High-pressure water jet cleaning spray gun

A high-pressure water jet and spray gun technology, which is applied to spray devices, cleaning methods and utensils, and cleaning methods using liquids, etc., can solve problems such as large pressure loss of water guns, and achieve the effect of ensuring safety and improving underwater cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

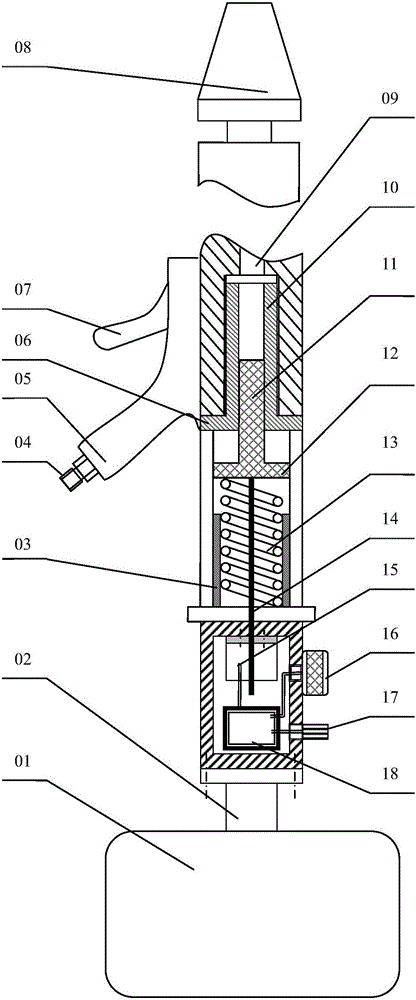

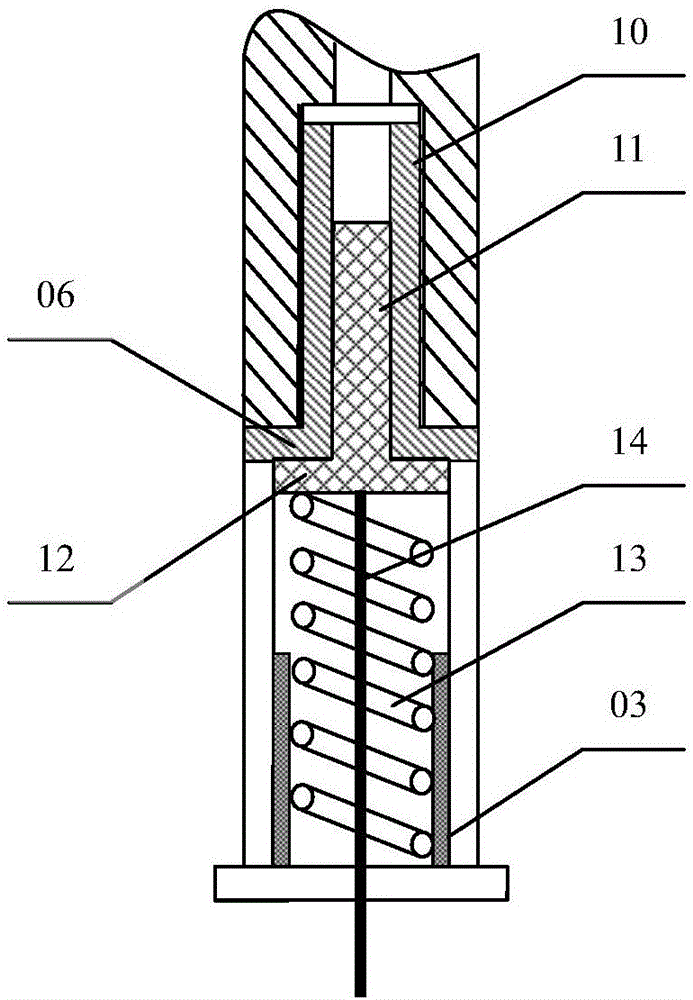

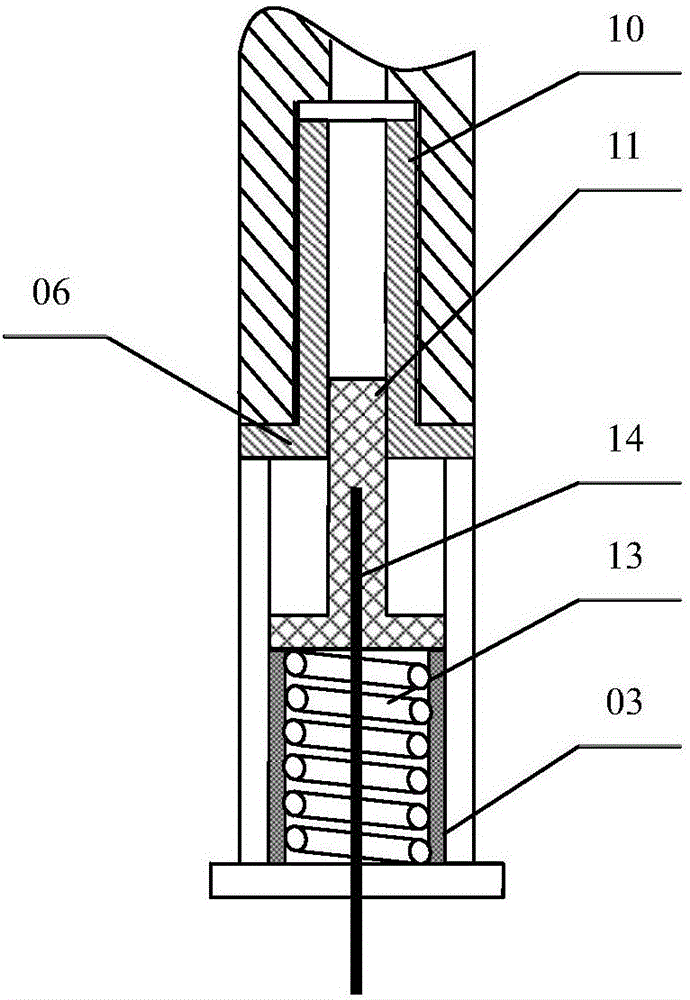

[0023] like figure 1 As shown, this embodiment is an underwater high-pressure water jet cleaning spray gun, including a nozzle 08, a spray rod, a step-down hydraulic cylinder, a rack and pinion adjustment knob, a pulse width modulation (PWM) DC motor governor 18, an underwater Thruster 01 and other components.

[0024] In this embodiment, the pressure-reducing hydraulic device includes a plunger 11 , a piston 12 , a piston cylinder 10 , a spring 13 and a rack 14 connected to the piston. The gear refers to the PWM knob 15 installed inside the spray gun, the circumference of the PWM knob 15 is a gear surface, and the piston 10 drives the rack 14 to rotate the knob during the movement to control the speed of the propeller.

[0025] The voltage adjustment knob 16 refers to the armature voltage regulator installed on the outer surface of the spray gun, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com