An aluminum-based welding material for friction stir welding of aluminum/steel filler and its preparation method

A friction stir welding, aluminum-based technology, applied in welding equipment, welding/cutting media/materials, manufacturing tools, etc., can solve the problem of restricting the development of lightweight structures and restricting the promotion and practice of aluminum alloy and steel dissimilar metal composite components Application and other issues, to achieve the effect of promoting high-quality bonding, improving tensile strength, and improving joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

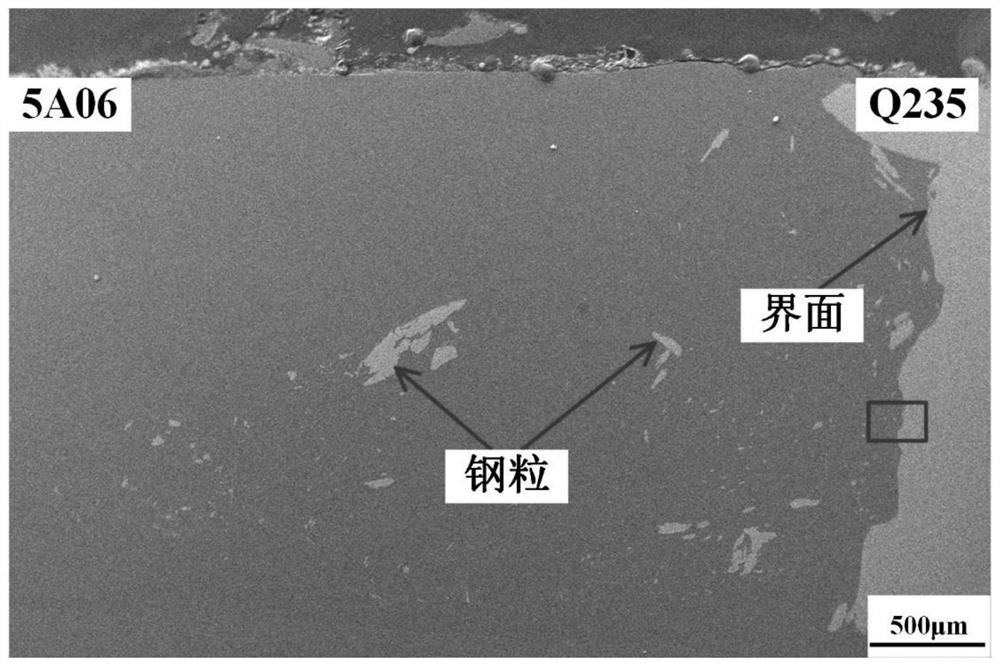

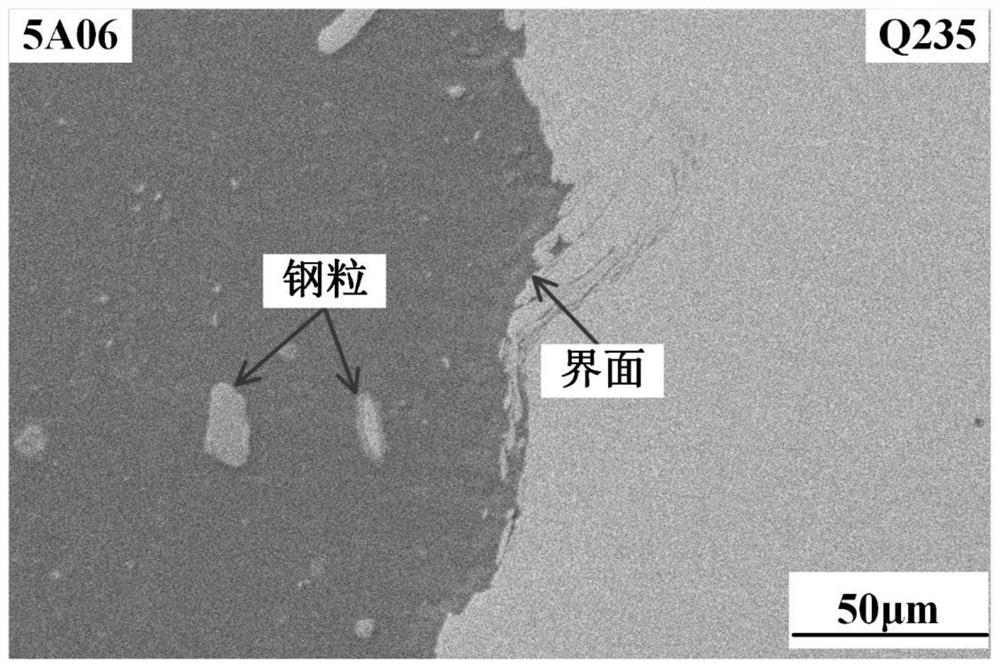

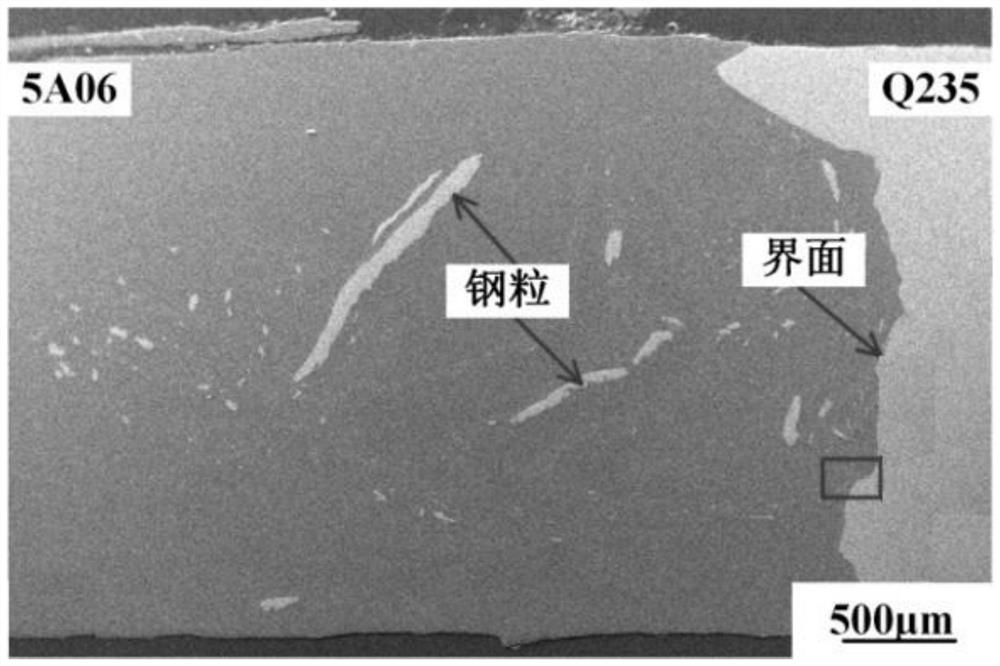

[0040] Embodiment 1, an aluminum-based welding consumable for friction stir welding of aluminum / steel fillers, comprising the following components by weight percentage: 9% silicon, 4% copper, 2% nickel, the balance is aluminum, and the alloy degree 15%, the preparation method of the aluminum-based welding material comprises the following steps:

[0041] Step 1, ingredients, according to the above-mentioned weight percentage of each component of the aluminum-based welding consumables to prepare the furnace charge, the proportion of aluminum in the form of pure metal, the proportion of silicon, copper, and nickel in the form of an intermediate alloy, cutting the prepared charge into flakes, and repeating Grinding to remove oxides on the surface of the sheet charge, cleaning, drying and weighing. see Figure 5 , pure aluminum, aluminum-silicon master alloy, aluminum-copper master alloy and aluminum-nickel master alloy are stacked from bottom to top to form a placement unit. It s...

Embodiment 2

