Patents

Literature

214results about How to "Stable moisture content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

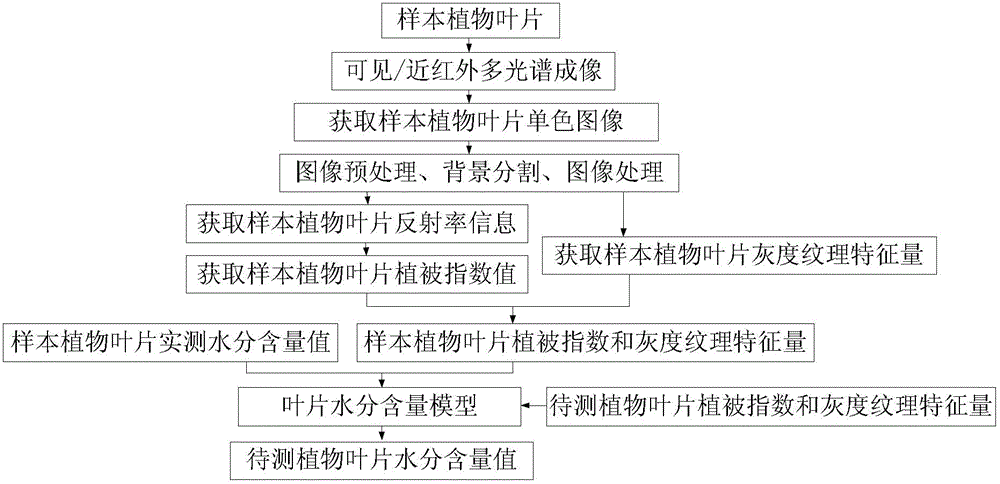

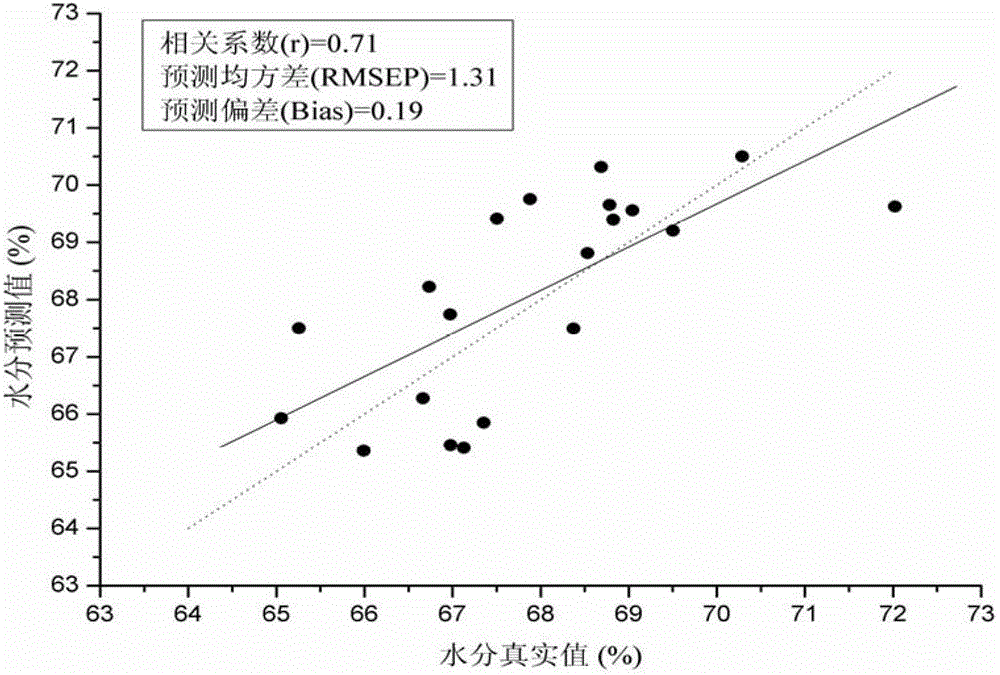

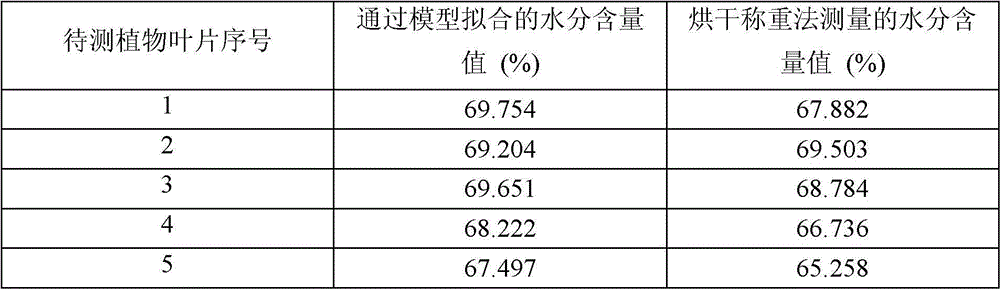

Detection method and system of water content in plant leaf based on multispectral image

ActiveCN102721651AMoisture content fastStable moisture contentColor/spectral properties measurementsMultispectral imageComputer science

The invention discloses a detection method and system of water content in a plant leaf based on a multispectral image. The detection method comprises the following steps: a) getting monochrome images of a green light wave band, a red light wave band and a near-infrared wave band of the plant leaf of a sample; b) getting grayscale information of the monochrome images and getting grayscale texture characteristic quantity of the plant leaf of the sample; c) transforming the grayscale information to reflectivity information of the plant leaf of the sample and getting leaf vegetation index value through the reflectivity information; d) taking the grayscale texture characteristic quantity and the leaf vegetation index value as input vectors, taking actually measured water content value of the plant leaf as an output vector, and establishing a model; and e) getting the grayscale texture characteristic quantity and the leaf vegetation index value of the plant leaf to be detected by operating according to the steps a)-c) and putting into the model in the step d) to get the water content value of the plant leaf to be detected. The method disclosed by the invention can realize accurate, fast, non-destructive and real-time detection of the water content in the plant leaf.

Owner:ZHEJIANG UNIV

Method for preparing full-silicide ABC dry powder fire fighting agent

InactiveCN101485927AMaintain water repellency and moisture resistanceStable moisture contentFire extinguisherPhosphateMoisture

The invention discloses a method for preparing a full siliconization ABC powder extinguishing agent, which comprises the following steps: pulverizing monoammonium phosphate and ammonium sulphate; weighing 2 to 4 percent of floridin, 1 to 3 percent of mica powder, 0.5 to 10 percent of talcum powder, 0.5 to 10 percent of ore fluorite, 2 to 4 percent of lyophobic white carbon black, 0.2 to 0.6 percent of organic silicon oil, 40 to 91 percent of pulverized monoammonium phosphate and 1.5 to 50 percent of ammonium sulphate in percentage by weight; mixing the materials evenly except the lyophobic white carbon black and the organic silicon oil; stirring the organic silicon oil, an organic solvent and water to form an emulsifying silicon oil solution in the ratio of 1:0.4:1; pressurizing the solution to between 0.4 to 0.6Mpa, and spraying the solution onto the mixed materials to be silicified for 30 to 60min; drying and stirring the silicified materials, and adding the lyophobic white carbon black to be mixed evenly, sieved and packaged. The extinguishing agent prepared by the invention has the advantages of stable water ratio, high performance of moisture prevention and agglomeration prevention and better fire-extinguishing efficiency.

Owner:NINGBO NENGLIN FIRE FIGHTING EQUIP

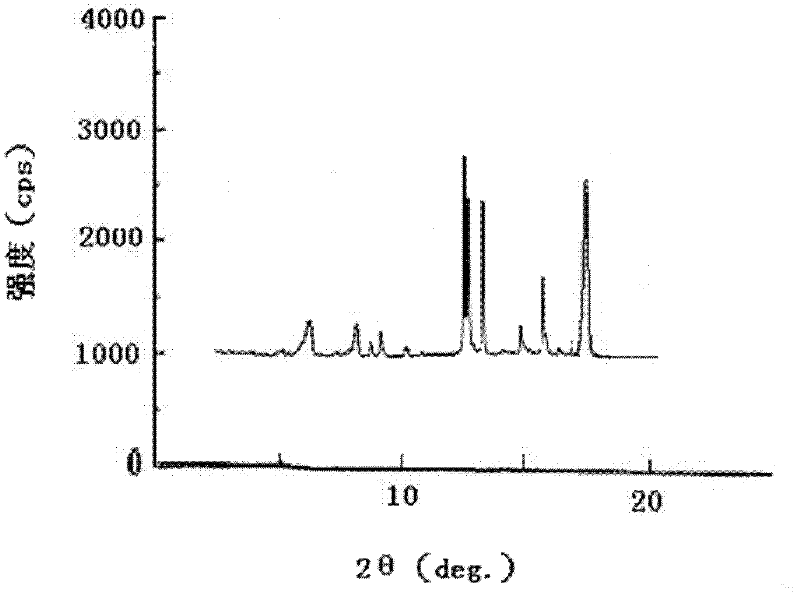

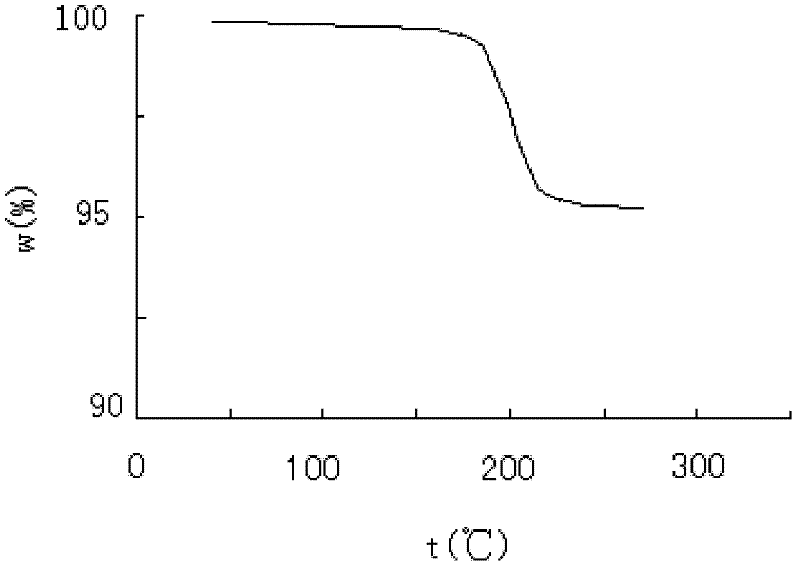

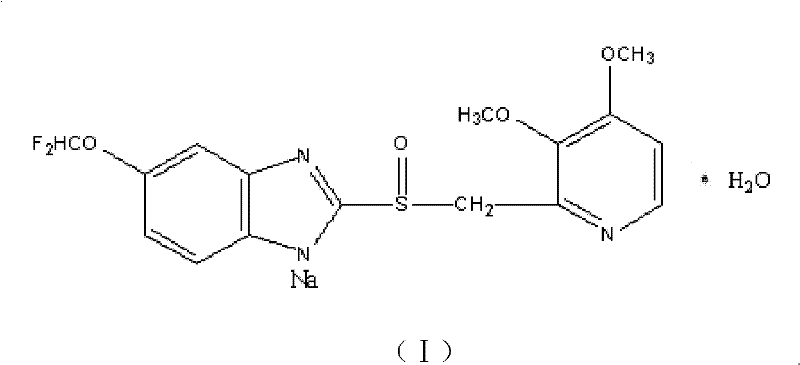

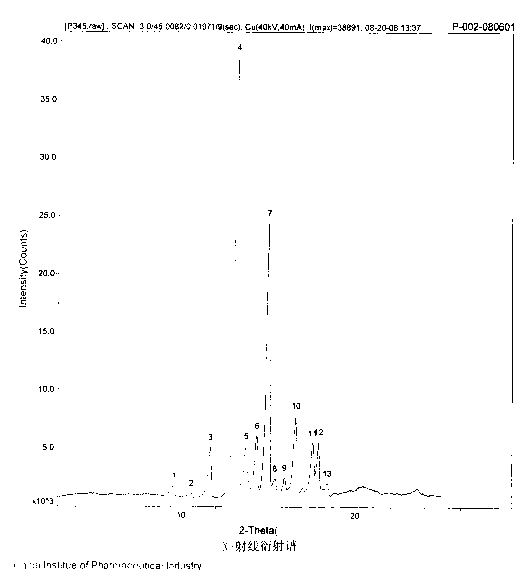

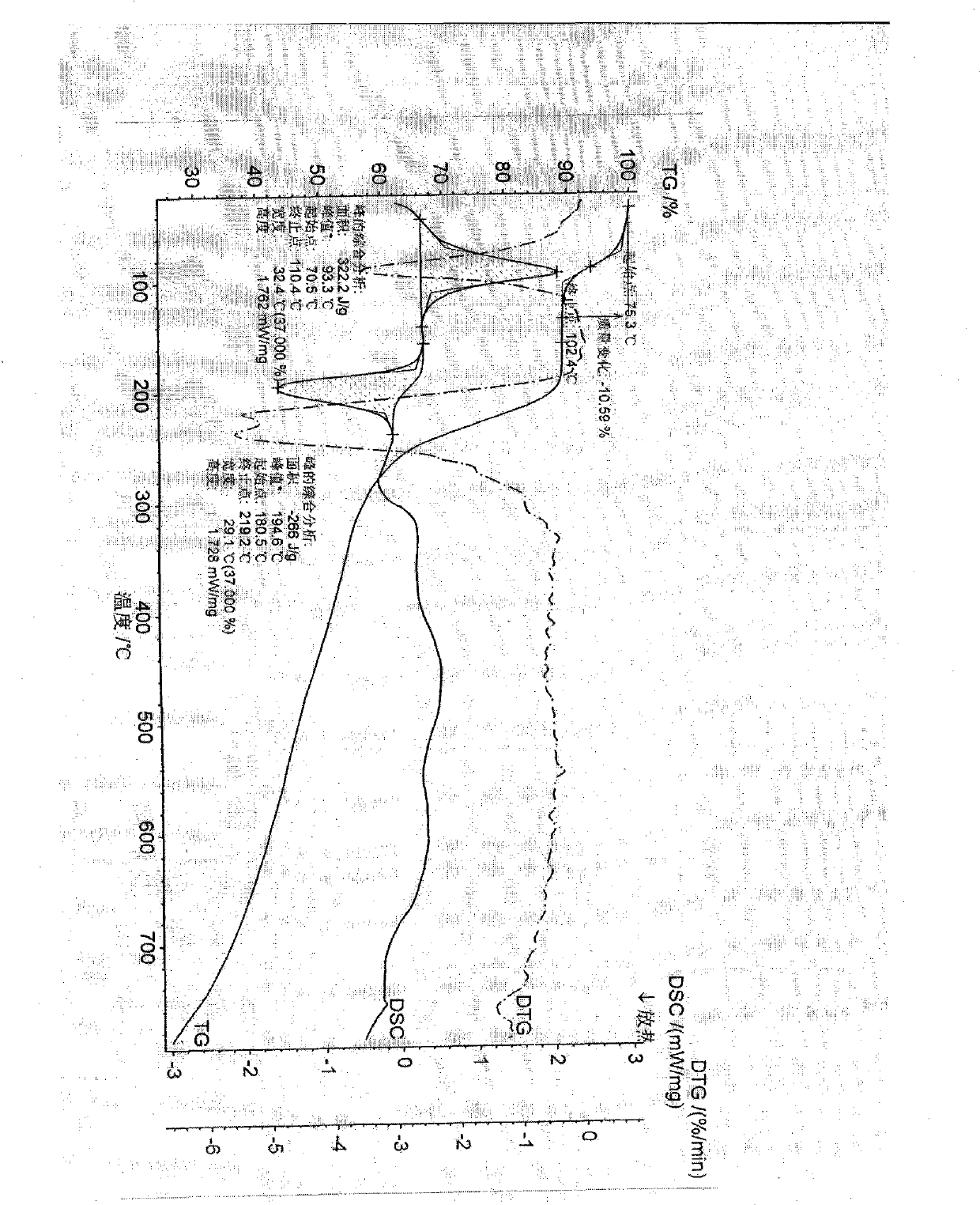

Pantoprazole sodium compound and pharmaceutical composition thereof

ActiveCN102351844AStable moisture contentNo changeOrganic active ingredientsPowder deliveryFreeze-dryingX-ray

