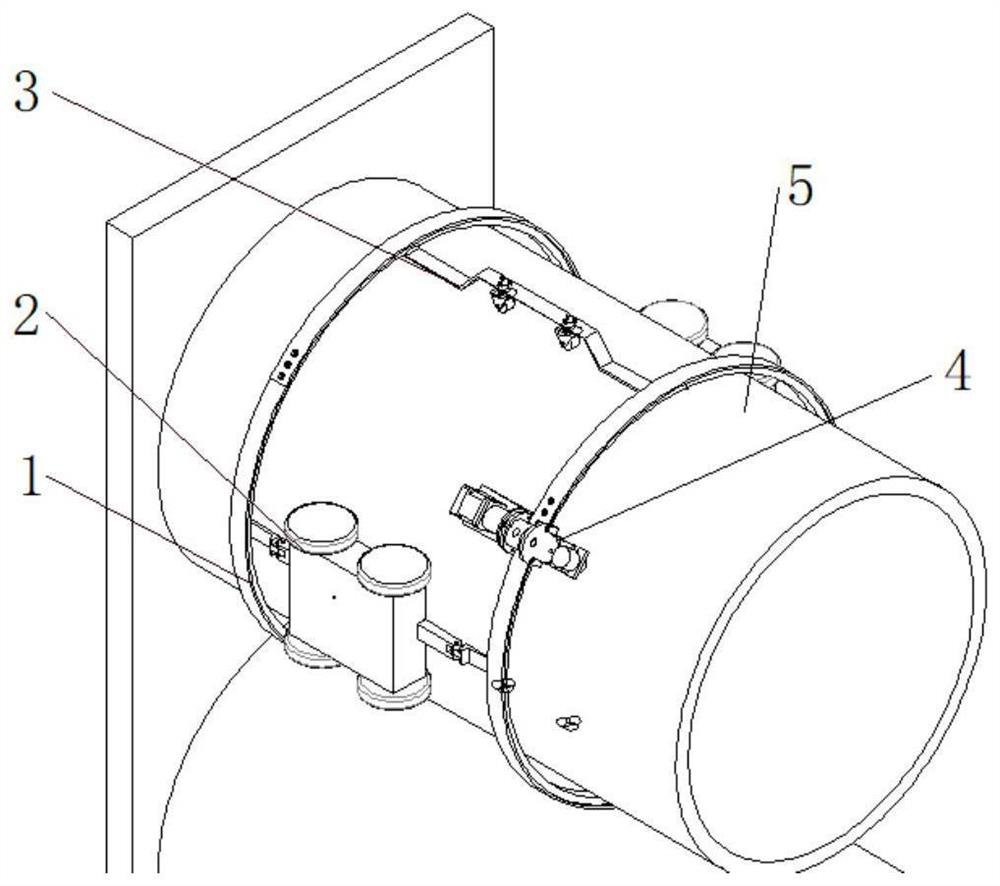

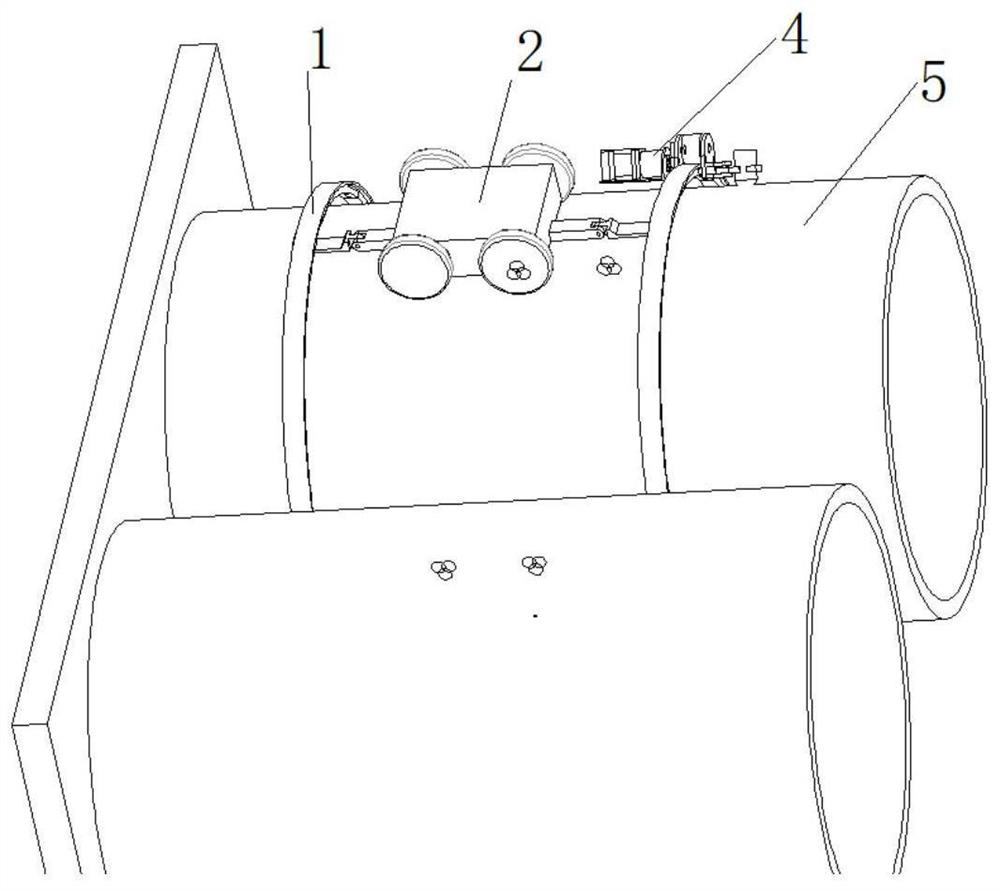

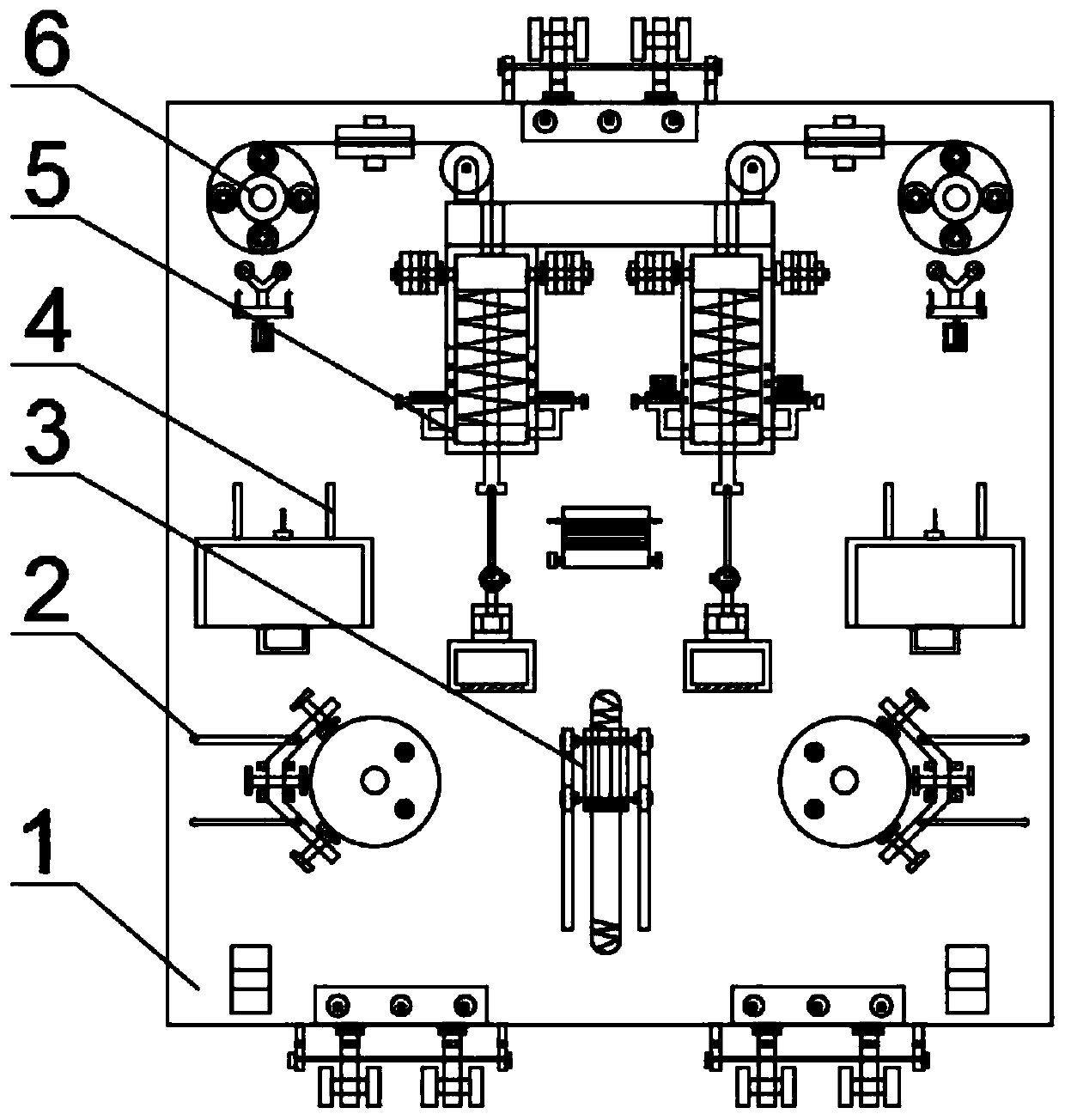

Pipeline outer wall omni-directional rapid detection robot

PendingCN113044128AHigh degree of modularityCompact structureVehiclesMaterial analysisReduction driveControl engineering

The invention discloses a pipeline outer wall omni-directional rapid detection robot, which comprises two guide rails, two moving trolley modules, two supporting wheel modules, a detection module and a control module, and is characterized in that the moving trolley modules and the supporting wheel modules are sequentially and alternately arranged at 90 degrees, and each moving trolley module comprises a trolley body and four wheels connected to two sides of the trolley body; the wheels are driven by a stepping motor, the stepping motor is connected with the wheels through a harmonic reducer, tires of the wheels are rubber tires, the detection module is installed on one guide rail, and the servo motor drives rolling wheels to drive the detection module to move on the guide rails. The device has the advantages of compact structure, compact and flexible, light weight, high integration, stable operation, high work efficiency and low cost, can be used in a narrow region, can comprehensively and systematically detect the condition of the outer wall of the pipeline, can normally work on magnetic-conducting and non-magnetic-conducting wall surfaces, can adapt to the sizes of the outer walls of different operation pipelines, has a wide application prospect, and is beneficial to popularization and application.

