Patents

Literature

235results about How to "Temperature does not drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air conditioner and defrosting control method thereof

ActiveCN104596032AReduce retentionImprove defrosting efficiencyMechanical apparatusSpace heating and ventilation safety systemsSuper coolingEngineering

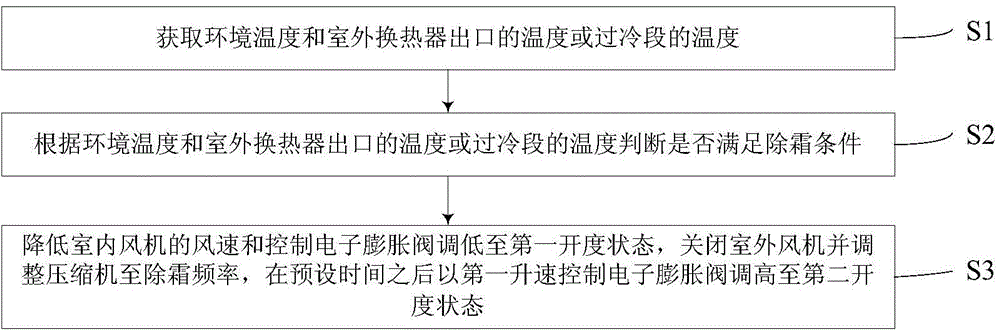

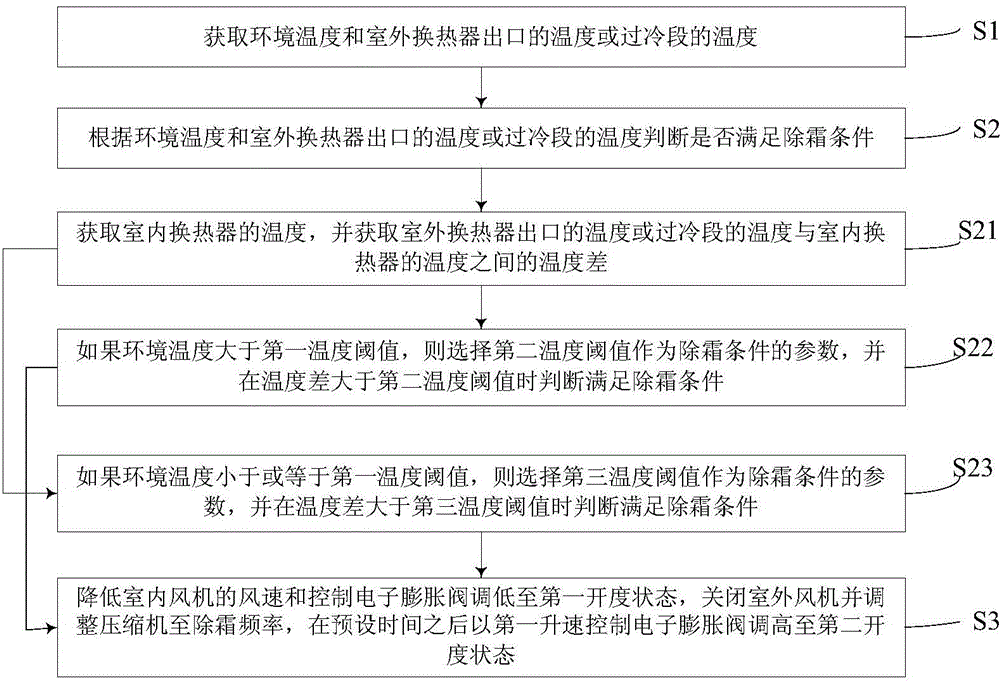

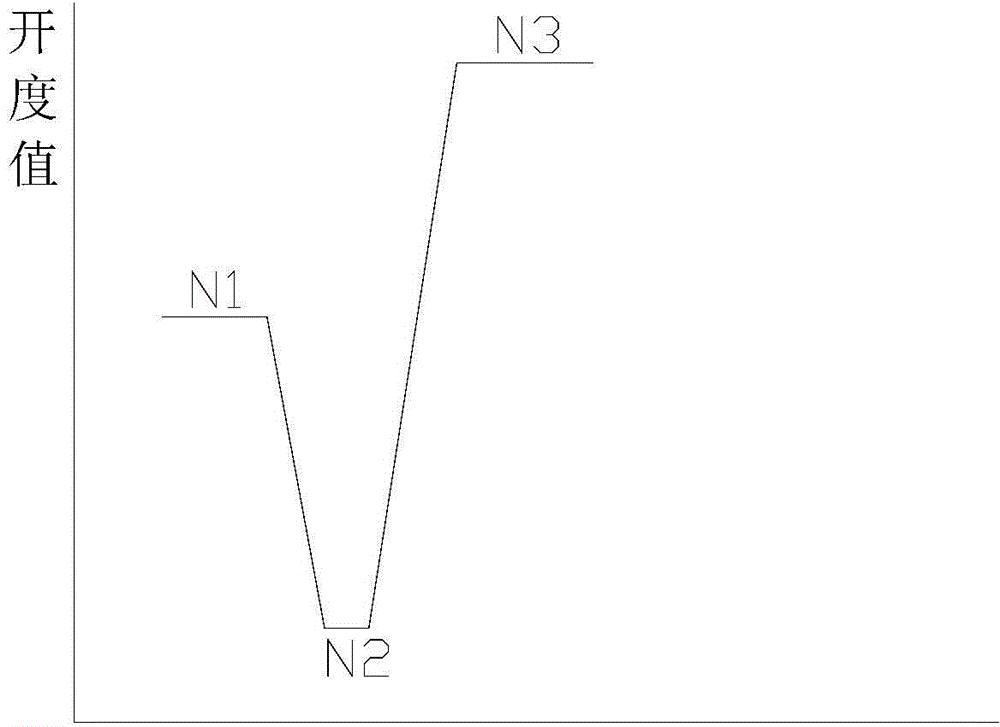

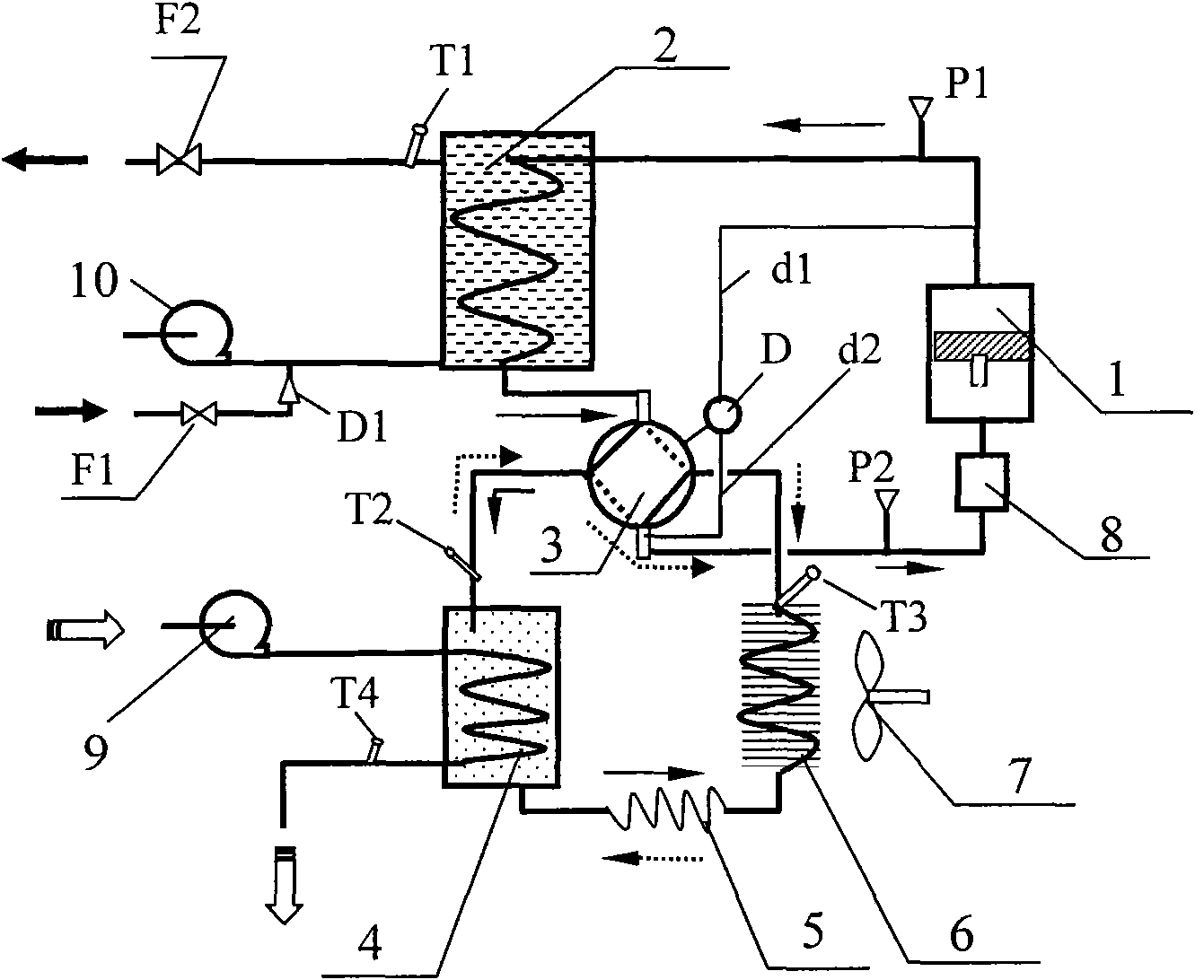

The invention discloses a defrosting control method of an air conditioner. The control method comprises the following steps that environment temperature and the temperature of an outdoor heat exchanger outlet or the temperature of a super cooling section are obtained; whether the defrosting condition is met or not is judged according to the environment temperature and the temperature of the outdoor heat exchanger outlet or the temperature of the super cooling section; when the judgment result shows that the defrosting condition is met, the wind speed of an indoor fan is decelerated, an electronic expansion valve is controlled to be lowered to the first opening degree state, an outdoor fan is closed, a compressor is regulated to the defrosting frequency, after the preset time, and the first ascending speed is used for controlling the electronic expansion valve to be raised to the second opening degree state, wherein the opening degree value of the second opening degree state is greater than the opening value of the first opening degree state. The defrosting control method of the air conditioner has the advantages that the defrosting can be realized without stopping the compressor, the method is simple, and the reliability is high. The invention also provides the air conditioner.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

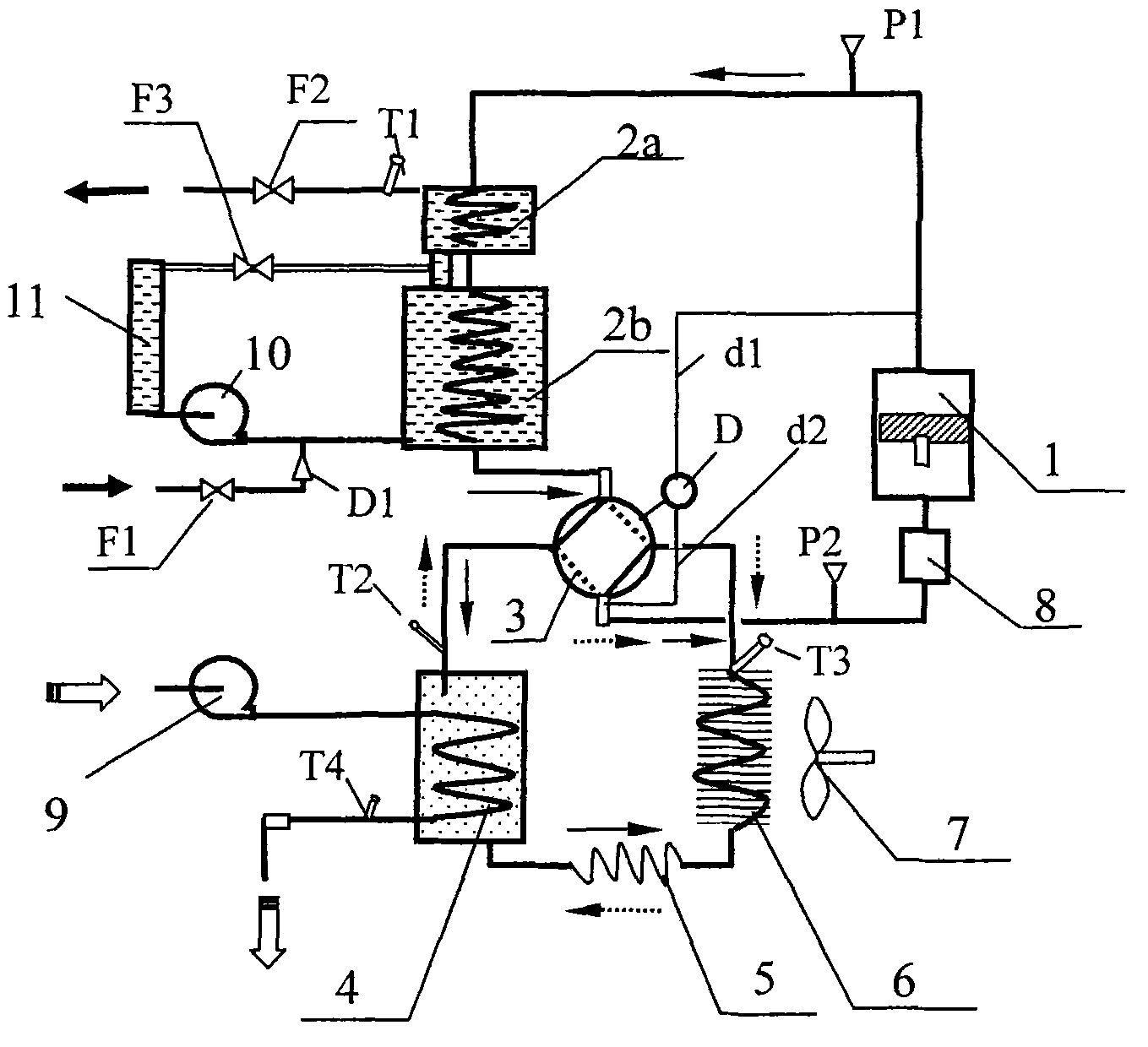

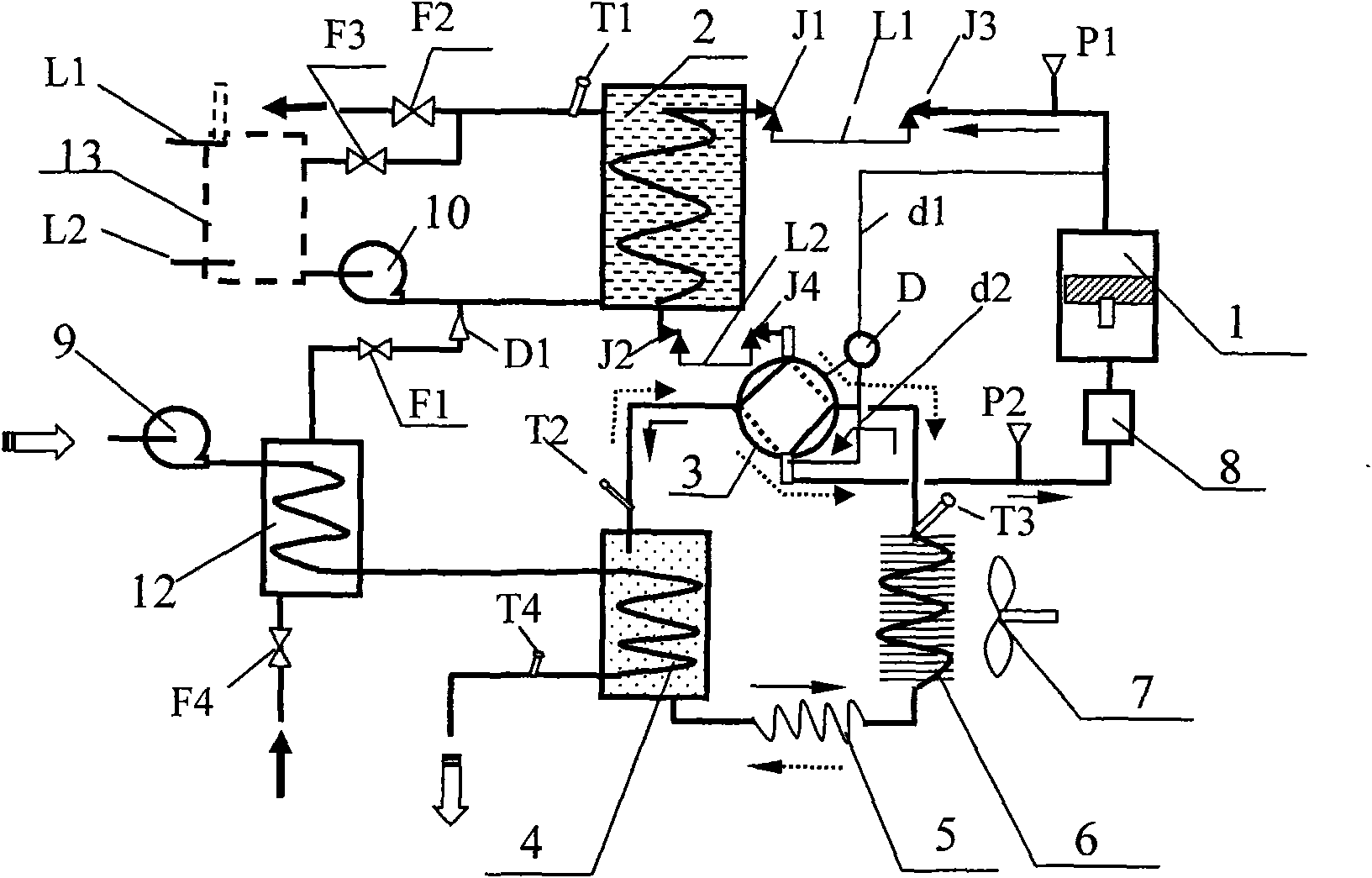

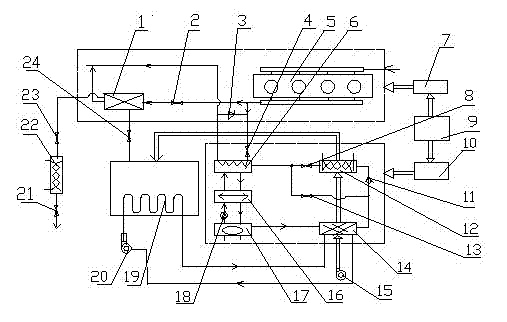

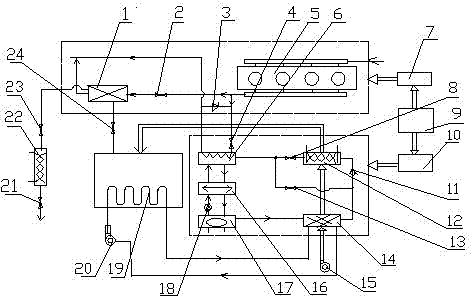

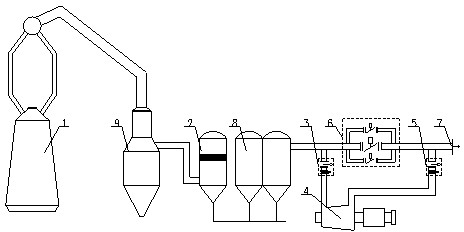

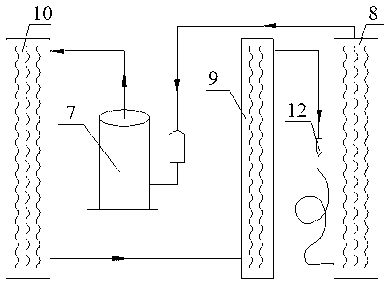

Dual heat-source heat-pump hot water device with extremely simple refrigerating loop

InactiveCN101943471AFix switching issuesSolve defrosting problemsFluid heatersHeat recovery systemsFour-way valveWater source

The invention discloses a dual heat-source heat-pump hot water device with an extremely simple refrigerating loop. The device is characterized by mainly comprising a compressor, a hot water condenser, a wind heat exchanger, a water heat exchanger, a four-way valve, a bidirectional throttle and the like, wherein a high pressure inlet of the four-way valve is connected with the outlet of the hot water condenser, and the other three ports thereof are connected with air inlets of the wind heat exchanger, the water heat exchanger and the compressor respectively; other ports of the wind heat exchanger and the water heat exchanger are connected with the bidirectional throttle; the exhaust port of the compressor is connected with the inlet of the hot water condenser, and is connected with high pressure air inlet of an electromagnetic pilot valve of the four-way valve; four functions of manufacturing hot water by utilizing water source or air energy and providing air-conditioning cool water by utilizing air-cooling or heating water can be realized by only switching the four-way valve, defrosting can be performed completely and quickly; and a water pre-heater is added to the device to reclaim the heat of waste hot water. The heat pump has the advantages of dual heat sources compensation and wide application range, has multiple functions, extremely simple structure, extremely convenient switching and over 5 of annual comprehensive energy efficiency ratio, and has great popularization value.