The invention discloses a pantoprazole sodium compound, which is crystal. In X-ray powder diffraction pattern obtained through Cu-Kalpha ray measurement, the characteristic peaks of the pantoprazole sodium compound are shown in positions where 2theta is 12.5, 12.6, 13.2, 16.2 and 17.3. The pantoprazole sodium compound can be used together with multiple freeze-drying supporting agents, the prepared freeze-dried powder injection has the advantages of good redissolution, good transparency after redissolution, low impurity content and the like; and moreover, the use amount of the freeze-drying supporting agent is lower, thus saving the pharmaceutical cost and improving the stability of a drug preparation. The invention also discloses a pharmaceutical composition. The pharmaceutical composition comprises a pharmaceutical active ingredient and pharmaceutical auxiliary materials, wherein the pharmaceutical active ingredient is the pantoprazole sodium compound. The stability of the pharmaceutical composition is obviously superior to that of commercial products, and especially, the stability duration of the pharmaceutical composition after being matched with common infusion fluid is prolonged, thus facilitating the clinical application.

Owner:江西新先锋医药有限公司

Material

ActiveUS20090317459A1Stable moisture contentGood phosphate bindingPowder deliveryBiocideWater insolublePhosphate

There is provided a granular material comprising (i) at least 50% by weight based on the weight of the granular material of solid water-insoluble mixed metal compound capable of binding phosphate of formula (I): MII1−xMIIIx(OH)2Λn−y.ZH2O (I) where MII is at least one of magnesium, calcium, lanthanum and cerium; MIII is at least iron(III); Λn− is at least one n-valent anion; x=Σny; 0<x≦0.67, 0<y≦1, and 0≦z<10; (ii) from 3 to 12% by weight based on the weight of the granular material of non-chemically bound water, and (iii) no greater than 47% by weight based on the weight of the granular material of excipient.

Owner:EIRGEN PHARMA LTD

Cutting cultivation method for acer palmatum

The invention discloses a cutting cultivation method for acer palmatum, which belongs to the field of horticultural production. The method comprises the following steps: inserting the cutting slips of the acer palmatum into a rooting agent cutting block which is dipped with a para-hydroxybenzoic acid containing 150 mg / l of IBA and having a mass ratio 0.001; and managing the cutting slips of the acer palmatum inserted into the rooting agent cutting block according to a full exposure cutting seedling cultivation mode, wherein calluses are formed after about 45 days; and the cutting slips of the acer palmatum inserted into the rooting agent cutting block can be transplanted after about 70 days. Tests show that the root-forming rate of the acer palmatum reaches 92 percent, the average formed root number of the cutting slips is 3.8 and an average root length is 3.5 cm. The cutting cultivation method for acer palmatum not only can quickly cultivate rare acer palmatum varieties in large scale under the condition of keeping the intrinsic excellent property of the original varieties, but also can provide a reference for plant varieties which are difficult to be cultivated by cutting, thereby having great popularization value.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Full-crown transplantation and growing method for waxberry trees

ActiveCN103975812AReduce wasteImprove breathabilityCultivating equipmentsForestryNematodeMyrica rubra

The invention discloses a full-crown transplantation and growing method for waxberry trees, which transplants and grows waxberry trees in autumn or spring and includes root cutting, digging, transportation, transplantation, nursing, root promotion and nematode control. When the full-crown transplantation and growing method is utilized to carry out full-crown transplantation for waxberry trees, each detail of waxberry tree transplantation is safeguarded by corresponding methods and measures, consequently, the growing period is effectively shortened, and moreover, the survival rate of transplantation is ensured. The survival rate of the waxberry trees grown with the full-crown transplantation and growing method reaches 95 percent, and the growing period of the waxberry trees is shortened from two years to half a year.

Owner:FUJIAN SPRING ECOLOGICAL TECH CO LTD

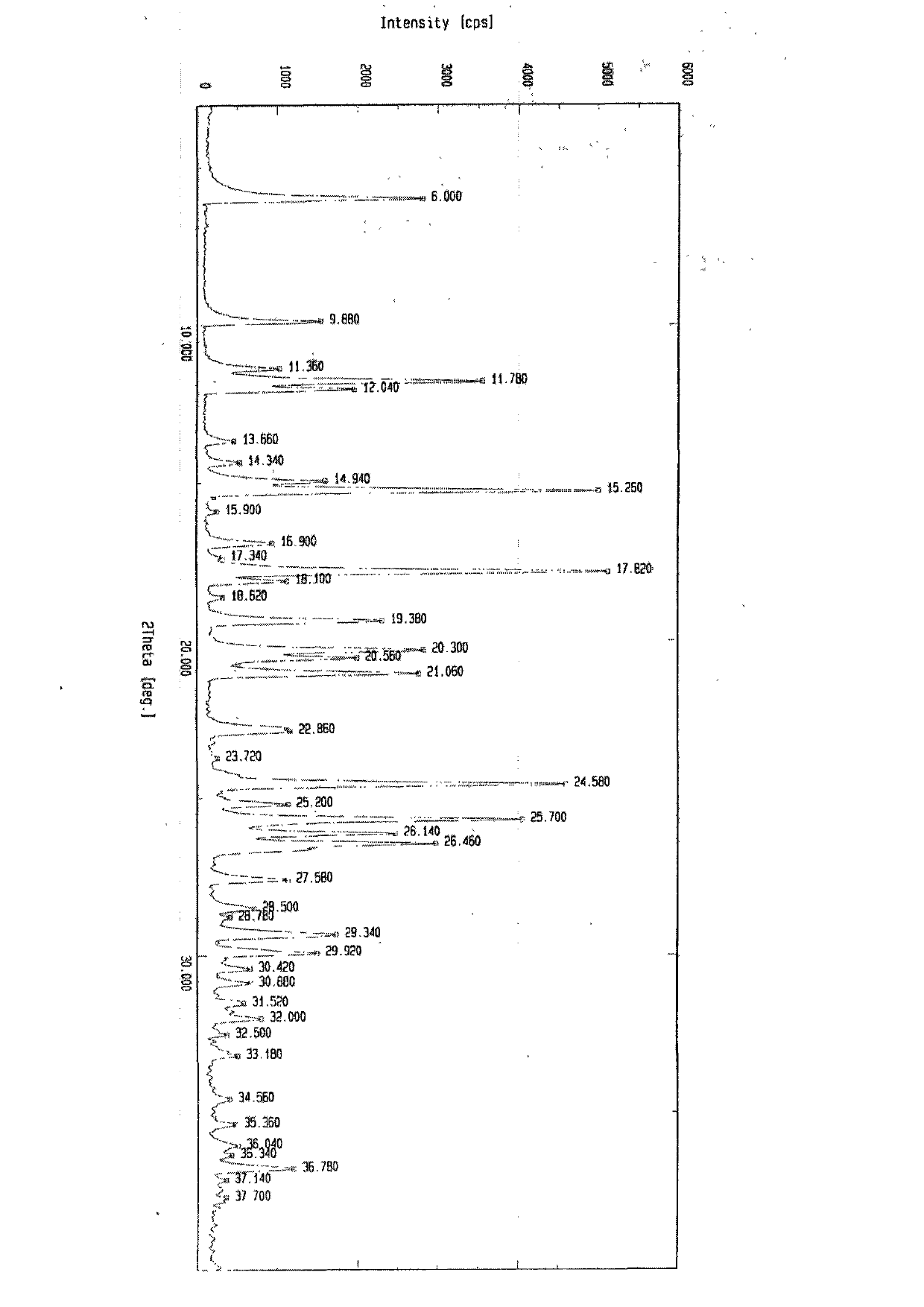

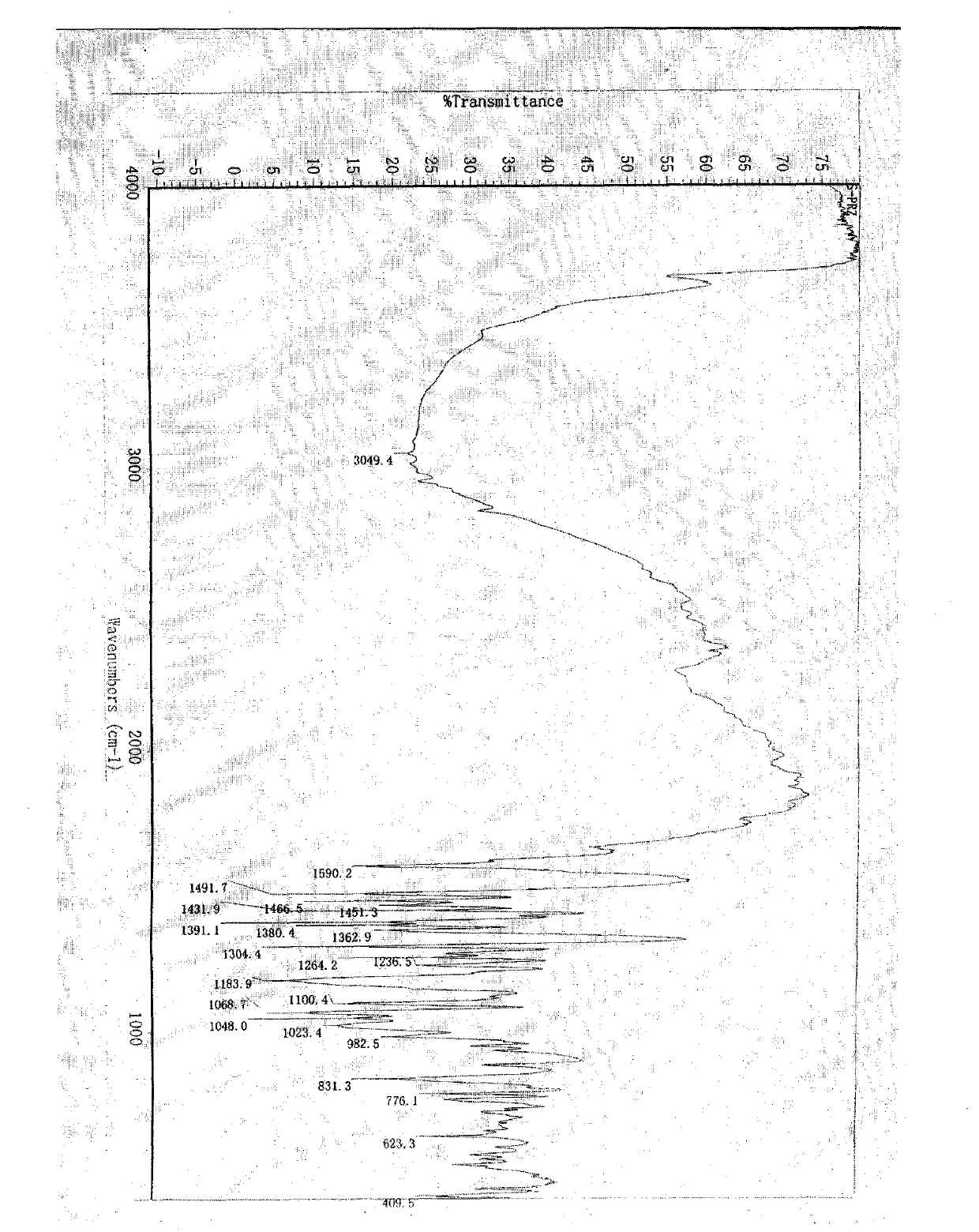

Pantoprazole compound, preparation methods and pharmaceutical preparations thereof

ActiveCN102796078AGood resolubilityHigh clarityOrganic active ingredientsPowder deliverySolubilityDrug compound

The invention belongs to the technical field of pharmaceutical compounds, and relates to a pantoprazole sodium compound entity, especially a pantoprazole sodium crystal form, preparation methods and pharmaceutical preparations thereof. The pantoprazole sodium compound is crystal, and measured by X-diffraction powder diffraction, and the diffraction pattern has the following diffraction angles (2Theta) in turn: 9.5 degrees, 10.4 degrees, 11.6 degrees, 13.1 degrees, 13.8 degrees, 14.2 degrees, 15.0 degrees, 15.3 degrees, 15.9 degrees, 16.5 degrees, 17.5 degrees, 18.0 degrees and 18.2 degrees. The pantoprazole sodium compound entity may be associated with a variety of lyophilization supporting agents and the prepared lyophilized powder for injection has good solubility, good clarity and low content of related substances, etc. simultaneously the use level of the used lyophilization supporting agent is relatively less, the cost of the products is reduced, and the stability and quality of the products are improved.

