V-belt

A belt and glass fiber technology, applied in the direction of belts/chains/gears, transmission belts, mechanical equipment, etc., can solve problems such as loss of strength and belt damage, and achieve improved bending resistance, improved tolerance, and good tolerance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

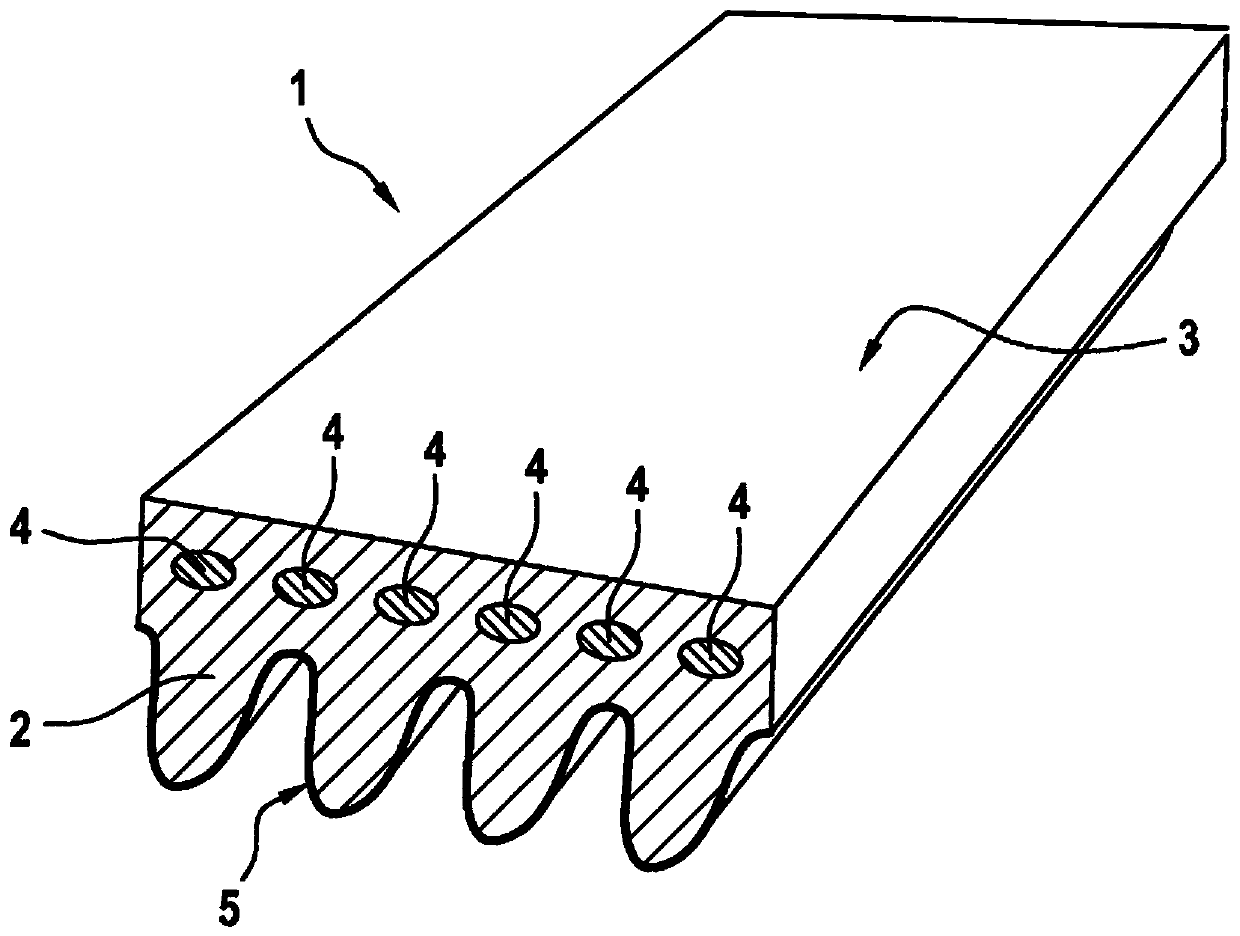

[0020] To illustrate the design according to the invention, figure 1 A schematic diagram of the ribbed belt 1 is shown in perspective section. Here the substructure 2 , the covering layer 3 , and the reinforcement carrier 4 , which are designed as glass fiber cords with a glass denier of 650 tex, can be clearly seen. The ribbed profile designed in this substructure has a coating 5 of a polyamide-cotton-elastane hook fabric comprising 50% by weight of polyamide 66. The coefficient of friction of such a belt is here between 1.2 and 1.9 according to the SAE J2432 standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com