Owner:陈则韶

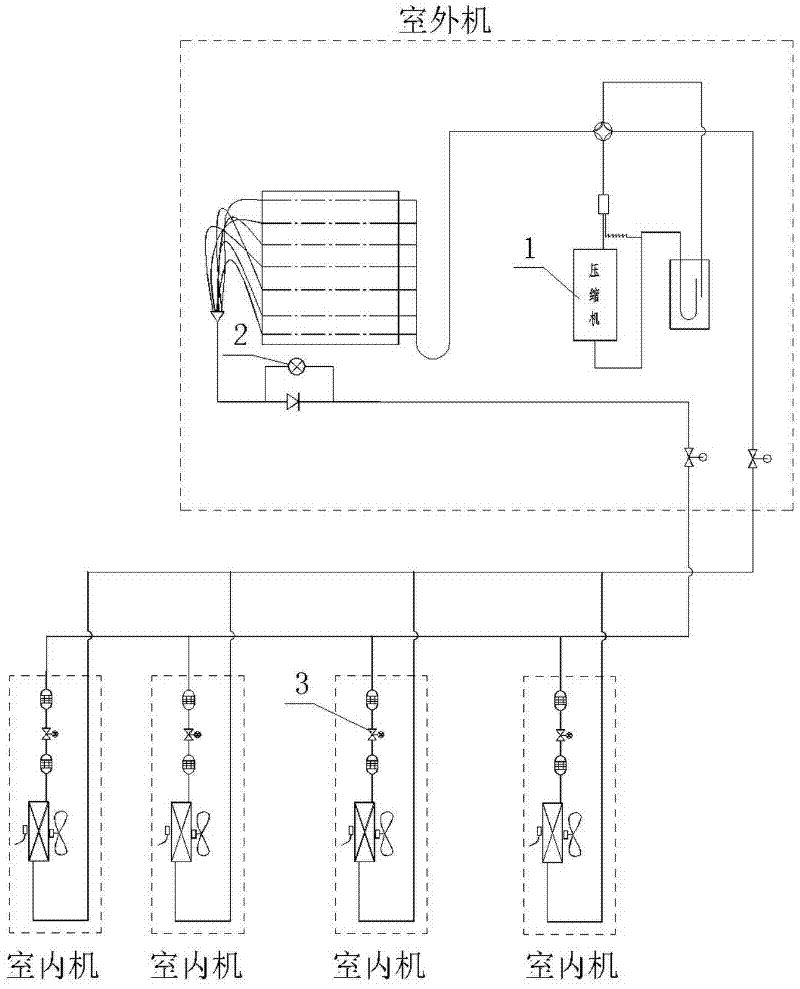

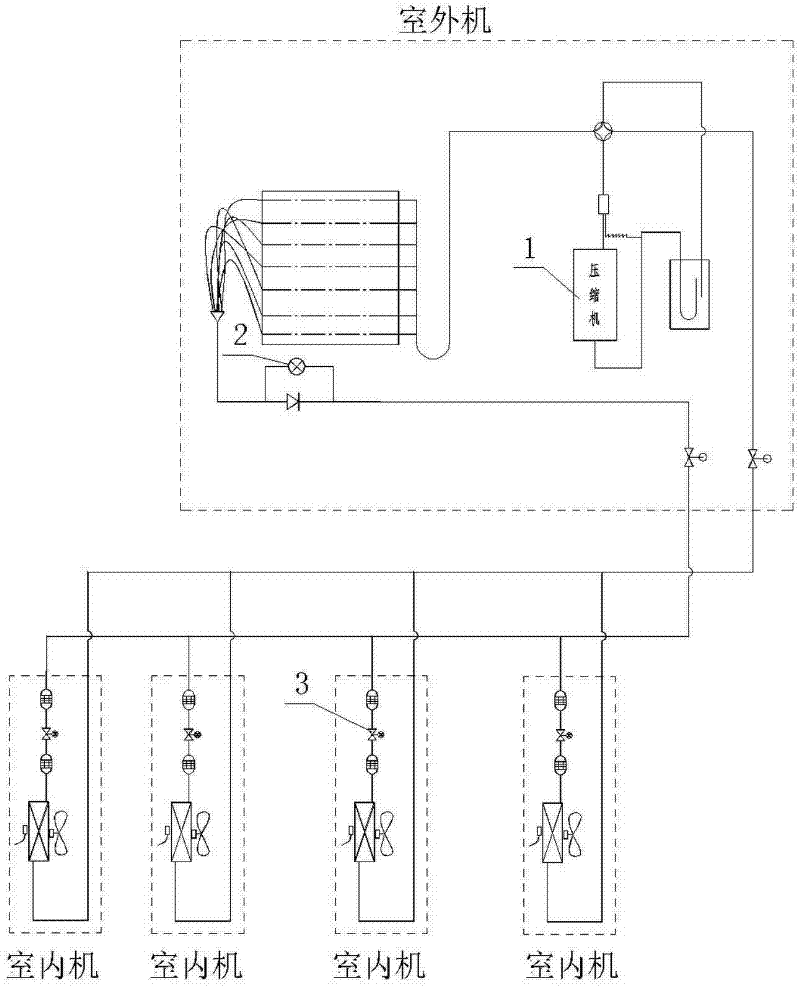

Oil returning method during heating of multi-split air-conditioning unit

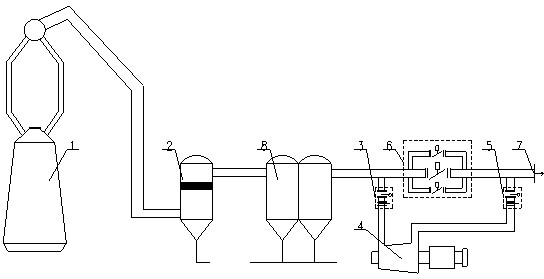

InactiveCN102645057ATemperature does not dropEasy to useCompressorRefrigeration safety arrangementElectronic expansion valveElectron

The invention discloses an oil returning method during heating of a multi-split air-conditioning unit. The oil returning method comprises the following steps of: a, carrying out normal heating on the multi-split air-conditioning unit; b, adjusting an operation frequency of a compressor (1) to an oil returning frequency, adjusting aperture of an external unit electronic expansion valve (2) to an external unit oil returning aperture, adjusting apertures of internal unit electronic expansion valves (3) of all the indoor units to an internal unit oil returning aperture, and returning oil for 2.5-3.5 minutes by maintaining the oil returning frequency of the compressor (1), the external unit oil returning aperture of the external unit electronic expansion valve (2) and the internal unit oil returning aperture of the internal unit electronic expansion valves (3); c, adjusting the operation frequency of the compressor (1) to a normal frequency, and operating for 15-25 seconds; and d, adjusting the aperture of the external unit electronic expansion valve (2) to the normal aperture, and adjusting the apertures of all the internal unit electronic expansion valves (3) to the normal aperture. The oil returning method disclosed by the invention can guarantee good oil returning effect without liquid impact on the compressor, and indoor heating can be continuously carried out in an oil returning process.

Owner:NINGBO AUX ELECTRIC

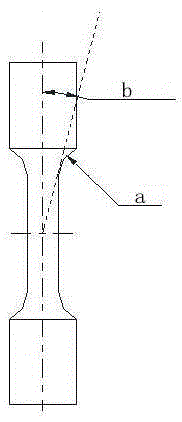

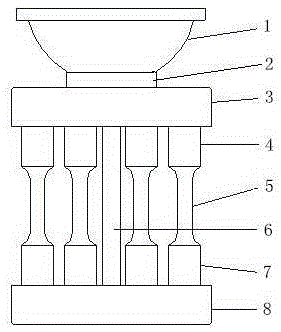

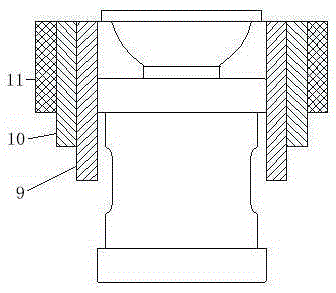

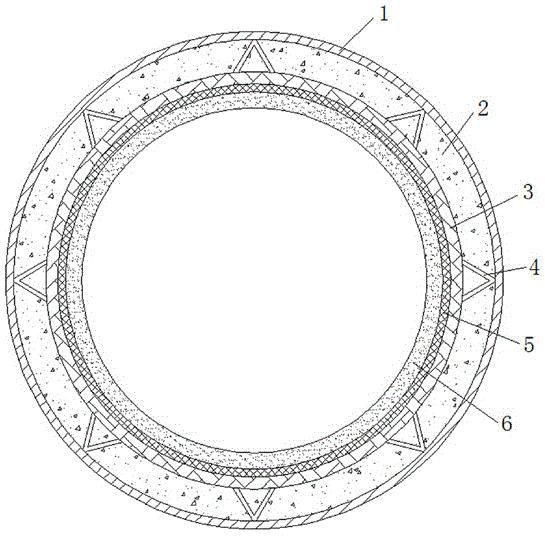

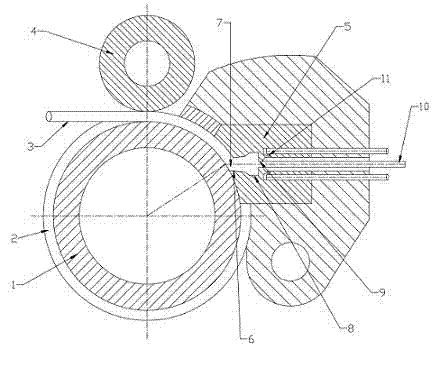

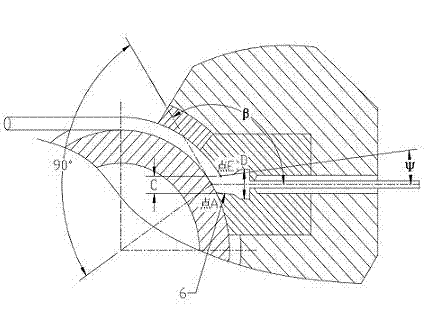

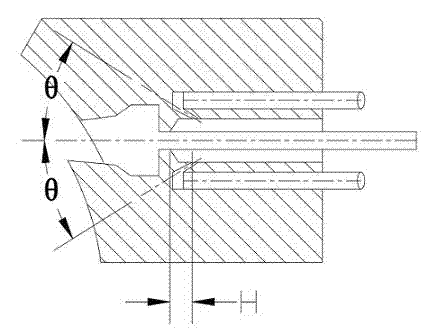

Method for using numerically-controlled pipe bender to process heating constant temperature bending pipe

InactiveCN101185949ARealize the heating effectRealize temperature controlShaping toolsNumerical controlTemperature control

The invention discloses a method making use of numerical control tube bender to heat constant temperature bent tube in the material technology field. The method has the detail steps that a hole is cut on a height direction in the internal part of a round die, and holes are respectively cut on a height direction in the internal parts of a guide die, an anti-crease die and a mandril. A heating medium and a temperature sensor are respectively arranged in the holes. Insulation medium is arranged on the touch area of the lower surface of the round die and a machine body, on the clinching area of the back face of the guide die and a slide block and on the contacting area of the anti-crease die and a support frame thereof. The heating medium and the temperature sensor are respectively connected with a temperature control system which consists of a digital-display temperature control instrument and a solid relay. A temperature control instrument controls the opening and closing of the solid relay through comparing a self-set value with a collected value by the temperature sensor so as to realize a temperature control to the die; the tubes are hot bended -for molding. The invention realizes heating bending in a constant temperature for tubes which are difficult to be transfigured with high shaping accuracy, and is suitable for a batch production.

Owner:SHANGHAI JIAO TONG UNIV

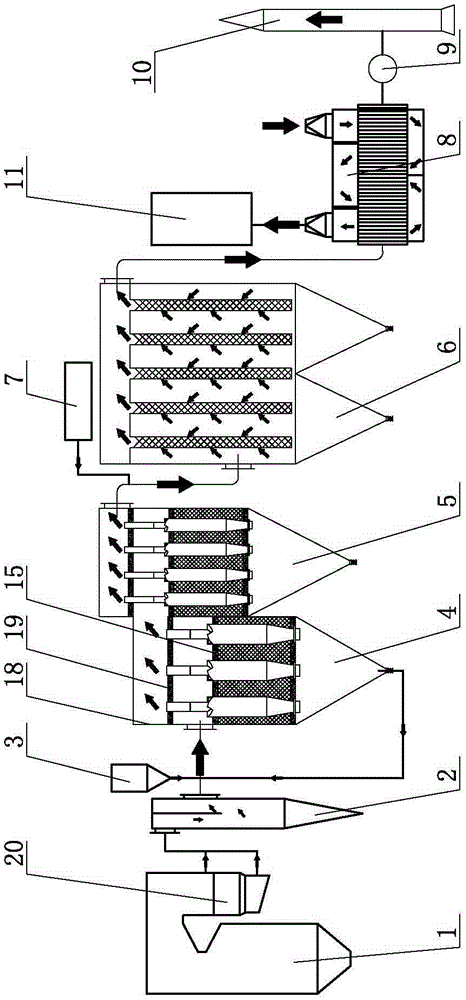

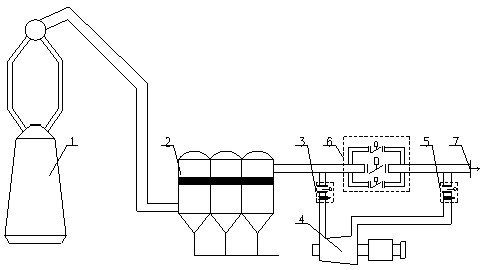

Coal-fired flue gas dust-removing desulfurization and denitrification integrated compound technology system

InactiveCN105233644AImprove utilizationAvoid water mistCombination devicesLighting and heating apparatusFlue gasOxide

The invention relates to a coal-fired flue gas dust-removing desulfurization and denitrification integrated compound technology system which is arranged as complete equipment for high-temperature flue gas dust-removing desulfurization and denitrification and waste heat utilization. A ceramic multi-tube dust cleaner is used for roughly removing dust and desulfurizing; a ceramic filtering film filter is used for deeply purifying, removing dust and denitration; the waste heat of the flue gas is utilized by a heat exchanger to change cold air into hot air; the hot air enters into a boiler combustion opening to support the combustion; metal and nonmetal oxides serve as the manufacturing materials of a micro-pore ceramic filtering pipe; the manufacturing materials serve as the catalyst main body and the carrier; a high-temperature ceramic method is combined for sintering and preparing the catalyst under certain temperature. The coal-fired flue gas dust-removing desulfurization and denitrification integrated compound technology is a high-temperature dust-removing desulfurization and denitrification integrated technique, is especially used for replacing an electric dust remover for purifying the coal-fired flue gas, is free from explosion hazard and is safe and reliable; the investment is saved; utilization for the heat energy is increased; the energy-saving effect is enhanced; the design is simple; the structure is reasonable; the coal-fired flue gas dust-removing desulfurization and denitrification integrated compound technology system is an energy-saving, emission-reducing, transforming and upgrading trans-century brand product made in China at present.

Owner:济南环保陶瓷除尘技术研究所

Method and system for independently controlling temperature and humidity of automobile air conditioner

InactiveCN102364259ATake advantage ofImprove protectionSpace heating and ventilation safety systemsLighting and heating apparatusLiquid waterLithium bromide

The invention discloses a method for independently controlling temperature and humidity of an automobile air conditioner. In the temperature control method, through a temperature control unit, a lithium-bromide absorption-type refrigerating device is operated by taking heat of tail gas of an automobile as a high temperature heat source, water in an aqueous solution of lithium-bromide is evaporated and the vapor enters a terminal heat exchanger to absorb heat in the environment to be condensed into liquid water, so that the environment is cooled, or is heated through condensing radiation afteradjustment; and in the humidity control method, through a humidity control unit, a lithium-bromide absorption-type heat pump device and a solid adsorption-type dehumidification device are jointly operated by taking heat of tail gas of the automobile as a high temperature heat source, and a condenser in the lithium-bromide absorption-type heat pump device dissipates heat to heat outside air, so that water in the air is evaporated, dry air is regenerated through moisture absorption of an adsorbent, and the environment is dehumidified. The heat of the tail gas of the automobile is fully utilized, the automobile tail gas exhaust temperature is reduced, and energy is saved by 30 percent effectively; and a system space is saved, the operating performance of the system is high, the manufacturingcost is low, the volume is small, the cost is low, and the invention has great economic and social benefits.

Owner:深圳泰博晟精密机电有限公司

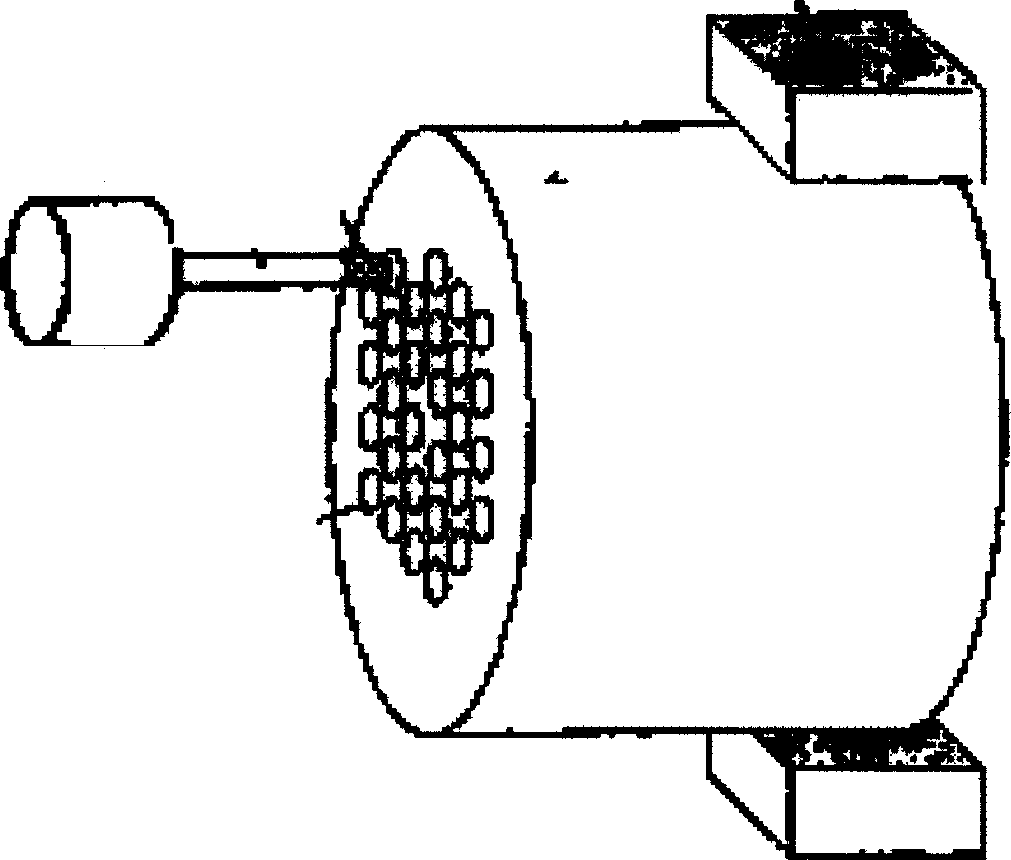

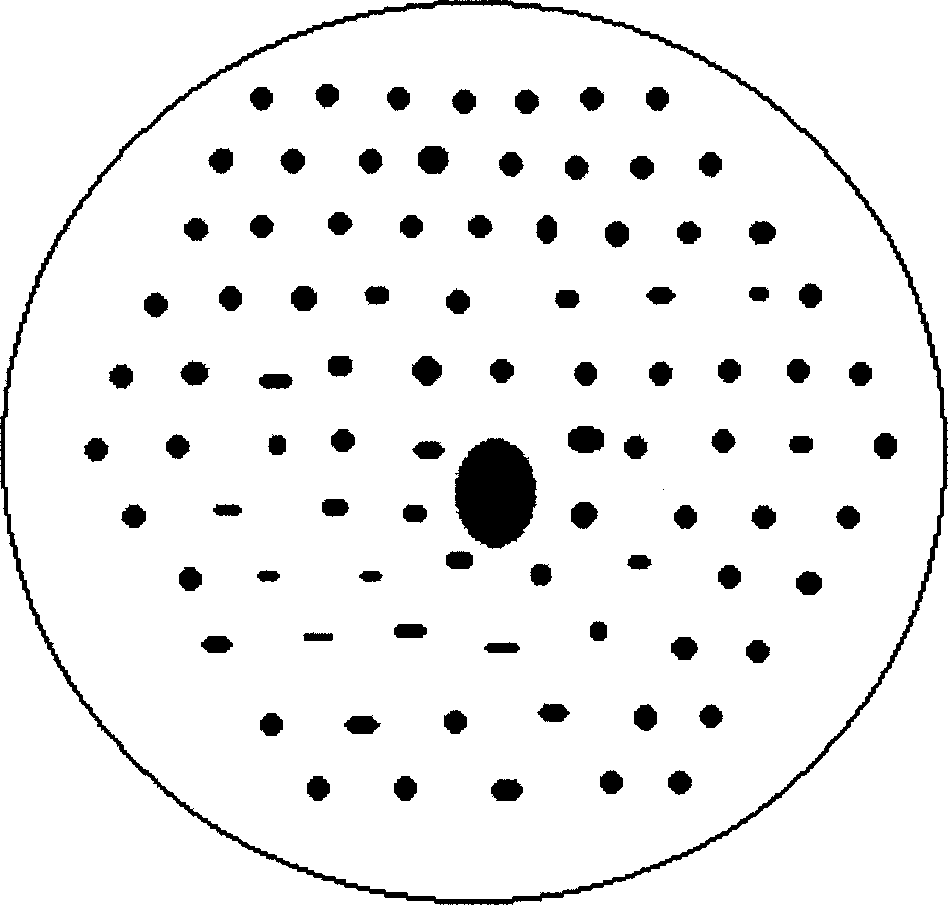

Method for preparing photon crystal optical fibre and apparatus therefor

ActiveCN1583617ASimple preparation procedureReduce lossGlass making apparatusGlass productionAtmospheric pressureMaterials science

The method is: Put many glass pipe in order to form a specific structure (photon crystal optical fibre prefab stick) in the glass cannula. The thin glass pipe is longer then the others. The equipment controls the pressure of photon-crystal optical fibre prefab stick. In another word is to vacuum the glass cannula, to input the thin glass pipe of 10 -1 mbar air.