Owner:彼合彼方机器人(天津)有限公司

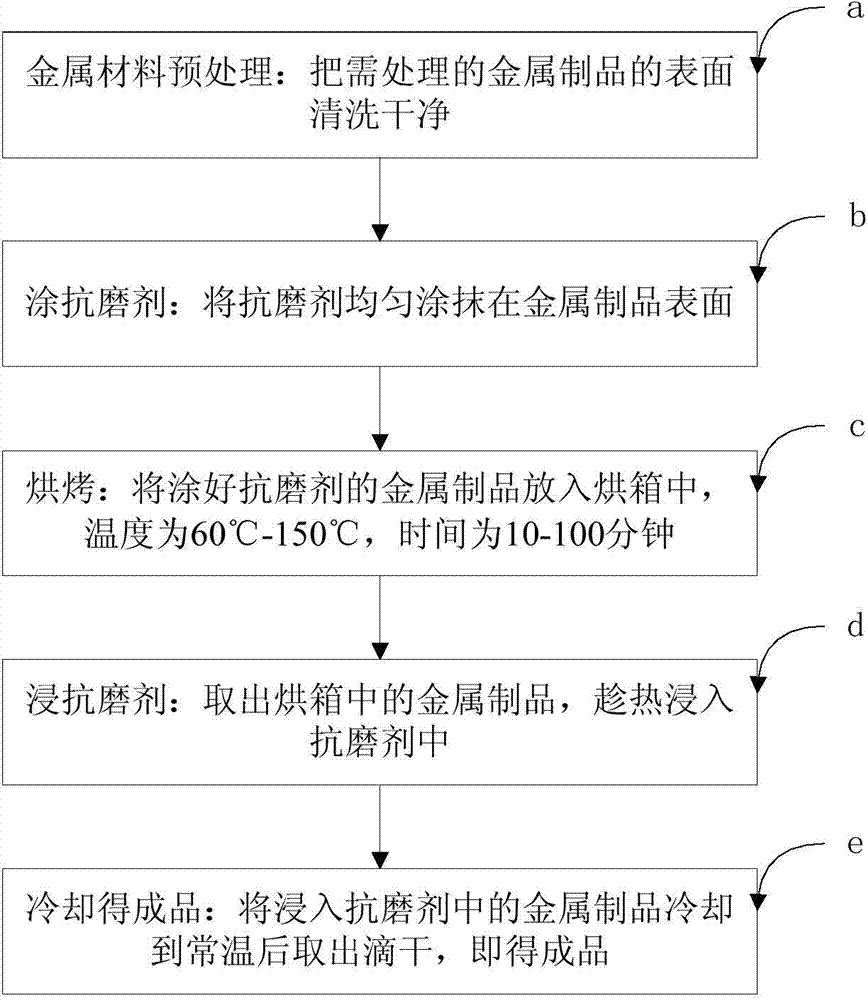

Wear-resisting pre-processing method and device of metal product

InactiveCN103480550AExtended service lifeReduce lossPretreated surfacesSolid state diffusion coatingCooking & bakingRoom temperature

The invention relates to the field of metal products, in particular to a wear-resisting pre-processing method and device of a metal product. The method includes metal material pre-processing which includes washing the surface of the metal product required to be processed, antiwear agent coating which includes coating an antiwear agent on the surface of the metal product evenly, baking which includes putting the metal product with the coated antiwear agent into an oven and baking for 10-100 minutes at the temperature of 60-150 DEG C, metal product soaking in the antiwear agent which includes taking out the metal product in the oven and immersing the product in the antiwear agent while the metal product is hot, and cooling to obtain the finished product. The metal product immersed in the antiwear agent is cooled to room temperature, taken out and drip-dried to obtain the finished product. A thermal activation pre-processing method is adopted, antiwear particles directly permeate the surface of the metal product, friction coefficient of the surface of the metal product is changed, the service life of the metal product is prolonged, machining efficiency is improved, noise is reduced, material loss is reduced, the process is simple, effect is remarkable, and pollution is avoided.

Owner:KUNSHAN KAINUOER METAL PROD

Multifunctional arm and breast muscle exercise device

InactiveCN109692429AAdjust the intensityChange intensityDumb-bellsFrictional force resistorsPhysical medicine and rehabilitationArm exercise

The invention relates to an exercise device, in particular to a multifunctional arm and breast muscle exercise device. The multifunctional arm and breast muscle exercise device comprises a mobile chassis mechanism, a breast muscle exercise mechanism, a sliding seat mechanism, a storage suspending mechanism, an arm exercise mechanism and a load adjusting mechanism; the device can be switched between a fixed mode and a mobile mode, and can be used for exercising breast muscle, adjusting strength of breast muscle exercise, storing clothes of an exerciser, suspending barbell slices, exercising arms, adjusting strength of arm exercise by changing weight, adjusting strength of arm exercise by changing a spring pre-tightening mode, adjusting strength of arm exercise by changing weight of a fly wheel and adjusting strength of arm exercise by changing friction coefficient; the breast muscle exercise mechanism is connected with the mobile chassis mechanism by partial bolted connection and partial welding, and the load adjusting mechanism is connected with the mobile chassis mechanism by welding.

Owner:范九华

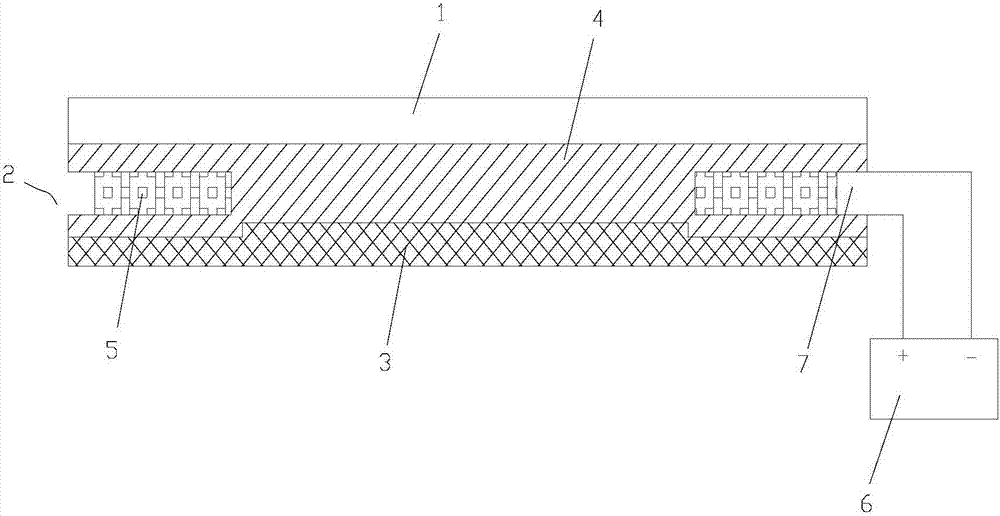

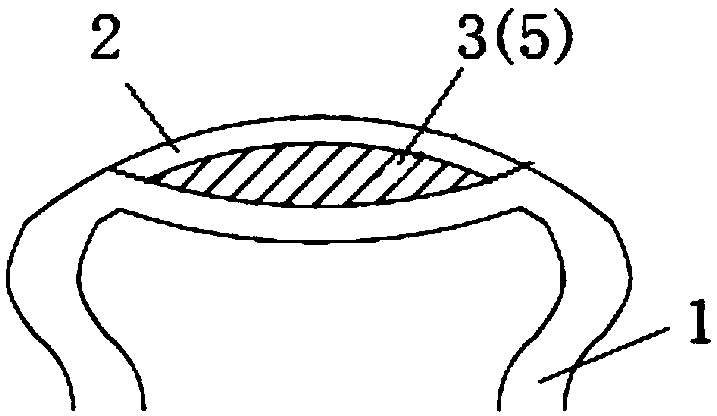

Friction-controllable foot anti-skid device

ActiveCN105686205AChange the coefficient of frictionImprove athletic performanceSolesEngineeringCompetitive sport

The invention discloses a friction-controllable foot anti-skid device, and belongs to the anti-skid technical field. The foot anti-skid device comprises an anti-skid layer made of magnetorheological rubber and a variable magnetic field of which magnetic lines penetrate through the anti-skid layer and enable a magnetorheological effect to appear, and the variable magnetic field comprises a magnet exciting coil and a controllable power source connected with the magnet exciting coil. According to the friction-controllable foot anti-skid device, under the action of the variable magnetic field, the friction coefficient of foot contact portions can be changed, therefore, the adhesion level is improved, all foot movement bodies such as a shoe sole, a foot pad and a robot palm and sole have a good anti-skid effect, and the foot anti-skid device is beneficial for reducing the sports load of an athlete and the risk of accidents and improving achievement of the athlete in competition; meanwhile, the working stability and working precision of a robot can be promoted, and rapid development of related industries such as competitive sports and robots can be promoted to some extent.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

