Test platform for testing automatic gearbox

A technology of automatic transmission and test bench, which is applied in the direction of machine gear/transmission mechanism testing, etc. It can solve the problems of fatigue test and life test, the inability to realize the comprehensive performance evaluation and verification of the transmission, and the inability to perform the type test of the transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

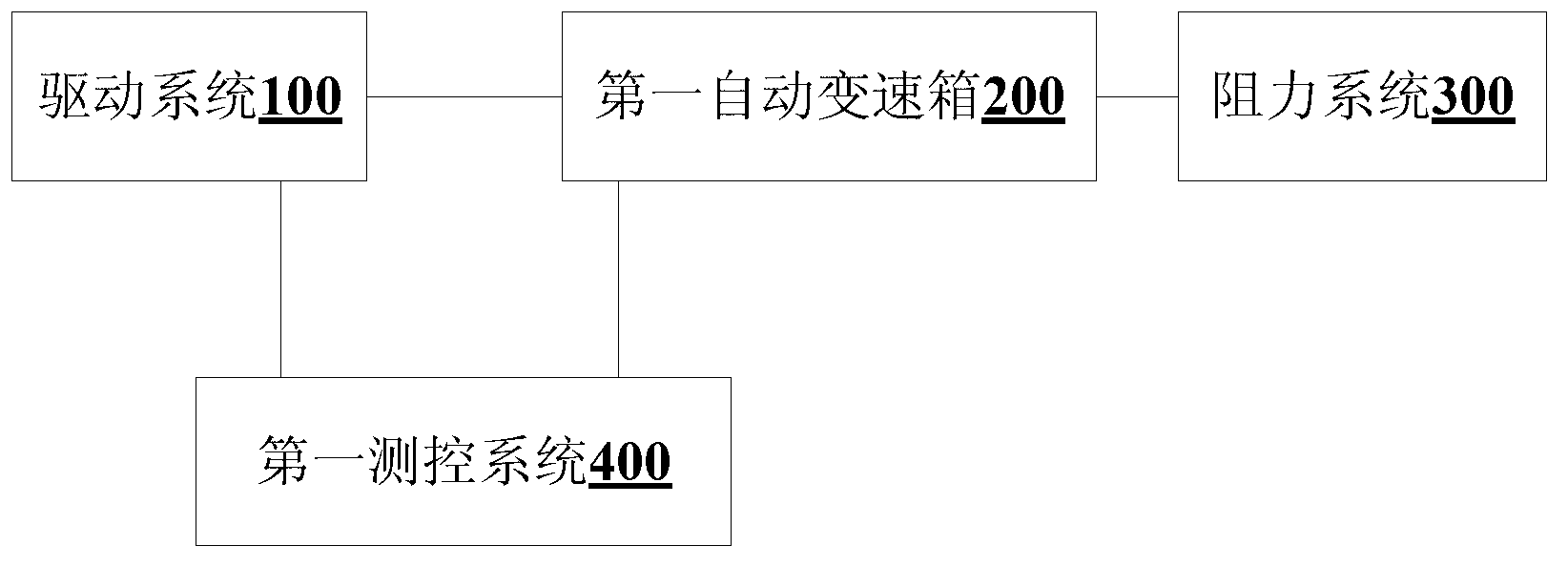

[0024] refer to figure 1 .

[0025] The automatic transmission test bench of this embodiment includes a drive system 100 , a resistance system 300 and a first measurement and control system 400 .

[0026] Wherein, the power output end of the drive system 100 is connected with the first automatic gearbox 200, and the first automatic gearbox is an automatic gearbox with comprehensive performance to be tested; the resistance output end of the resistance system 300 is coaxial with the first automatic gearbox 200 installed for applying a second torque to the first automatic transmission 200, and the second torque is in the opposite direction to the first torque generated by the drive system; the first measurement and control system 400 is connected to the drive system 100 and the first automatic transmission 200 respectively connected, including a plurality of sensors for measuring performance 200 of the first automatic transmission.

