Three-chamber type intelligent periodically controllable atmosphere furnace

A periodic and atmosphere furnace technology, applied in furnaces, furnace cooling, muffle furnaces, etc., can solve the problems of low production efficiency, energy waste, and large energy consumption of controllable atmosphere reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

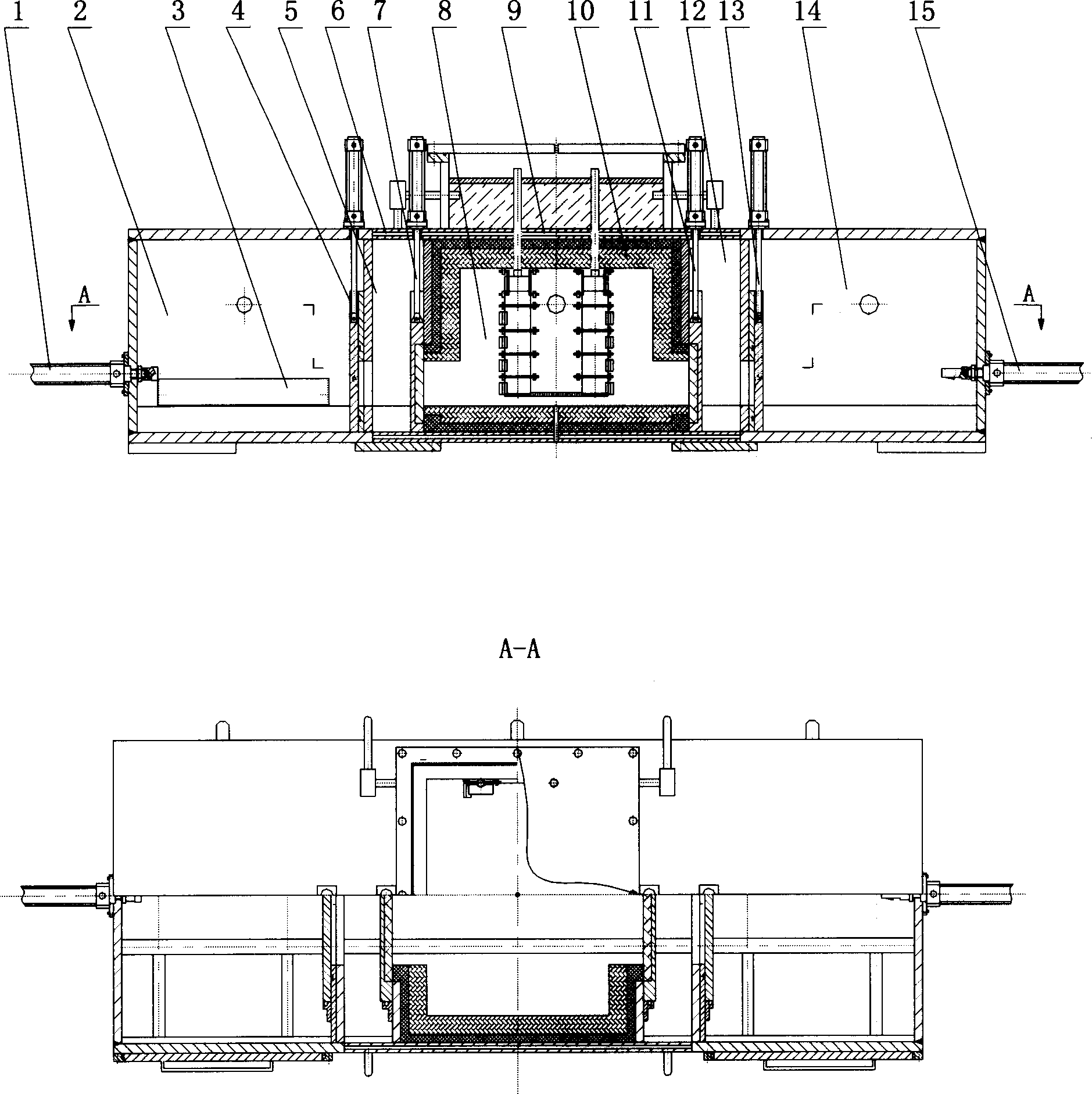

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings of the embodiments, and is not a limitation of the present invention:

[0009] As shown in the drawings: the furnace body of this embodiment adopts a three-stage structure, and a feeding chamber (2) is added at the front end of the reaction chamber (8), and a guide rail is installed at the bottom of the feeding chamber (2), and a The material box (3) of the reactant, the front end of the feeding chamber (2) is equipped with a feeding hydraulic cylinder (1), and the output shaft of the hydraulic cylinder matches the material box, and the reaction cylinder (1) will be equipped with a reaction when the feeding hydraulic cylinder (1) moves. The material box (3) of the material is smoothly pushed into the reaction chamber (8) from the feed chamber (2) through the water-cooled transition zone (5) along the guide rail. A discharge chamber (14) is added behind the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com