Patents

Literature

297results about How to "No explosion hazard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

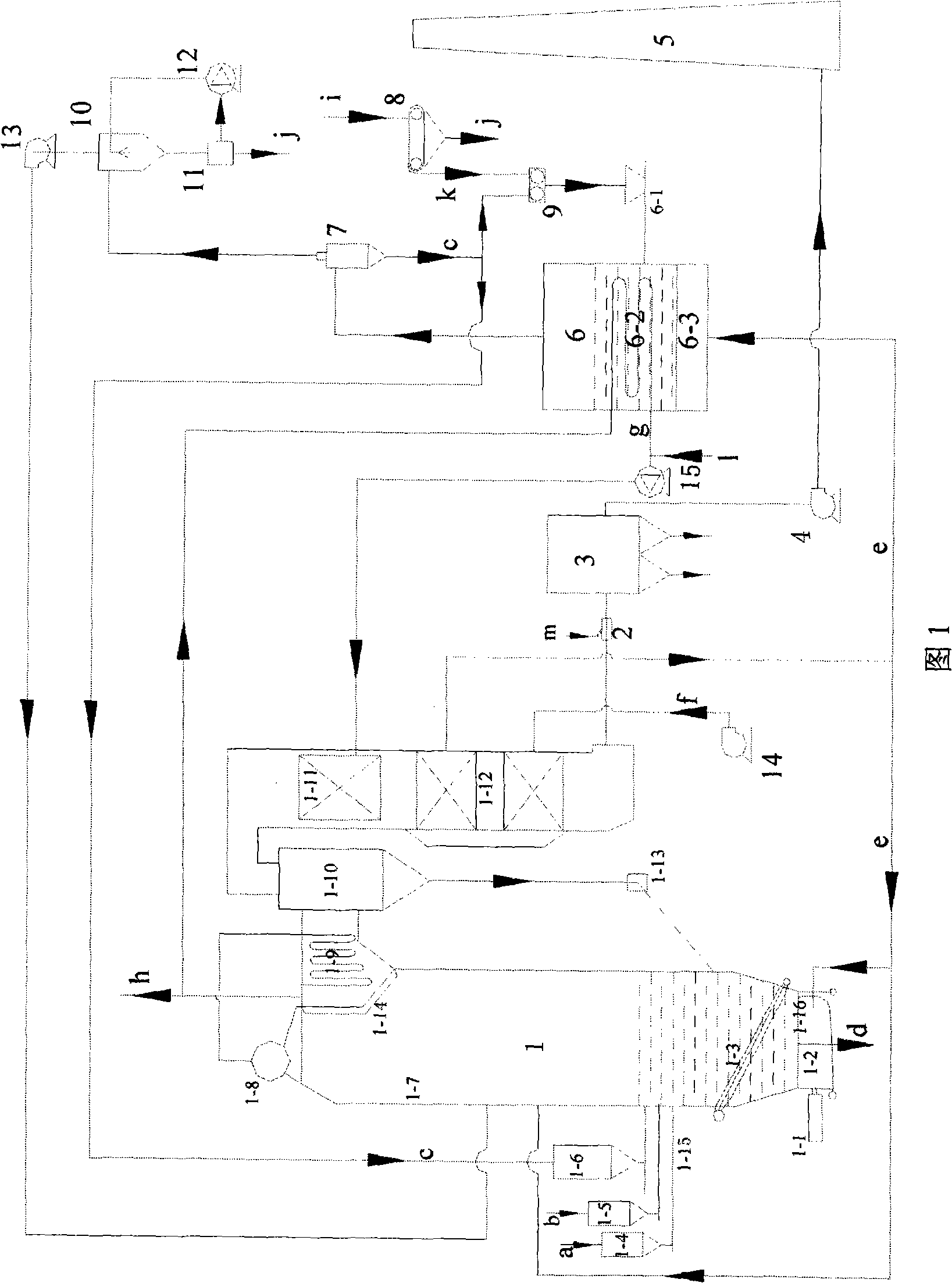

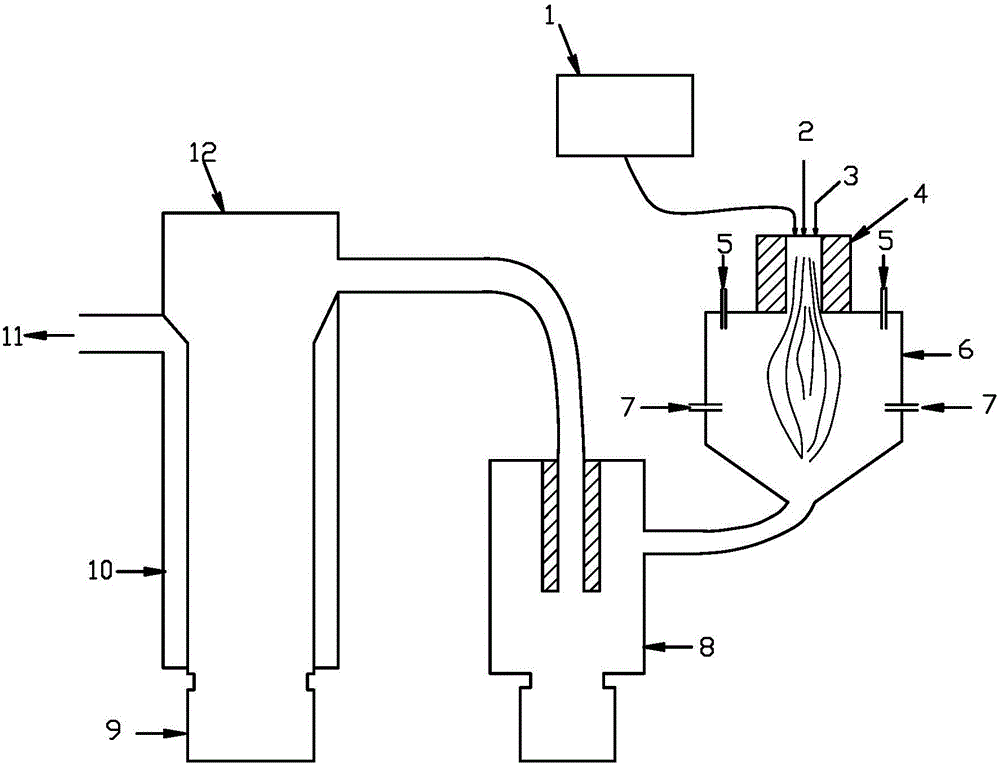

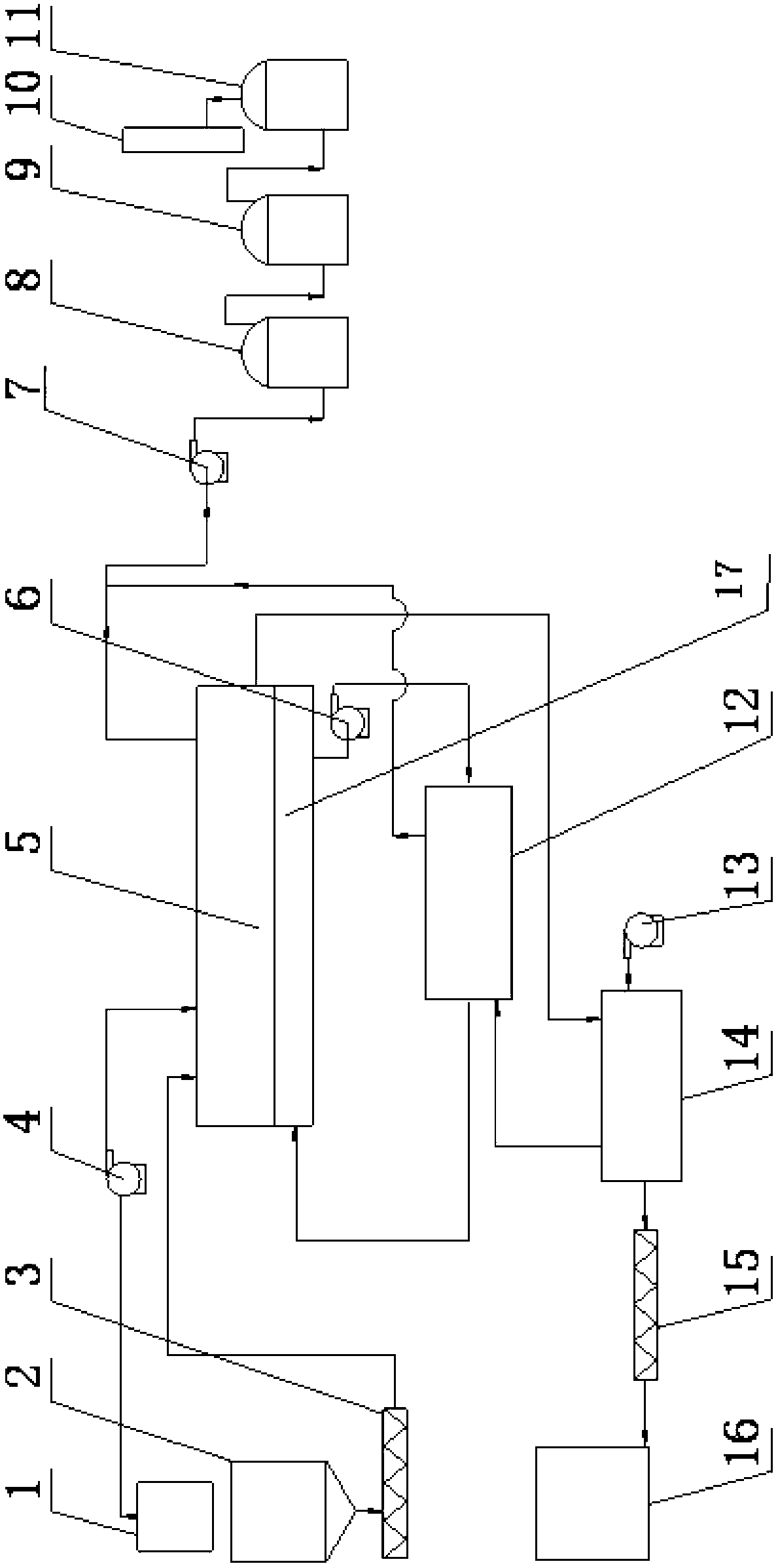

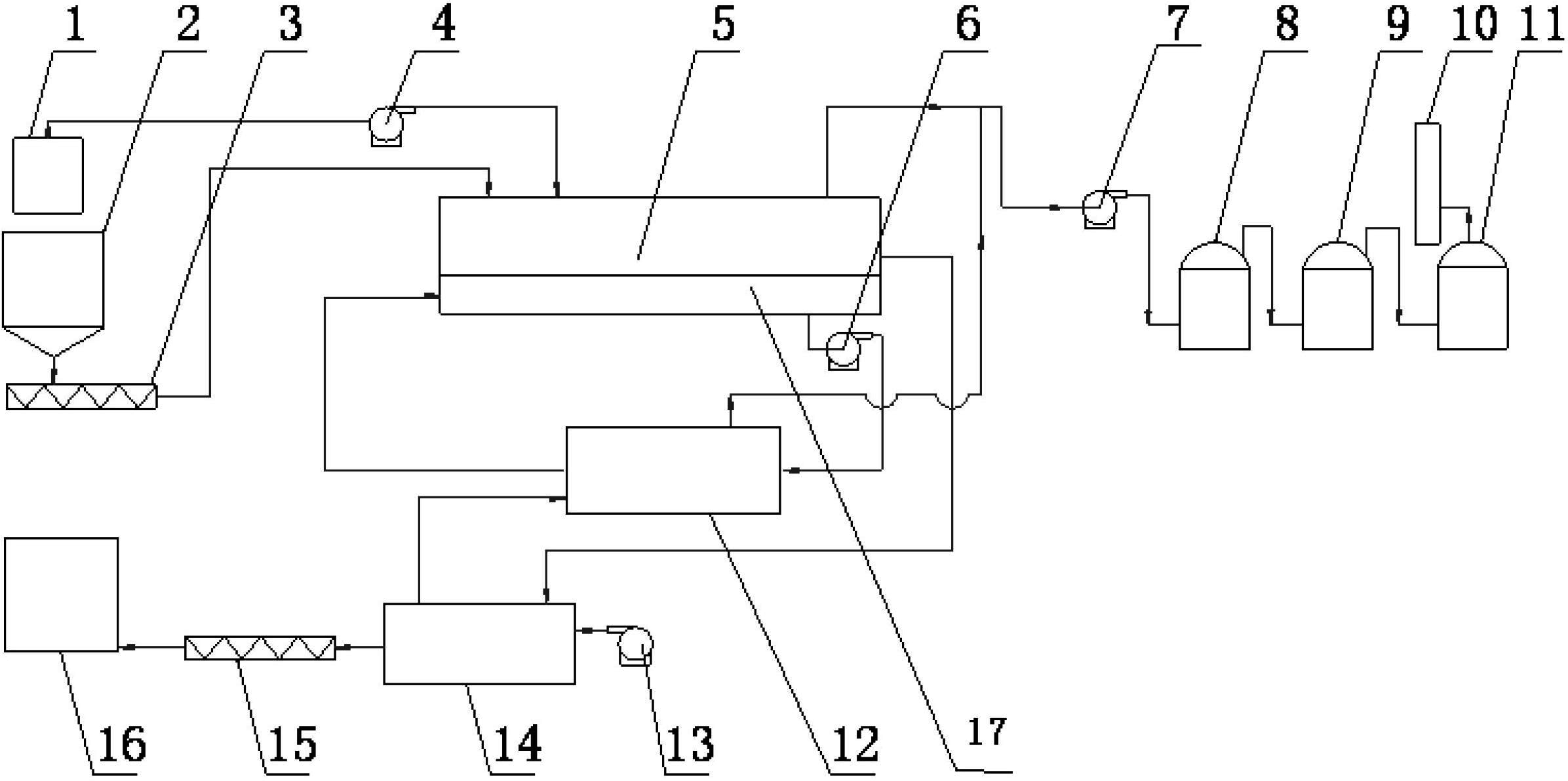

Sludge drying burning combination treatment method

ActiveCN101265008ASimple processLower the altitudeSludge treatment by de-watering/drying/thickeningIncinerator apparatusFluidized bed dryingTreatment effect

The invention relates to a sludge drying and incineration combined treatment method with good treatment effect, wide sludge adaptability, and safe and stability system. To avoid agglomeration of mechanically dewatered sludge (k) in a fluidized bed dryer (6), a part of dried sludge (c) is premixed with the mechanically dewatered sludge (k) and then fed into the fluidized bed dryer (6). The dried sludge (c) is incinerated into a circulating fluidized bed incinerator (1) to generate superheated vapor. The superheated vapor is condensed to hot water in a heat exchange tube (6-2) of the fluidized bed dryer (6) and then recycled to the circulating fluidized bed incinerator (1). The arrangement of buried pipes (1-3) and fractional air supply inside the circulating fluidized bed incinerator (1) can effectively control the lower temperature of the circulating fluidized bed incinerator (1) to prevent deflagration of dried sludge. The entire system has no emission of pollutants such as unpleasant odor, acidic gases, heavy metals and dioxin; is safe and reliable; and can operate for a long time.

Owner:JIANGSU JINSHAN SOLID WASTE RESOURCE TECH

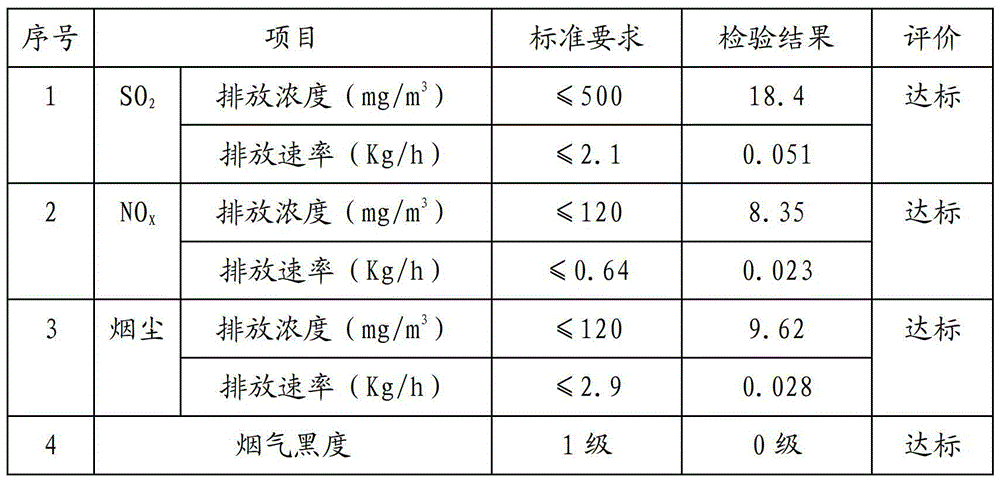

Alcohol-based fuel oil

ActiveCN103184081AProduct performance is stableClean and environmentally friendly oxygen contentLiquid carbonaceous fuelsSolventGlycerol

The invention discloses alcohol-based fuel oil which consists of the following components in part by weight: 70 to 75 parts of methanol, 4 to 6 parts of dimethylbenzene, 4 to 6 parts of No.200 solvent oil, 4 to 6 parts of paraffin oil, 4 to 6 parts of glycerol and 5 to 10 parts of water. Flame generated in the burning process of the alcohol-based fuel oil disclosed by the invention is stronger than that generated in the burning process of diesel oil and liquefied petroleum gas; the alcohol-based fuel oil is more completely and more sufficiently burnt; tail gas generated in the burning process of the alcohol-based fuel oil is cleaner and has no odor; and the alcohol-based fuel oil has the advantages of stable performance, high thermal efficiency, economy, safety and no pollution.

