Patents

Literature

61results about How to "Reduce the amount of fly ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste burning smoke purification process and purification system

InactiveCN102233230AEmission reductionSuppress generationLighting and heating apparatusDispersed particle separationEnvironmental engineeringSpray dried

The invention discloses a waste burning smoke purification process. The process comprises a denitration step and an acid removal step. The denitration step comprises a combination step of a smoke recycling process and a selective non-catalytic reduction (SNCR) denitration process; the acid removal step comprises a primary acid removal step and a secondary acid removal step; and a spray drying method is used for removing acid in the primary acid removal step, and a suspension boiling method is used for removing acid in the secondary acid removal step. The generation of NOx is inhibited by the smoke recycling process, acidic gases in the smoke are removed by the secondary acid removal process, and the burned smoke is efficiently purified with relatively low operating cost. The deep purification effect of the smoke is achieved by organically combining several processes.

Owner:瀚蓝(厦门)固废处理有限公司 +3

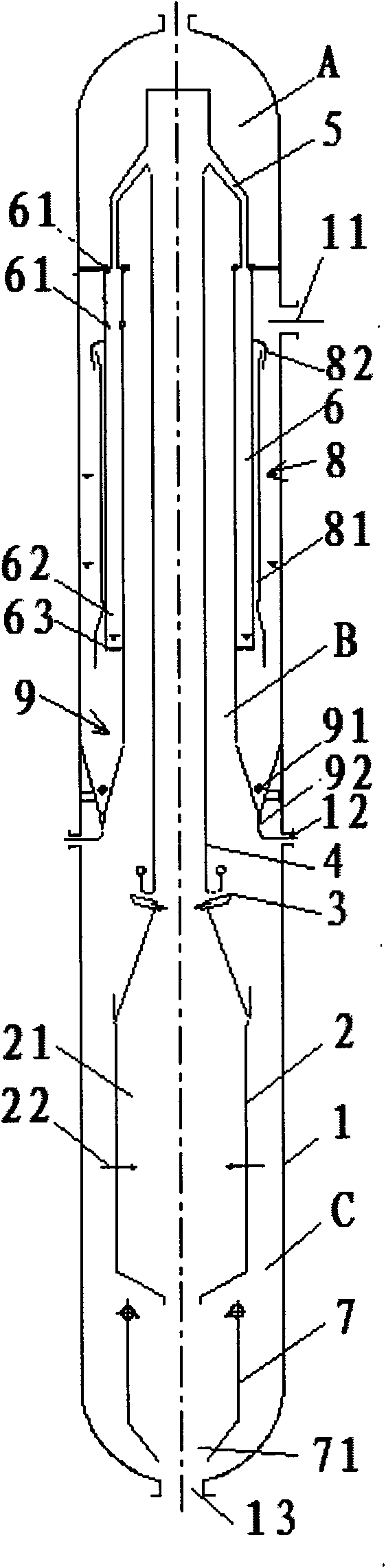

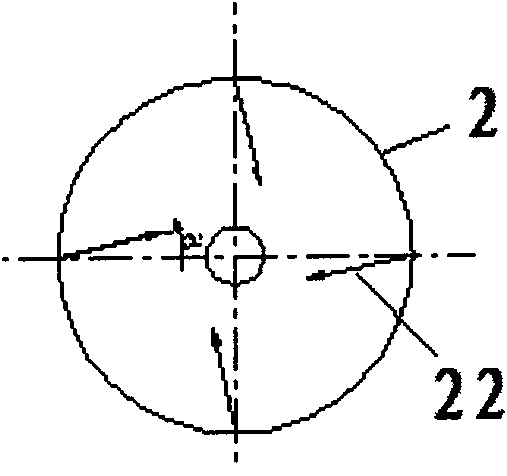

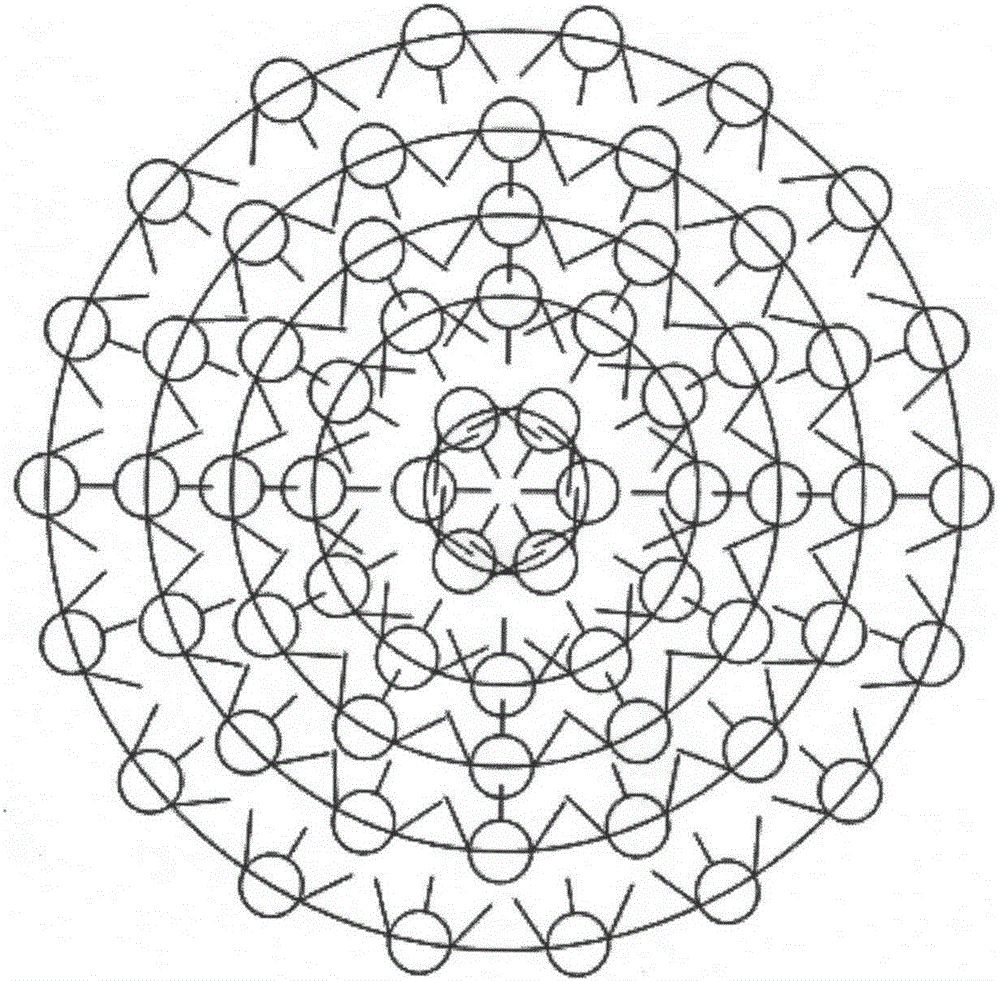

Tower-type powdered coal pressure gasification device with chilling process

ActiveCN101885991ALower the altitudeIncrease catch rateGranular/pulverulent flues gasificationSlagEngineering

The invention discloses a tower-type powdered coal pressure gasification device with a chilling process. The device comprises a pressure shell, and a gasification unit and a steam / water or dust-free gas chilling unit which are hung in the pressure shell. The device is characterized in that the gasification unit is arranged below the steam / water or dust-free gas chilling unit coaxially; the gasification unit comprises a reaction chamber and four nozzles arranged near the bottom of the reaction chamber at interval; the device of the invention also comprises a cooling channel and a returning chamber which are in coaxial arrangement with the gasification unit or the steam / water or dust-free gas chilling unit, and a chilling chamber and a slag pool; the cooling channel is arranged above the steam / water or dust-free gas chilling unit; the returning chamber is arranged on the top of the cooling channel; the chilling chamber is arranged around the cooling channel; the slag pool is arranged below the gasification unit; and the pressure shell is provided with a synthesis gas outlet, a grey water exhaust port and a slag-discharging hole. By using the device of the invention, dust and slag generated by gasification can be effectively separated and processed and the problem of performing thermal compensation to the entire equipment is effectively solved.

