Automatic regulating device for roller traction force of flat knitting machine

An automatic adjustment, flat knitting roller technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of imperfect sheets, easy winding on rollers, fabric damage, etc., to achieve complete and beautiful cloth sheets, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

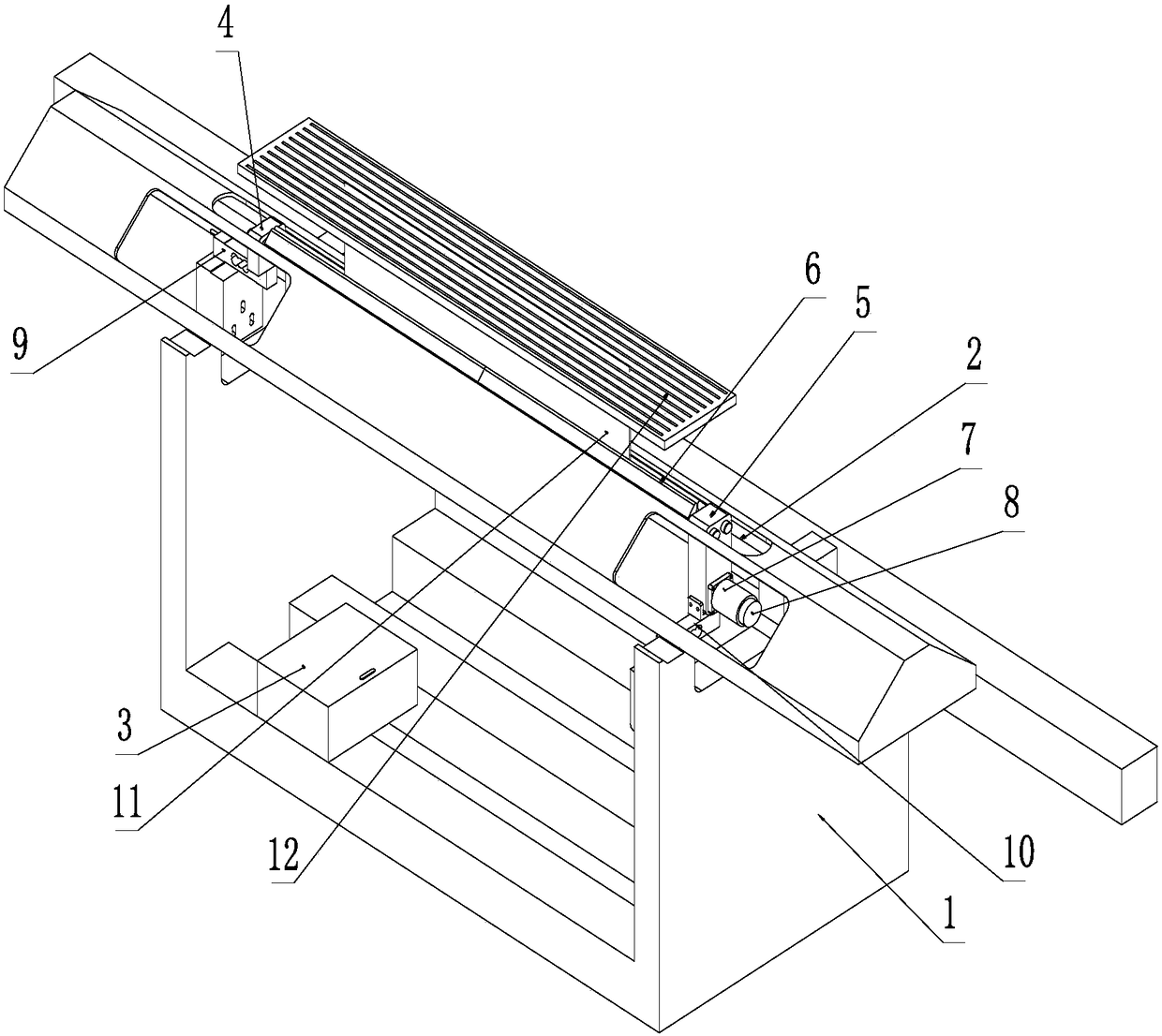

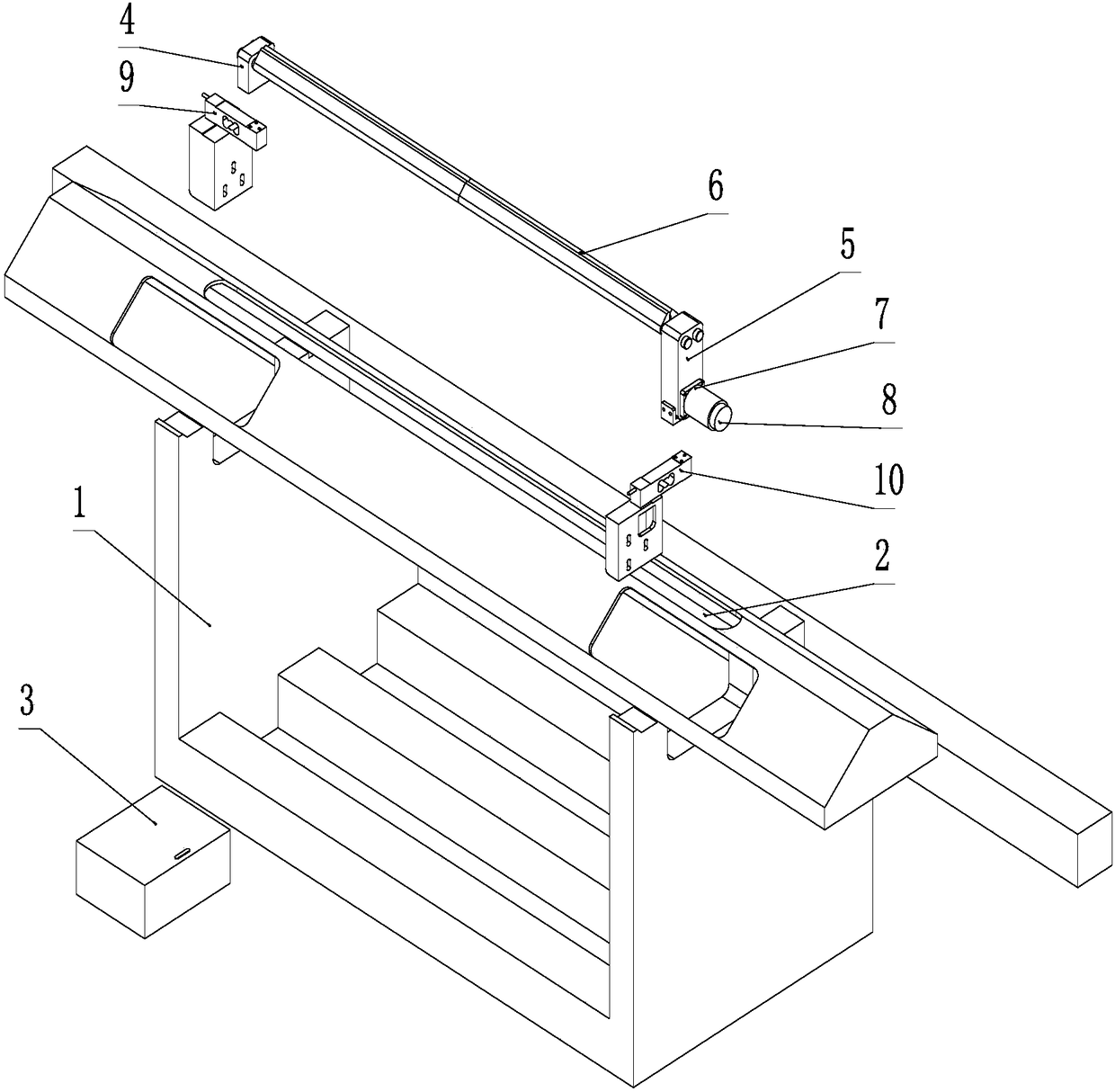

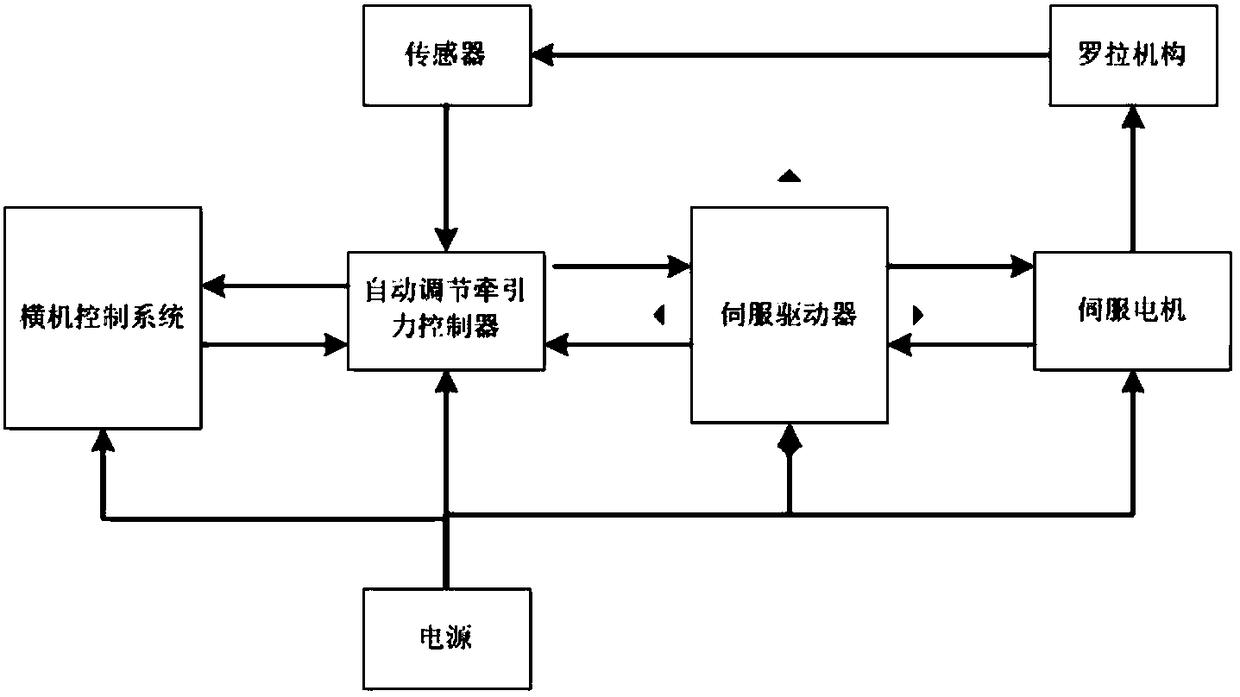

[0017] refer to Figure 1 to Figure 3 , the present invention includes a flat knitting machine frame 1 and a roller mechanism for pulling fabrics, the flat knitting machine frame 1 is provided with an accommodating cavity 2 for accommodating the roller mechanism, and the gap between the roller mechanisms is set in the accommodating cavity 2, also includes an automatic adjustment traction controller 3 connected with the flat knitting machine control system, the two sides of the roller mechanism are connected to the flat knitting machine frame 1 through force measuring devices, and the force measuring device can control the roller mechanism. The traction data is sampled and fed back to the automatic adjustment traction controller 3, the roller mechanism is drivingly connected to the servo drive mechanism, the automatic adjustment traction controller 3 is connected to the servo drive mechanism, and the automatic adjustment traction controller 3. Control the speed of the servo dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com