Owner:杭州澳亚生物技术股份有限公司

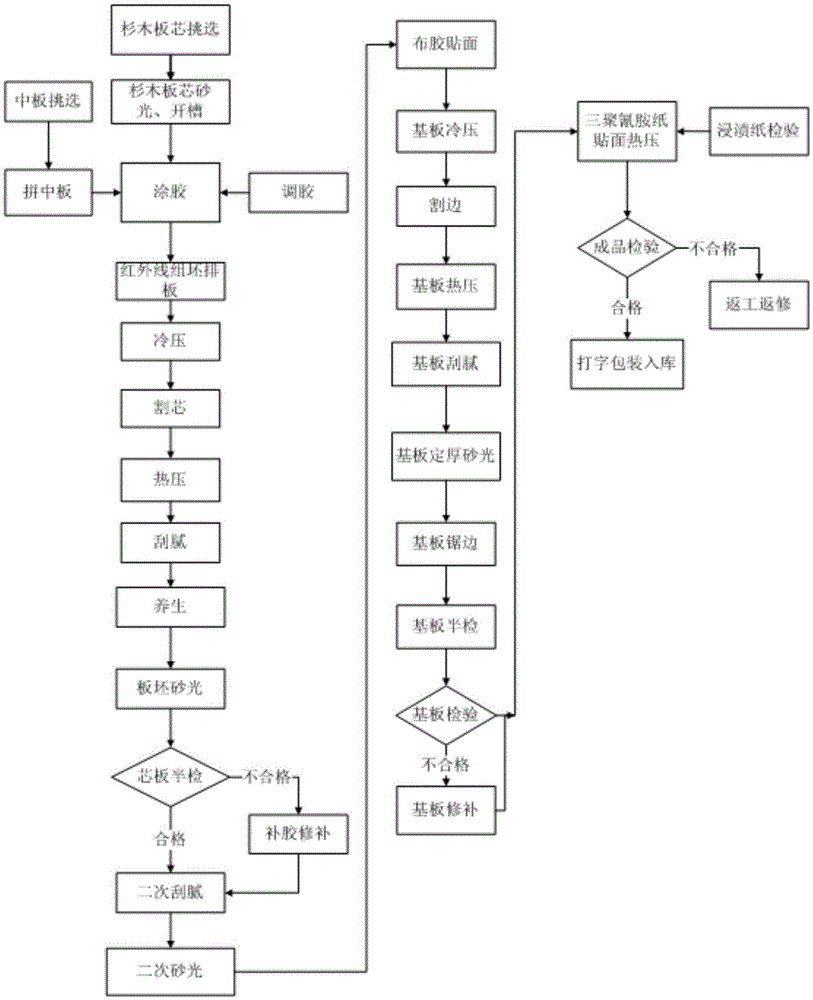

Production process of high-grade fir melamine ecological board

ActiveCN105459221AReduces surface white bloomsReduce defects such as carbonizationOther plywood/veneer working apparatusLaminationInfraredProduct inspection

The invention belongs to the field of board machining and particularly relates to a production process of a high-grade fir melamine ecological board. The process particularly includes the following steps of poplar middle plate selection, poplar middle plate splicing, fir core veneer selection, fir core veneer sanding, fir core veneer slotting, core veneer gluing, infrared ray board arrangement for forming a blank, cold pressing, core cutting, hot pressing, putty application, maintenance, sanding, semi-checking, secondary putty application, secondary sanding, gluing and veneering, base board cold pressing, base board edge cutting, base board hot pressing, base board putty application, base board fixed-thickness sanding, base board edge sawing, base board inspection, repairing, melamine impregnated paper hot pressing and finished product inspection, packaging and warehousing of finished products. The production process has the advantages that fir core veneers are adopted, the hardness, nail-holding ability and static bending strength of the board is improved; eucalyptus middle plates are replaced with poplar middle plates, and the defects that the surface of the finished products is stained and carbonized caused by multiple burrs and scabs on the surfaces of the gum wood are reduced effectively.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

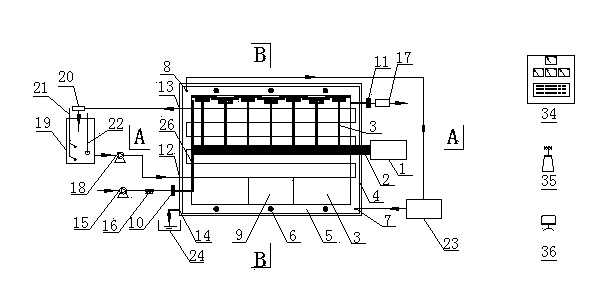

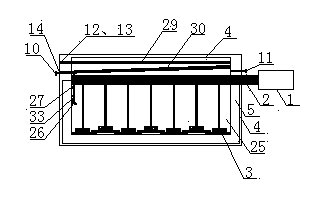

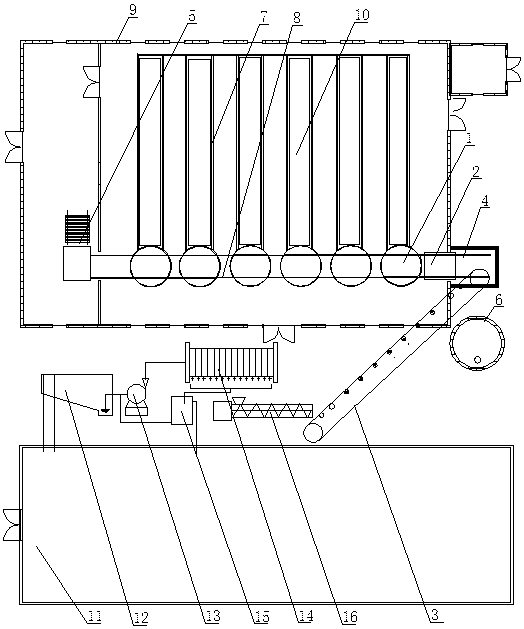

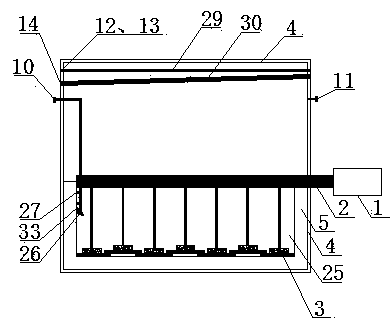

Compact kitchen waste aerobic fermentation equipment

ActiveCN103992148ACompact structureImprove internal space utilizationClimate change adaptationOrganic fertilisersWater bathsThermal insulation

The invention provides compact kitchen waste aerobic fermentation equipment, which is composed of a reaction chamber with a stirrer, a cooling water circulating and condensate water collecting system, an air heating ventilation system having the function of deodorizing, a water bath heating and thermal insulation system, and an intelligent control system with a remote supervisor; a travel switch is arranged in the reaction chamber and used for changing the stirring direction of a motor; a heater and a temperature sensor are arranged in a water bath cavity; heat is supplied to the reaction chamber in time according to reaction requirements; a thermal insulation interlayer is outside the water bath cavity and used for insulating the chamber; the air heating ventilation system is capable of ensuring enough oxygen concentration in the reaction chamber in the treatment process; the cooling water circulating and condensate water collecting system is capable of condensing and guiding out water vapour in the reaction chamber in time; a tail gas deodorizing system is capable of preventing secondary pollution to the environment by malodorous gas in the reaction chamber; and the equipment is controlled to operate by a PLC (Programmable Logic Controller) intelligent control system. The compact kitchen waste aerobic fermentation equipment disclosed by the invention is simple in structure, high in space utilization rate, low in operation energy consumption and good in processing effect.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