Owner:中国船舶集团有限公司第七一一研究所

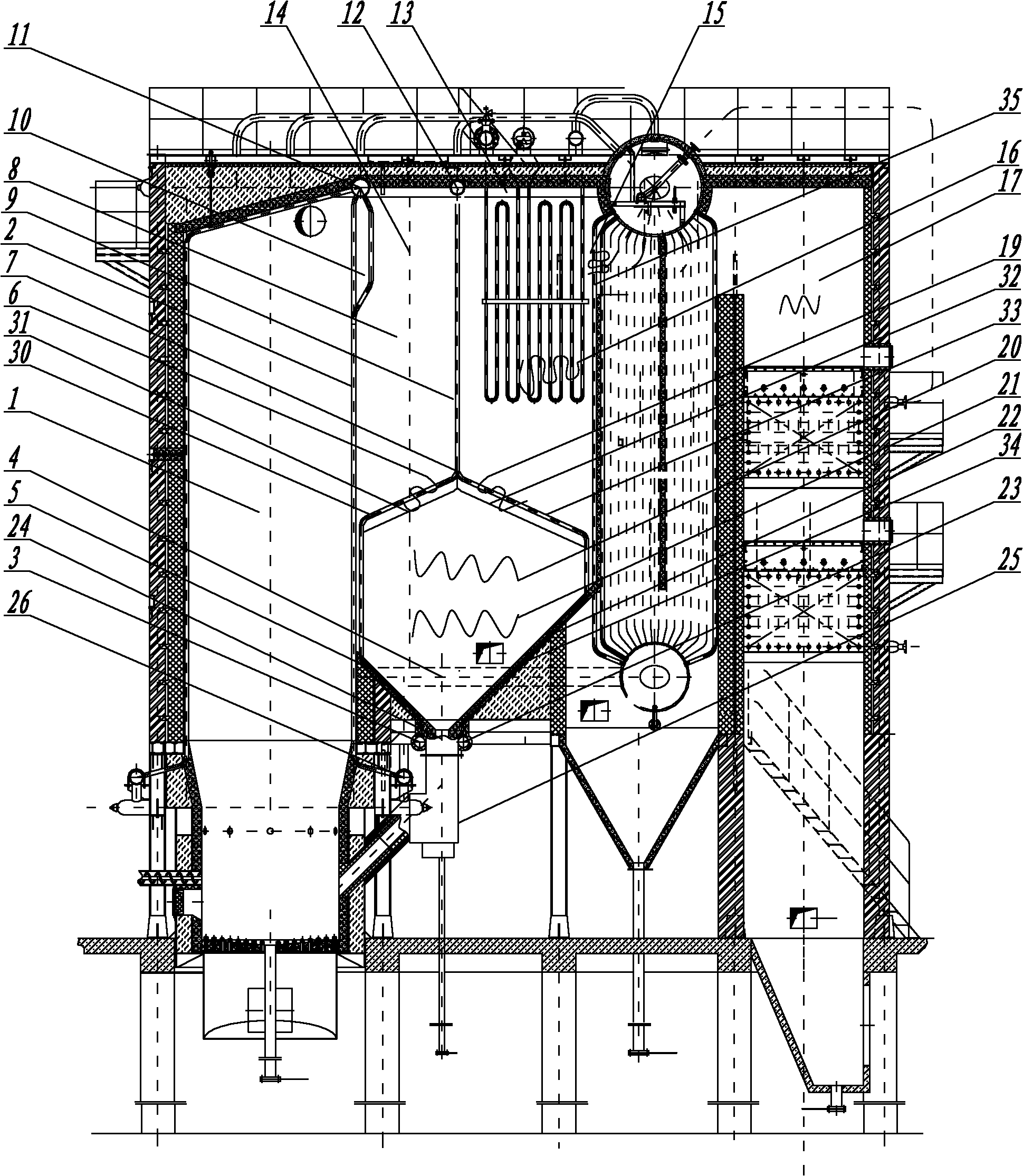

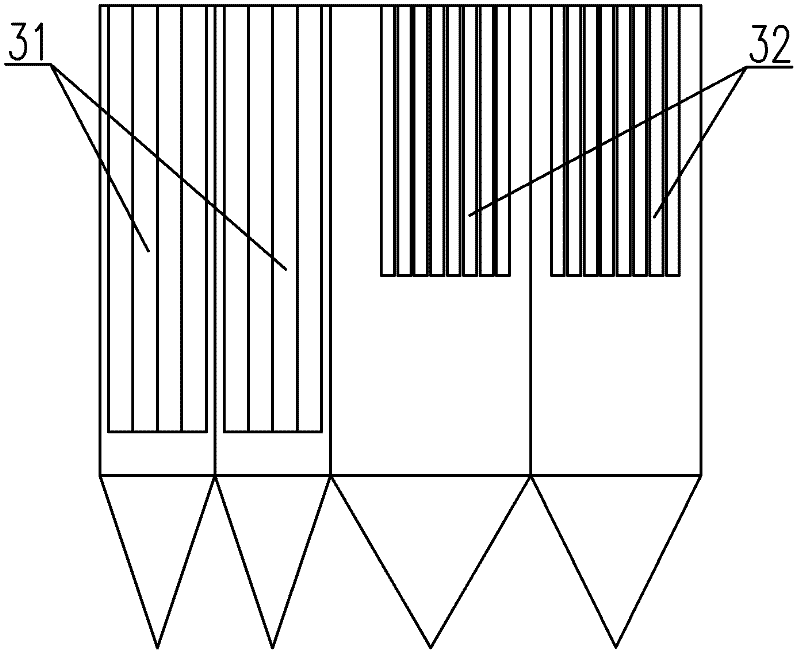

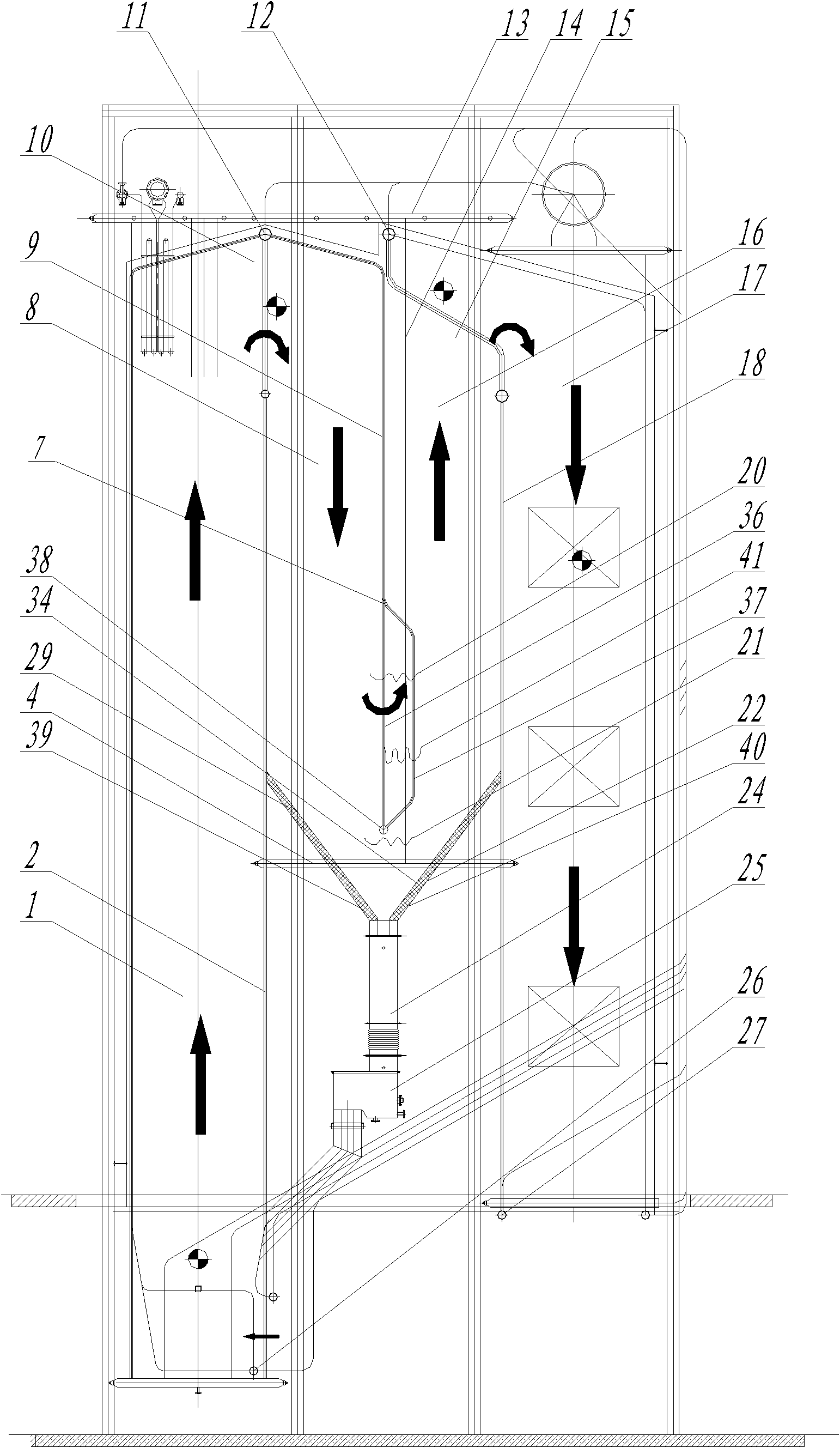

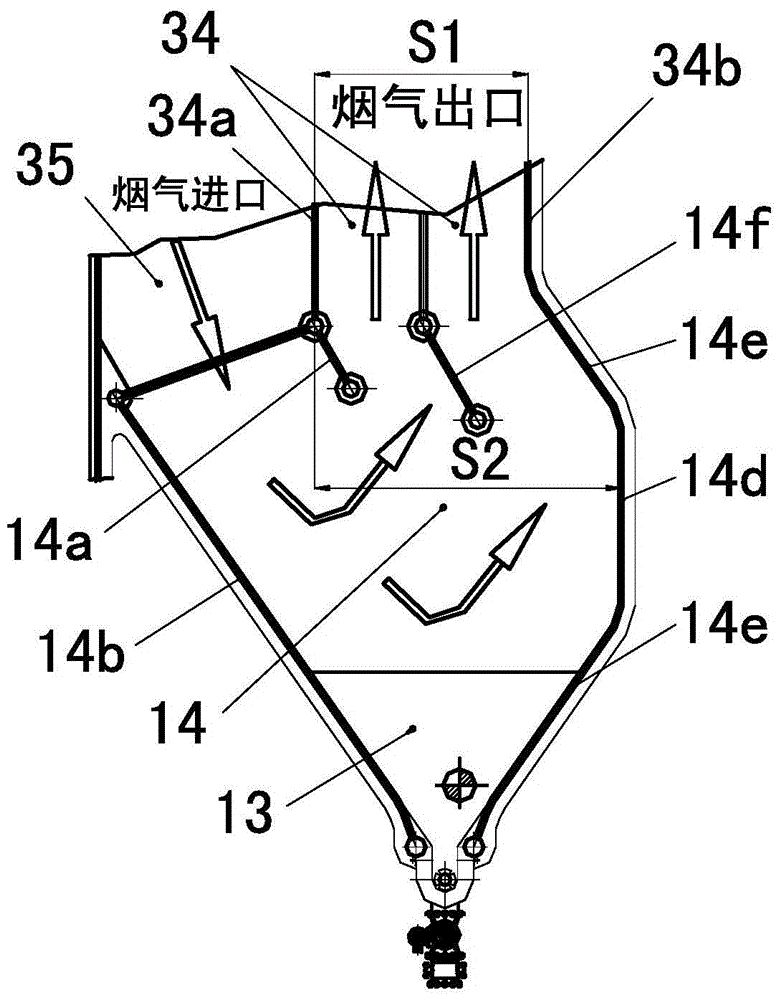

Gas-solid separator of recirculating fluidized bed boiler and boiler comprising same

ActiveCN102588959AReduce power consumptionSave long runFluidized bed combustionDispersed particle separationCycloneEngineering

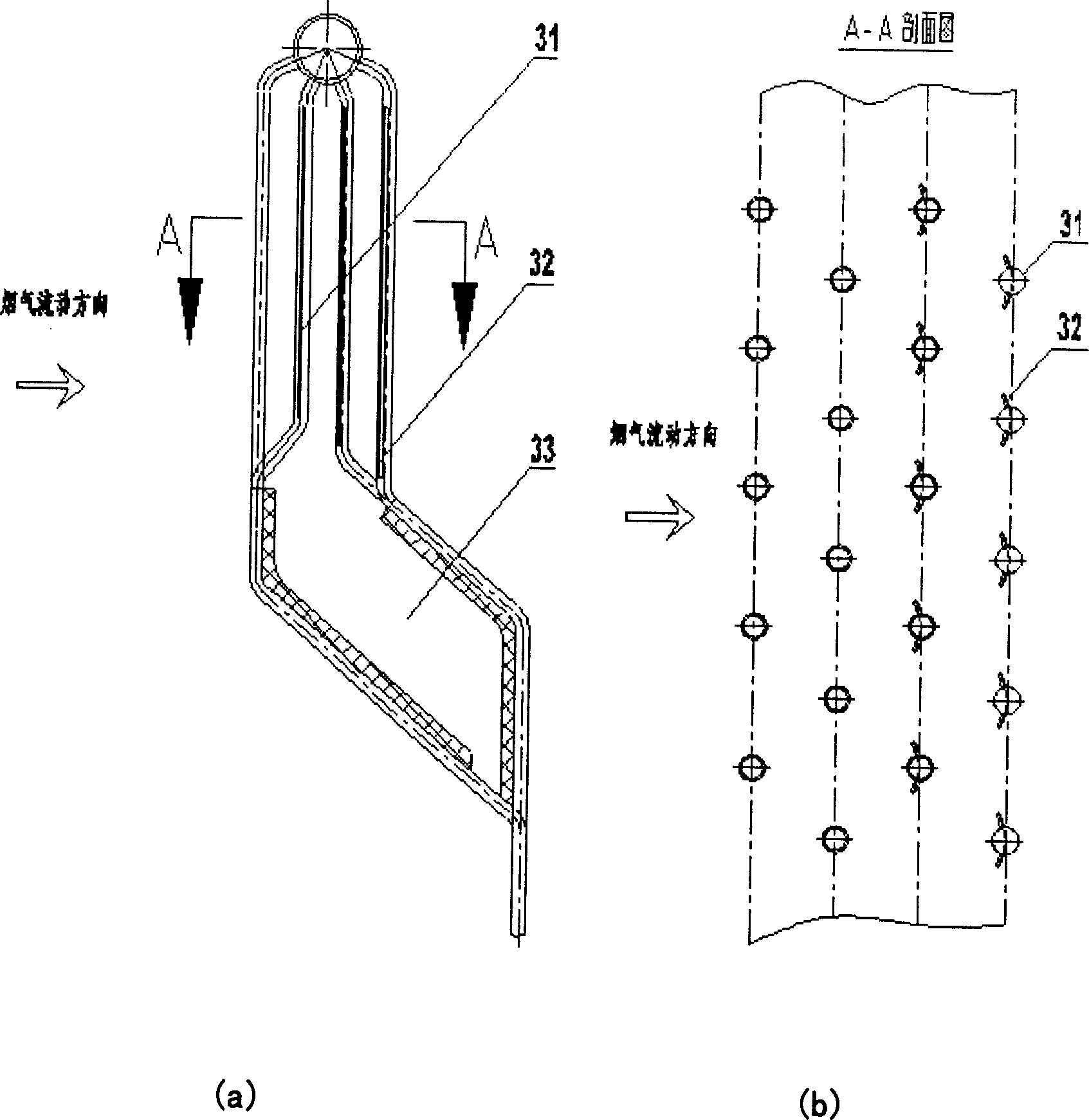

A gas-solid separator of a recirculating fluidized bed boiler comprises a downward flue and an upward flue which are separated from front to back by a membrane-type guided flue gas downward and upward turning screen; the downward flue and the upward flue are communicated with each other through a swerving passageway and a feed bin which is hermetically installed below the downward flue and the upward flue; a flue gas inlet is arranged at the front upper part of the gas-solid separator and a flue gas outlet is arranged at the back upper part of the gas-solid separator; four walls of the gas-solid separator are all water cooled walls which are integrated with the boiler; the gas-solid separator further comprises a flow equalizing and separating tube bundle and an abrasion-proof communication pipe which are located on the swerving passageway; the upper end of the flow equalizing and separating tube bundle on the swerving passageway is communicated with a lower cross collecting tank of the membrane-type guided flue gas downward and upward turning screen, and the lower end of the flow equalizing and separating tube bundle on the swerving passageway is communicated with a cross collecting tank of the feed bin; and the upper end of the abrasion-proof communication pipe on the swerving passageway is communicated with the lower cross collecting tank of the membrane-type screen, and the lower end of the abrasion-proof communication pipe on the swerving passageway is communicated with a cross collecting tank of the communication pipe. In the case of circulation at low ratio, inertia gravity is used for single stage separation, and in the case of circulation at high ratio, when the speed of the smoke in the upward flue is high, low-temperature cyclone separation can be combined with inertia gravity separation for double-stage separation.