Owner:FENGHUO COMM SCI & TECH CO LTD

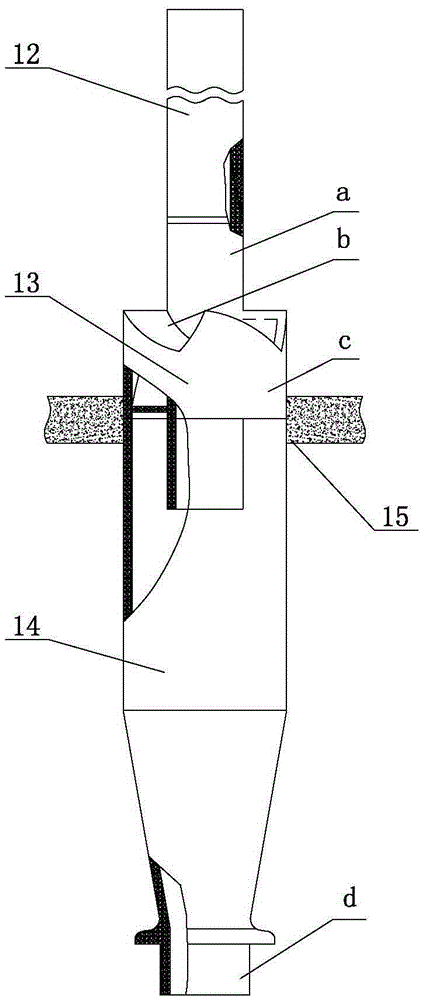

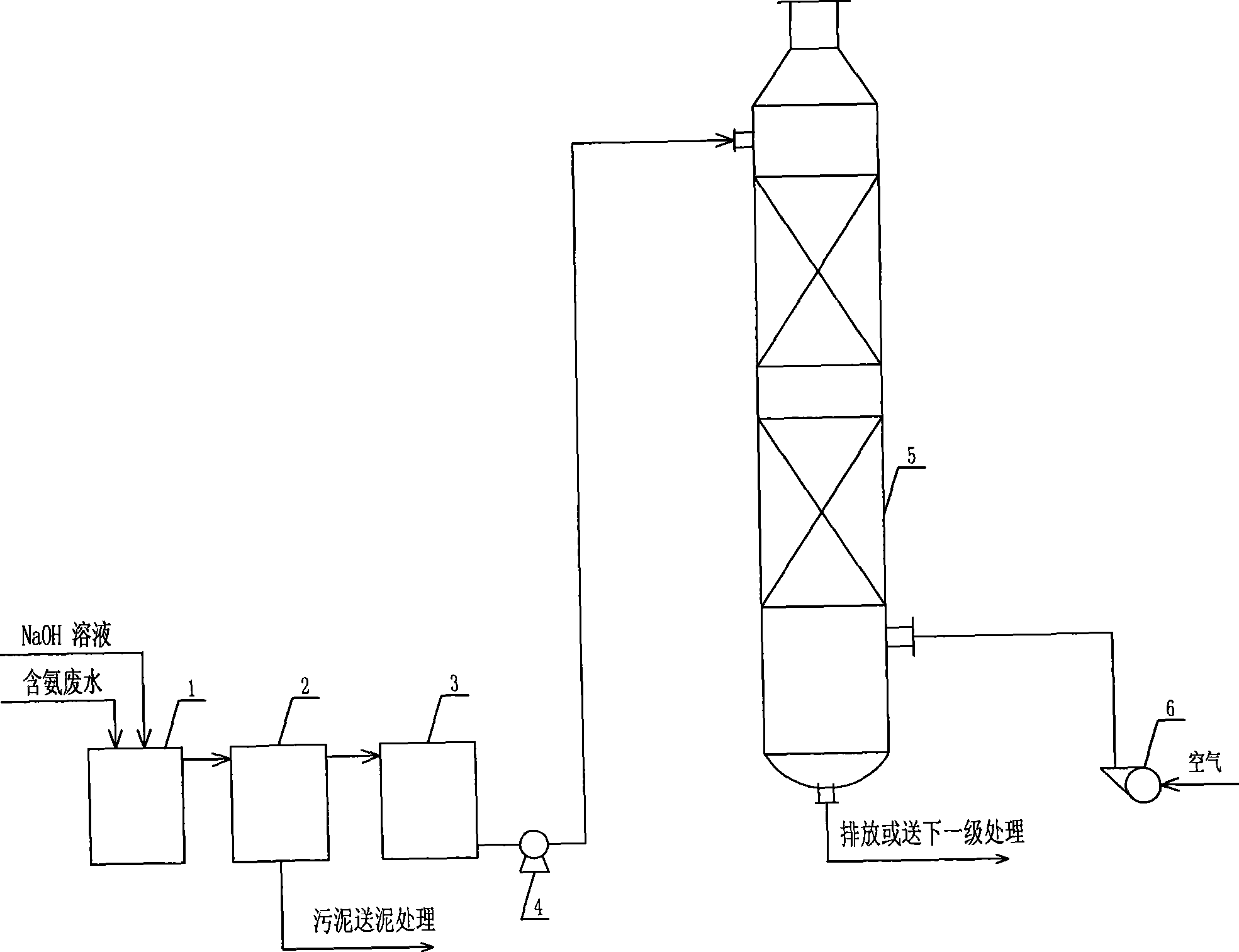

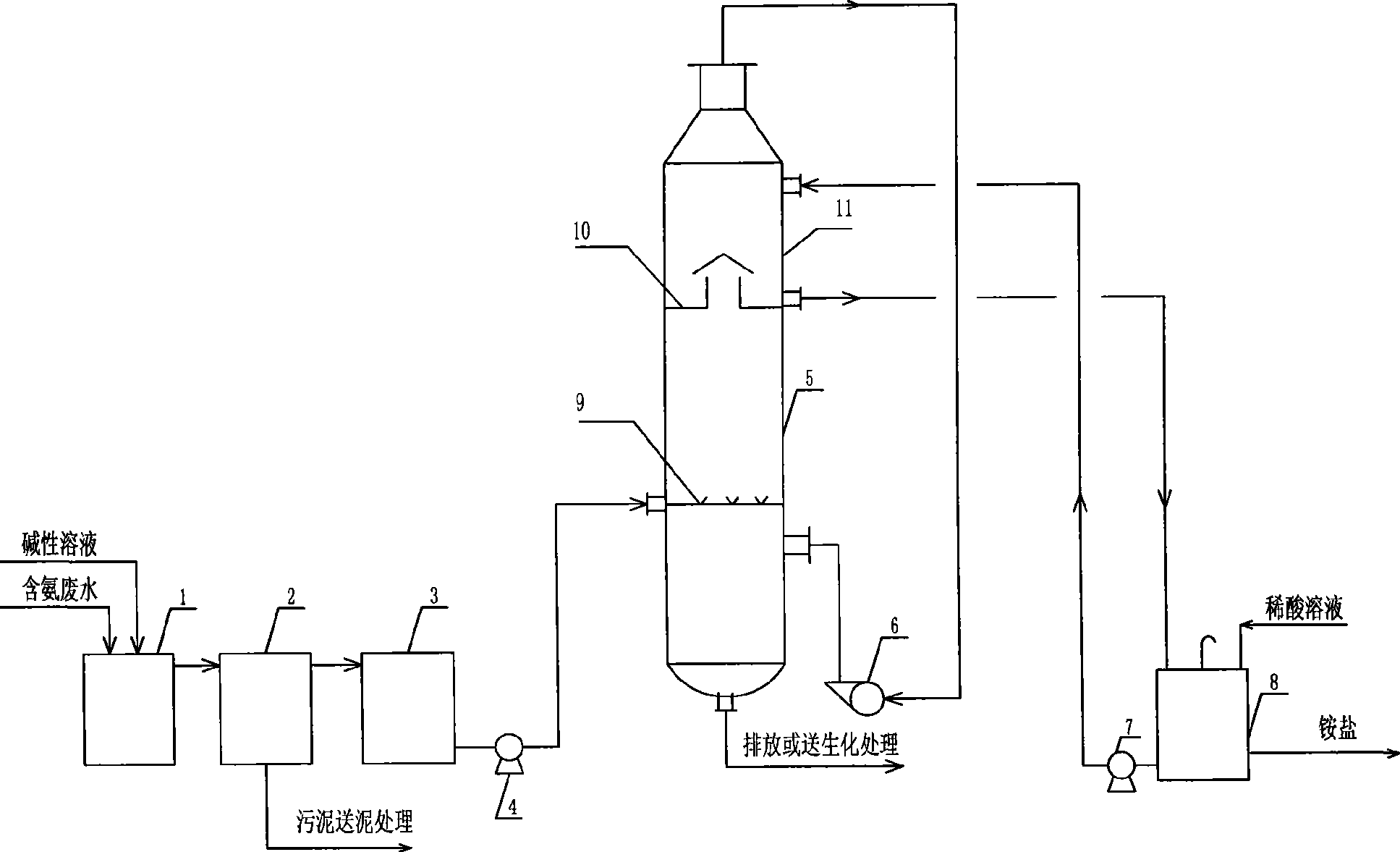

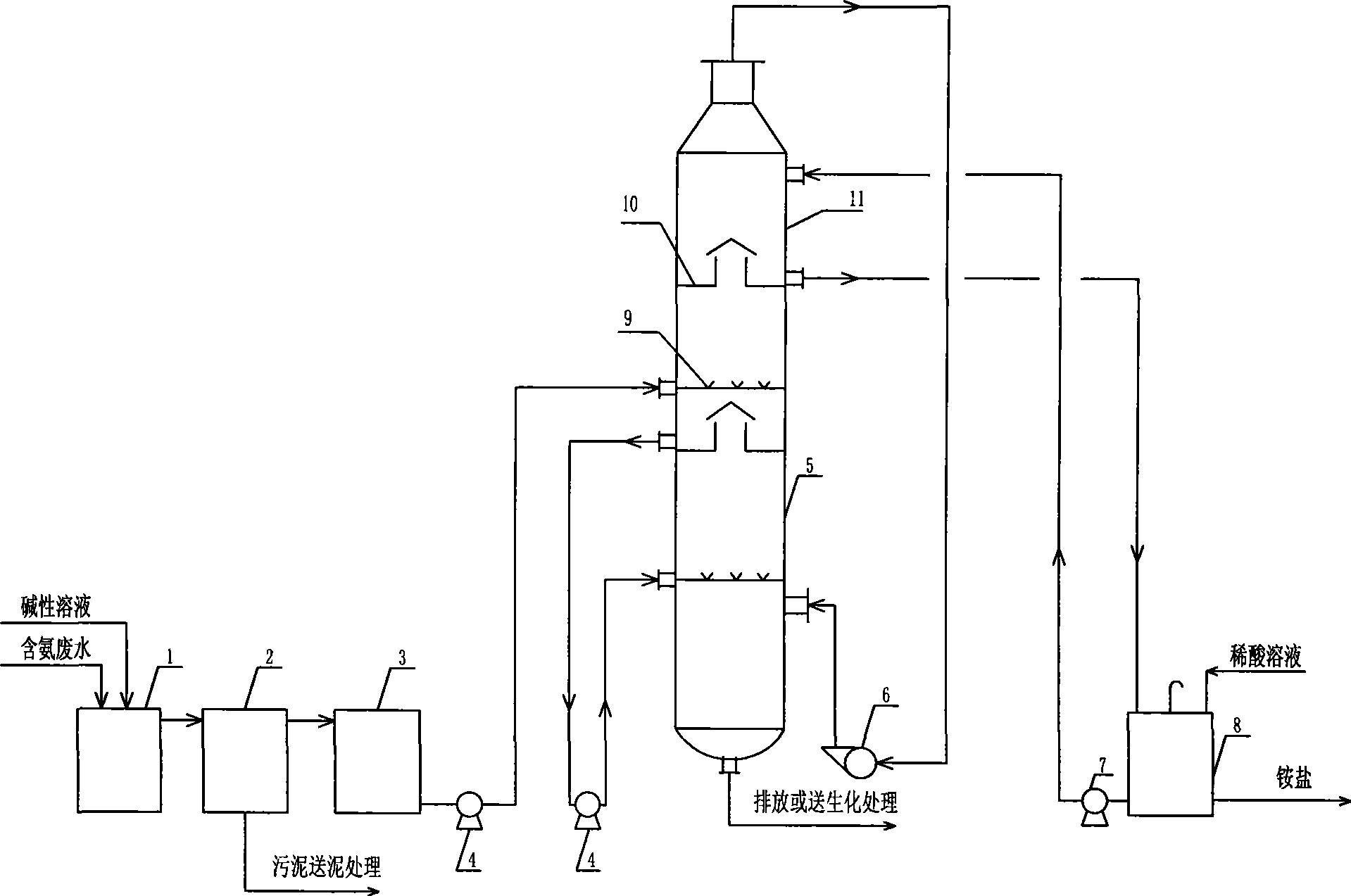

Environment-friendly high-performance waste water ammonia-removal process and device thereof

InactiveCN101445290AAvoid temperature dropHigh removal rateDispersed particle separationWater/sewage treatment by neutralisationAmmoniacal nitrogenTower

The invention relates to an environment-friendly high-performance waste water ammonia-removal process, which absorbs ammonia in tail gases to remove ammonia by a dilute acid solution, and leads air containing no ammonia or infinitesimal ammonia to the inlet of a blower for recycled use. The invention further comprises a device which comprises a pH adjusting pond, a sedimentation tank, a waste water intermediate vessel, a waste water feed pump, an ammonia-removal tower, a blower or an induced draft fan, an absorption liquid circulating pump, an absorption liquid circulating groove, a highly dispersing element and a vapor riser, wherein, the absorption liquid circulating pump is connected with the two interfaces on the absorbing section of the ammonia-removal tower to circulate; and the top part and the lower end of the ammonia-removal tower are connected with the blower simultaneously to circulate. The process has the advantages that no tail gas is exhausted while removing ammonia and nitrogen in waste water; and as the temperature of the waste water is kept unchanged, the temperature of the waste water can not decline along with the series increasing of ammonia removing stage by stage during ammonia-removal process, thereby further keeping the ammonia-removal efficiency in a higher range.

Owner:武汉科梦科技发展有限公司

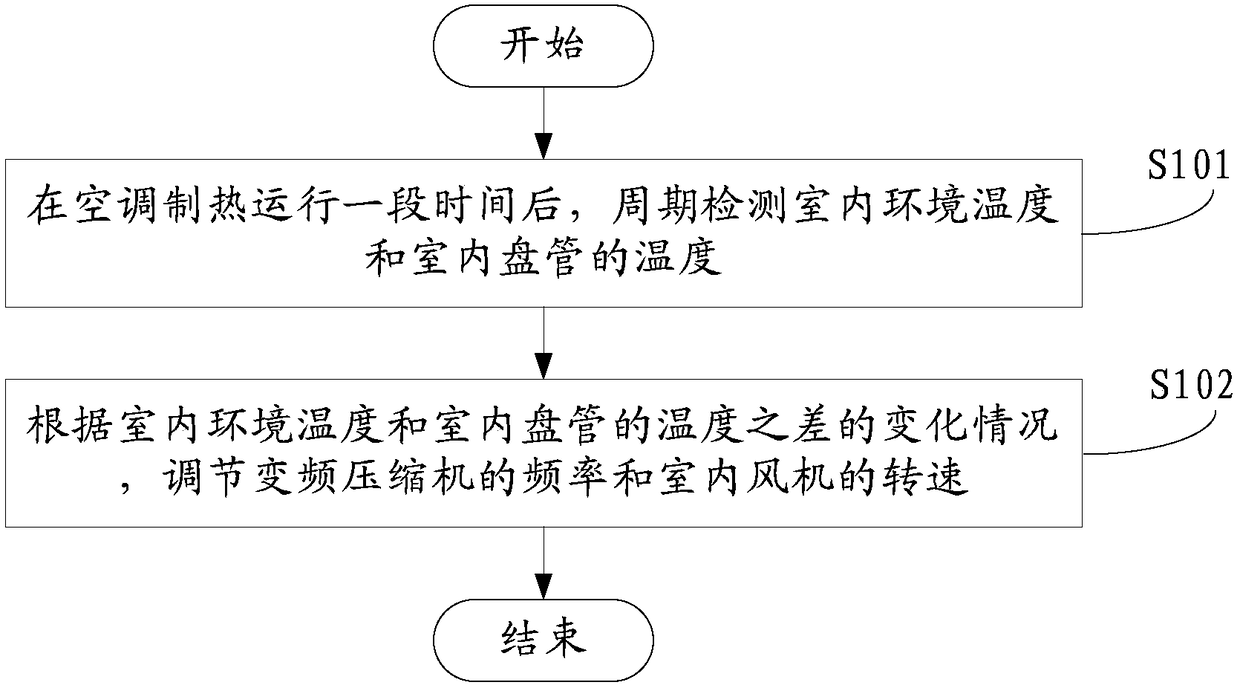

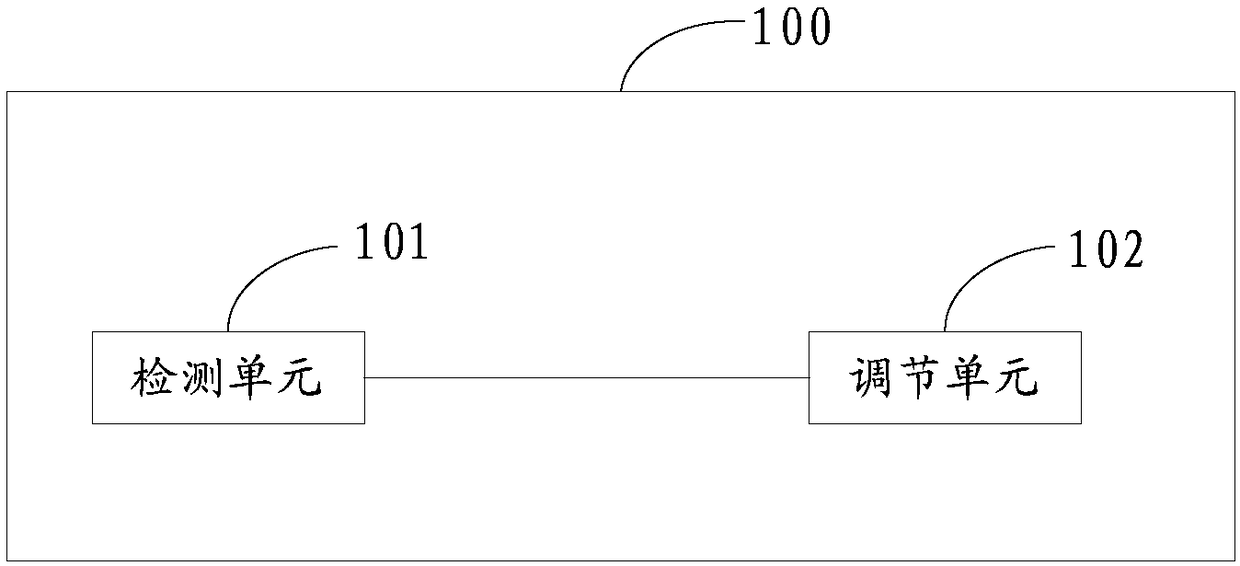

Variable-frequency air conditioner control method and device

InactiveCN108088055AReduce the temperatureImprove comfortMechanical apparatusSpace heating and ventilation safety systemsEngineeringInverter compressor

The invention discloses a variable-frequency air conditioner control method and device, and relates to the technical field of air conditioners. The variable-frequency air conditioner control method and device are used for ensuring the effect that the temperature of an indoor air outlet is not lowered. The method is applied to a variable-frequency air conditioner which is provided with an indoor coil pipe, a variable-frequency compressor and an indoor fan. The method is characterized by comprising the steps that after the heating function of the air conditioner is operated for a period of time,the indoor environment temperature and the temperature of the indoor coil pipe are detected periodically; and the frequency of the variable-frequency compressor and the rotating speed of the indoor fan are adjusted according to the change condition of the difference between the indoor environment temperature and the temperature of the indoor coil pipe. The embodiment of the invention is applied to control over the variable-frequency air conditioner.

Owner:HISENSE (GUANGDONG) AIR CONDITIONER

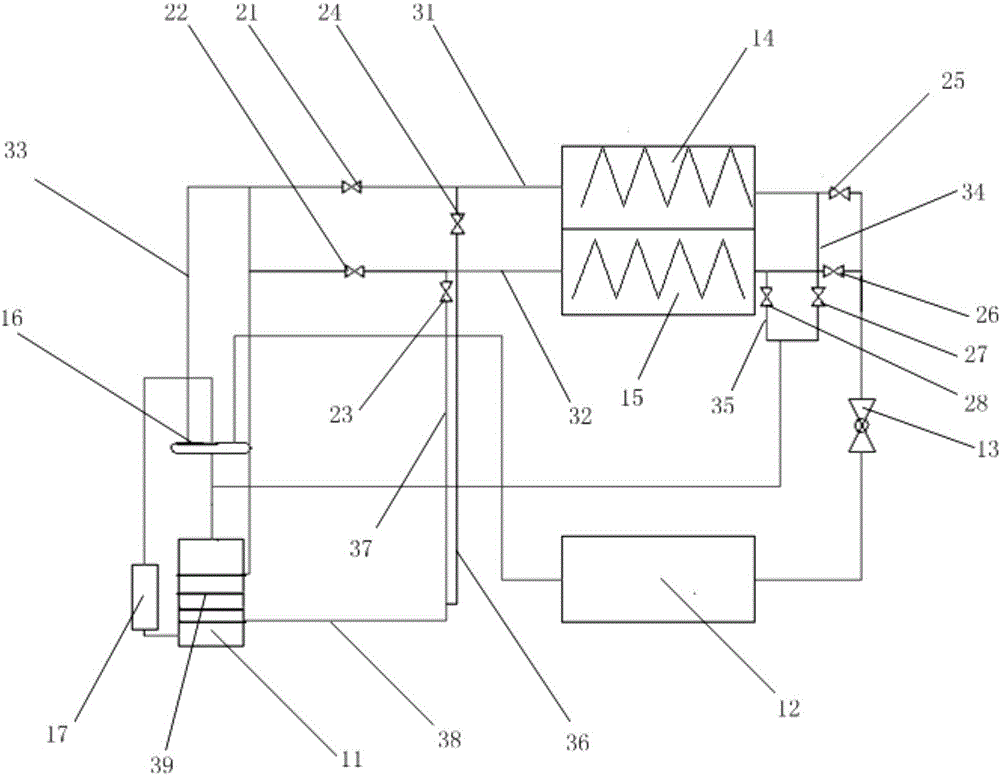

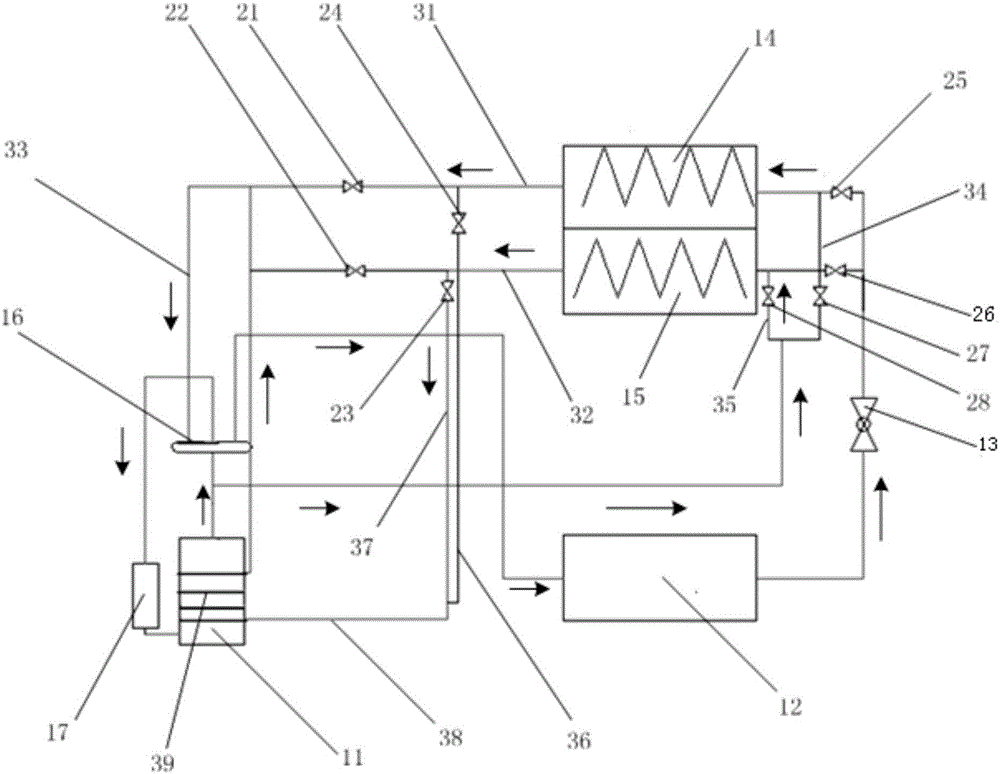

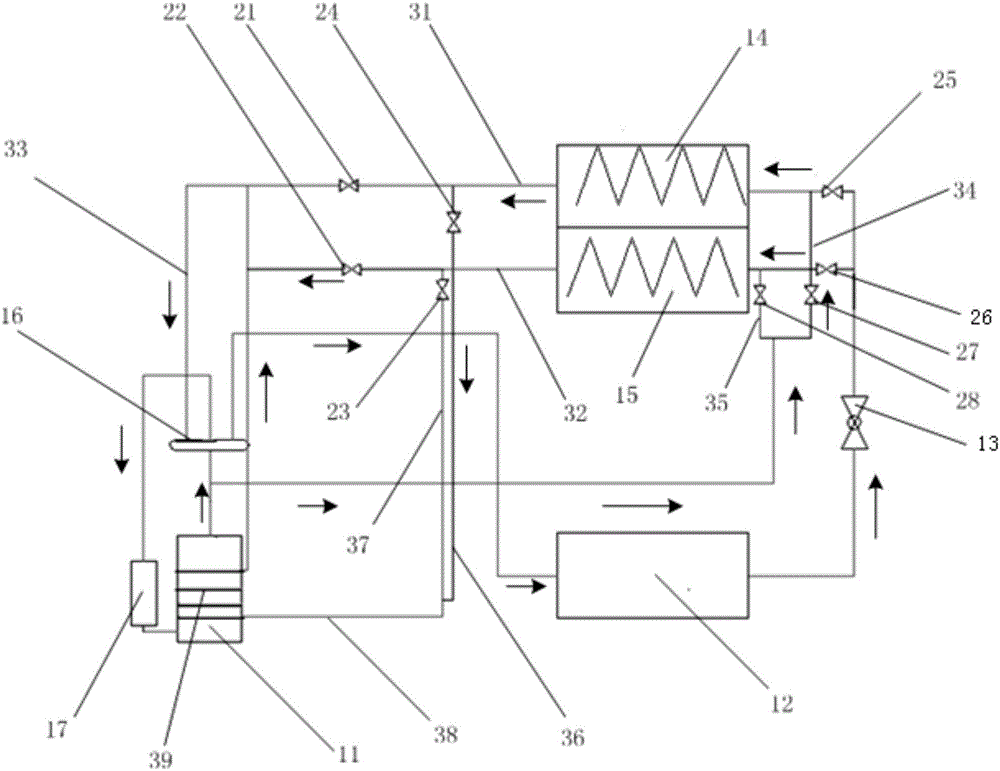

Air conditioning unit and control method for same

InactiveCN106440462AImprove cooling effectTemperature does not dropMechanical apparatusCorrosion preventionFour-way valveEngineering