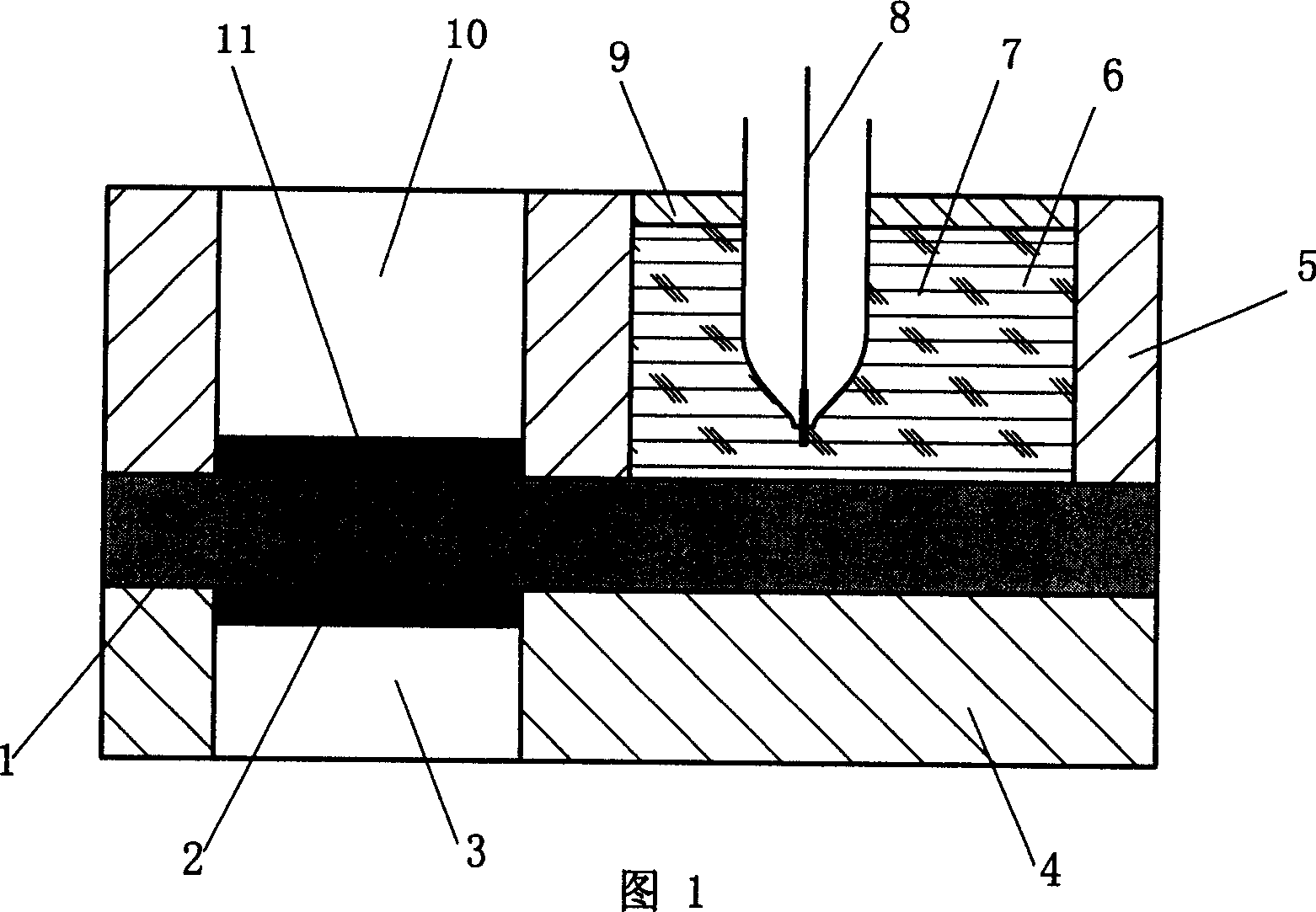

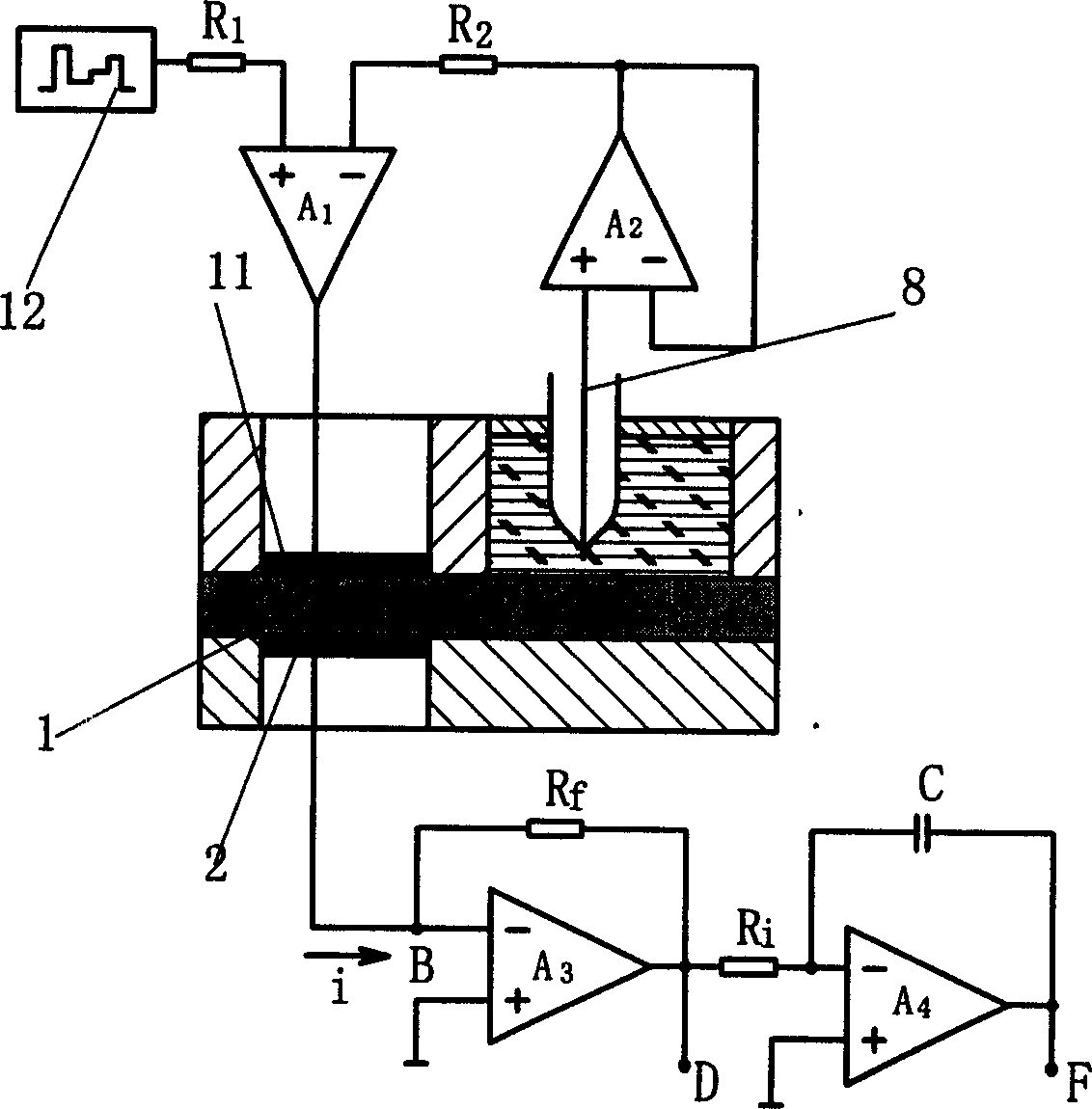

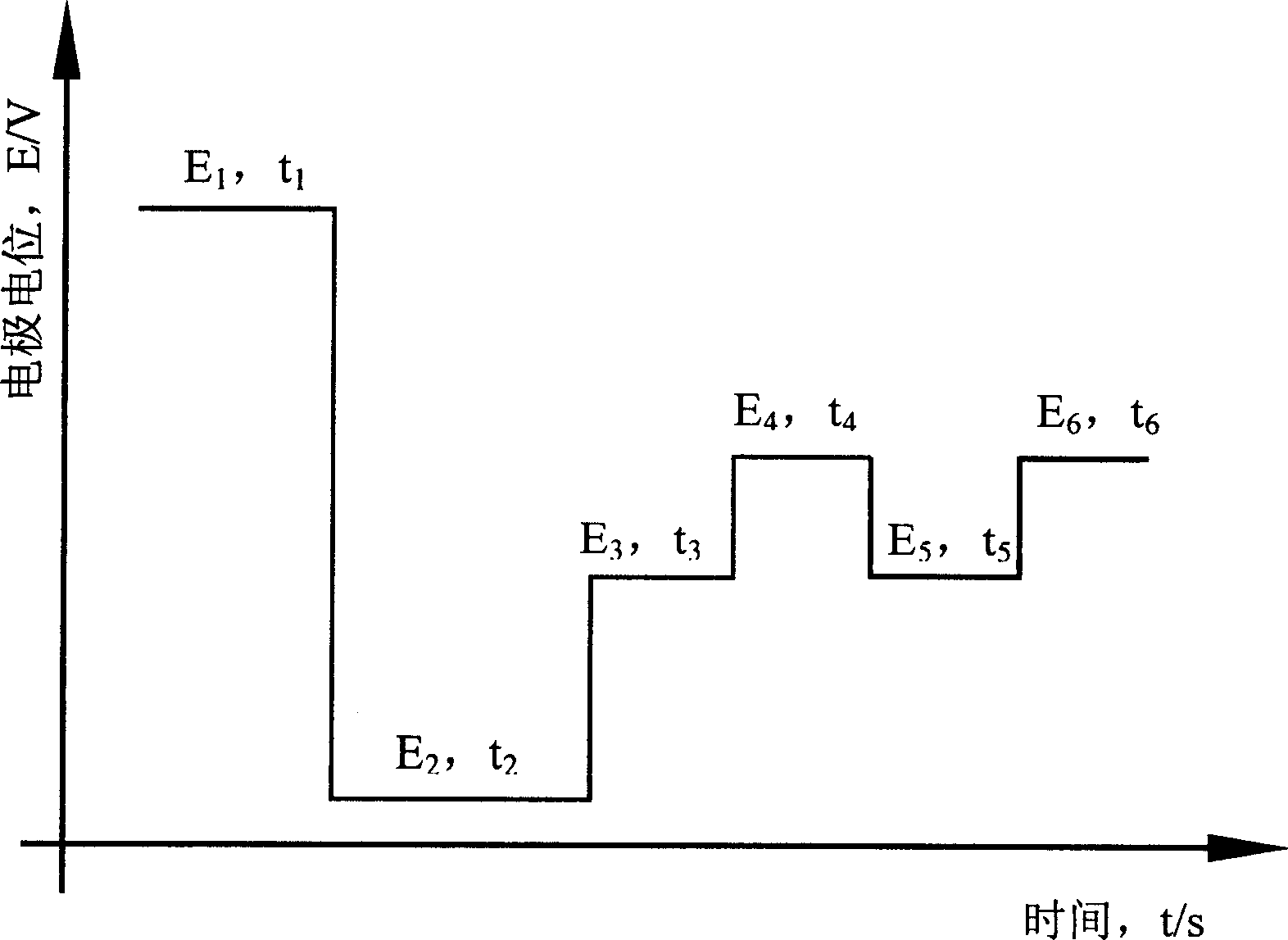

Electrochemical sensor with solid polymer electrolyte and gas detection method using the same

InactiveCN1734262AStable moisture contentSuitable for transient detection of gas samplesMaterial analysis by electric/magnetic meansImpulse controlChemical sensor

This invention relates to a solid polymeric electrolyte electrochemical gas sensor of high precision and good reproducibility, which comprises the following parts: solid polymeric electrolytic film, checking room wherein there are present sensitive pole and reference electrode room which consists of reference electrode and double electrodes. The sensitive electrode and double electrode adhere to the electrolytic film. The reference electrode room is full of stagnant electrolyte and connects many multi-impulse signal senders and detecting routes. The sensor detects the program gas by multi-impulse signal sender, which forces electric potential between the sensitive and reference electrolyte. Two respond current differential values detect the content of present gas, which adapt an one-impulse respond current under multi-impulse controlling electric potential and a respond current under another impulse potential without present electrochemical gas for sensitive electrode.

Owner:杭州生源医疗保健技术开发有限公司

Grouting reinforcement construction process capable of realizing draining and plugging combined effect for underground water in vertical shaft

InactiveCN103089301AAvoid the tendency to diffuse penetrationPrevent sinkingFoundation engineeringDrainagePhosphoric acidSlurry

The invention relates to a grouting reinforcement construction process capable of realizing a draining and plugging combined effect for underground water in a vertical shaft. The grouting reinforcement construction process includes steps of (1), temporarily sealing the bottom of the vertical shaft, arranging grouting pipes on inner and outer sides of the vertical shaft, arranging drain pipes matched with the grouting pipes on the vertical shaft and locally pumping the water by a vacuum pump; (2), diluting sodium silicate of raw grout 39Be' by water to obtain grout 28Be', mixing TGRM grouting materials with cement according to a proportion of 1:3 to obtain second grout, mixing the grout 28Be' with the second grout according to a proportion of 1:1 to obtain liquid A, diluting sodium silicate of raw grout 39Be' by water to obtain grout 30Be', diluting strong phosphoric acid by water according to a proportion of 1:6 to obtain diluted phosphoric acid, and mixing the grout 30Be' with the diluted phosphoric acid according to a proportion of 1:1 to obtain liquid B; (3), alternately filling the liquid A and the liquid B into reinforcement soil layers of the vertical shaft via the grouting pipes and completing grouting for the periphery of the vertical shaft; and (4), feeding small pipes within a 1.5m range of the periphery of the vertical shaft by the aid of high-pressure blast, and alternately filling the liquid A and the liquid B into the periphery of the vertical shaft via the small pipes. The grouting reinforcement construction process has the advantages that 'draining' and 'plugging' are combined and work along both lines in the grouting construction process for the vertical shaft, so that water layers are prevented from diffusing and permeating towards feeble grouted positions, the vertical shaft construction difficulty is lowered, and the construction safety degree is increased.

Owner:BEIJING MUNICIPAL CONSTR

Green tea processing method

InactiveCN104430988AStable moisture contentImprove qualityPre-extraction tea treatmentGreen teaMoisture

The invention discloses a green tea processing method. The methodcomprises the following steps: selecting raw materials, tedding fresh leaves,carrying out fixation with steam, dehydrating, tedding for cooling, rolling, firstly drying, improving aroma, drying and selecting. The green tea processing method provided by the invention has the advantages of utilizing steam to fix, ensuring that the moisture content of tea leaves is stable during processing, and providing an effective basis for subsequent aroma improvement, and the tea leaves processed by the method provided by the invention are extremely high in quality and deep in soup color and aroma.

Owner:TONGJIANG COUNTY LONGHUSHAN TEA TECH CO LTD

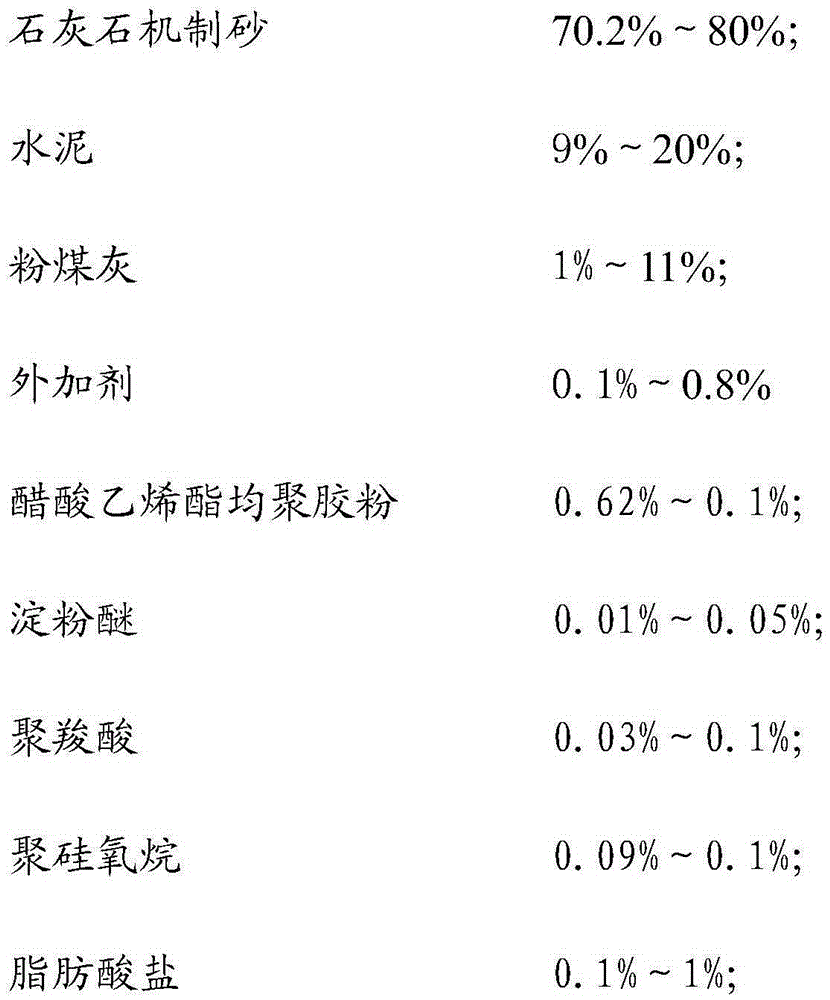

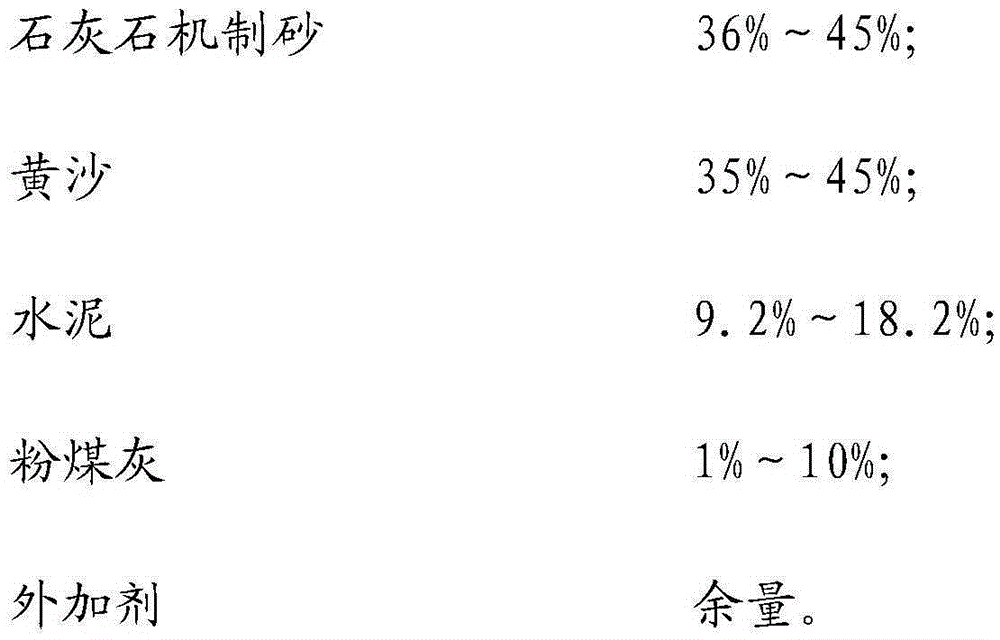

Dry mixing building mortar

The invention relates to a dry mixing building mortar, which is characterized by comprising, by mass, 70.2-80% of limestone machine-made sand, 9-20% of cement, 1-11% of fly ash, and 0.1-0.8% of an admixture, wherein the admixture comprises a thickening agent and a modifier, the modifier is a mixture of starch ether, polysiloxane and polycarboxylic acid, the thickening agent is vinyl acetate homopolymerization rubber, and a weight ratio of the omopolymerization rubber to the starch ether to the polysiloxane to the polycarboxylic acid is 100:1.6:14.5:4.8.

Owner:浙江兆山建材科技有限公司

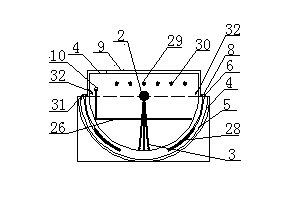

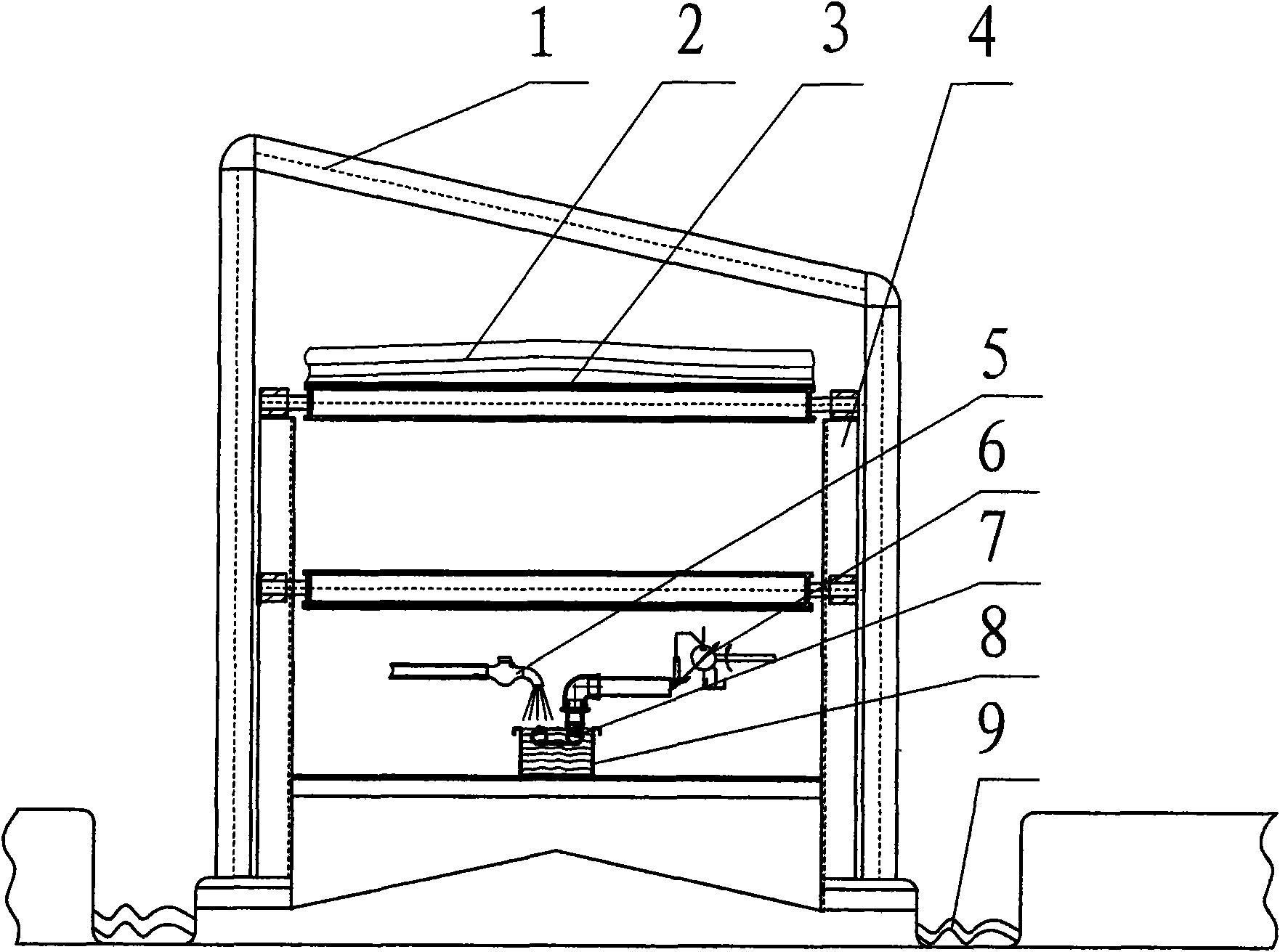

Ripening technology and ripening device in fine dried noodle production

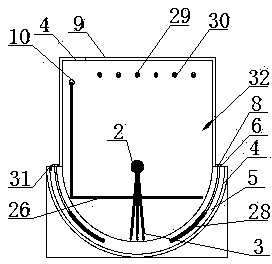

ActiveCN101606655AEasy to adjust temperatureAvoid drippingFood preparationDough processingTemperature controlStable state

