Automatic generation method of printed circuit board thermal simulation metal path line area ratio

A metal trace and area ratio technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as error-prone and low efficiency, and achieve the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

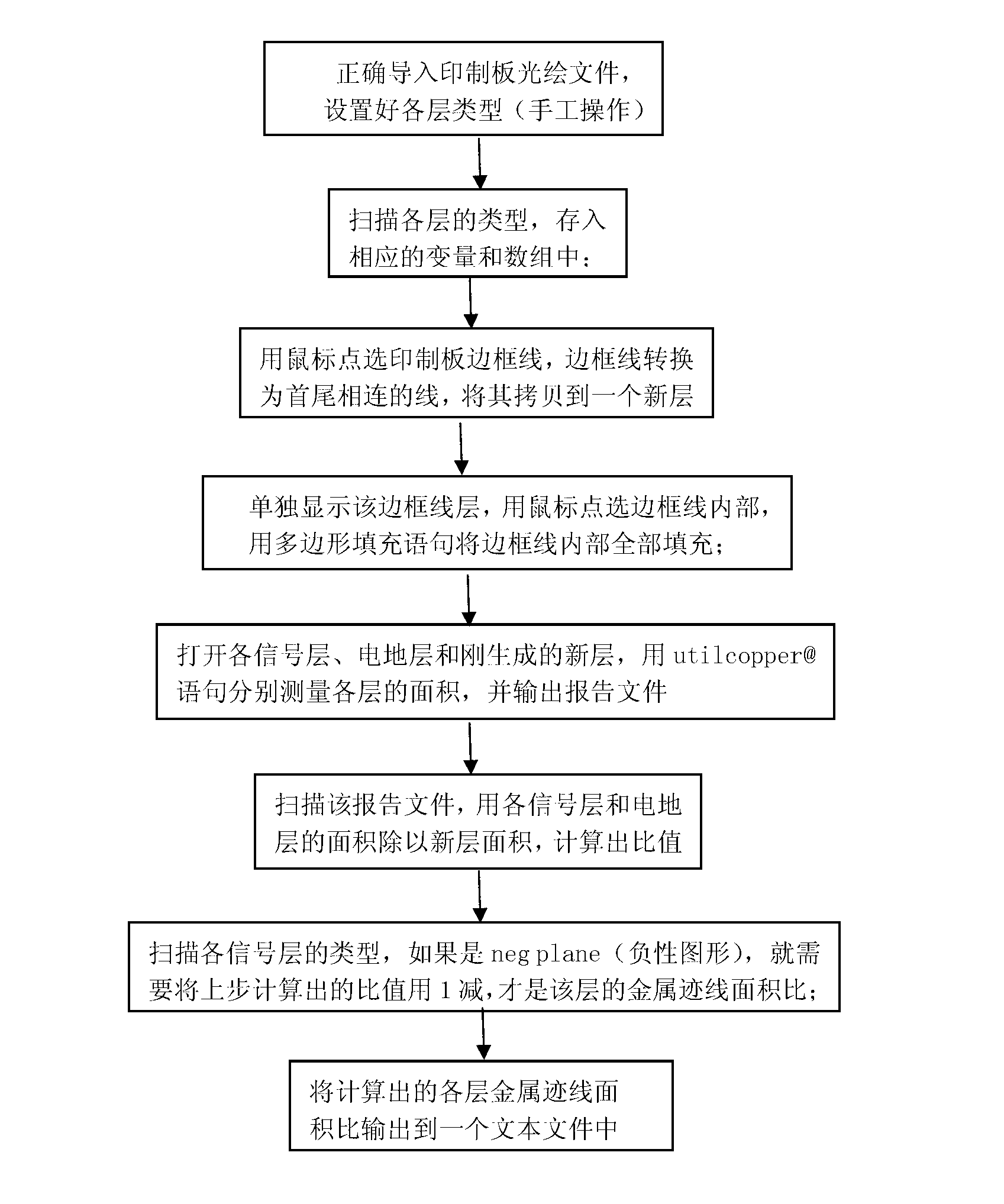

[0028] The operation process of the present invention is specifically described below in conjunction with accompanying drawing:

[0029] The present invention is made based on CAM350 software. When obtaining the metal trace area ratio, the program guides the computer to complete the corresponding operation to obtain the area ratio. The specific operation process is as follows:

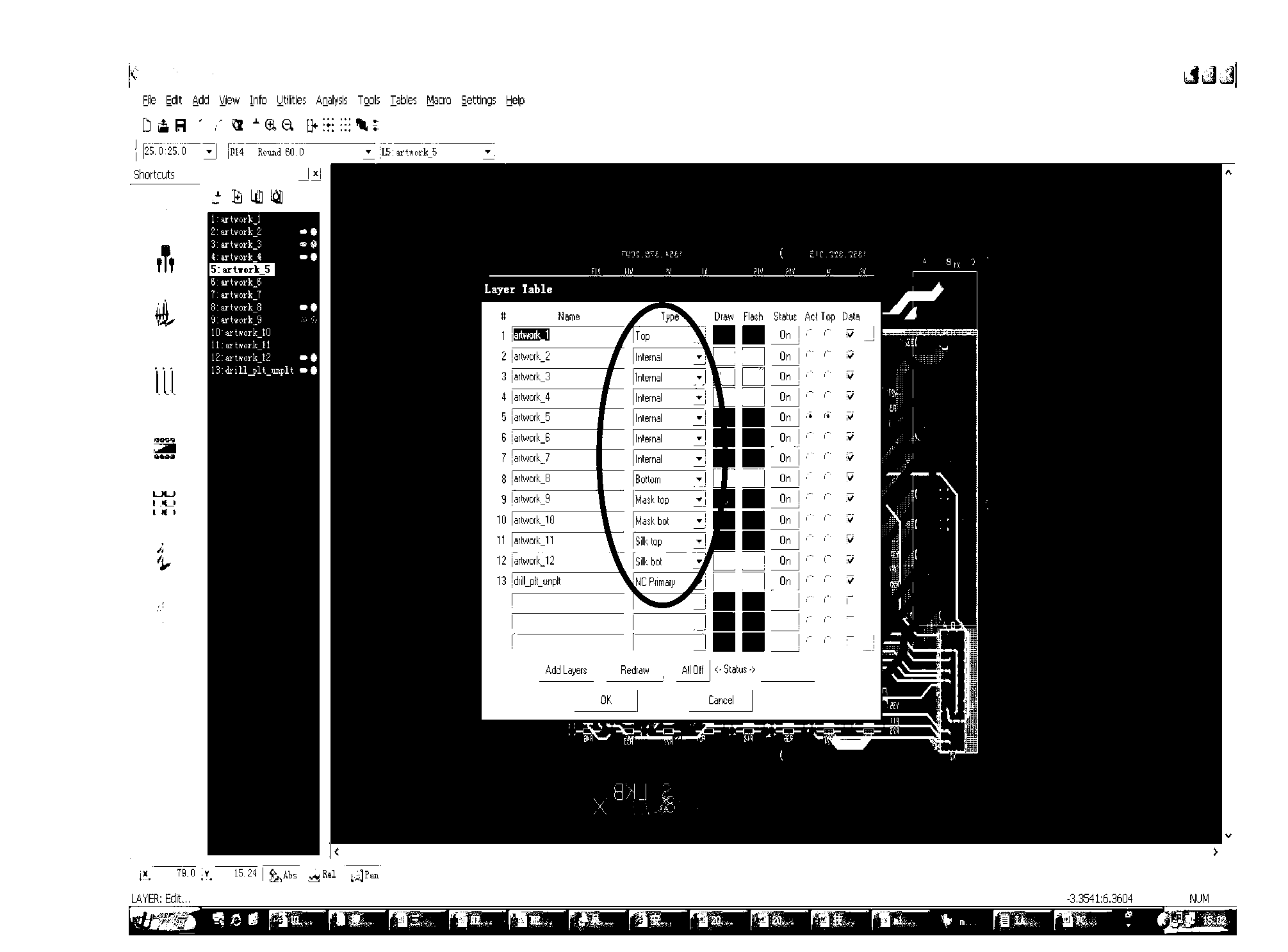

[0030] 1] Manually import the photopainting file of the printed board into the CAM software, set the type of each layer, and the layer setting interface is as follows figure 1 shown;

[0031] 2] The program scans the types of each layer and stores them in corresponding variables and arrays;

