Drainage type segment lining model pore hydrostatic test device

A pore water pressure and test device technology, which is applied in the direction of measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve the problems of long test period, cumbersome operation, large data error, etc., and achieve accurate and reliable test basis and operation Simple and convenient, the effect of small data error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

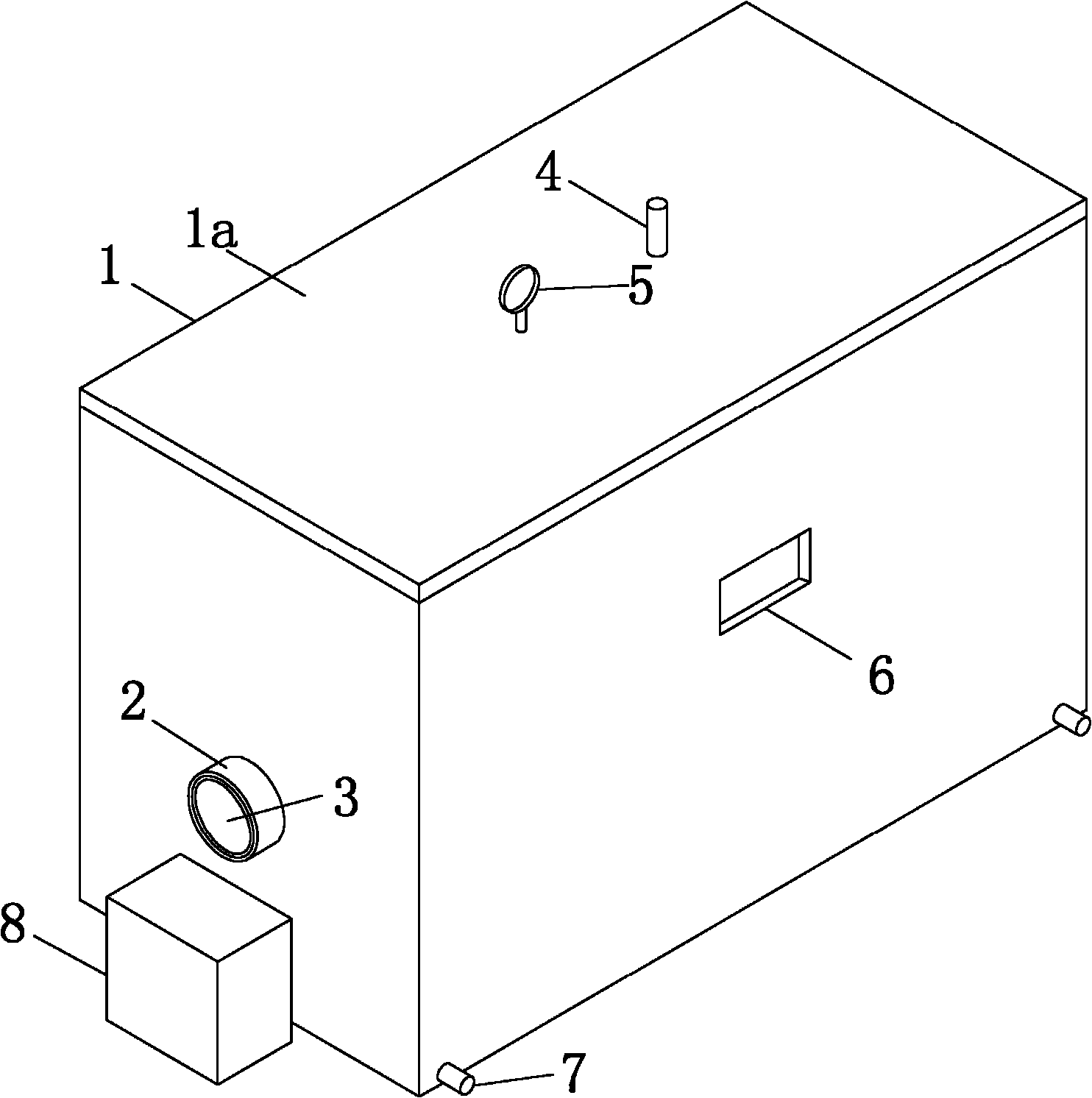

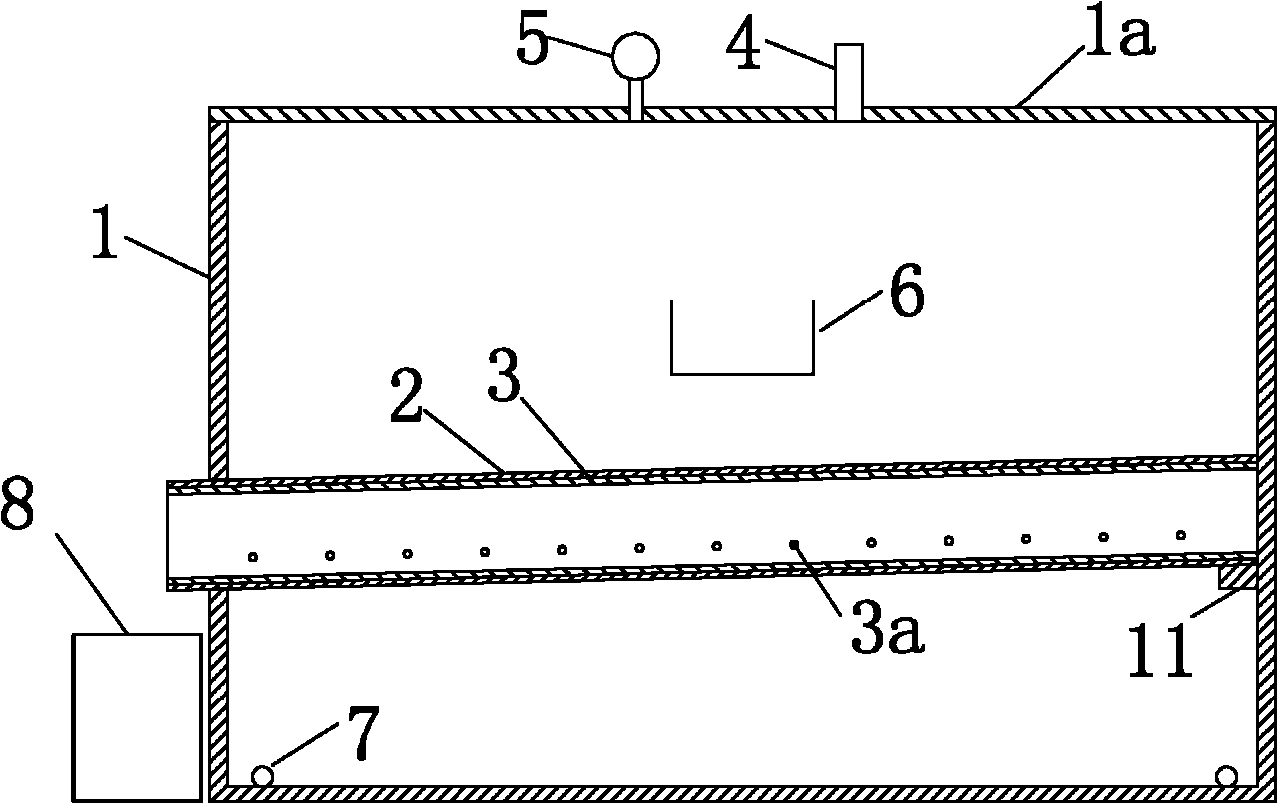

[0026] Figure 1-4 As shown, a specific embodiment of the present invention is a drainage type segment lining model pore hydraulic test device, which includes a tank cover 1a, a tank body 1, and a pressure measuring device is installed in the middle of the front and rear