Distribution mode of nonmetal sliding plate of friction pair of bridge bearing

A technology of bridge bearings and friction pairs, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of increasing the risk of slipping out of the slide, increasing the size of the bearing, and weak restraint of the slide, so as to reduce risks and support The structural size of the seat, the improvement of reliability and durability, and the outstanding effect of high load-bearing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

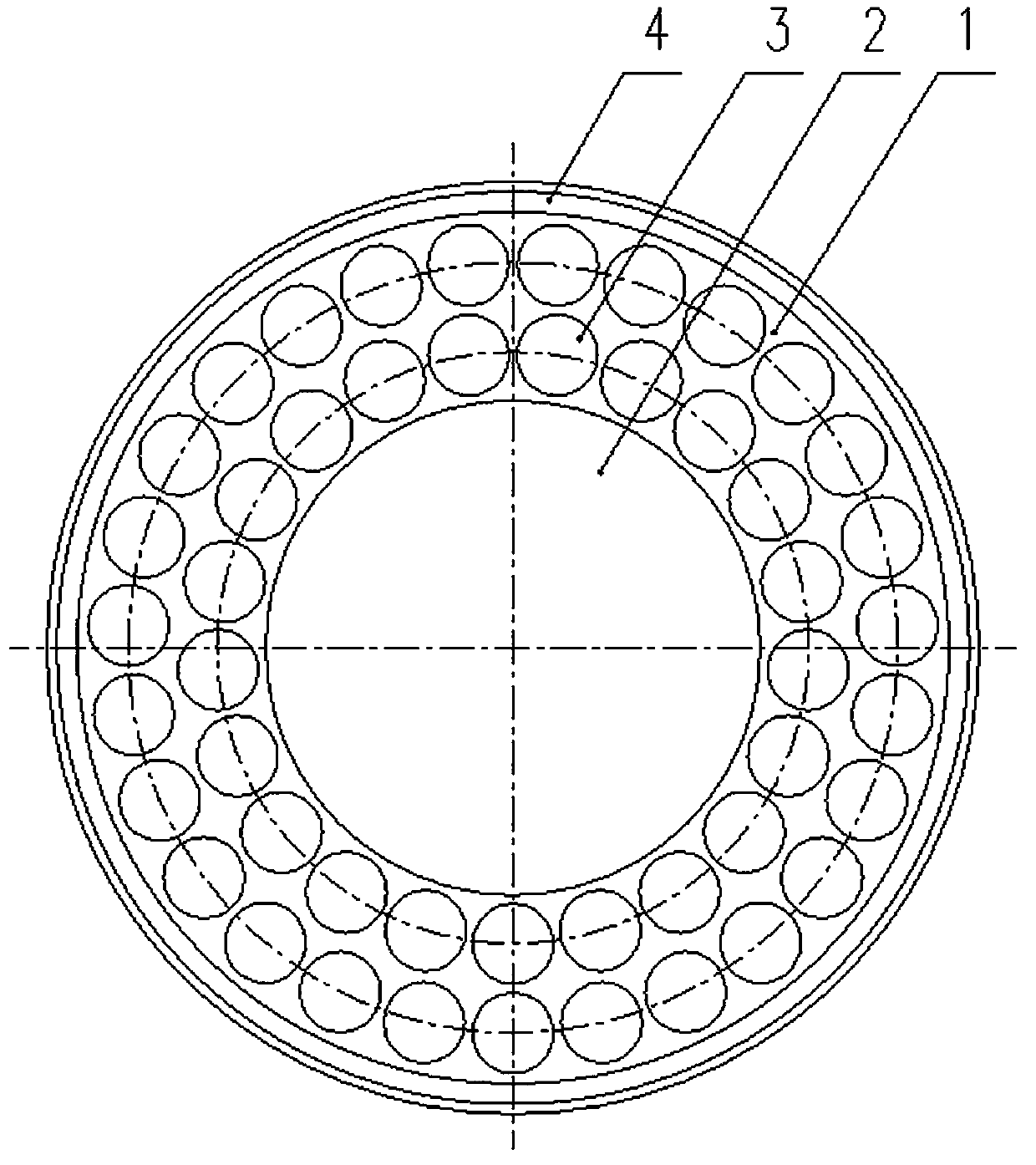

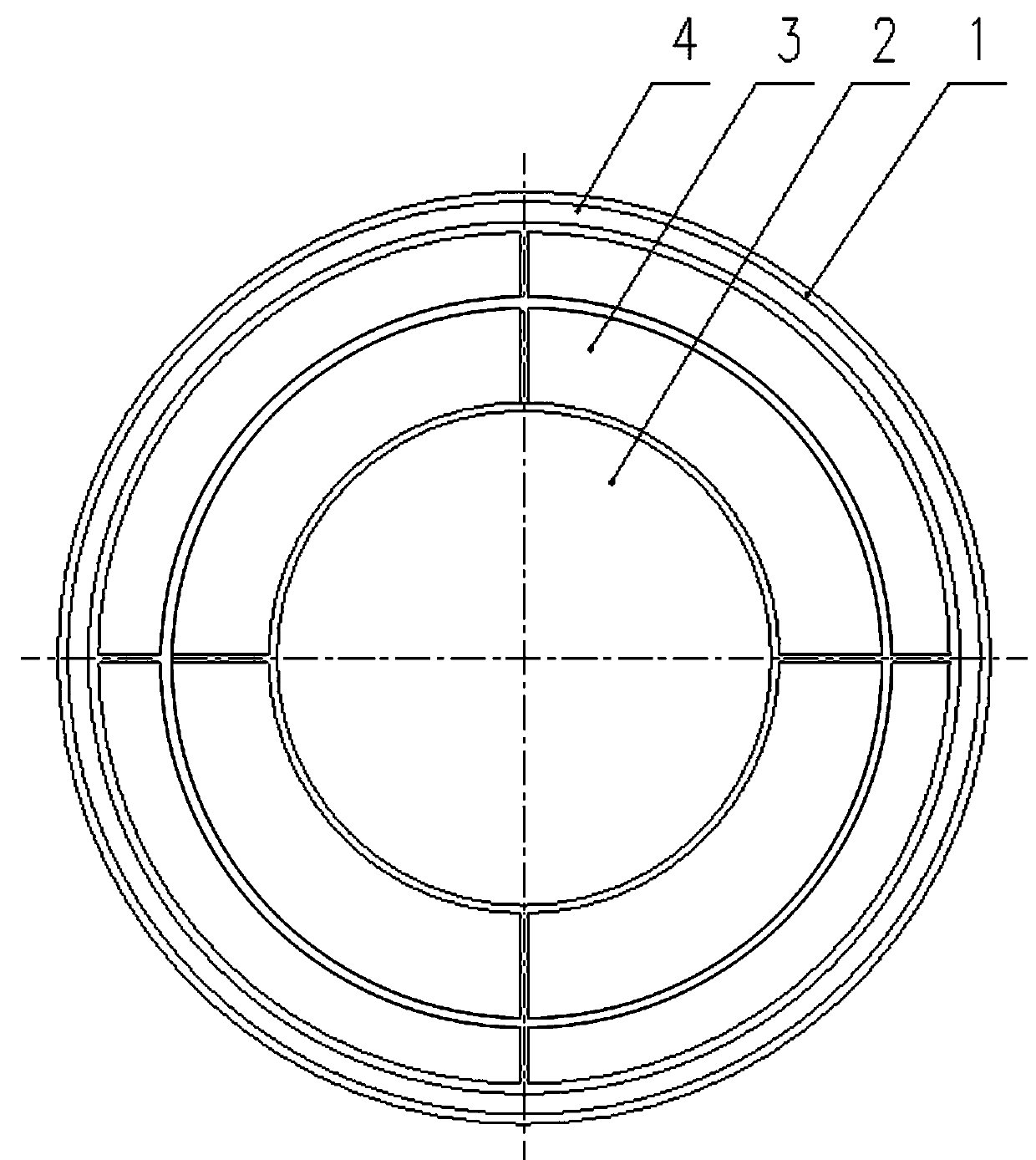

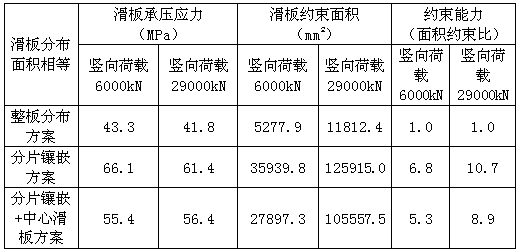

[0034] A distribution method of non-metallic sliding plates for friction pairs of bridge supports. The non-metallic sliding plates are composed of a central sliding plate 2 and a segmented sliding plate 3. The central sliding plate 2 is a whole circular sliding plate, and its center is set corresponding to the center of the friction pair of bridge supports. On the outer side of the central slide plate 2 there are evenly distributed a plurality of circular sliced slide plates 3 , and the multiple sliced slide plates 3 are distributed on the outer side of the central slide plate 2 with two layers of concentric circles.

Embodiment 2

[0036] A distribution method of non-metallic sliding plates for friction pairs of bridge supports. The non-metallic sliding plates are composed of a central sliding plate 2 and a segmented sliding plate 3. The central sliding plate 2 is a whole circular sliding plate, and its center is set corresponding to the center of the friction pair of bridge supports. On the outside of the center slide plate 2 there are eight fan-shaped slice slide plates 3 evenly distributed, and four fan-shaped slice slide plates 3 are distributed on the outside of the center slide plate 2 as a group of two-layer concentric circles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com