Zirconia ceramics for oil and gas wells and its manufacturing method

A technology of zirconia ceramics and a manufacturing method is applied in the fields of well workover ceramics, well completion, and oil and gas field drilling. coefficient, the effect of improving the intergranular strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

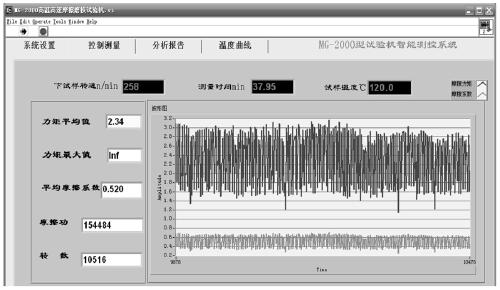

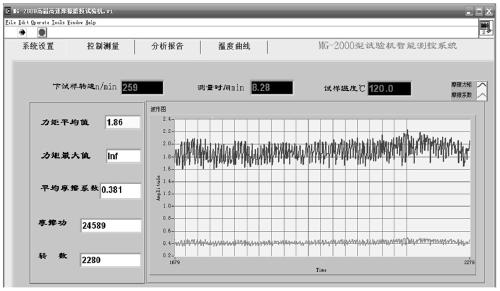

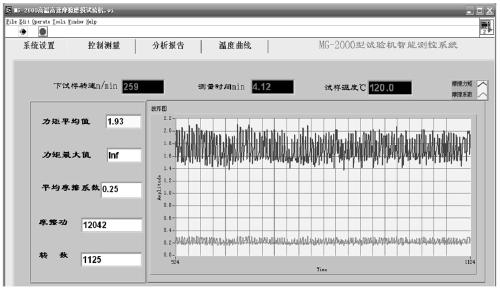

Image

Examples

Embodiment 1

[0023] (1) Add zirconia, magnesia, alumina, yttrium oxide, lanthanum oxide and samarium oxide into the ball mill according to the following weight to form a mixed powder, ZrO 2 , 74kg; MgO, 16kg; Al 2 o 3 , 4.4kg; Y 2 o 3 , 2kg; 2 o 3 , 1kg; Sm 2 o 3 , 0.6kg. Then add 0.8kg ethyl cellulose and 1.2kg polyammonium methacrylate to the mixed powder, then open ball mill ball mill to obtain slurry;

[0024] (2) Spray-dry the slurry obtained in (1) in a granulation spray tower, remove moisture therein to obtain granulated powder;

[0025] (3) Use polyvinyl chloride material to make the bag, and the proportioning ratio of polyvinyl chloride material is as follows: polyvinyl chloride resin, 49kg; dioctyl phthalate, 49kg; tribasic lead sulfate, 1.85kg; stearic acid, 0.15kg, heat the manufactured steel mold to 180°C in an oven, put the heated mold into the prepared polyvinyl chloride material, put the coated mold into the oven at 180°C to heat again, after 10min After the slurr...

Embodiment 2

[0029] (1) Mix powder, add zirconia, magnesia, aluminum oxide, yttrium oxide, lanthanum oxide and samarium oxide into the ball mill according to the following ratio. ZrO 2 , 74kg; MgO, 16kg; Al 2 o 3 , 4.5kg; Y 2 o 3 , 2kg; 2 o 3 , 0.8kg; Sm 2 o 3 , 0.7kg. Then add 1kg ethyl cellulose and 1kg polyethyl methacrylate in the mixed powder, start the ball mill;

[0030] (2) Spray-dry the slurry obtained in (1) in a granulation spray tower, remove moisture therein to obtain granulated powder;

[0031] (3) Use polyvinyl chloride material to make the bag, and the ratio of polyvinyl chloride material is as follows: polyvinyl chloride resin, 47kg; dioctyl phthalate, 50kg; tribasic lead sulfate, 2.85kg; stearic acid, 0.15kg, heat the manufactured steel mold to 180°C in an oven, and put the heated mold into the prepared polyvinyl chloride material. Put the coated mold into the oven at 180°C to heat again, take it out after 15 minutes after the slurry turns yellow, put it in wat...

Embodiment 3~8

[0034] Embodiment 3~8: step and experiment temperature are identical with embodiment 1, and concrete composition is as shown in table 1 below:

[0035] Table 1 The amount of each component of the mixed powder

[0036]

[0037] Where to prove the superiority of the present invention, also carried out following comparison test:

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com