[0027] In this embodiment, the drive system ...

no. 2 example

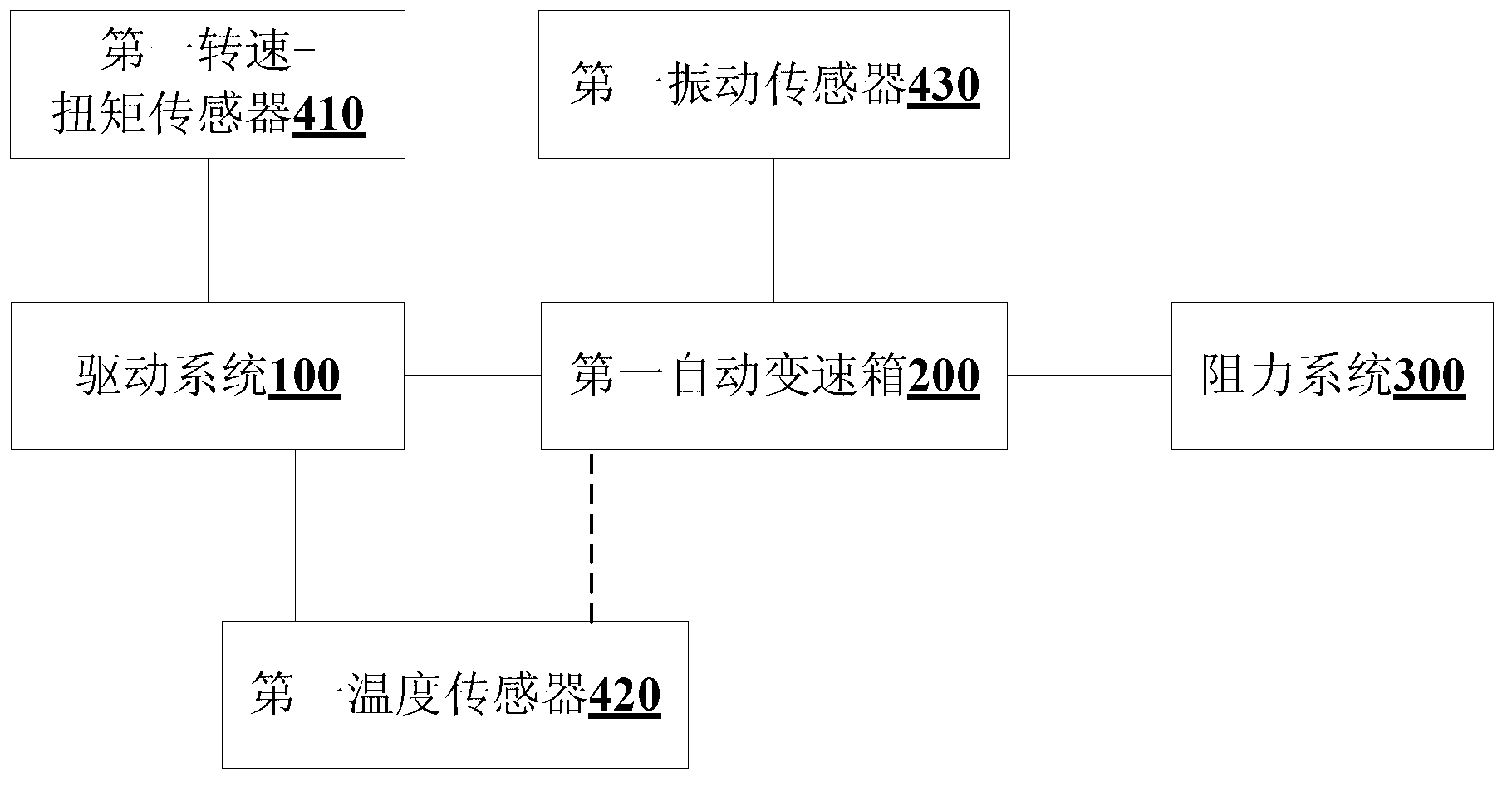

[0029] refer to figure 2 .

[0030] The automatic transmission test bench of this embodiment includes a drive system 100 , a resistance system 300 and a first measurement and control system 400 .

[0031] Wherein, the power output end of the drive system 100 is connected with the first automatic gearbox 200, and the first automatic gearbox is an automatic gearbox with comprehensive performance to be tested; the resistance output end of the resistance system 300 is coaxial with the first automatic gearbox 200 installed for applying a second torque to the first automatic transmission 200, and the second torque is in the opposite direction to the first torque generated by the drive system; the first measurement and control system 400 is connected to the drive system 100 and the first automatic transmission 200 respectively connected, including a plurality of sensors for measuring performance 200 of the first automatic transmission.

