Manufacturing process of three-dimensional reticular layer

A manufacturing process and three-dimensional mesh technology, applied in the field of mesh structure preparation, can solve problems such as large cost difference and spring cost difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

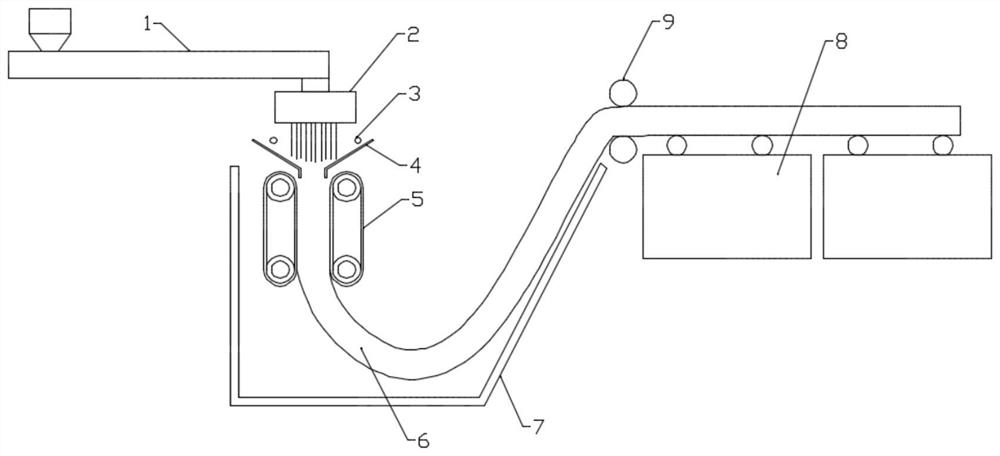

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

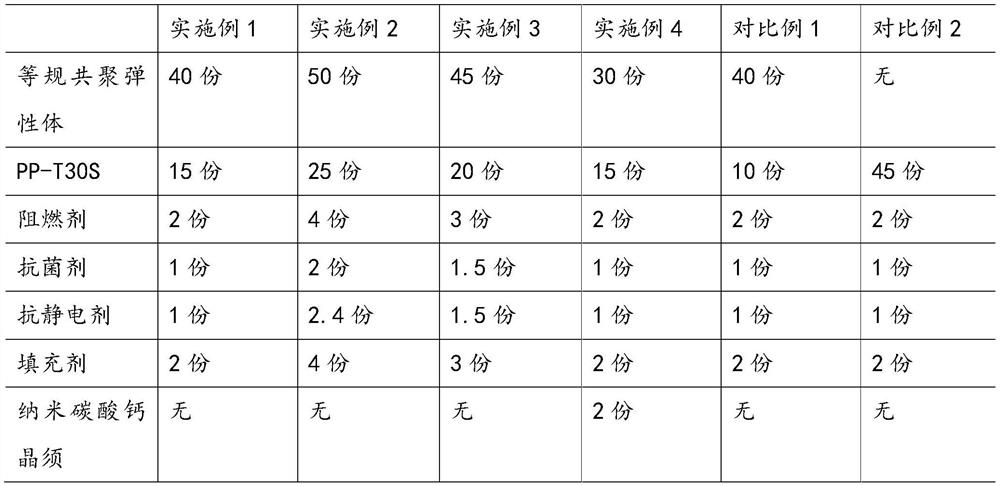

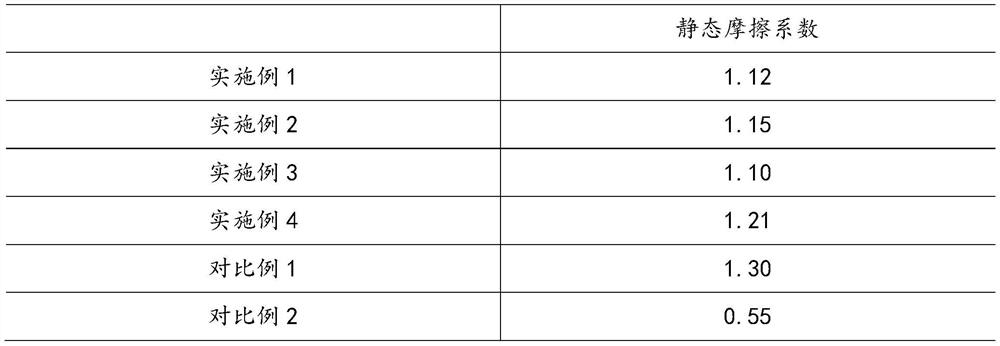

[0025] The manufacturing process of the three-dimensional network layer includes the step of mixing non-viscous isotactic copolymerized polypropylene elastomer with high friction coefficient, homopolypropylene and auxiliary agents through a screw extruder to melt and extrude it. In this step, the selected PP is the main material, and conventional homopolypropylene is mixed with non-viscous isotactic copolymerized polypropylene elastomer with high friction coefficient to increase the friction coefficient of the molding material, and increase the hardness of the mattress through the increase of friction between each other , as for conventional homopolypropylene, such as Changling Refining and Chemical PP: T30S, non-viscous isotactic copolymer polypropylene elastomer with high friction coefficient, such as polypropylene elastomer formed by copolyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com