Owner:王森

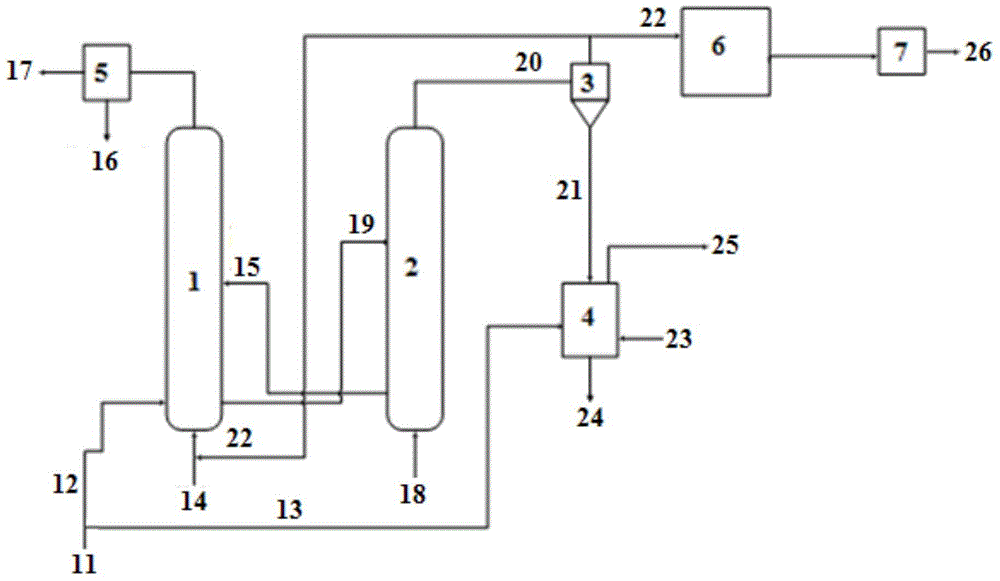

Coal pyrolysis and gasification coproduction method

ActiveCN105441138ASolve the whereabouts problemImprove carbon conversionSpecial form destructive distillationGranular/pulverulent flues gasificationCoal pyrolysisProcess engineering

The invention relates to a coal pyrolysis and gasification coproduction method. The method comprises the following steps: 1, separating coarse coal dusts and fine coal dusts from raw coal; 2, pyrolyzing the coarse coal dusts in a fluidized bed mode to obtain coal tar and semicoke; 3, gasifying the semicoke generated after pyrolysis in a fluidized bed mode to obtain a gas flow and high temperature semicoke, separating a product gas and solid particles from the gas flow, and returning at least parts of the high temperature semicoke and / or at least parts of the product gas to the above pyrolysis process in order to be used as a heat source in the pyrolysis process; and 4, carrying out coal dust gasification on the fine coal dusts separated in step 1 and the solid particles separated in step 3. The coal pyrolysis and gasification coproduction method realizes combined supply of heat, gas, oil and a chemical substance, and also realizes a high carbon conversion rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

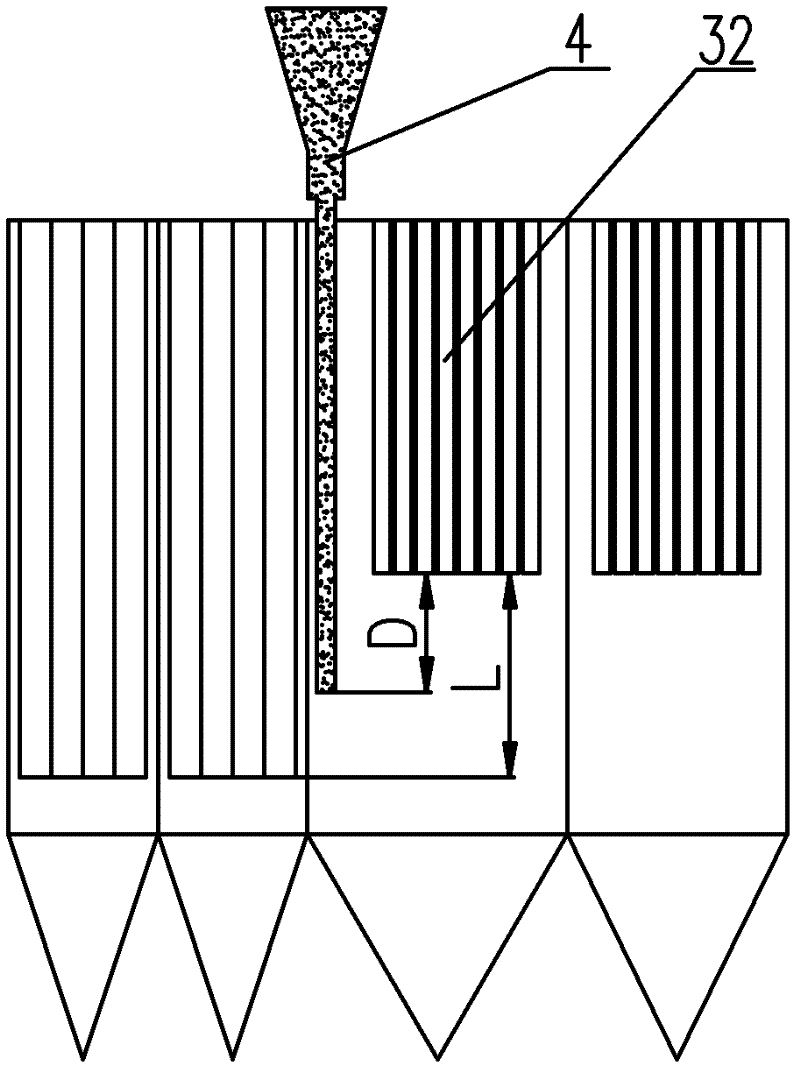

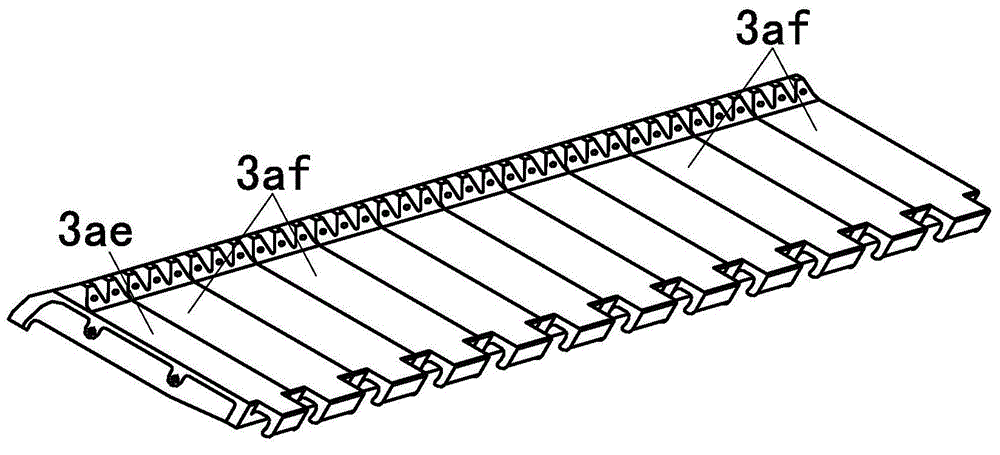

Material separator for circulating fluidized bed boiler

PendingCN101963350AExtended service lifeSave electricityFluidized bed combustionDispersed particle separationFluidized bedPulp and paper industry

The invention discloses a material separator for a circulating fluidized bed boiler. The material separator is characterized in that: the lower end of a fume guide film-type screen which can be bent over is branched into two front rows of light tube bundles and two back rows of light tube bundles, wherein the two front rows of light tube bundles and the two back rows of light tube bundles are bridged above a storage bin and form a fume inlet and a fume outlet of a turning channel respectively; and the lower ends of the two front rows of light tube bundles and the two back rows of light tube bundles are communicated with a middle transverse collecting box of the boiler. The invention also discloses another material separator for the circulating fluidized bed boiler. The other material separator is characterized in that: the lower end of the fume guide film-type screen which can be bent over is branched into a front row of tube bundles and a back row of tube bundles, wherein the front row of tube bundles and the back row of tube bundles are positioned on the turning channel. The material separator has the advantages of advanced process, simple manufacturing and installation, wide application range, energy conservation, consumption reduction and remarkable emission reduction.

Owner:王森

Dust collection and mercury removal integrated electric-bag composite dust collector

The invention discloses a dust collection and mercury removal integrated electric-bag composite dust collector, and relates to a dust collector. The dust collector comprises a preheater, an electric-bag composite dust collector and an active carbon adsorbent spraying device, wherein an air inlet of the preheater is connected with a smoke outlet of a boiler; the electric-bag composite dust collector consists of a pre-level electric field dust collection area and a post-level filter-bag filtering area; a smoke inlet of the pre-level electric field dust collection area is connected with a smoke outlet of the preheater; a smoke outlet of the pre-level electric field dust collection area is connected with a smoke inlet of the post-level filter-bag filtering area; the active carbon adsorbent spraying device is arranged between the pre-level electric field dust collection area and the post-level filter-bag filtering area; and the smoke flowing to the post-level filter-bag filtering area is discharged to the atmosphere through a chimney. The dust collector disclosed by the invention has higher efficiency in collecting fine dust PM2.5 than an electrostatic dust collector and bag-type dust collector, and also has a good effect in collecting tiny mercury particles. Due to the long ash removal period, the acting time of the adsorbent on mercury is prolonged, and the mercury collection efficiency is improved.

