Sputtering film forming method and sputtering film forming apparatus

A film forming method and sputtering technology, which is applied in sputtering plating, ion implantation plating, coating, etc., can solve problems such as difficulty in obtaining uniform film thickness, and achieve the effect of roughly uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0046] (Sputtering film forming device)

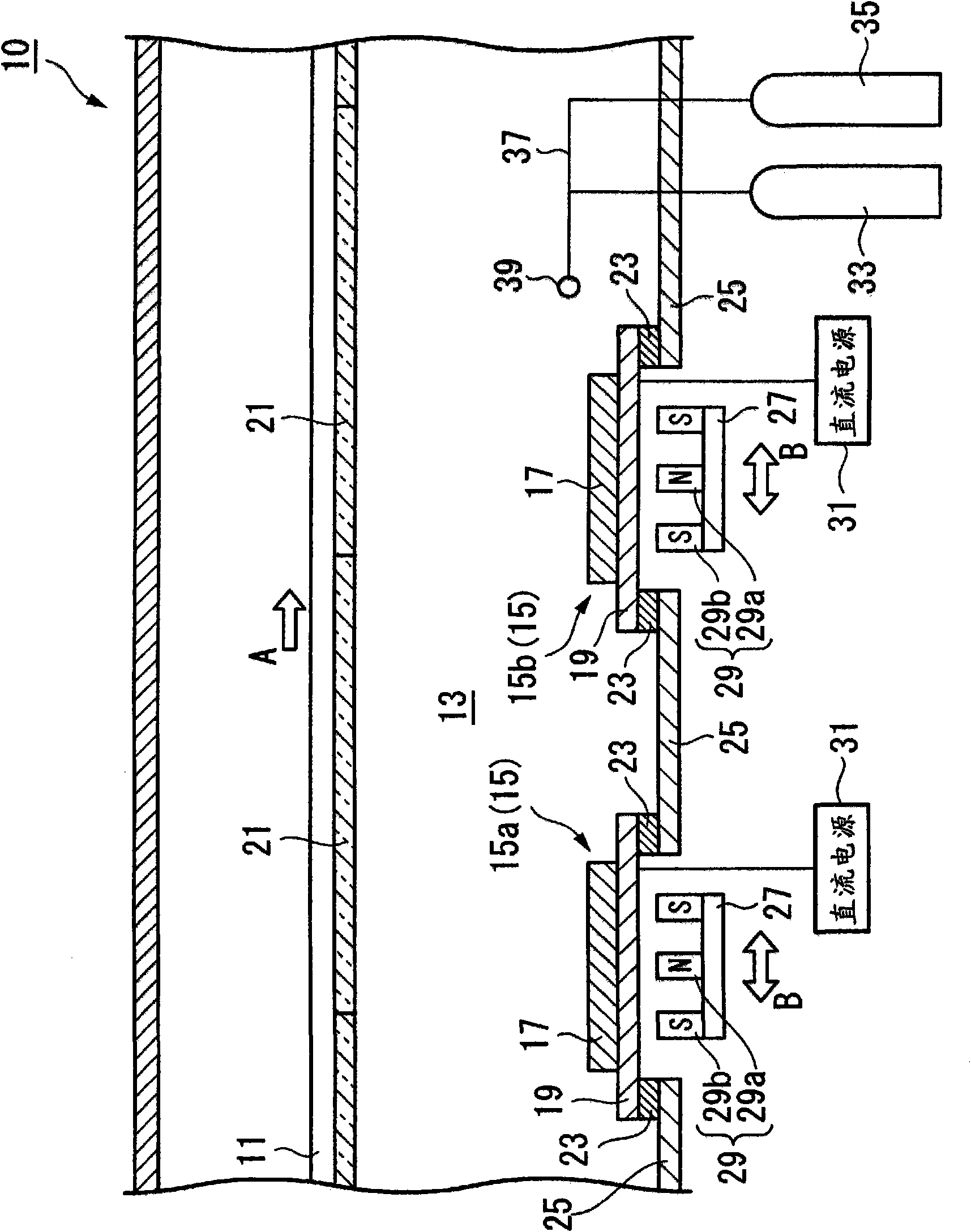

[0047] The following is based on Figure 1 to Figure 5 The sputtering film forming apparatus according to the first embodiment of the present invention will be described.

[0048] figure 1 It is a schematic configuration diagram (plan view) of the main part of the sputtering film deposition apparatus. Such as figure 1 As shown, the sputtering film forming device 10 is a mass-produced in-line sputtering device. In such a sputtering film forming apparatus 10 , substrates 21 are placed on a carrier 11 driven at a constant speed, and the substrates 21 are continuously and sequentially transported in the direction of arrow A (first direction) in the sputtering chamber 13 . As the conveyance method of the carrier 11 (substrate 21 ), a conveyance method such as a conveyance roller connected to a motor or a rack-and-pinion mechanism can be used. Alternatively, the upper edge and the lower edge of the substrate 21 may be sandwiched by gr...

no. 2 approach

[0088] Below, according to Figure 6 ~ Figure 8 A second embodiment of the present invention will be described.

