Oil-water separation material and preparation method and application thereof

A technology for oil-water separation and modification of materials, applied in separation methods, liquid separation, chemical instruments and methods, etc., to achieve the effects of easy control, simple preparation and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

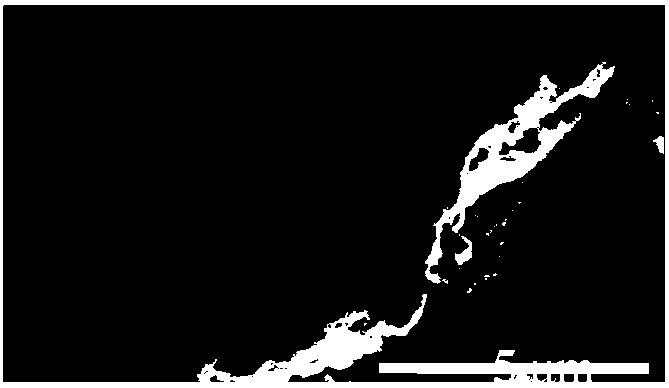

Image

Examples

Embodiment 1

[0050] After washing 1.3g of cotton fabric with water, dry it for later use. Dissolve 0.15g of dopamine hydrochloride and 1.2g of trishydrochloride in 95.2mL of distilled water, and then disperse 0.2g of silica nanoparticles (about 200nm in diameter) in the above solution. After stirring for 15 min, a suspension was obtained. Then, add cotton fabric into the suspension, stir and react at 20° C. for 24 hours, wash until neutral, and dry to obtain a cotton fabric material modified with silica nanoparticles. The oil separation efficiencies of the product in this example to n-hexane / water, toluene / water and chloroform / water mixtures (the volume ratio of oil and water is 1:3) can reach 95.5%, 96.2% and 97.5%, respectively.

Embodiment 2

[0052] After washing 1.3g of cotton fabric with water, dry it for later use. Dissolve 1.6g of dopamine hydrochloride and 0.2g of trishydrochloride in 95.2mL of distilled water, then disperse 1.5g of silica nanoparticles (about 200nm in diameter) in the above solution, at 1500 rpm After stirring for 15 min, a suspension was obtained. Then, add cotton fabric into the suspension, stir and react at 20° C. for 24 hours, wash until neutral, and dry to obtain a cotton fabric material modified with silica nanoparticles. The oil separation efficiencies of the product in this example to n-hexane / water, toluene / water and chloroform / water mixtures (the volume ratio of oil and water is 1:2) can reach 96.5%, 95.8% and 97%, respectively.

Embodiment 3

[0054] After washing 1.3g of cotton fabric with water, dry it for later use. Dissolve 1.6g of dopamine hydrochloride and 1.2g of trishydrochloride in 95.2mL of distilled water, and then disperse 2g of silica nanoparticles (about 200nm in diameter) in the above solution. After stirring for 15 min, a suspension was obtained. Then, cotton fabric was added into the suspension, stirred and reacted at 35°C for 24 hours, washed until neutral, and dried to obtain a cotton fabric material modified with silica nanoparticles. The oil separation efficiencies of the product in this example to n-hexane / water, toluene / water and chloroform / water mixtures (the volume ratio of oil and water is 1:2) can reach 97.5%, 98% and 98.4%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com