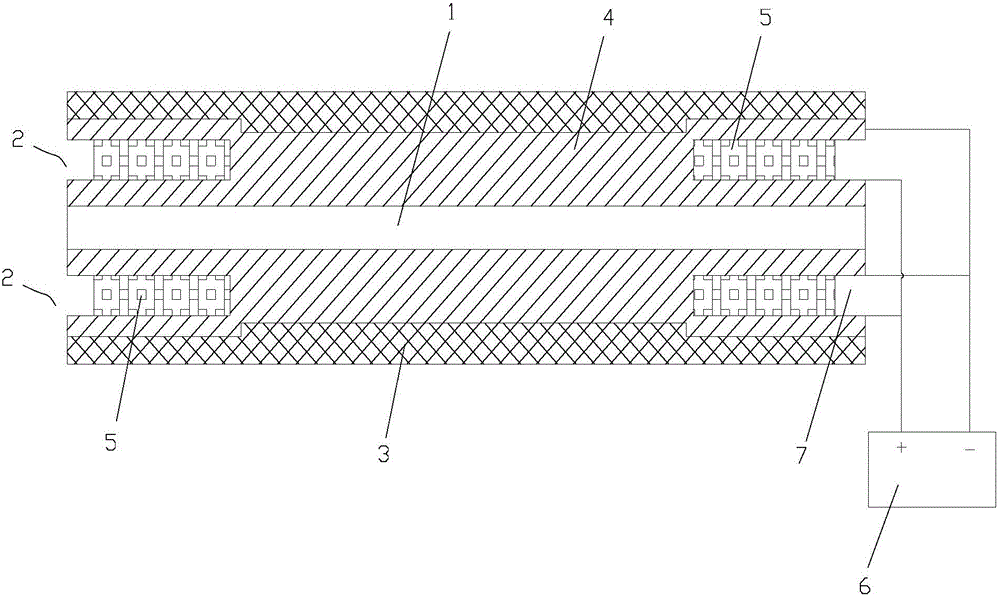

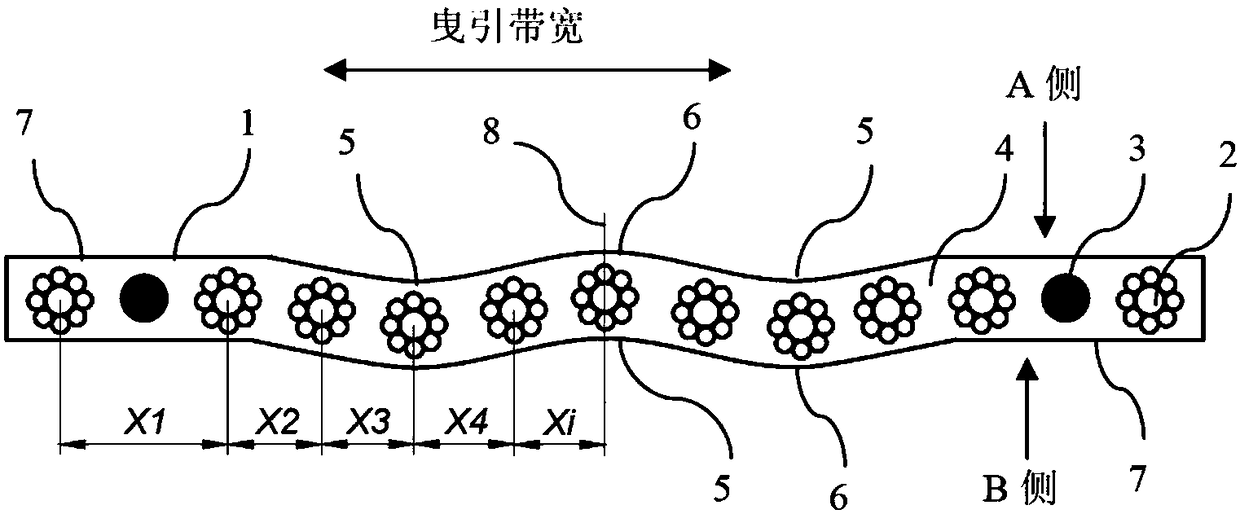

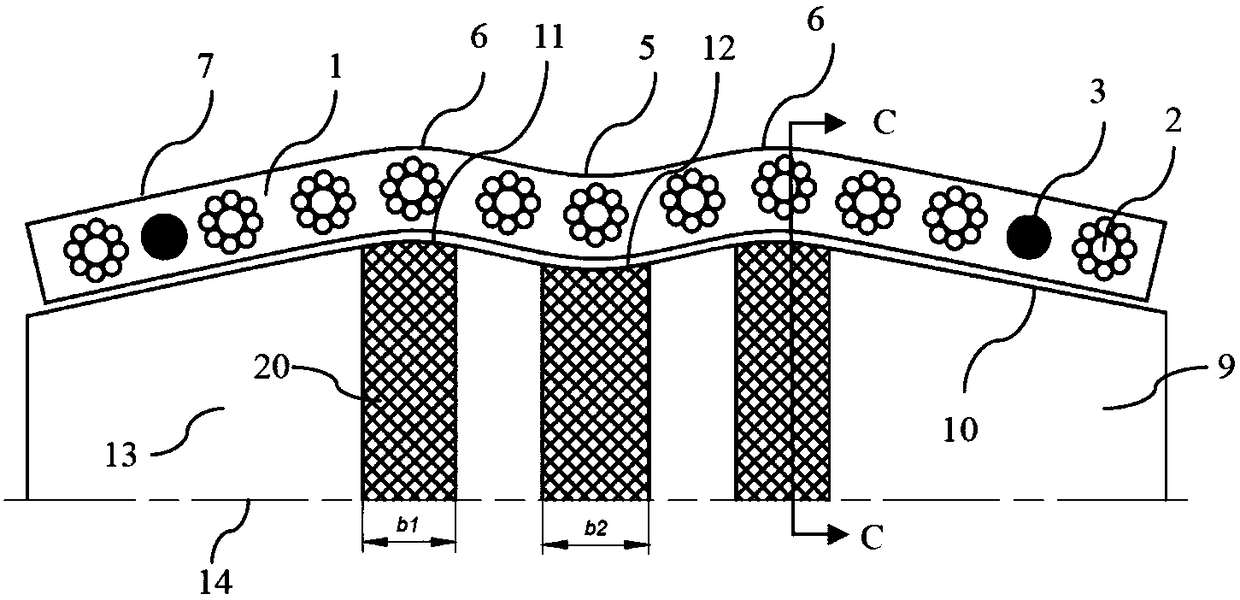

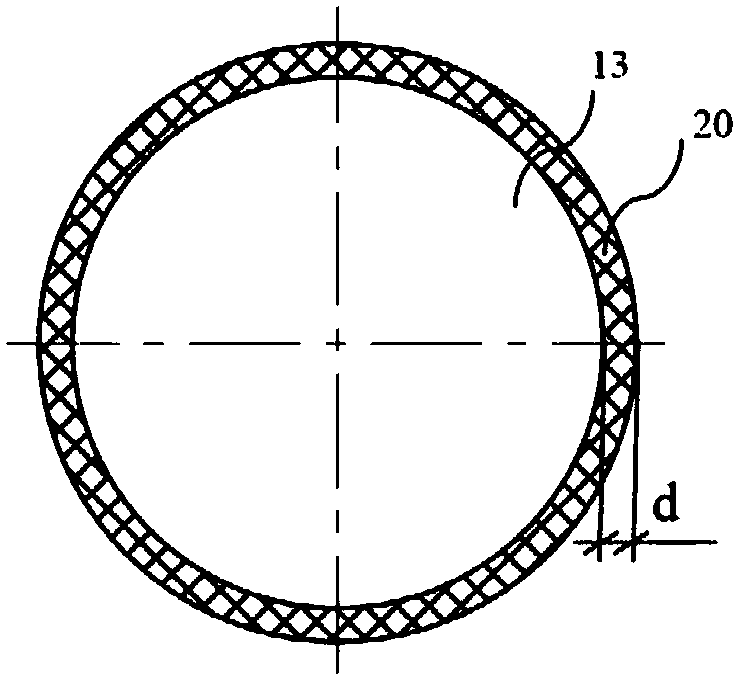

Traction belt and belt wheel of elevator system, and elevator adopting traction belt and belt wheel

PendingCN108861955APrevent axial movementChange the coefficient of frictionElevatorsBuilding liftsElevator systemFrictional coefficient

The invention provides a traction belt and a belt wheel of an elevator system and an elevator adopting the traction belt and the belt wheel. The traction belt of the elevator system comprises a bearing unit, an early warning unit and a coating layer, wherein the bearing unit extends along the length of the whole traction belt, the early warning unit extends along the length of the whole traction belt and is parallel to the bearing unit, and the bending fatigue life of the early warning unit is lower than that of the bearing unit; and the coating layer wraps the bearing unit and the early warning unit, the traction belt is in a strip shape with a uniform thickness, and at least one continuously fluctuating contour is formed in the width direction, so that a concave part and a convex part are formed on the side A matched with a traction wheel and the side B matched with a guide wheel. The belt wheel comprises the traction wheel and the guide wheel, and the surface of the traction wheel is provided with two different friction coefficients. Through cooperation of the continuously fluctuating contours, axial movement of the traction belt is prevented when passing through a wheel train.