[0032] Moreover, the first measurement and ...

no. 3 example

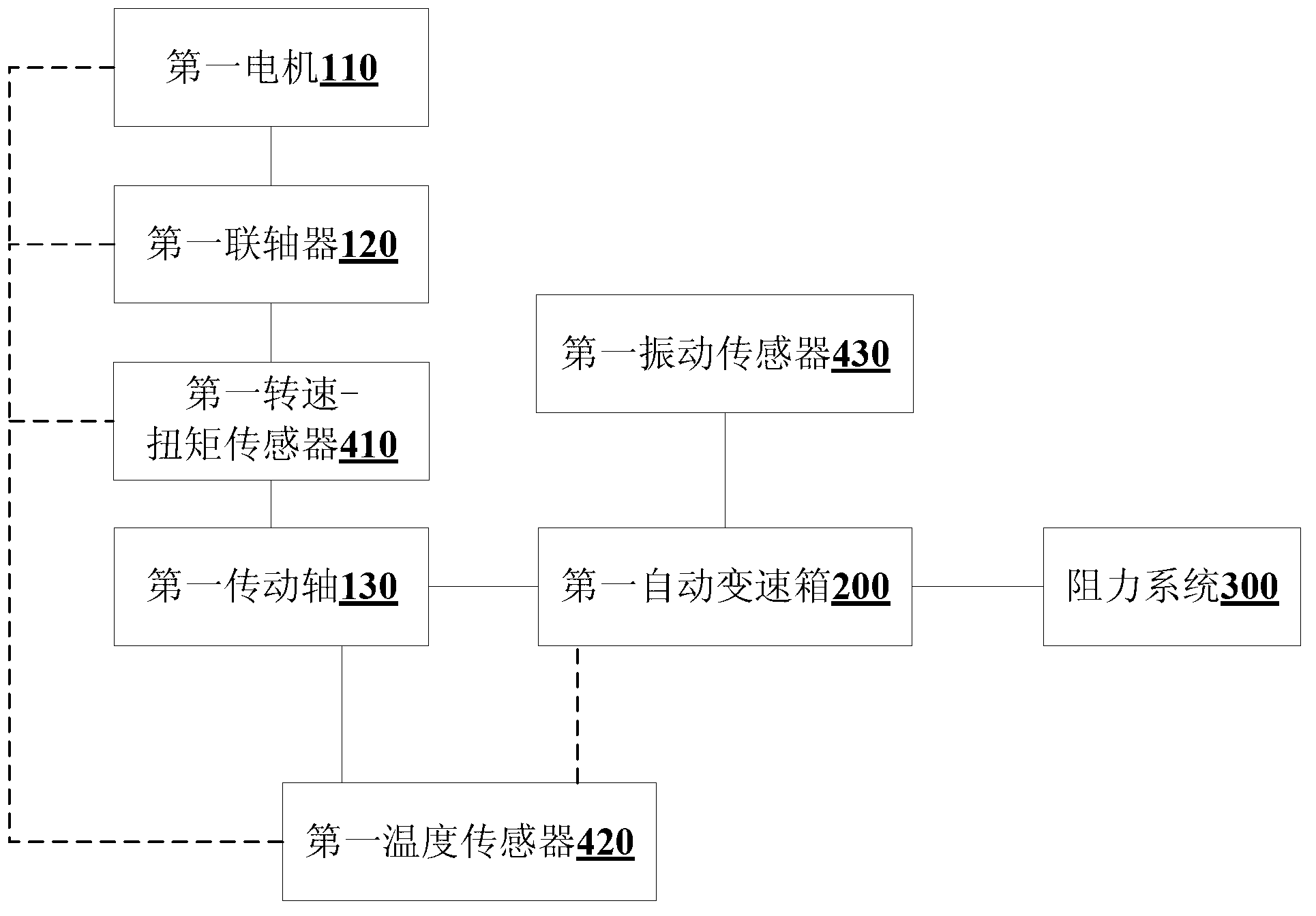

[0035] refer to image 3 .

[0036] As in the above two embodiments, the automatic transmission test bench in this embodiment includes a drive system, a resistance system 300 and a first measurement and control system.

[0037] Specifically, the first measurement and control system includes a first speed-torque sensor 410 , a first temperature sensor 420 and a first vibration sensor 430 .

[0038] The drive system includes a first motor 110, the first motor 110 is connected to the input end of the first speed-torque sensor 410 through the first coupling 120; and, the output end of the first speed-torque sensor 410 is passed through the first transmission shaft 130 is connected to the first automatic transmission 200 .

[0039]In the first measurement and control system, the connection relationship of the other two sensors is as follows: the first temperature sensor 420 is connected with the first motor 110 in the drive system, the first shaft coupling 120 or the first transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com