The invention discloses an air conditioning unit and a control method for the same and relates to the technical field of air conditioning. An outdoor heat exchanger comprises two or more outdoor heat exchange devices. A compressor, a four-way valve, an indoor heat exchanger, a throttling device and the two or more heat exchange devices are connected to form a refrigerant loop. The refrigerant loop is internally provided with a first control valve unit. The compressor and the two or more outdoor heat exchange devices are connected to form a defrosting loop. The defrosting loop is internally provided with a second control valve unit. According to the air conditioning unit and the control method for the same, heating and defrosting of the air conditioning unit are conducted at the same time through control valves; in addition, in the defrosting process, the four-way valve does not reverse; by means of heat, generated in the operation process of the compressor, of a shell, liquid refrigerant obtained after defrosting is evaporated; meanwhile, through variable diameter throttling design of pipes, waste heat of a cylinder body of the compressor can be effectively utilized; and meanwhile, heat dissipation of the compressor can be enhanced, the temperature of an indoor environment can be maintained not to be lowered, and user experience is improved.

Owner:GREE ELECTRIC APPLIANCES INC

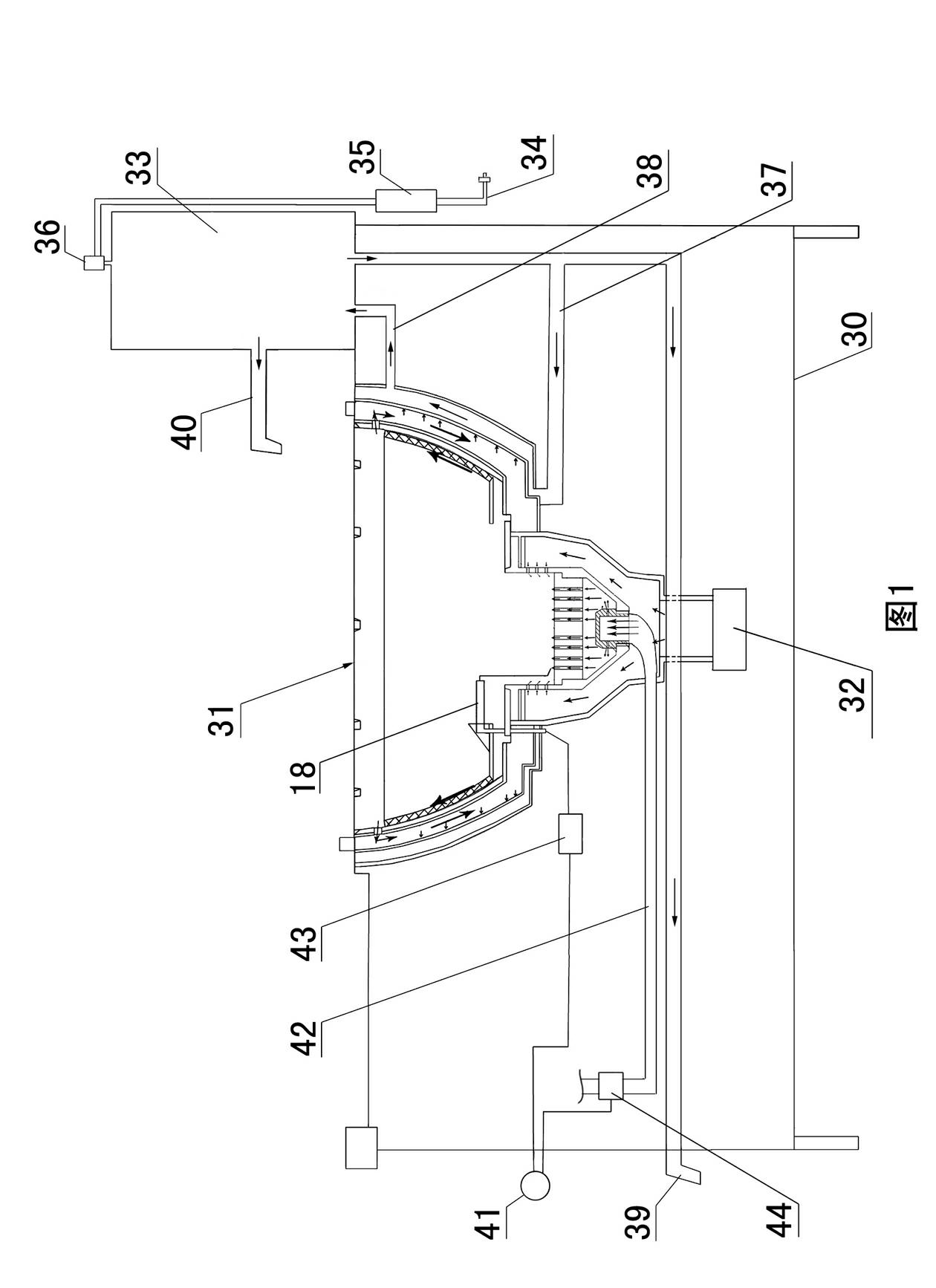

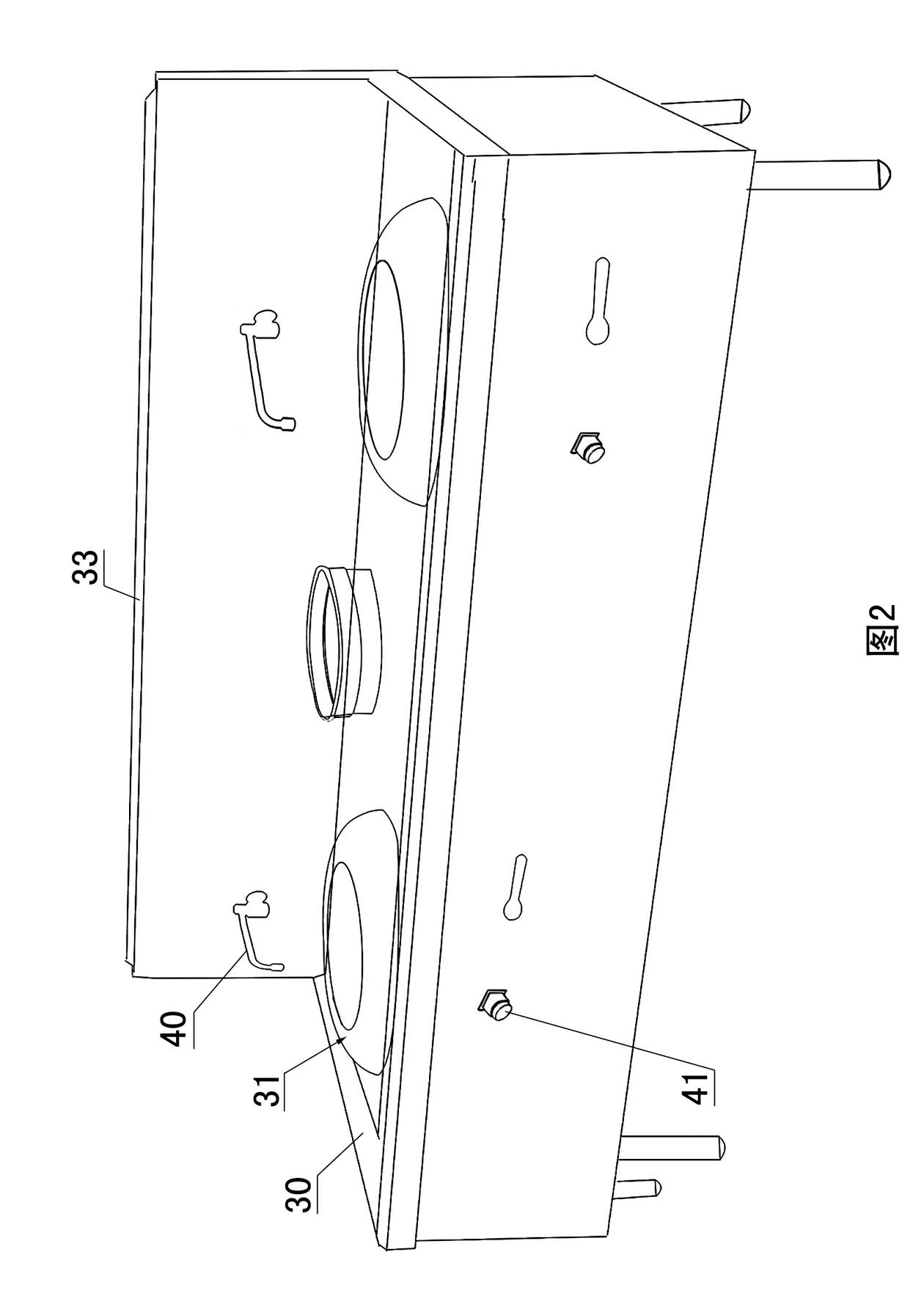

Collected heat type high efficient and energy-saving burning Chinese food frying-oven

InactiveCN102221228ATemperature does not dropSpeed will not decreaseWater heating stoves/rangesCooking fumes removalThermal energyCombustor

The invention relates to a collected heat type energy-saving burning Chinese food frying-oven which comprises a cooking stove and a burner assembly, a fan, a storage water tank, an electronic ignition device arranged on the cooking stove, wherein, the burner assembly comprises a burner and a hearth, the storage water tank is connected with a swing hot-water cock, the hearth comprises a side wall of the hearth and a waste heat collected jacket, the side wall of the hearth is of a hollow structure and comprises an inner side wall, an outer side wall and an air cavity clipped the inner side wall and the outer side wall, wherein, the upper part of the inner side wall is provided with a waste gas air hole which is communicated with the air cavity, the lower part of the outer side wall is provided with a waste gas air inlet which is communicated with the air cavity, the waste heat collected jacket is attached to the outer side surface tightly and is connected with the storage water tank to form a cycling water way through a water inlet and a return water pipe. The frying-oven has the advantages of energy-saving effect and high economic benefit, providing hot water to the kitchen, meanwhile, the frying-oven effective reduces the influence of the Chinese style frying-furnace on kitchen environment, and the capability of collecting the heat energy from hearth is greatly improved.

Owner:宫润涛

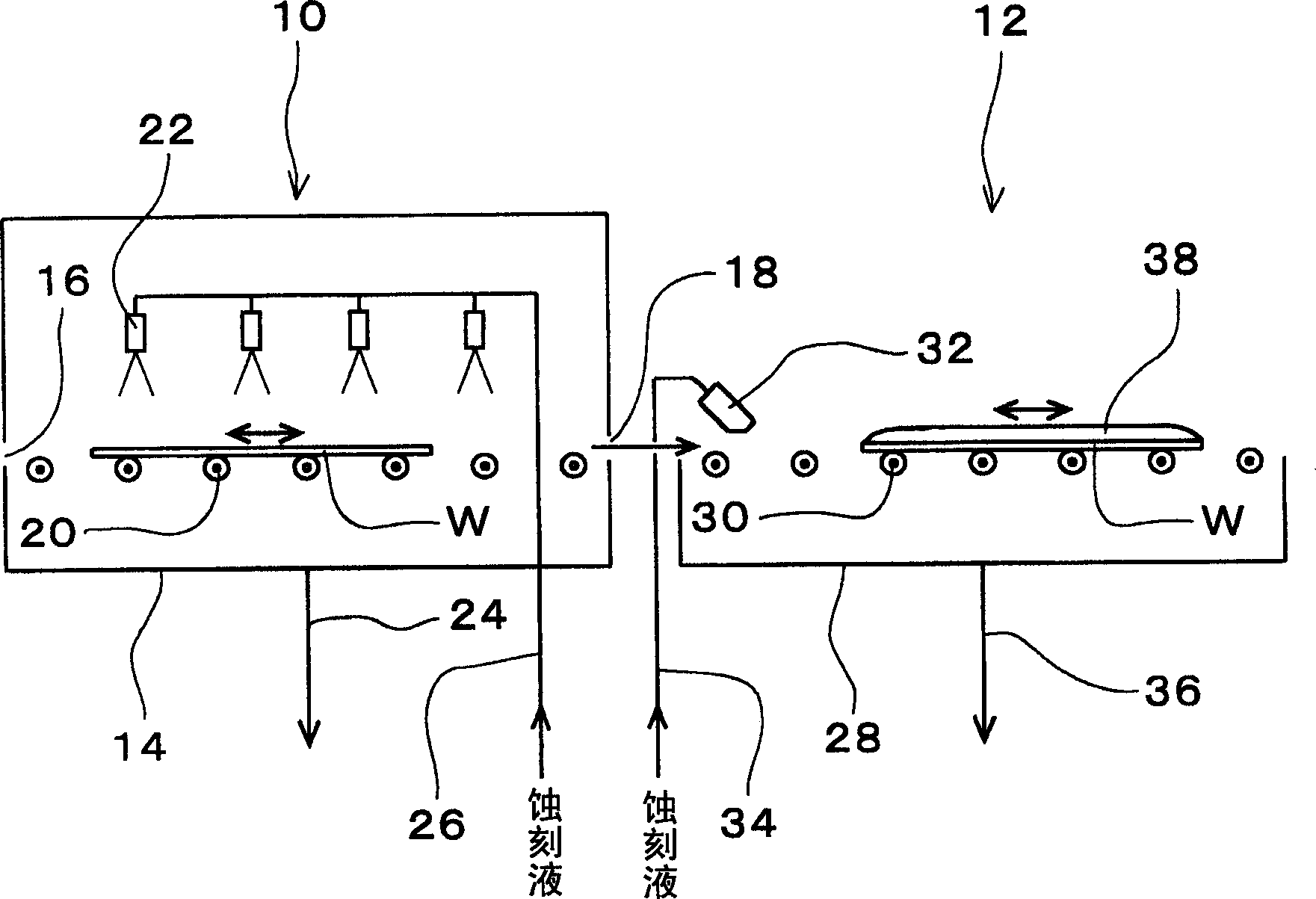

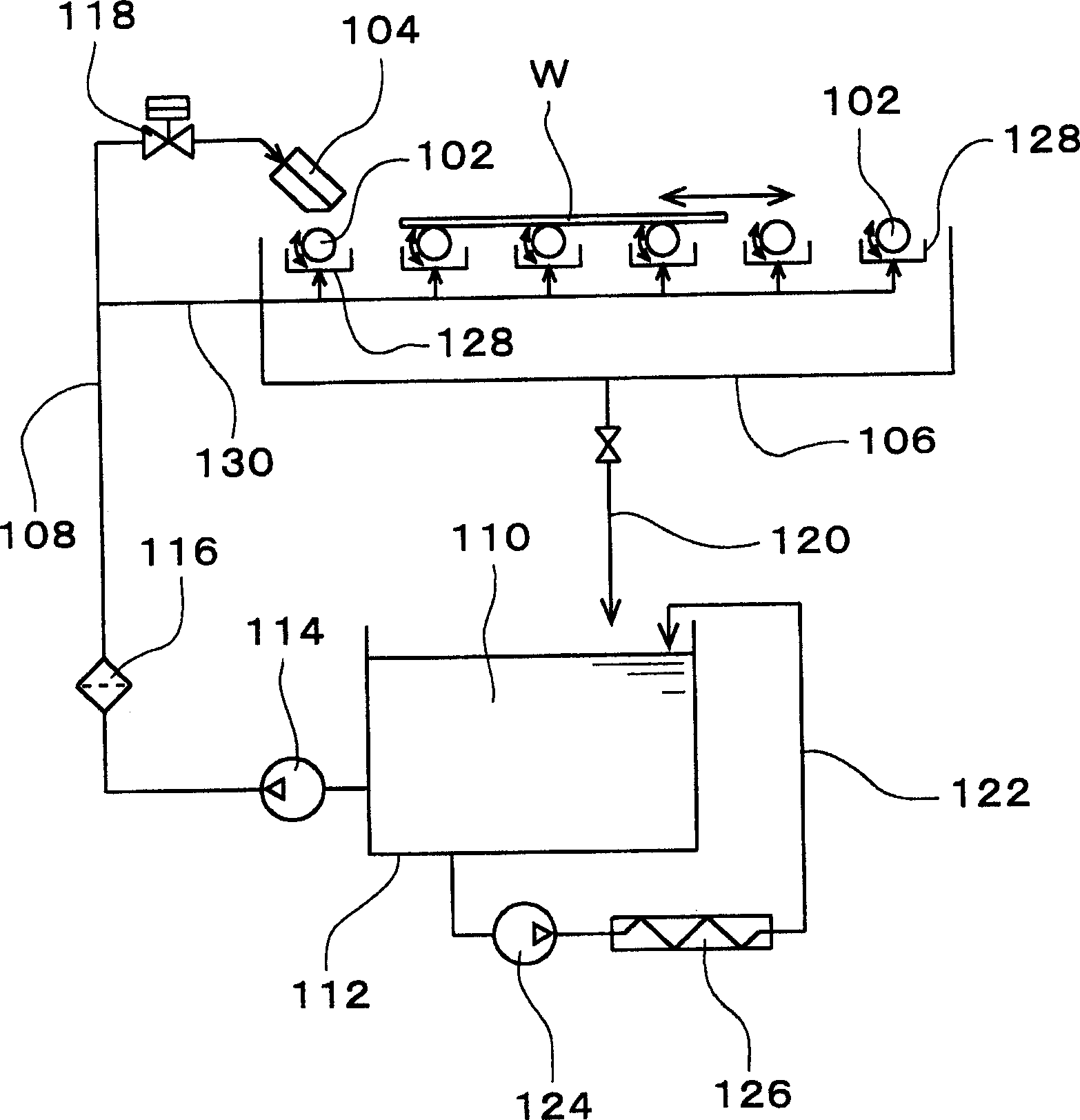

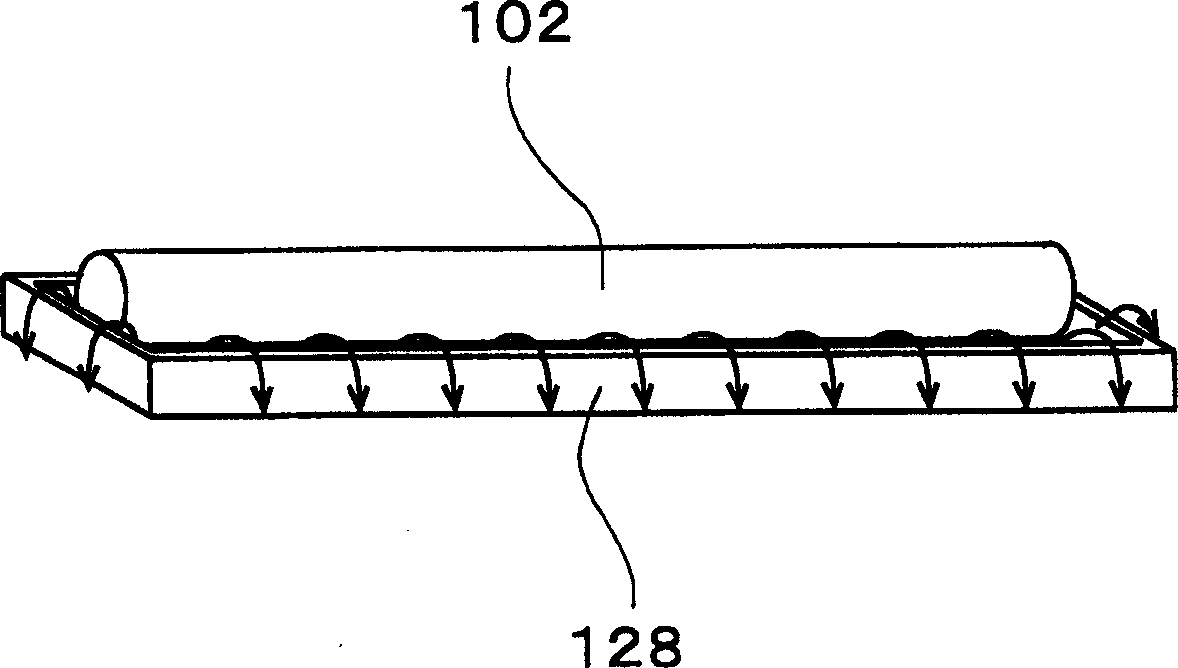

Substrate etching method and etching disposal device

InactiveCN1574251ATemperature does not dropUniform temperatureSemiconductor/solid-state device manufacturingPhotosensitive material processingEtchingEngineering

Provided is a device where treatment tanks are not required to be so enlarged for corresponding to the enlargement of a substrate, and the defect in etching does not occur as in the case where dipping treatment is performed. The device is provided with: a first treatment tank 14; conveyance rollers 20 arranged at the inside of the first treatment tank 14 and supportingly conveying a substrate W; spray nozzles 22 arranged at the upper part of a substrate conveyance path and jetting an etching liquid toward the surface of the substrate W; a second treatment tank 28 connected to the first treatment tank 14; conveyance rollers 30 arranged at the inside of the second treatment tank 28 and supportingly conveying the substrate W; and a discharge nozzle 32 feeding the etching liquid to the surface of the substrate W carried out from the inside of the first treatment tank 14 and carried into the second treatment tank 28 and applying the etching liquid to the whole of the surface of the substrate W.