Owner:DONGGUAN CITY QUAN RAN TRADING

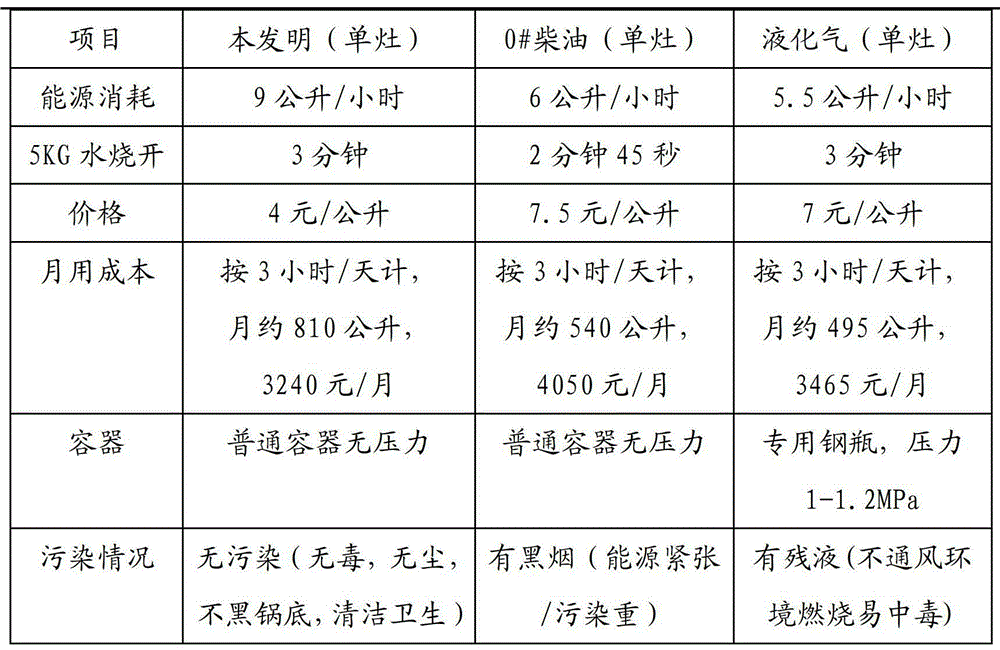

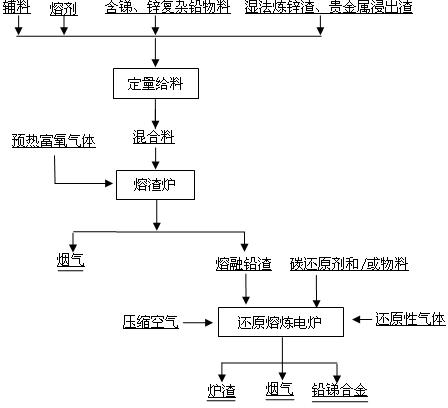

Smelting method of lead concentrate containing antimony and zinc

InactiveCN102433448AEfficient use ofNo explosion hazardProcess efficiency improvementFlue gasSmelting process

The invention relates to a nonferrous metal, and in particular relates to a smelting method of lead concentrate containing antimony and zinc. The smelting method is characterized in that in the smelting process, oxidizing smelting is performed to the lead concentrate containing antimony and zinc in a slagging furnace to generate a flue gas containing SO2, smelting dust and slagging furnace slag; then reduction smelting is performed to the slagging furnace slag in an electric furnace to generate a lead-antimony alloy, a flue gas and slag, and after the slag and the lead-antimony alloy are clarified and layered, the lead-antimony alloy is discharged from a lead discharge hole; and zinc oxide is recycled from the flue gas obtained in the reduction process and then the obtained flue gas is discharged to the outside. The method has the following advantages: the flow is short, continuous production is realized, energy is saved, the production capacity is large, resources can be efficiently utilized, the environment can be protected, the safety and labor hygiene are good, foamed slag has no explosion danger and the production is safe. The smelting method is suitable for not only the treatment of the complex lead materials containing antimony and zinc, but also the treatment of wet method zinc metallurgical slag and lead-precious metal system slag, lead, zinc and antimony are matched mutually, the lead-zinc-antimony combination enterprises are more superior and the recovery rates of lead and the associated valuable metals such as copper and antimony, and precious metals are higher.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

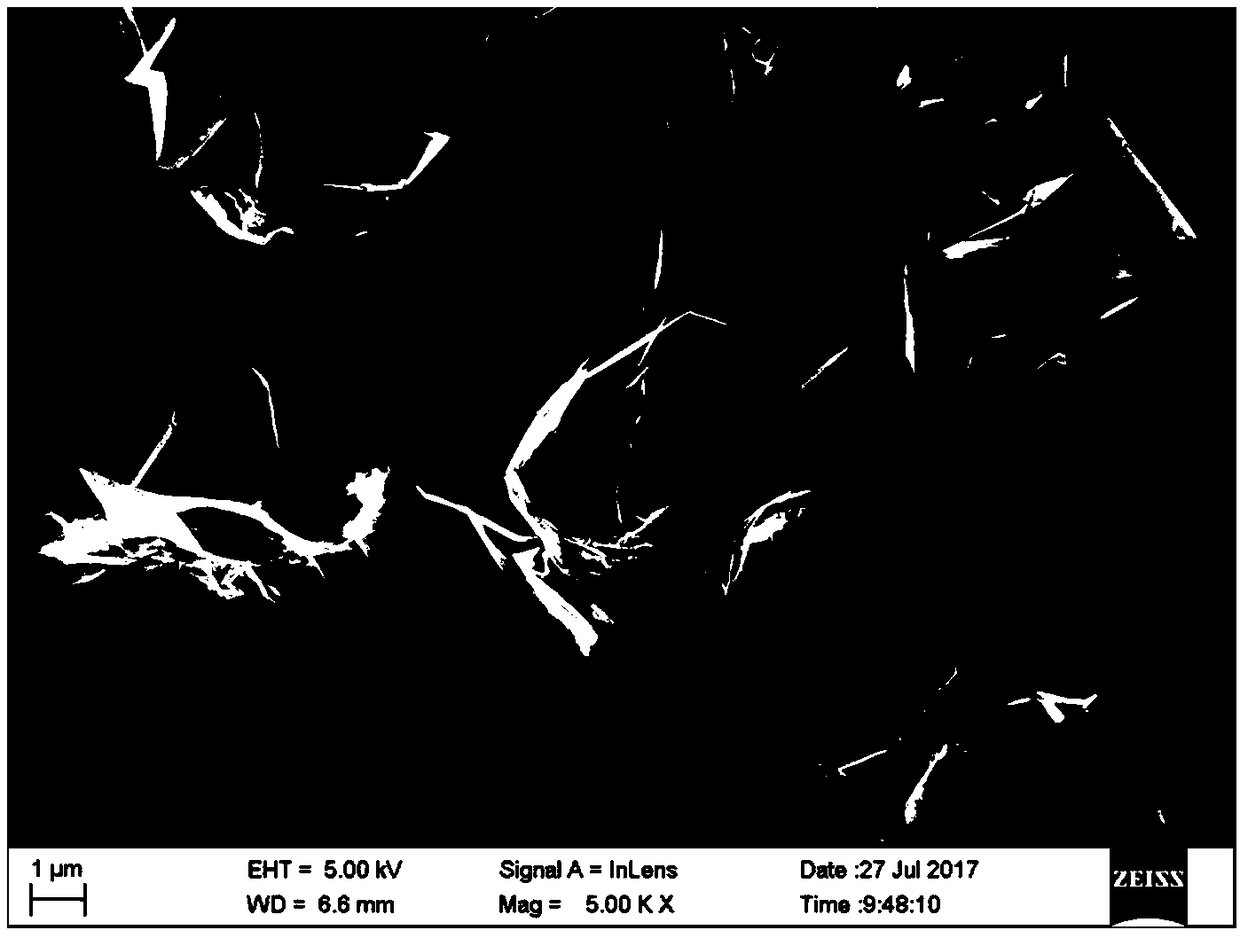

Pollution-free low-cost technology for preparing monolayer graphene oxide

The invention discloses a pollution-free low-cost technology for preparing graphene oxide. The technology comprises the following steps: 1, mixing graphite with a strong acid to infiltrate graphite, adding a strong oxidant, and continuously stirring to oxidize and exfoliate graphite layers; 2, centrifuging the obtained reaction solution, recovering the strong acid to be used in a next reaction, slowly pouring the obtained muddy product into deionized water, stirring, washing by using dilute hydrochloric acid, repeatedly cleaning by using deionized water, and centrifuging to obtain monolayer graphene oxide; 3, introducing ammonia gas into wastewater until the pH value approaches 7 to obtain an inorganic fertilizer containing nitrogen, potassium, iron and phosphorus; and 4, concentrating an aqueous solution of graphene oxide, and drying to obtain graphene oxide with high density and high specific surface area. The technology has the advantages of simple, safe and controllable preparation process, less time and energy consumption, no explosion danger and no pollution. The cycle use of concentrated sulfuric acid in the raw material-to-fertilizer process makes all raw materials and elements fully used, so the preparation cost of graphene oxide is greatly reduced.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

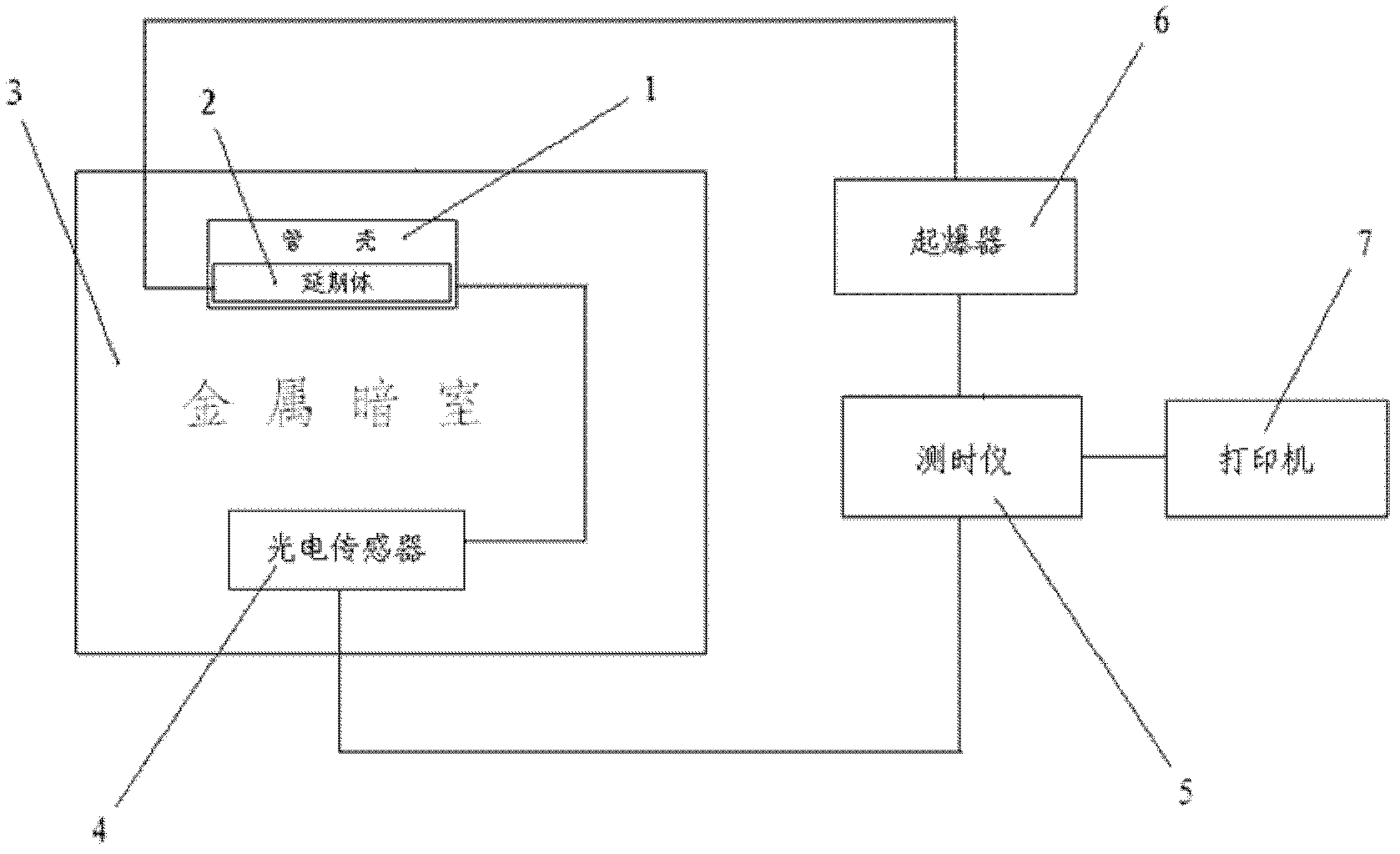

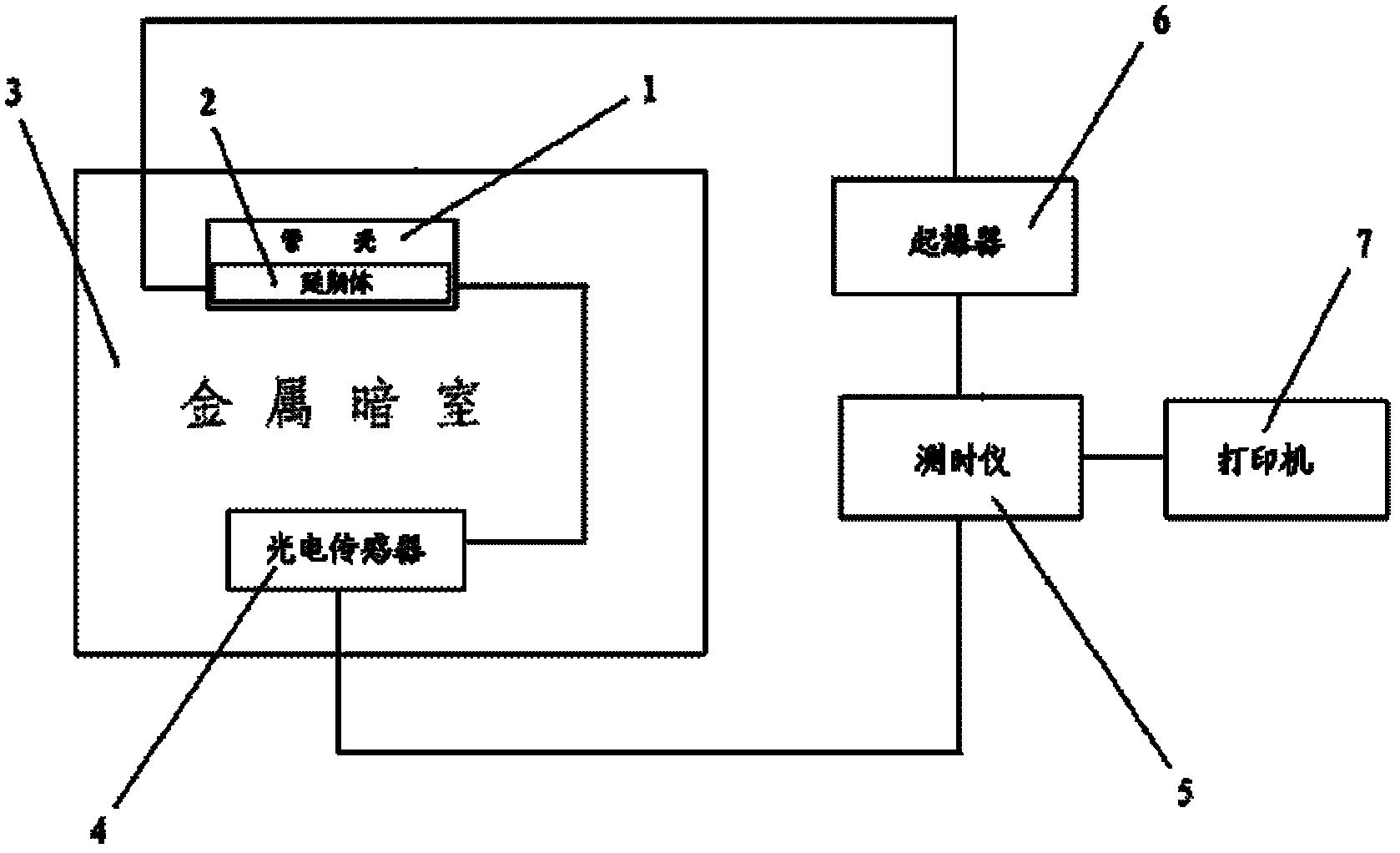

Method and device for testing delay of detonator delay element

The invention discloses a method and a device for testing delay of a detonator delay element, and solves the technical problems of danger, long time period, low efficiency and high testing cost in the traditional method for testing the delay of the detonator delay element. The method comprises the following steps of: filling a cut lead delay element into a steel detonator shell of which two ends are open and which has the length of 50-80mm, and fixing the position of the delay element in the detonator shell; arranging a detonating primer at one end of the delay element for exciting delay; putting the detonator shell filled with the delay element in a metal dark chamber; arranging a photoelectric sensor at the other end of the delay element; arranging a chronoscope, connecting an initial signal end with the detonating primer, and connecting a termination signal end with the photoelectric sensor; exciting the delay element by using the detonating primer; and reading data displayed by the chronoscope. By the invention, the delay of the detonator delay element is tested safely in a short time, the testing cost is low, and the measured data is accurate.

Owner:FUJIAN CIVILIAN BLASTING CHEM

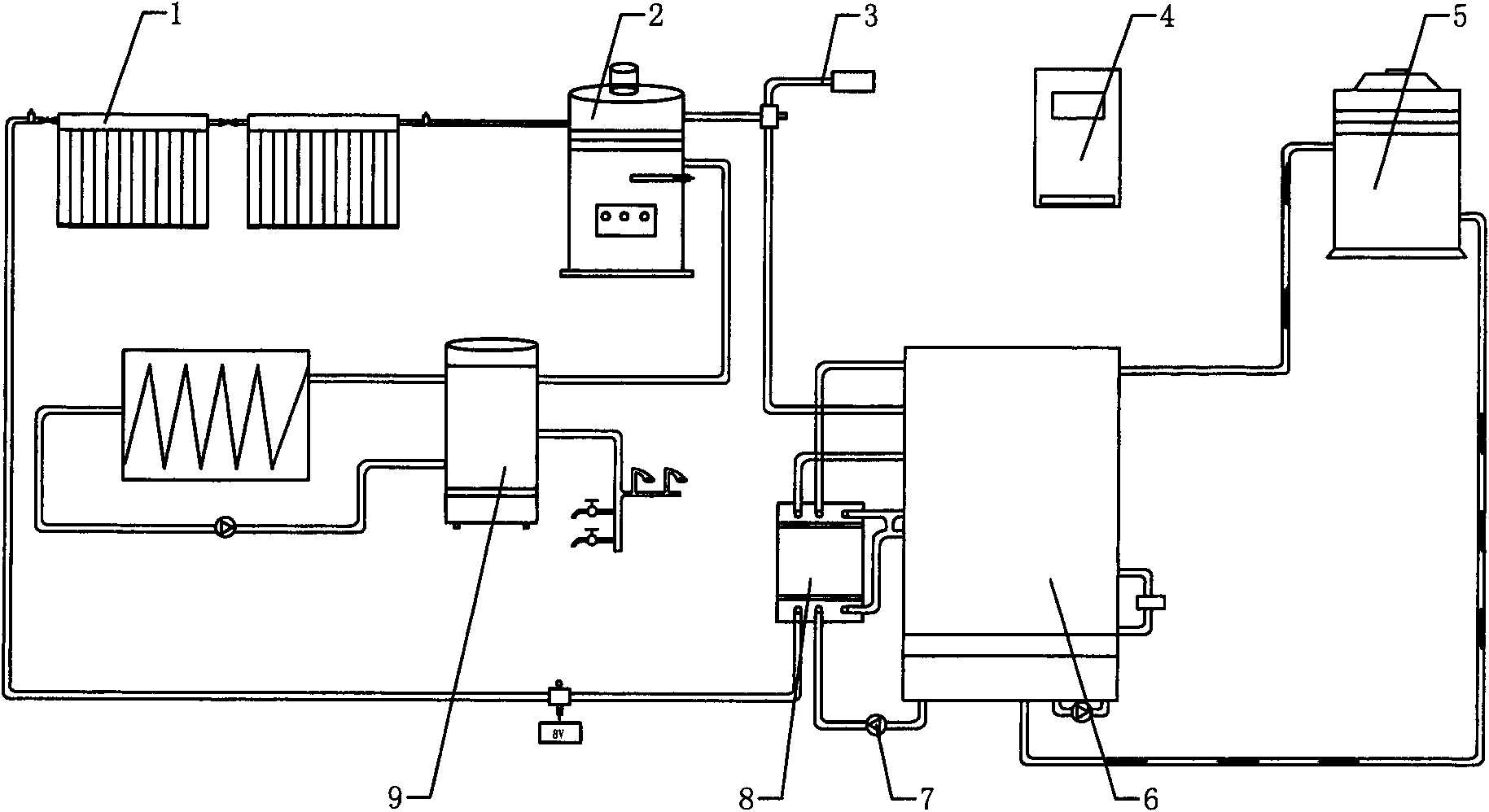

Solar air-conditioner

InactiveCN101666529AEfficient use ofImprove economyChemical industryEvaporators/condensersAutomatic controlLithium bromide

The invention relates to a solar air-conditioner comprising a U-shaped heat pipe collector, a lithium bromide absorption-type refrigerating machine, a heat storage water tank, a cold storage water tank, a circulation pump, a cooling tower, an air-cooled coil pipe, an auxiliary oil-fired boiler and an automatic control system. The lithium bromide absorption-type refrigerating machine comprises a high-pressure generator, a low-pressure generator, an evaporator, an absorber, a cooling tower, a cooled heat exchanger, a concentrator and a generator pump. Lithium bromide-water separators are respectively arranged in the high-pressure generator and the low-pressure generator. Surfactants are added in refrigerant solution. The solar air-conditioner does not need to consume lots of energy and has low requirement on heat energy, can utilize various low-grade heat energy besides the solar heat sources, and has good electricity saving and energy saving effects and high economic efficiency. The cold capacity regulating range is wide. Along with the change of external load, the unit can carry out stepless regulation on the cooling capacity within the range from 10% to 100%, and during low load regulation, the heat efficiency hardly falls and the properties are stable; therefore, the solar air-conditioner can better adapt to the requirement of variable load.

