Passive follow-up force-applied linear guiderail pair test bed with controllable load

A linear guide pair, passive technology, used in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc. Reliable test basis, easy implementation, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

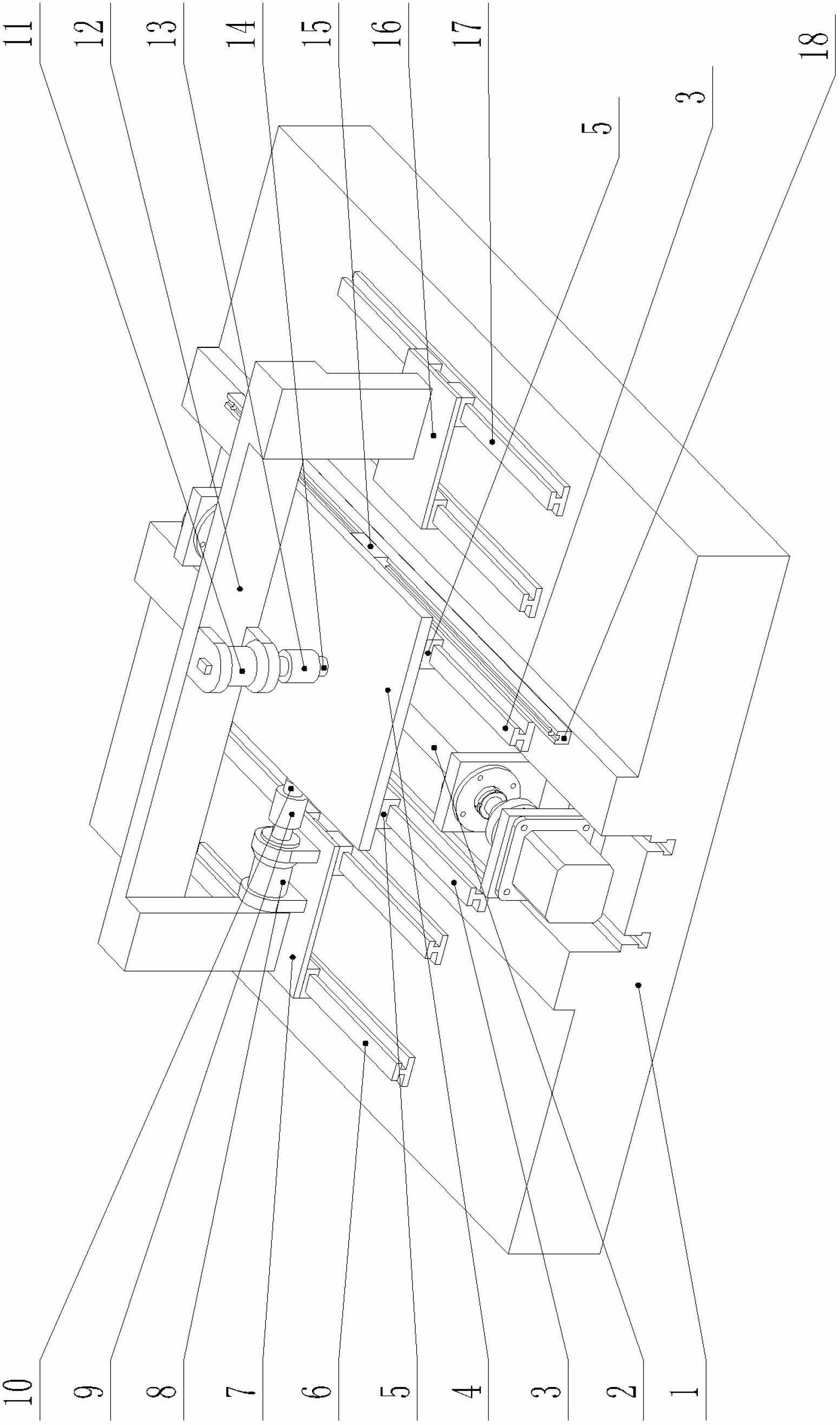

[0017] figure 1 It is shown that the specific embodiment of the present invention is a load-controllable passive follow-up linear guide rail auxiliary test bench, which consists of:

[0018] The machine base 1, the screw drive mechanism 2 on the machine base 1, and the two guide rails 3 are respectively installed on both sides of the screw drive mechanism 2, and the bottom surface of the stressed slide table 4 is connected with the lead screw drive mechanism 2, and the stressed slide table 4 The four corners of the bottom surface are correspondingly connected with the four guide rail sliders 5, and each two of the four guide rail sliders 5 form a guide rail pair with the corresponding guide rail 3; the lower surface of the stressed slide table 4 is also connected with a grating ruler reading head 15. The grating ruler reading head 15 cooperates with the grating main ruler 18 fixed on the machine base 1. There is a lateral loading mechanism on the side of the force sliding tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com