Owner:THYSSENKRUPP ELEVATORS SHANGHAI CO LTD

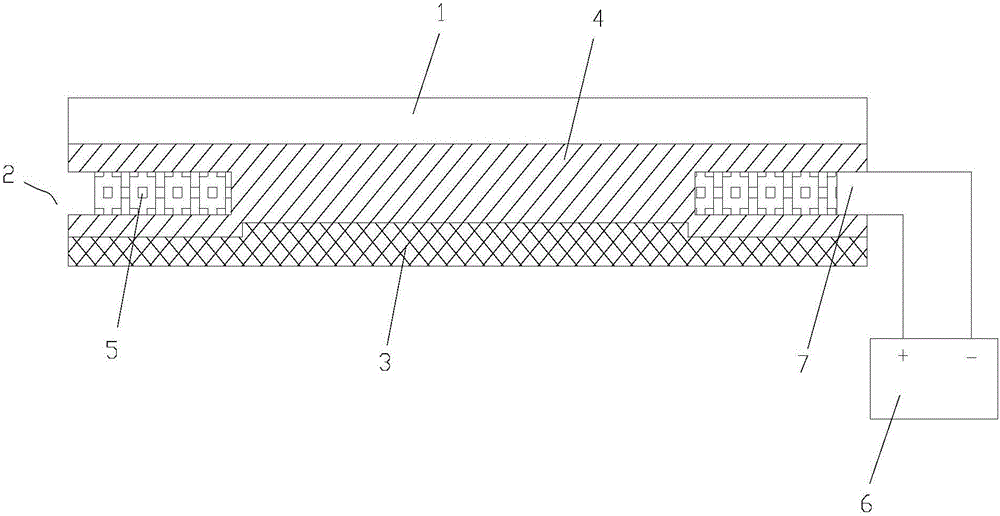

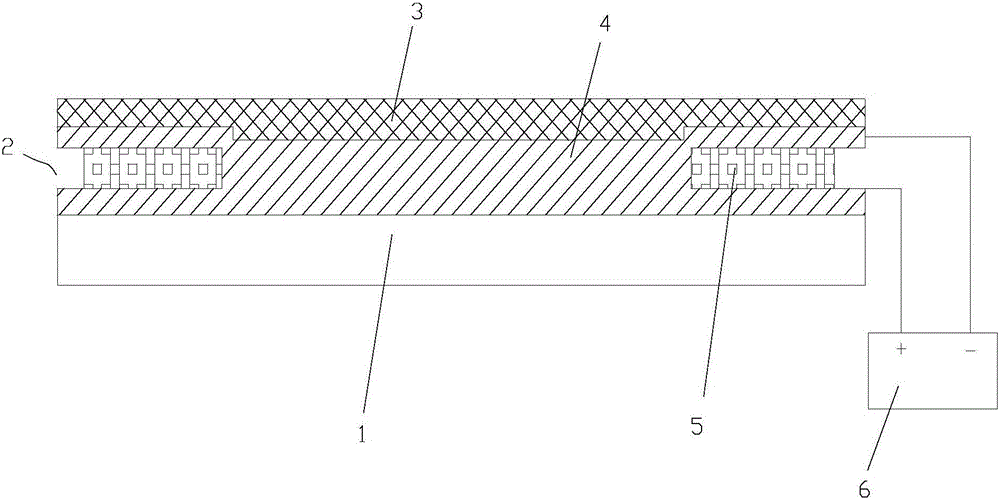

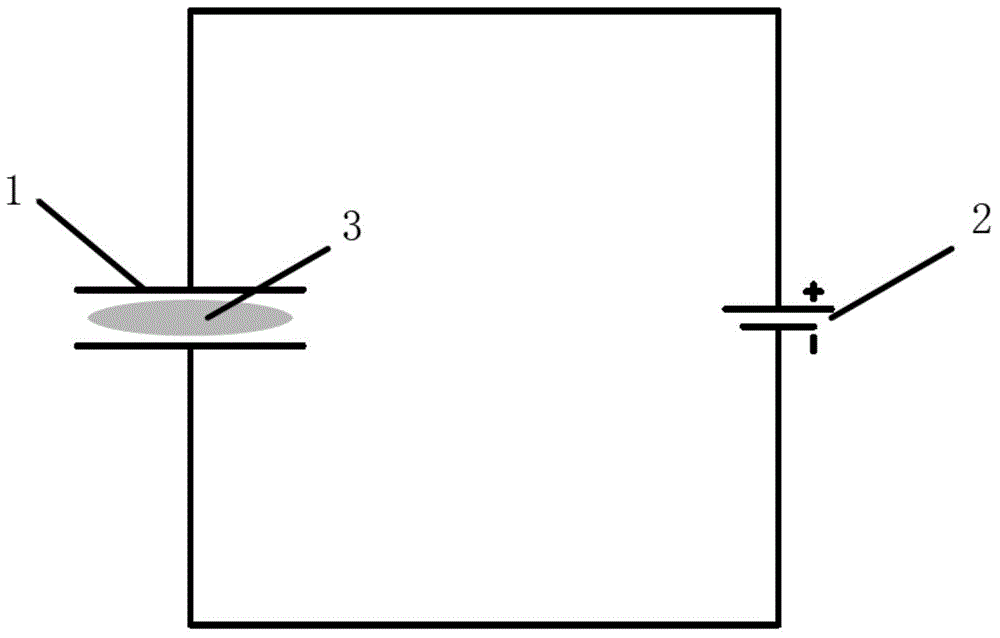

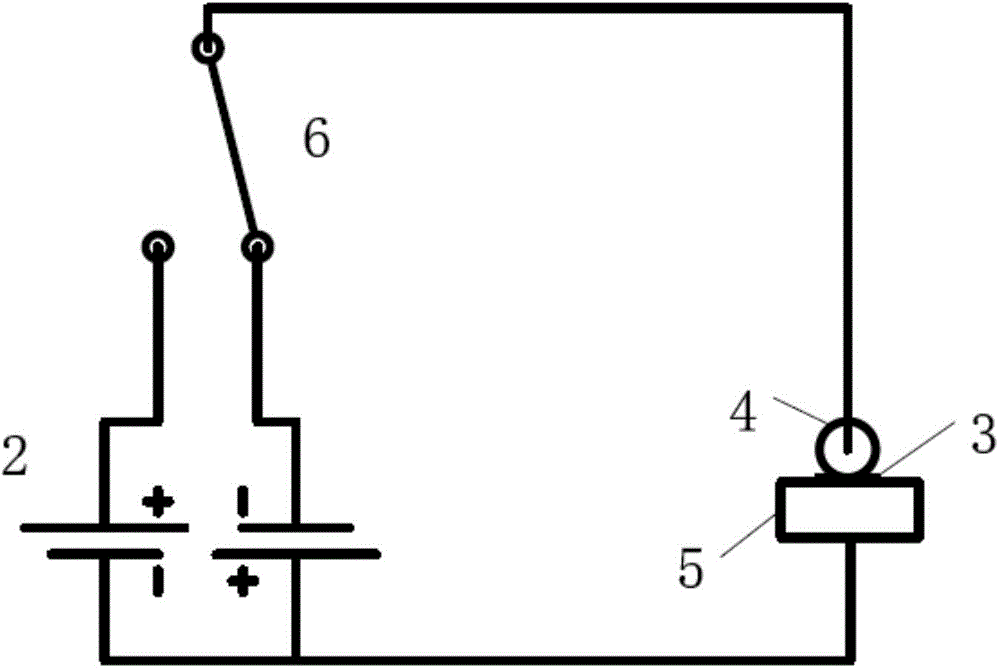

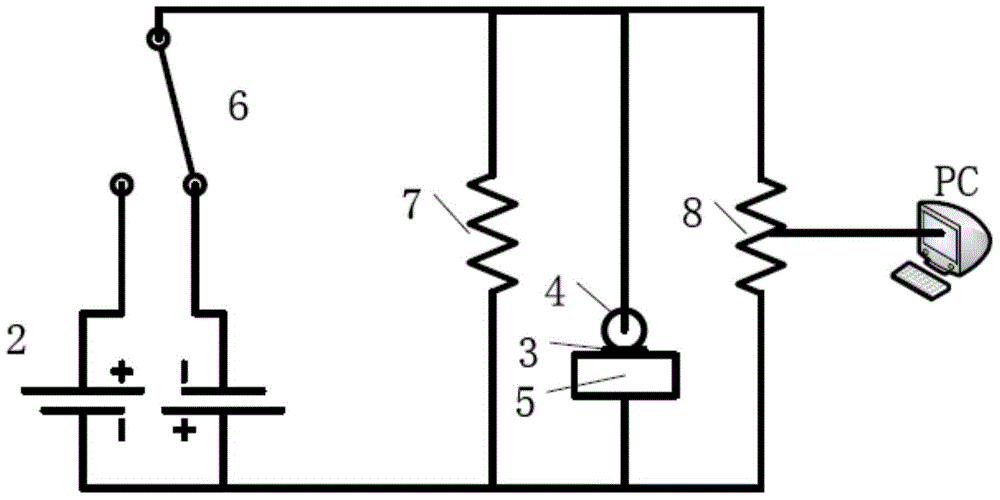

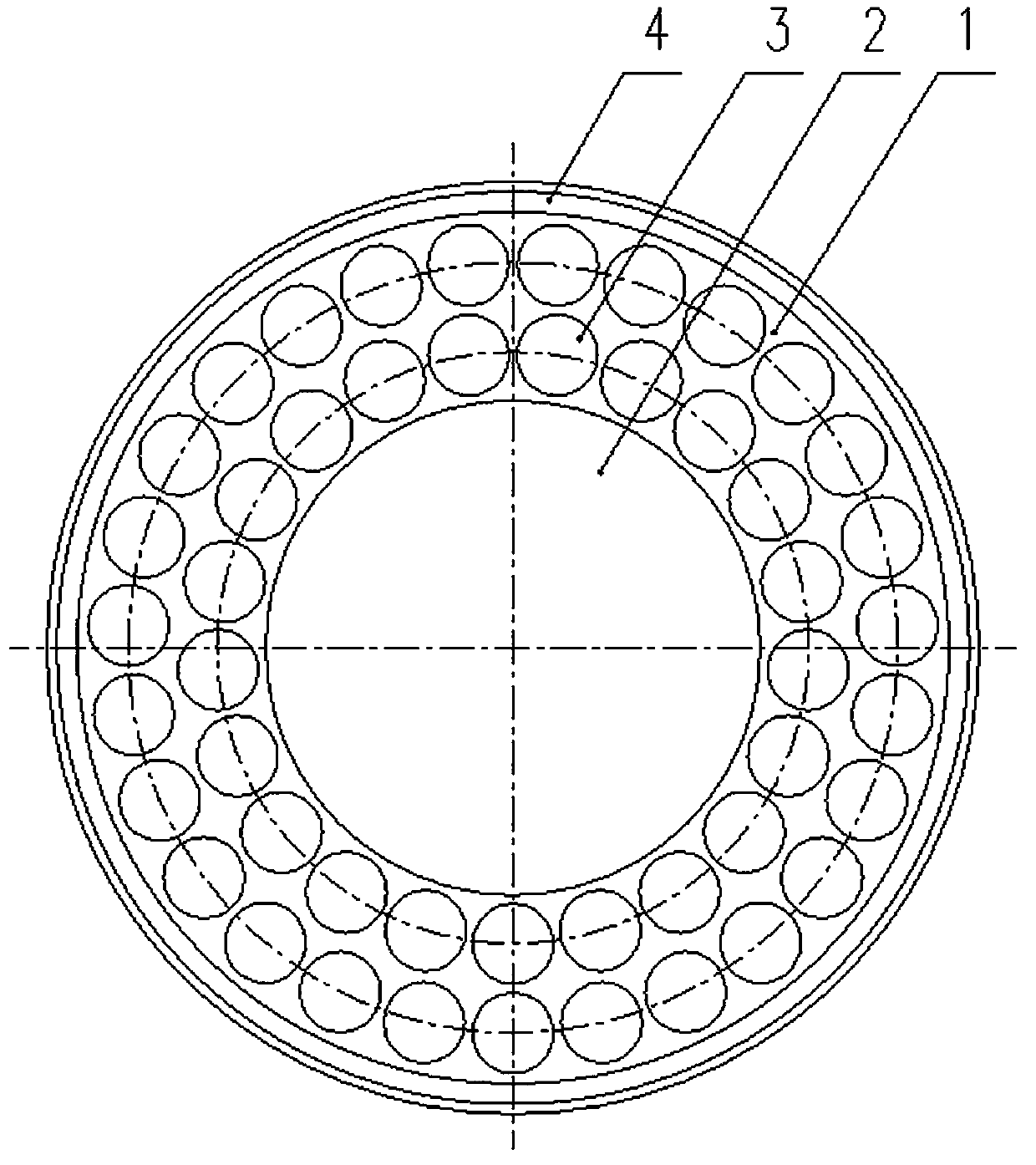

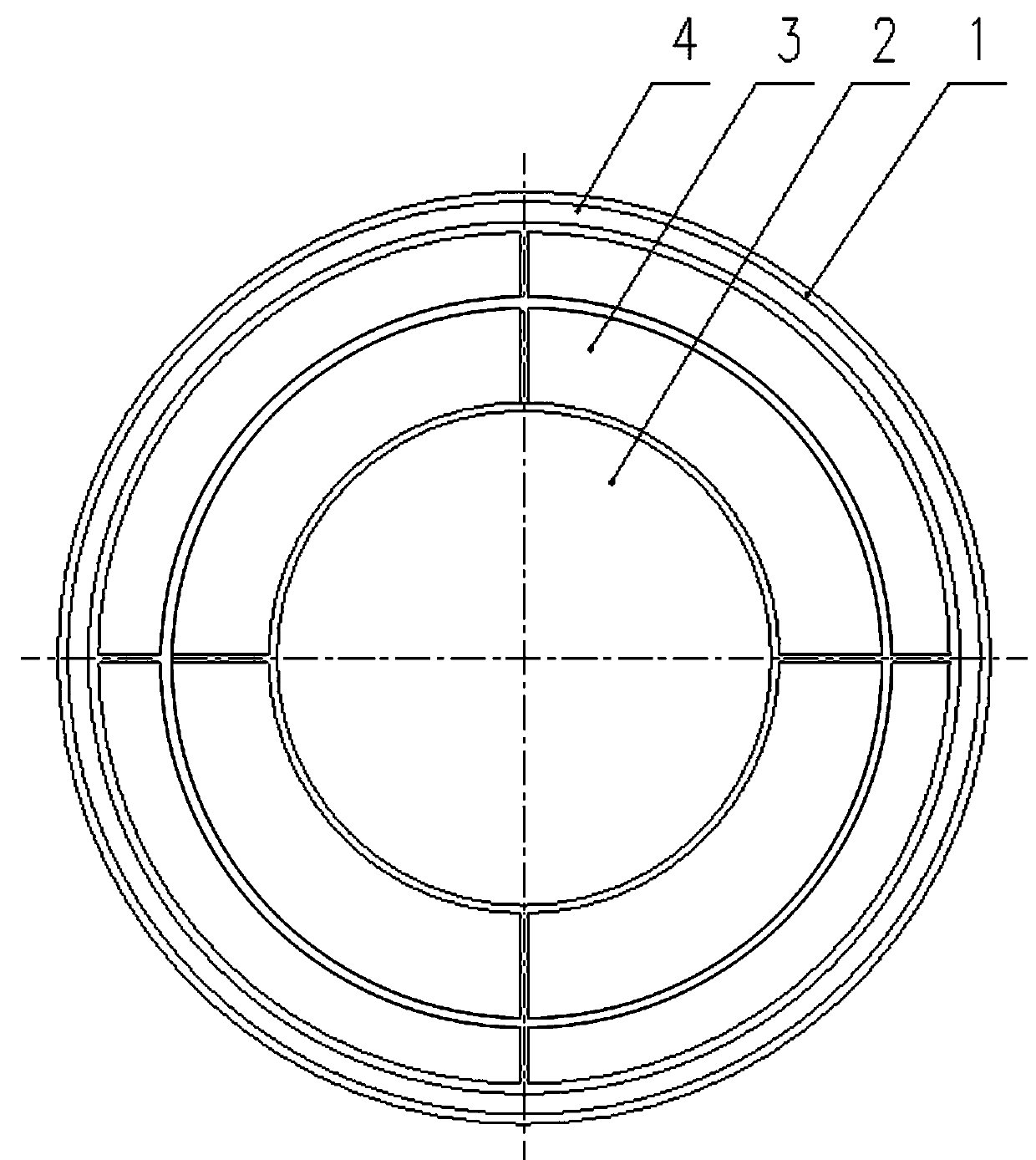

Method for changing friction coefficient between interfaces and device thereof

ActiveCN105586117AChange the coefficient of frictionIncrease coefficient of frictionAdditivesElectric fieldFriction effect

The invention provides a method for changing friction coefficient between interfaces and a device thereof. According to the method for changing friction coefficient between interfaces, an electric field is applied between two interfaces containing a lubricant. The lubricant contains a polar additive capable of changing friction coefficient of the lubricant when voltage of the electric field changes. By the method and the device, friction coefficient between interfaces can be changed. For example, friction coefficient can be raised or reduced. Friction effect is changed, reliability of equipment is enhanced, and lubricating property requirement of equipment under different working conditions is met.

Owner:CHINA PETROLEUM & CHEM CORP +1

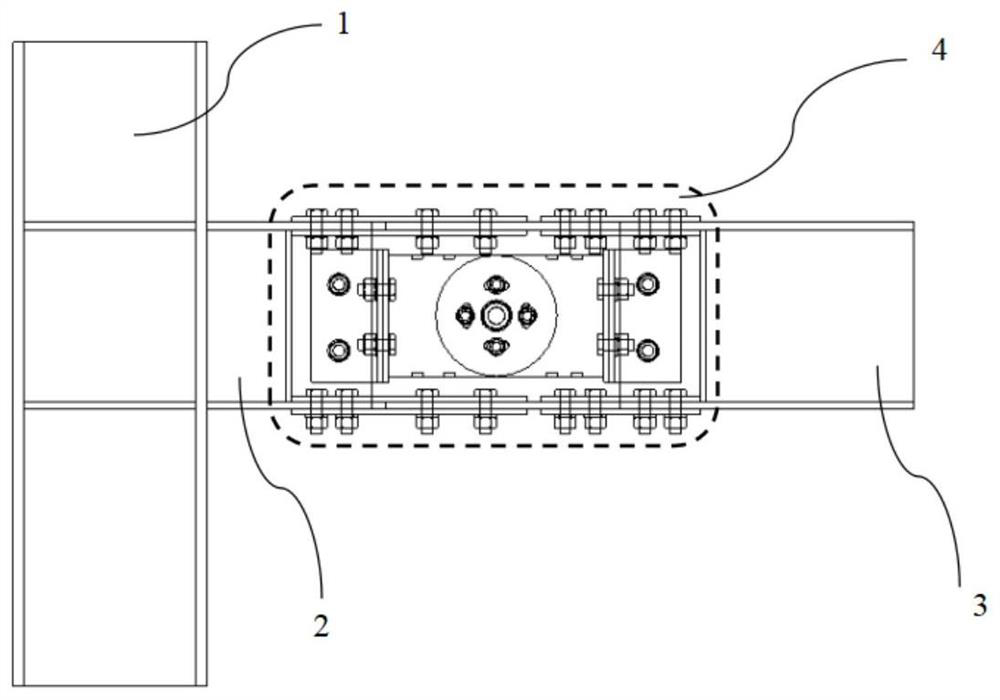

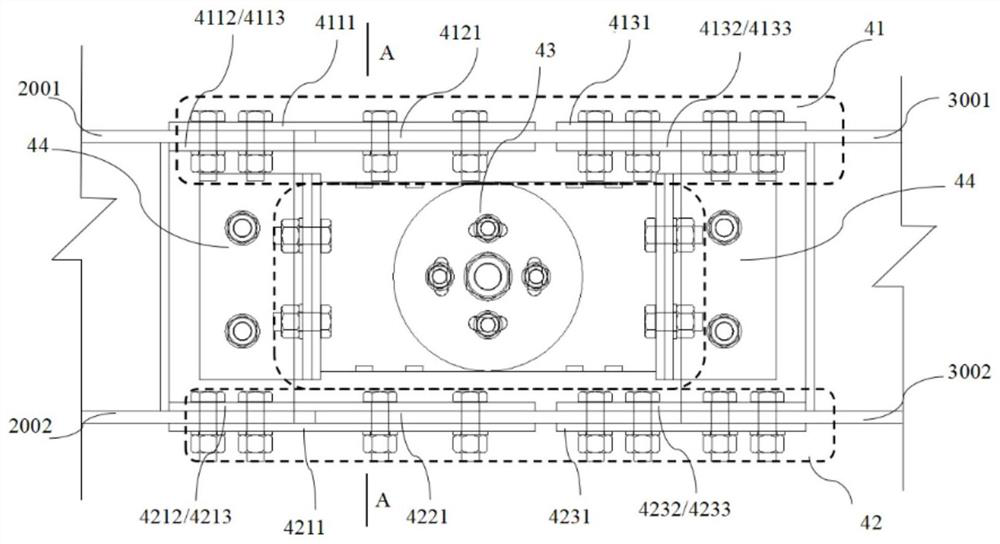

Assembly type friction type energy dissipation connection beam column joint

PendingCN113530333ALittle or no plasticityLittle or no plastic deformationProtective buildings/sheltersShock proofingEnergy consumptionNormal force

The invention discloses an assembly type friction type energy dissipation connection beam column joint based on a sliding mechanism. A sliding energy dissipation plate is provided with a long circular groove-shaped bolt hole, the sliding phenomenon does not exist in the normal use stage, normal force transmission between spliced beam sections is guaranteed, and loads on beams are transmitted to a joint core area and a frame column; along with the increase of the load, the sliding energy consumption plate starts to slide, a web steel hinge rotates, friction energy consumption is generated, and the bearing capacity of a connecting joint is kept unchanged; the load is continuously increased, bolts are in extrusion contact with the bolt hole walls of connecting plates, the high-strength bolts are converted from a friction type to a pressure-bearing type, the joint bearing capacity is increased, and the connecting plates are subjected to extrusion deformation; and the load is continuously increased, and the sliding energy consumption plate is locally bent or yielded under tension. The energy dissipation capacity and the deformation capacity of the connecting joint are improved based on the sliding mechanism, damage is concentrated on a friction energy dissipation damper, plastic damage of the beams, the columns and the joint can be protected, prefabrication assembly and post-earthquake detachability can be achieved through bolt connection, and good engineering practicability is achieved.

