Nanometer crystalline compound coating and its prepn process

A nanocrystalline composite and nanocrystalline technology, applied in the field of material science, can solve the problems of short coating life and high preparation cost, achieve good high temperature and thermal corrosion resistance, avoid interdiffusion, and ensure quality and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

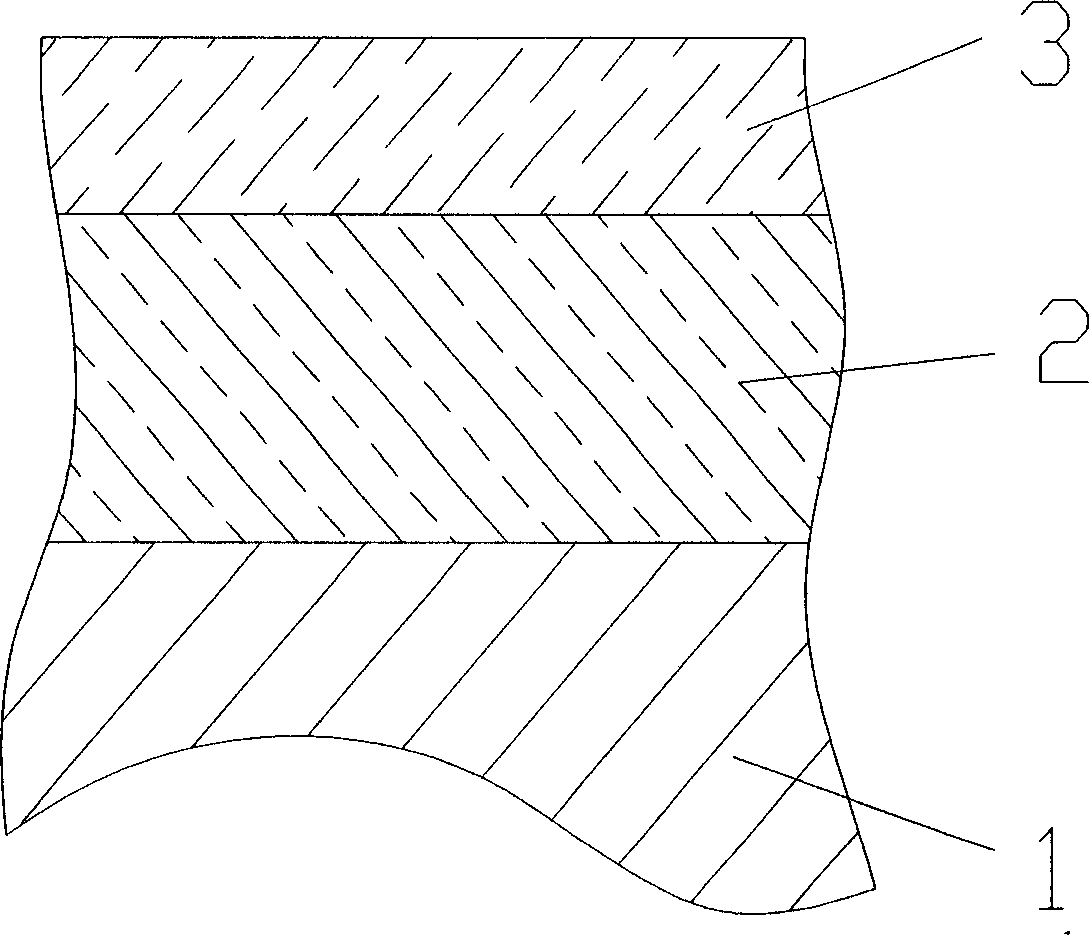

Image

Examples

Embodiment 1

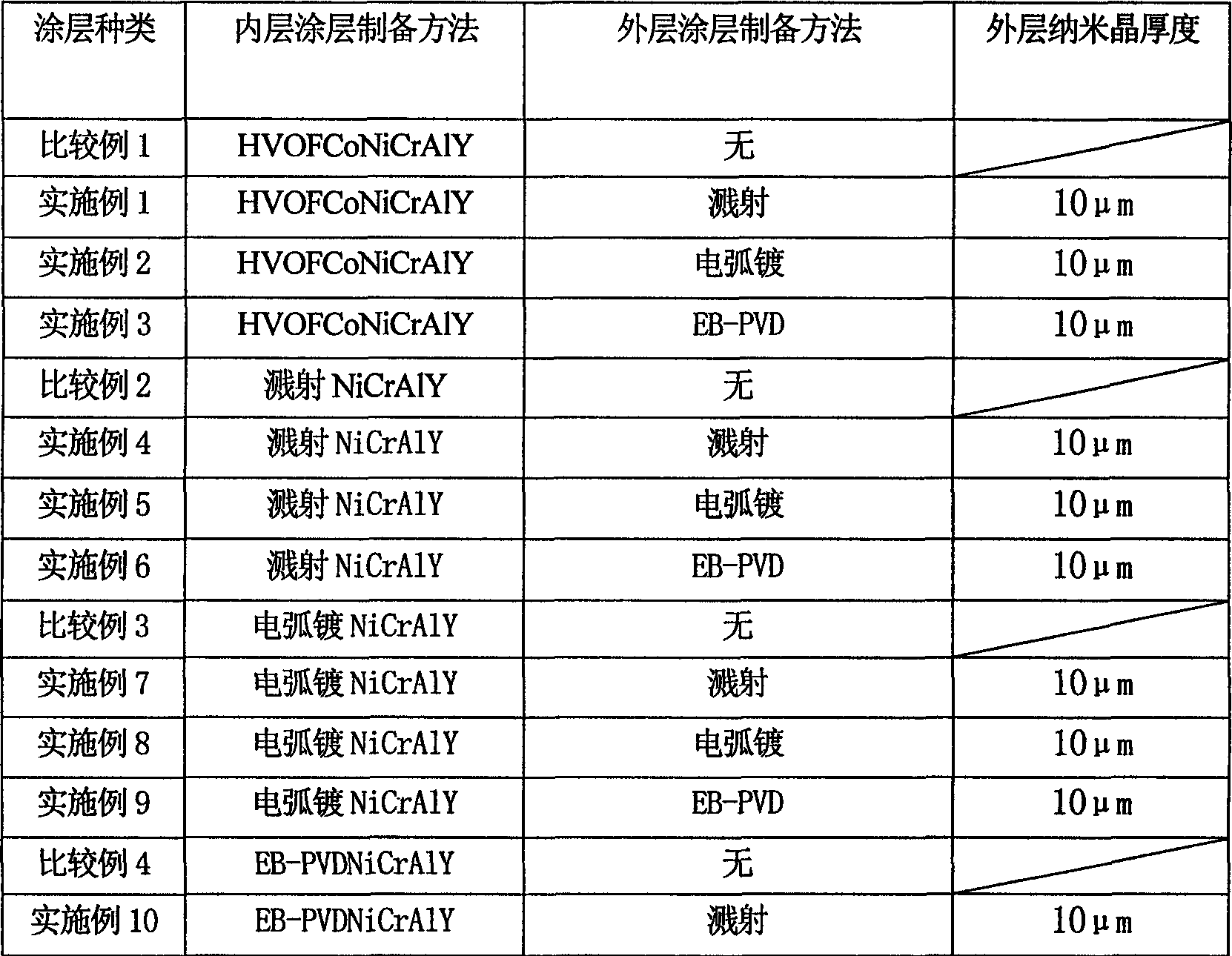

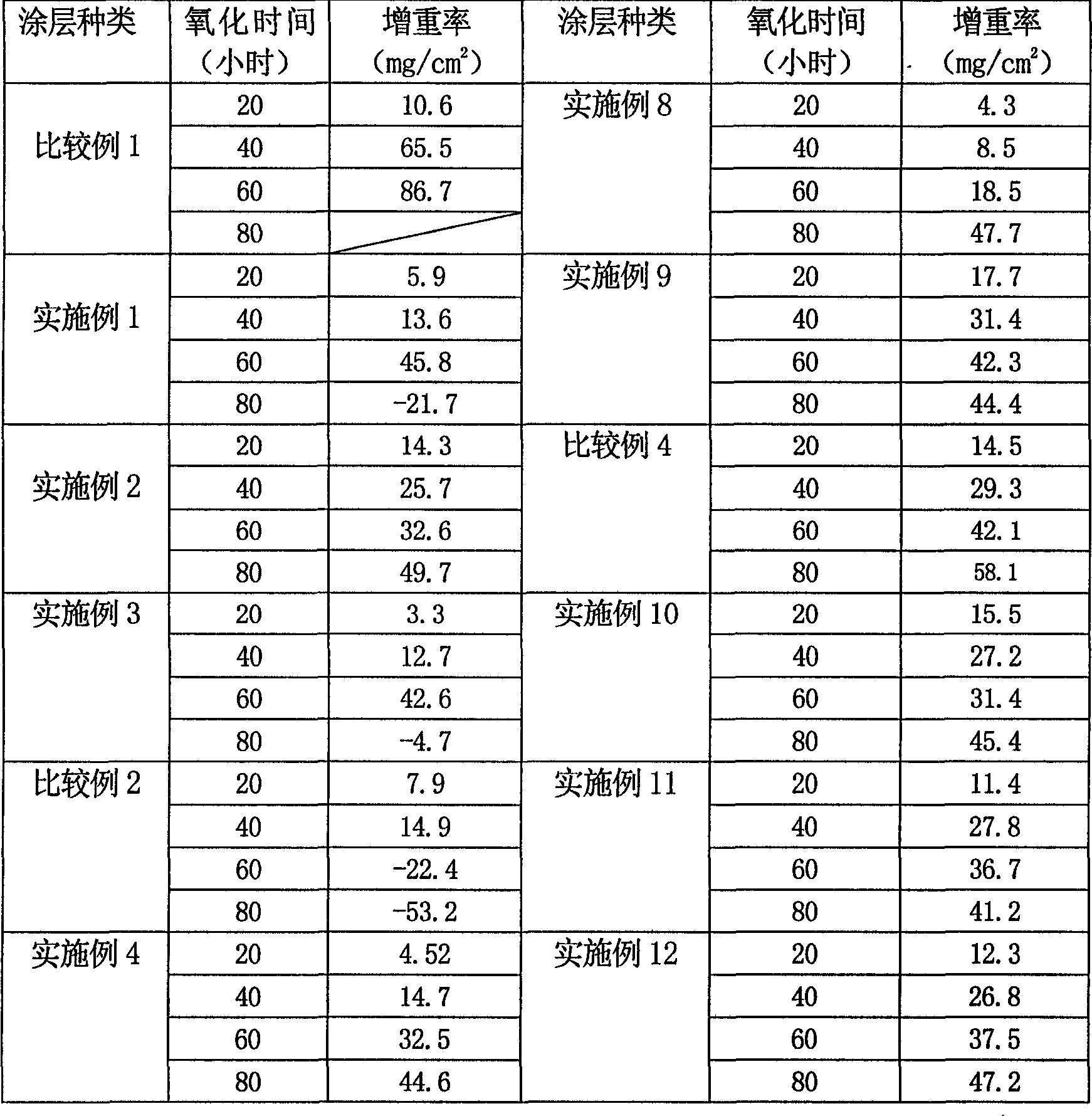

[0033] Sample cast state M17, size is 20mm * 10mm * 3mm, use HVOF (hypersonic flame spraying) method to make a layer of CoNiCrAlY (21wt%Ni, 