Magneto-electric speed regulator

A speed governor, magnetoelectric technology, applied in the field of magnetoelectric combined speed control drive system, can solve the problems of eddy current thermal temperature rise, the overall efficiency is not high, increase, etc., to solve the temperature rise and efficiency problems, save energy Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

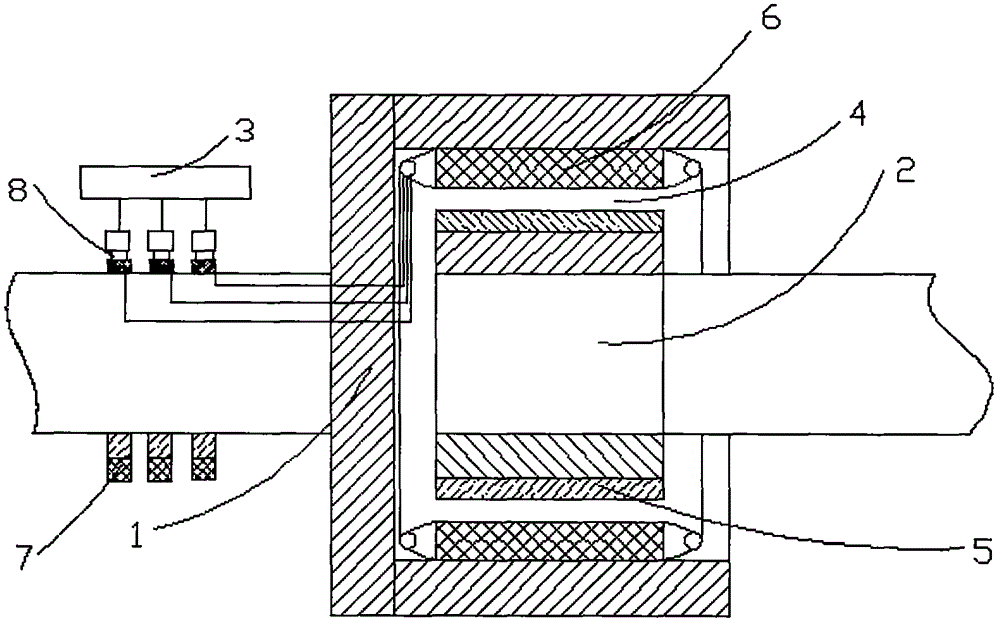

[0036] Reference attached figure 1 This embodiment discloses a magnetoelectric governor, which is characterized in that it includes a permanent magnet rotor 1 and an electromagnetic rotor 2, and also includes a current controller 3. Uniform and fixed circumferential air gap 4, the permanent magnet rotor 1 and the electromagnetic rotor 2 are concentrically installed and socketed, and the permanent magnet rotor 1 is inside, and its inner wall is provided with alternately arranged N and S poles. The permanent magnet 5, the electromagnetic rotor 2 is a salient pole armature on the outside. In the present invention, the excitation winding 6 is installed on the salient pole of the electromagnetic rotor 2, and the winding directions on the two adjacent iron cores of the same direction winding are opposite, so that the polarities of the magnetic poles generated by the adjacent iron cores are opposite, that is, the N and S poles are arranged alternately , the electromagnetic rotor 2 i...

