Refractory metal nitride barrier layer with gradient nitrogen concentration

a technology of refractory metal nitride and barrier layer, which is applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems that the use of such barrier materials often compromises the electrical performance of microelectronic fabrication, and achieves the effect of being ready to manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

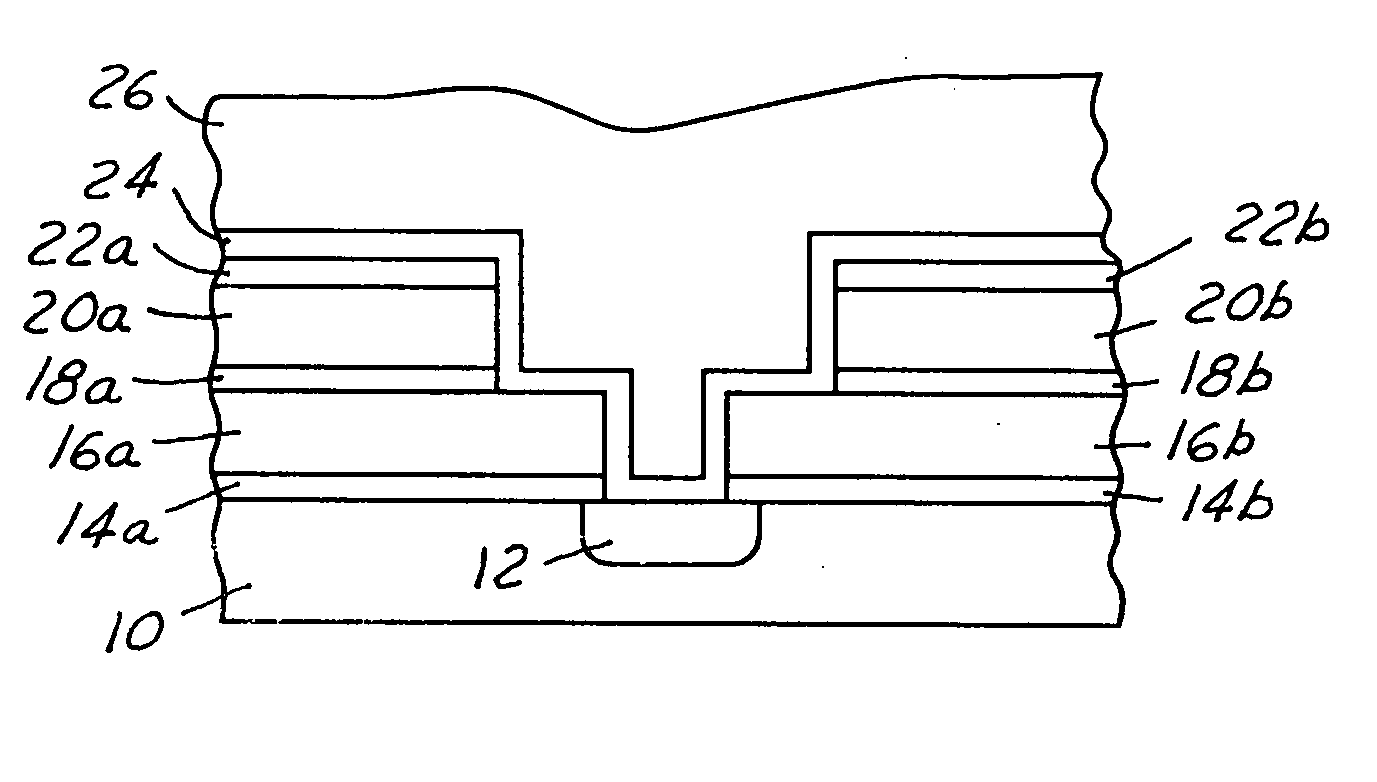

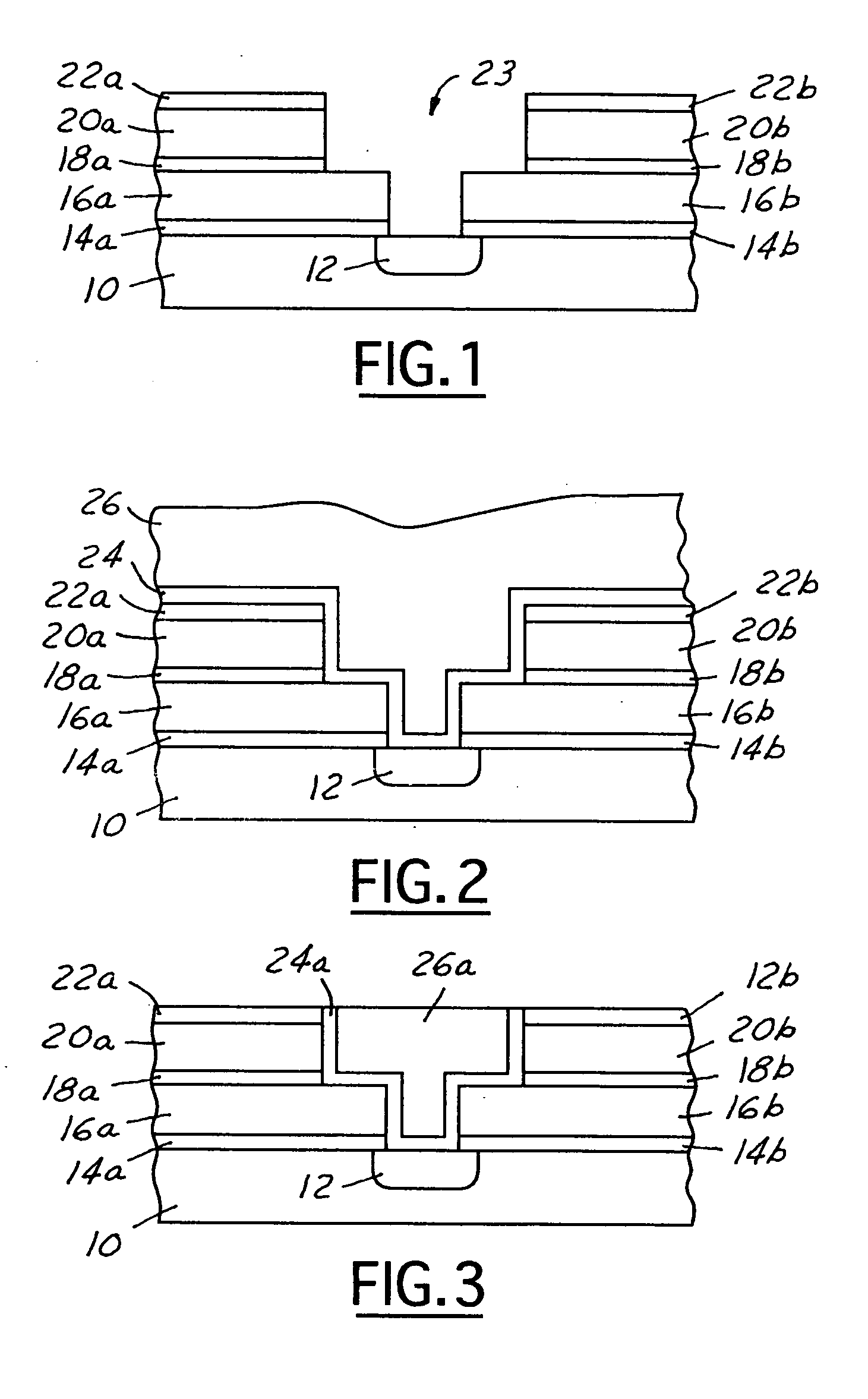

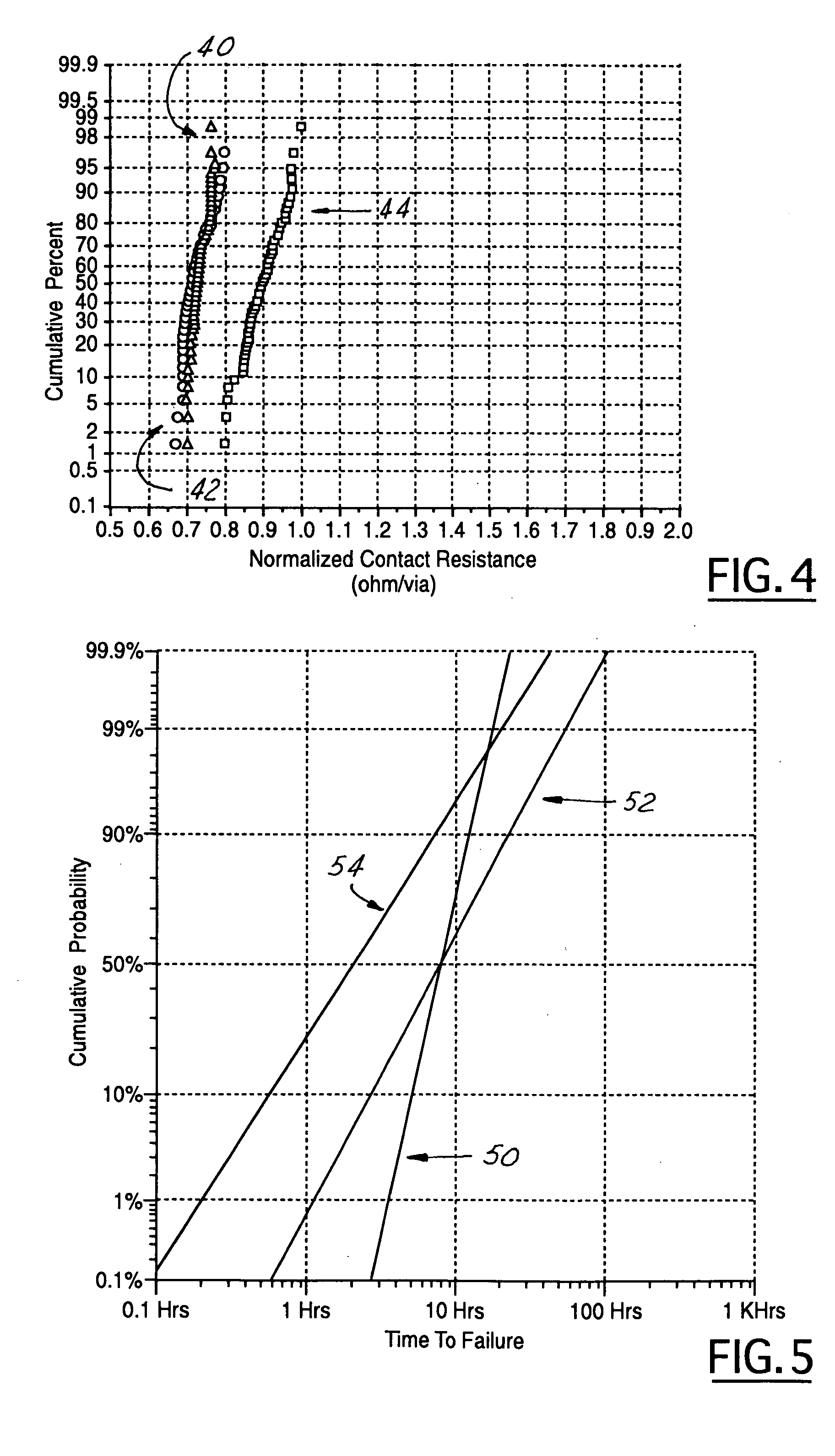

[0057] In order to illustrate the value of the present invention, there was fabricated three series of microelectronic fabrications generally in accord with the microelectronic fabrication whose schematic cross-sectional diagram is illustrated in FIG. 3, but wherein there was formed within each of the three series of microelectronic fabrications a patterned conductor barrier layer formed of one of three different compositions. A first of the three different compositions was a tantalum nitride barrier layer formed in accord with the present invention, wherein the tantalum nitride barrier layer was formed of a substantially stoichiometric tantalum nitride material layer of thickness about 90 angstroms, having formed thereupon a nitrogen deficient tantalum nitride material layer of tantalum:nitrogen atomic ratio about 1:0.3 of thickness about 130 angstroms, in turn having formed thereupon a tantalum material layer formed to a thickness of about 30 angstroms. A second of the three diffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com