38wt%Cr, 8wt%Al, 0.5wt%Y, Co 1) The thickness is 20 μm; then, a 10 μm thick nanocrystalline CoNiCrAlY layer with the same composition is prepared on the surface of the CoNiCrAlY layer by sputtering, the coating surface is flat and the structure is dense. High temperature and NaCl corrosion resistance are shown in Table 2 and Table 3.

Embodiment 2

[0035] Sample cast state M17, size is 20mm * 10mm * 3mm, use HVOF (hypersonic flame spraying) method to make a layer of CoNiCrAlY (21wt%Ni, 38wt%Cr, 8wt%Al, 0.5wt%Y, Co I) thickness is 20 μm; then, a 10 μm thick nanocrystalline CoNiCrAlY layer with the same composition is prepared on the surface of the CoNiCrAlY layer by arc plating, the coating surface is smooth and the structure is dense. High temperature and NaCl corrosion resistance are shown in Table 2 and Table 3.

Embodiment 3

[0037] Sample cast state M17, size is 20mm * 10mm * 3mm, use HVOF (hypersonic flame spraying) method to make a layer of CoNiCrAlY (21wt%Ni, 38wt%Cr, 8wt%Al, 0.5wt%Y, Co I) the thickness is 20 μm; then, a 10 μm thick nanocrystalline CoNiCrAlY layer with the same composition is prepared on the surface of the CoNiCrAlY layer by EB-PVD (Electron Beam Physical Vapor Deposition), the coating surface is smooth and the structure is dense. High temperature and NaCl corrosion resistance are shown in Table 2 and Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com