Explosion-proof cap of micro-resistance cylindrical lithium ion battery

A lithium-ion battery and micro-resistor technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of easy dislocation and fracture of the explosion-proof membrane and the orifice plate, failure to open and release pressure normally, and easy deformation and rupture of the explosion-proof membrane. Achieve the effect of no explosion hazard, improve the compression resistance of the overall structure, and regular deformation

Inactive Publication Date: 2010-08-25

TAIXING ZHENGXING ELECTRON

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the problem that in the prior art, after the explosion-proof film of the lithium-ion battery cap is turned over, the notch cannot be opened normally to release the pressure, the internal resistance of the cap is reduced and the structure of the cap is stable, the battery life is short, and the explosion-proof film of the cap is easily deformed when the cap is packaged with the shell. Disadvantages such as rupture, explosion-proof film and orifice plate easy misalignment and fracture lead to battery scrapping, explosion-proof film deformation and folding lead to battery explosion, etc. The purpose of the present invention is to provide a kind of anti-explosion film that can normally burst open and release pressure after the explosion-proof film is turned over, and the internal resistance of the cap is reduced and the cap structure Both stability and long service life of the battery, the explosion-proof membrane and the orifice plate are not deformed and dislocated when the cap and the shell are packaged, the battery explosion-proof performance is stable, and the production and use of the micro-resistance cylindrical lithium-ion battery explosion-proof cap is safe.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