The invention discloses a ripening technology in fine dried noodle production and a ripening device which has simple structure and easy operation control. The ripening technology comprises the step of putting dough sheets in an insulating and moistening cover (1) for ripening, and is characterized in that the time is controlled to be 15-25 min, the temperature is controlled to be 25-32 DEG C and the relative humidity is controlled to be 80-90 percent during the ripening. The ripening device comprises a transport unit connected with a composite calender and a continuous calendar, wherein the continuous calendar is arranged on a stand (4) and arranged in the insulating and moistening cover (1), and a heating and moistening device is arranged in the insulating and moistening cover (1). The invention has the advantages that the internal gluten structure of the dough sheets after ripening has stable state and has flexibility, viscoelasticity and very good tractility so as to be convenient for being processed by the following procedures; the heating and moistening device is simple, and compared with heating and moistening by steam generated by a boiler, the operation control is convenient and also pollution to the environment is reduced.

Owner:KEMEN NOODLE MFG CO LTD

Bamboo flour producing process

InactiveCN1406724ASolve the waste problemStable moisture contentWood working apparatusGranularityEngineering

A process for preparing bamboo powder from raw bamboo or bamboo leftover includes such steps as cutting, breaking, drying while sterilizing at 80-280 deg.C, pulverizing by 40 meshes, and grinding by 40-200 meshes. Its advantages are stable water content, uniform granularity, and low cost.

Owner:杨三

Ecological breeding system and breeding method for livestock and poultry

InactiveCN107711520AStable moisture contentEasy to feedSievingGas treatmentEcological farmingScrew conveyor

A livestock and poultry ecological breeding system and breeding method, comprising a livestock and poultry breeding room and a black soldier fly breeding room; a collection tank; a delivery pump connected to the collection tank; a filter press; a clarification tank; a screw conveyor; a conveyor; Insect breeding tank; first track; second track; right-angle reversing mechanism; feeding and receiving car; sorting screen; induced draft fan; Send it to the filter press for pressing and dehydration, send the filtrate to the clarification tank, and send the filter residue to the screw conveyor. After being dispersed in the screw conveyor, it is sent to the storage tower through the conveyor. Distribute the material evenly in the insect breeding tank; inoculate black soldier fly larvae after distributing; repeat the distributing several times; after the feeding and receiving vehicle collects the mixture of black soldier fly and insect sand, transport it to the sorting sieve; the sorting sieve separates the black soldier fly and Insect sand; the odorous gas in the breeding room and the storage tower is treated by the deodorization tower.

Owner:HUNAN LUSHI ENVIRONMENT PROTECTION TECH CO LTD

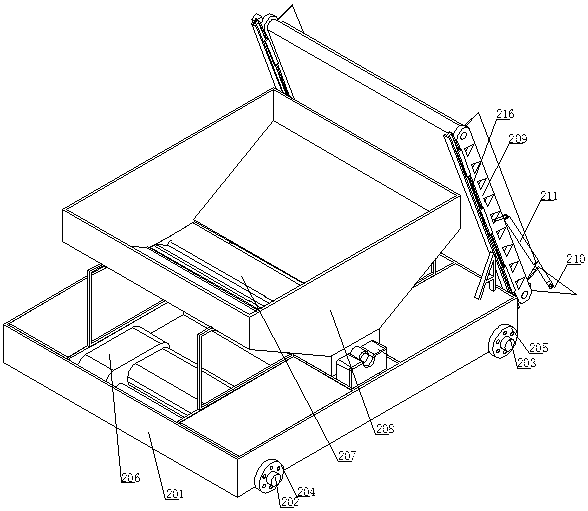

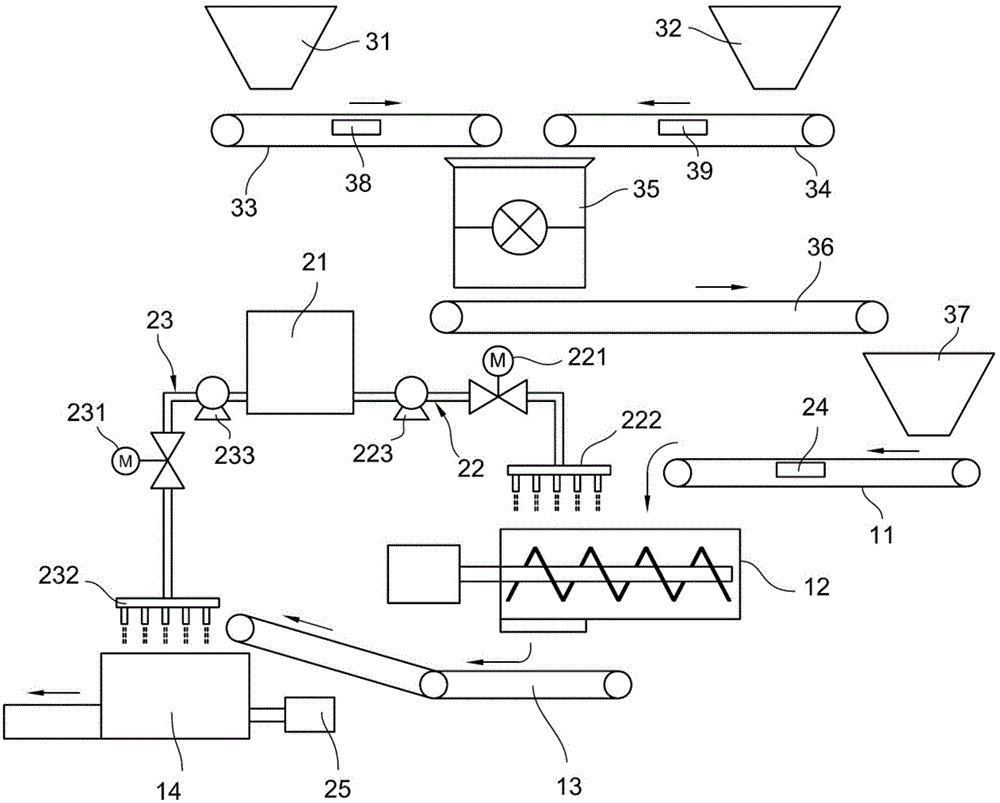

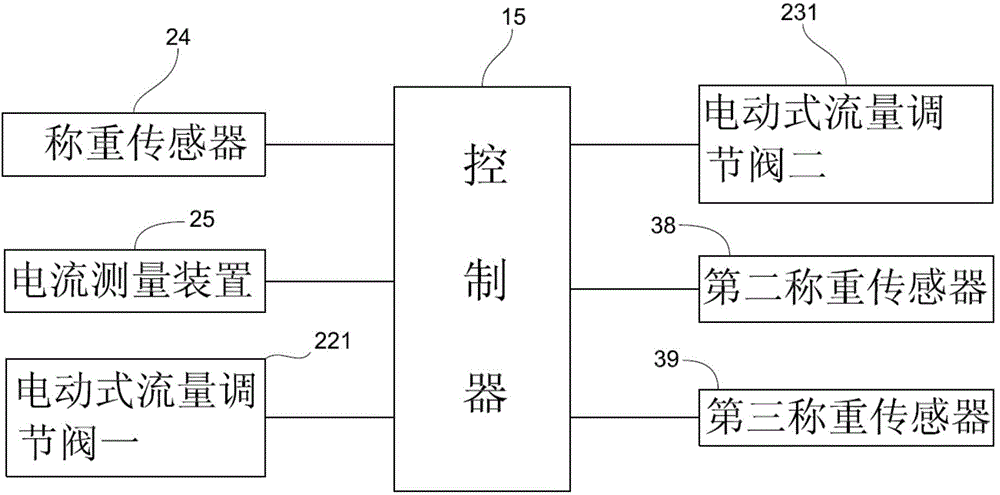

Automatic water distribution system for brick manufacturing device

ActiveCN104441209ATo achieve the purpose of auxiliary regulationTo achieve the purpose of closed-loop feedback regulationAuxillary shaping apparatusBrickMeasurement device

The invention discloses an automatic water distribution system for a brick manufacturing device. The automatic water distribution system comprises a water tank, a main water supply portion connected with the water tank, an auxiliary water supply portion connected with the water tank and used for supplying water to a brick manufacturing machine, a weighing sensor arranged on a brick manufacturing raw material conveying belt and used for detecting material flow of the brick manufacturing raw conveying belt, a current measuring device electrically connected with the brick manufacturing machine and used for detecting the actual working current of the brick manufacturing machine, a controller electrically connected with the current measuring device, the main water supply portion, the auxiliary water supply portion and the weighing sensor. The controller adjusts the water flow in the main water supply portion according to the material flow measured by the weighing sensor and the given required water proportion. The controller adjusts the water flow in the auxiliary water supply portion according to the difference value of the actual working current, measured by the current measurement device, of the brick manufacturing machine and the given working current. The water distribution system is provided with double water supply portions and capable of adjusting the water content of materials precisely to meet the forming requirement.