Owner:DAINIPPON SCREEN MTG CO LTD

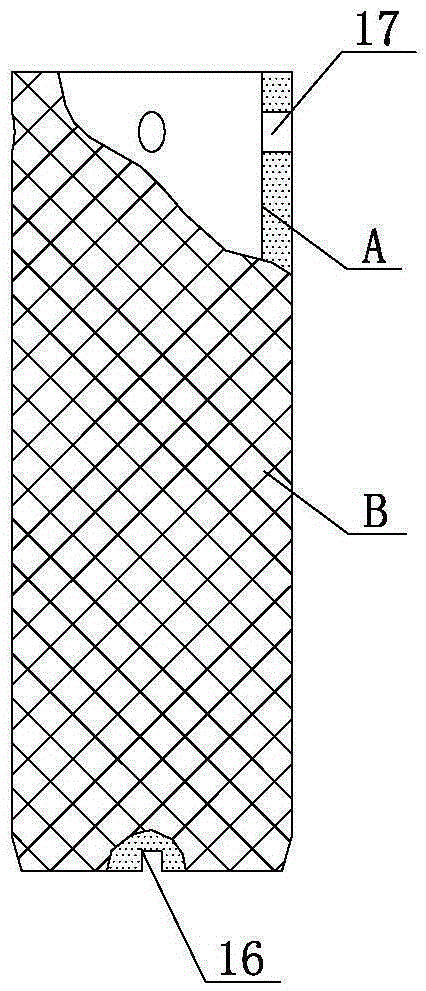

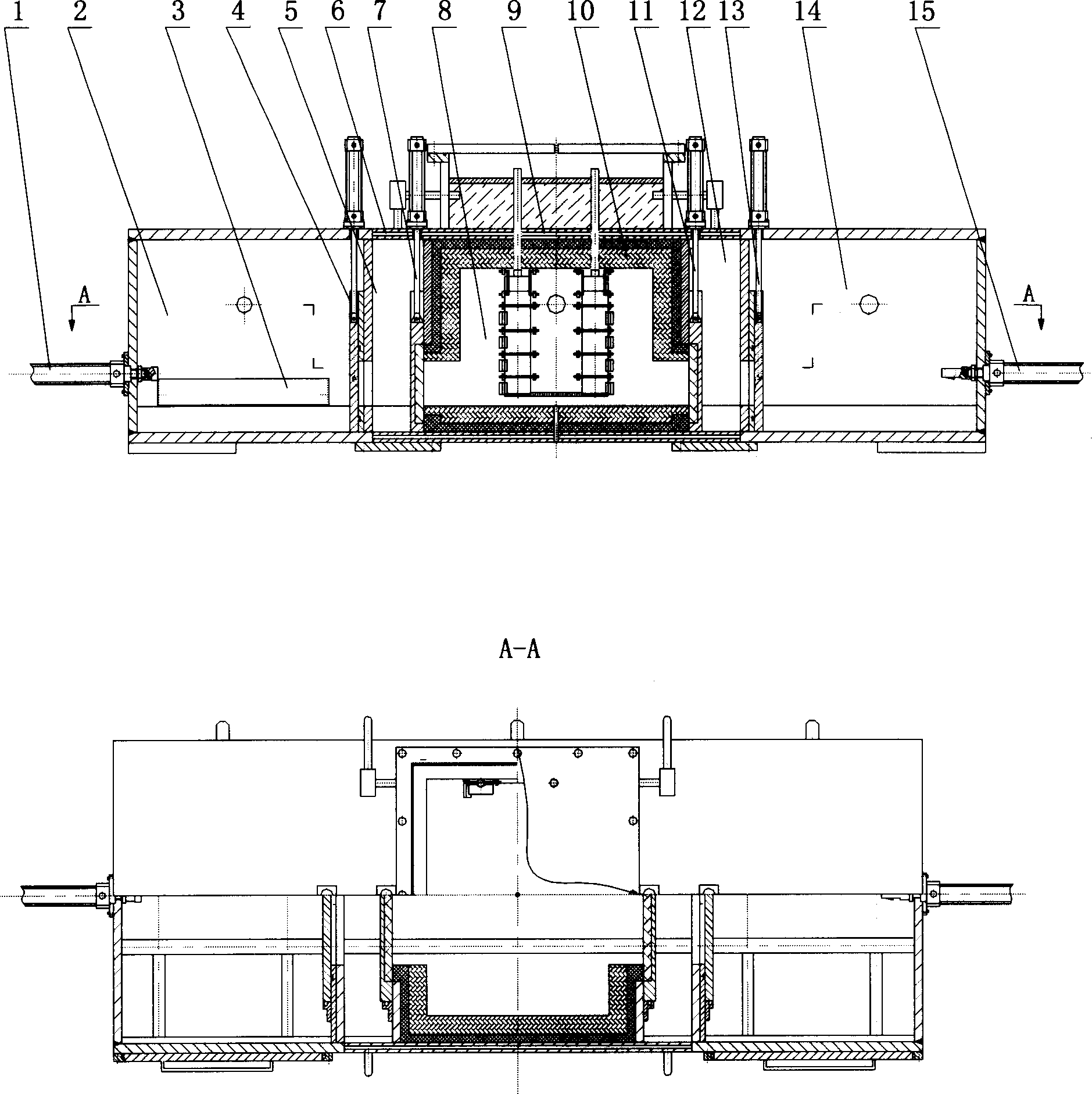

Dry-process dust-removing and dechlorination combined device for blast furnace gas

InactiveCN102534082AImprove dust removalImprove desulfurization efficiencyDust arrestersAdditive ingredientChloride

The invention discloses a dry-process dust-removing and dechlorination combined device for blast furnace gas. The device comprises a power generation device and a reducing valve group which are connected to the back of a blast furnace through a pipeline and connected with each other in parallel, and is characterized in that a grain bed dust remover before the power generation device and the reducing valve group is connected in series with the power generation device and the reducing valve group; and dechlorination grains, desulfuration grains and deamination grains are filled in the grain bed dust remover. The device can be used for conducting dust removing, dechlorination, desulfuration, deamination, moisture absorption, and recycling of residual heat and excess pressure on blast furnace gas effectively, and has the advantages as follows: the suitability on ingredient variation of blast furnace gas is high; problems of corrosion on equipment and pipelines and salification caused by dry-process dust removing are solved; and no corrosion-resistant measure is required in pipelines and equipment to follow-up users. The dust content of purified gas at the outlet of the device is 0 to 5 mg / Nm<3>; the chloride ion content in gas condensed water is smaller than 300 mg / L; and the pH value is 6 to 8.

Owner:CISDI ENG CO LTD

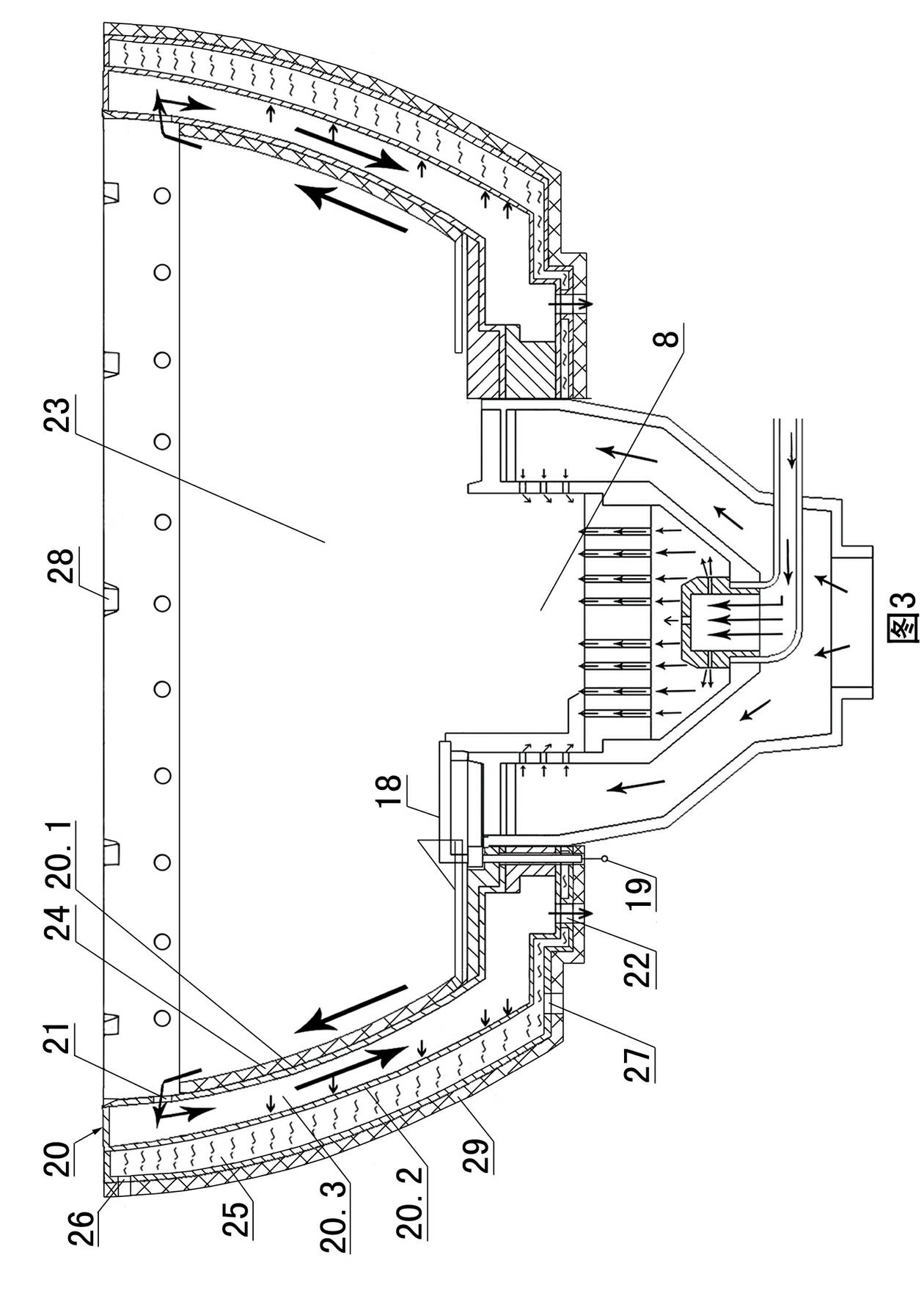

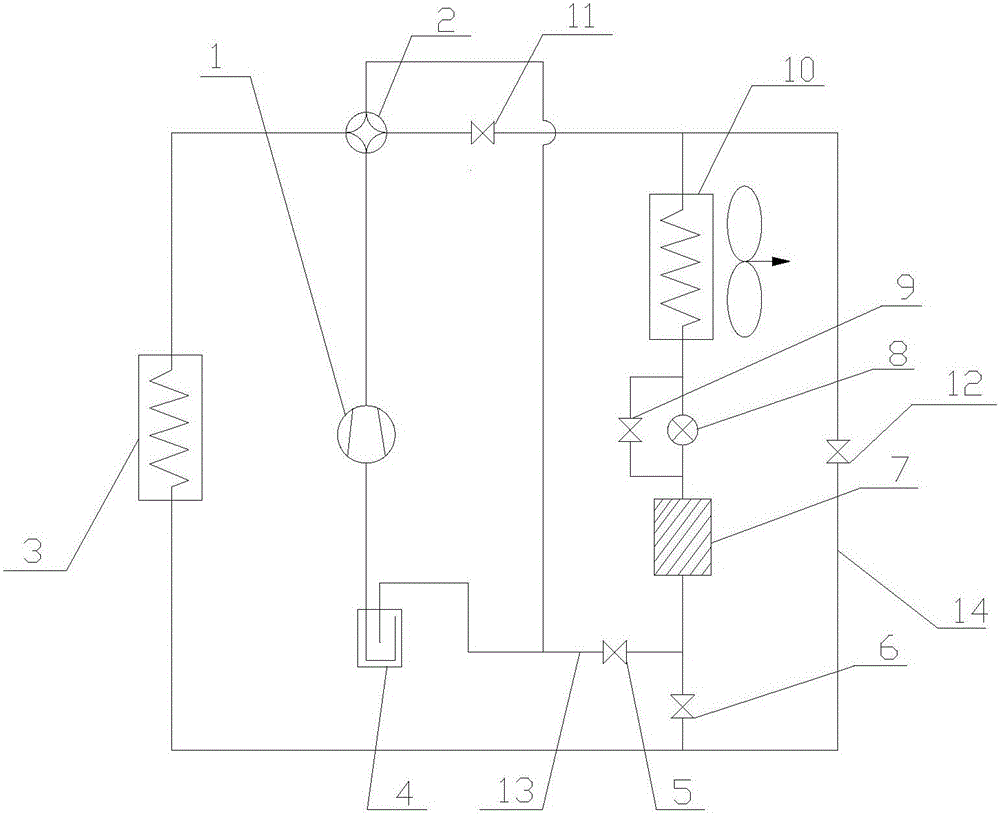

Defrosting control device and method for air source heat pump system

ActiveCN106288562AImprove reliabilityImprove running stabilityCorrosion preventionRefrigeration safety arrangementVapor–liquid separatorFour-way valve

The invention discloses a defrosting control device for an air source heat pump system. The device is characterized by comprising a compressor, a four-way reversing valve, an indoor heat exchanger, a gas-liquid separator, a throttling part, an outdoor heat exchanger, a phase change heat accumulator, a first solenoid valve, a second solenoid valve, a third solenoid valve, a fourth solenoid valve, a fifth solenoid valve, a first bypass pipeline and a second bypass pipeline, wherein the phase change heat accumulator is connected to the downstream position of the indoor heat exchanger to be used as a subcooler when the system supplies heat and to be used as a low-temperature heat source when the system defrosts, high and low pressure butt joint of the system before and after defrosting is completed by switching the bypass pipelines and the solenoid valves, so that the four-way valve does not perform reversing, the indoor temperature does not decrease, and the indoor comfort is guaranteed. The device has the advantages of simple structure, reliable performance, good defrosting effect, long service life and the like, and the method which is scientific, reasonable, high in adaptability and high in popularization and application value is provided.

Owner:NORTHEAST DIANLI UNIVERSITY

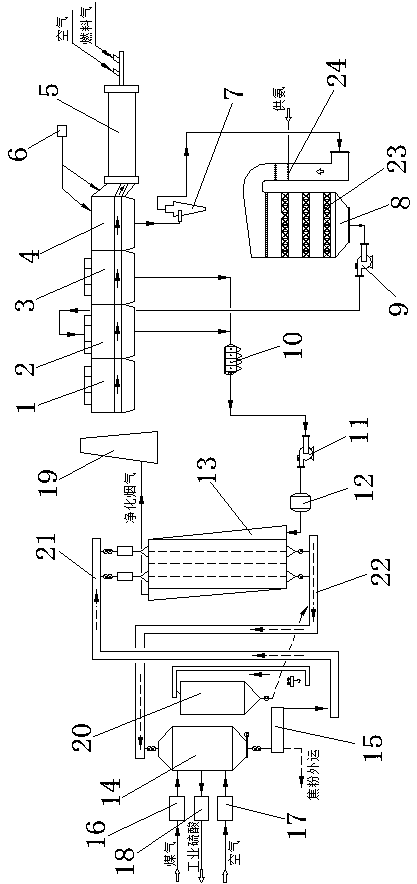

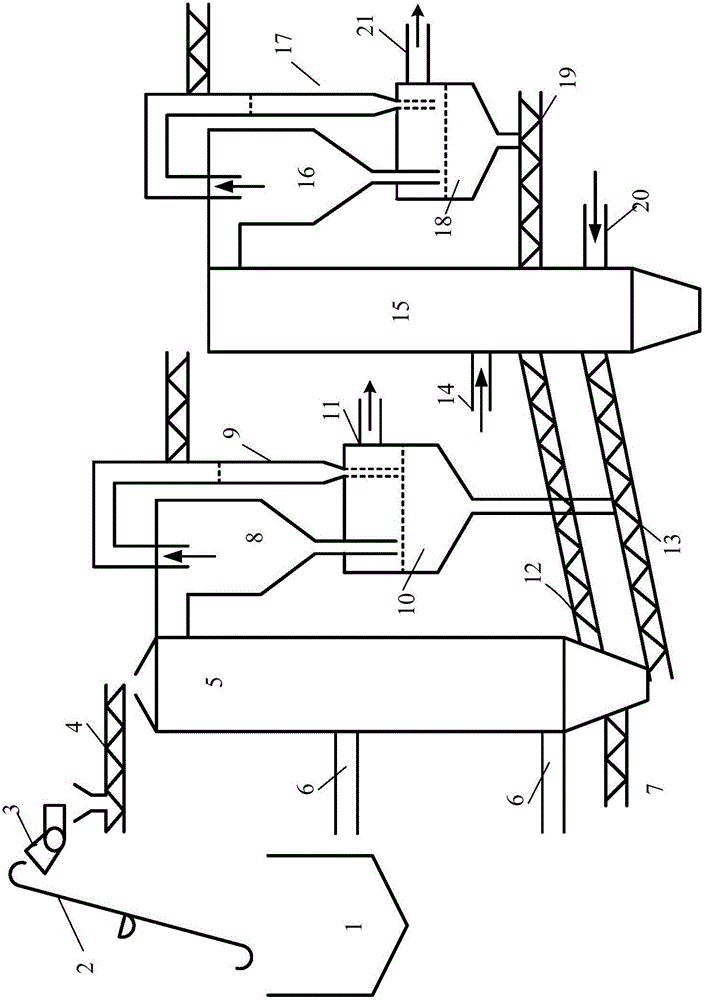

Grate-kiln SNCR/SCR (selective non-catalytic reduction/selective catalytic reduction) denitration and active coke desulfurization combined system and grate-kiln SNCR/SCR denitration and active coke desulfurization combined process

PendingCN109794146AReduce escapeImprove denitrification efficiencyDispersed particle separationMixed gasToxic industrial waste

The invention belongs to the technical field of industrial waste gas control, and relates to a grate-kiln SNCR / SCR (selective non-catalytic reduction / selective catalytic reduction) denitration and active coke desulfurization combined system. A denitration reductant injector of an SNCR system is communicated with one side, close to a rotary kiln, of a preheating section II; the preheating section II is communicated with an SCR system, and the SCR system is communicated with a drying section II; the drying section II and a preheating section I are communicated with an active coke desulfurizationand adsorption tower. The invention also provides a grate-kiln SNCR / SCR denitration and active coke desulfurization combined process. Flue gases of the rotary kiln enter the preheating section II, and the SNCR system sprays ammonia water into the flue gas inlet side of the preheating section II for denitration; the flue gases enter the SCR system for denitration, and then enter the drying sectionII to be mixed with the flue gases of the drying section I; the mixed gases enter the active coke desulfurization and adsorption tower for desulfurization after passing through an electric dust remover, a main exhaust fan and a flue gas heat exchanger. The grate-kiln SNCR / SCR denitration and active coke desulfurization combined system and the grate-kiln SNCR / SCR denitration and active coke desulfurization combined process have the advantages of improved denitration efficiency, reduced cost, high desulfurization and dust removal efficiency, and capability of meeting ultra-clean requirements.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