Owner:FUJIAN UNIV OF TECH

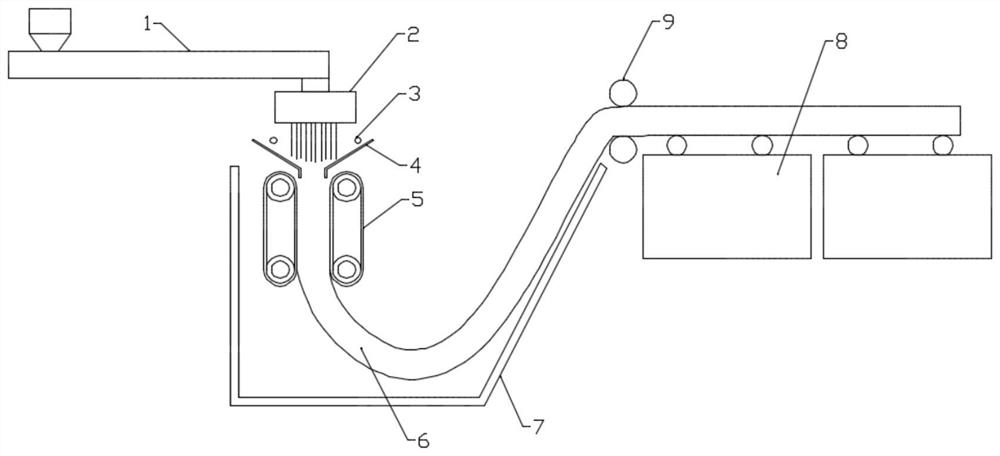

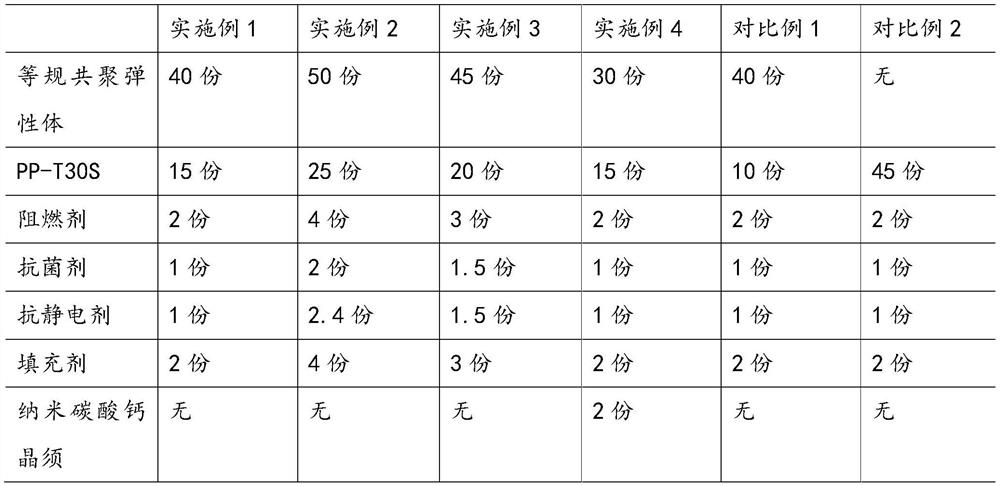

Manufacturing process of three-dimensional reticular layer

ActiveCN112793109AChange the coefficient of frictionImprove support strengthDomestic netsElastomerPolymer science

The invention discloses a manufacturing process of a three-dimensional reticular layer. The manufacturing process comprises the following steps: mixing a non-viscous high-friction-coefficient isotactic co-polypropylene elastomer, homo-polypropylene and an auxiliary agent, and carrying out melt extrusion through a screw extruder; spraying the melt liquid extruded by the screw extruder from a nozzle containing a plurality of spraying holes to form a plurality of thin strip compositions; and contacting and bending the thin strip compositions and cooling water to form irregular rings to form the three-dimensional reticular layer. According to the process, the high-friction-coefficient copolymerized PP and conventional PP raw materials are creatively mixed and applied to preparation of the reticular layer, and the thin strip compositions are in contact with the cooling water and then are randomly bent to form a special structure of the disordered three-dimensional reticular layer, by introducing the high-friction material, the friction force of the strip-shaped objects in contact with each other is increased so as to improve the supporting strength, under the special structure, the effect of the high-specification PP material can be achieved through the low-specification PP material, and the cost is reduced.

Owner:宁波木生家居有限公司

Particle dispersing device

InactiveCN101949794AReduce preparation timeThe overall structure is simple and reliablePreparing sample for investigationMaterial analysis by optical meansElastomerEngineering

The invention relates to a particle dispersing device. A motor is fixed at the lower part of the motor frame, and the output shaft of the motor penetrates upwards through the motor frame and is connected with a driving screw; the periphery of the driving screw is provided with a shaft sleeve, and a lifting screw sleeve is assembled on the driving screw and positioned in the shaft sleeve; the lifting screw sleeve is driven by the driving screw to move up and down in the shaft sleeve; the outer wall of the lifting screw sleeve is provided with a guide groove in the axial direction of the lifting screw sleeve, the inner wall of the shaft sleeve is provided with a vertical guide pin, and the guide pin is embedded in the guide groove and forms a slide fit with the guide groove; the top of the lifting screw sleeve is provided with a top plate, the top plate is a round flat plate, a planar elastic body is flatly spread on the upper surface of the top plate, and the edge of the planar elastic body is clamped on a bracket through a pressure plate; the upper end of a sensor mounting rack is fixed on the lower surface of the top plate; and a height sensor is installed at the lower end of the sensor mounting rack. The device has ingenious and reasonable structure and can uniformly disperse the particle sample, so that the sample is arranged in the form of single particles and the food sample particles do not adhere to each other.

Owner:布勒(无锡)机械技术服务有限公司

Stiffness/damping adjustable double-cantilever beam sealed passive damper

InactiveCN102418769BChange the coefficient of frictionWith stiffnessNon-rotating vibration suppressionCantilevered beamNumerical control

Owner:BEIHANG UNIV

Adjustable multifunctional landslide blockage and dam failure mechanism test device and test method

InactiveCN106290790BRealize motion simulation testAccurate test basisEarth material testingLandslideEngineering

Owner:SOUTHWEST JIAOTONG UNIV

V-belt

V-ribbed belt having a main body made of an elastomeric material, wherein the V-ribbed belt has a cover layer forming the back of the belt, a force-transmission zone with a plurality of tensile members forming reinforcements, and a substructure, which is provided with a V-ribbed profile, characterized in that the V-ribbed belt, as reinforcement, contains glass-fibre cords with a glass fibre count of between 320 and 1050 tex.

Owner:CONTITECH ANTRIEBSSYST GMBH

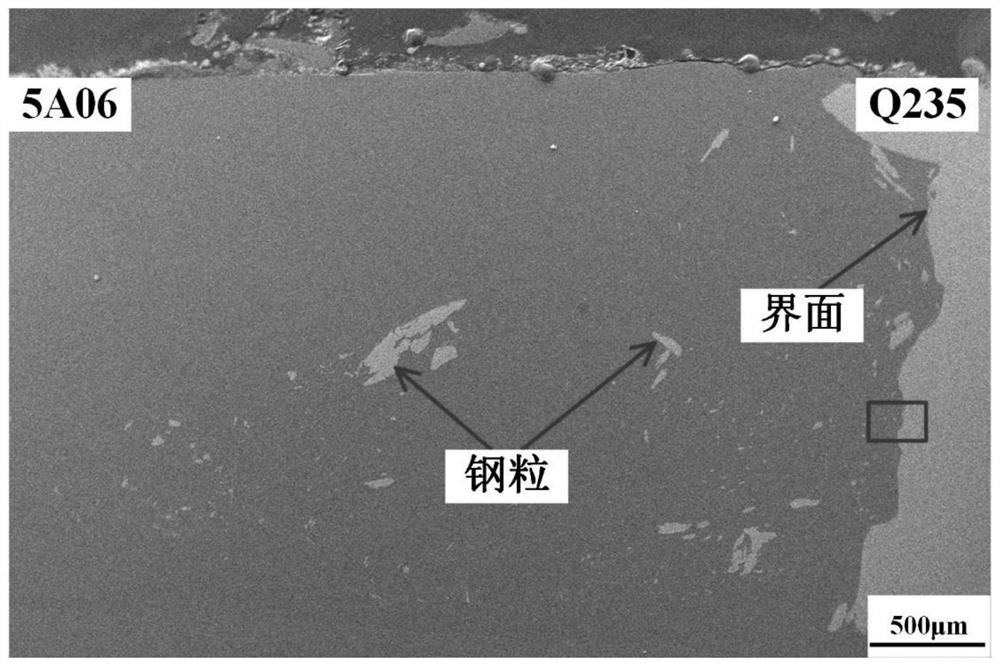

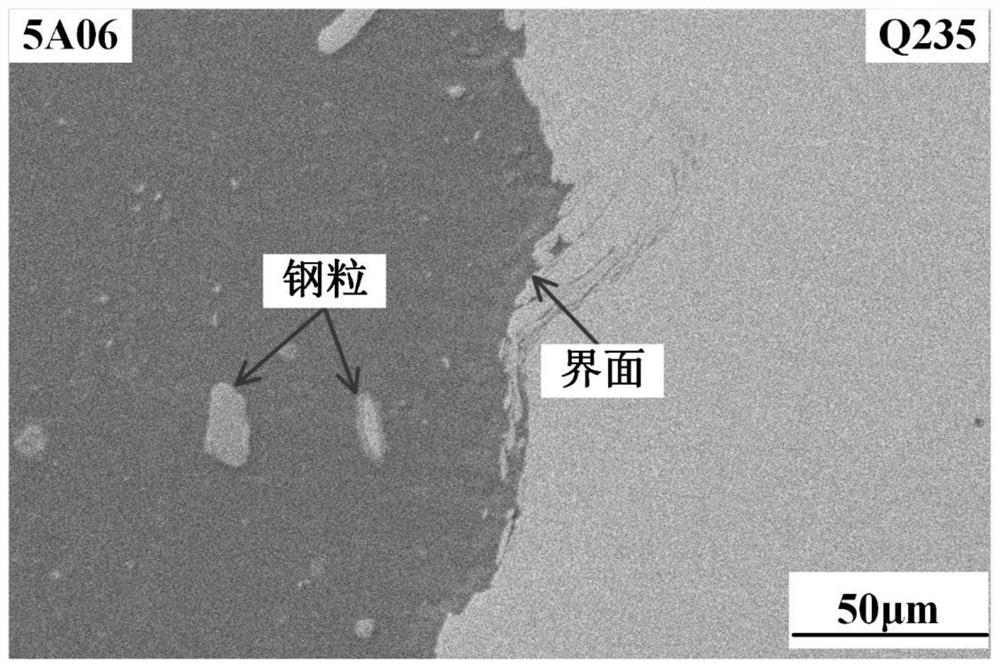

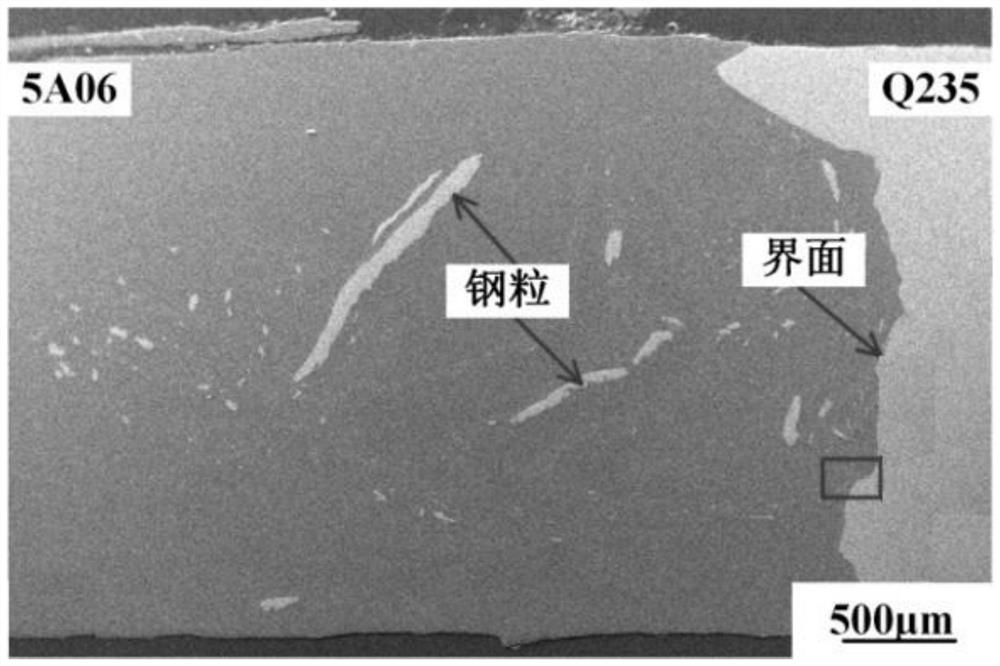

An aluminum-based welding material for friction stir welding of aluminum/steel filler and its preparation method