Owner:FUJIAN LONGKING

Internally circulating fluidized reburning device for fly ash based on high temperature separation

InactiveCN1884909AReduce carbon contentWith slagFluidized bed combustionApparatus for fluidised bed combustionSlagWater cooling

The invention relates to an ash internal cycle fluid afterburning device, based on high-temperature separation, wherein the invention uses furnace and secondary wind to realize initial high-temperature separation and sets high-temperature combined water cooling separator at the heated surface of water condense slag tube beam at the outlet of high-temperature smoke to realize ash high-temperature separation; and the separated ash is feedback to the high-temperature area to be cycle fluidized burnt, to meet the burning conditions as temperature, time, and disturbing mixing, to improve the burning rate and reduce the pollution. The invention can improve the burnt rate and the burning efficiency of coal.

Owner:XI AN JIAOTONG UNIV

Gas and solid separator of recirculating fluidized bed boiler and boiler containing same

InactiveCN102062395AExtended service lifeSave wear-resistant and high-temperature resistant materialsFluidized bed combustionDispersed particle separationFlue gasFluidized bed

The invention discloses a gas and solid separator of a recirculating fluidized bed boiler, which comprises a downstream flue and an upstream flue which are partitioned by a guiding flue gas up-down replicating film type screen, wherein the downstream flue and the upstream flue are communicated with storage bins hermetically installed below the downstream flue and the upstream flue through a turning channel, the front upper part of the gas and solid separator is provided with a flue gas inlet, the back upper part of the gas and solid separator is provided with a flue gas outlet, and four walls of the gas and solid separator are all heated water-cooling walls integrated with the boiler; and the gas and solid separator also comprises a uniform flow separating pipe bundle positioned on the turning channel, the upper end of the uniform flow separating pipe bundle on the turning channel is communicated with the guiding flue gas up-down replicating film type screen, and the lower end of the uniform flow separating pipe bundle on the turning channel is communicated with a lower transverse container. The invention also discloses a recirculating fluidized bed boiler containing two sets of gas and solid separators. The recirculating fluidized bed boiler has the advantages of wide application range, advanced process, simple manufacturing and installation, energy saving, consumption reduction and obvious emission reduction.

