High-precision secondary processor

A secondary processing, high-precision technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unbearable users, high production costs, and difficult to guarantee accuracy, achieve simple and compact structure, reduce production costs, Efficient and precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

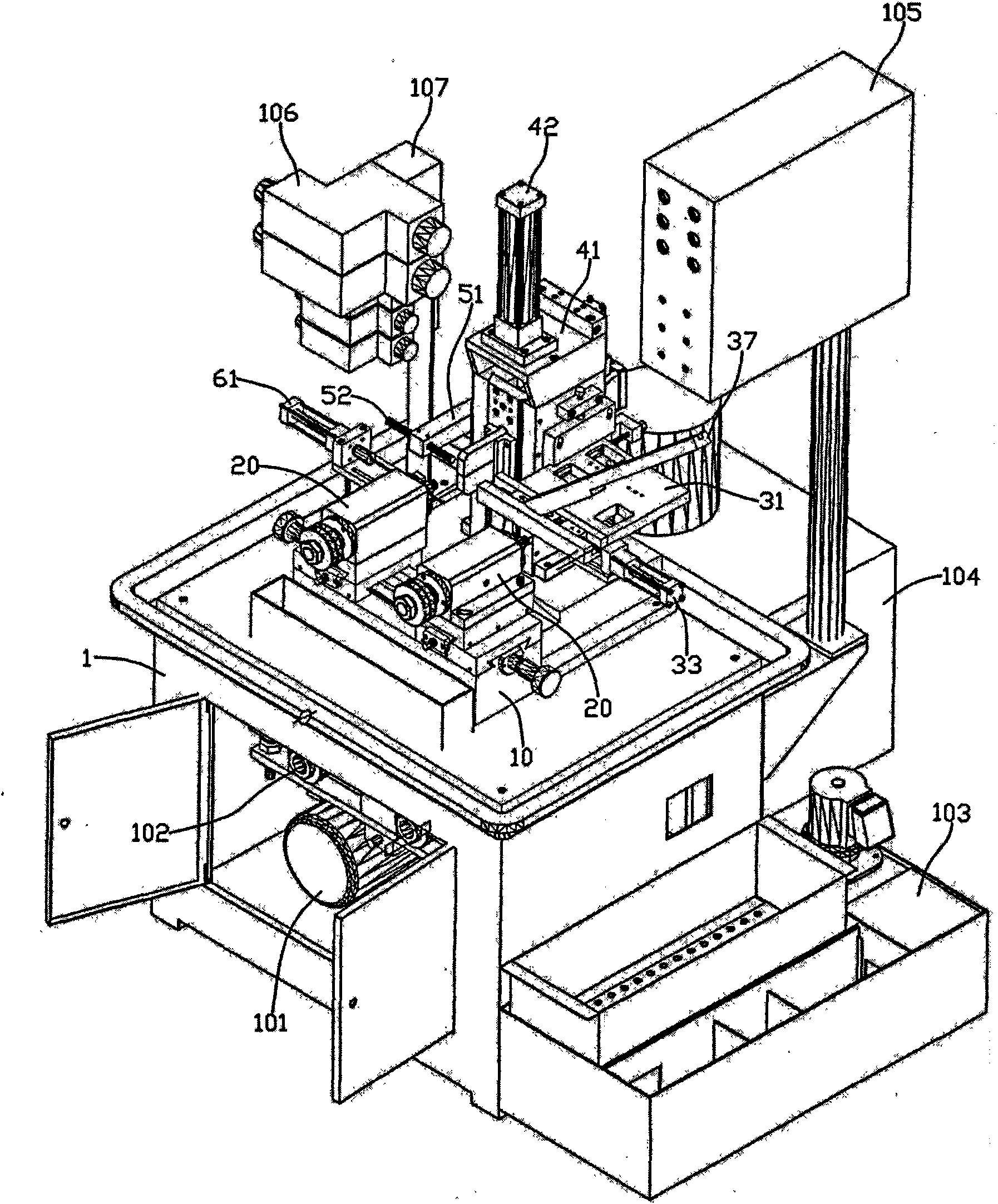

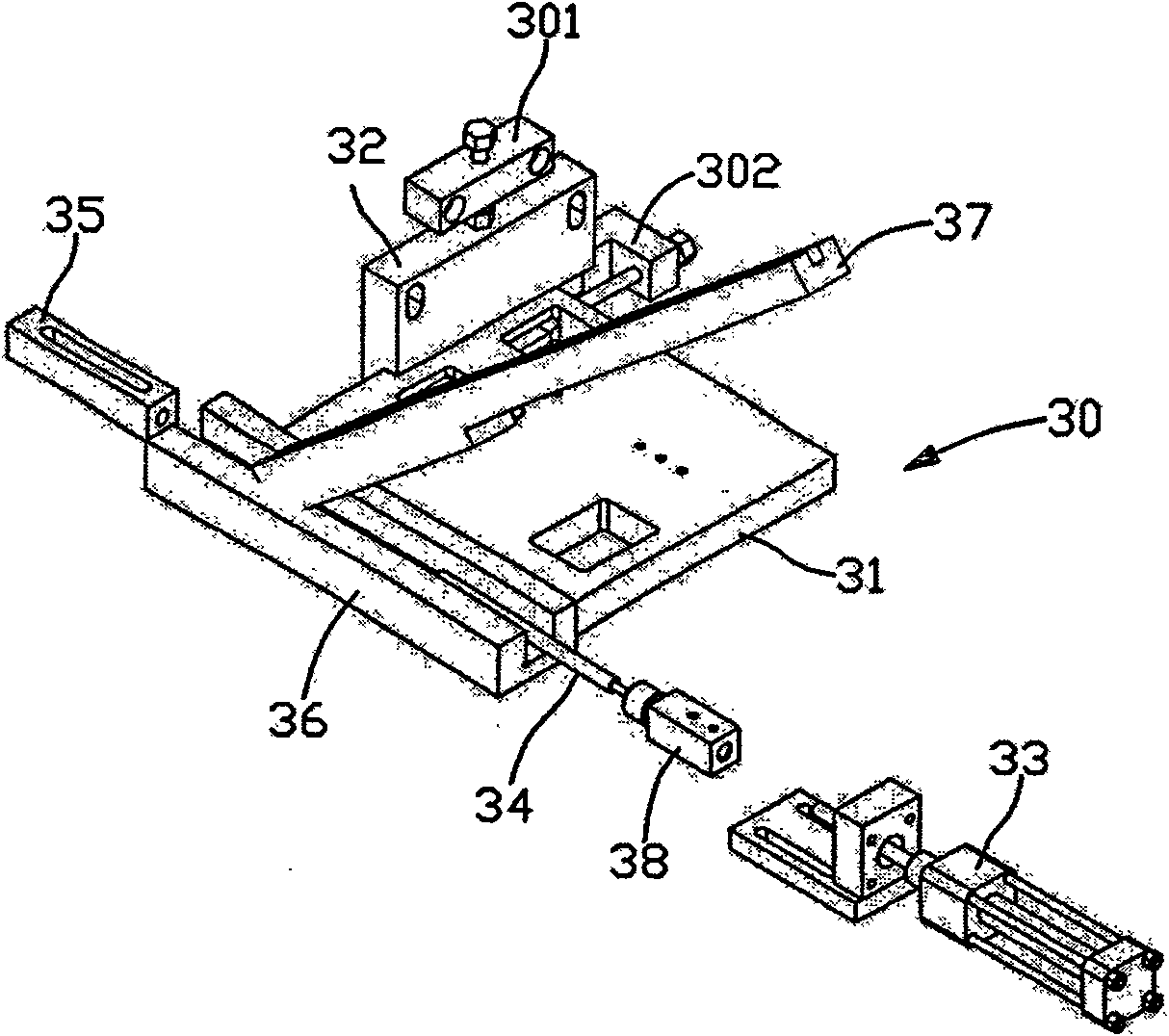

[0027] See Figure 1 to Figure 4 Shown: the high-precision secondary processing machine of the present invention adopts PLC control, is used for the secondary processing of mechanical parts, mainly includes the following parts:

[0028] Machine 1, a motor 101 and a transmission mechanism 102 are arranged inside the machine, and a cutting oil tank 103, a power oil pump box 104, an electric control box 105, a solenoid valve 106, and an oil distribution block 107 are arranged on the outside, wherein the electric control box 105 is provided with There are various indicator lights and operation switches, which are convenient for users to control the machine.