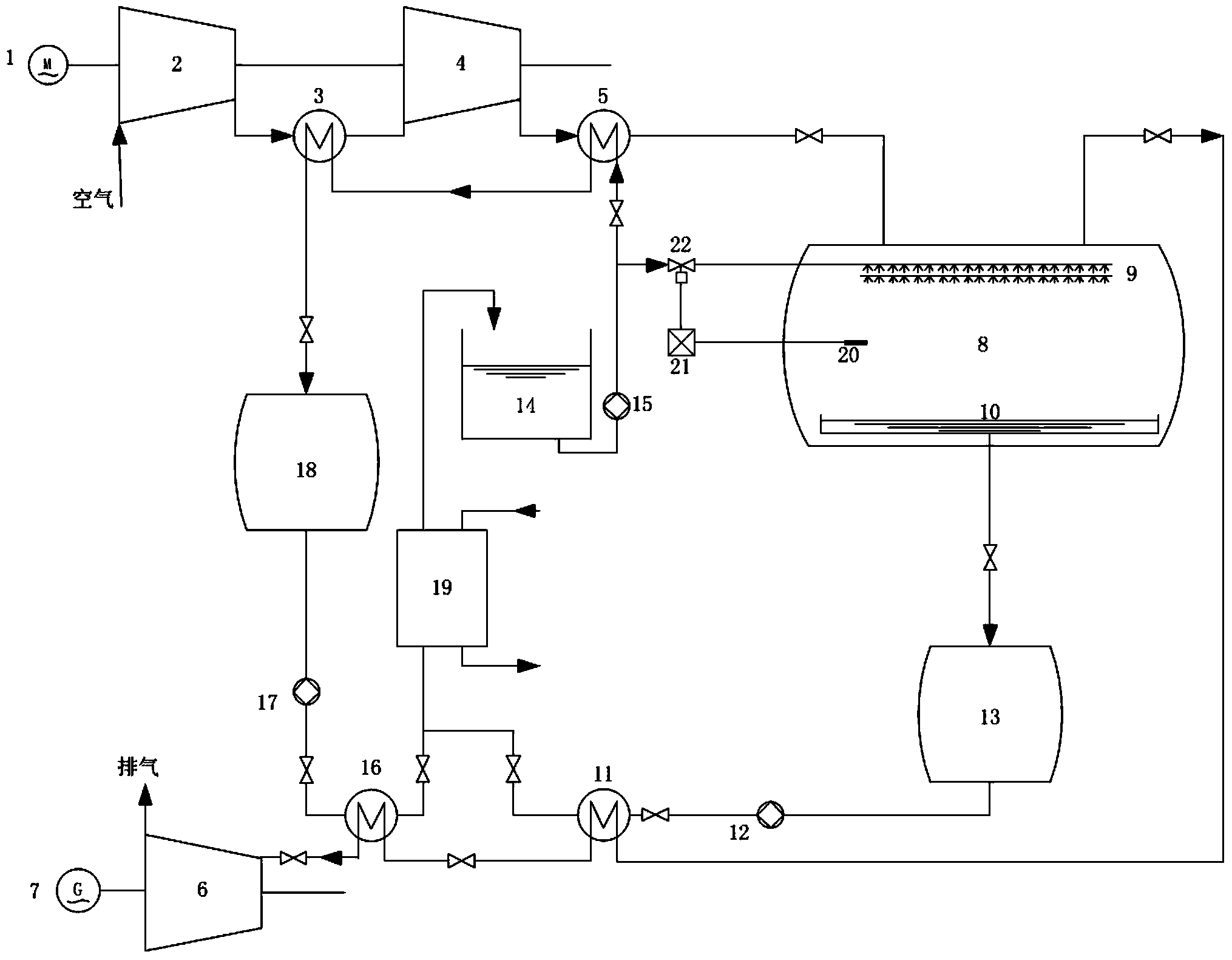

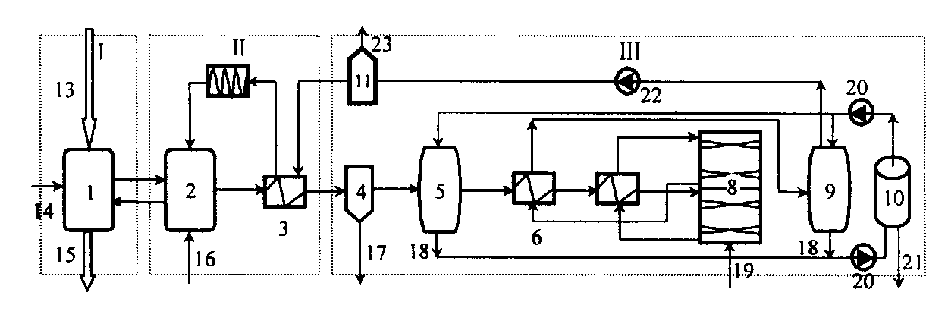

Compressed air energy storage system

InactiveCN103727011AEnsure safety and stabilityPrevent alternating hot and coldPump installationsPositive-displacement liquid enginesAir compressionThermal energy storage

The invention discloses a compressed air energy storage system which comprises a motor, an air compression unit connected with the motor, an air storage chamber storing compressed air and a temperature controller controlling the temperature inside the air storage chamber. A water atomizing and spraying mechanism used for keeping the temperature inside the air storage chamber stable and a temperature sensor used for measuring the temperature inside the air storage chamber. The air compression unit is used for sucking in air, and after the air is compressed, the air compression unit delivers the compressed air to the air storage chamber through an air channel to be stored. The temperature controller is connected with the temperature sensor so as to receive signals of the temperature sensor. The temperature controller is arranged in a pipeline connected with the water atomizing and spraying mechanism so as to control the work state of the water atomizing and spraying mechanism according to the signals, guarantee that the temperature of the air inside the air storage chamber is kept in a relatively stable temperature interval all the time, prevent frequent alternation of heat and cold of the inner wall of the air storage chamber and guarantee that the air storage chamber is safe and stable.

Owner:TSINGHUA UNIV +1

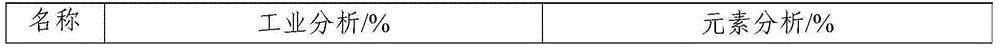

Medium-low rank coal pyrolysis and gasification system and medium-low rank coal pyrolysis and gasification method

ActiveCN105001891AReduce the burden of dust removalReduce corrosionSpecial form destructive distillationCombustible gas productionCoal pyrolysisSyngas

The present invention provides a medium-low rank coal pyrolysis and gasification system, which comprises a pyrolysis reactor, a first cyclone separator, a second cyclone separator, a first semi-coke bin, a second semi-coke bin, a gasification reactor and a first downer, wherein the pyrolysis reactor is provided with a synthetic gas inlet and is connected with the first cyclone separator, the cyclone separator is connected with the first semi-coke bin and the first downer, the bottom portion of the pyrolysis reactor is connected with a gasification semi-coke screw and a hot-state semi-coke discharge screw, the gasification semi-coke screw is connected with the gasification reactor, and the hot-state semi-coke discharge screw is connected with the first downer and a second downer. According to the present invention, the hot-state pyrolysis semi-coke is adopted as the dust removal and desulfurization adsorbent of the coarse synthetic gas, such that the dust content and the sulfur content in the coarse synthetic gas meet the downstream treatment requirements after the first-stage cyclone dust removal and the downer second-stage dust removal are performed; the partial synthetic gas refluxes to the pyrolysis reactor and the hydrogen content in the synthetic gas is high so as to provide the important effect on the lightweight of the pyrolysis tar; and the with the combined way, the low rank coal pyrolysis and gasification is achieved while the high quality tar and the high quality synthetic gas can be obtained.

Owner:北京恒丰亚业科技发展有限公司

Method for reducing microporosity during casting of high-temperature alloy test bar

ActiveCN105290328AReduce non-metallic inclusionsLower narrowFoundry mouldsFoundry coresFilter systemAlloy

The invention belongs to the technical field of precision casting and particularly relates to a method for reducing microporosity during casting of a high-temperature alloy test bar. According to the method, by enlarging a feeding channel of molten steel in the test bar pouring process, the pouring temperature and a mode of heat dissipation of the test bar are improved, too quick solidification on the surface of the test bar is reduced, and the feeding effect of a pouring system is improved. The smoothness of the feeding channel of a test bar detection part is achieved, the microporosity defect in the middle of the test bar is completely introduced into the pouring system, and the microporosity caused by too many impurities in alloy liquid is reduced by utilizing a filtering system.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

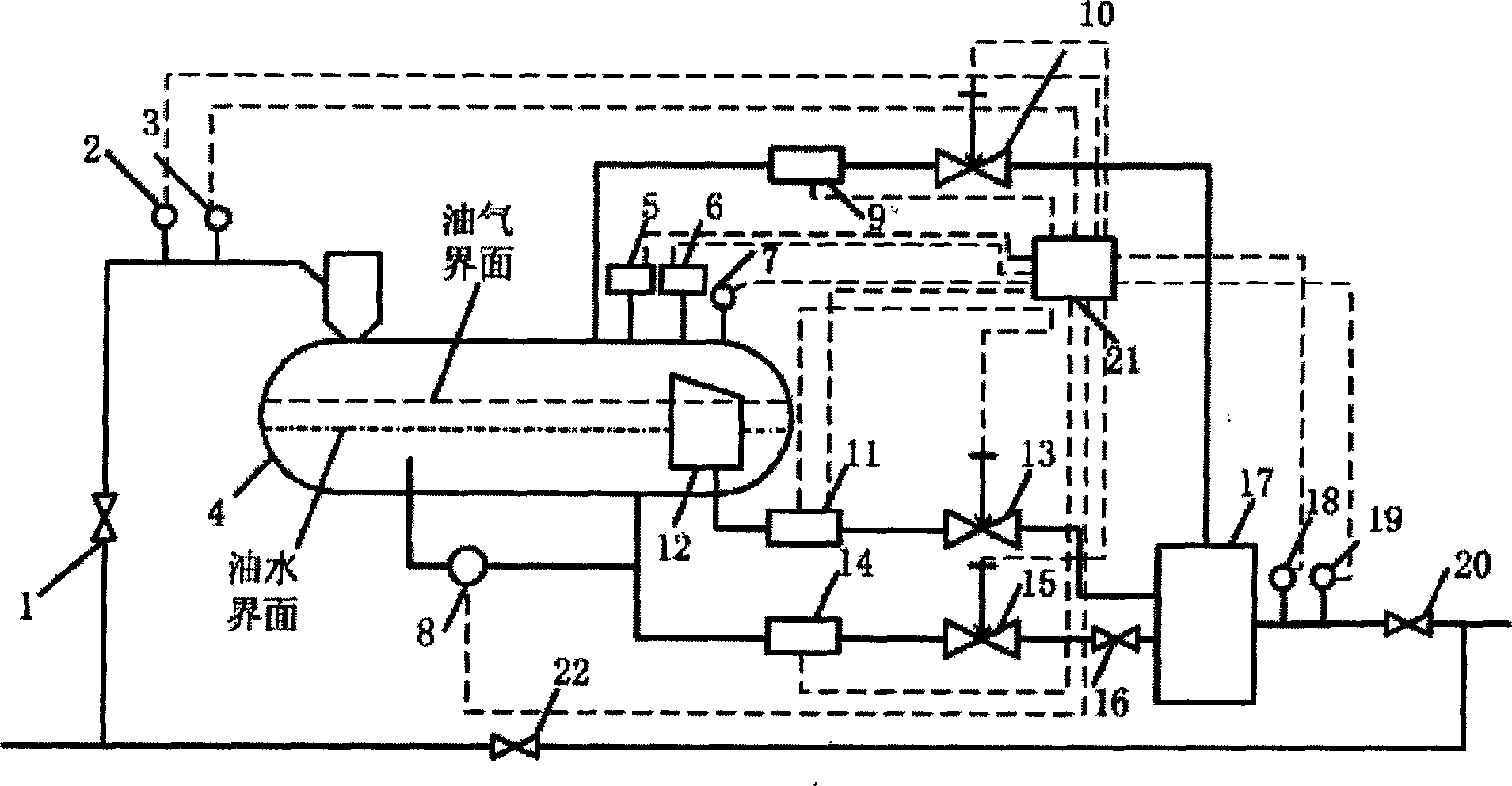

Oil-gas-water three phase flow continuously metering system

ActiveCN1570572ATemperature does not dropGuaranteed liquidityVolume flow measuring devicesVolume/mass flow by differential pressurePunchingOil field

This is a continuous measuring system of tri-phase flux that consists of oil, gas and water. The system comprises horizontal tri-phase analyzer, level gauge, electric control valve, hydraulic pump punching sand, gas flow counter, oil duct counter, watercourse counter, pressure sensor and so on. This invention can be used to measure tri-phase flux of oil, gas and water in the oil field. It is characterized by adopting horizontal tri-phase analyzer used in small-sized highly effective oil chamber internally-arranged, and adopts observing and controlling scheme of pressurization and stability of bi-liquid-level, keeping pressure, water-oil interface in the water header and liquid level of oil chamber stable, carrying-off the effect about the fluctuation of incoming gas flow or incoming liquid flow to the separating effect and measuring accuracy, increasing accuracy of flow discharged measuring and accomplishing series automatic gauging of oil, gas and water.

Owner:ZHEJIANG UNIV +1

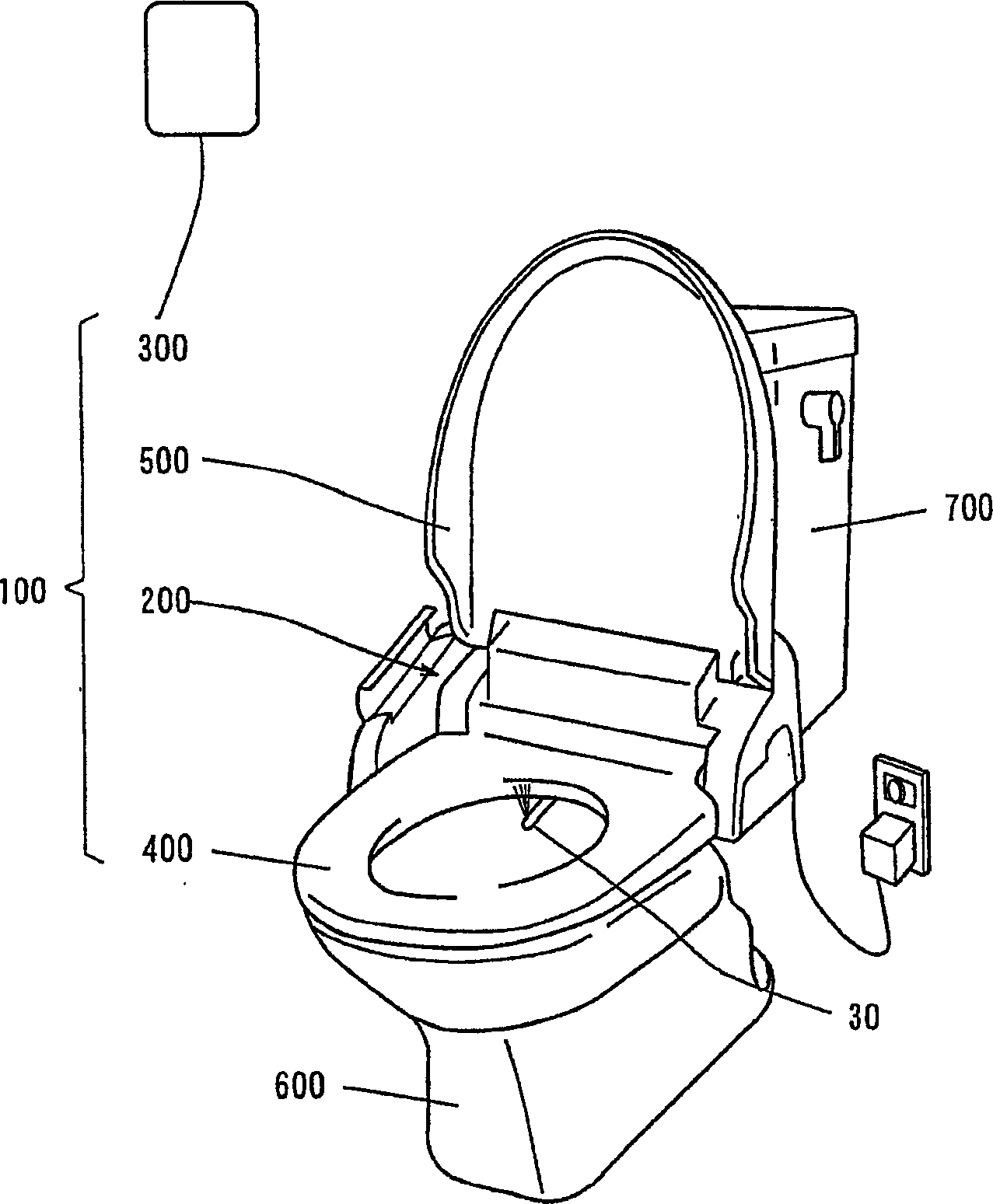

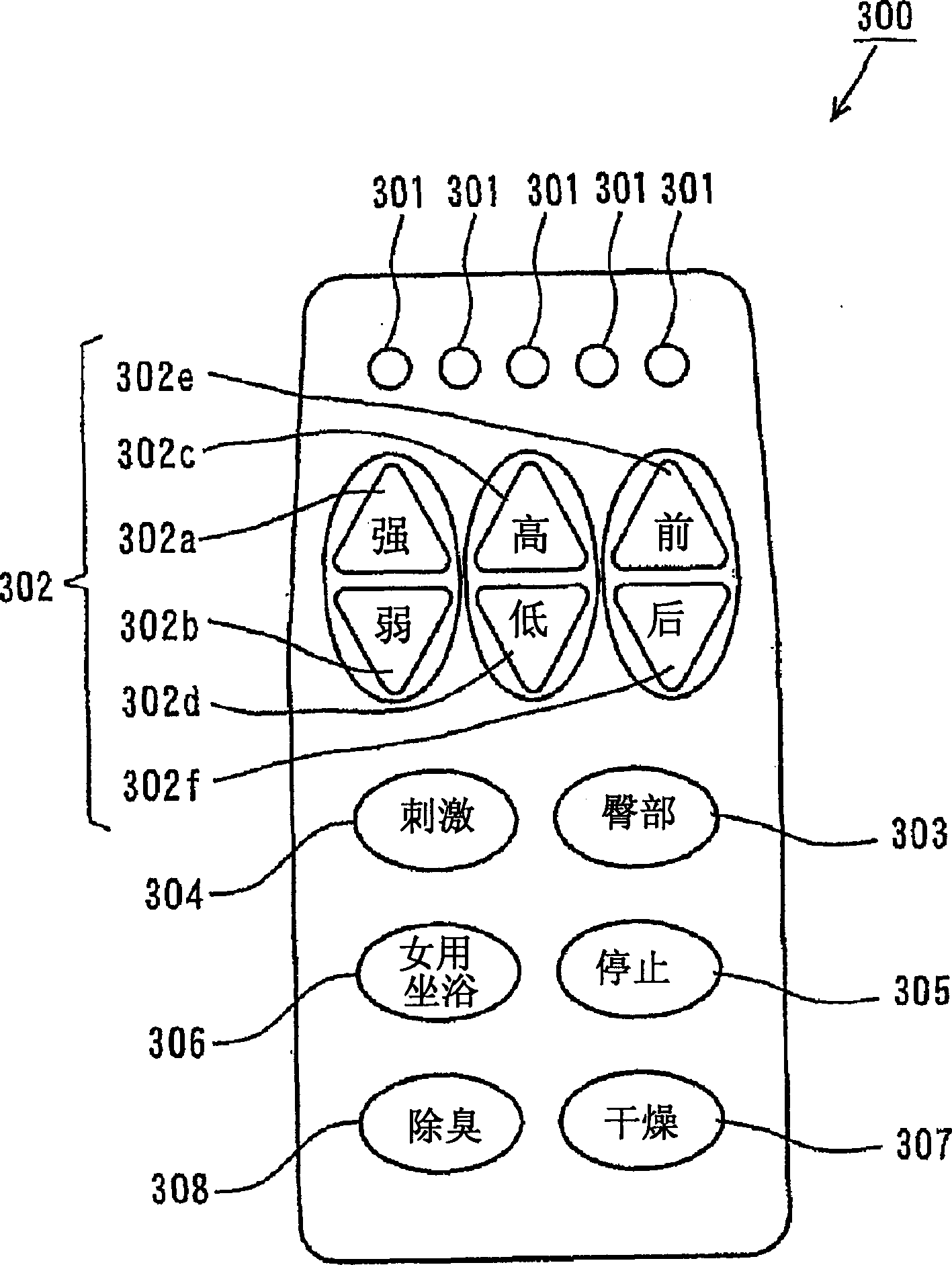

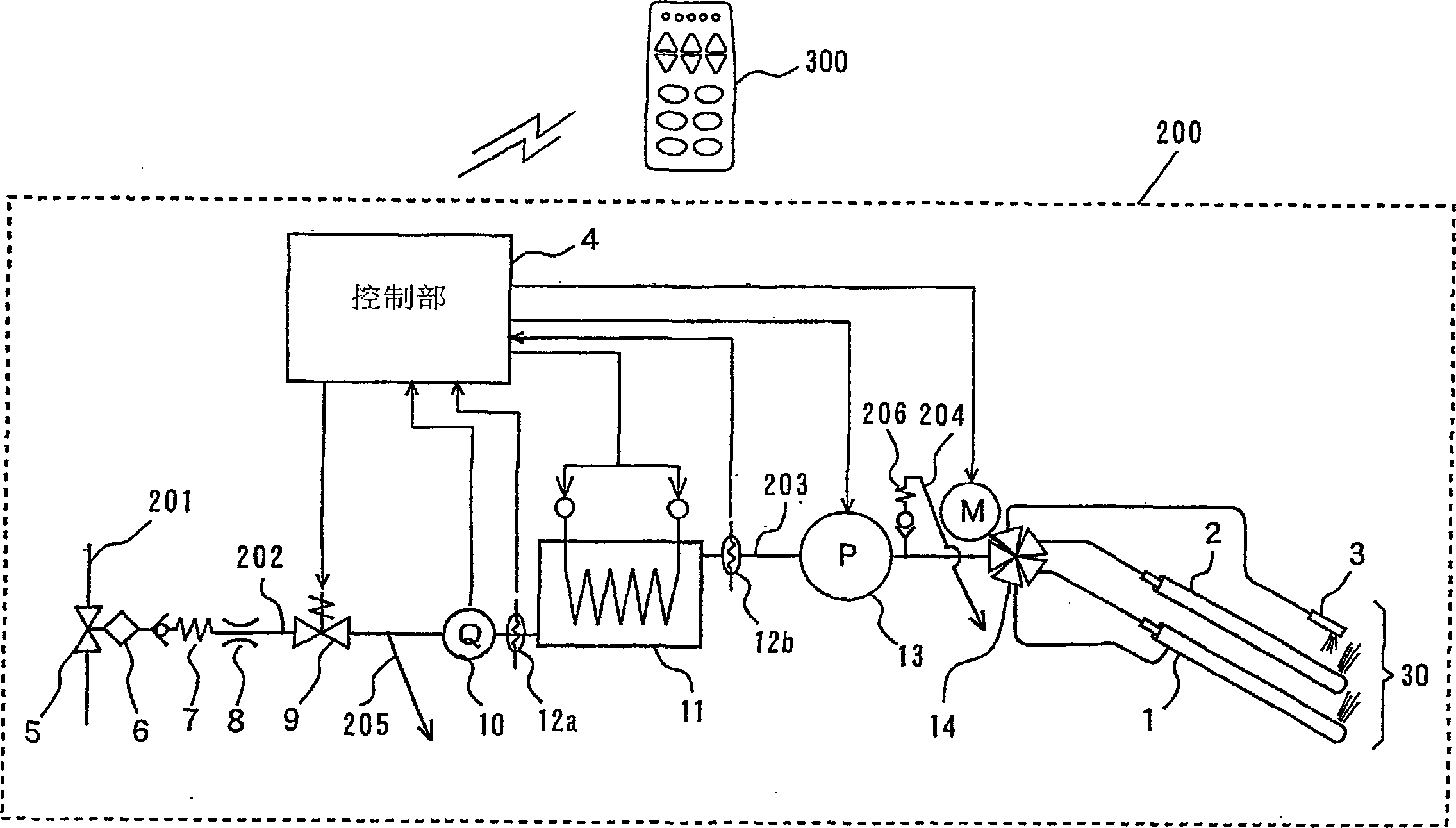

Nozzle device and hygienic washing device with same

Since the inner diameter of the constriction portion decreases continuously toward the cylindrical swirl chamber, the flow velocity of the washing water flowing through the constriction portion continuously increases. Since the inner diameter of the constriction portion is continuously reduced toward the spray hole, the flow velocity of the washing water flowing through the constriction portion is continuously increased. The washing water supplied to one channel of the second channel tube flows through the first channel tube and is supplied to the confluence of the channel channels. The washing water supplied to the other channel of the second channel tube flows through the space between the first channel tube and the nozzle cover, and then is supplied to the channel confluence part. The washing water sprayed from the nozzle washing hole spirally rotates along the outer peripheral surface of the piston in the space between the inner wall of the nozzle washing cylinder and the outer peripheral surface of the piston, and flows out from the front end opening of the nozzle washing cylinder. A position fixing piece having a curved surface shape along the inner surface of the front end portion of the nozzle cover is formed at the front end portion of the flow path confluence portion. Dispersed swirling streams are ejected alternately with straight streams during movement of the rear nozzle from the front position to the rear position.