Owner:王森

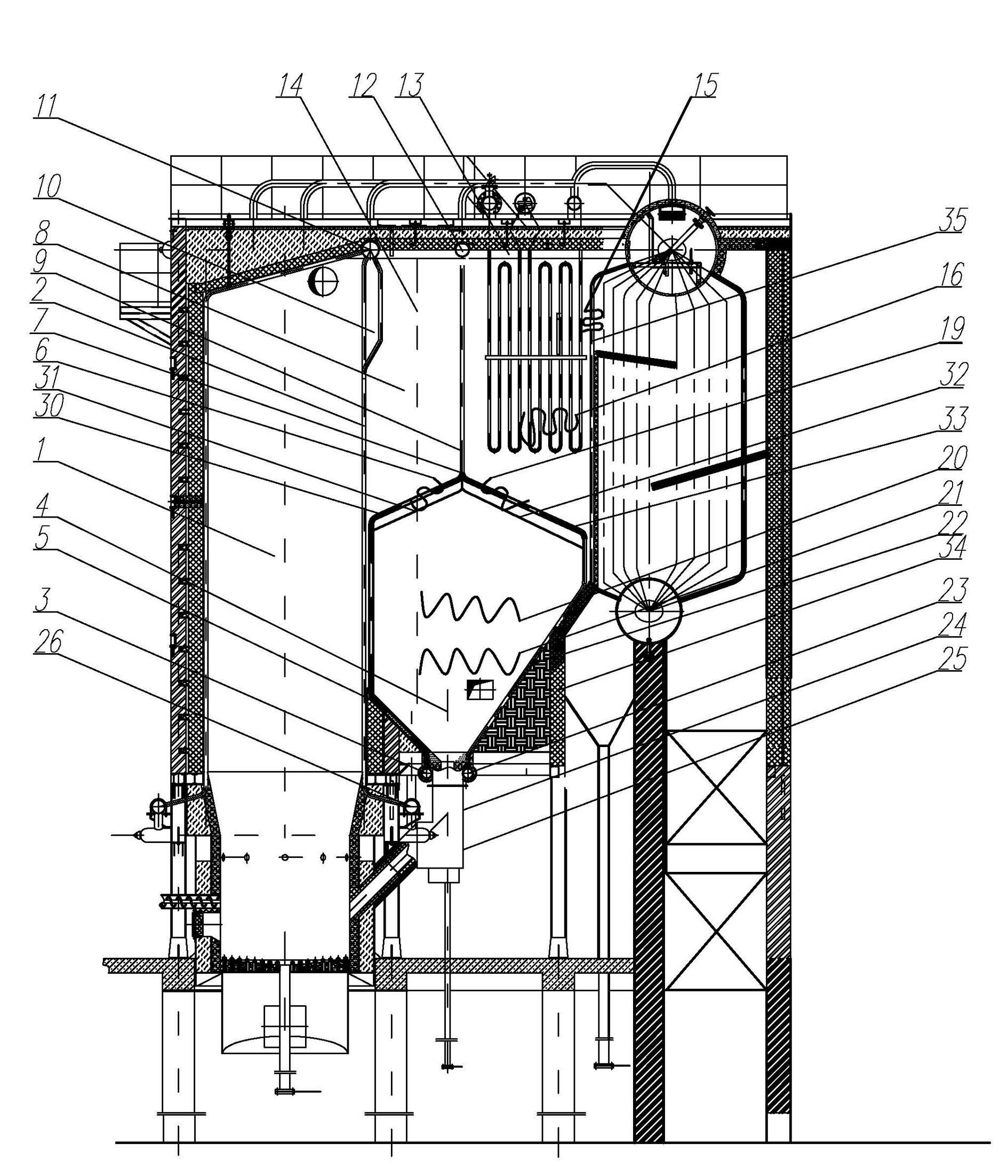

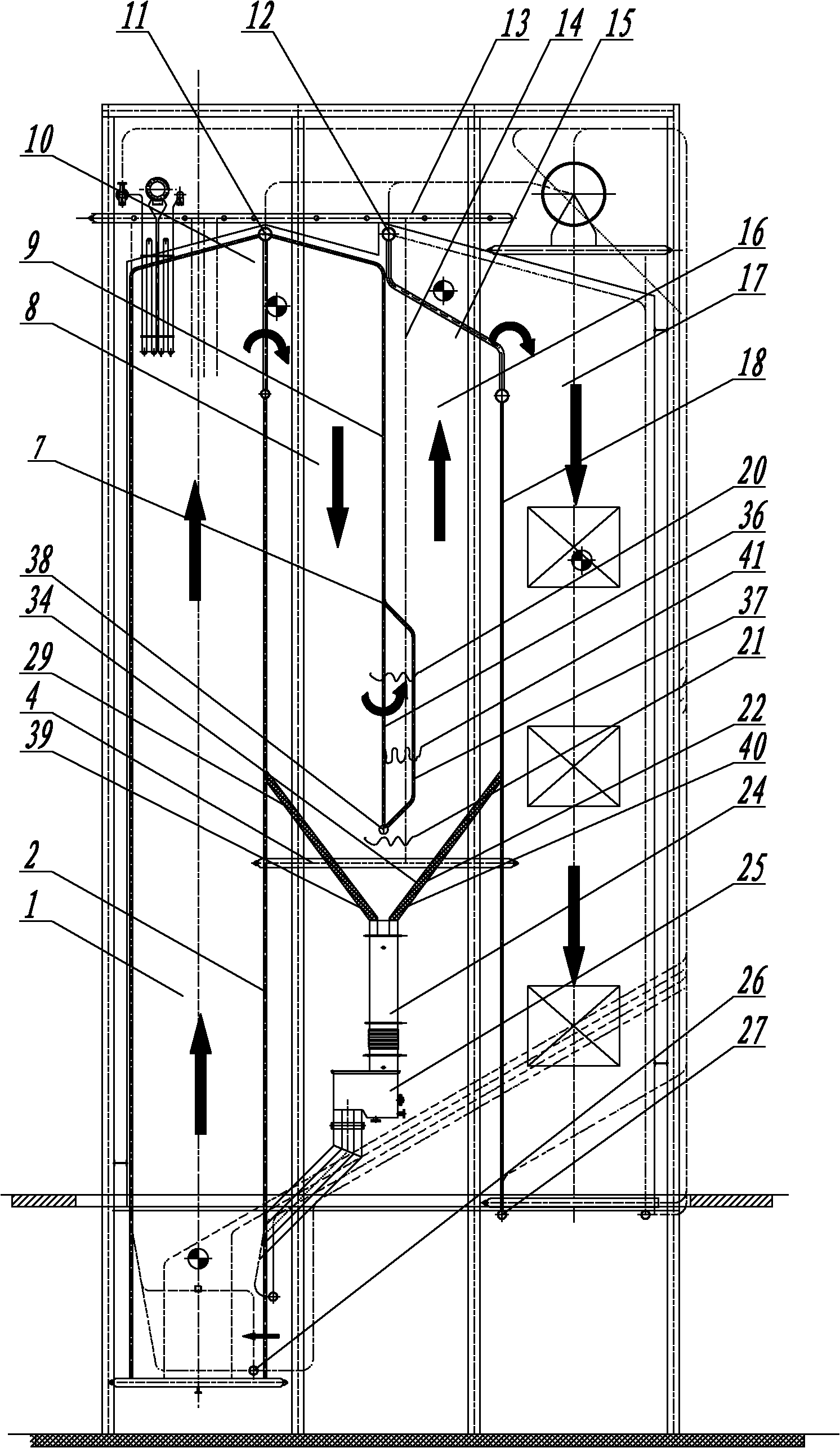

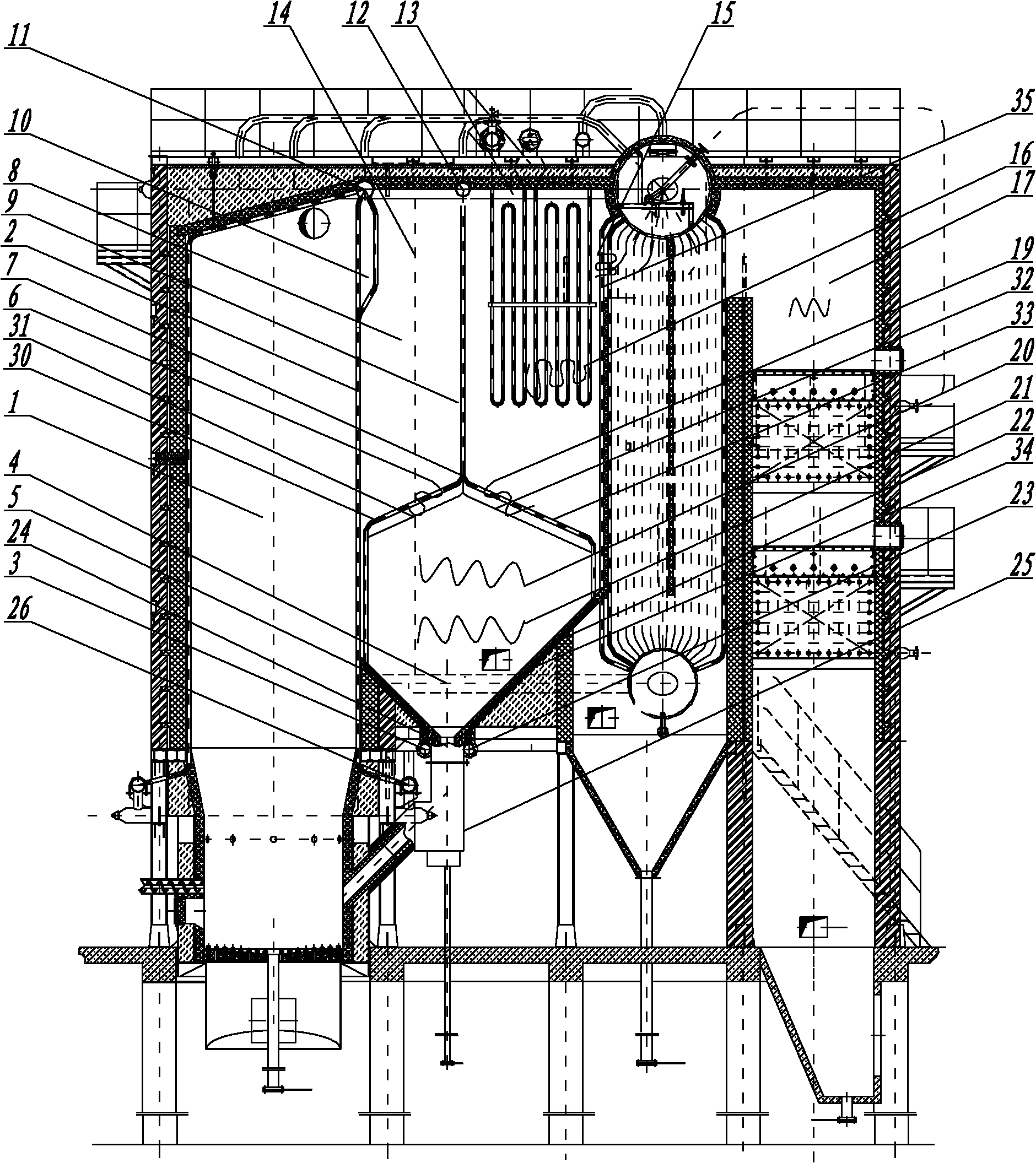

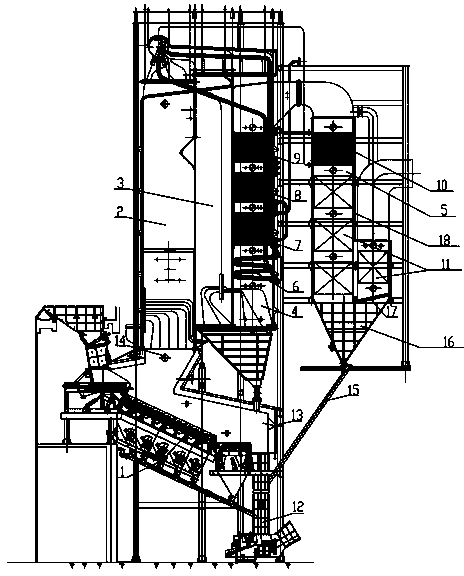

Compound-type waste incineration boiler

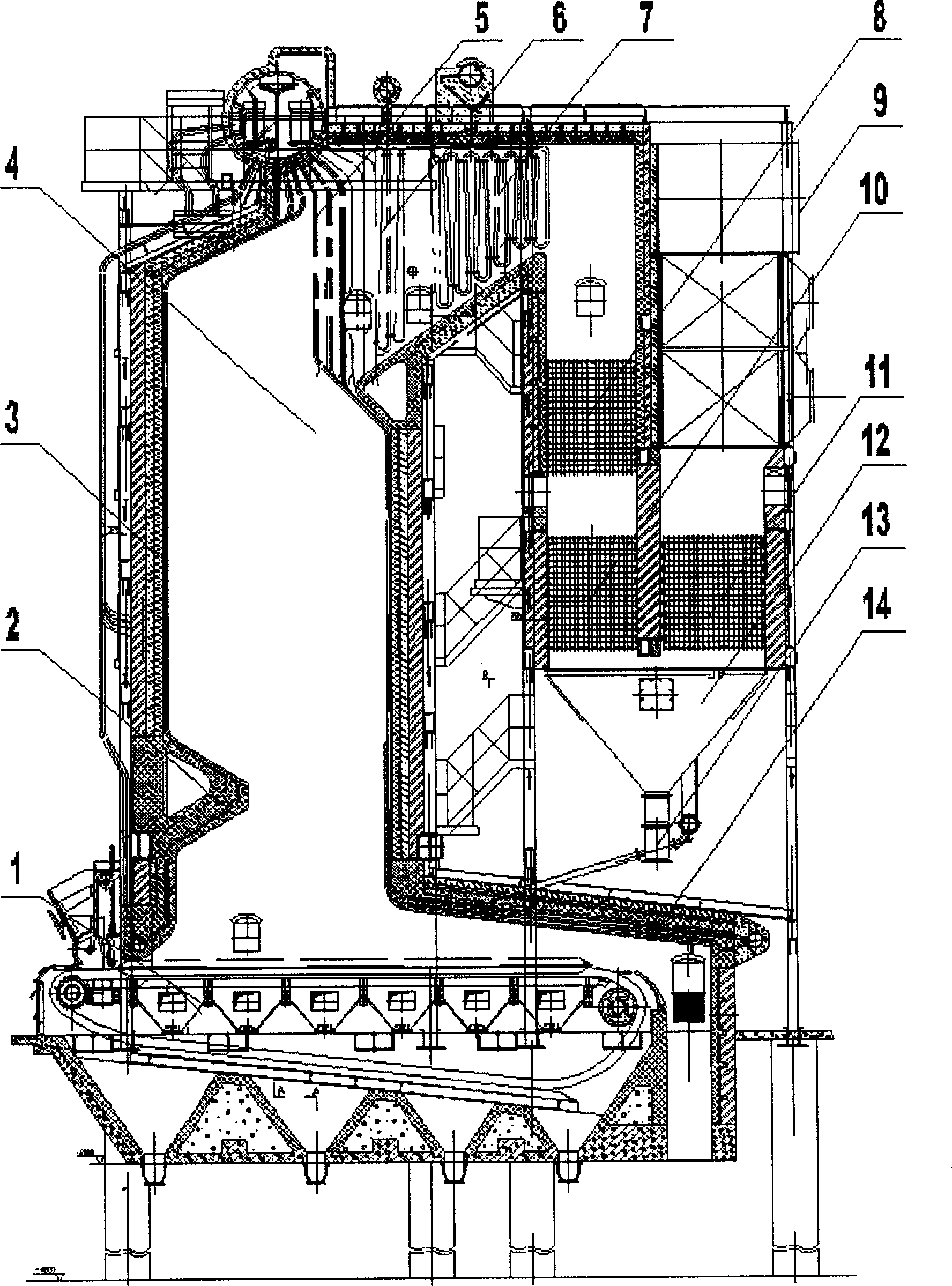

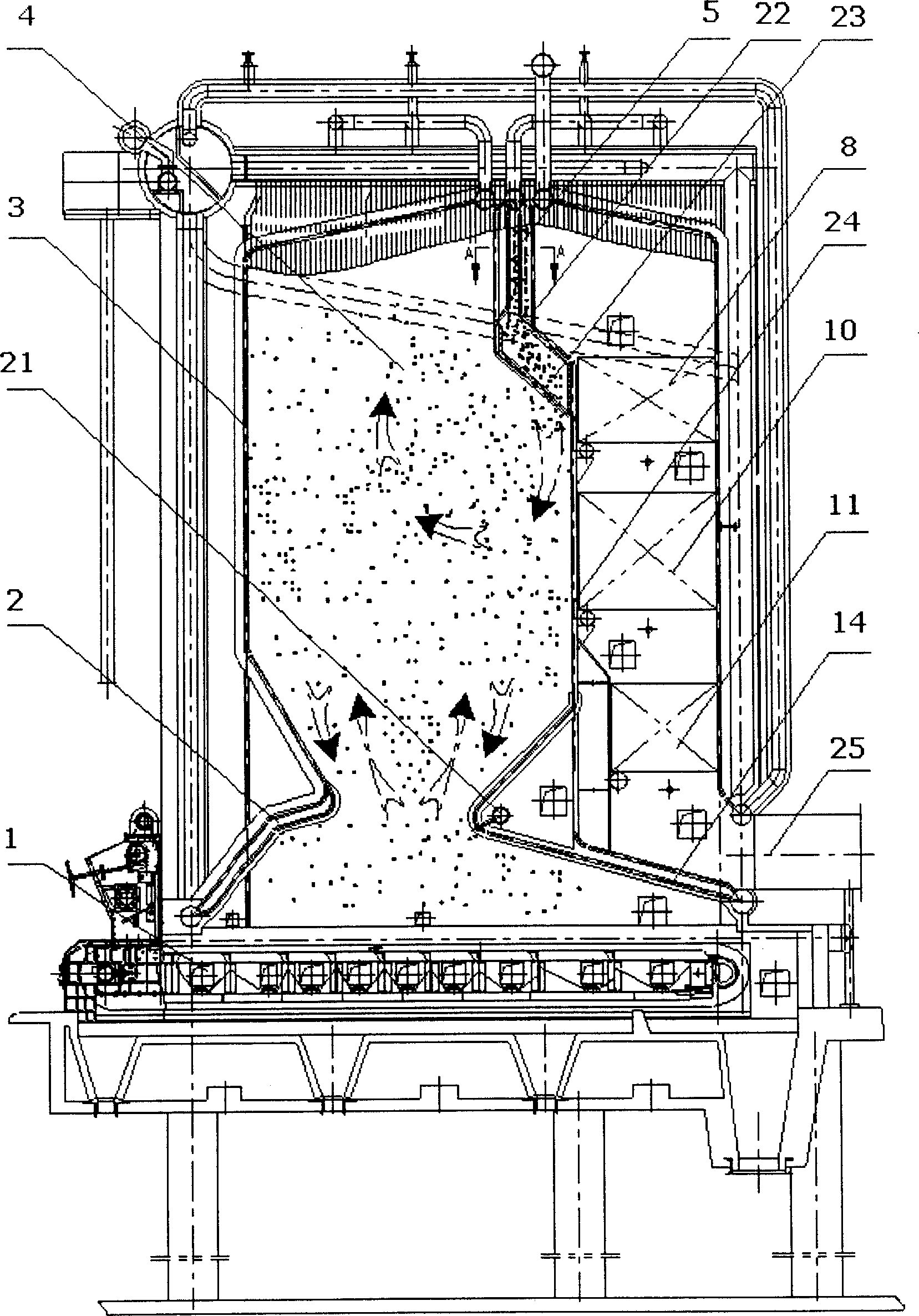

InactiveCN103256607AIncreased radiant heating surfaceIncrease heat absorptionIncinerator apparatusSteam boilersEngineeringSteel frame

The invention relates to a boiler which is used for incinerating household garbage and generating steam to be used for steam supply and electricity generation. According to the technical scheme, the waste incineration boiler with a furnace dedusting device comprises a steel frame, a boiler chamber and a fire grate, wherein the boiler chamber is composed of a hearth, a burned ash chamber and three smoke flues, and a horizontal flue and a flue with a U-shaped tail portion are arranged behind the boiler chamber. By mean of the technical scheme, the compound-type waste incineration boiler is capable of guaranteeing timely drying, full burning and burning out of the household garbage which is low in calorific value, high in moisture and high in ash specification and effectively reducing flying ash amount in smoke.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

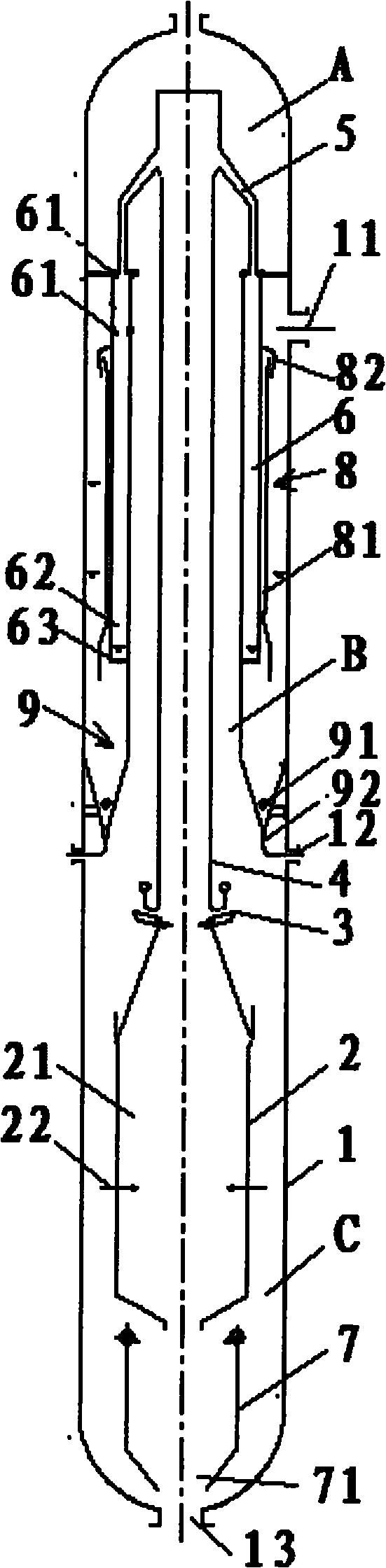

