Coal-fired flue gas dust-removing desulfurization and denitrification integrated compound technology system

A desulfurization and denitrification and composite process technology, which is applied in the field of coal-fired flue gas dust removal, desulfurization and denitrification integrated composite process system, can solve the problems of large equipment area, complex process, high investment and operation costs, and achieve investment saving and energy saving effect , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

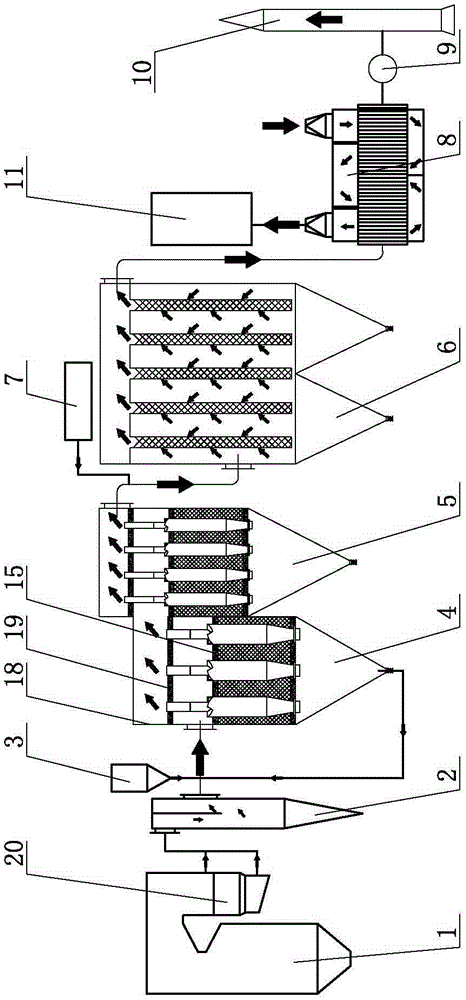

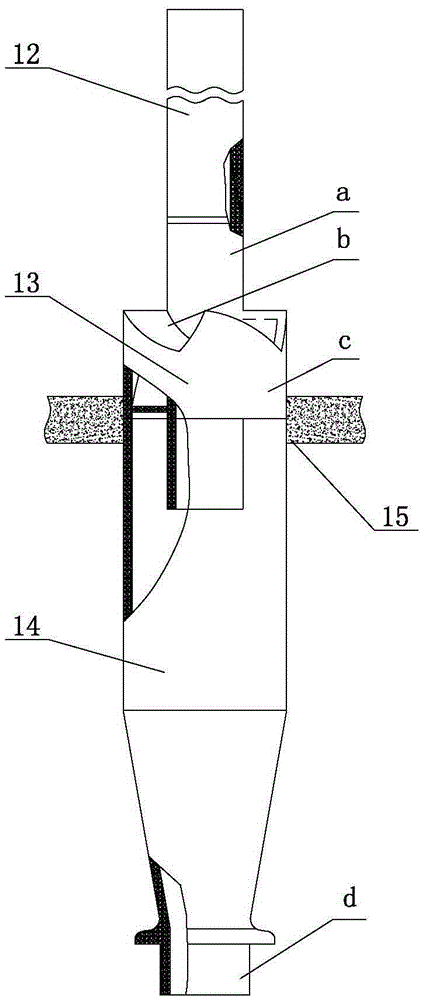

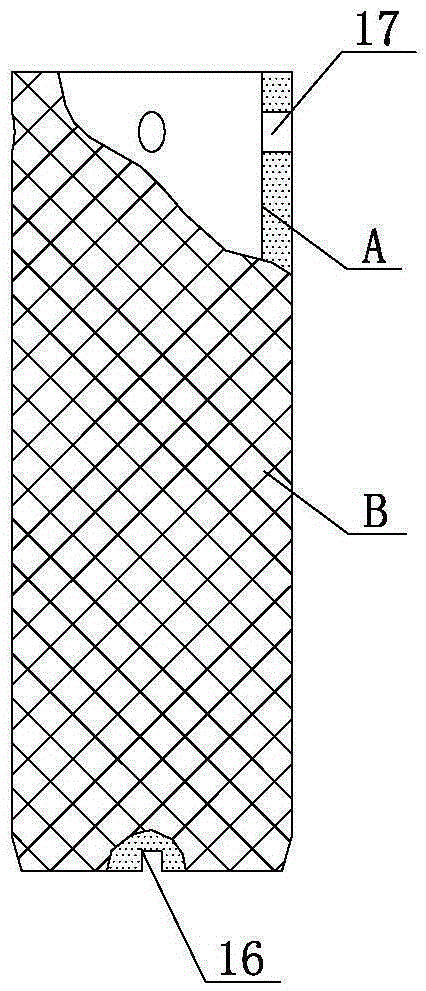

[0026] Such as figure 1 As shown, the coal-fired boiler flue gas dedusting, desulfurization and denitrification composite process system described in the patent of the present invention is mainly composed of a multi-tube dust collector, a ceramic filter membrane filter 6, a heat exchanger 8, an induced draft fan 9 and a vent chimney 10 through the pipeline in sequence Composed in series. The multi-tube dust collector can be a Dg250 multi-tube dust collector 4 or a Dg160 multi-tube dust collector 5 . Such as figure 2 As shown, the shape and structure of the dust removal unit of the multi-pipe dust collector is as follows: it is composed of an air guide pipe 12, a guide 13 and a cyclone 14 and is made as a whole. The guide 13 is composed of a straight pipe a, a helical blade assembly b and a cylinder c. The upper part of the cylinder c is provided with several V-shaped openings. The spiral blade assembly b is installed in the cylinder c. The spiral blade assembly b has at le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com