Owner:CHONGQING CENGTER GRAND TECH

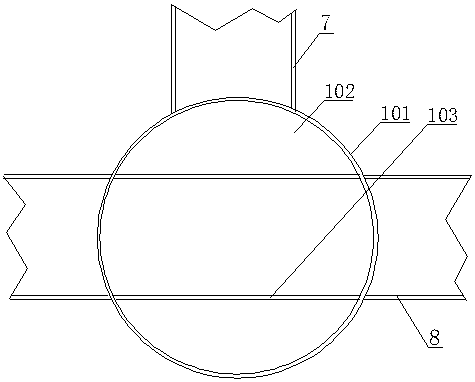

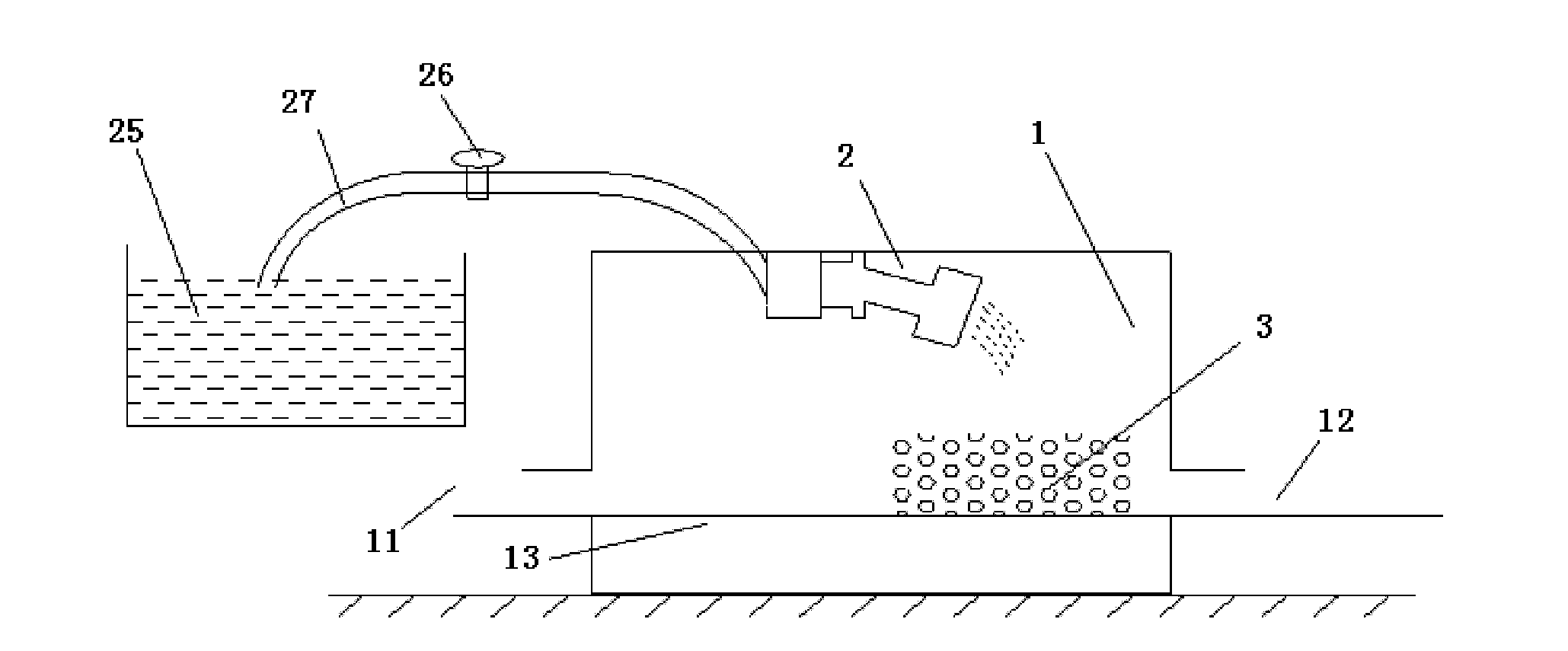

Drying machine with sprinkler

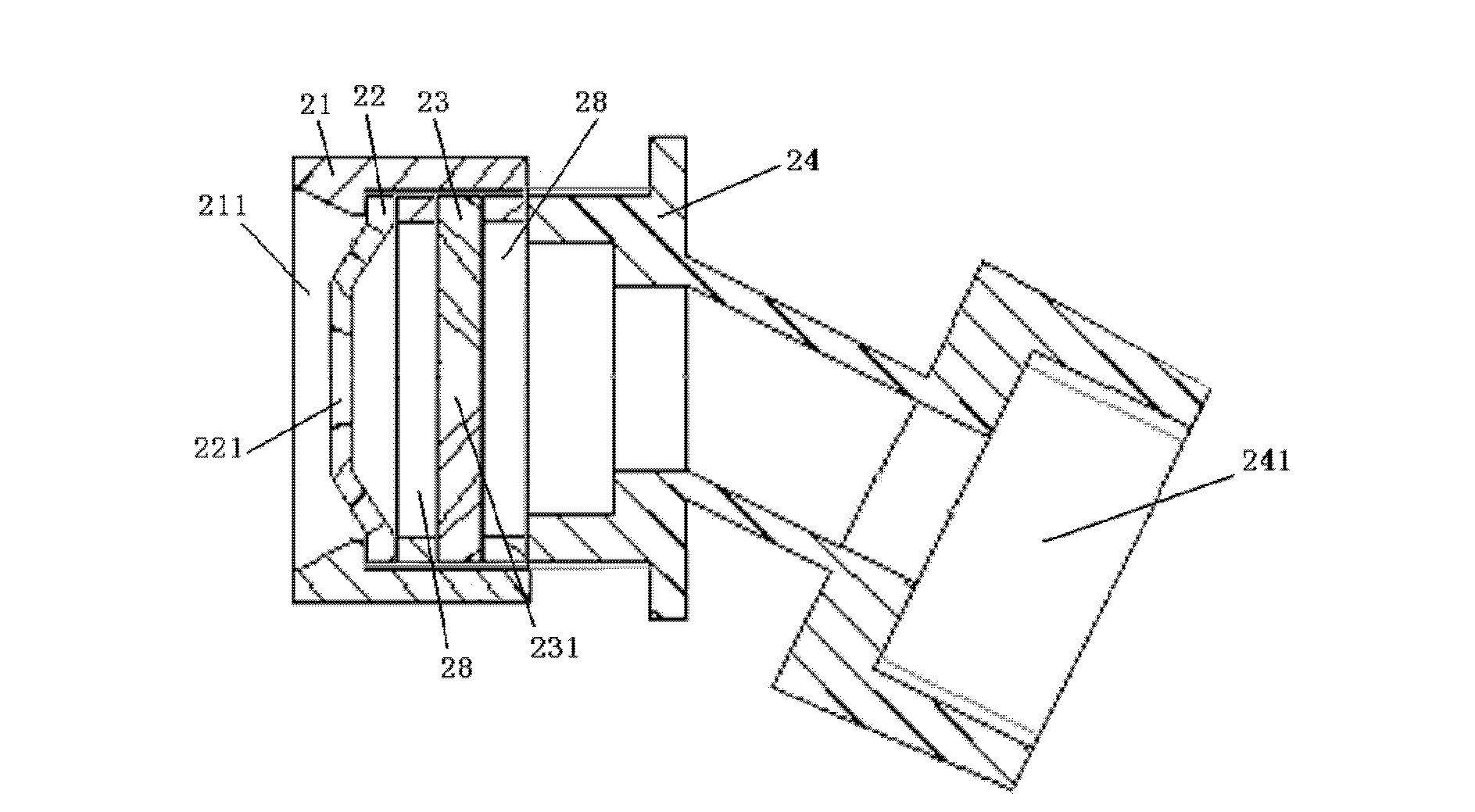

ActiveCN102997620AIncrease moisture contentStable moisture contentDrying solid materials without heatPolyesterPulp and paper industry

The invention discloses a drying machine with a sprinkler. The top of the drying machine is provided with the sprinkler; the sprinkler comprises a nozzle body; one side of the nozzle body is provided with a water inlet, and the other side of the nozzle body is provided with a nozzle; the nozzle is connected with an atomizing disc; the atomizing disc is connected with a nozzle cap; the nozzle cap is provided with a water orifice; and the nozzle cap is positioned above a conveyor of the drying machine. By the drying machine, the water content of polyester chips is proper and stable and can be adjusted according to actual requirements, and the drying machine can be matched with a centrifugal dryer to be widely applied to the production process of polyester chips.

Owner:JIANGSU SHENJIU CHEM FIBER CO LTD

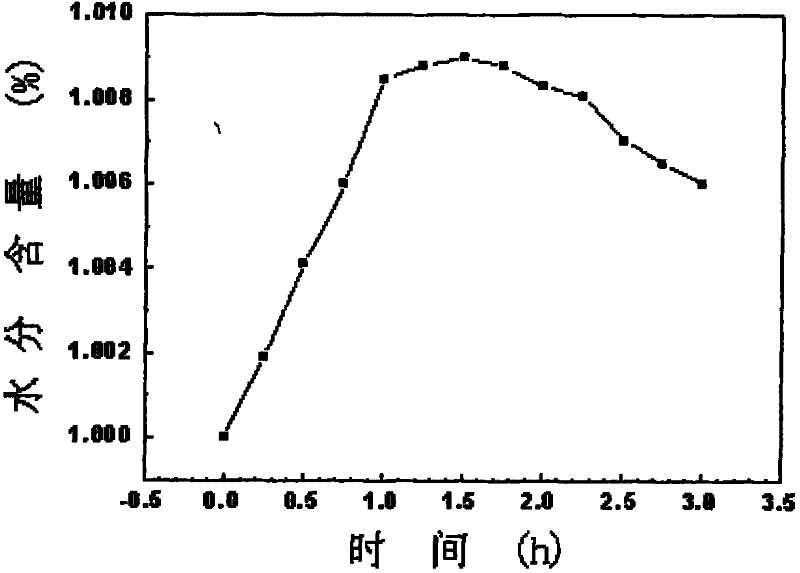

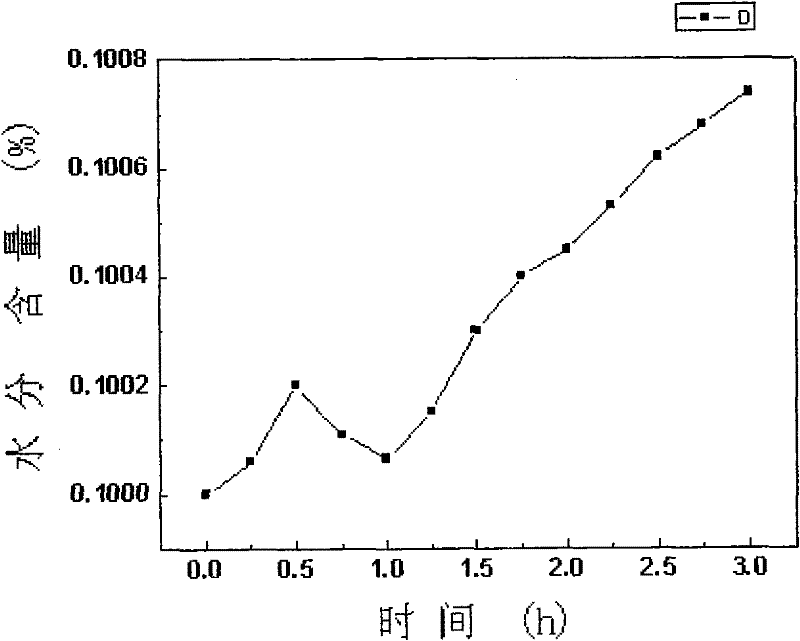

Preparation method of water content standard material

InactiveCN102252885AGood uniformity between bottlesStable moisture contentPreparing sample for investigationBottleVolumetric flask

The invention relates to a preparation method of a water content standard material. The method comprises the steps of: weighing the mass of a dried glass volumetric flask, adding propylene carbonate, 1-butanol and xylene in proportion, and weighing the mass of the mixed solution; measuring water in the mixed solution, and calculating the mass of water needing to be added according to a preparation target value; adding deionized water into the volumetric flask and mixing the solution well; shifting part of the mixed solution into an ampoule bottle, adjusting the humidity of a constant temperature and humidity chamber, monitoring water content variations over time under different humidity conditions; recording the humidity within the constant temperature and humidity chamber when the solution water content varies minimally; under a humidity condition with stable solution water content, charging ampoule bottles with the mixed solution separately, and sealing the ampoule bottles; taking the mean of the results measured by Coulometry and volumetric methods as the water content of a standard material; and evaluating the water uncertainty. The water content standard material prepared by the method of the invention is beneficial for improving the accuracy of a Karl Fischer water titrator measuring result.

Owner:NAT INST OF METROLOGY CHINA

Kitchen waste aerobic fermentation equipment with capability of rapid drying

ActiveCN104003767AEnables continuous processingStable moisture contentClimate change adaptationOrganic fertilisersWater bathsThermal insulation

The invention provides kitchen waste aerobic fermentation equipment with the capability of rapid drying. The kitchen waste aerobic fermentation equipment comprises a reaction cavity with the function of mixing, a cooling water circulation and condensate water collection system, an air heating and ventilation system with the function of deodorization, a water bath heating and thermal insulation system and an intelligent control system with the function of remote monitoring, wherein a temperature / humidity sensor and an oxygen concentration sensor are installed in the reaction cavity and used for monitoring the temperature, the humidity and the oxygen concentration in the reaction cavity; a heater and a temperature sensor are installed in a water bath cavity and can be used for providing heat to the reaction cavity timely, a thermal insulation interlayer is arranged outside the water bath cavity and used for preserving the heat of the water bath cavity; the air heating and ventilation system can be used for ensuring the oxygen concentration in the reaction cavity in the treating process; the cooling water circulation and condensate water collection system can be used for educing water vapor in the reaction cavity timely; a tail gas deodorization system can be used for preventing secondary environmental pollution due to the gas; and the equipment is controlled to run by a PLC (Programmable Logic Controller) intelligent control system. The kitchen waste aerobic fermentation equipment has a simple structure, is low in the running energy consumption and is good in the treating efficiency.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

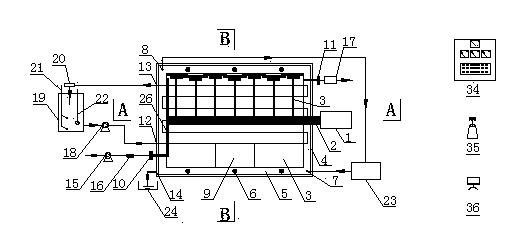

Oil-gas-water three phase flow continuously metering system

ActiveCN1570572ATemperature does not dropGuaranteed liquidityVolume flow measuring devicesVolume/mass flow by differential pressurePunchingOil field

This is a continuous measuring system of tri-phase flux that consists of oil, gas and water. The system comprises horizontal tri-phase analyzer, level gauge, electric control valve, hydraulic pump punching sand, gas flow counter, oil duct counter, watercourse counter, pressure sensor and so on. This invention can be used to measure tri-phase flux of oil, gas and water in the oil field. It is characterized by adopting horizontal tri-phase analyzer used in small-sized highly effective oil chamber internally-arranged, and adopts observing and controlling scheme of pressurization and stability of bi-liquid-level, keeping pressure, water-oil interface in the water header and liquid level of oil chamber stable, carrying-off the effect about the fluctuation of incoming gas flow or incoming liquid flow to the separating effect and measuring accuracy, increasing accuracy of flow discharged measuring and accomplishing series automatic gauging of oil, gas and water.