[0089] In addition, since this embodiment differs from the first embodiment only in the arrangement structure of the magnetron cathodes, and other structures are substantially the same as the first embodiment, the same symbols are assigned to the same parts and detailed descriptions are omitted.

[0090] Image 6 It is a schematic configuration diagram (plan view) of the main part of the sputtering film deposition apparatus. Such as Image 6 As shown, the sputtering film forming device 110 is configured with three sets of magnetron cathodes 115 . In the magnetron cathode 115, the side where the substrate 21 first passes is set as the first magnetron cathode 115a, the second pass side is set as the second magnetron cathode 115b, and the third pass side is set as the third magnetron cathode 115b. control cathode 115c.

[0091] Here, the conveying speed of the su...

no. 3 approach

[0099] Below, according to Figure 4 , Figure 9 A third embodiment of the present invention will be described.

[0100] Since this embodiment differs from the second embodiment only in the moving speed of the permanent magnet of the magnetron cathode, and other structures are substantially the same as the second embodiment, the same symbols are assigned to the same parts and detailed description is omitted.

[0101] The sputtering film forming apparatus of this embodiment is substantially the same as that of the second embodiment. The sputtering film forming device 110 is equipped with three sets of magnetron cathodes 115 . In the magnetron cathode 115, the side where the substrate 21 first passes is set as the first magnetron cathode 115a, the second pass side is set as the second magnetron cathode 115b, and the third pass side is set as the third magnetron cathode 115b. control cathode 115c.