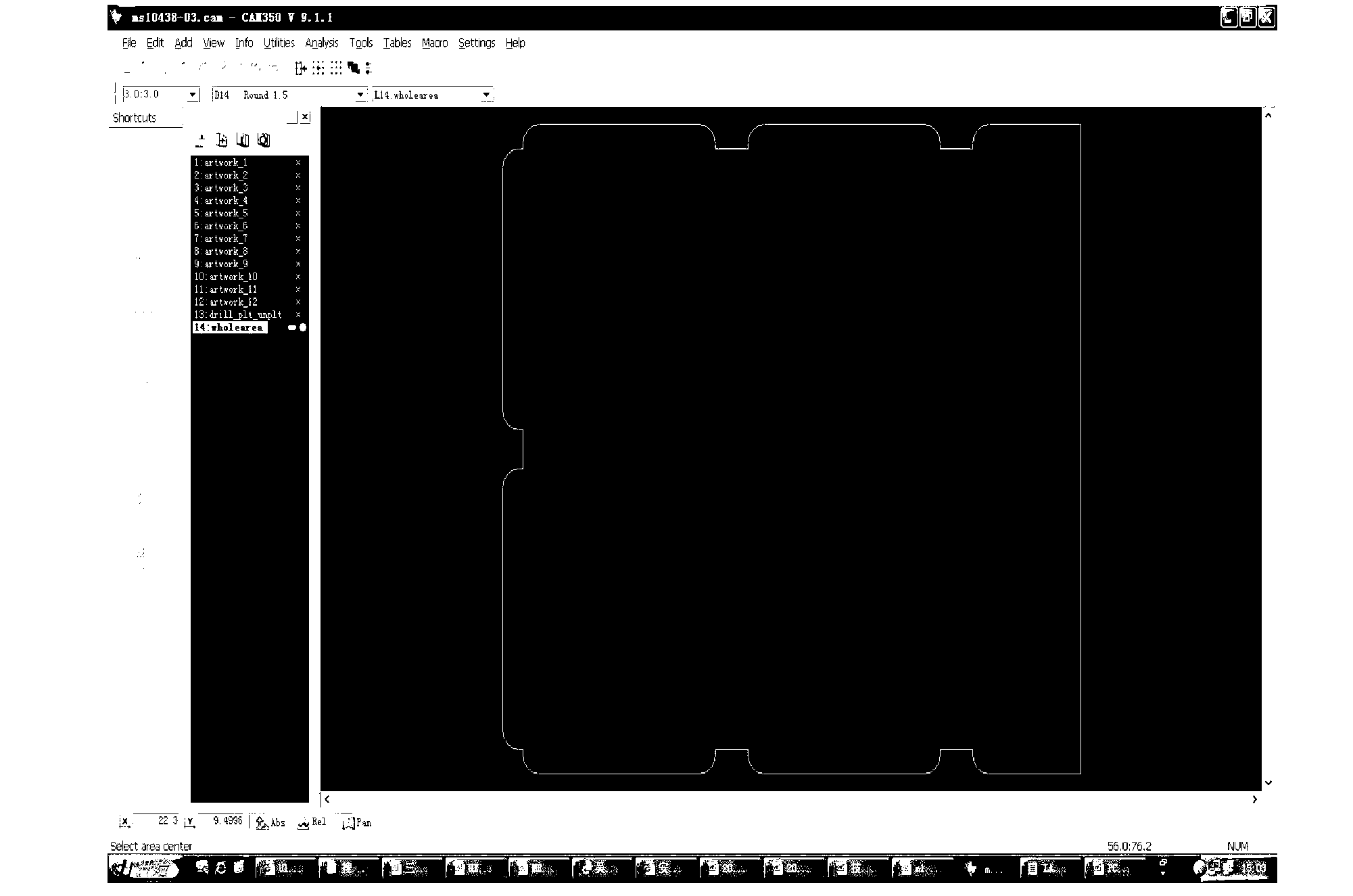

[0032] 3] Program operation Click the border line of the printed board with the mouse, convert the border line into a line connected end to end, and copy it to a new layer, the interface is as follows image 3 shown;

[0033] 4], the program displays the border line layer, click the inside of the border line wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com