Nozzle device and hygienic washing device with same

A nozzle device and sanitary washing technology, which is applied to sanitary equipment for toilets, water supply devices, buildings, etc., can solve the problems of reduced washing water flow rate, insufficient washing, low washing water density, etc., and achieve pressure loss. Small, miniaturized sanitary cleaning device, easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

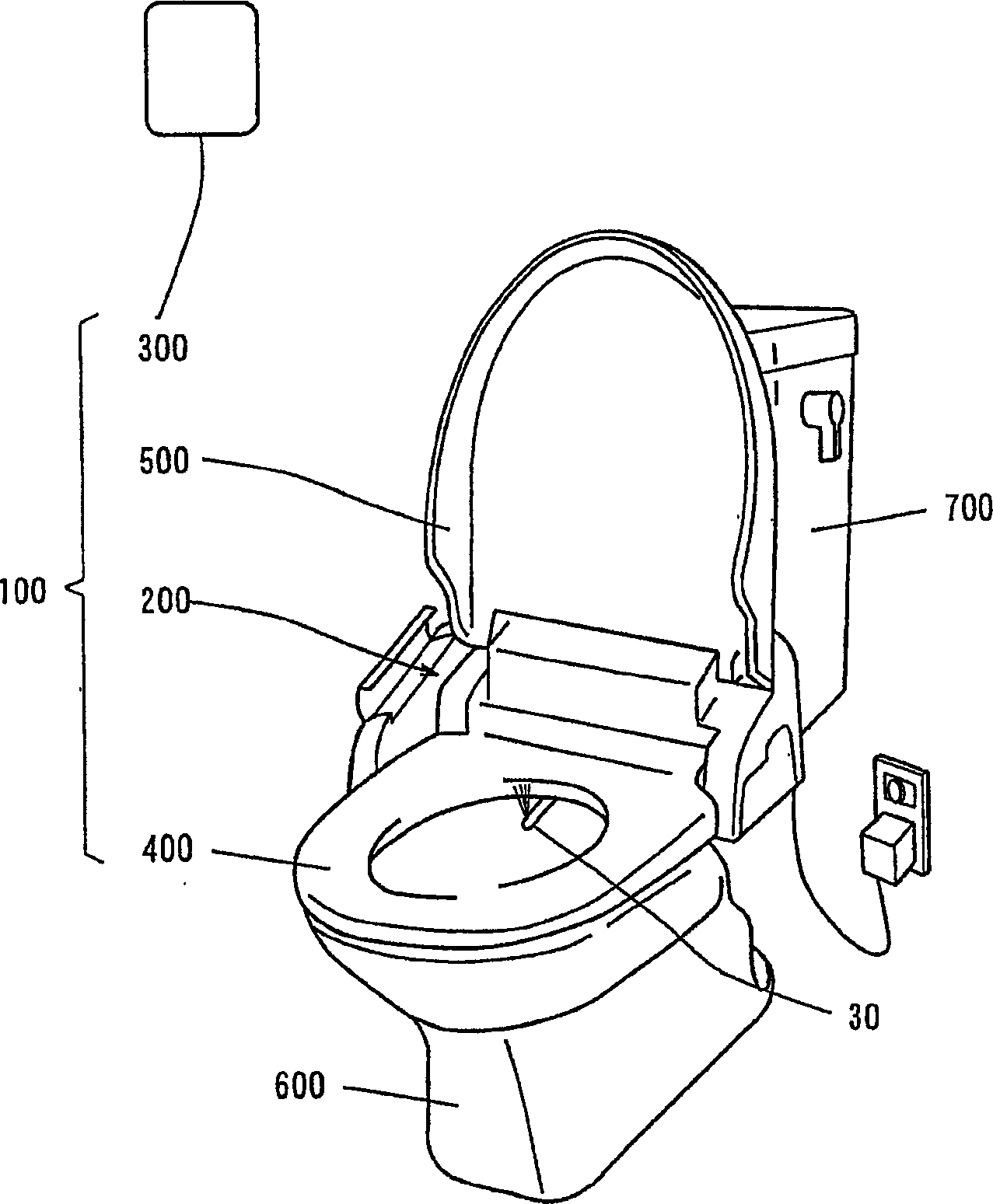

[0172] figure 1 It is a perspective view showing a state in which the sanitary washing device according to Embodiment 1 of the present invention is attached to a toilet.

[0173] Such as figure 1 As shown, the sanitary washing device 100 is installed on a toilet 600 . The water tank 700 is connected to a water pipe to supply flush water into the toilet 600 .