ActiveCN111203671BPrevent interdiffusionHigh tensile strengthWelding/cutting media/materialsSoldering mediaFriction weldingIngot

Owner:CHONGQING UNIV OF TECH

Fluorine-containing plastic-coated guide rail mechanism

InactiveCN112894398AChange the coefficient of frictionHigh movement accuracyLarge fixed membersPositioning apparatusFrictional coefficientStructural engineering

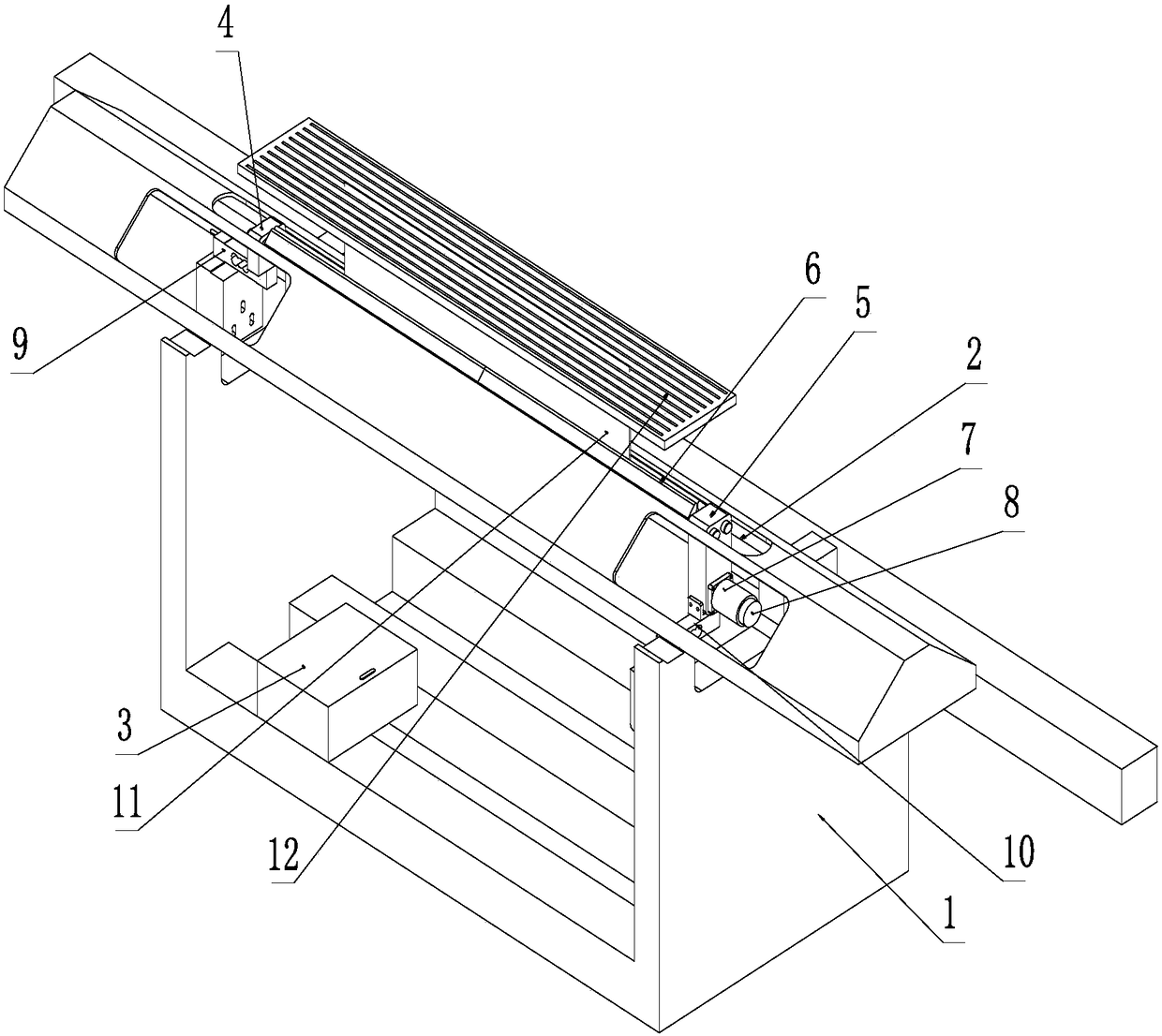

The invention discloses a fluorine-containing plastic-coated guide rail mechanism, and particularly relates to the field of machine tool machining and manufacturing. The mechanism comprises a base, wherein a static guide rail is installed in a groove in the left side of the base through an inner hexagonal screw, an adjusting pin and a movable guide rail are clamped in a groove in the right side of the base, an elastic pressing plate is installed at the left end of the top face of the base, fluorine-containing guide rail soft belts are attached to the bottom ends of the static guide rail and the movable guide rail, a sliding base is slidably installed on the top faces of the static guide rail and the movable guide rail, oil scraping plates are installed at the two ends of the sliding base, and bottom wedges are installed at the two ends of the bottom face of the sliding base through screws. The fixed guide rail and the movable guide rail are used for jointly supporting the sliding base, meanwhile, the position of the movable guide rail is finely adjusted through an adjusting pin, and the friction coefficient between the sliding base and the guide rail can be changed, so that sliding damping is increased or reduced, the moving precision of the plastic-coated guide rail is improved, the unique guide rail structure of the plastic-coated guide rail is more convenient to disassemble and assemble, the maintenance convenience is greatly improved, and the installation and maintenance efficiency is improved.

Owner:无锡六机机床有限公司

A foot anti-slip device with controllable frictional force

ActiveCN105686205BChange the coefficient of frictionImprove athletic performanceSolesEngineeringCompetitive sport

The invention discloses a friction-controllable foot anti-skid device, and belongs to the anti-skid technical field. The foot anti-skid device comprises an anti-skid layer made of magnetorheological rubber and a variable magnetic field of which magnetic lines penetrate through the anti-skid layer and enable a magnetorheological effect to appear, and the variable magnetic field comprises a magnet exciting coil and a controllable power source connected with the magnet exciting coil. According to the friction-controllable foot anti-skid device, under the action of the variable magnetic field, the friction coefficient of foot contact portions can be changed, therefore, the adhesion level is improved, all foot movement bodies such as a shoe sole, a foot pad and a robot palm and sole have a good anti-skid effect, and the foot anti-skid device is beneficial for reducing the sports load of an athlete and the risk of accidents and improving achievement of the athlete in competition; meanwhile, the working stability and working precision of a robot can be promoted, and rapid development of related industries such as competitive sports and robots can be promoted to some extent.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