walls of the tank body 1. The pipe outlet hole 6, the bottom of the front and rear walls of the box body 1 are provided with drain holes 7, and the box cover 1a has a precision water pressure gauge 5 and a water inlet hole 4 communicated with the inside of the box body 1.

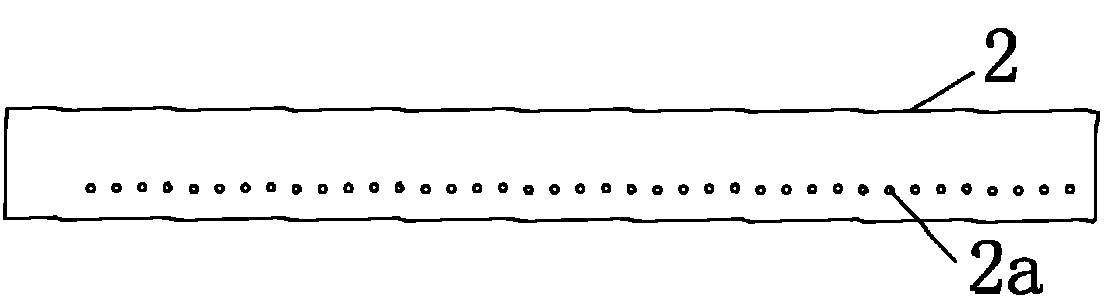

[0027] In the box body 1, an inner mold 3 formed by a circular PVC pipe is longitudinally arranged, and the bottom of the inner mold 3 is provided with an inner mold drain hole 3a, and the water outlet end of the inner mold 3 stretches out from the side wall of the box body 1; A water storage container 8 is placed below the water outlet; a steel outer mold 2 is overlaid on the inner mold 3, and an outer mold drain hole 2a is opened on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com