Particle dispersing device

A dispersing device and granular material technology, which is applied in the direction of measuring device, material analysis and material analysis through optical means, can solve the problem that the data accuracy and processability are difficult to meet the requirements of grain quality analysis, the arrangement is messy, and the accuracy is low and other problems, to achieve the effect of improving the image acquisition effect and testing accuracy, preventing falling off or biting, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

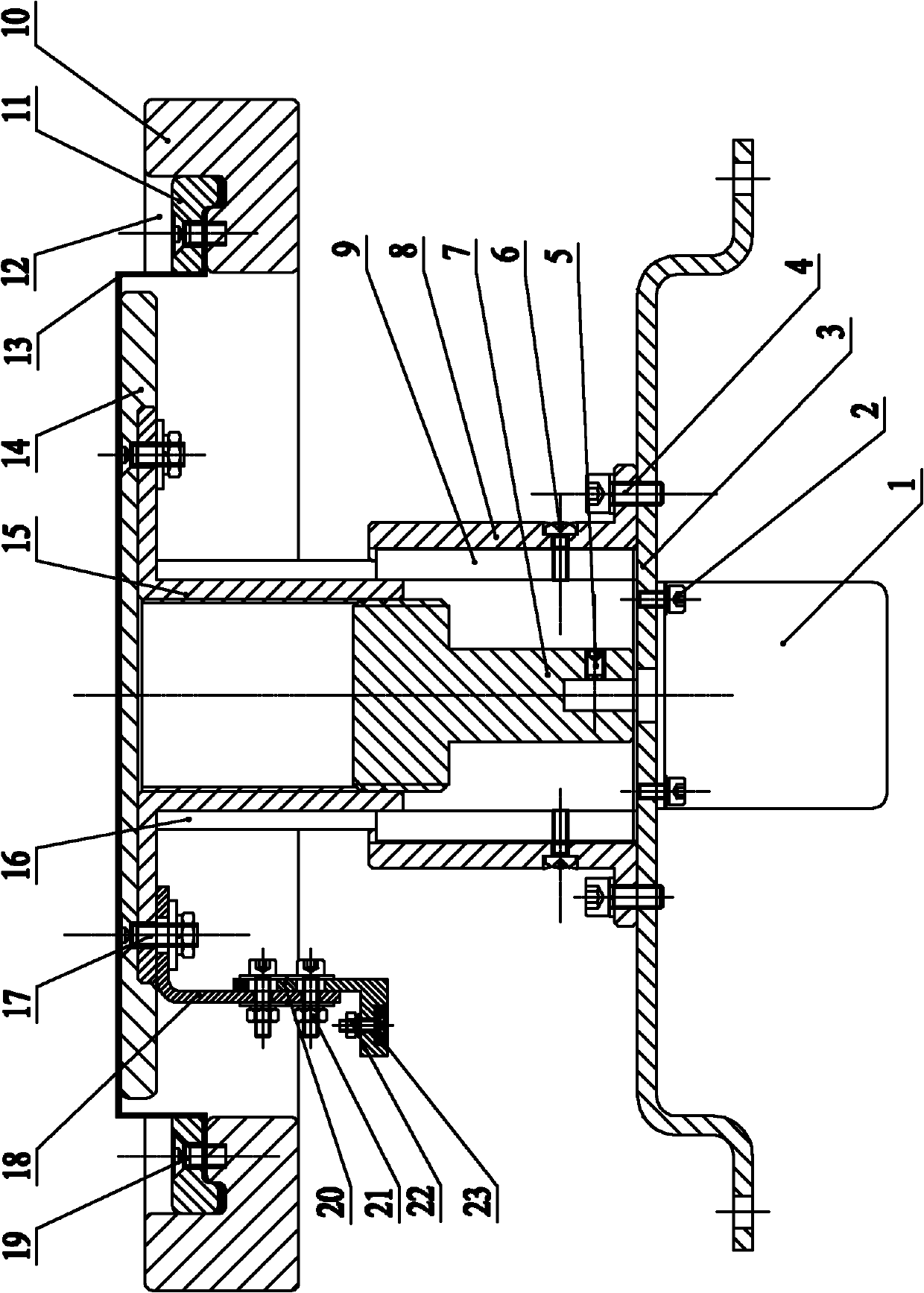

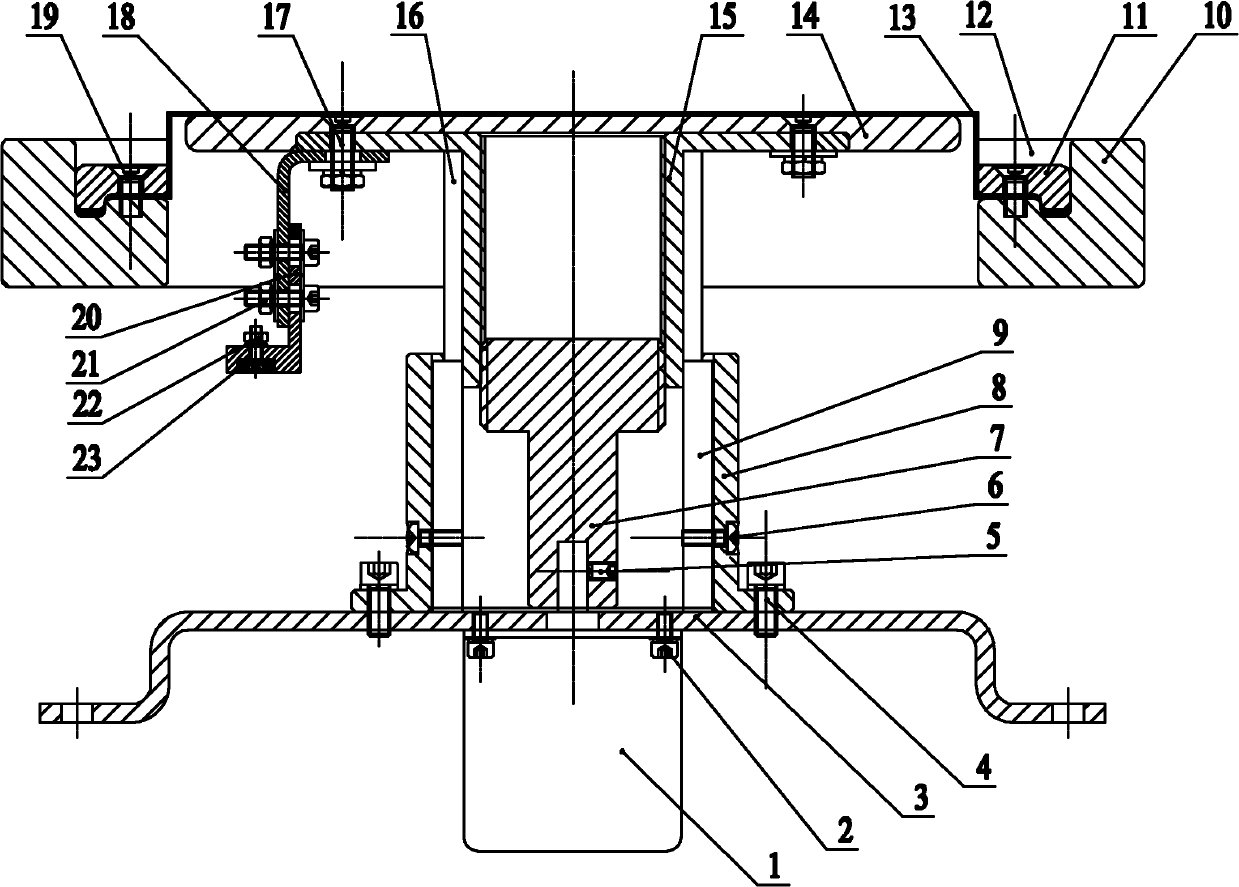

[0018] As shown in the figure: the granular material dispersing device in the embodiment is mainly composed of a motor 1, a connecting bolt 2, a motor frame 3, a connecting bolt 4, a set screw 5, a set screw 6, a driving screw 7, a shaft sleeve 8, a guide Pin 9, bracket 10, pressure plate 11, plane elastic body 13, top plate 14, lifting nut 15, bolt and nut fastener 17, connecting bracket 18, connecting bolt 19, adjusting bracket 20, bolt and nut connecting piece 21, connecting screw 22 and parts such as height sensor 23 constitute.

[0019] like figure 1 As shown, the motor 1 is fixed on the lower part of the motor frame 3 by connecting bolts 2, the output shaft of the motor 1 passes through the motor frame 3 and is connected to the drive screw 7, and the set screw 5 is used between the output shaft of the motor 1 and the drive screw 7 Phase is fixed; the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com