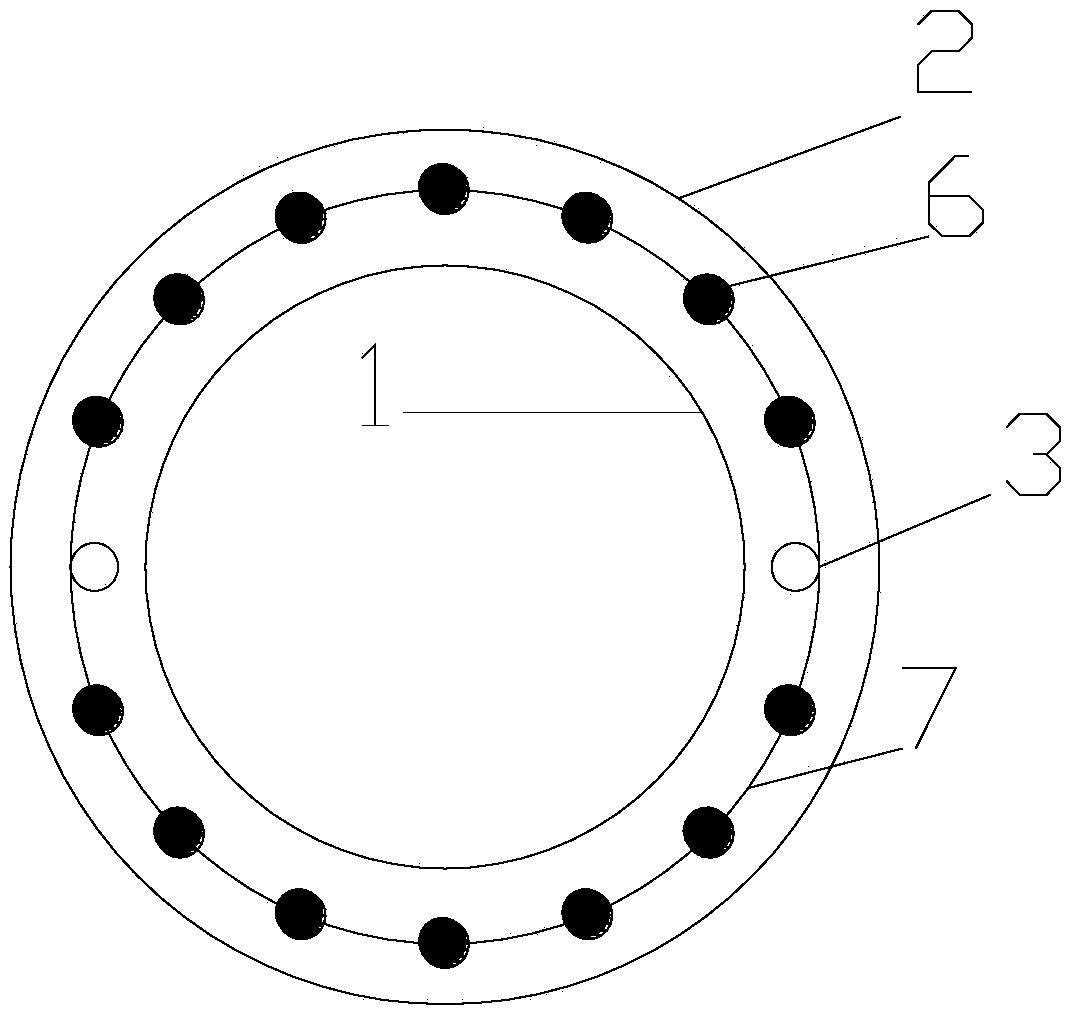

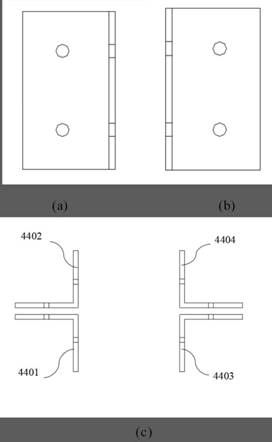

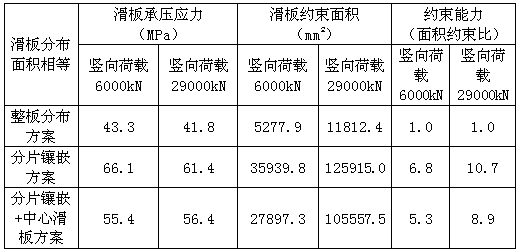

Distribution mode of nonmetal sliding plate of friction pair of bridge bearing

PendingCN110409291ASmall structure sizeReduce manufacturing costBridge structural detailsBridge materialsSlide plateControl theory

Disclosed is a distribution mode of a nonmetal sliding plate of a friction pair of a bridge bearing. The nonmetal sliding plate consists of a central sliding plate and split sliding plates which are separately embedded in corresponding grooves formed in a base plate; the central sliding plate is an integral sliding plate; the center of the central sliding plate is arranged in correspondence with the center of the friction pair of the bridge bearing; the split sliding plates are a plurality of sliding plates of which the size is smaller than the size of the integral sliding plate; and the splitsliding plates are evenly distributed on the outer side of the central sliding plate in the distribution mode of at least one layer of concentric circle. The distribution mode of the nonmetal slidingplate of the friction pair of the bridge bearing has the beneficial effects of realizing the high bearing capacity of the friction pair of the bearing, effectively improving the bearing capacity andconstraining ability of the nonmetal sliding plate of the friction pair of the bearing, effectively reducing the risk of detachment of the nonmetal sliding plate of the friction pair of the bearing, effectively reducing the structural size of the bearing, and further reducing the manufacturing cost of the bearing.

Owner:中船双瑞(洛阳)特种装备股份有限公司

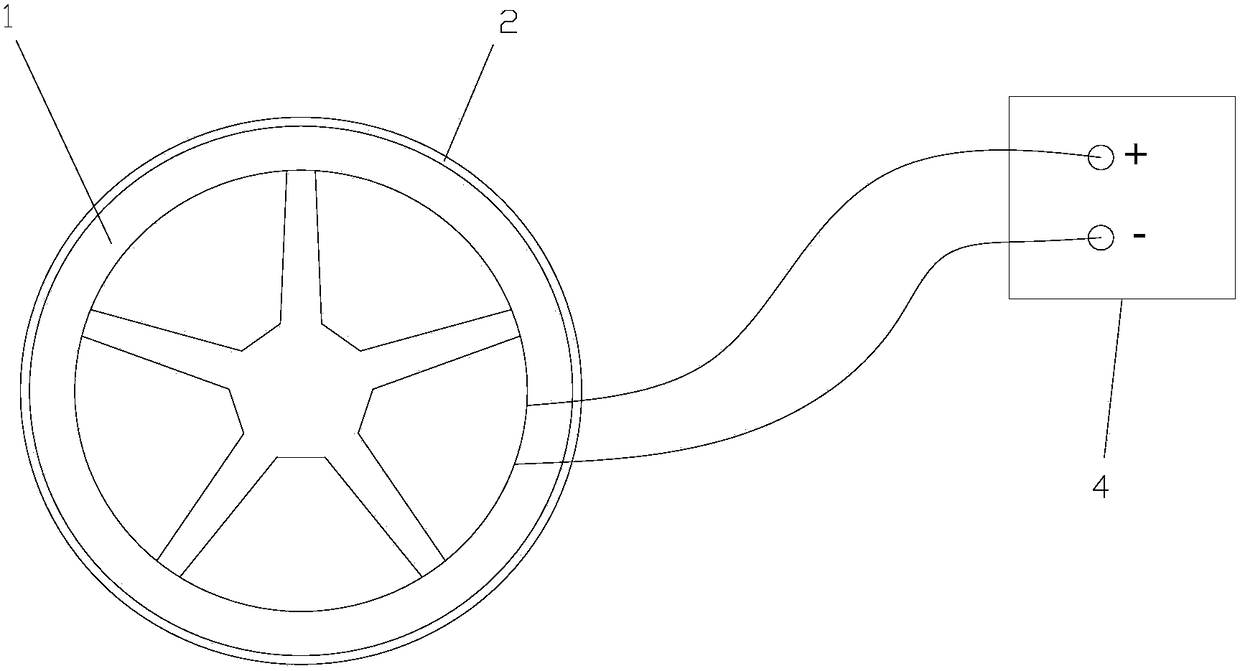

A tire with controllable friction

ActiveCN105774419BSolve slippageChange the coefficient of frictionTyre partsEngineeringMagneto rheological

The invention discloses a frictional-force-controllable tyre, and belongs to the technical field of tyres. The frictional-force-controllable tyre comprises a tyre body and further comprises an anti-slipping structure fixed to the tyre body. The anti-slipping structure comprises an anti-slipping layer and a variable magnetic field capable of generating magnetic action on the anti-slipping layer. The anti-slipping layer is magneto-rheological rubber which is fixed on the tread of the tyre in a whole-circle mode or spaced-arc mode. The magneto-rheological rubber is arranged on the tread of the tyre, under the action of the magnetic field, the magneto-rheological effect is generated by the magneto-rheological rubber, then the friction coefficient of the surface of the tyre is changed, and the frictional force between the tyre and a contact object is adjustable; therefore, the adhesive force level is improved, and the slipping problem of the tyre can be solved in the true sense.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Ultra-high molecular weight polyethylene processing formula

The invention discloses an ultra-high molecular weight polyethylene (UHMWPE) processing formula which comprises the following components in parts by weight: 70-100 parts of UHMWPE, 10-40 parts of high-fluidity resin, 1-1.5 parts of a nucleating agent, 5-30 parts of a liquid crystal polymer, 0.8-1 part of a flow modifier and 3-5 parts of nano layered silicate. According to the invention, the melt flow index of UHMWPE is improved, and processing of a common extruder is facilitated.

Owner:KUNSHAN HENGGUANG PLASTIC PROD

Zirconia ceramics for oil and gas wells and its manufacturing method

The invention relates to a zirconium oxide ceramic used for an oil and gas well and a preparation method thereof and belongs to the technical fields of ceramics for well drilling, well completion and well repair in an oil and gas field. The zirconium oxide ceramic is prepared by mixing following components, by mass: 73-76% of zirconium oxide, 15-17% of magnesium oxide, 4-6% of aluminum oxide, 1.8-2.2% of yttrium oxide, 0.5-1% of lanthanum oxide, 0.3-0.8% of samarium oxide, 0.8-1.2% of an adhesive and 0.8-1.2% of a dispersing agent. The preparation method includes the following steps: ball-milling the powder materials, performing granulation, producing a cover sleeve, performing isostatic cool pressing treatment, and sintering a blank material. The zirconium oxide ceramic is increased in compactness and reduced in sintering temperature, processing difficulty and processing cost by adding the yttrium oxide, the lanthanum oxide and the samarium oxide. By means of optimization of ratio of magnesium oxide to aluminum oxide, the zirconium oxide ceramic is significantly reduced in friction coefficient at the temperature of lower than 120 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

An adjustable multifunctional high-speed debris flow friction test device and its test method

InactiveCN105973798BAdjust relative speedUncovering Friction Fracture PhenomenaUsing mechanical meansMaterial analysisCircular discReduction drive

An adjustable and multifunctional debris flow movement crushing test device and its test method, the device is composed of: the bottom of the vertical steel plate is hinged to the ground, the upper part of the steel plate is hinged to the top of the telescopic connecting rod, and the working surface of the steel plate is hinged to the ground. The motor, reducer, torque sensor and bearing are fixed in order from bottom to top. The motor shaft is connected to the lower end of the main shaft through the reducer and the torque sensor. The upper end of the main shaft is connected to the lower part of the bracket through the bearing. The upper part of the bracket fixes the disc; Place two square, bottomless, and transparent model boxes symmetrically; the four corners on the top of the model box are hinged to the lower end of the upper link, and the upper end of the upper link passes upward through the transverse channel of the gantry beam; And the inside of the two model boxes is embedded with a pressure-bearing steel cover; a jack is fixed on the beam of the gantry frame, and the jack rod is aligned with the middle of the pressure-bearing steel cover; a high-speed camera is installed on the side of the model box through a camera connecting rod.

Owner:SOUTHWEST JIAOTONG UNIV

Self-lubricating running board production method

InactiveCN1259987CChange the coefficient of frictionAdjustable thicknessSynthetic resin layered productsMovement coordination devicesChemical compositionDiluent

A self-lubricating running board belongs to the technical field of sports equipment. The technical problem to be solved by the present invention is to provide a running board for a flat treadmill with complete self-lubricating properties. For this reason, directly cast and solidify a layer of self-lubricating layer on the elastic layer after bonding the elastic layer on the hard base plate or the hard base plate. The manufacture method of this lubricating layer is: (1) self-lubricating layer chemical composition (weight points) is: resin 100, initiator 0.8-2.0, promotor 0.4-1.0, diluent 0-15.0, lubricant 0.6-1.0, A small amount of color paste; (2) Select the weight of each component in the formula according to the conditions and requirements of the construction site temperature of 5-38 ° C, curing time of 8-16 minutes, and friction coefficient of 0.09-0.25, and then add the above-mentioned groups in a certain order Divide and stir evenly, pour it on the surface of the board, press and shape, wait for the resin to solidify, and then it will be a finished product.

Owner:吴小凤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com