Owner:ZHEJIANG UNIV +1

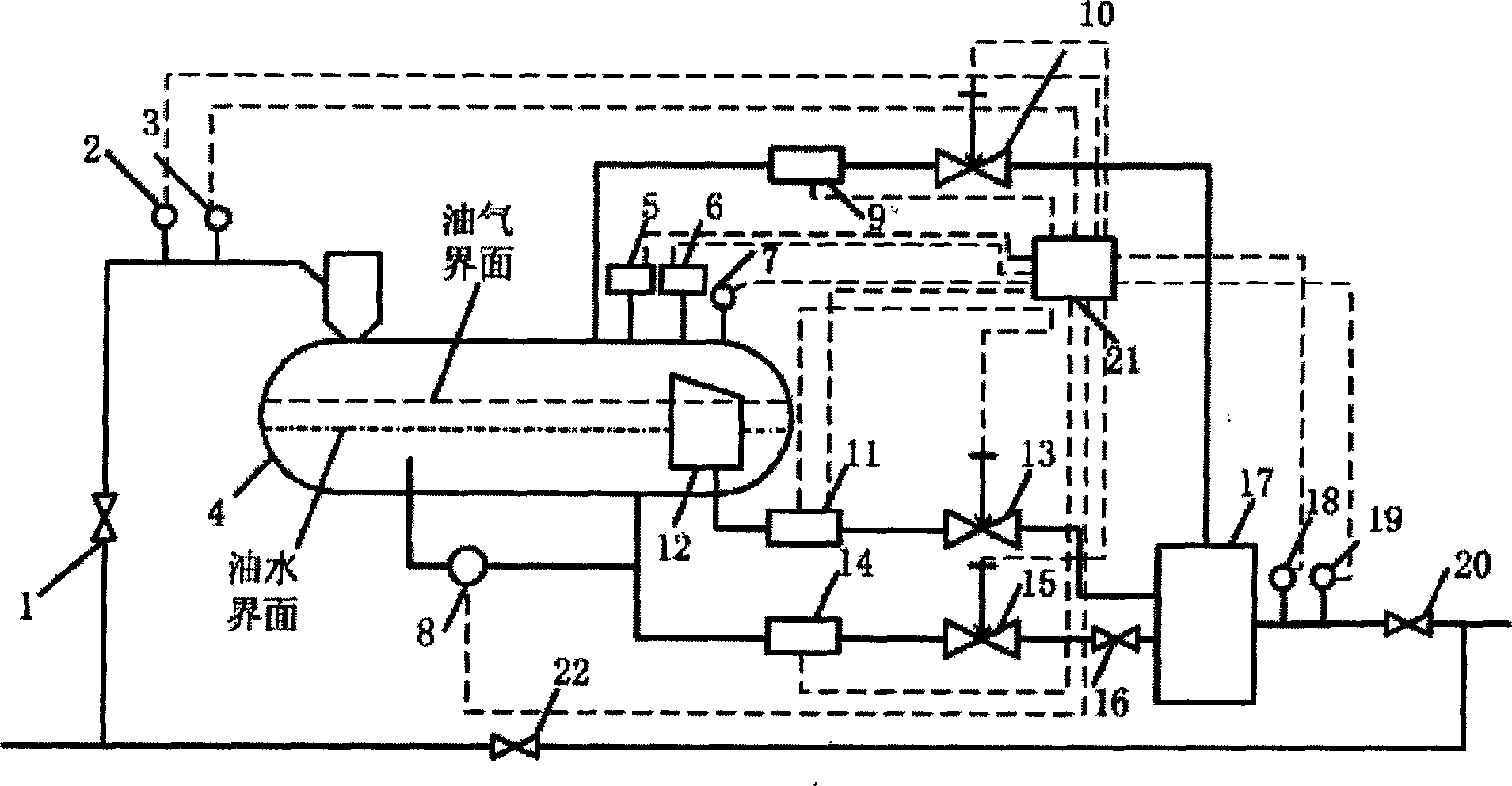

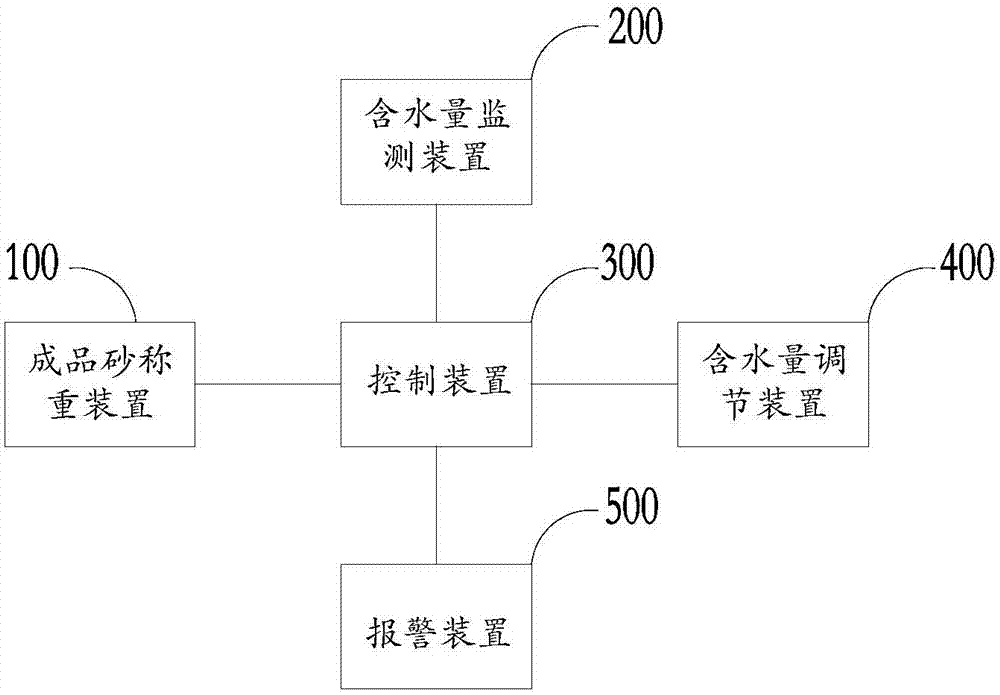

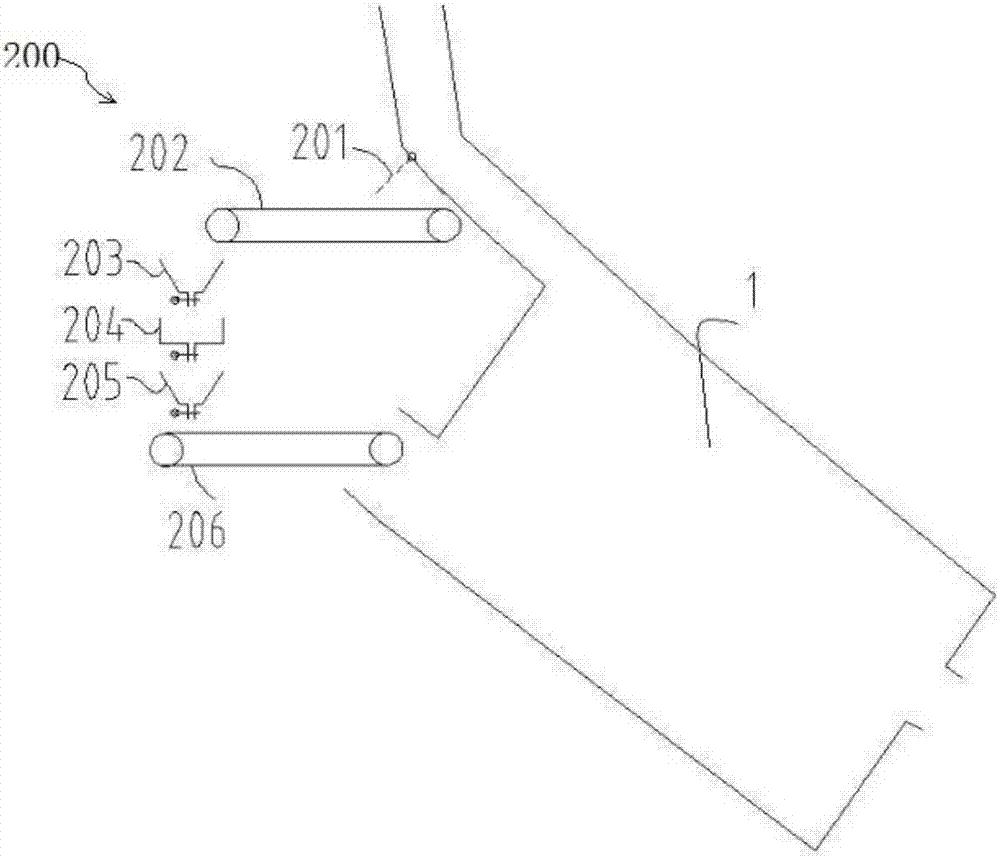

Machine-made sand water content control system and sand making equipment

The invention discloses a machine-made sand water content control system. The system comprises a finished sand weighing device, a water content monitoring device, a water content adjusting device and a control device, wherein the finished sand weighing device is used for measuring the weight of finished machine-made sand; the water content monitoring device is used for detecting water content information of the machine-made sand and sending the water content information to the control device; the control device is used for receiving the water content information, calculating the amount of water to be added to the finished machine-made sand according to the water content information and the weight of the finished machine-made sand and sending a control signal to the water content adjusting device; the water content adjusting device is used for receiving the control signal and adding the water in the required water amount to the finished machine-made sand. The machine-made sand water content control system can control the water content of the machine-made sand accurately and the water content of the machine-made sand subjected to water content control is stable.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Orchard soil layer management water-fertilizer-saving root and tree nurturing technical method

InactiveCN104396672AIncrease contentImprove accumulation abilityFertilising methodsCultivating equipmentsSoil scienceRoot growth

The invention discloses an orchard soil layer management water-fertilizer-saving root and tree nurturing technical method. By combing functional characteristics of an apple root system, the method of surface layer covering, middle layer micro-complementing and lower layer water reserving is adopted, and a local stability excellent environment suitable for root growth is established, so that aims of water and fertilizer conservation, leaf protection, and root and tree nurturing are achieved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Grouting water sealing and reinforcement construction process capable of realizing draining and plugging combined effect for underground water in tunnel

InactiveCN103089280AAvoid the tendency to diffuse penetrationPrevent sinkingUnderground chambersTunnel liningPhosphoric acidSlurry

The invention discloses a grouting water sealing and reinforcement construction process capable of realizing a draining and plugging combined effect for underground water in a tunnel. The grouting water sealing and reinforcement construction process includes steps of (1), arranging grouting pipes from the inner side to the outer side of the tunnel, simultaneously arranging drain pipes matched with the grouting pipes in the tunnel, connecting the drain pipes with a vacuum pump so as to locally pump the water; (2), diluting sodium silicate of raw grout 39Be' to obtain grout 28Be', mixing TGRM grouting materials with cement according to a proportion of 1:3 to obtain second grout, mixing the grout 28Be' with the second grout according to a proportion of 1:1 to obtain liquid A, diluting sodium silicate of raw grout 39Be' by water to obtain grout 30Be', diluting strong phosphoric acid by water according to a proportion of 1:6 to obtain diluted phosphoric acid, and mixing the grout 30Be' with the diluted phosphoric acid according to a proportion of 1:1 to obtain liquid B; (3), alternately filling the liquid A and the liquid B into reinforcement soil layers outside an excavation range of the tunnel via the grouting pipes to complete grouting for the periphery of the tunnel; and (4), alternately filling the liquid A and the liquid B into a 1.5m range of the periphery of an excavation face via small pipes. The grouting water sealing and reinforcement construction process has the advantages that 'draining' and 'plugging' are combined and work along both lines in the construction process, accordingly, the underground water is prevented from diffusing and permeating to feeble grouted positions, the tunnel construction difficulty is reduced, and the construction safety degree is increased.

