Fatigue testing machine and testing method capable of synchronously radiating light source for in-site imaging

A fatigue testing machine and light source technology, applied in the field of fatigue testing machines, can solve the problems that the measurement accuracy and detection sensitivity need to be improved, the three-dimensional image cannot be obtained, the signal-to-noise ratio of optical signal detection is low, etc., and the imaging accuracy and sensitivity are high. Accurate reflection, high image signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

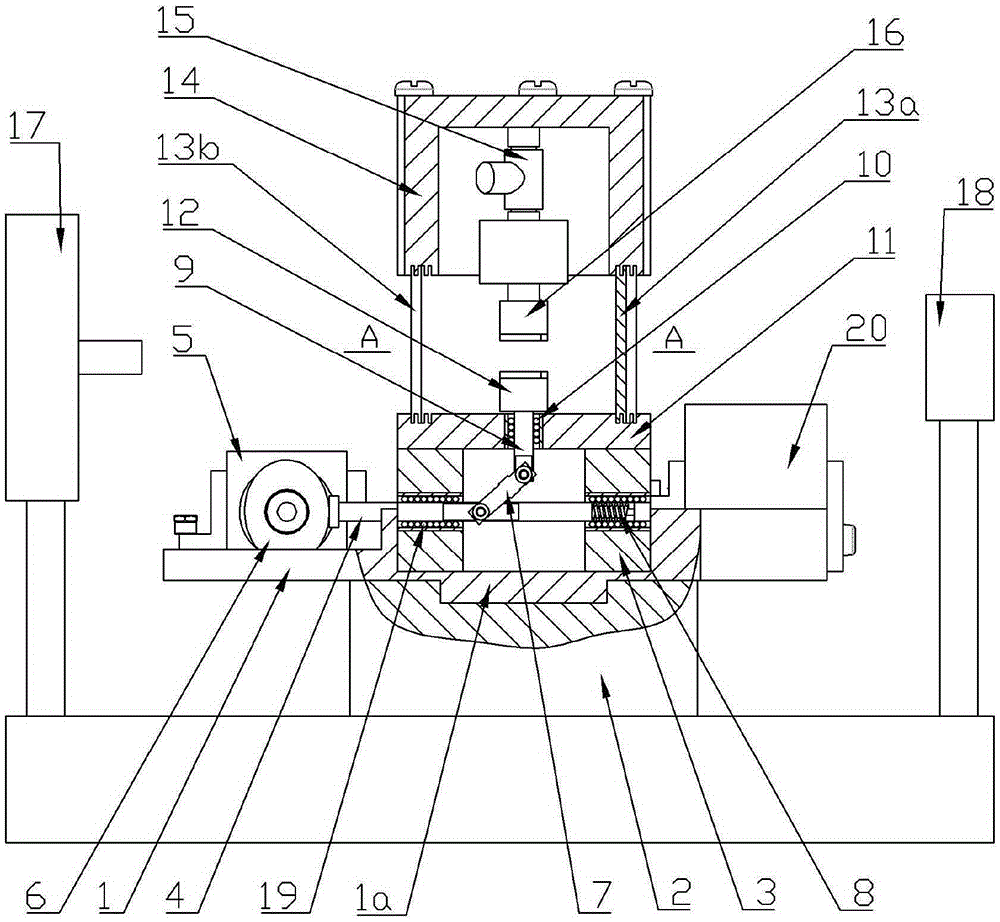

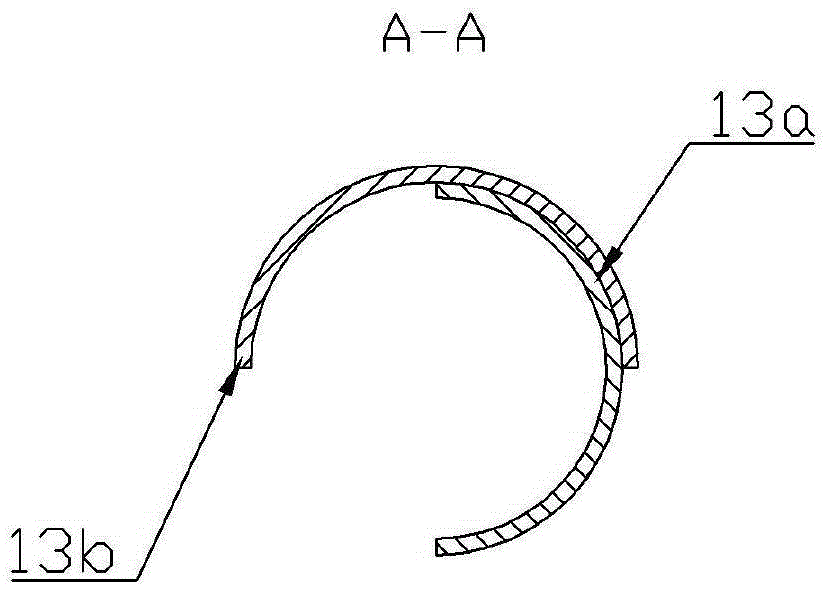

[0025] figure 1 , figure 2 Shown, a kind of specific embodiment of the present invention is, a kind of fatigue testing machine that can carry out in-situ imaging with synchrotron radiation light source, its composition is:

[0026] The cross 1a at the bottom of the base plate 1 is fitted on the platform 2 of the synchrotron radiation source, and the middle part of the upper surface of the base plate 1 is fixed with a circular base 3; the push rod 4 is installed on the left wall of the base 3 through a horizontal linear bearing-19 and On the right wall; the left side of the upper surface of the bottom plate 1 is equipped with a servo motor 5, and a cam 6 is installed on the servo motor 5 shaft; The lower end of the rod 7 is hinged, and the right end of the push rod 4 is connected to the right wall of the base 3 by a spring 8;

[0027] The upper end of connecting rod 7 is hinged with the bottom end of driven rod 9, and driven rod 9 is installed on the cover plate 11 of base 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com