Owner:黄山创鑫企业管理咨询有限公司

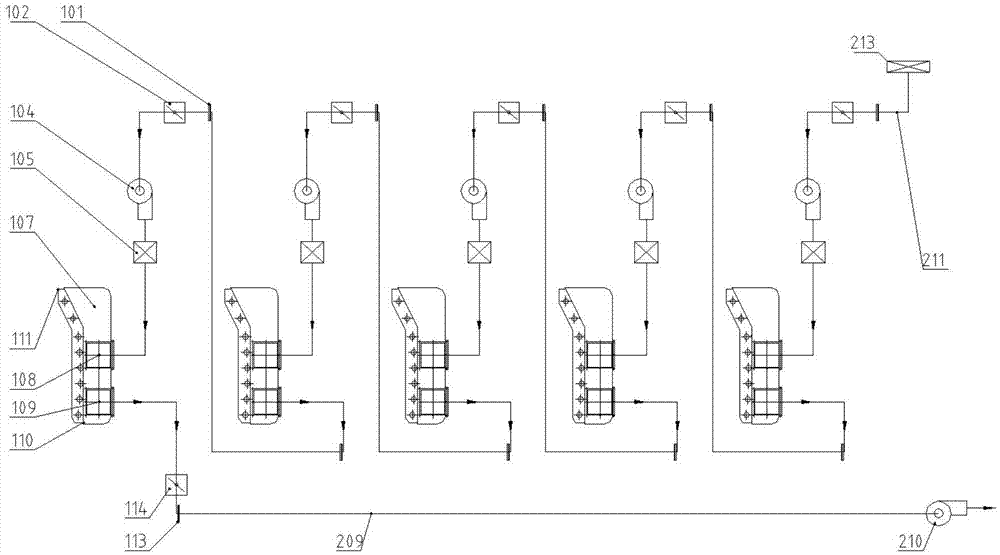

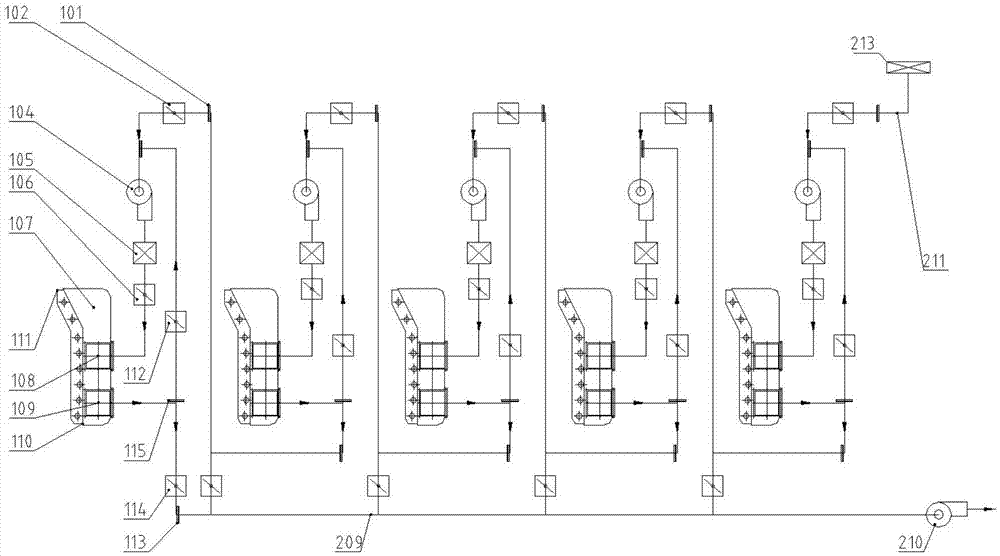

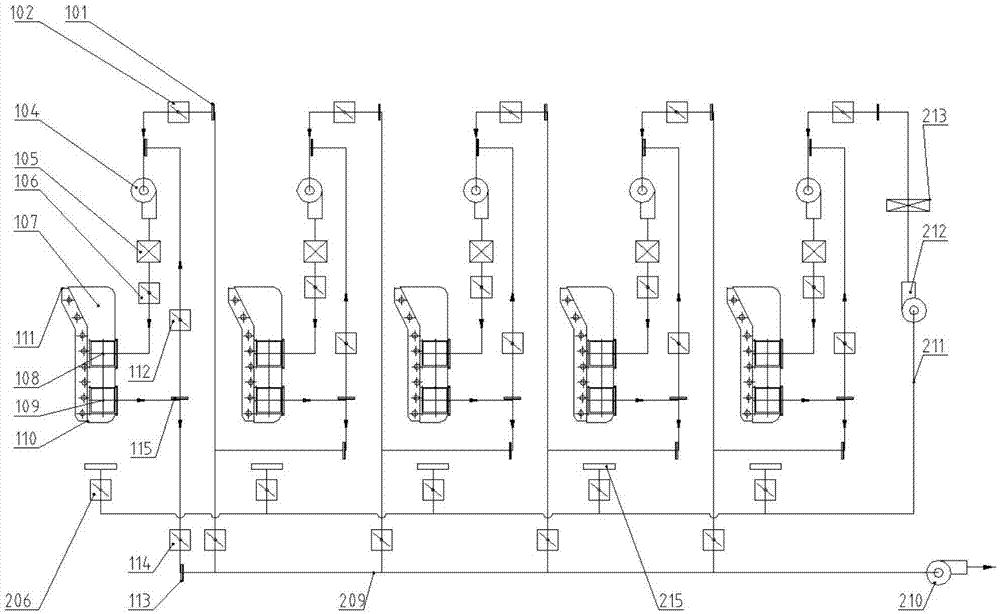

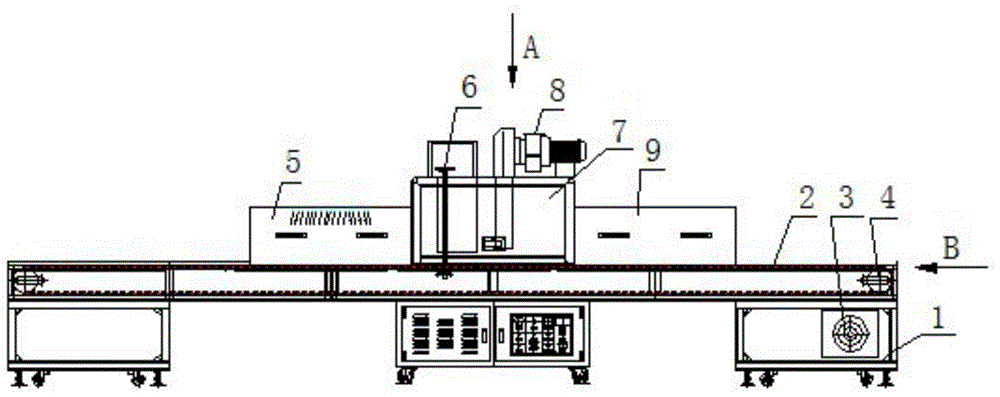

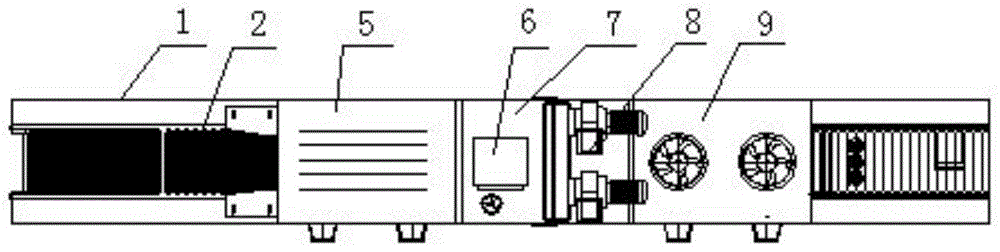

Tandem drying system

ActiveCN105444536AEasy to set upReduce exhaust air volumeDrying gas arrangementsPretreated surfacesWaste management

The invention provides a tandem drying system. The tandem drying system comprises at least two drying units, wherein each drying unit comprises a unit air supply fan and a drying box; a unit air inlet and a unit air outlet are formed in each drying unit; a drying box air inlet and a drying box air outlet are formed in each drying box; each unit air inlet is connected with the corresponding drying box air inlet; each unit air outlet is connected with the corresponding drying box air outlet; an exhaust air inlet which is connected with the unit air outlet of the last drying unit is formed in an exhaust air header pipe; a supply air outlet which is connected with the unit air inlet of the first drying unit is formed in a supply air header pipe; in every two adjacent drying units, the unit air outlet of the former drying unit is connected with the unit air inlet of the latter drying unit; each unit air supply fan is arranged between the corresponding unit air inlet and the corresponding drying box air inlet; and an exhaust air fan is arranged on the exhaust air outlet of the exhaust air header pipe. The tandem drying system has the advantages of simplicity and stability, easiness in adjustment, small exhaust air amount, low energy consumption, no potential safety hazards, low environment protection cost and the like.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

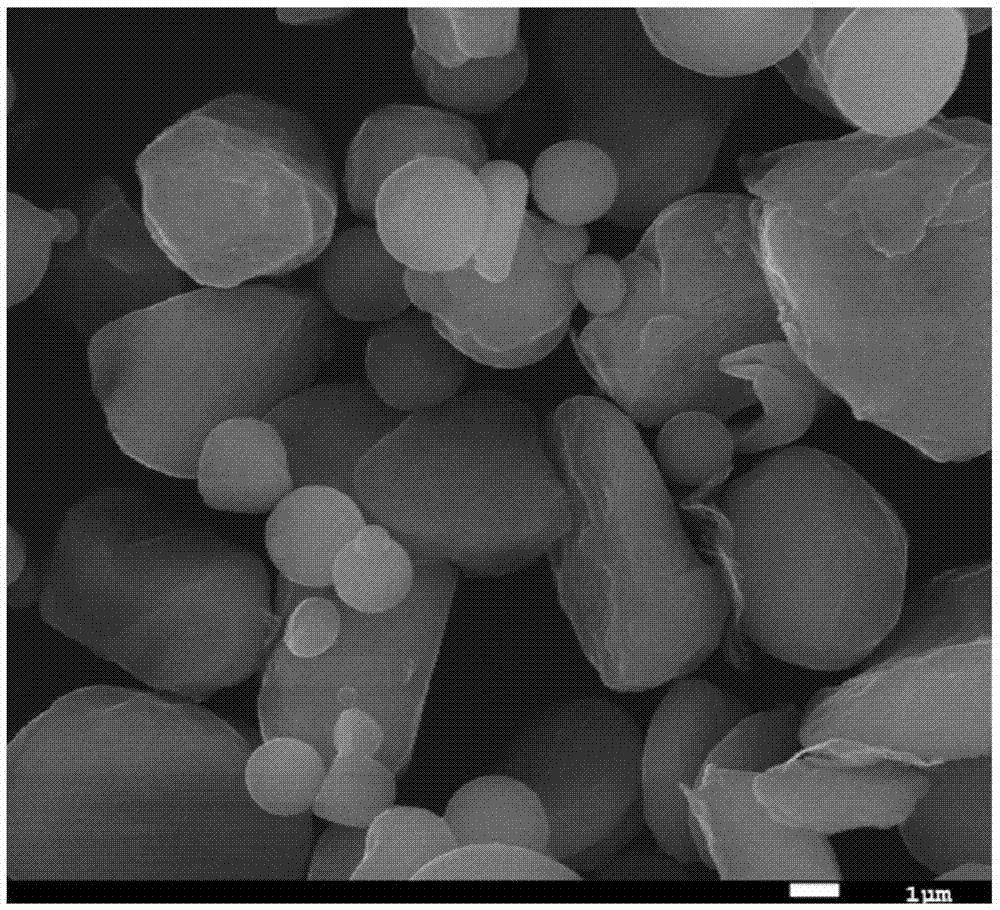

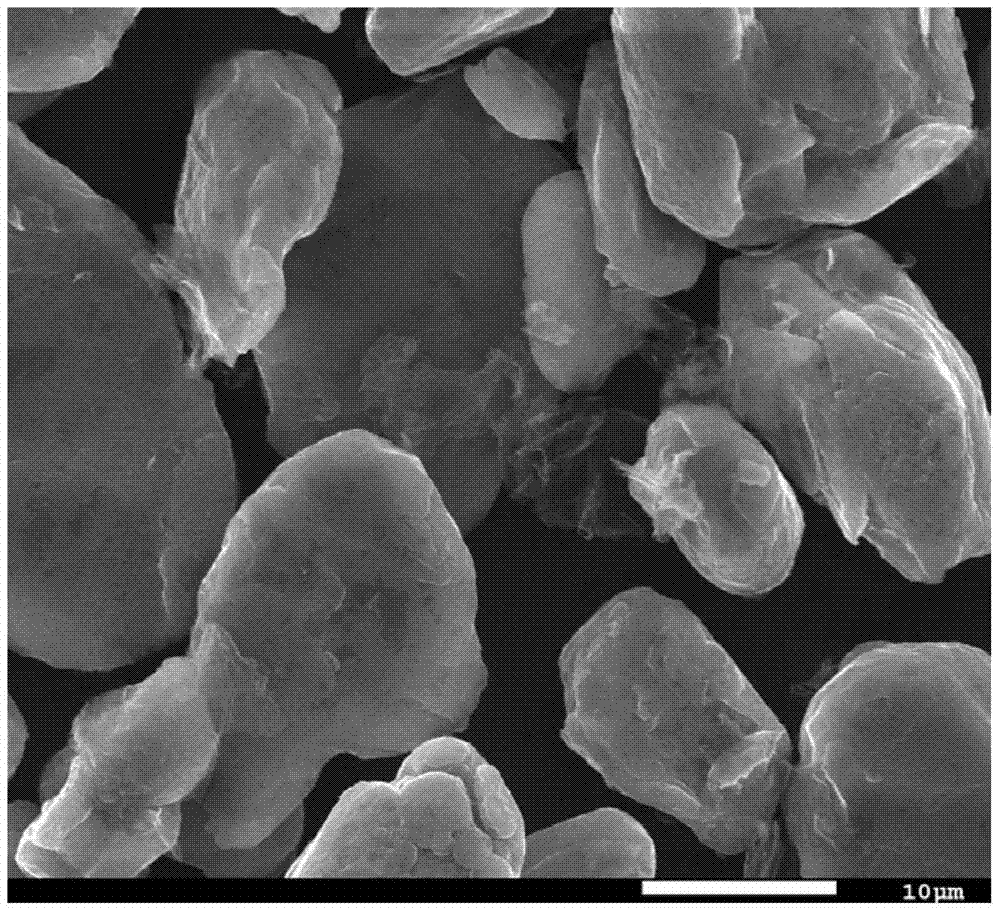

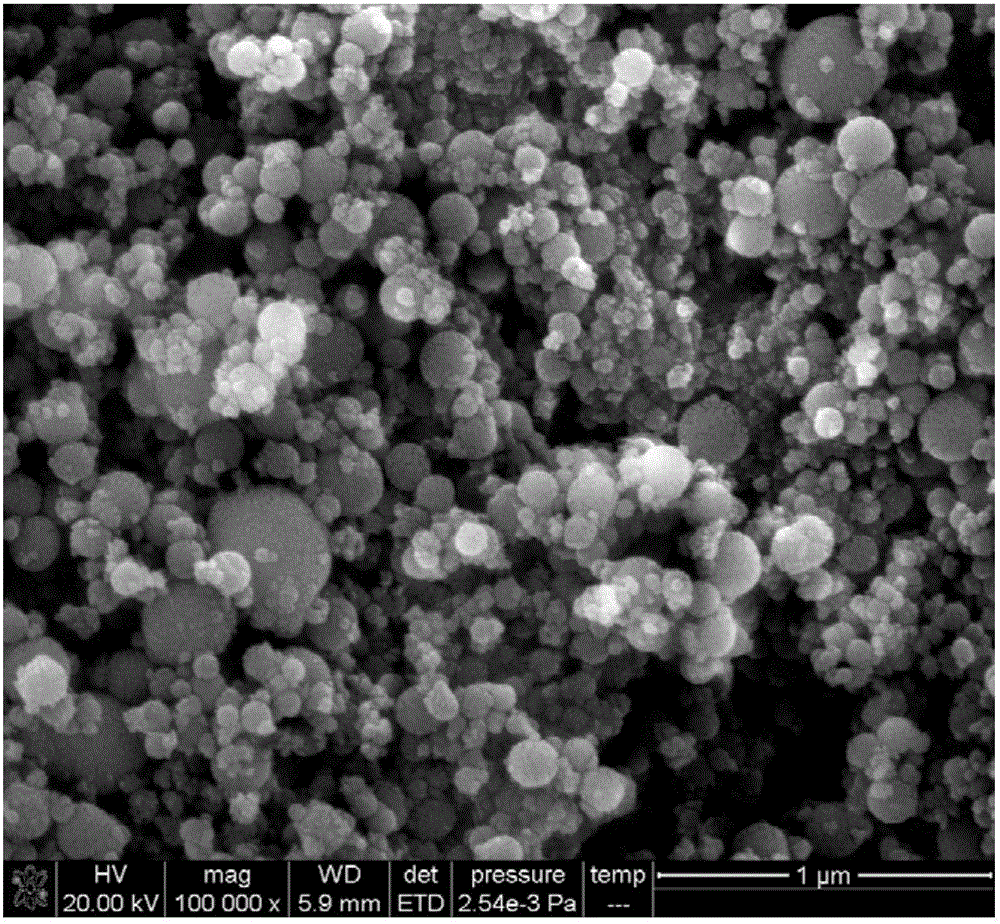

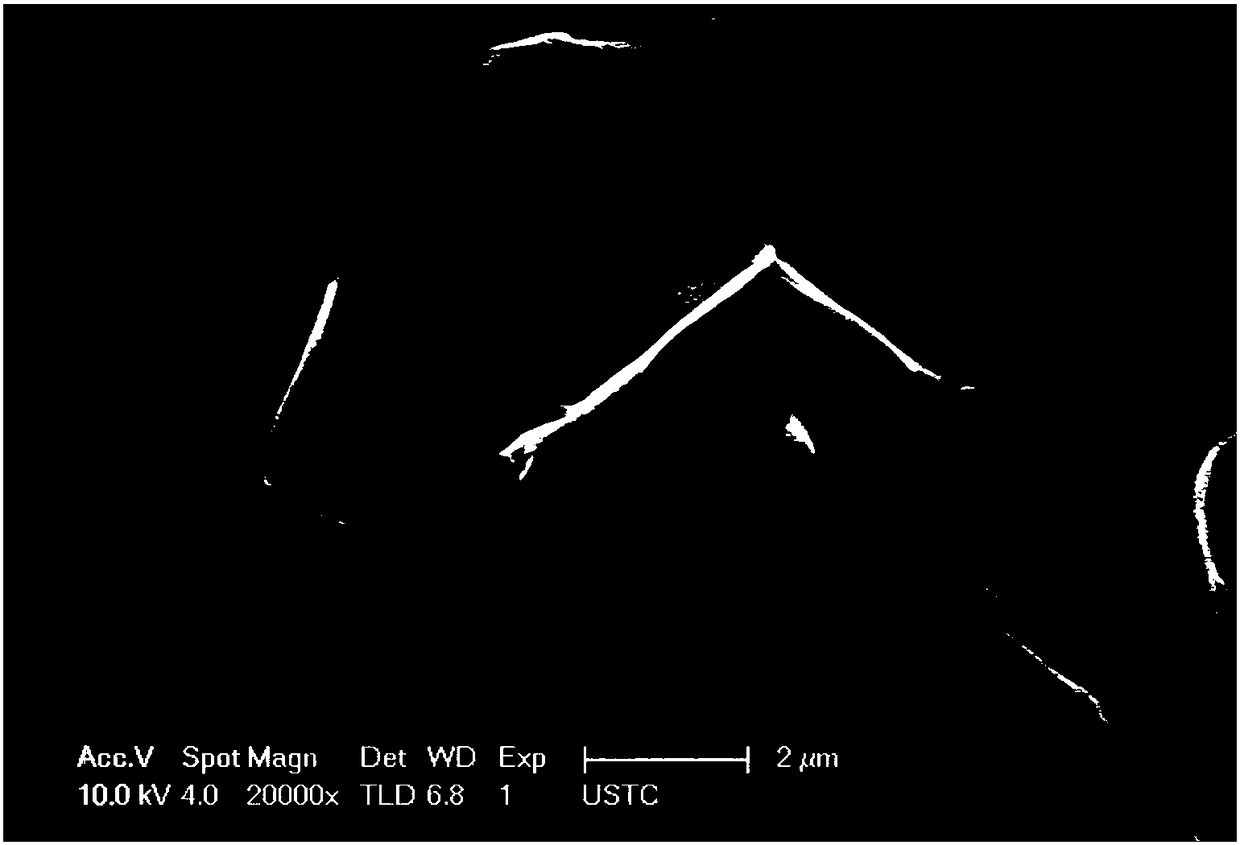

Preparation method for composite powder of graphene and metal aluminum powder

InactiveCN106914611AImproved reunion statusGuaranteed preprocessing effectAluminium powderSpherical shaped

The invention relates to a preparation method for composite powder of graphene and metal aluminum powder, and belongs to the field of nanosheet structure reinforced metal base composite materials. The preparation method comprises the following steps of: taking grapheme and metal aluminum powder as raw materials, and performing pre-dispersing through a mechanical stirring method, an ultrasonic vibrating method and a chemical reagent dispersing method; and then, preparing the composite powder by ball-milling, wherein the composite powder comprises the following components in percentage by weight: 0.3 wt.%-8.5wt.% of graphene and 91.5wt.%-99.7wt.% of aluminum powder. According to the preparation method, aluminum powder generates the laminarization effect, so that the morphology of the aluminum powder is changed into a cake shape or an ellipsoid shape from a spherical shape, dimension deformation percentage of the aluminum powder ranges from (-)200% to 200%, and graphene is uniformly distributed in aluminum powder. The obtained composite powder is low in impurity content, has moisture content lower than 0.01wt.%, and realizes kilogram-level composite powder preparation; and the preparation method is nontoxic and safe.

