Oil-gas-water three phase flow continuously metering system

A metering system, oil, gas and water technology, applied in the direction of volume flow measurement device, liquid/fluid solid measurement, volume/mass flow generated by mechanical effects, etc., can solve the problems of decreased measurement accuracy, inability to automatically process, increase control management, etc. Achieve the effects of improving measurement accuracy, eliminating adverse effects, and ensuring fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

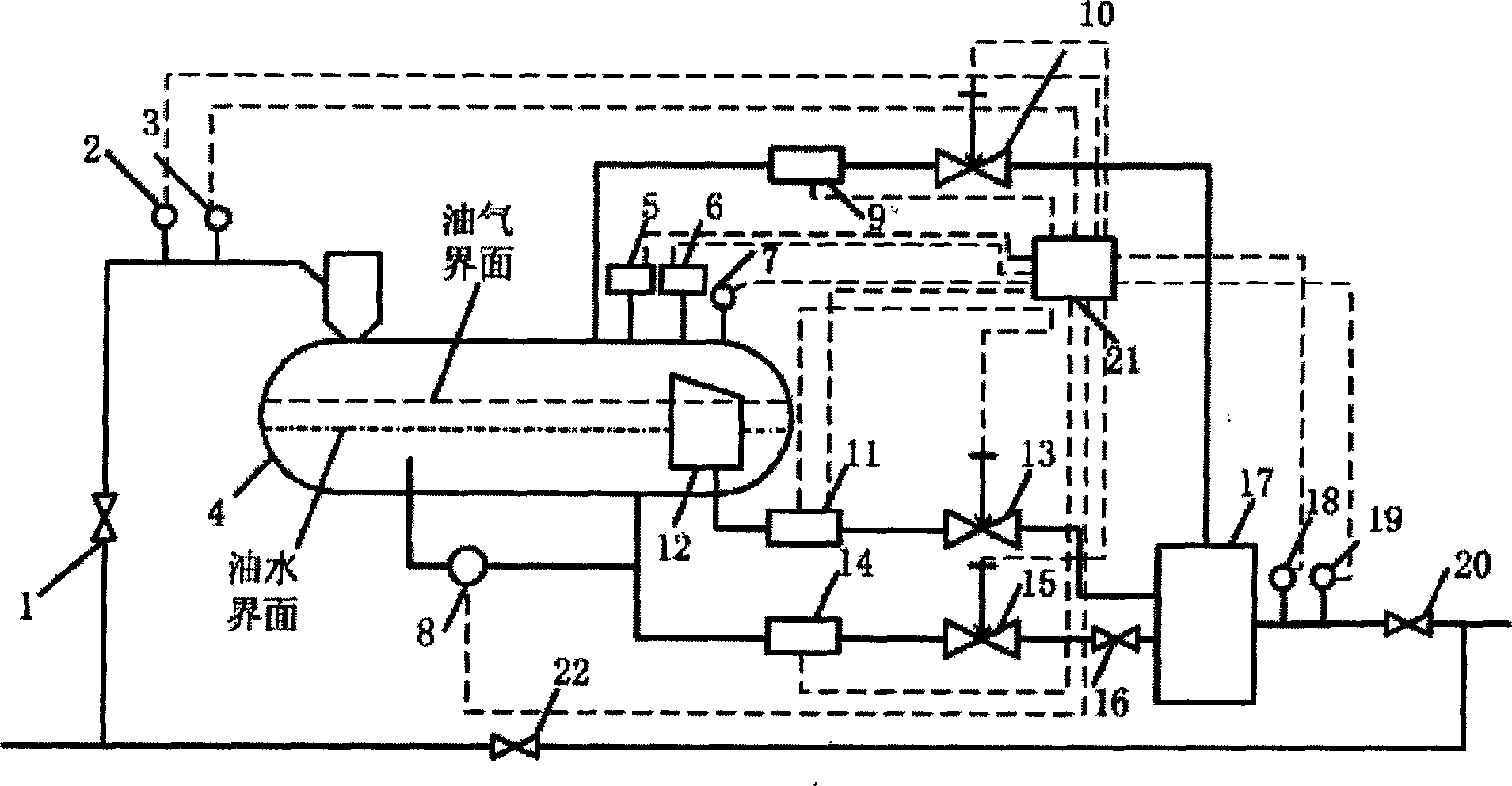

[0027] The oil-gas-water three-phase flow continuous metering system has a horizontal three-phase separator 4, and an oil chamber 12 is arranged in the horizontal three-phase separation device. 17 connected, on the top of the horizontal three-phase separator, there are oil-water interface instrument 5, liquid level gauge 6, pressure sensor II7, gas outlet pipe, and the gas outlet pipe is connected with gas flow meter 9, gas path regulating valve 10, and phase mixer 17 , the upper part of the horizontal three-phase separator is provided with an oil inlet pipe and is connected with the inlet valve 1, the pressure sensor I2, and the temperature sensor I3. Valve 15, flow resistance regulating valve 16 are connected to phase mixer 17, and the outlet pipe is connected to the sand washing pipe inserted into the lateral middle of the horizontal three-phase separator through sand washing pump 8, and phase mixer 17 is connected to pressure sensor III18 and temperature sensor II19 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com