Login to View More

Abstract

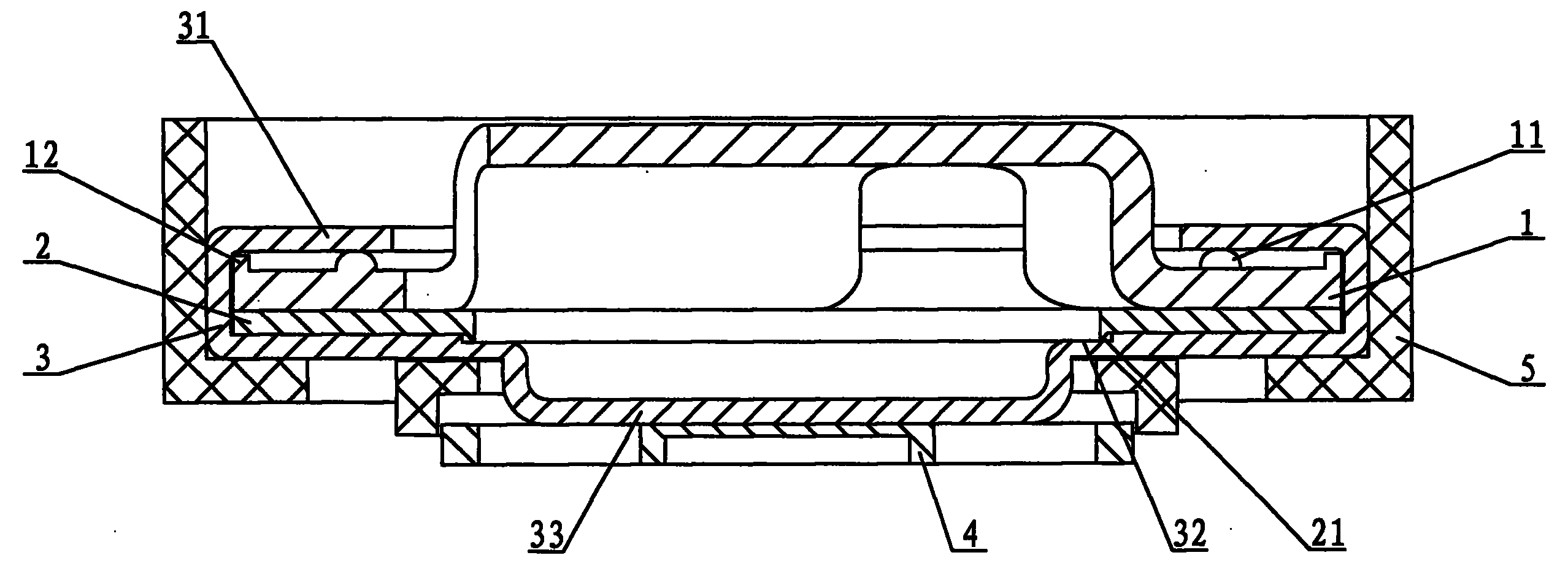

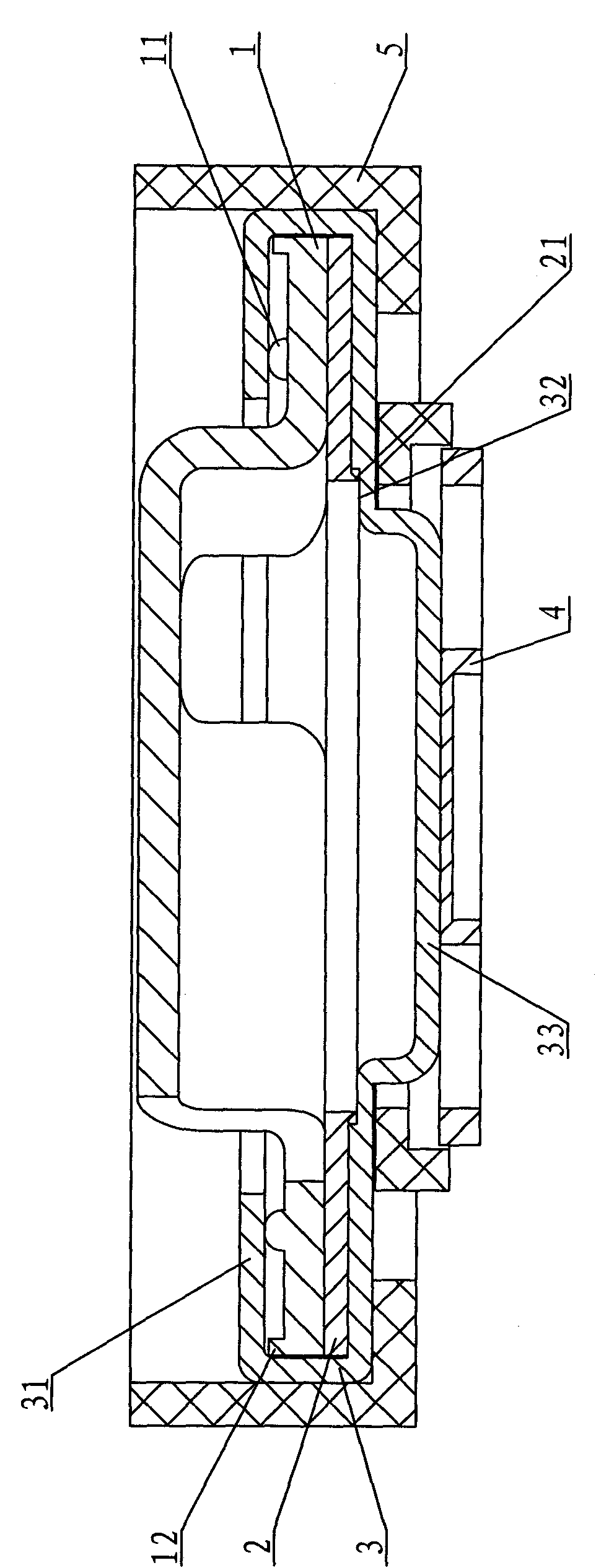

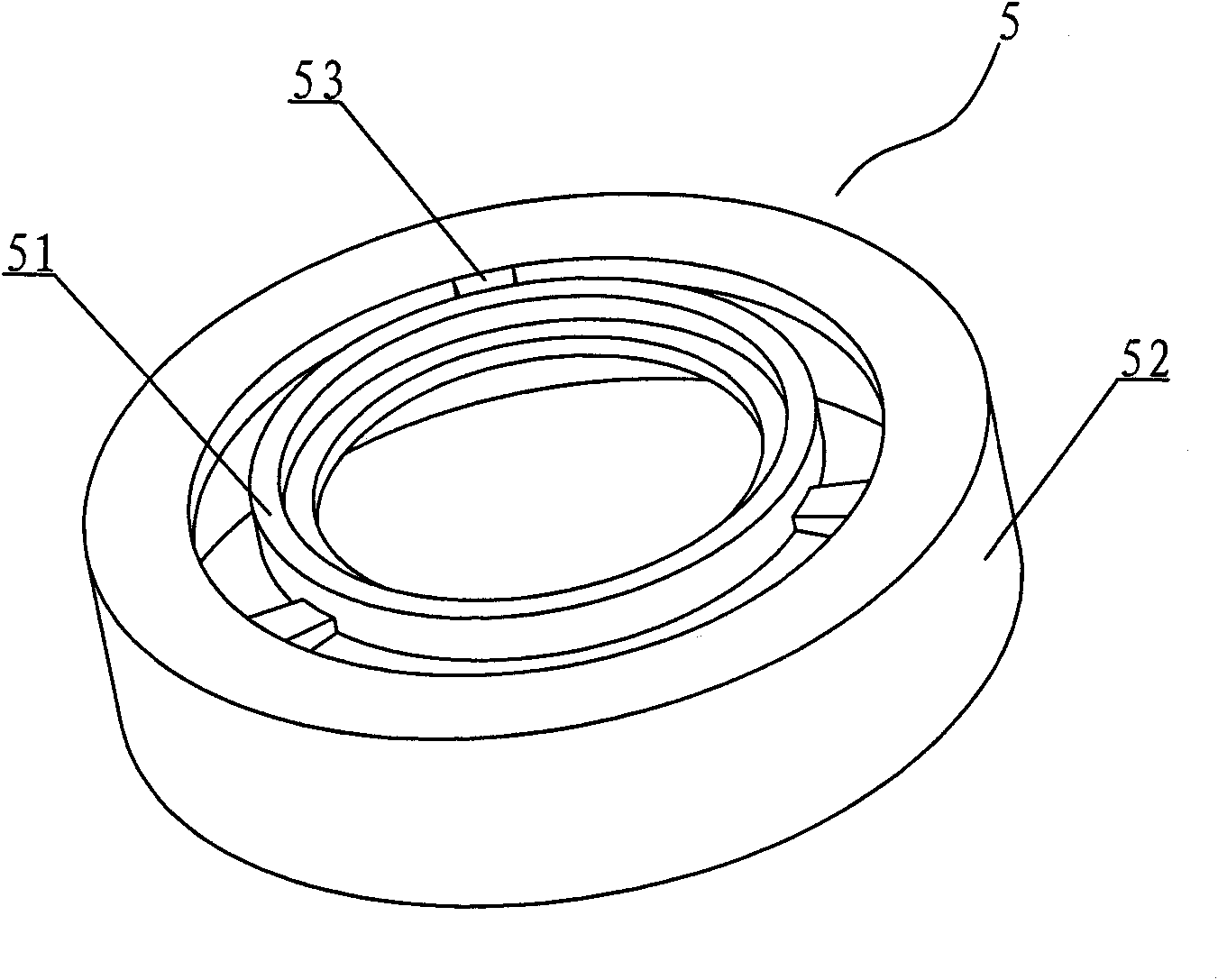

The invention relates to an explosion-proof cap of a micro-resistance cylindrical lithium ion battery. The explosion-proof cap comprises an upper cap, a gasket, an explosion-proof membrane with a wall body, an orifice plate and a sealing ring. A plurality of air holes are arranged on the upper cap. The wall body of the explosion-proof membrane is bent and wraps the gasket and the upper cap in the cavity of the explosion-proof membrane. After the explosion-proof membrane wraps the gasket and the upper cap, the explosion-proof membrane is embedded in the sealing ring coated with glue. The orifice plate is embedded at the bottom surface of the sealing ring. The orifice plate is welded with the explosion-proof membrane through laser spot welding. A circular welding platform which protrudes downward is arranged on the bottom surface of the explosion-proof membrane. A prestressed pressure relief ring is formed between the circular welding platform and the bottom surface of the explosion-proof membrane. In combination with the cutting of the prestressed pressure relief ring along a sharp spiny flanged edge in the gasket, the flanging of the cap edge of the upper cap and the tight welding between a convex welding spot on the cap edge and the bent wall body of the explosion-proof membrane, the invention realizes that the explosion-proof membrane can be exploded open when being turned over and the overall internal resistance of the cap is reduced, and has the advantages