Owner:GRIMAT ENG INST CO LTD

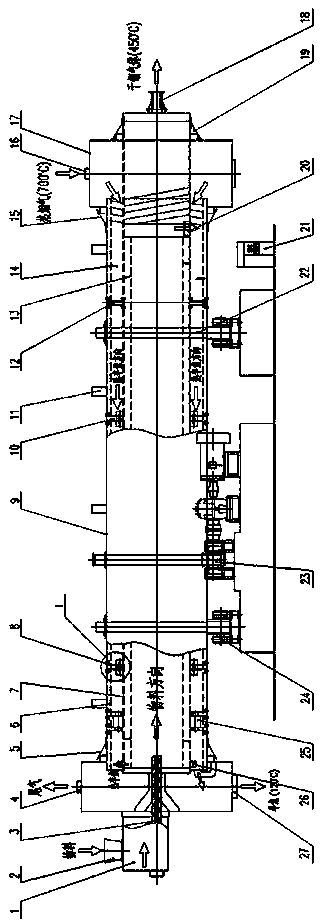

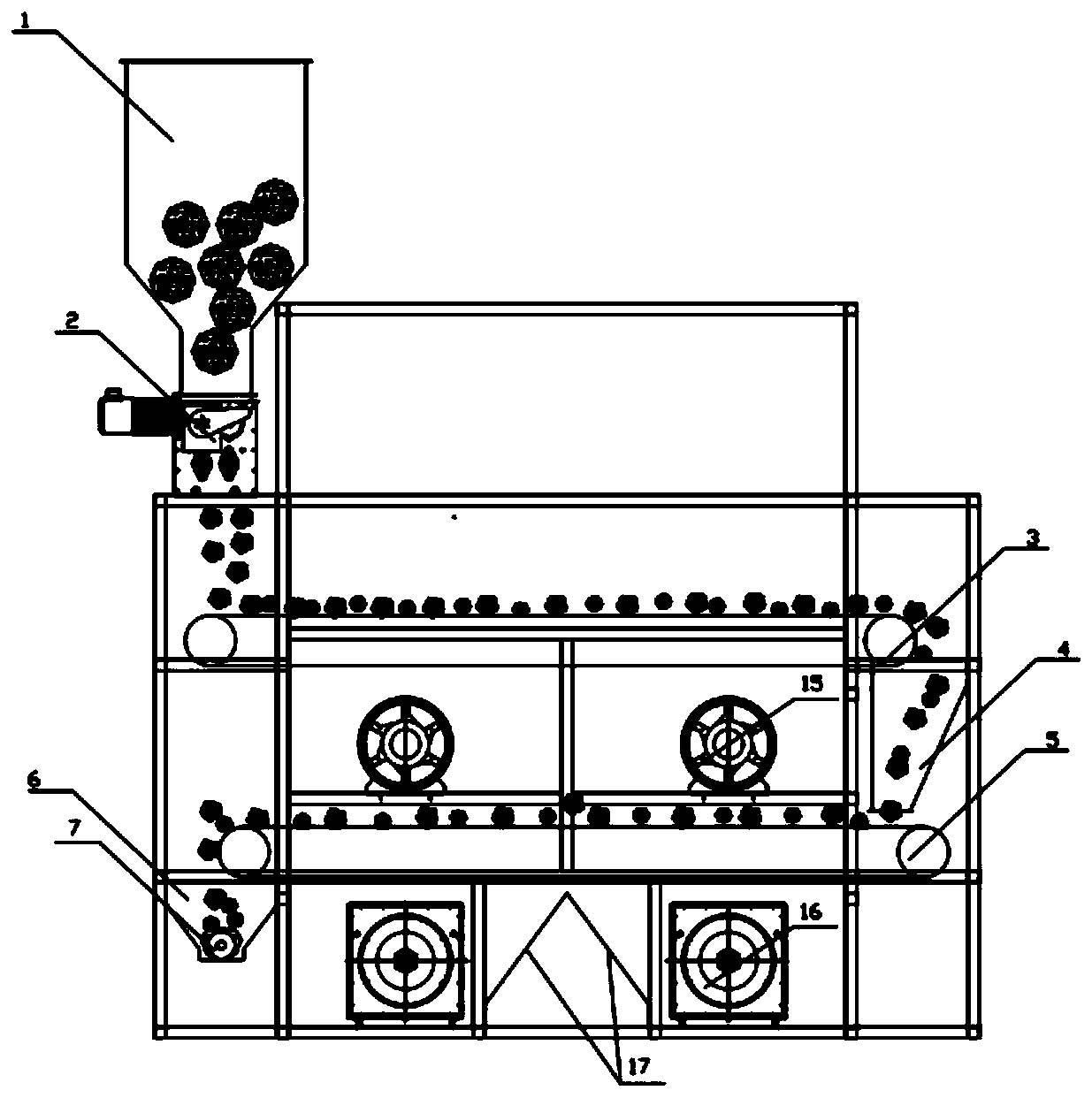

Multilayer rotary kiln based small granular material destructive distillation method

ActiveCN103952165ALow running costGuaranteed concentrationEnergy inputIndirect heating destructive distillationGranularityFlue gas

The invention relates to a multilayer rotary kiln based small granular material destructive distillation method. The method comprises the following steps: adding oil shale granules (with the granularity of 0-20mm) with the water content of below 5% to a bunker from a kiln head, sending to the inner cylinder of a rotary kiln by a spiral conveying device, heating the material in the inner cylinder to 500DEG C through the circulation of high temperature hot flue gas (with the temperature of 700DEG C) from a hot blast stove in an annular channel between an outer cylinder and the inner cylinder to pyrolyze the oil shale material in order to generate a destructive distillation gas and semicoke, and carrying out purifying recovery on the destructive distillation gas to obtain gas and shale oil; and adding the semicoke into the annular channel from the inner cylinder, allowing the semicoke to run along a direction opposite to the material running direction in order to carry out heat exchange of the material in the inner cylinder and absorb the waste heat of the semicoke, discharging parts of the semicoke from the stove, and adding a small amount of the semicoke to the inner cylinder for the mixing of the small amount of the semicoke with a normal temperature mixture in order to further utilize the waste heat of the semicoke. The method has the advantages of simple technology, low energy consumption, no pollution, high product quality, realization of the industrial large-scale production, and easy large-area popularization.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Glass detergent

InactiveCN103952123AEasy to makeLong anti-fog timeNon-ionic surface-active compoundsOther chemical processesAlcoholSodium silicate

The invention discloses a glass detergent. The glass detergent is prepared from the following raw materials in parts by mass: 1-1.3 parts of absolute ethyl alcohol, 0.2-0.3 part of sodium lauryl sulfate, 0.1-0.3 part of ethanol, 0.2-0.3 part of saponin, 0.8-1 part of sodium silicate, 1.5-2 parts of saponin, 2-6 parts of alkanolamide and 90-95 parts of deionized water. The antifogging agent disclosed by the invention is simple in preparation, has two functions of cleaning and fog prevention, and is long in antifogging time, wide in usable range, free of explosion risk and convenient to carry.

Owner:江苏紫石化工科技有限公司

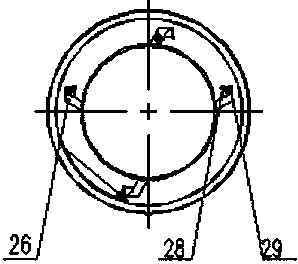

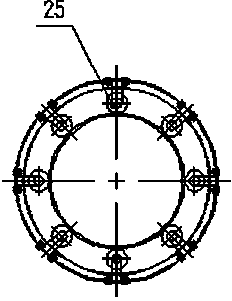

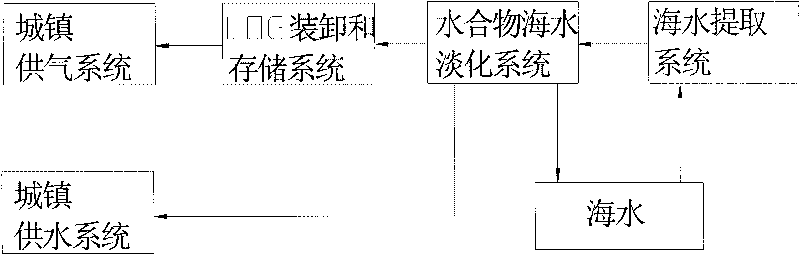

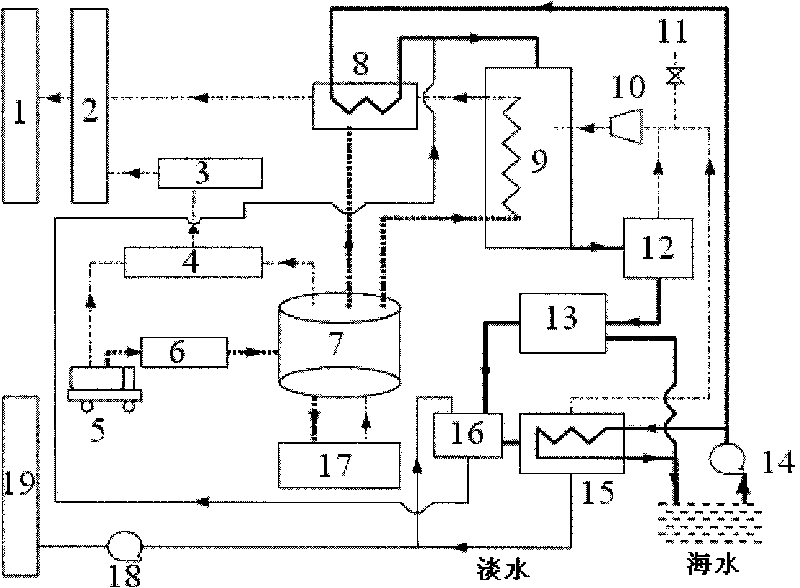

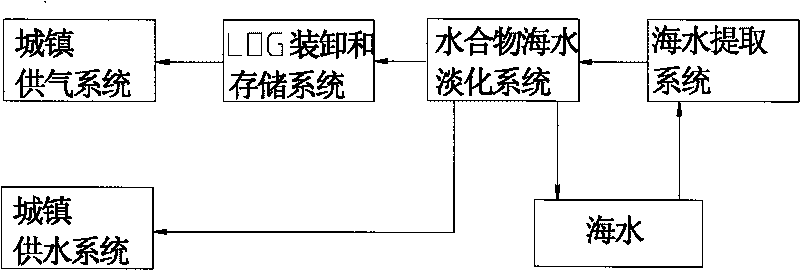

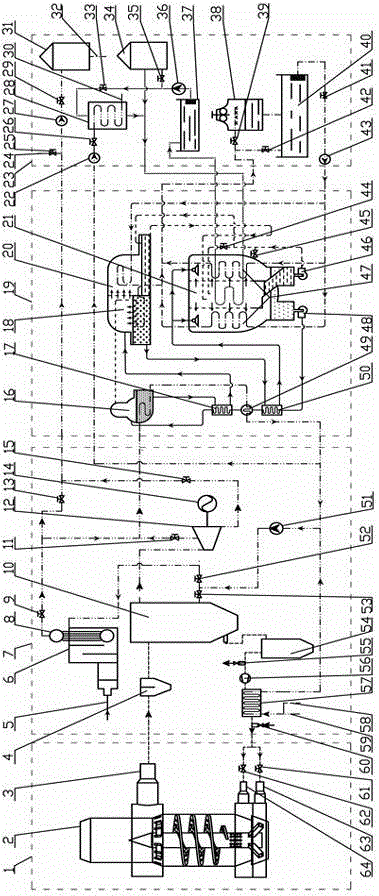

System for desalination of sea water by utilizing LNG cold energy

InactiveCN101746840AReduce energy consumptionReduce solubilityDomestic cooling apparatusGeneral water supply conservationSolubilityWater desalination

The invention discloses a system for desalination of sea water by utilizing LNG cold energy, comprising a town water system and town gas supply system, an LNG loading and unloading and storage system, a hydrate sea water desalination system and a sea water extraction system; one end of the LNG loading and unloading and storage system is connected with the town gas supply system, the other end is connected with the hydrate sea water desalination system, the LNG loading and unloading and storage system is used for receiving and storing liquefied natural gas (LNG) transmitted from an LNG receiving end and transmitting the LNG into the hydrate sea water desalination system, and the LNG is gasified and then is transmitted to the town gas supply system; the other end of the hydrate sea water desalination system is also connected with the sea water extraction system, and hydrate sea water desalination system is used for decomposing the sea water extracted by the sea water extraction system into fresh water by virtue of combination reaction of hydrate and the LNG; and the town water system is also connected with the hydrate sea water desalination system and used for transmitting the fresh water obtained by decomposition of the hydrate sea water desalination system. The invention has the characteristics that: energy consumption is low, equipment is simple; solubility in water or saline water is low; LNG cold energy utilization factor is high, economic benefit is high, investment cost is low, and environmental effect is less.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