[0047] Embodiment 2, an aluminum-based welding consumable for friction stir welding of aluminum / steel fillers, comprising the following components by weight percentage: 9% silicon, 4% copper, 3.5% nickel, the balance is aluminum, alloy degree 16.5%, the preparation method of the aluminum-based welding material comprises the following steps:

[0048] Step 1, ingredients, according to the above-mentioned weight percentage of each component of the aluminum-based welding consumables to prepare the furnace charge, the proportion of aluminum in the form of pure metal, the proportion of silicon, copper, and nickel in the form of an intermediate alloy, cutting the prepared charge into flakes, and repeating Grinding to remove oxides on the surface of the sheet charge, cleaning, drying and weighing. see Figure 5 , pure aluminum, aluminum-silicon master alloy, aluminum-copper master alloy and aluminum-nickel master alloy are stacked from bottom to top to form a placement unit. In the ...

Embodiment 3

[0055] Embodiment 3, an aluminum-based welding consumable for friction stir welding of aluminum / steel fillers, comprising the following components by weight percentage: 9% silicon, 4% copper, 6% nickel, the balance being aluminum, alloy degree 19%, the preparation method of the aluminum-based welding material comprises the following steps:

[0056] Step 1, ingredients, according to the weight percentage of each component of the above-mentioned aluminum-based welding consumables, the charge is prepared, the aluminum is proportioned in the form of pure metal, the proportion of silicon, copper, and nickel is in the form of an intermediate alloy, and the prepared charge is cut into flakes, and repeated Grinding to remove oxides on the surface of the sheet charge, cleaning, drying and weighing. see Figure 5 , pure aluminum, aluminum-silicon master alloy, aluminum-copper master alloy and aluminum-nickel master alloy are stacked from bottom to top to form a placement unit. In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com