that the structure is simple, compact and stable, the deformation and the misplacement are not apt to occur, the internal resistance of the cap is low, the battery performance is high, the explosion-proof membrane can be normally exploded open to relieve pressure after the explosion-proof membrane is turned over, the explosion-proof performance is stable and the service life is long.

Description

Explosion-proof caps for micro-resistance cylindrical lithium-ion batteries technical field The invention relates to a cap for a cylindrical lithium ion battery, in particular to an explosion-proof cap for a cylindrical lithium ion battery with micro resistance and no explosion. Background technique Lithium-ion battery cap is a key component of lithium-ion batteries, which is directly related to battery reliability, service life, capacity, production and use safety of producers and consumers. The existing cylindrical lithium-ion battery cap is composed of an upper cover, a gasket, an explosion-proof diaphragm, a hole plate, and a sealing ring. After the improvement of the positive and negative electrode material technology of the battery, the traditional technology of using PTC gaskets to control the thermal expansion of the battery is basically eliminated. The main reason is that the internal resistance of the PTC gasket (high temperature thermistor) itself is relatively ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M2/04H01M2/12H01M2/22H01M2/08H01M50/143H01M50/147H01M50/188H01M50/30H01M50/528

CPCY02E60/10

Inventor 朱剑

Owner TAIXING ZHENGXING ELECTRON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com