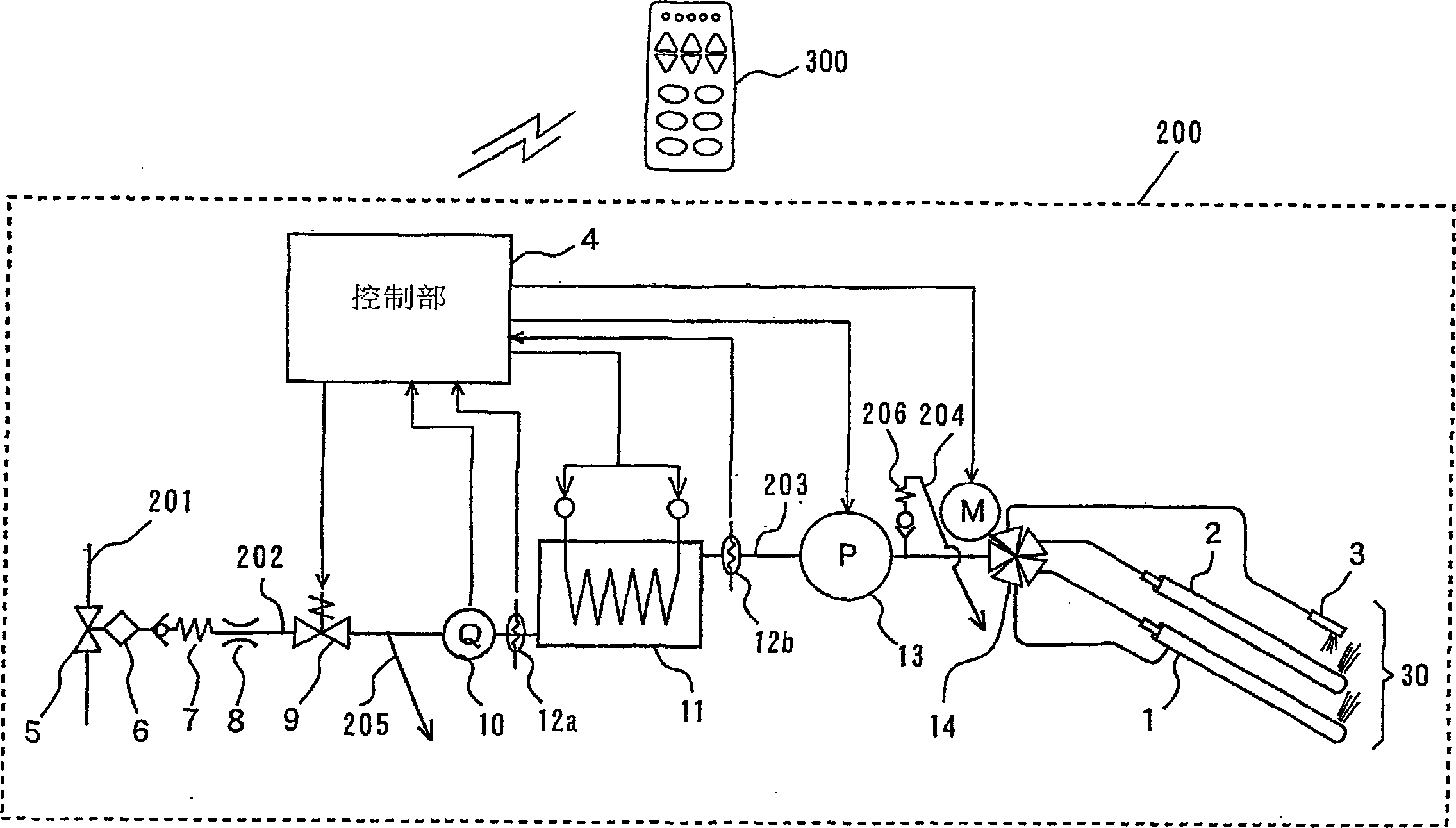

[0174] The sanitary washing device 100 is composed of a main body 200 , a remote control device 300 , a toilet seat 400 and a cover 500 .

[0175] The toilet seat part 400 and the cover part 500 are attached to the main body part 200 openably and closably. Furthermore, a washing water supply mechanism including a nozzle unit 30 is provided on the main body unit 200, and a control unit is incorporated therein. The control unit of the main body unit 200 controls the washing water supply mechanism based on a signal transmitted from the remote control device 300 as will be described later. Moreover, the control part of ...

Embodiment 2

[0296] The difference between the structure of the piston part of the buttock nozzle 1 of the second embodiment and the structure of the piston part 20a of the buttock nozzle 1 of the first embodiment, and their effects will be described below with reference to the drawings.

[0297] Figure 22 (a) is a perspective view showing the piston part of the rear nozzle, Figure 22 (b) is an exploded perspective view showing the washing water supply part of the piston part. Figure 23 It is an exploded perspective view showing the piston part of the rear nozzle, Figure 24 (a) is a side view of the piston part 20a, Figure 24 (b) is a top view of the piston part 20a.

[0298] Such as Figure 22 As shown in (a), the piston part 20 a includes a nozzle cover 401 and a washing water supply part 420 . exist Figure 22 In (a), the nozzle cover 401 is shown by the dashed-dotted line. The washing water supply part 420 includes a second channel pipe 402c, a first channel pipe 403c, and ...