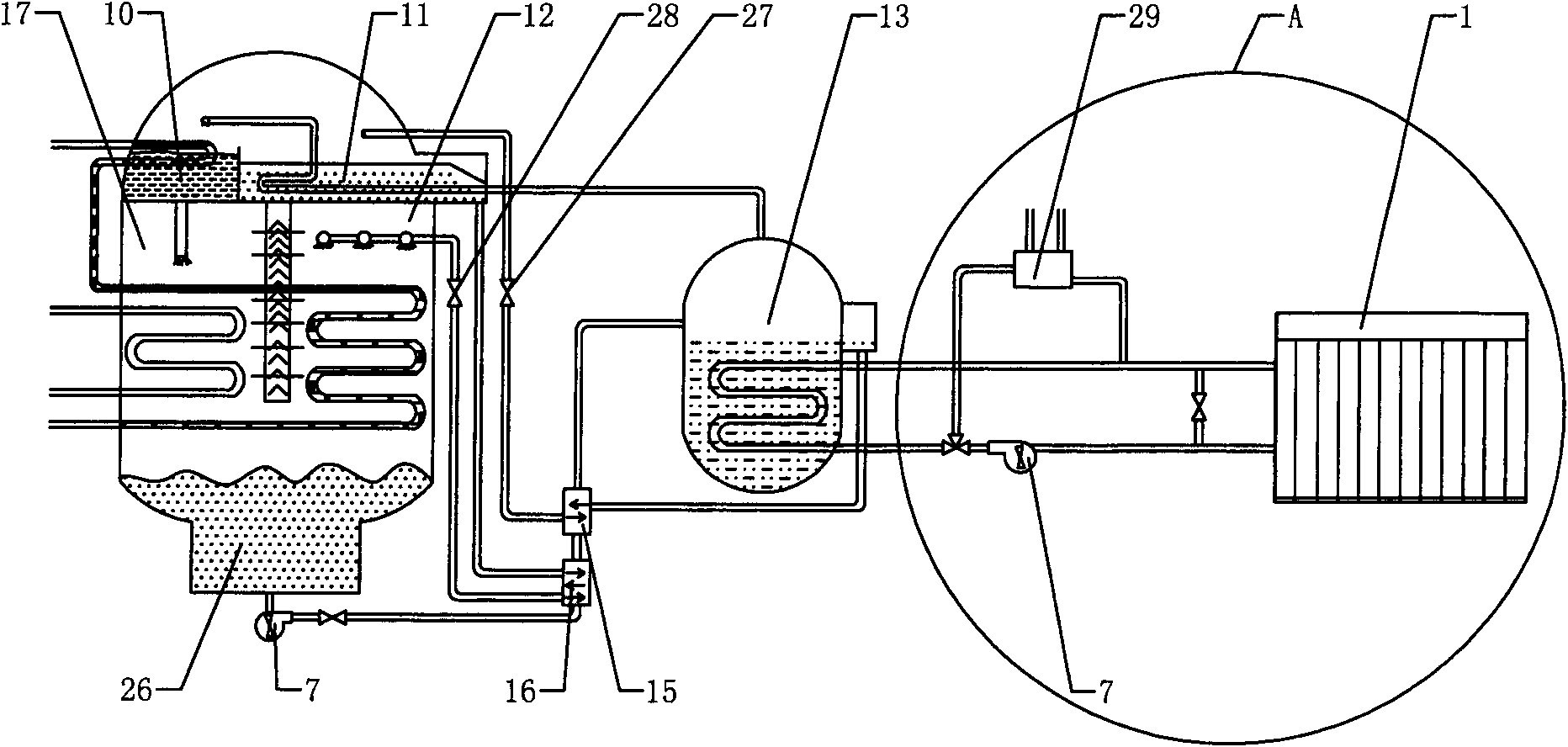

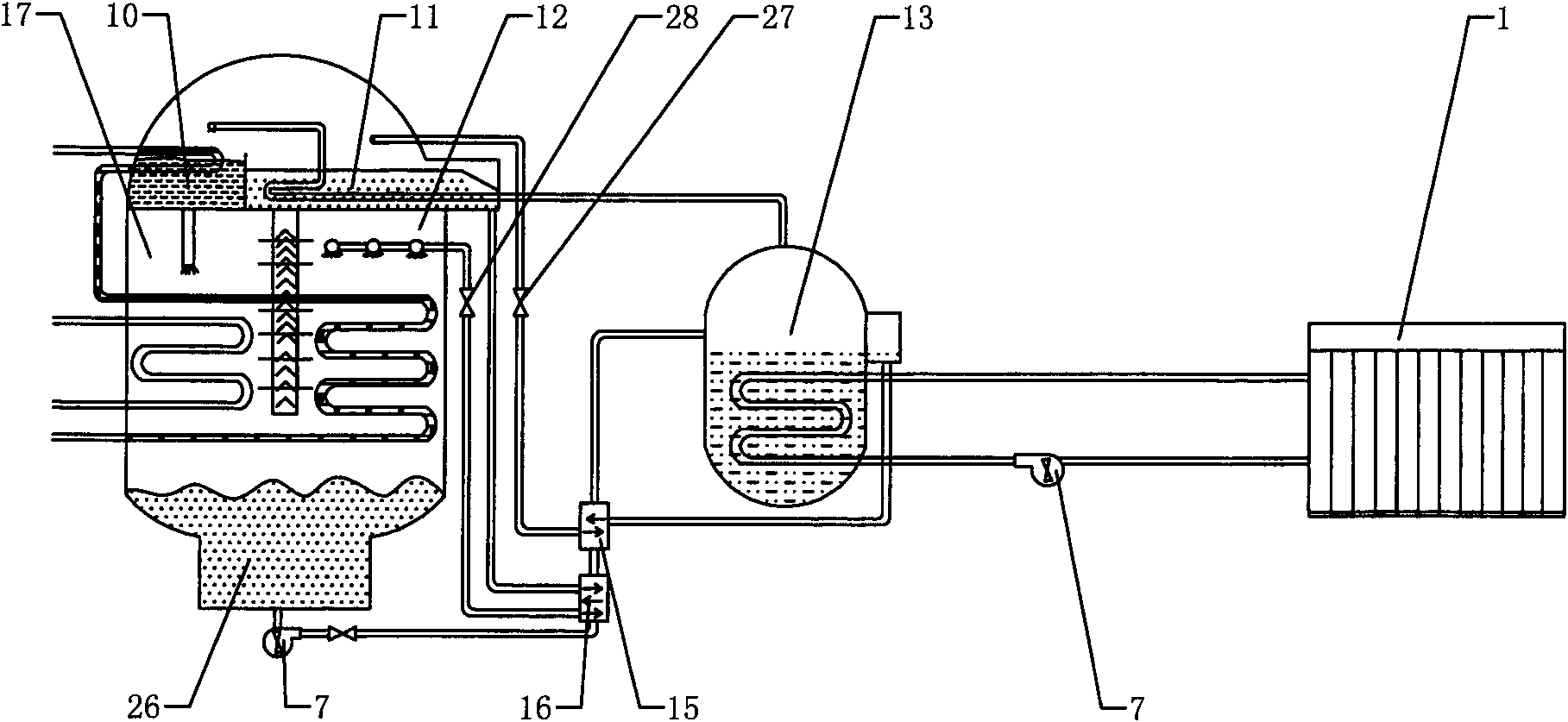

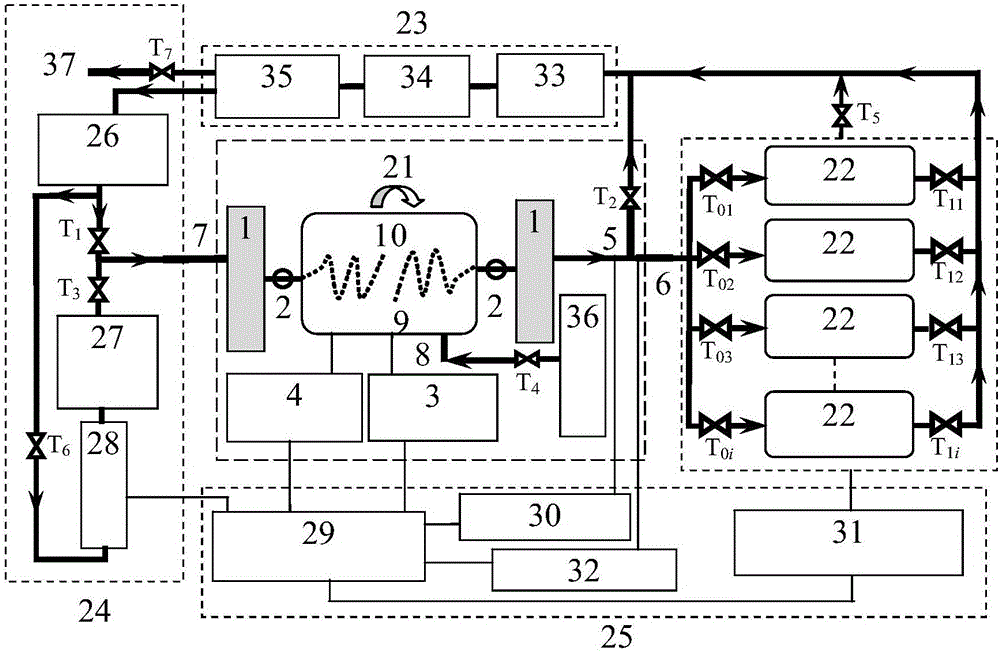

Vertical sintering waste heat drive cooling heating and power generation system and method thereof

InactiveCN104482772AImprove economyReduce noiseEnergy efficient heating/coolingClimate change adaptationThermal energySolid particle

The invention discloses a vertical sintering waste heat drive cooling heating and power generation system and a method thereof. The system comprises a vertical sinter cooling device, a waste heat boiler power and steam generation system, a double effect LiBr absorption chiller and a coolant cooling water client system. The method includes after the vertical sinter cooling device recovers heat of high-temperature sinter, allowing water to produce high temperature and high pressure steam through a heating boiler, driving a turbine to generate power, supplying hot steam extracted from the middle level of the turbine to the double effect LiBr absorption chiller, producing coolant water of the temperature of 7 to 10 DEG C to supply to cool users, and mixing the steam of the tail end of the turbine with room temperature supplement water to form hot water of the temperature of 75 to 90 DEG C to supply to heat users. Heat recovered through the vertical sinter cooling device can be used for power generation and concentrated heating and cooling, the comprehensive recovery and utilization efficiency of solid grain waste heat resource is improved effectively, the system and method can be popularized and applied to the metallurgical industry, particularly the steel industry, and energy saving and emission reduction are promoted effectively.

Owner:ZHEJIANG UNIV

Mixed refrigerant suitable for 120-150K cryogenic temperature region

ActiveCN102618220AMeet environmental protection requirementsGood environmental characteristicsHeat-exchange elementsEngineeringMolar concentration

The invention relates to a mixed refrigerant suitable for a 120-150K cryogenic temperature region of a single automatic cascading refrigeration system. The mixed refrigerant comprises the following six type refrigerants, by molar concentration, 3-20% of a first type refrigerant which is R740, R728 or a mixture of the R740 and the R728, 5-25% of a second type refrigerant which is R50, R784 or a mixture of the R50 and the R784, 15-30% of a third type refrigerant which is R14, 15-25% of a fourth type refrigerant which is R23, 5-15% of a fifth type refrigerant which is R125, R218, R22, R32 or a mixture of two, three or four of the R125, the R218, the R22 and the R32, and 20-30% of a sixth type refrigerant which is R236fa, R123, R124 or a mixture of two or three of the R236fa, the R123 and the R124. The corresponding mixed refrigerant is obtained through physical mixing at normal temperature, so the temperature of the system can reach 120-150K; and the mixed refrigerant has a good intersolubility with lubricating oil, so the ODP value is almost zero. The mixed refrigerant has the advantages of economy, environmental protection, safety, incombustibility and the like.

Owner:北京天地精仪科技有限公司

Cleaning and antifogging agent for glass

InactiveCN103409110AEasy to makeLong anti-fog timeNon-ionic surface-active compoundsOther chemical processesPolyvinyl alcoholDual effect

The invention discloses a cleaning and antifogging agent for glass, which is prepared from the following raw materials in parts by mass: 7-10 parts of anhydrous ethanol, 1-2 parts of alkanolamide, 0.2-0.3 part of sodium lauryl sulfate, 0.2-0.4 part of sodium dodecyl benzene sulfonate, 0.1-0.3 part of propanol / ethanol, 0.2-0.3 part of essence, 0.8-1 part of sodium silicate, 1.5-2 parts of polyvinyl alcohol and 90-95 parts of deionized water. The antifogging agent disclosed by the invention is simple to manufacture, has the dual effects of cleaning and fog inhibition, has the advantages of long antifogging time, wide application range and no explosion hazard, and is convenient to carry.

Owner:南通市通州区益君劳务有限公司

Method for preparing nanometer silicon powder

ActiveCN106185947AHigh purityLarge specific surface areaNanotechnologySilicon compoundsInduction plasma technologyPlasma generator

The invention discloses a method for preparing nanometer silicon powder. The nanometer silicon powder is made of coarse silicon powder. Inert gas is used as carrier gas. The method includes carrying the coarse silicon powder by the carrier gas, allowing the coarse silicon powder to penetrate plasmas generated by a high-frequency plasma generator and feeding the coarse silicon powder into a reaction chamber; quickly gasifying the coarse silicon powder in high-temperature plasma regions in the reaction chamber to generate silicon atom steam cloud; forming tiny silicon particles by the generated silicon atom steam cloud under the effects of cooling gas flow when the silicon atom steam cloud flows through cooling regions; driving the silicon particles by gas flow to flow into a cyclone classification chamber; detaining the classified coarse silicon particles in the cyclone classification chamber; carrying the fine silicon particles into a gas-solid separation chamber by the aid of the gas flow; ultimately depositing the fine silicon particles on a filter of the gas-solid separation chamber; collecting the silicon particles on the filter to obtain the nanometer silicon powder. The method has the advantages that the induction plasmas are used as heat sources, accordingly, electrode pollution can be prevented in preparation procedures, the nanometer silicon powder prepared by the aid of the method is high in purity, and the particles are in spherical or approximately spherical morphology, have large specific surface areas and are high in surface activity and good in flowability and dispersibility.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

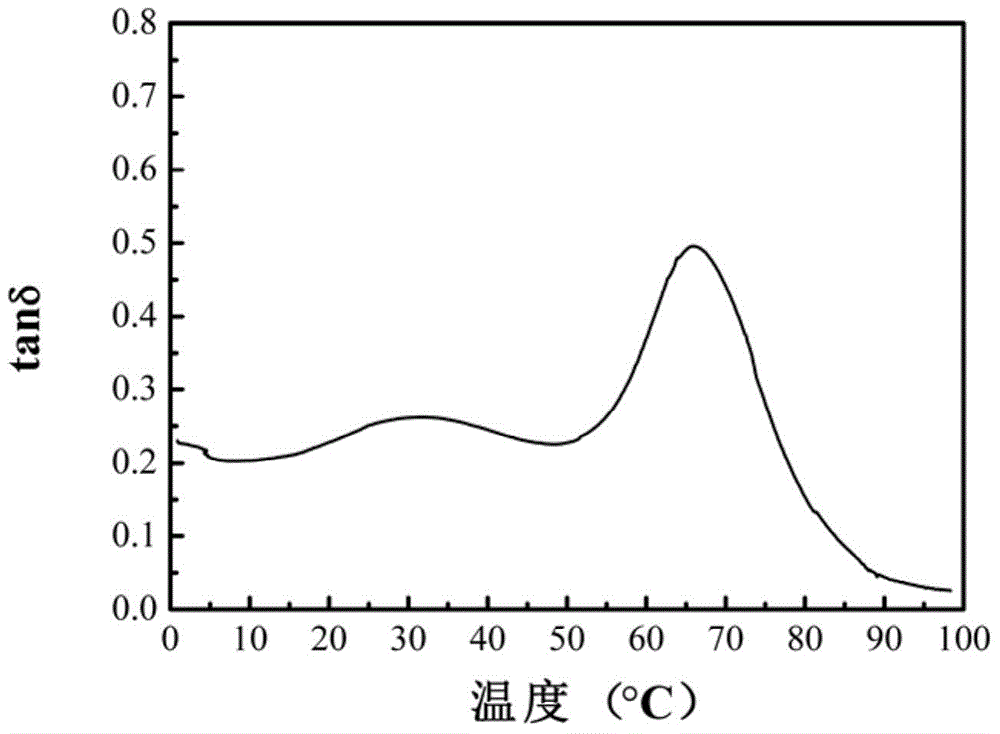

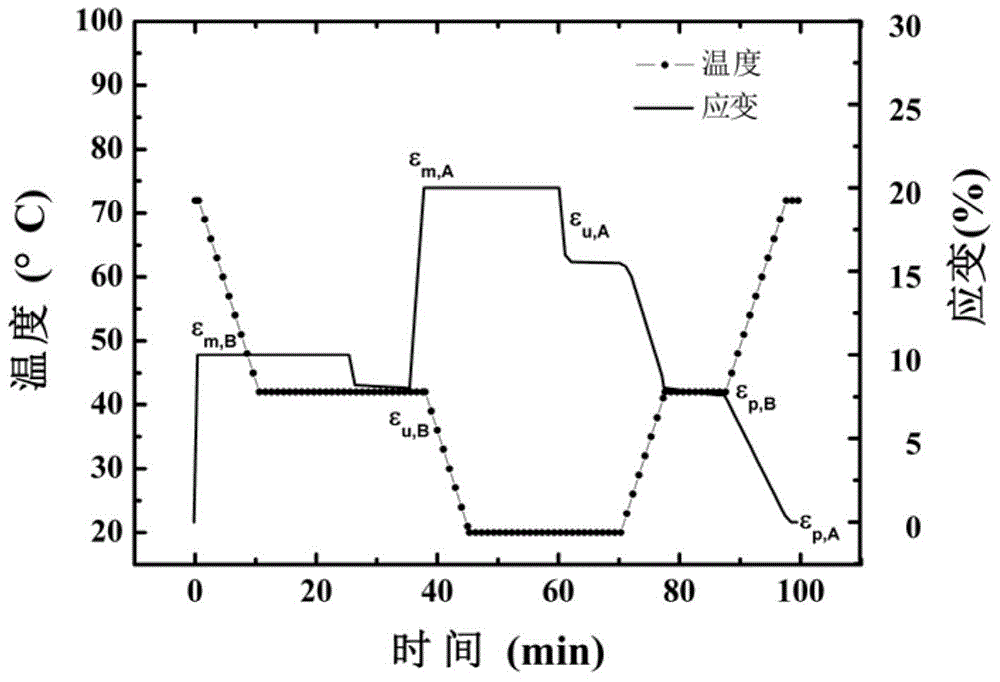

Preparation method of triple shape memory composite material

ActiveCN104893250AHigh elongation at breakThe triple shape memory effect does not existEpoxyPolyethylene glycol

The invention discloses a preparation method of a triple shape memory composite material. The method comprises two processes, namely, modification of a double shape memory material and preparation of the triple shape memory composite material. Firstly, the double shape memory material is modified, low-molecular-weight PEG (polyethylene glycol) and epoxy resin are mixed in different proportions, the GTT (glass transition temperature) of the double shape memory material is decreased, the low-molecular-weight PEG dispersed nano-silica and epoxy resin are mixed in different proportions, the GTT of the double shape memory material is increased, the double shape memory material with the low GTT and the double shape memory material with the high GTT are stacked, and the triple shape memory composite material is prepared. The method has the advantages that the technology is simple, preparation conditions are mild, the prepared material has the good shape memory effect and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Epoxy pouring type solid insulation switch with three-cabin

ActiveCN101677177ANo risk of leakageUndisturbedBus-bar/wiring layoutsSwitchgear arrangementsEngineeringElectrical and Electronics engineering

The present invention provides an epoxy pouring type solid insulation switch with three-cabin which is composed of three switch bodies having same structure. The switch body comprises an isolation cabin, a vacuum explosion-chamber cabin and a fuse cabin; a bus contact is arranged on the top of the isolation switch, the bus contact fixedly connects with an isolation contact through a master row; agrounding contact and the isolation contact are arranged on two ends of the isolation switch, a middle contact is in the middle; three contacts have same contact bases, sliding guide holes are arranged on the centre of the bases; the front connects with an insulation nut, the rear end connects with an operating mechanism. a through hole is arranged on the centre of the isolation moving contact andfixedly connects with the insulation nut, the insulation nut is sheathed on the nut and rotately connects with the nut; the vacuum explosion-chamber cabin and the fuse cabin are arranged below the isolation cabin respectively. The switch provided by the invention has advantages of reasonable design, higher electric safety performance, little volume, light weight, stable performance, reliable motion, stronger practicability and advancement. The switch provides assurance for reliability of electric supply, which is a precondition condition for reducing user investment.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

