Optical thread position detection device

A detection device, detection device technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of error sources, expensive manufacturing or acquisition, etc., achieve rapid activation, avoid waiting time, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

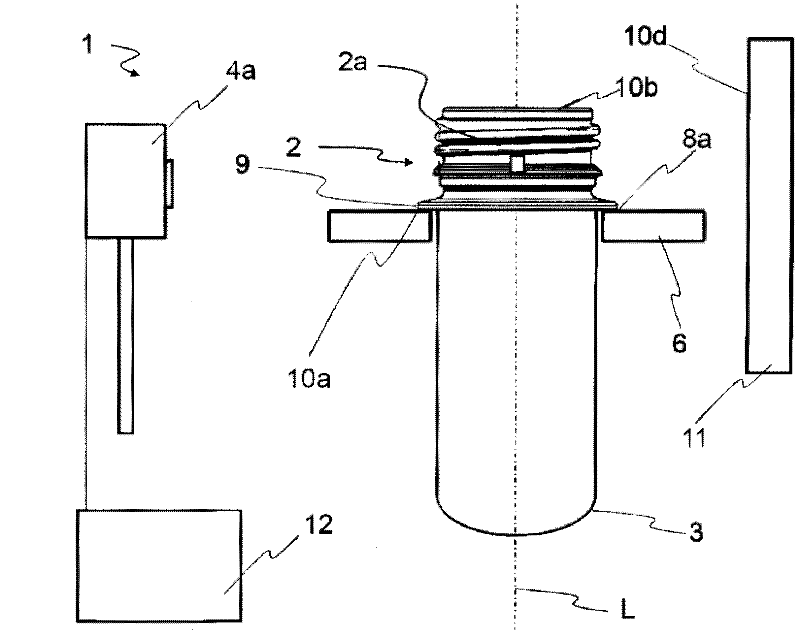

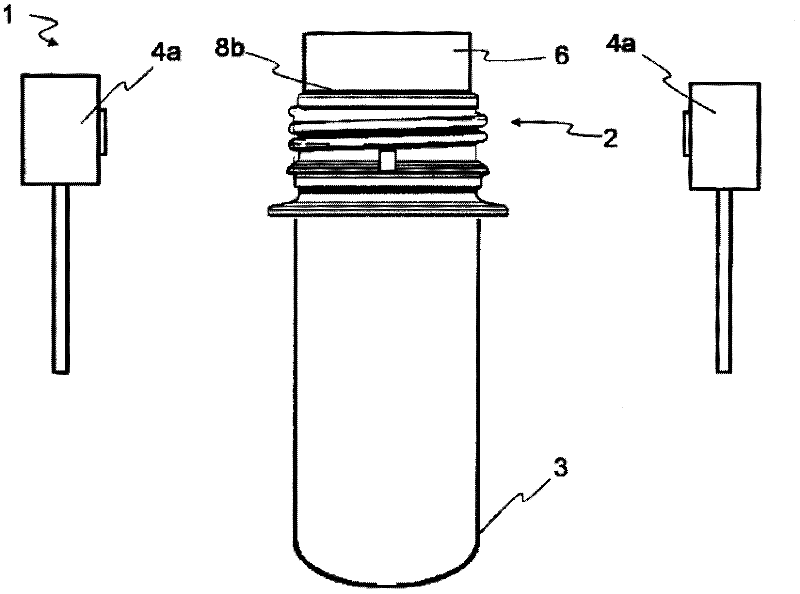

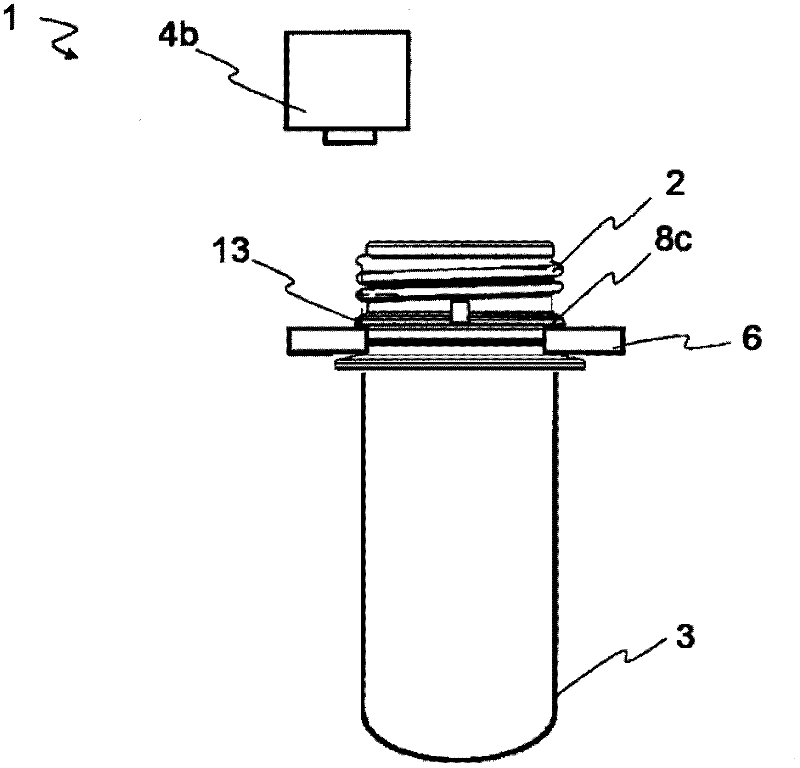

[0062] figure 1 It is an optical thread position detecting device according to the present invention.

[0063] The optical thread detection device 1 comprises a detector 4a for recording an image or video. The detector 4a is more preferably an imaging device 4a, but it can also include direct or indirect lighting equipment for the parison 3. It is also applicable to add a lighting device in the area of the detector 4a, so that it can be used for the container from the same direction of taking pictures. Mouth lighting. In addition, the lighting device can be a flash memory device, and the camera device 4a is used to store the image of the thread 2 , especially the image of the threaded part 2a of the container 3 . The registered images are preferably evaluated in the processor device 12 .

[0064] The image or image information registration is preferably expressed perpendicular to the long axis L of the container 3 , and can also be recorded at an angle of 0-90° to the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com