Finger friction test device

A test device and finger technology, applied in the field of finger friction test device, can solve the problems of great influence of friction tribological characteristics, great variation of contact area, large error, etc., and achieve the effect of wide application range and accurate parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

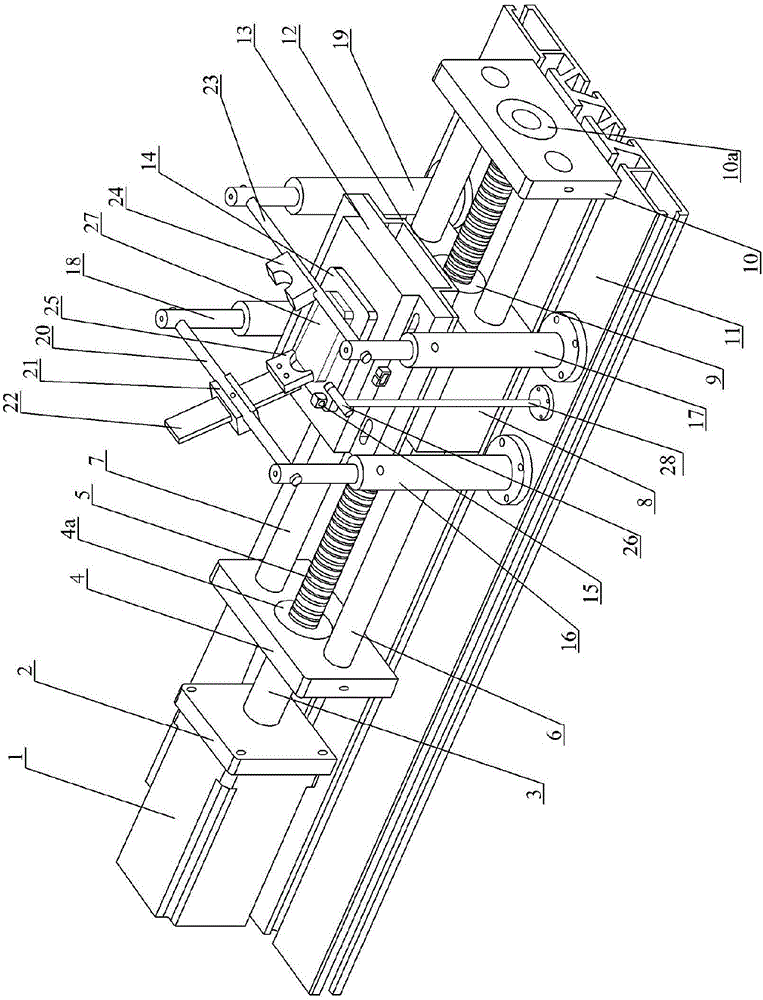

[0026] figure 1 It is shown that a specific embodiment of the present invention is a finger friction test device, which is characterized in that: the upper surface of the rectangular base 11 is sequentially installed with a vertical plate 2, a left support plate 4, and a right support plate 10 from left to right. ; The servo motor 1 is installed horizontally on the left vertical surface of the vertical plate 2. The output shaft of the servo motor 1 is connected to the left end of the screw rod 5 through the coupling 3; the left part of the screw rod 5 is installed on the left support plate 4 through the left rolling bearing 4a The right part of the screw rod 5 is mounted on the right support plate 10 through the right rolling bearing 10a; the left ends of the front optical shaft 6 and the rear optical shaft 7 are fixed on the left support plate 4, and the front optical shaft 6 and the rear optical shaft 7 The right ends are all fixed on the right support plate 10, the front opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com