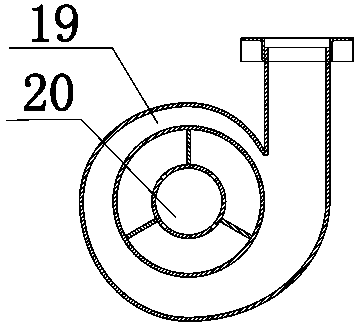

J-shaped entrained-flow gasifier

ActiveCN105779014ASolve the problem of short circuitImprove conversion rateGasifier mechanical detailsGranular/pulverulent flues gasificationSyngasThermal energy

The invention discloses a J-shaped entrained-flow gasifier. The J-shaped entrained-flow gasifier is characterized in that the gasifier has a J-shaped design, a slag-drip opening is formed in the lowest point at the bent position of the J-shaped gasifier, and a slag collection chamber is formed in the lower part of the slag-drip opening; a gasifying raw material inlet is formed in the higher side of the J-shaped gasifier, and a synthesized gas outlet is formed in the lower side of the J-shaped gasifier. According to the entrained-flow gasifier, the gasifier is designed into J shape, flying gas carried in synthesized gas is collected by the wall surface of the bent position, so that the carbon conversion rate can be effectively improved, and the ash carrying capacity at the synthesized gas outlet can be reduced; and slag bonding and ash accumulation can be prevented when heat of a synthesized gas is reclaimed by a radiant syngas cooler and a convective syngas cooler. The slag-drip opening is close to the high-temperature region of the gasifier, so that the temperature of the slag-drip opening is higher, and smooth slag drip can be ensured.