Embodiment 2

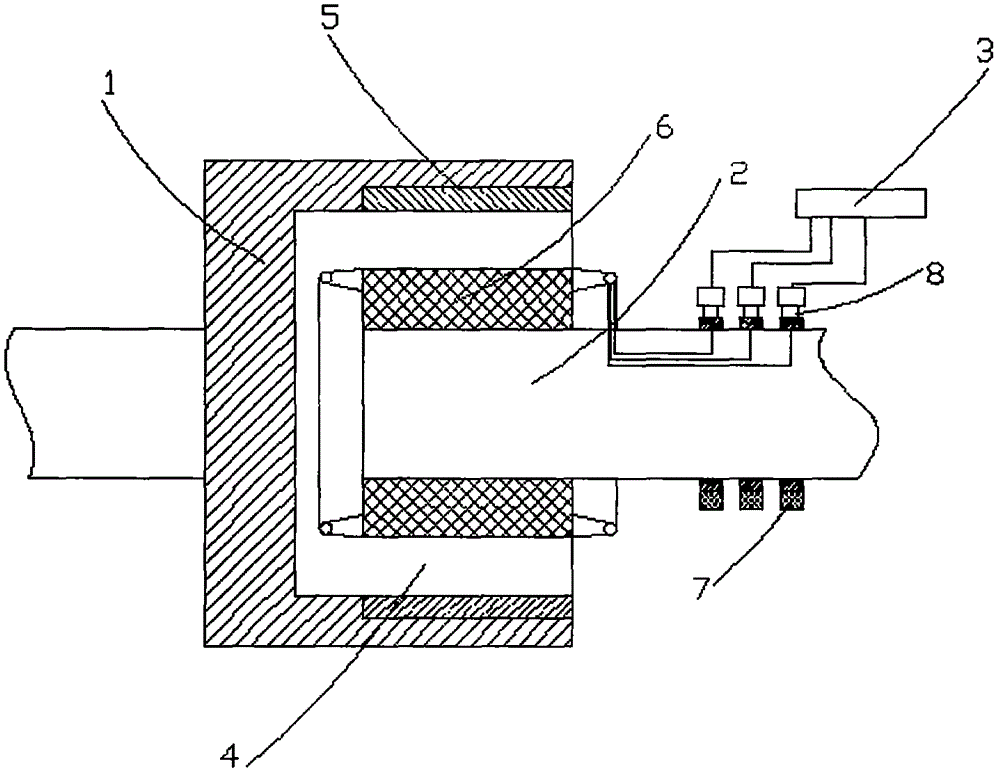

[0038] On the basis of Embodiment 1, this embodiment discloses a magnetoelectric speed governor, which is characterized in that it includes a permanent magnet rotor 1 and an electromagnetic rotor 2, and also includes a current controller 3. The permanent magnet rotor 1 and the A uniform and fixed circumferential air gap 4 is formed between the electromagnetic rotors 2. The permanent magnet rotor 1 and the electromagnetic rotor 2 are concentrically installed and socketed. The permanent magnet rotor 1 is outside, and N , permanent magnets 5 arranged alternately with S poles, and the electromagnetic rotor 2 is a salient pole armature inside.

Embodiment 3

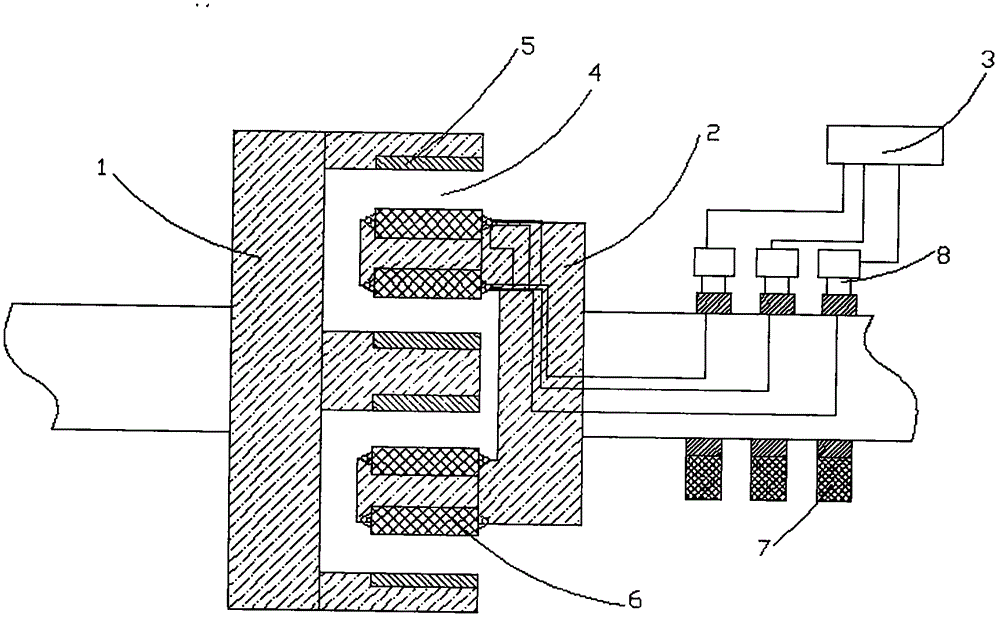

[0040] On the basis of Embodiment 1, this embodiment discloses a magnetoelectric speed governor, which is characterized in that it includes a permanent magnet rotor 1 and an electromagnetic rotor 2, and also includes a current controller 3. The permanent magnet rotor 1 and the A uniform and fixed circumferential air gap 4 is formed between the electromagnetic rotors 2. The permanent magnet rotor 1 is a double cylinder type, and the electromagnetic rotor 2 is concentrically installed and sleeved between the two cylinders of the permanent magnet rotor 1. The permanent magnets 5 arranged alternately with N and S poles are arranged on both cylinders of the permanent magnet rotor 1, and the electromagnetic rotor 2 is a salient pole armature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com