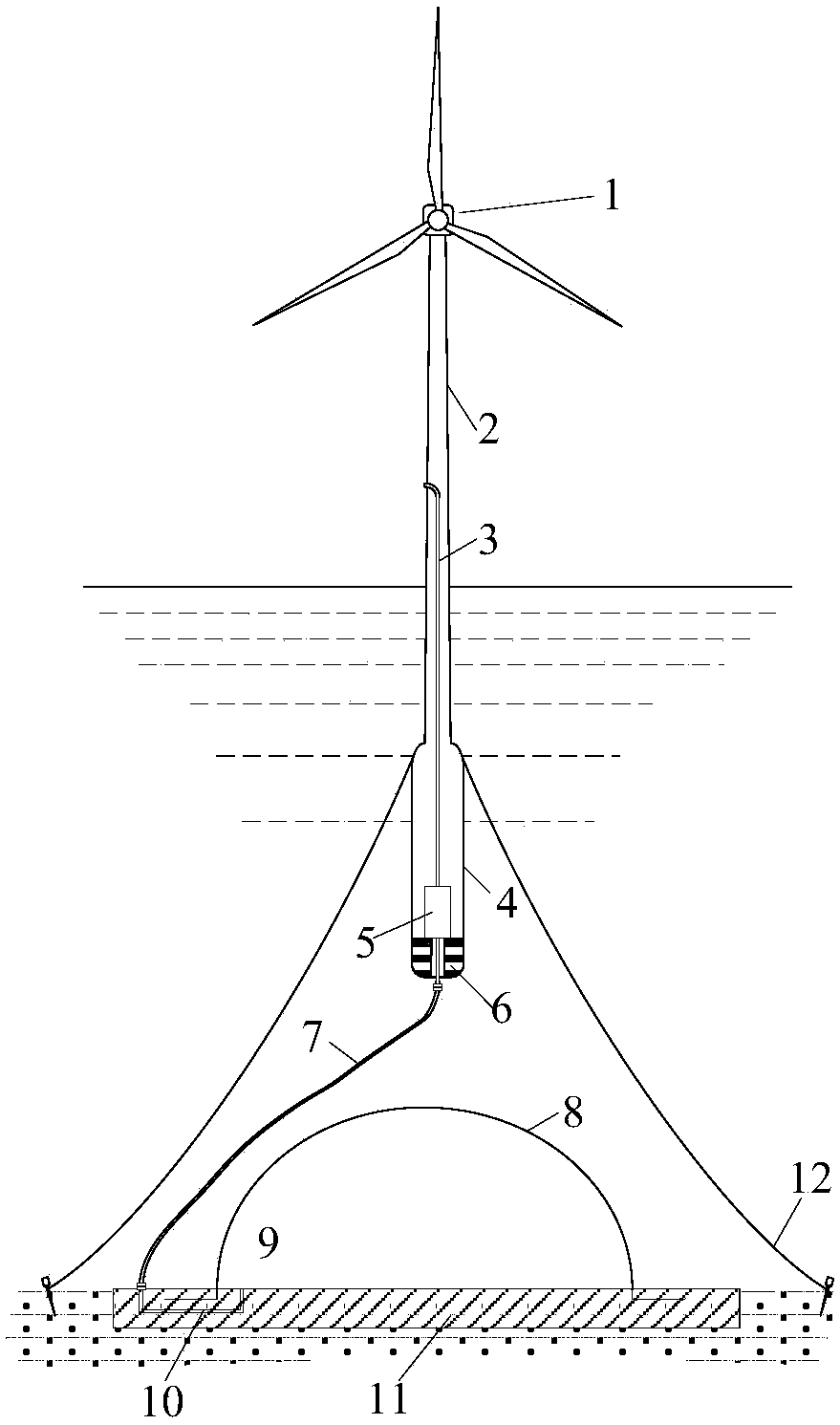

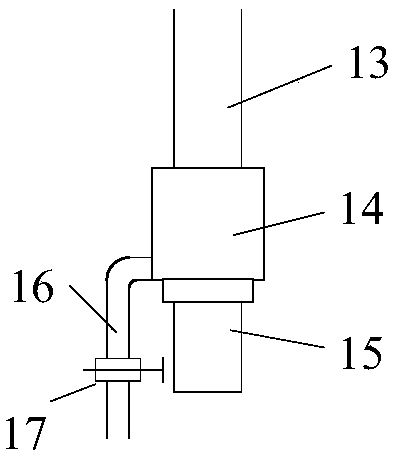

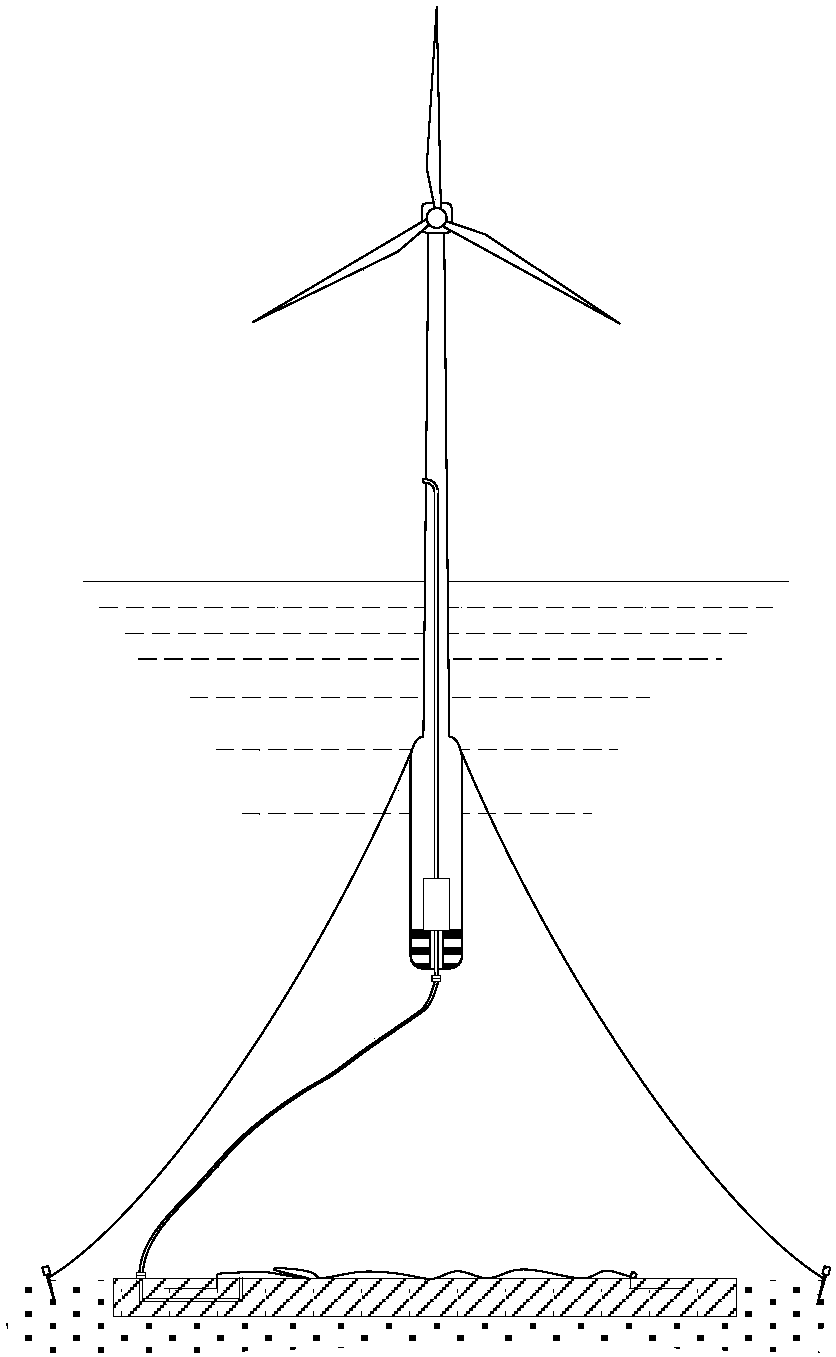

Offshore wind power generation system with seabed compressed air energy storage

PendingCN107559146ARealize output load regulation functionReduce peak loadWind energy with garvitational potential energyWind motor supports/mountsOcean bottomThermal energy storage

The invention relates to an offshore wind power generation system with seabed compressed air energy storage. The system comprises an offshore wind power generation unit, an air compression and expansion power generation unit and a seabed high pressure air energy storing device. When electricity generated by the offshore power generation unit exceeds the demand of a power grid, an air compressor ofthe air compression and expansion power generation unit is driven by surplus electricity to fill the seabed high pressure air energy storing device with high pressure air; when the load of the powergrid is increased while the load of the offshore wind power generation unit cannot meet the demand of the power grid, high pressure air in the seabed high pressure air energy storing device is released, and an expansion machine of the air compression and expansion power generation unit acts to drive a power generator to generate power so as to provide a power load to the power grid. According to the invention, energy is stored by means of compressed air to absorb surplus power when the wind power is relatively great and the demand on the load of the power grid is low while the compressed air stored in the seabed expands to act when the wind power is relatively small or the demand on the load of the power grid is high to provide power to the power grid, so that a power regulating function of the wind power generation system is achieved.

Owner:HUANENG POWER INT INC +2

Preparation method of graphene aerogel powder and graphene aerogel powder

The invention belongs to the technical field of functional materials, relates to the preparation of aerogel, and particularly relates to a preparation method of graphene aerogel powder and the graphene aerogel powder. The preparation method of the graphene aerogel powder comprises the following steps: firstly freezing graphene-based slurry or dispersion liquid, thus obtaining a frozen sample; thencrushing and screening the frozen sample at a low temperature, thus obtaining iced particles; and freeze drying the iced particles, thus obtaining the graphene aerogel powder. By virtue of the method, the explosion danger in the process of crushing the graphene oxide aerogel can be avoided, the drying speed in the freeze drying process can be increased, and the preparation method has the advantages of simplicity, safety and easiness in amplification.