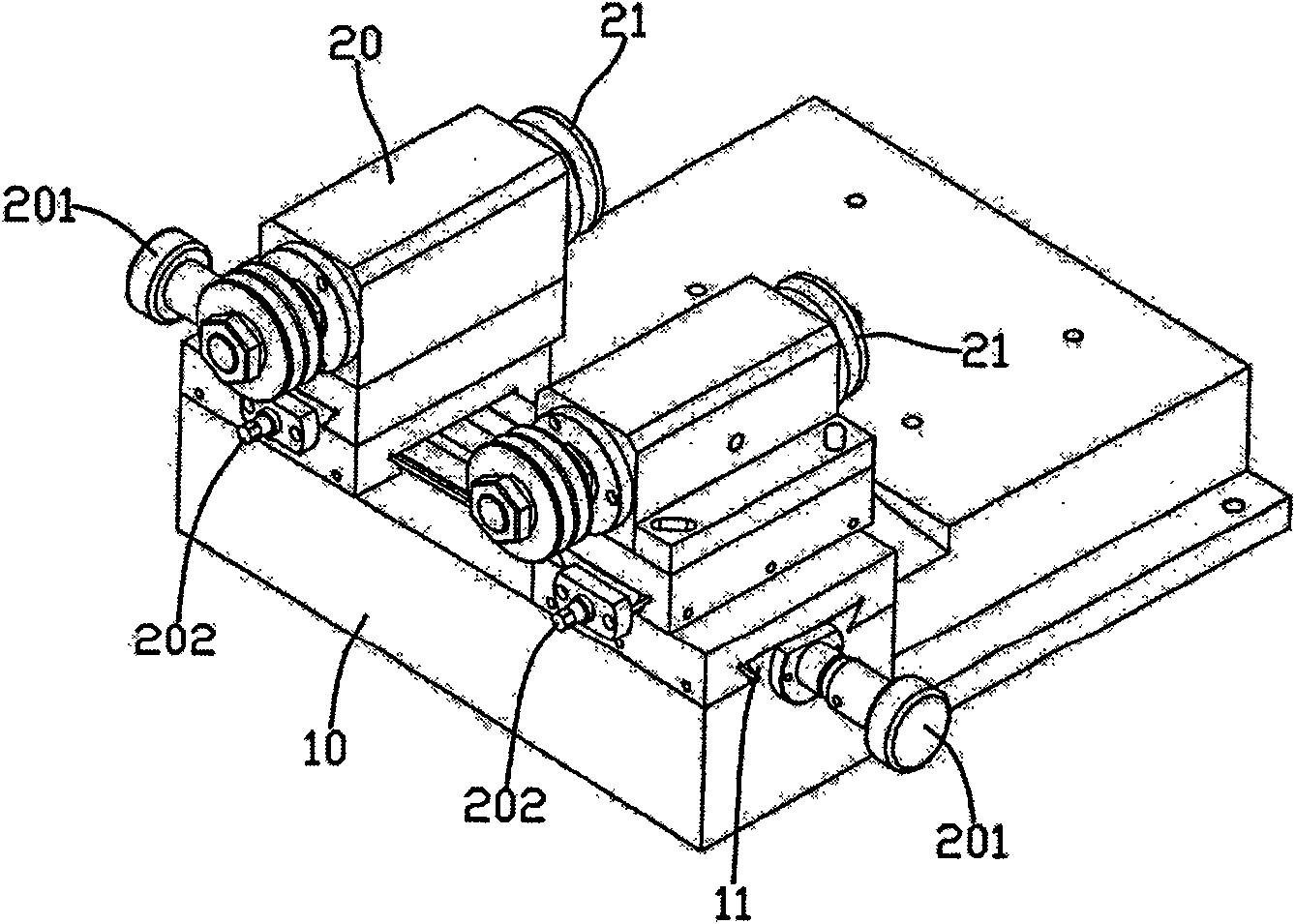

[0029] The base 10 is fixed on the machine platform 1 and is in the shape of a block, and a guide rail 11 is provided at its rear end.

[0030] Two groups of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com