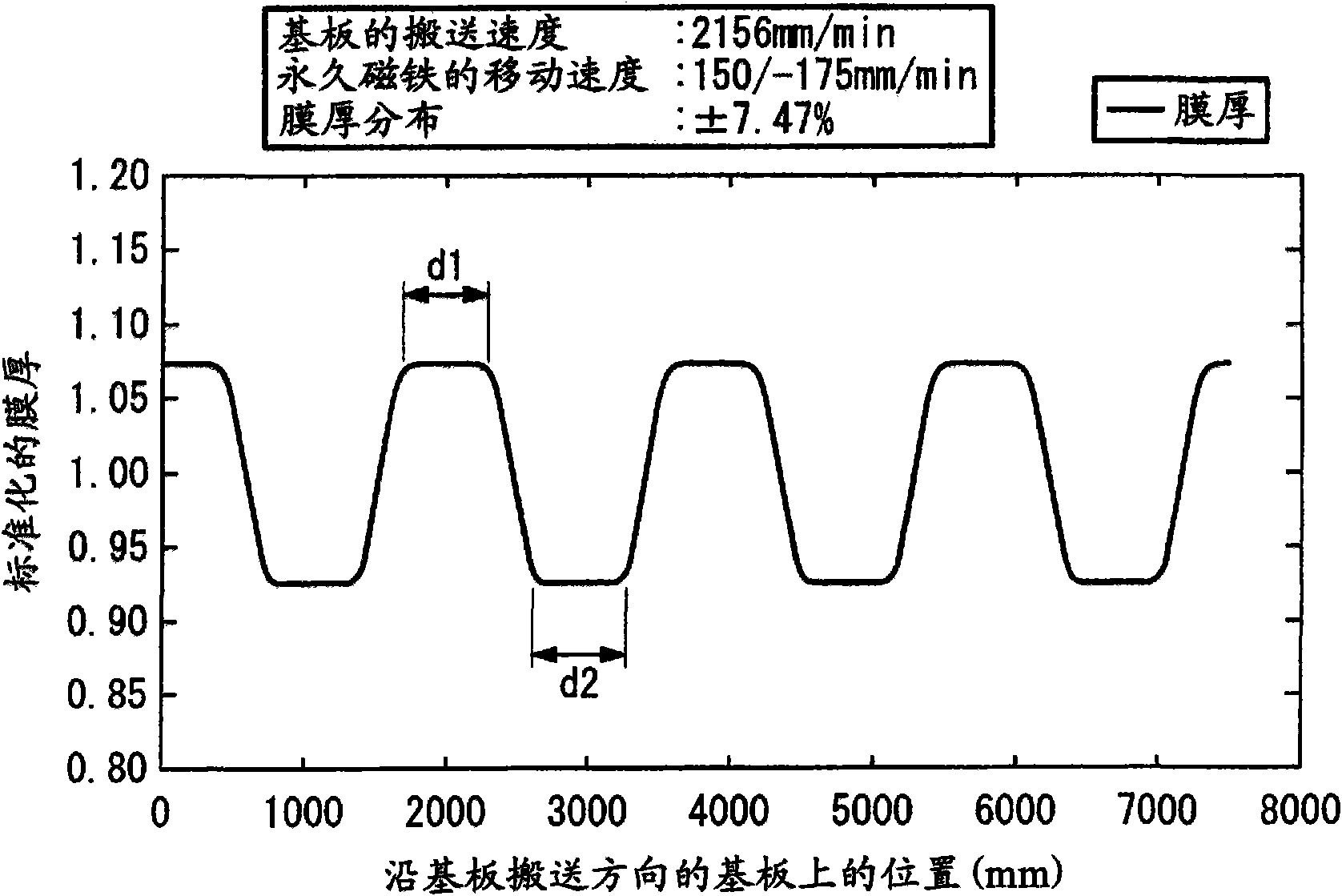

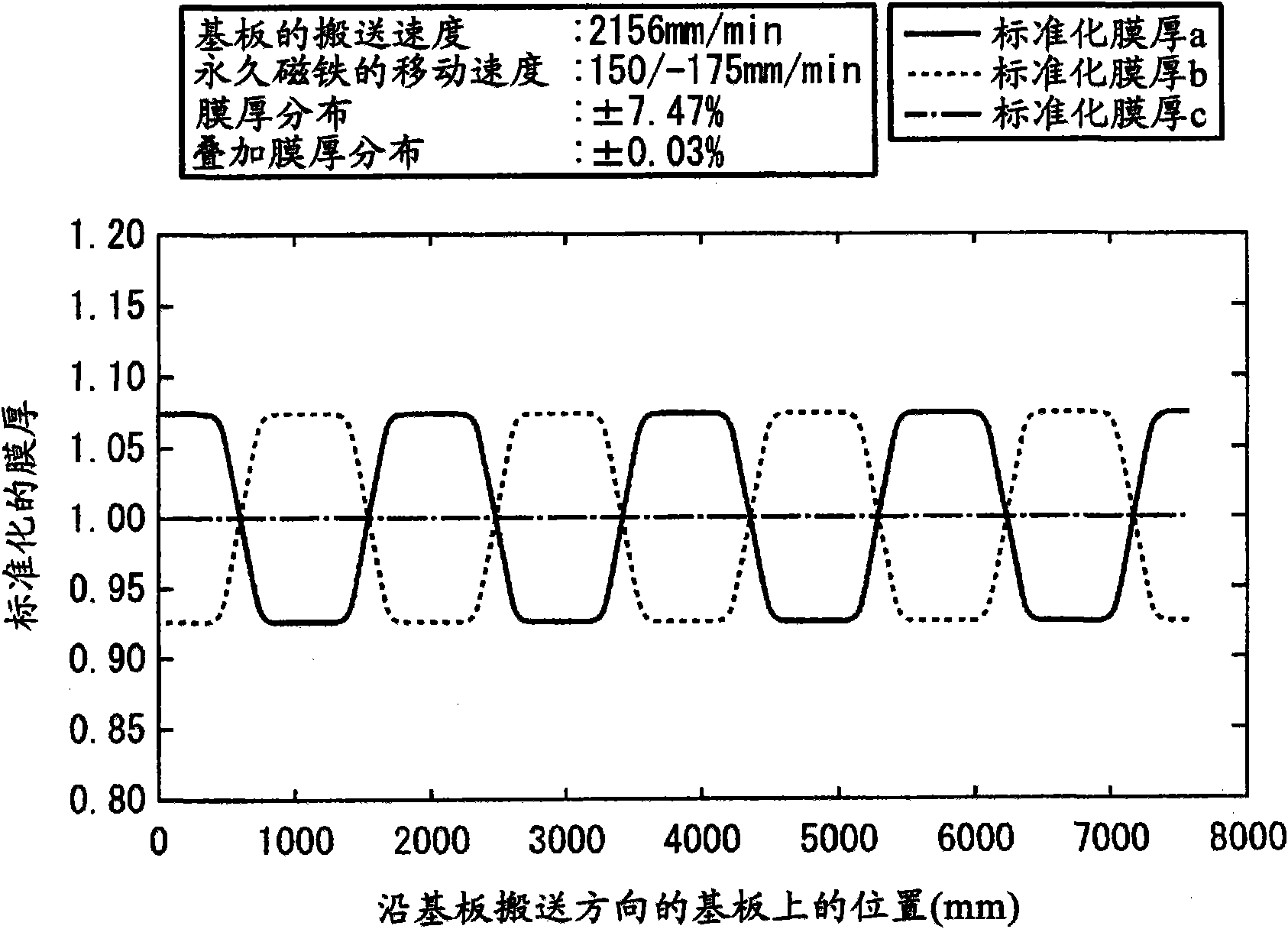

[0102] Here, the conveyance speed of the substrate 21 is set to 2156 mm / min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com