Owner:昂星新型碳材料常州有限公司

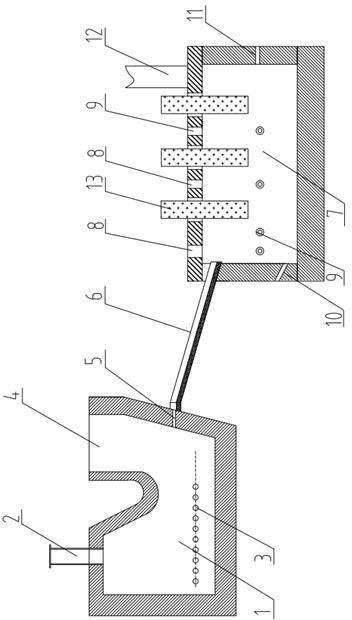

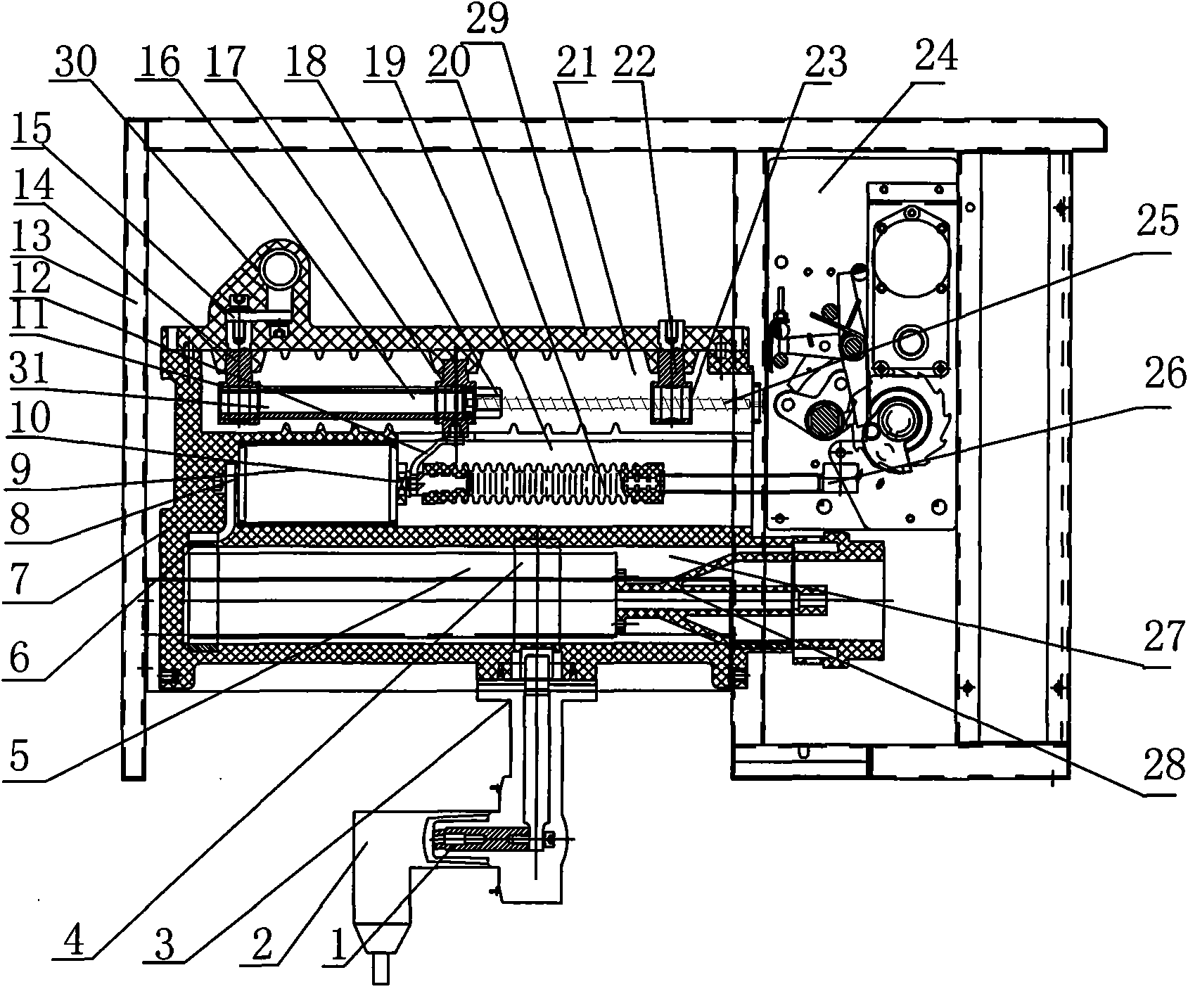

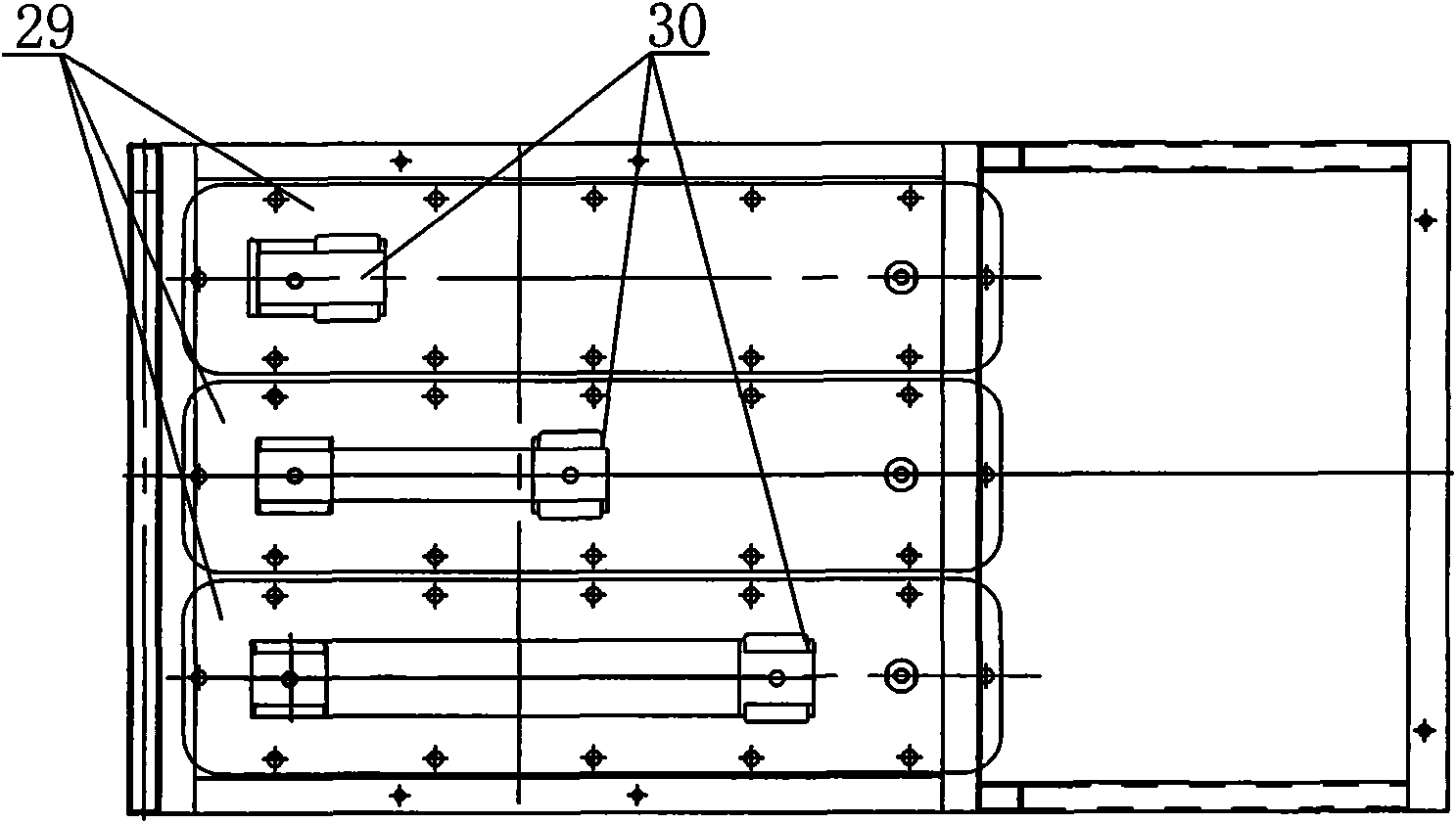

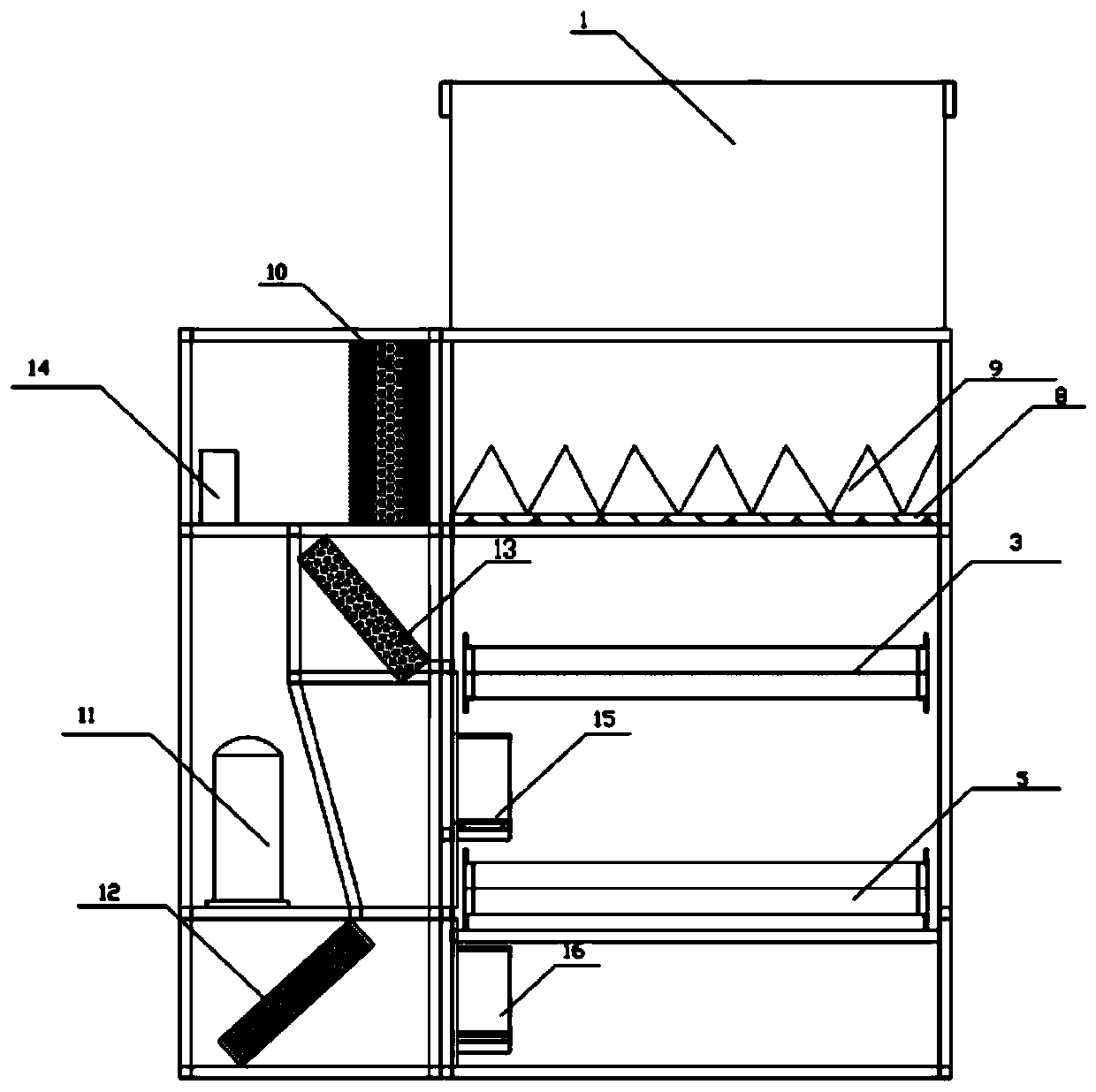

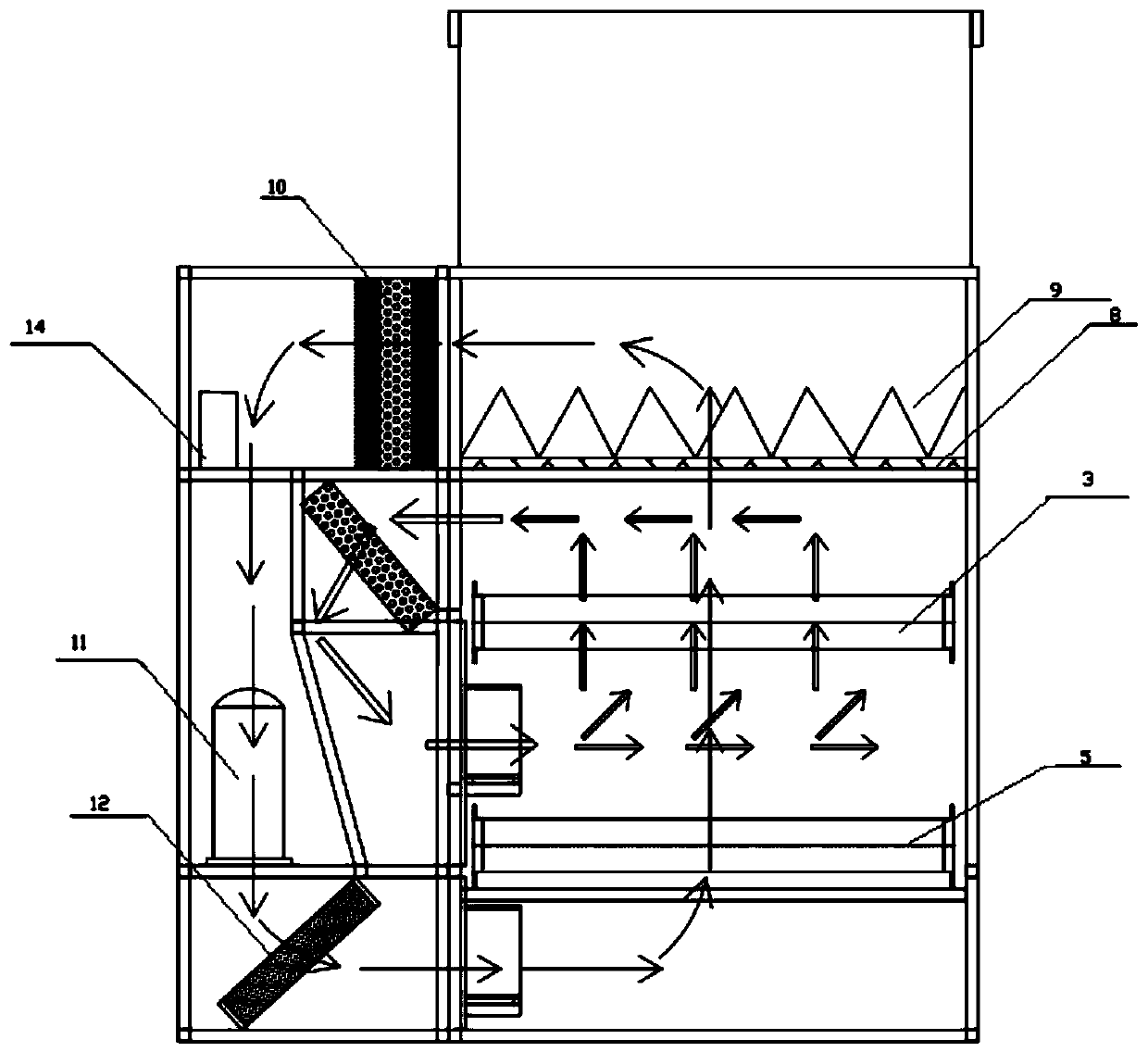

Sludge low-temperature heat pump drying equipment

PendingCN110127984AReduce loadIncrease load ratioSludge treatment by de-watering/drying/thickeningHeat pumpsSludgeAir filter

The invention relates to sludge low-temperature heat pump drying equipment, which comprises a sludge drying chamber, wherein a sludge feeding and distributing device is arranged above one side of thesludge drying chamber; a heat pump system chamber is arranged at one side of the sludge drying chamber; a heat pump system is arranged in the heat pump system chamber; the sludge feeding and distributing device comprises a sludge feeding hopper and a sludge distributing machine which are arranged from top to bottom; the sludge drying chamber is provided with a sludge inlet; the distributing machine is connected with the sludge inlet; a sludge outlet is arranged at the bottom of the sludge drying chamber; and an air filtering device is arranged at the upper part of the sludge drying chamber. Aplurality of layers of conveyor mesh belts are arranged in the middle of the sludge drying chamber, a discharging device is arranged below the lowermost conveyor mesh belt, the discharging device is connected with the sludge outlet, an auxiliary fan is arranged between any two adjacent layers of conveyor mesh belts, and a plurality of main fans are arranged at the bottom of the sludge drying chamber. The sludge low-temperature heat pump drying equipment has the advantages of low drying energy consumption, no secondary pollution, high safety performance, compact structure and small occupied area.

Owner:四川天润德环境工程有限公司

Method and device for comprehensively treating sludge generated by sewage treatment plant and kitchen waste oil

InactiveCN102701559AShorten drying timeDry fastSludge treatment by de-watering/drying/thickeningBurn unitsSludge

The invention relates to a method for comprehensively treating sludge generated by a sewage treatment plant and kitchen waste oil, which comprises the following steps of: (1) sludge formation; (2) frying dehydration; (3) burning and heat exchange; (4) tail gas processing; and (5) slag collection. The invention also relates to a comprehensive treatment device which consists of a sludge forming unit, a frying and drying unit, a burning unit, a heat exchange unit, a solid slag processing unit and a waste gas processing unit. A discharge port of the sludge forming unit is connected to a feed inlet of the frying and drying unit; a discharge port of the frying and drying unit is connected with a feed inlet of the burning unit; a slag outlet of the burning unit is connected to a slag inlet of the solid slag processing unit; a high temperature flue gas exhaust port of the burning unit is connected with the heat exchange unit; the heat exchange unit is connected to a heating chamber of the frying and drying unit; and the frying and drying unit and a waste gas exhaust port of the heat exchange unit are connected to the waste gas processing unit. According to the method and device provided by the invention, the resource recovery, the reduction and the harmless treatment of two types of wastes in towns, i.e. the kitchen waste oil and the sludge generated by the sewage treatment plant, can be implemented.

Owner:TIANJIN UNIV OF SCI & TECH

Multifunctional coal-fired energy-saving additive

The invention provides a multifunctional coal-fired energy-saving additive for a boiler to remove coke and dust and prevent corrosion. The multifunctional coal-fired energy-saving additive comprises the following components by weight percent: 5-15 percent of potassium nitrate, 1-9 percent of copper nitrate, 4-12 percent of magnesium nitrate, 8-12 percent of zinc, 20-30 percent of sodium chloride,10-20 percent of copper sulphate, 15-25 percent of aluminium nitrate and 1-7 percent of boric acid. The coal-fired additive has little dosage, occupies 0.02-0.05 percent of fuel, does not have toxicity, taste, corrosion or explosion dangers, is harmless for a human body and has no pollution for the environment.

Owner:袁锁营

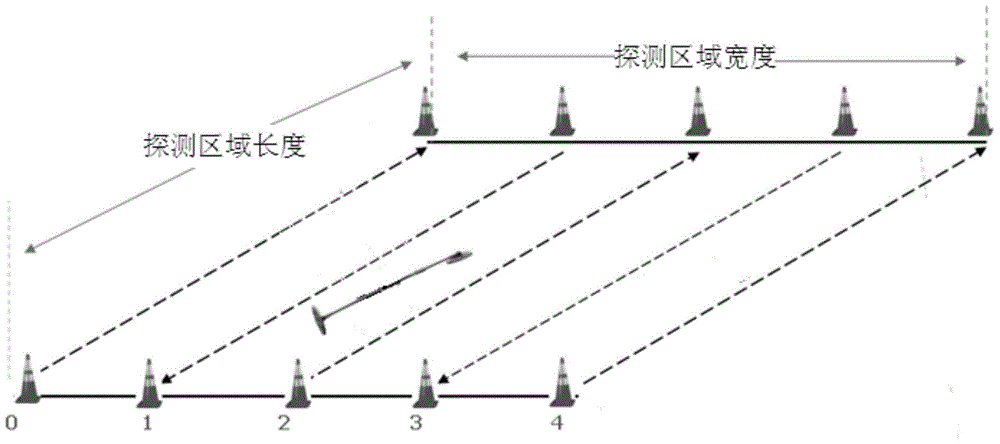

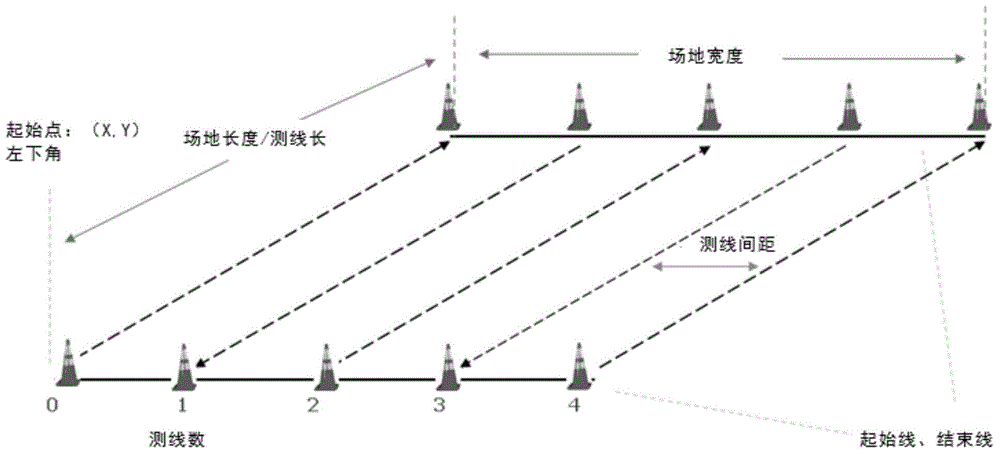

Method for detecting chemical weapons abandoned by Japan and buried in land

ActiveCN103605164AHigh sensitivityEasy to operateElectric/magnetic detectionAcoustic wave reradiationChemical weaponEngineering

The invention belongs to the technical field of geophysical exploration, relates to a method for detecting chemical weapons abandoned by Japan and buried in land, and is suitable for detecting single-shot or multi-shot chemical weapons which are abandoned by Japan and buried in various depths. The method comprises nine steps of arranging a metal detection work area, carrying out metal detection and marking a shell reaction point, excavating and removing a shell in an excavating while detecting manner, arranging a magnetic method detection work area, carrying out magnetic method detection data acquisition, analyzing a magnetic method detection result, determining the analyzed result, excavating while detecting by using a metal detector and excavating to remove a magnetic anomaly point, and excavating and thoroughly confirming detection. A known shell the buried depth of which is no more than 1 meter and the surface of which is free of metal object interference, a known shell the buried depth of which is more than 1 meter and the surface of which is free of metal object interference, and an area where the surface of a shell is provided with strong metal object interference are distinctively excavated. The method for detecting the chemical weapons abandoned by Japan and buried in land is advantaged by being high in sensitivity, high in safety, high in detection result accuracy, timeliness and reliability and the like.

Owner:中国人民解放军防化学院

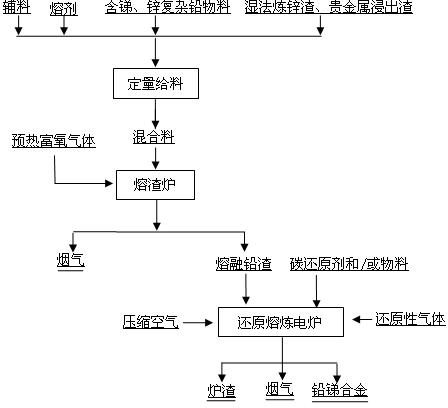

Liquid fuel and preparation thereof

InactiveCN101475857AReduce volatilityImprove performanceLiquid carbonaceous fuelsThermal energyHexamethylenetetramine

The invention relates to a liquid fuel and a preparation method thereof. The liquid fuel is mainly prepared from the following raw materials in portion by mass: 150 to 300 portions of water, 650 to 850 portions of methanol, 5 to 20 portions of butyl acetate, 5 to 20 portions of sodium hydroxide, 2 to 10 portions of hexamethylenetetramine, 10 to 30 portions of hydrogen peroxide with a mass concentration of 30 percent, and 50 to 150 portions of ethanol. The liquid fuel has low volatility and steady performance, is safe during the transportation and storage when being distributed to users due to the high temperature resistance, is difficult to ignite if no open flame exists, does not splash liquids and fumigate eyes during the use, can completely burn, is difficult to generate harmful gas such as formaldehyde and the like, has no smoke, no toxicity, no carbon deposition, no pot blackening, violent fire, high heat energy, no pressure, and no explosion danger, has a combustion calorie more than 9,500kcal / kg, can be extinguished by water during the fire extinguishing, and has the characteristics of cleanliness, environment protection, safety, simple and convenient production, and low production cost. The liquid fuel can substitute diesel oil and liquefied gas, and is suitable to be used by diesel furnaces, liquefied gas furnaces, boilers and the like.

Owner:廖新明 +1

Oil-water separation material and preparation method and application thereof

PendingCN107715499AEasy to makeLow costFatty/oily/floating substances removal devicesWater treatment compoundsSilica nanoparticlesOil water

The invention discloses a preparation method of a silicon dioxide nanoparticle modified material with an oil-water separation function. The preparation method is characterized in that silicon dioxidenanoparticles as a surface modification material simulate the bioadhensive effect and the lotus effect of marine mussel foot proteins, and an oil-water separation material having a special wettabilityis prepared through dopamine self polymerization, silicon dioxide nanoparticle adhesion and oleophobic modification. By means of the prepared oil-water separation material, the separation efficiencyof various oil-water mixtures can reach 95% or above. According to the technology, the raw materials are low in price and easy to obtain, the technology is simple and easy to operate, and the oil-water separation material is prepared at the room temperature, the product is good in oil-water separation function, tolerance and recyclability, and the oil-water separation material can be used in the fields of oil pollution on the water surface, chemical engineering, food production and the like.

Owner:吕艳 +1

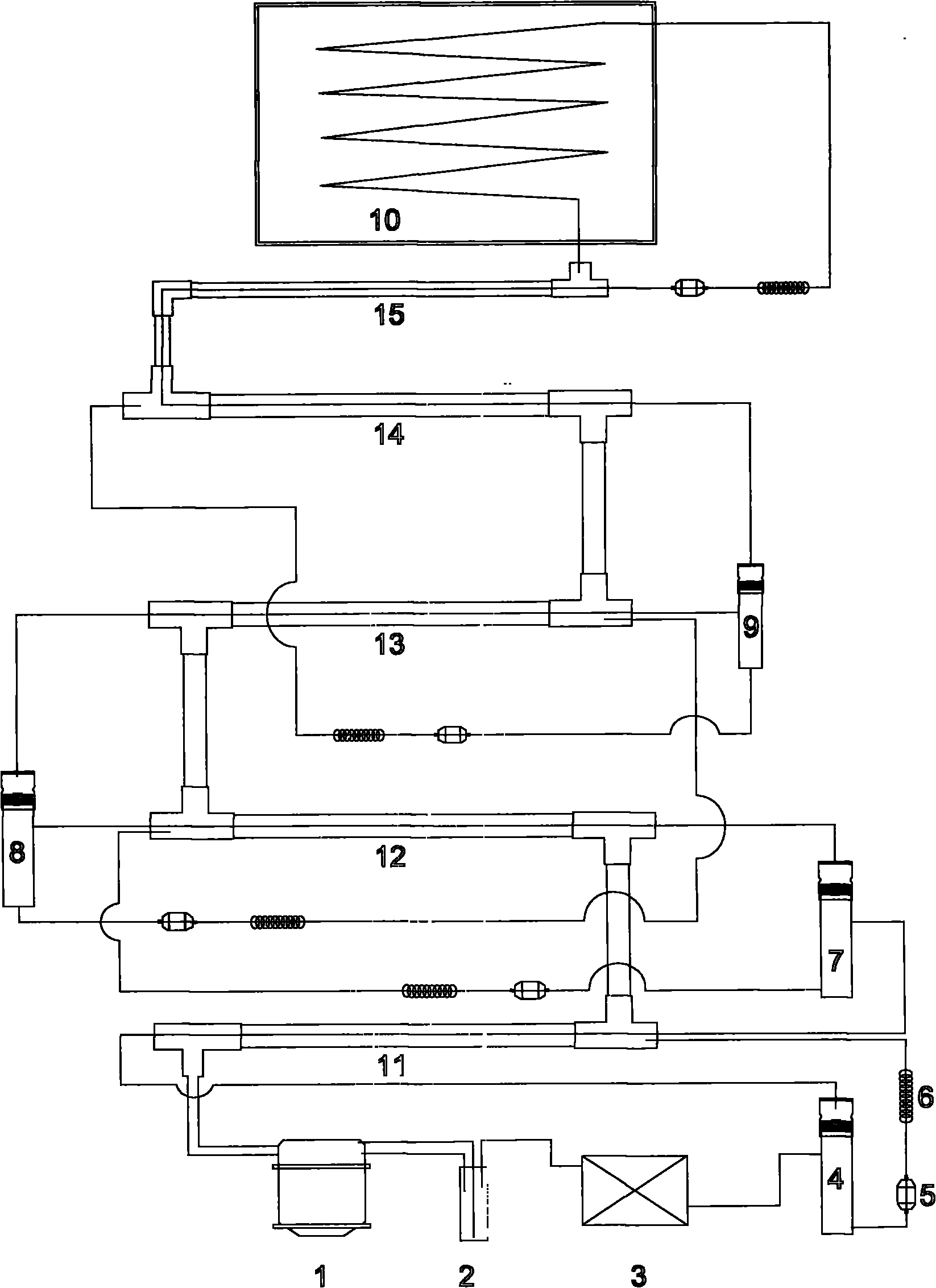

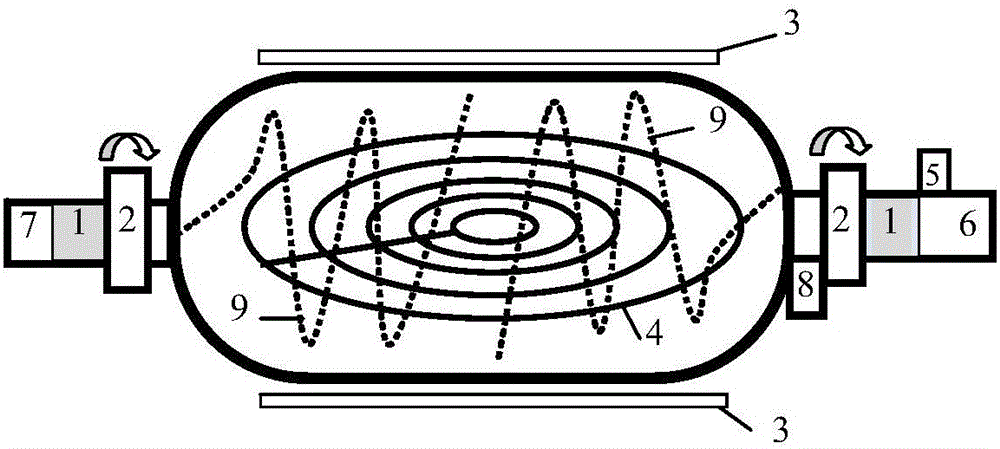

Rare-earth permanent magnet hydrogen storage device for hydrogen demolishing and hydrogen cyclic utilization and system and method thereof

ActiveCN106001582AStoring evenlyDehydrogenation can be controlledMagnetic materialsRare earthProcess engineering

The invention belongs to the technical field of rare-earth permanent magnet materials and relates to a rare-earth permanent magnet hydrogen storage device for hydrogen demolishing and hydrogen cyclic utilization and a system and method thereof. A rotary hydrogen storage tank body (10) of the device is made of a hydrogen storage alloy material. An output end (6) and an input end (7) which are symmetrical and communicate with each other are arranged on the rotary hydrogen storage tank body (10). The output end (6) and the input end (7) are each internally provided with a filter screen (1). A sealing rotating shaft (2) is arranged at the outer side of each filter screen (1), and the sealing rotating shafts (2) are mounted on a storage tank rotation driving mechanism. An exhaust opening (5) is formed in the output end (6). A spiral piece (9) is arranged inside the rotary hydrogen storage tank body (10). A heating device (3) and a cooling device (4) are arranged at the outer side of the rotary hydrogen storage tank body (10) in a manner that the heating device (3) and the cooling device (4) are close to but not in contact with each other. The rare-earth permanent magnet hydrogen storage device and the system and method thereof are reasonable in process flow and simple in equipment structure and have industrial application value and wide application prospect.