Owner:PANASONIC CORP

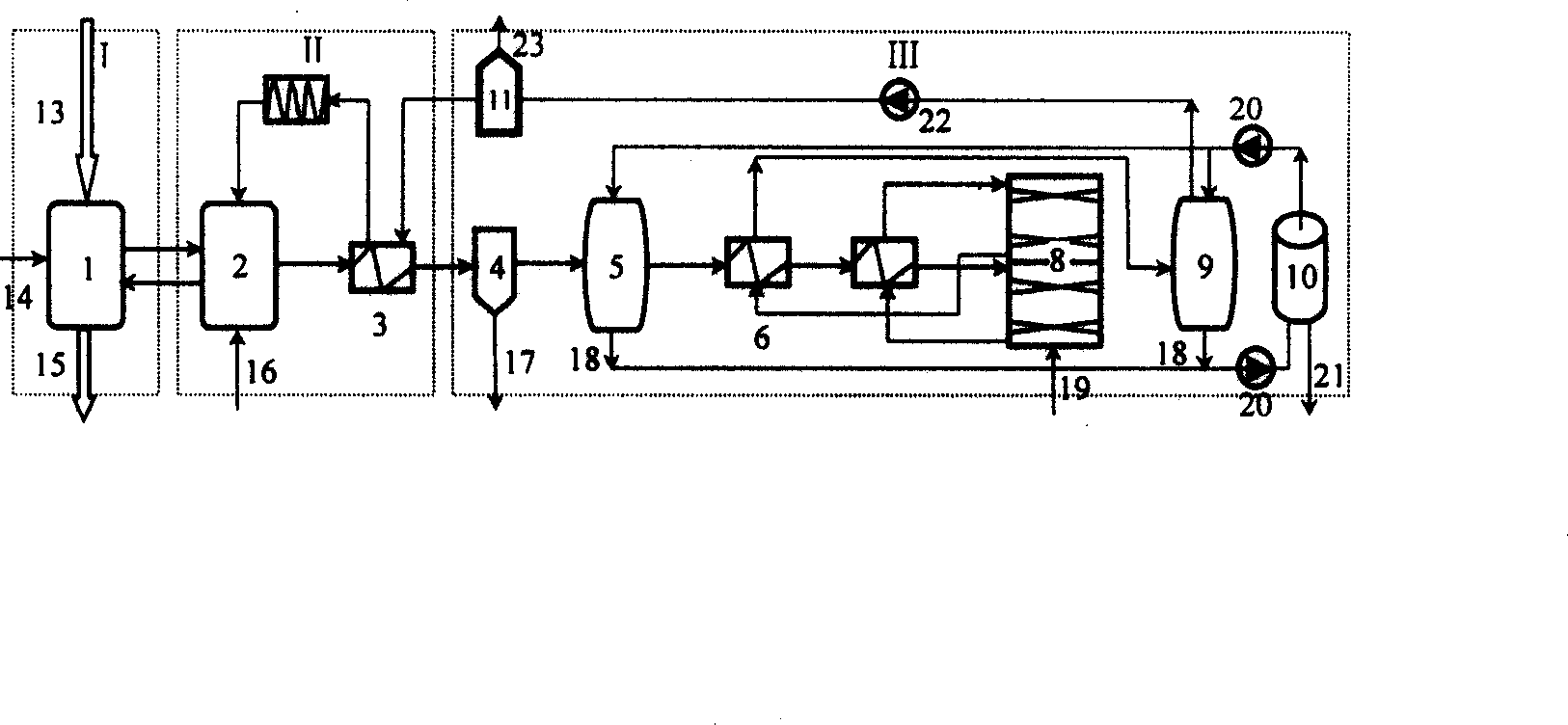

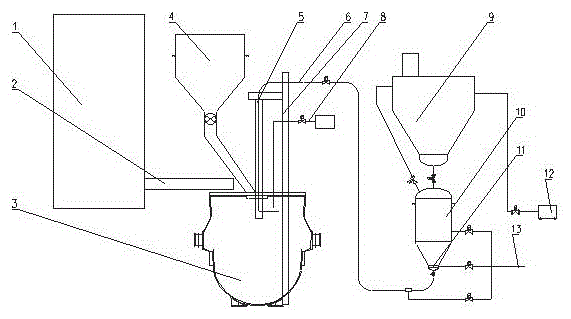

Desulfurizing technology and system with regenerable metal oxide as desulfurizing agent

InactiveCN1348830AReduce desulfurization costImprove system economyDispersed particle separationFossil fuelOxide

The present invention relates to regenerable metallic oxide sulfur removal technology and system, said system includes desulfurization part, regeneration part and by product treatment part. The desulfurizing agent is prepared by using regenerable metallic oxide active component as absorbent and assisted by catalyst, to remove SO2 in smoke in desulfurization reactor, the SO2 saturated desulfurizing agent is regenerated in regenerator to produce mixed gas containing high concentration SO2, SO3, which is then catalyzed, transferred and absorbed to obtain concentrated sulfuric acid by product with concentration higher than 92%. The sulfur removal efficiency can be higher than 88%, the sulfurizing agent can be cyclically reused, it is low in cost and has no secondary pollution.

Owner:孙学信 +1

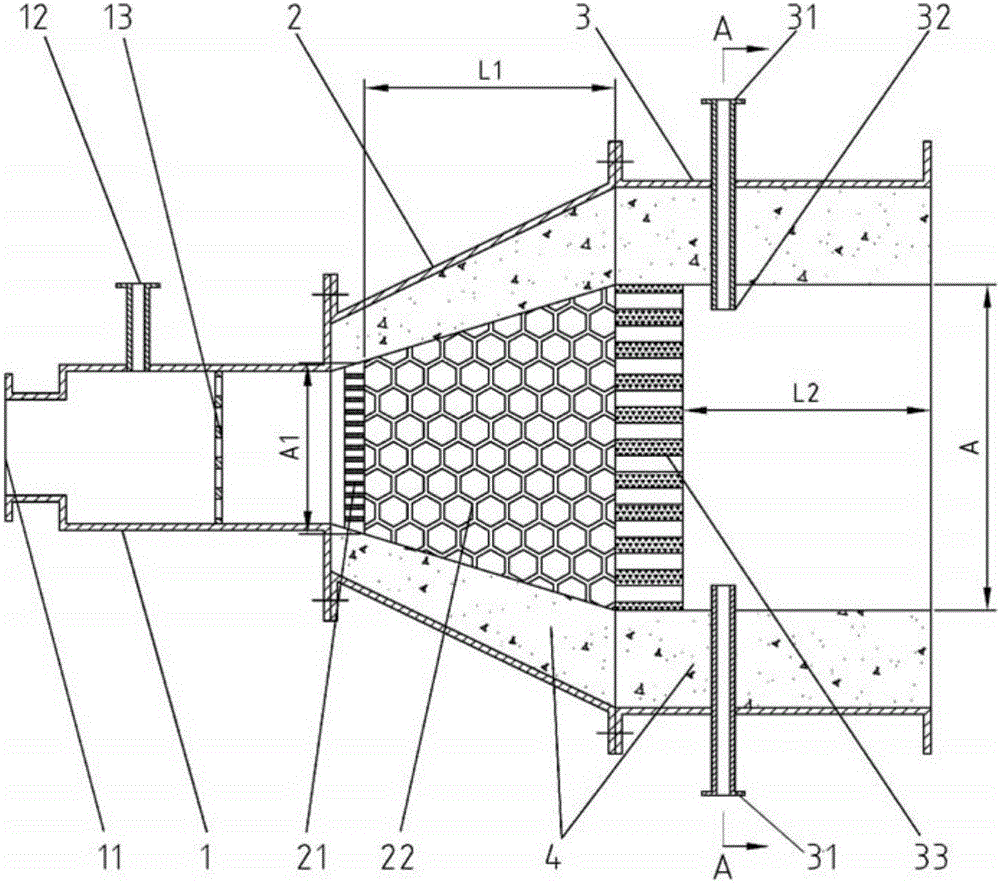

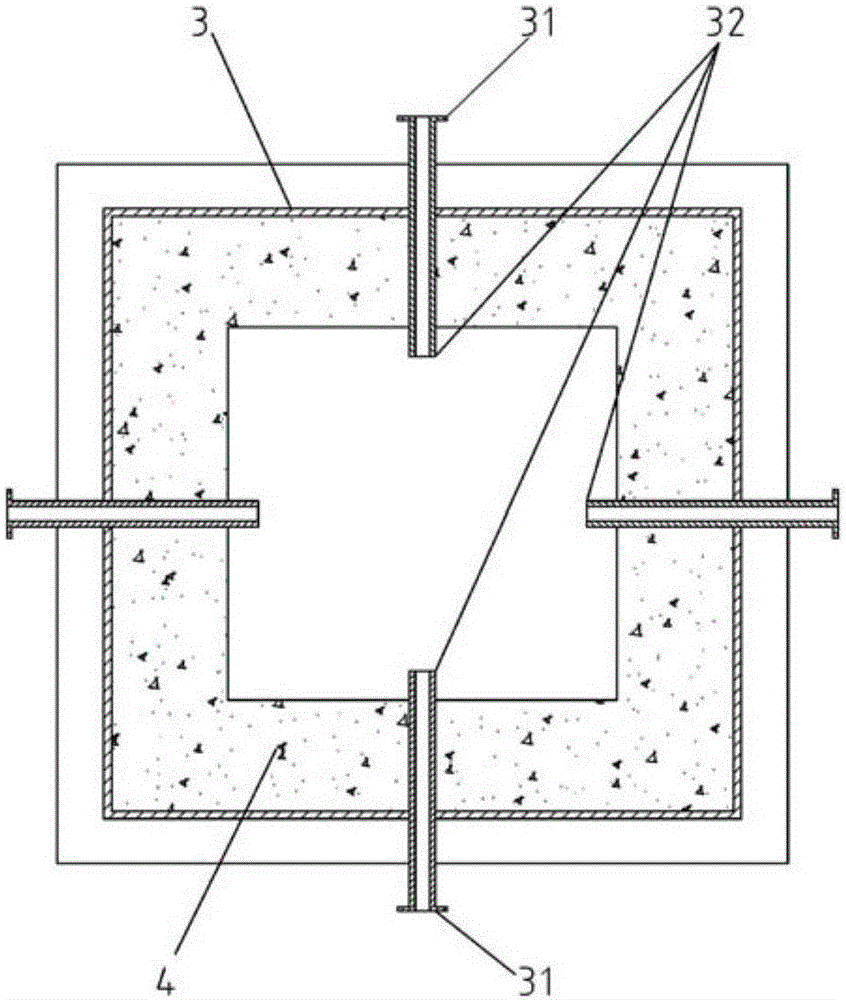

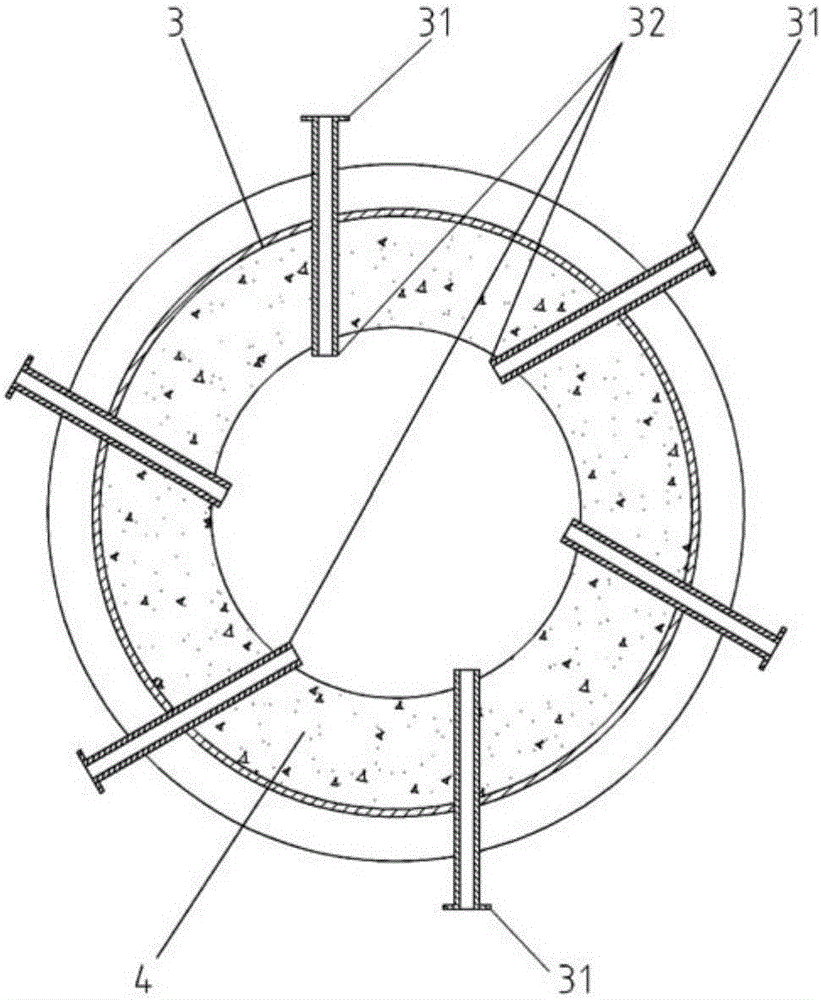

Gas burner and burning method achieving ultra-low nitrogen oxide emission

InactiveCN105805741APrevent backfireImprove securityNon-combustible gases/liquids supplyGaseous fuel burnerExhaust gasNitric oxide

The invention relates to the technical field of energy conservation, emission reduction and low-pollution burning, in particular to a gas burner and burning method achieving ultra-low nitrogen oxide emission. The gas burner achieving ultra-low nitrogen oxide emission comprises a mixer, a pre-mixing burning section and an after-burning section. Total gas is divided into primary fuel and secondary fuel; the primary fuel accounts for 25%-55% of the total gas and is evenly mixed with total combustion-supporting air, and emission of nitric oxide is restrained through the low-fuel-concentration pre-mixing burning principle; the secondary fuel accounts for 45%-75% of the total gas, and emission of the nitric oxide is restrained through the low-oxygen-concentration diffusive burning principle; and meanwhile the low content of residual oxygen in a burnt product is ensured, and the temperature of exhaust gas is high. In the pre-mixing burning section, ceramic porous filler is used as a medium for stable flames, and the stability of low-fuel-concentration pre-mixing burning is achieved; and the ceramic porous filler is of a divergent structure, so that tempering is effectively avoided, and safety is improved. Compared with a conventional burning mode, the nitrogen oxide emission can be reduced by 50%-90%, and the nitrogen oxide emission concentration under rated loads is lower than 30 mg / m<3>.

Owner:王建学

Method for manufacturing electric arc furnace fume heat insulating pipe and electric arc furnace fume heat insulating pipe

ActiveCN102979994ATemperature does not dropThermal insulationPipe protection by thermal insulationFiberAsbestos sheet

The invention relates to a method for manufacturing an electric arc furnace fume heat insulating pipe and the electric arc furnace fume heat insulating pipe thereof. The method comprises the following steps of welding V-shaped screw clasp nails on the inner wall of a fume pipeline; brushing a coal tar paint on the inner wall of the pipeline and the thread clasp nails; paving an aluminum silicate layer in the pipeline which is welded with the thread clasp nails and brushed with the coal tar paint; adding a steel wire net on the aluminum silicate layer; adding an asbestos plate on the galvanized steel wire net, and brushing an asphalt paint and a volatile agent on the asbestos plate; and using a ceramic fiber casting material to cast the asbestos plate, and carrying out plastering treatment, so as to obtain the electric arc furnace fume heat insulating pipe. The method for manufacturing the electric arc furnace fume heat insulating pipe can be used for manufacturing the electric arc furnace fume heat insulating pipe with the advantages that the heat insulating effect is good, and the service life is long.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Intermixture briquette obtained by direct alloying of V2O5 and application method thereof

The invention relates to an intermixture briquette obtained by direct alloying of V2O5 and an application method thereof. The technical scheme is as follows: the raw materials and the contents of the intermixture briquette are as follows: 10-25 wt% of V2O5 powder, 5-20 wt% of reducing agent, 50-75 wt% of additive and 5-15 wt% of water glass. A preparation method of the intermixture briquette obtained by direct alloying of V2O5 comprises the following steps of: adding the V2O5 powder, the reducing agent and the additive according to the raw materials and the contents, adding water glass, uniformly stirring, briquetting and drying to obtain the intermixture briquette obtained by direct alloying of V2O5. According to the invention, the prepared intermixture briquette has the advantages of quick V2O5 reduction speed, high yield of vanadium, simple and easy operation, capability of obtaining the required middle-low carbon vanadium-containing micro-alloy steel at a single step, and remarkable economic benefit.