Embodiment 3

[0350] The difference between the structure of the main body portion of the sanitary washing device of Embodiment 3 and the structure of the main body portion 200 of the sanitary washing device of Embodiment 1 and their effects will be described below with reference to the drawings.

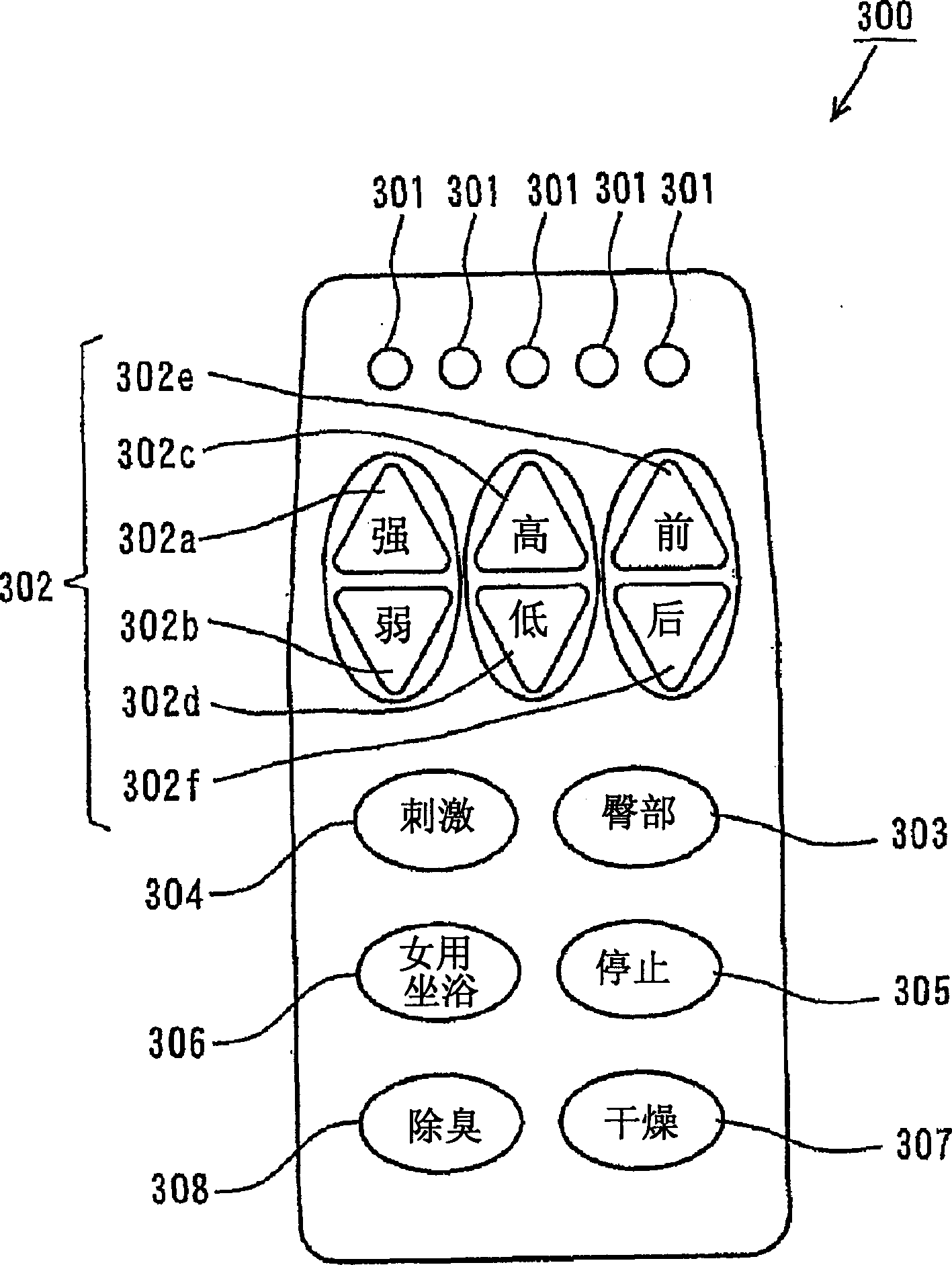

[0351] Figure 29 yes figure 1 A schematic diagram of another example of the remote operating device 300.

[0352] Such as Figure 29 As shown, the remote control device 300 is the same as that of Embodiment 1 figure 1 The difference of the remote control device 300 is that it also has a nozzle cleaning switch 309 and a nozzle high temperature cleaning switch 310 .

[0353] When the nozzle cleaning switch 309 is pressed, the nozzle part 30 is cleaned with washing water, and when the nozzle high temperature cleaning switch 310 is pressed, the nozzle part 30 is washed with the washing water heated to a high temperature. Details of the cleaning operation of the nozzle unit 30 performed by pressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com