Owner:CENT IRON & STEEL RES INST

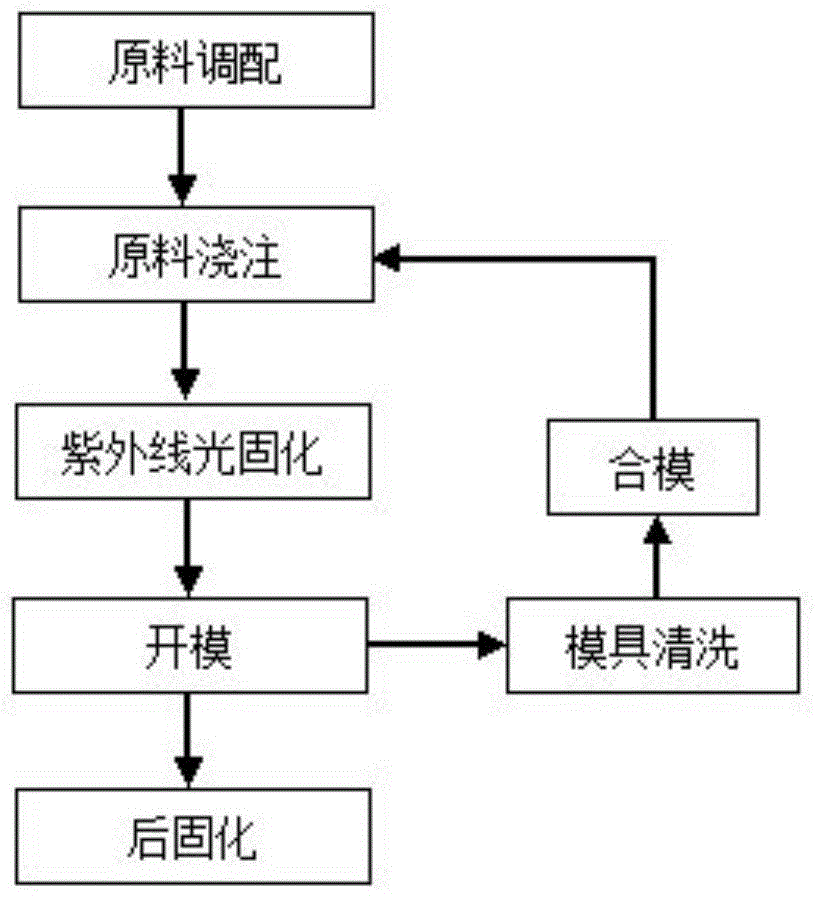

Light curing forming process for resin lens

InactiveCN105690783AHigh technology automationExcellent performanceOptical articlesSolid-stateUV curing

The invention provides a light curing forming process for a resin lens. The light curing forming process comprises the following steps of raw material blending, raw material pouring, ultraviolet light curing, mold making and postcuring; specifically, blended monomer raw materials are put into a special curing machine after raw material pouring, a to-be-cured mold are sequentially subjected to an IR preheating stage, a UV curing stage, a cooling stage and then discharging; after the mold receives light energy at the UV curing stage, monomers are polymerized into a solid state from the liquid state in the mold; and a preliminarily formed product obtained through mold making is fed into a postcuring furnace, and a finally formed product is obtained after curing. Light-heat combination curing is adopted for the light curing forming process for the resin lens, a forming cycle only needs several minutes, and the light curing forming process is a first creation in China and in the world. The light curing forming process for the resin lens is different from the current resin lens heat curing forming process of which a forming cycle needs twenty hours. The light curing forming process for the resin lens is capable of saving energy, protecting the environment, efficient, high in technological automation, simple and easy to learn. The finished product is more excellent in performance through detection.

Owner:蔡征宇 +3

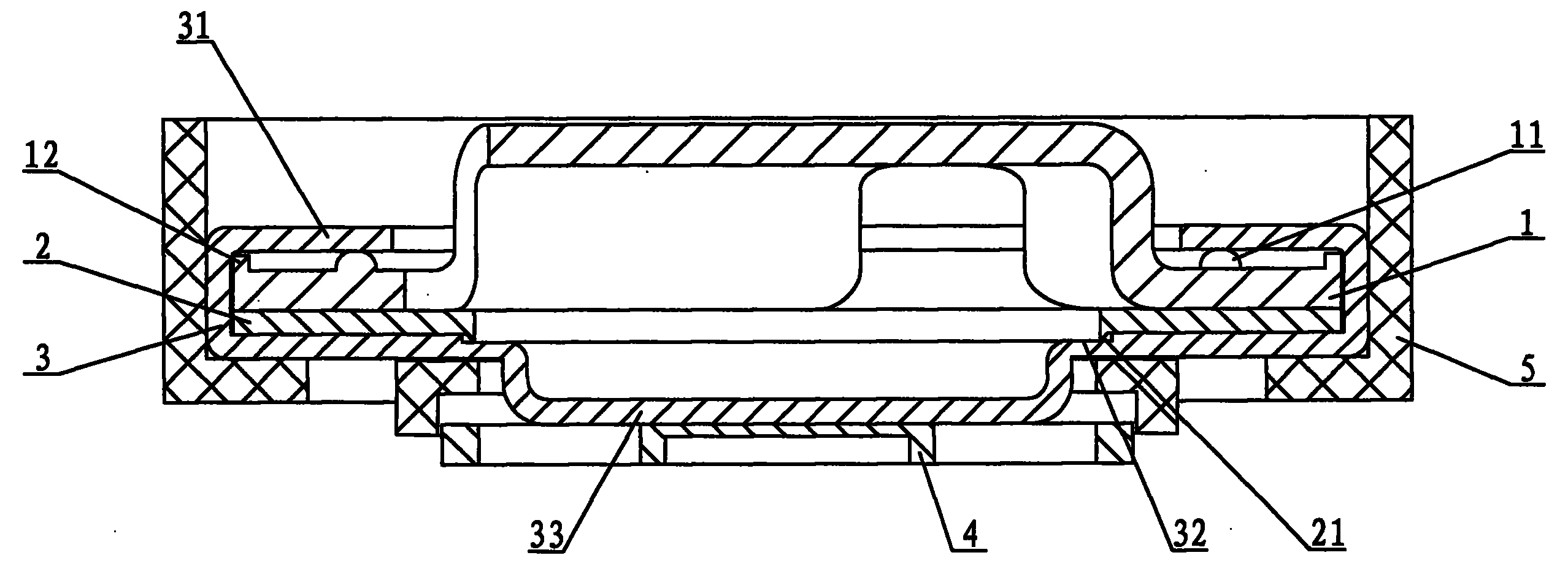

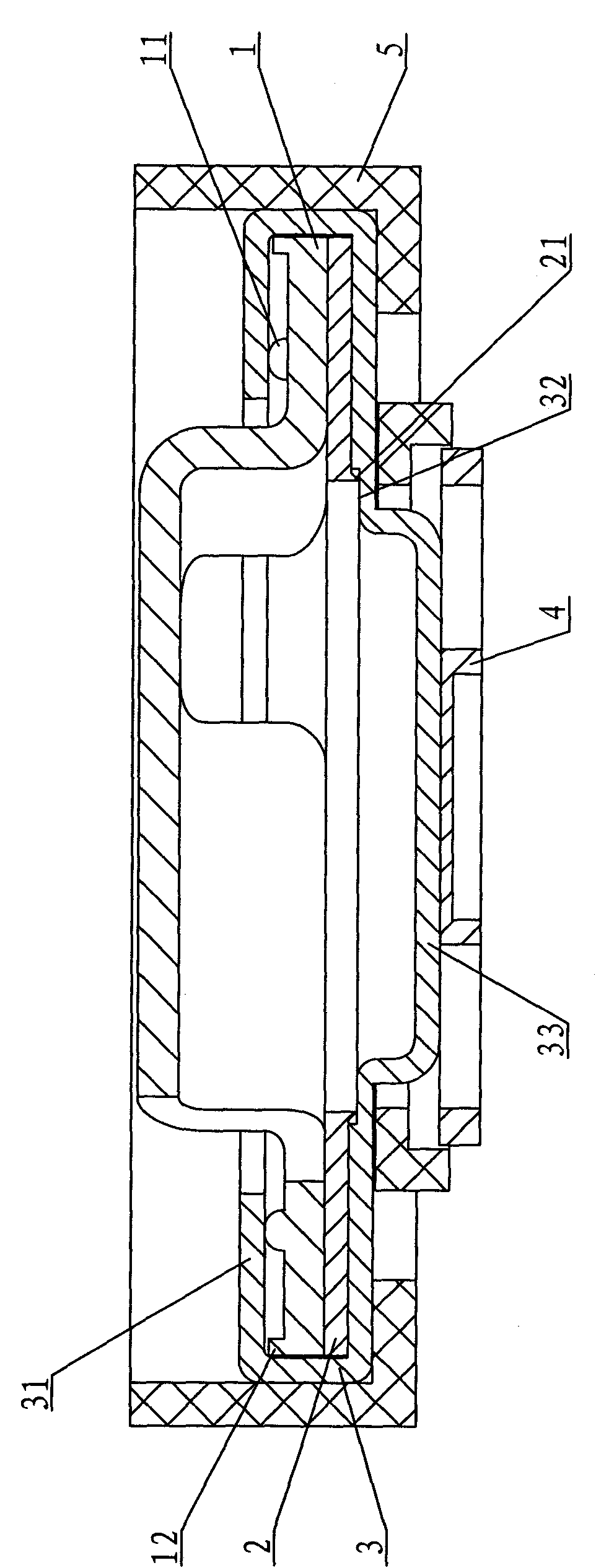

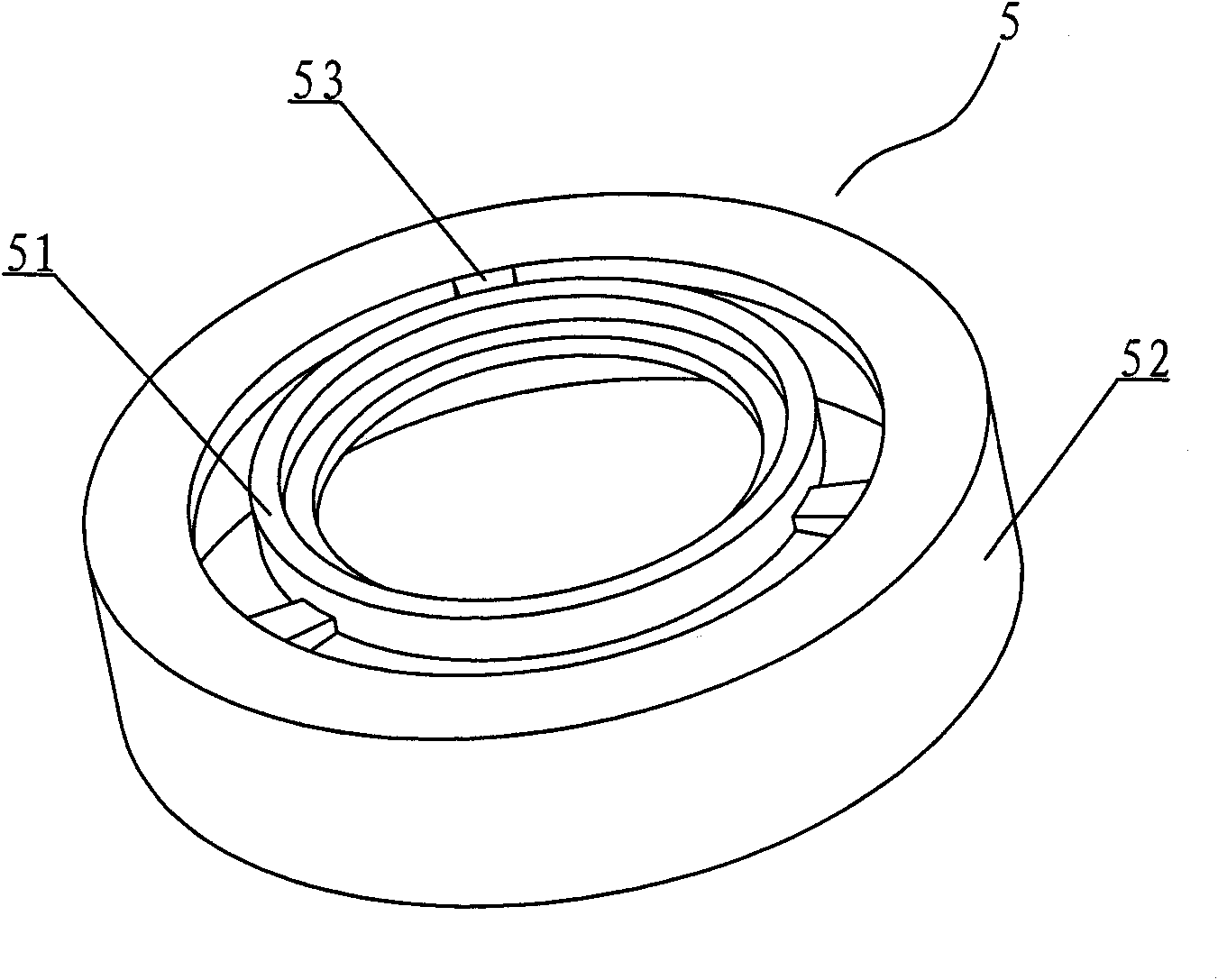

Explosion-proof cap of micro-resistance cylindrical lithium ion battery

InactiveCN101814589ANo explosion hazardImprove securityVent arrangementsCell lids/coversVena contracta diameterInternal resistance

The invention relates to an explosion-proof cap of a micro-resistance cylindrical lithium ion battery. The explosion-proof cap comprises an upper cap, a gasket, an explosion-proof membrane with a wall body, an orifice plate and a sealing ring. A plurality of air holes are arranged on the upper cap. The wall body of the explosion-proof membrane is bent and wraps the gasket and the upper cap in the cavity of the explosion-proof membrane. After the explosion-proof membrane wraps the gasket and the upper cap, the explosion-proof membrane is embedded in the sealing ring coated with glue. The orifice plate is embedded at the bottom surface of the sealing ring. The orifice plate is welded with the explosion-proof membrane through laser spot welding. A circular welding platform which protrudes downward is arranged on the bottom surface of the explosion-proof membrane. A prestressed pressure relief ring is formed between the circular welding platform and the bottom surface of the explosion-proof membrane. In combination with the cutting of the prestressed pressure relief ring along a sharp spiny flanged edge in the gasket, the flanging of the cap edge of the upper cap and the tight welding between a convex welding spot on the cap edge and the bent wall body of the explosion-proof membrane, the invention realizes that the explosion-proof membrane can be exploded open when being turned over and the overall internal resistance of the cap is reduced, and has the advantages that the structure is simple, compact and stable, the deformation and the misplacement are not apt to occur, the internal resistance of the cap is low, the battery performance is high, the explosion-proof membrane can be normally exploded open to relieve pressure after the explosion-proof membrane is turned over, the explosion-proof performance is stable and the service life is long.

Owner:TAIXING ZHENGXING ELECTRON

Environment-friendly liquid fuel with high heating value and preparation method

InactiveCN101531927AReduce consumption costReduce consumptionLiquid carbonaceous fuelsParaffin waxLiquid fuel

The invention relates to an environment-friendly liquid fuel with high heating value, comprising the ingredients with the following weight ratio contents: 70-75 of methanol, 10-15% of water, 13-16 turpentine oil and 1-4 of additive. The additive is prepared by hydrogen peroxide with weight percent concentration of 30%, cyclohexane, ferrocene, liquid paraffin and ethanol. The preparation method comprises the following steps: firstly preparing the additive, then adding the methanol, water and turpentine oil into an agitated tank, finally adding the prepared additive in proportion to obtain the product after agitating. The invention has the advantages of low fuel cost, simple and convenient production technique, high heat value of combustion, easy procurement of raw materials, no pollution and saved energy, produces no harmful gases in the process of combustion, thus being convenient, practical, safe and environment-friendly.

Owner:SHAOGUAN FUDE ENVIRONMENTALLY FRIENDLY FUELS

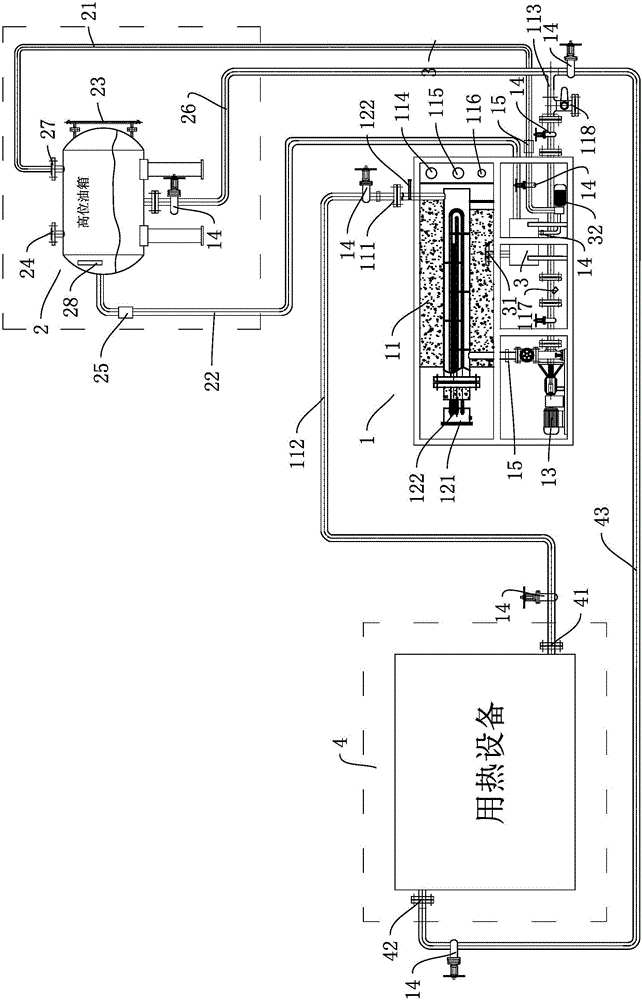

Electric heating thermal oil furnace system

The invention relates to an electric heating thermal oil furnace system. Oil in a thermal oil furnace oil cavity of the system is fed into heat equipment through a hot oil pump, and returns to the thermal oil furnace oil cavity to form a cycle; the system is characterized in that a thermal oil furnace is connected with a high-position oil tank, the high-position oil tank and an auxiliary oil tank can form an oil cycle, the auxiliary oil tank is further connected with the thermal oil furnace oil cavity; an electric heating thermal oil device is small in size, mounting is flexible, the device is suitable for being mounted nearby the heat equipment, meanwhile, power serves as a power source, pollution is small, the heat utilization rate is high, the equipment investment is small, and due to the fact that a thermal oil heating system is simple, no water treatment device or more auxiliary devices exist, and a thermal oil boiler bears low pressure, the whole system is small in investment; due to the fact that the system only bears the pump pressure, the thermal oil heating system has no explosion hazards and is safer; the environment-friendly organic carrier thermal oil furnace system mainly has the environment-friendly effects of being extremely small in smoke discharge amount and free of sewage pollution and heat pollution.

Owner:付志权

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com