Owner:BEIJING MUNICIPAL CONSTR

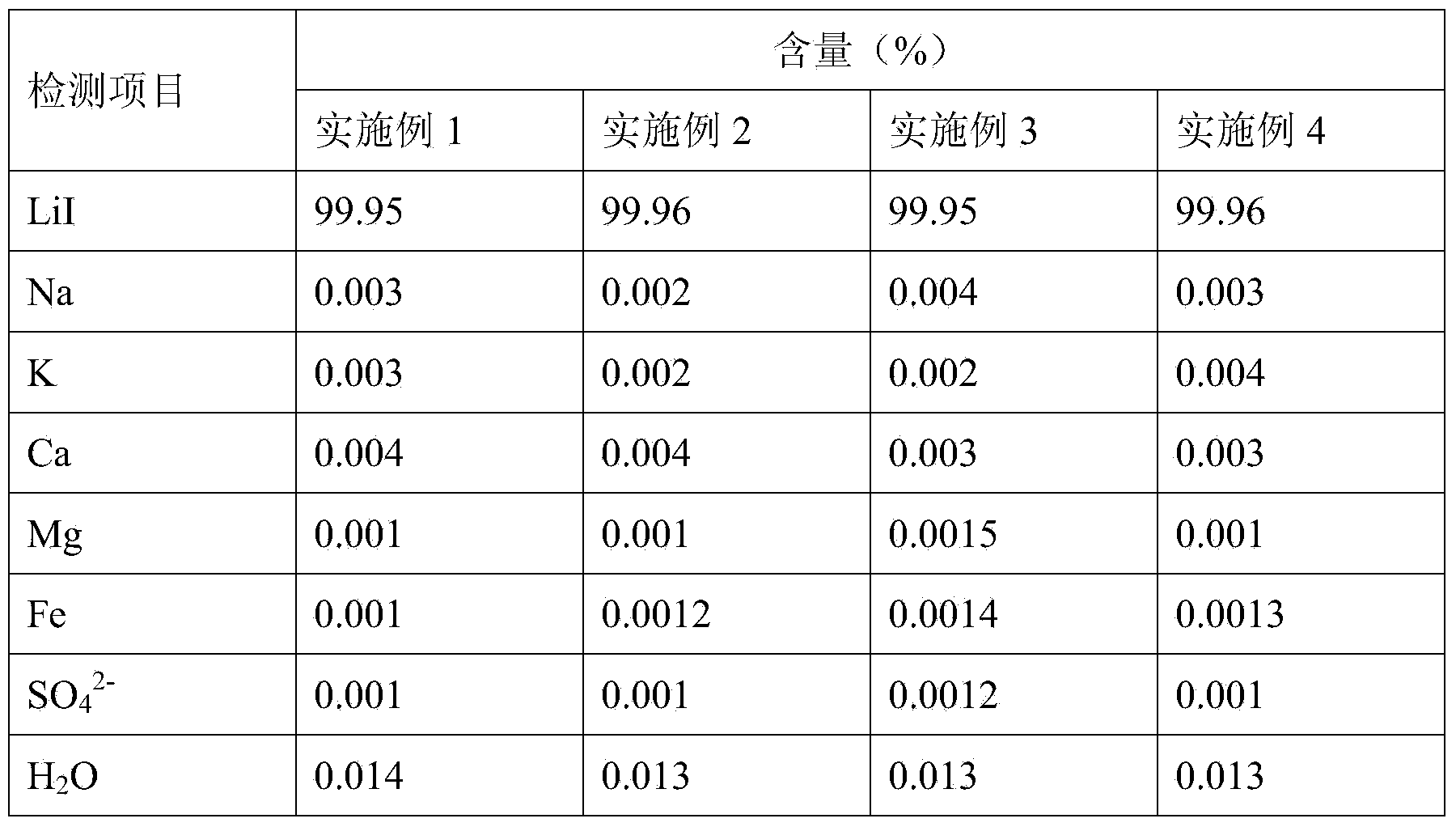

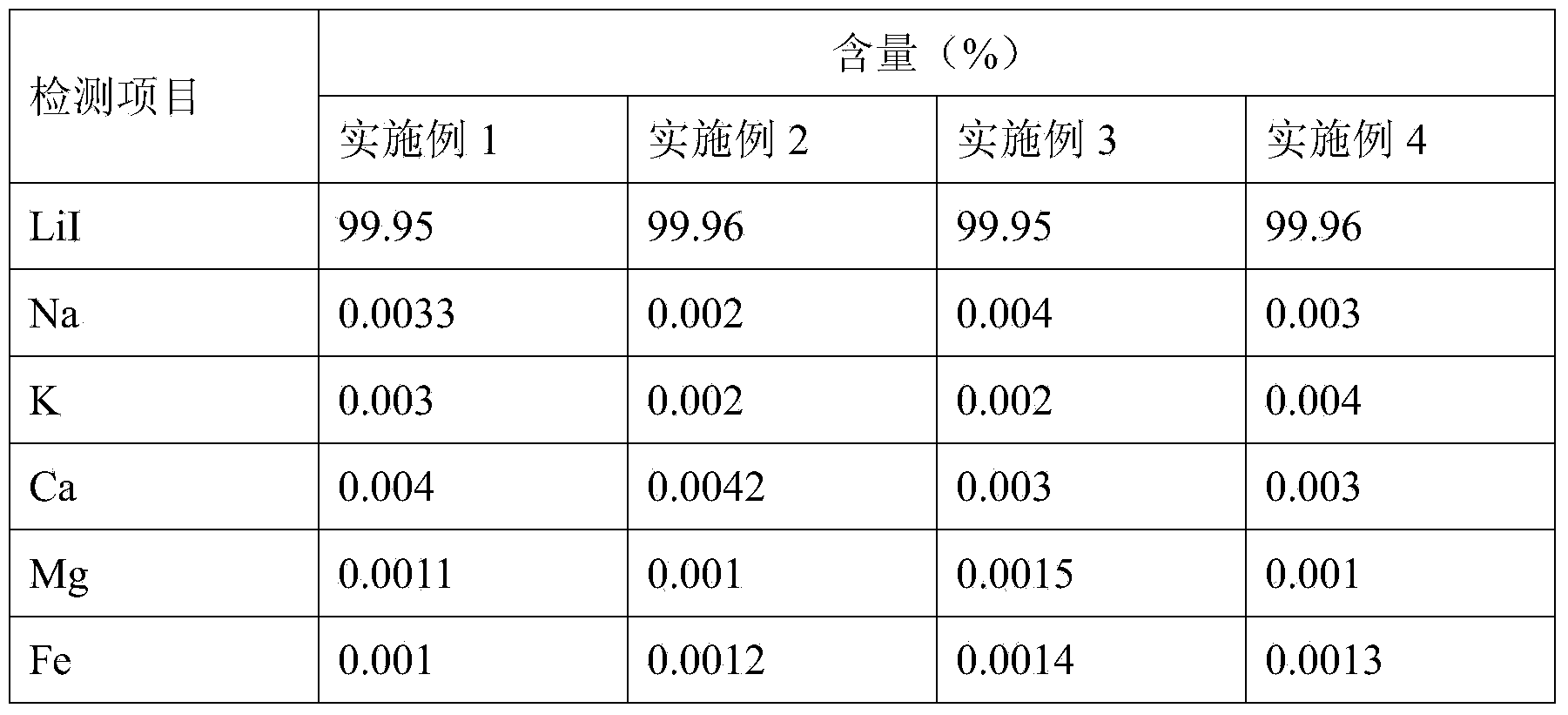

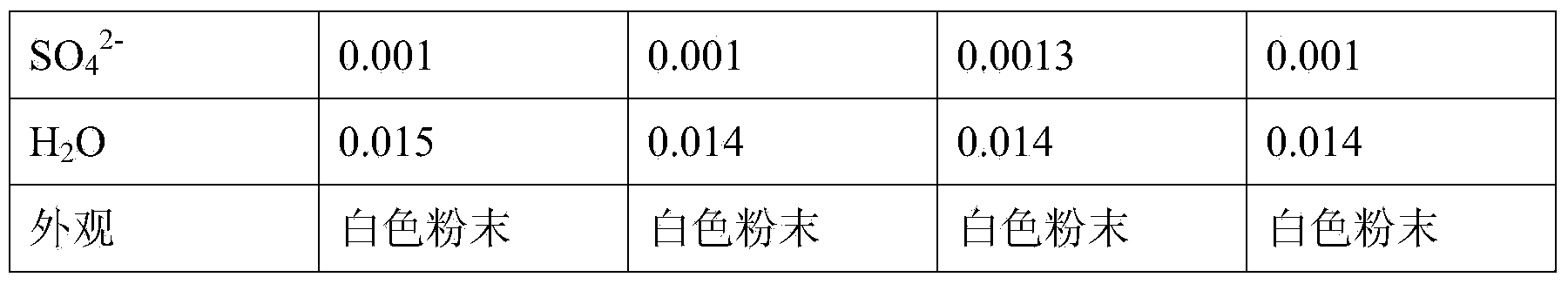

Preparation method of anhydrous lithium iodide

The invention belongs to the technical field of electrolyte preparation of lithium battery electrolytic liquids, and particularly relates to a preparation method of anhydrous lithium iodide. The preparation method of anhydrous lithium iodide comprises the following steps of reacting iodine, hydrazine hydrate and lithium hydroxide by using an aqueous liquid method, sequentially carrying out evaporation and concentration, filtration, and heated concentration on the obtained product, feeding inert gas into the obtained product to dehydrate, and packaging the obtained product under the protection of the inert gas. No organic solvent is added in the whole process; and the method is simple in technological process and short in time consumption, and solves the problems that traditional production methods are long in time consumption, iodide lithium packages are deliquescent, and the like.

Owner:HUBEI BAIJIERUI ADVANCED MATERIALS

Compound for the treatment of gastrointestinal disease

ActiveCN102199145AStable crystal structureLow hygroscopicityOrganic active ingredientsOrganic chemistryDisease causeWater content

The invention provides a compound for the treatment of gastrointestinal diseases. The crystallization of the compound has the characteristics of a stable crystalline structure, small hygroscopicity and stable water content. Under normal preservation condition and in mechanical pulverization which might be included in the preparation process, the water content and the crystalline structure show good stability.

Owner:SHANDONG NEWTIME PHARMA

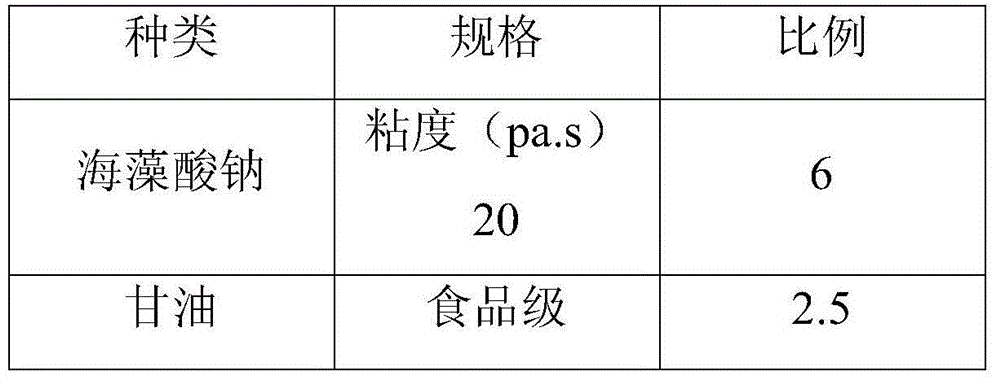

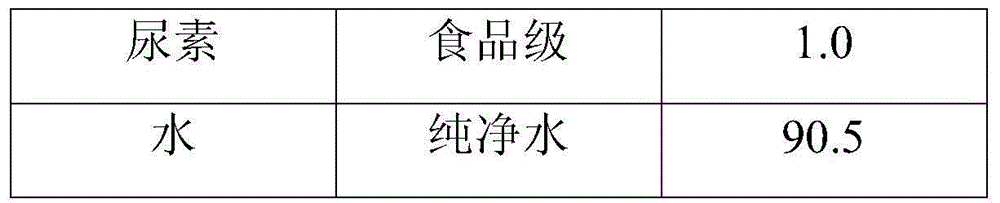

Tobacco additive dropping pill with improved brittleness and preparation method thereof

ActiveCN104621714AReduced crush strengthStable moisture contentTobacco smoke filtersWater basedManufacturing technology

The invention belongs to the field of manufacturing technologies of tobacco additives and particularly relates to a tobacco additive dropping pill with improved brittleness and a preparation method of the tobacco additive dropping pill. The tobacco additive dropping pill is formed by wrapping dropping pill wrapping materials and tobacco additives. The dropping pill wrapping materials are formed by mixing raw materials of sodium alginate tech grade, glycerol, urea and water based on the weight ratio being 1-8:0.5-3:1-5:85-100. The tobacco additive dropping pill with improved brittleness and the preparation method of the tobacco additive dropping pill can reduce crushing strength of the dropping pill to a certain extent and maintain stable water content, so the dropping pill can have good brittleness hand feeling when crushed, and consumption experience of dropping pill products is greatly promoted.

Owner:HUBEI CHINA TOBACCO IND

Cation polyacrylamide swelled ground modifying agent

InactiveCN101012379AStrong adsorptionReduce water absorption and swellingBuilding constructionsOrganic fertilisersIonChemistry

The invention discloses a cationic polyacrylamide swelled ground modifier and constructing method, which is characterized by the following: weighing 0.2% modifier into dried soil with saturation less than 95%; stirring; dispersing cationic polyacrylamide in the water evenly without knob; reducing the thickness of adsorbing water film on the clay particle surface; reinforcing the stability of soil mass.

Owner:HOHAI UNIV

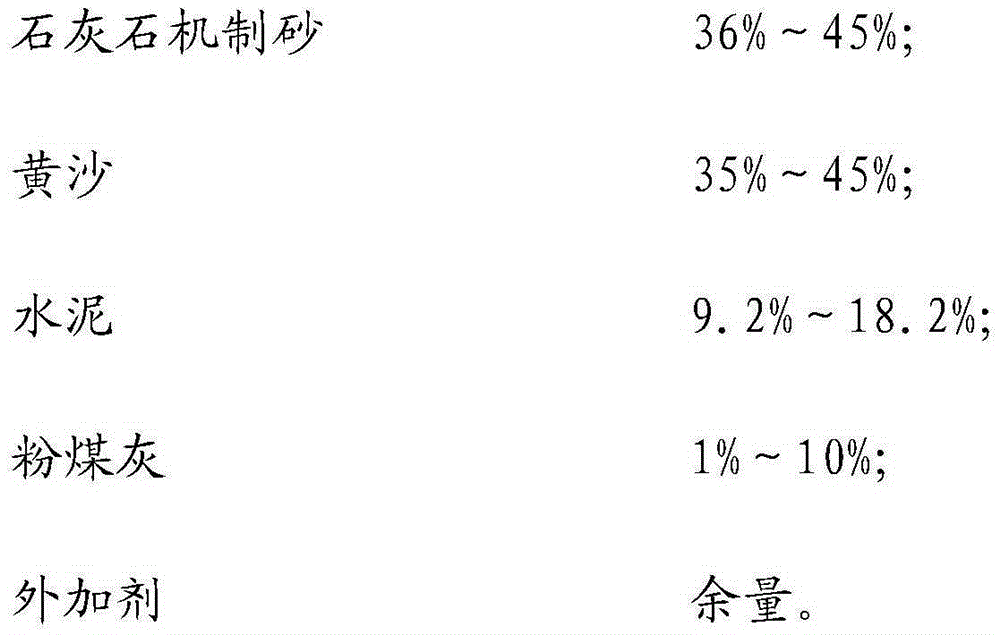

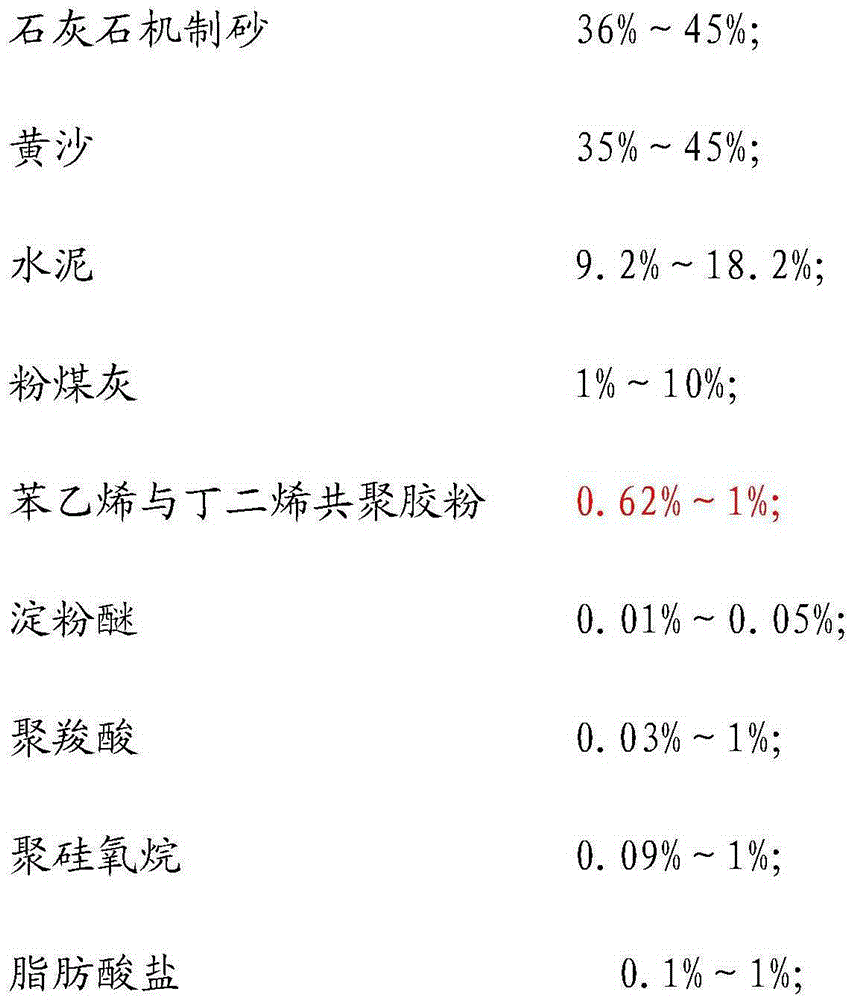

Anti-cracking-shedding and strong-adhesion dry mixing plastering mortar

InactiveCN105294012AHigh bonding strengthImprove water retentionSolid waste managementPolymer scienceDry mixing

The invention relates to an anti-cracking-shedding and strong-adhesion dry mixing plastering mortar, which is characterized by comprising by mass: 36-45% of limestone machine-made sand, 35-45% of yellow sand, 9.2-18.2% of cement, 1-10% of fly ash, and the balance of an admixture, wherein the admixture comprises a modifier and a thickening agent, the modifier is a mixture of starch ether, polysiloxane and polycarboxylic acid, the thickening agent is styrene and butadiene copolymerization rubber powder, and a weight ratio of the styrene and butadiene copolymerization rubber powder to the starch ether to the polysiloxane to the polycarboxylic acid is 100:1.6:14.5:4.8.

Owner:浙江兆山建材科技有限公司

Wood modifying reinforcer

ActiveCN105690521AImprove permeabilityStable moisture contentWood treatment detailsWood impregnation detailsDiluentTannic acid

The invention provides a wood modifying reinforcer. The wood modifying reinforcer comprises a component A, a component B and a component C, wherein the component A comprises 60-90 parts by weight of modified polyurethane resin, 0.6-1.0 part by weight of a defoaming agent, 0-1 part by weight of a dispersing agent, 0.2-0.5 part by weight of a flatting agent, 0-1 part by weight of bentonite and 0-30 parts by weight of talcum powder; the component B is isocyanate polymer; and the component C is a diluent. The wood modifying reinforcer provided by the invention is extremely strong in permeability to a wood substrate, can obviously stabilize moisture content of wood, and can slow down changes of moisture content, so that inner stress generated by rapid changes of moisture content inside the wood is reduced, the wood cracking and bending problem is prevented, and the effect of sealing tannic acid further can be remarkably achieved; and the treated wood is almost free of resin residues on surface, and is free of an obvious reinforcing phenomenon, so that convenience is provided for a follow-up processing process.

Owner:SHENZHEN EGO NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com