Light curing forming process for resin lens

A technology of light-curing molding and resin lenses, which is applied to optical components, household appliances, and other household appliances. It can solve the problems of large number of molds, long production cycle, respiratory tract infection, etc., and achieve high-tech automation and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The process of the embodiment adopts the combined curing method of ultraviolet light heating and curing. The products produced are tested and meet the standards, and some performances are better than those produced by the current heat curing method.

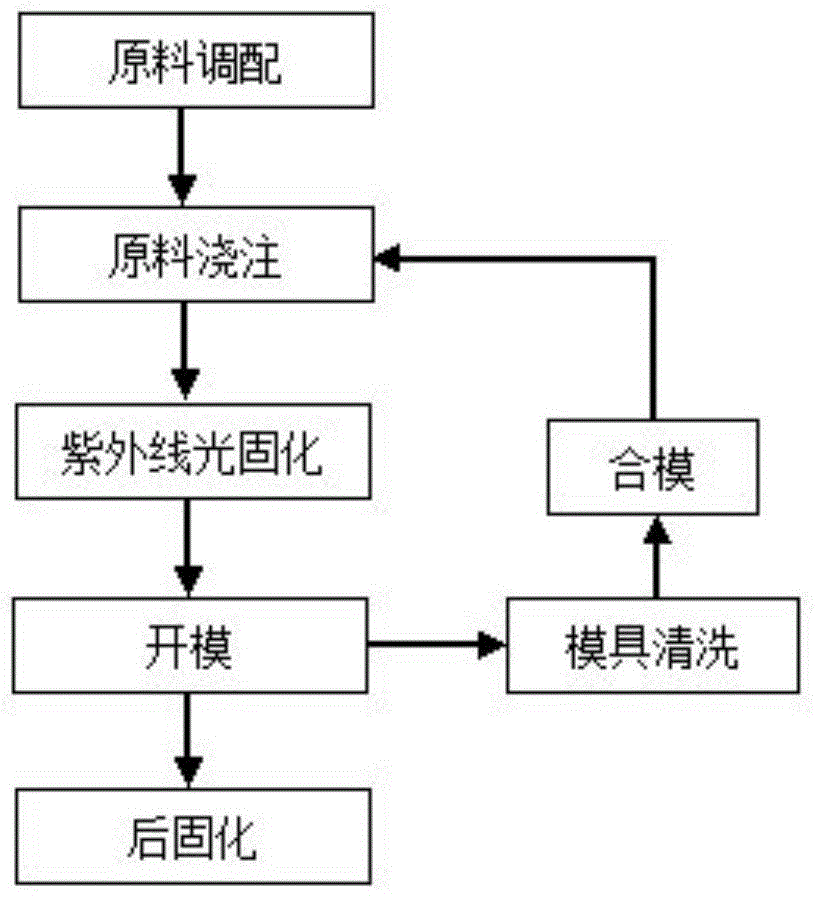

[0030] The light-curing molding process of this resin lens includes: raw material deployment, raw material pouring, UV curing, mold opening, mold closing, and post-curing of the lens, such as figure 1 .

[0031] Raw material deployment

[0032] The monomer raw material is divided into two parts: main material and auxiliary agent. The main material is mixed with acrylic acid monomers, and the auxiliary agents include functional modifiers, ultraviolet absorbers, internal release agents, initiators, and color pastes. The main materials and auxiliary agents are mixed in a certain proportion.

[0033] The main material is mixed with acrylic monomers, including at least one of monofunctional acrylate monomers, bifunctional acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com