Owner:WUHAN UNIV OF SCI & TECH

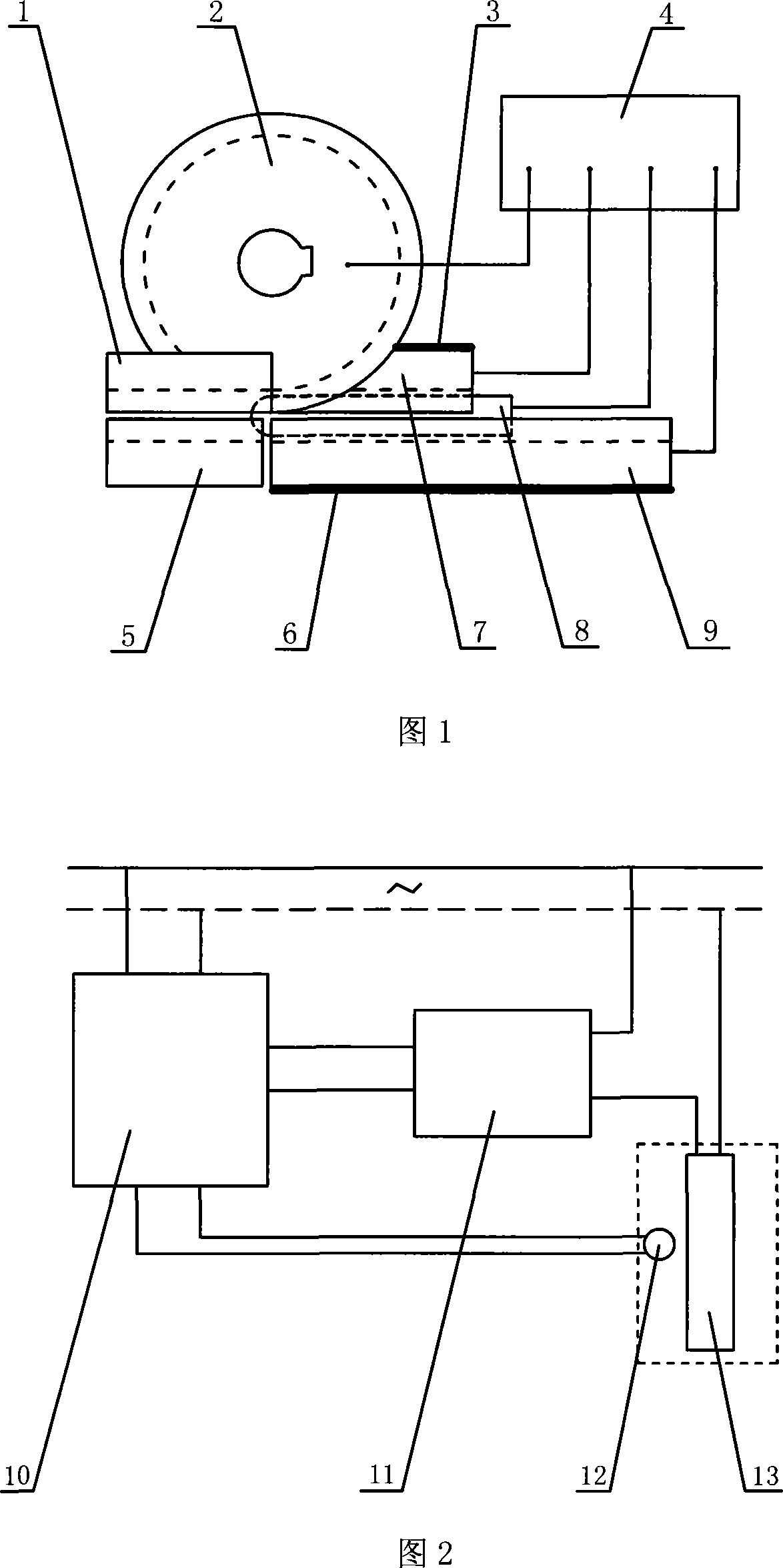

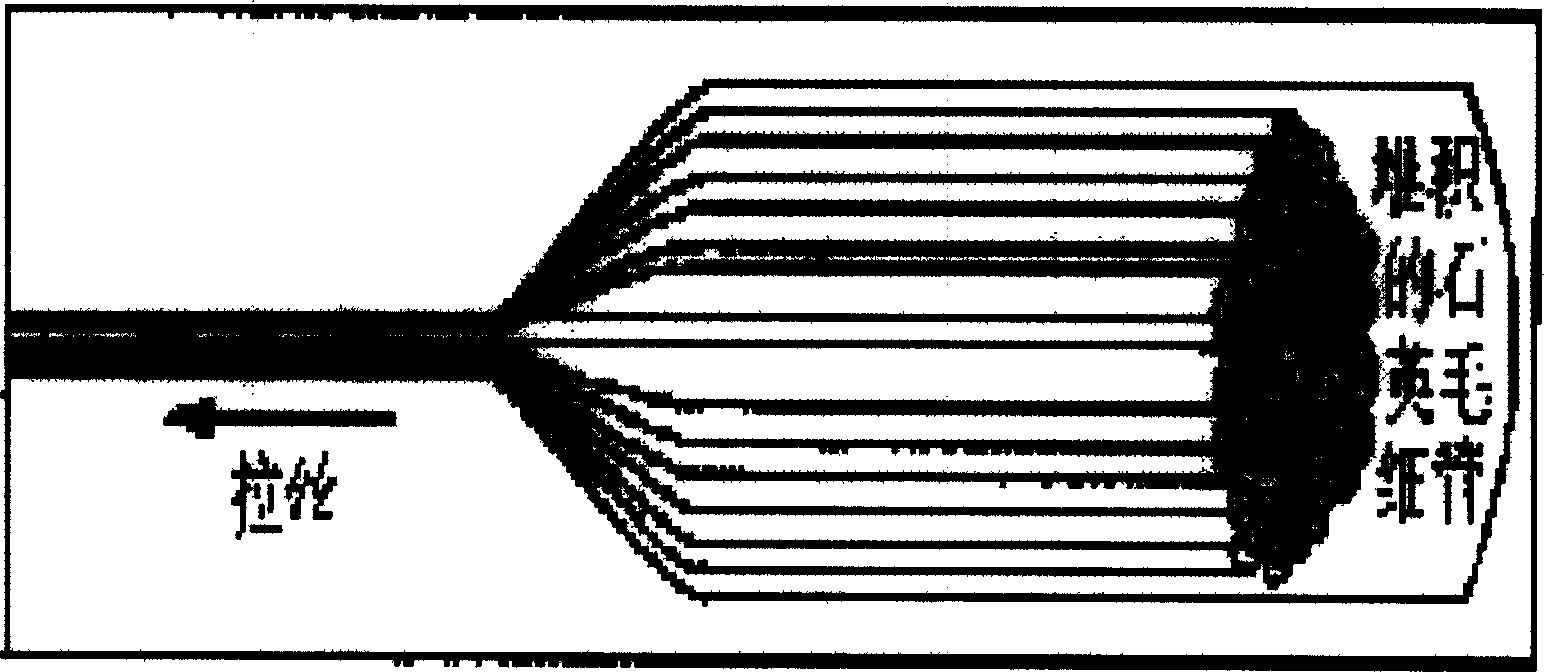

Continuously extruding method and extruding device of non-radial feeding

The invention discloses a continuously extruding method of non-radial feeding, comprising the steps of a, depressing the blank by a compaction wheel and enabling the blank to enter into an extruding tool due to the friction force generated by rotating the groove of an extruding wheel and the blank; b, enabling the blank to enter into the feed port of an extruding tool after the blank advances to a stop block, wherein the center line of the feed port of the extruding frock is at the chord direction of the extruding wheel; c, extruding the product from the die and fast cooling the product through a jet cooling device by arranging a metal molding cavity at the tail end of the feed port of the extruding tool and arranging a die at the tail end of the metal molding cavity. Different from the continuous channel corner extrusion, in the whole working process of which the geometrical shape of the blank basically remains the same, the continuously extruding method and extruding device of non-radial feeding disclosed by the invention aim at obtaining high-performance materials of fine grain tissue finally by shear deformation.

Owner:大连康丰科技有限公司

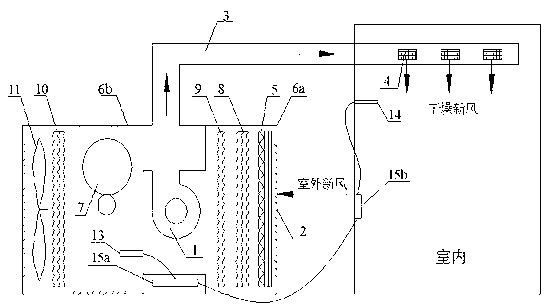

Building micro-ventilation system for improving indoor air quality and humidity environment

InactiveCN102840638AEffective filteringMeet fresh air demandSpace heating and ventilation safety systemsLighting and heating apparatusAir filtrationResidence

The invention discloses a building micro-ventilation system for improving indoor air quality and humidity environment, comprising an air-supply subsystem, an air filtering device, a dehumidifying subsystem and a smart control subsystem. The building micro-ventilation system is used for providing fresh air to a building, and capable of filtering, drying and dehumidifying the fresh air according to requirements; therefore, the system is capable of effectively adjusting the indoor humidity, improving the indoor air quality environment, avoiding outdoor noise interference and preventing rainwater from entering the indoor space, guaranteeing the health and comfort of people staying in the indoor space and preventing the building and articles in the indoor space from being moisturized and mildewed; as a result, the building micro-ventilation system is suitable for improving the indoor environment of buildings such as villas, high-grade residences, hotel guest rooms and the like in humid areas, in particular for improving the indoor air quality and the humidity environment of residential buildings in central urban areas and besides heavy traffic roads.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

Three-chamber type intelligent periodically controllable atmosphere furnace

InactiveCN1800763AAvoid wastingReduce the temperatureMuffle furnacesMaintainance of heating chambersHydraulic cylinderMaterial synthesis

The invention relates to a nanometer material composite technique, belonging to a intelligent periodic controllable furnace for using phase method to continuously prepare the nanometer material. The inventive furnace is formed by a feeding room, a reaction room, and a discharging room. Wherein, two water-cooling transition areas are arranged between the reaction room and the feeding room, the reaction room and the discharging room. In production, putting the raw material in the material disc to be fed into feeding room; using hydraulic cylinder to push the material disc into reaction room; using another hydraulic cylinder to draw the reacted product from reaction room into discharging room to be cooled; and the feeding and discharging of material can be processed synchronously; the temperature of reaction room only need one increase, and the production can be continuously processed by keeping the working temperature. Compared to single-room furnace, it can improve the producing efficiency and the service life of reaction furnace and save the energy.

Owner:QINGDAO UNIV OF SCI & TECH +1

Method for tempering high temperature slag and mineral cotton production method

InactiveCN104986961AExcellent performanceTemperature does not dropGlass making apparatusAluminiumOxygen supply

A method for tempering high temperature slag and a mineral cotton production method belong to the metallurgical technical field of steel, ferronickel, ferromanganese, copper and the like. A tempering process is carried out by spraying coal ash, dolomite, aluminum ash and the like by using a heat-resistant spray gun, and the mixture is heated by using a heating agent in an oxygen blowing manner; moreover, by virtue of a sufficient condition of pouring hot slag into a slag tank in kinetics, the used equipment comprises a powder spraying system and an oxygen supply system. According to the components of the hot slag, a corresponding tempering agent is sprayed into the slag and the heating agents such as aluminum ash and the like are added to be in reaction with oxygen; the tempering agent is prompted to be fully mixed with the slag by virtue of flowability of the hot slag pouring into the slag tank so as to quickly form a silicate system; the heating agents are added, so that the slag temperature is not reduced, and a slag tank cover further covers the tank, so that the heat loss is reduced. Thereofe, the component is tempered into the slag blowing slag wool, the temperature of which is proper, and the viscosity is 1-3Pa.s. The problem that the slag is hardly mixed with the tempering agent and a temperature drop happens is solved. A melting furnace (an electric furnace) is not needed for secondary heating, so that the method has a relatively high economical benefit. The slag tank with a top cover is conveyed to a mineral cotton workshop and a travelling crane conveys the slag tank to a pouring site. Then, the slag tank is overturned by using a winch, and a slag fluid in a fixed quantity is controlled to enter a closed and heated blowing tank from an upper opening of the slag tank. The slag fluid in the fixed quantity enters the closed and heated blowing tank from the upper opening of the slag tank, so that the problem that in production of mineral cotton, the slag fluid amount is unstable as the height of the liquid level of a slag tank is different and the pressure of the liquid level is different in a manner that the melt is discharged from the bottom of the tank and the problem that the bottom-discharged slag blowing tank is blocked as the slag temperature is reduced are solved.

Owner:CHINA JINGBLUE BEIJING ENVIRONMENTAL ENG CO LTD

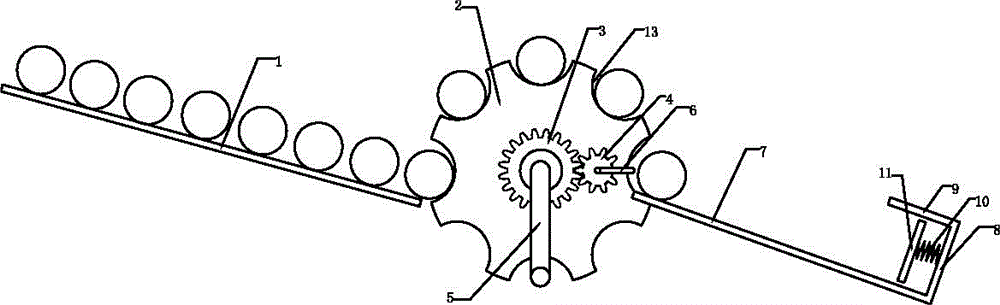

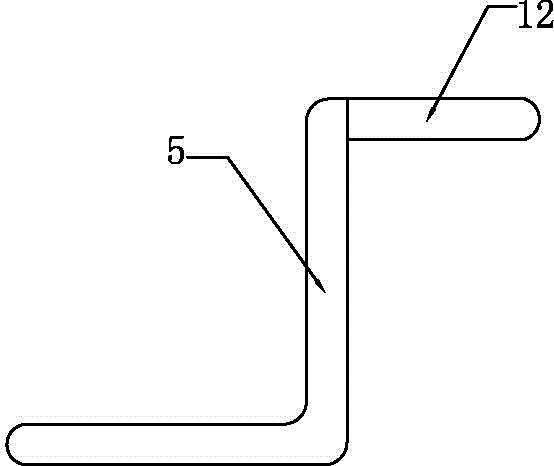

Ice cream vending machine

InactiveCN104966354AReduce labor intensityImprove work efficiencyCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringIce cream

The invention discloses an ice cream vending machine which comprises a rotating disc. The left side of the rotating disc is provided with a feeding plate, material grooves are circumferentially distributed on the rotating disc, the center of the rotating disc is connected with a rotation shaft, the rotation shaft is connected with a first gear, and the right side of the first gear is provided with a second gear in a meshed mode; the center of the second gear is connected with a material pushing rod, the length of the material pushing rod is larger than the distance from the center of the second gear to the material groove close to the second gear, the lower portion of the material groove close to the second gear is provided with a discharging plate used for receiving materials, and the feeding plate and the discharging plate each has an included angles with a horizontal plane and are inclined upwards. According to the ice cream vending machine, ice cream can be conveniently taken out, and electric energy can be saved.

Owner:ZHEJIANG HUAWEI WEIYE INTELLIGENT TECH CO LTD

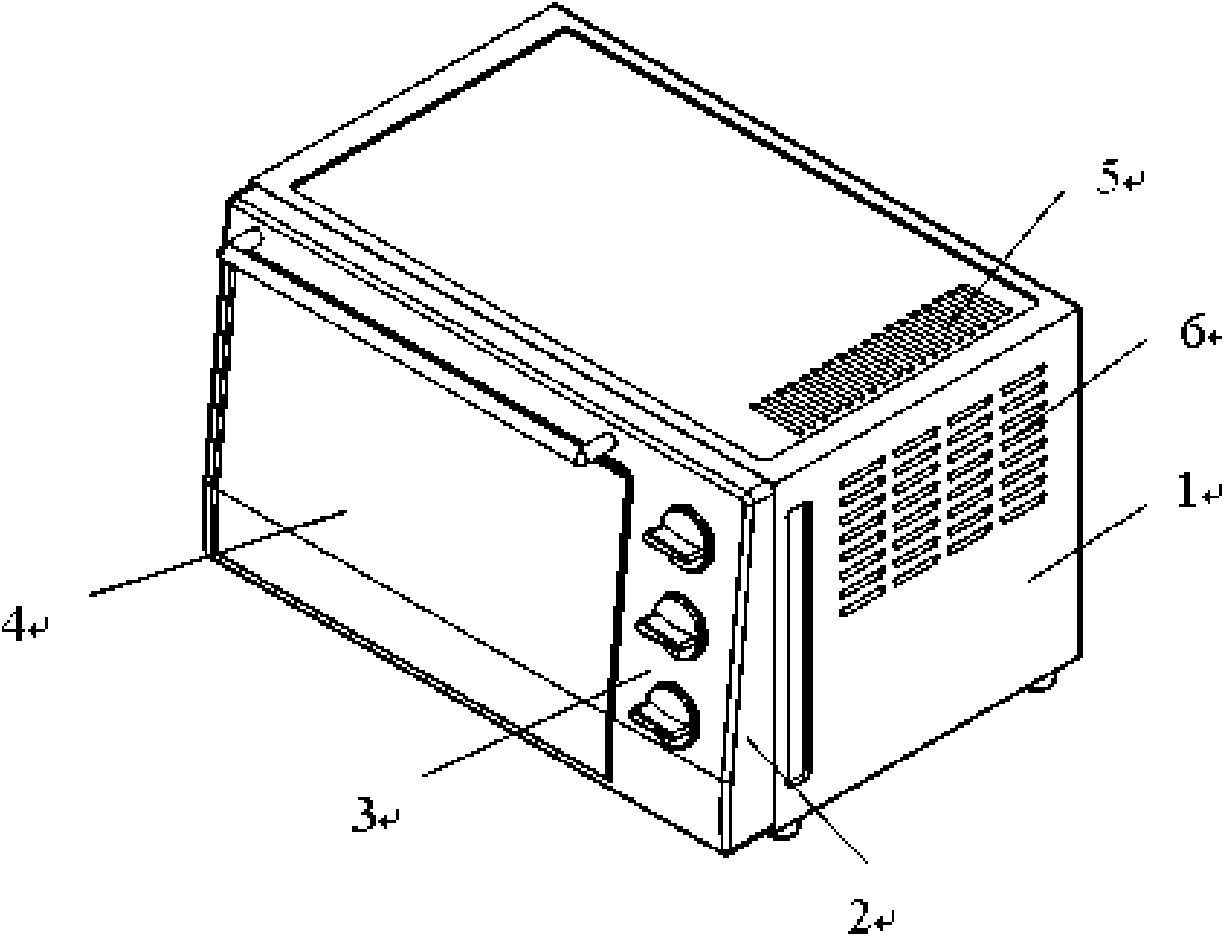

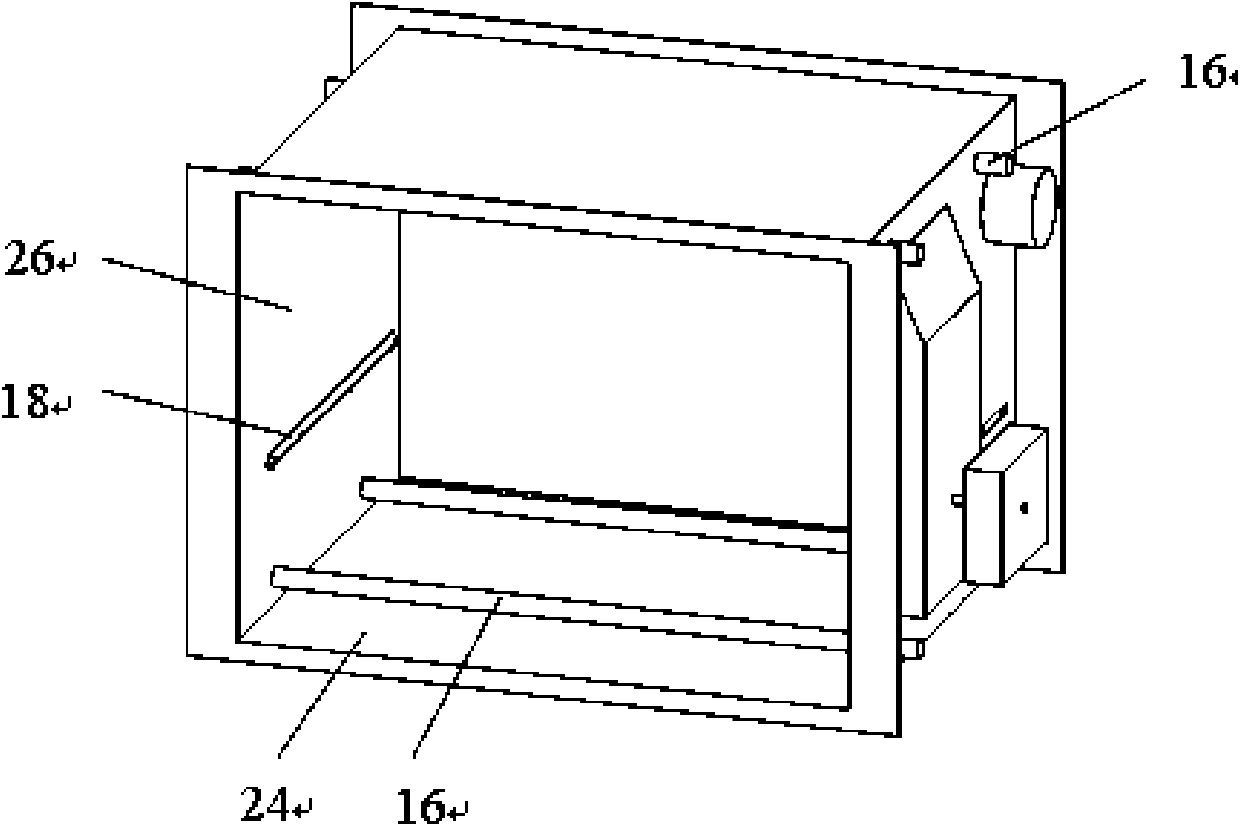

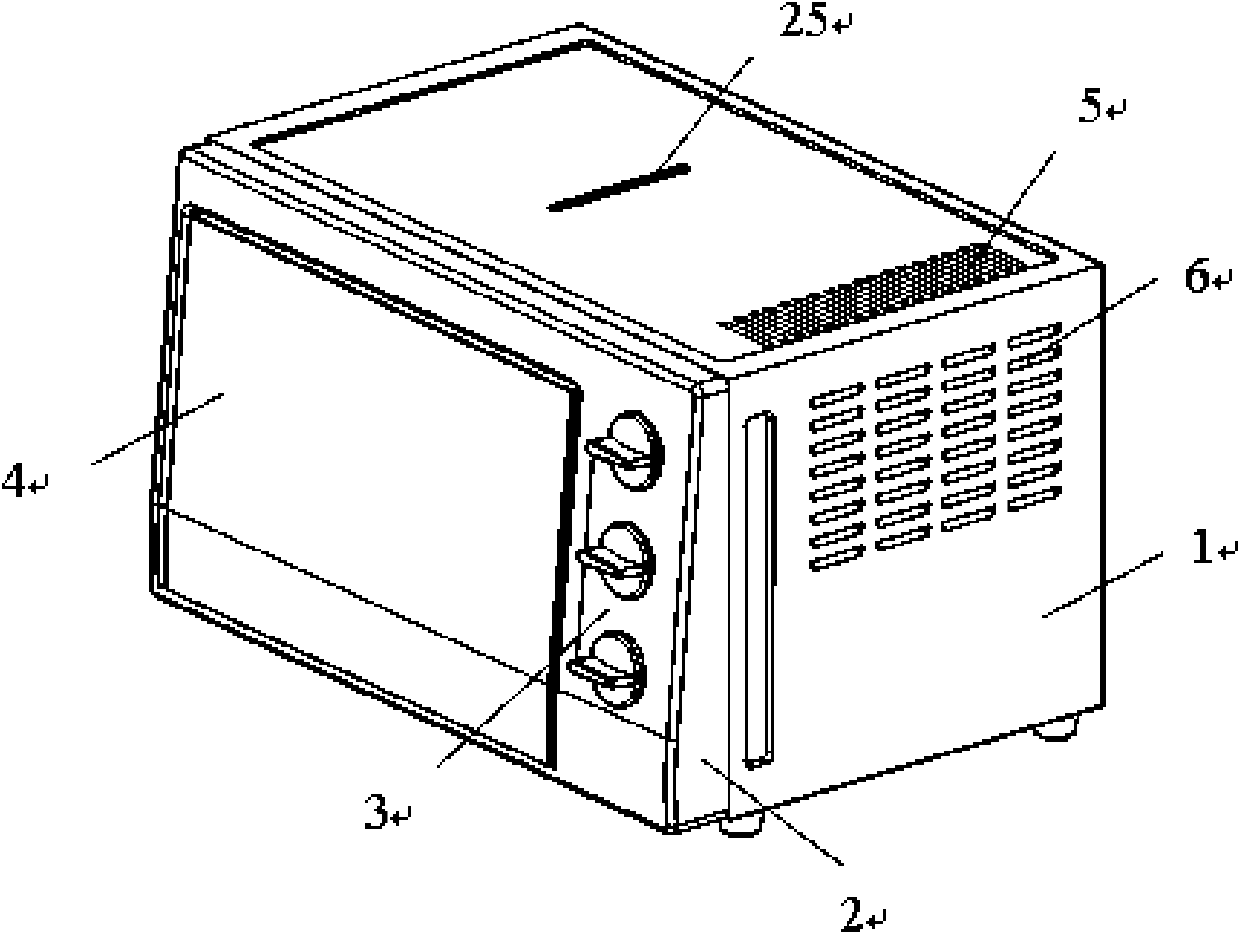

Electric oven with oily fume removal device

The invention discloses an electric oven with an oily fume removal device, comprising a shell, an oven door, a control panel, an electric apparatus room and a cavity, wherein the shell forms the appearance and is internally provided with the cavity for forming a furnace chamber, and the oven door is connected to the shell. The electric oven is characterized by also comprising an oily fume removal device installed on the upper part of the chamber. The oily fume removal device is composed of a motor, a fan, an air vent net below the fan, a filter and a fan cover, wherein the motor is connected to the upper wall of the cavity, the fan is driven by the motor to rotate and is vertically installed, the filter is installed on the side surface of the fan and vertical to the top surface of the shell, and the fan cover is covered outside the fan and the filter. The electric oven has the effect on removing oily fume in the electric oven without lowering temperature in the hearth chamber. Thus, influence of the oily fume on the inner wall of the furnace chamber and indoor environment can be effectively avoided; and meanwhile, the visibility of the electric oven furnace chamber is improved to obtain good observation effect. The electric oven is novel in design, convenient to use, and simple in structure, and has good safety and good customer perception, thereby increasing selling points.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com