Owner:SHANGHAI BOILER WORKS

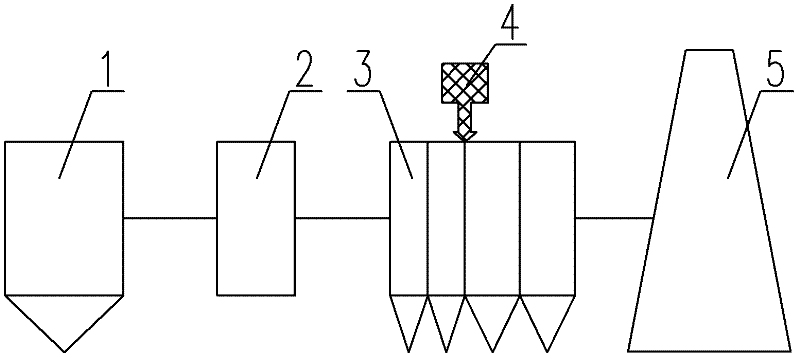

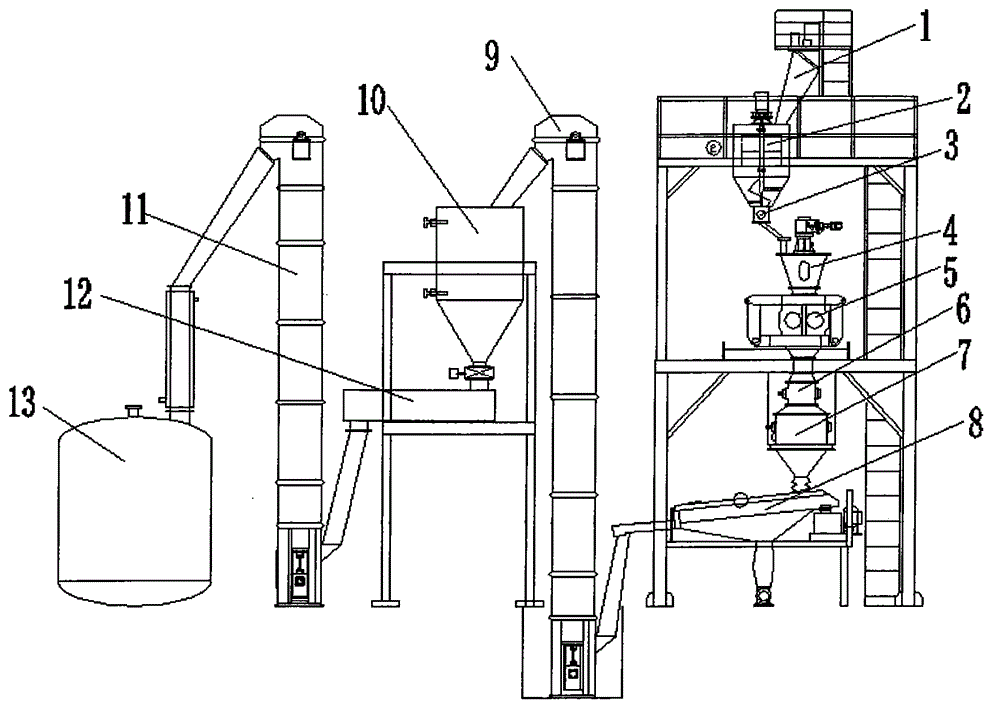

Fly ash smelting pre-treatment system and fly ash treating method

InactiveCN104399738AReduce the number of devices usedSmall footprintSolid waste disposalExhaust gasPre treatment

The invention provides a fly ash smelting pre-treatment system which comprises a raw material storage bin, a pelleting device and a smelting furnace, wherein the rear part of the raw material storage bin is connected to the pelleting device; the rear part of the pelleting device is connected with a first hoister; the rear part of the first hoister is connected to a finished product bin; the rear part of the finished product bin is connected to a second hoister; the rear part of the second hoister is connected to the smelting furnace; the pelleting device comprises a forced feeding machine connected with the raw material storage bin; the rear part of the forced feeding machine is connected to a piece rolling main engine; the rear part of the piece rolling main engine is connected to a crushing machine; the rear part of the crushing machine is connected to a straightening granulator; the rear part of the straightening granulator is connected with a grading sieve; the grading sieve is connected with the first hoister. According to the fly ash smelting pre-treatment system provided by the invention, powdered fine fly ash are compressed to be blocky, are crushed into particles with proper size by using the crushing machine, and cannot diffuse into air during the transportation process; the particulate matters cannot drift into a tail gas treating system along with tail gas after being conveyed to the thermolysis smelting furnace; therefore, the bridging phenomenon and the phenomenon that particles are adhered to a wall are avoided.

Owner:安徽中科华炬环保科技有限公司

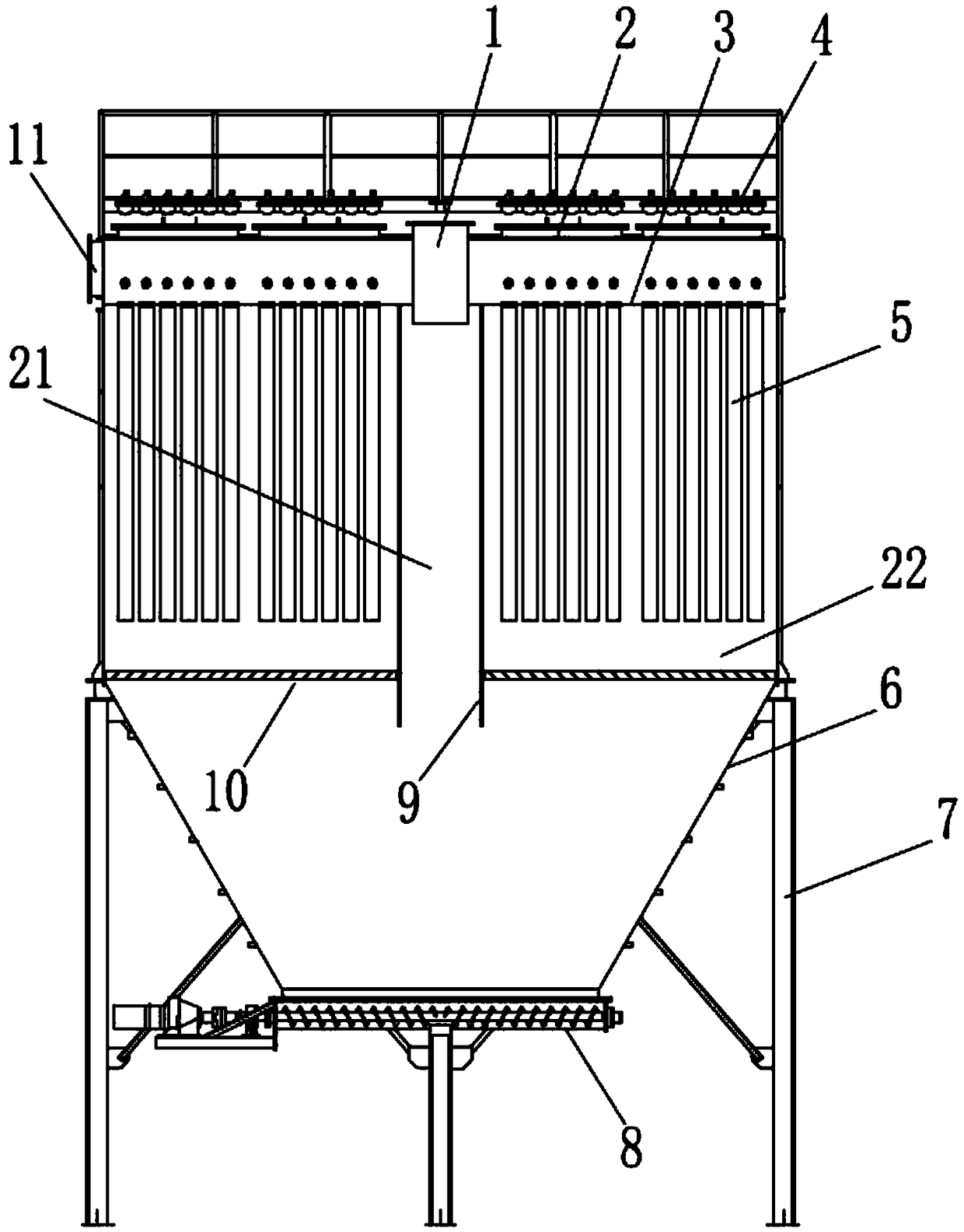

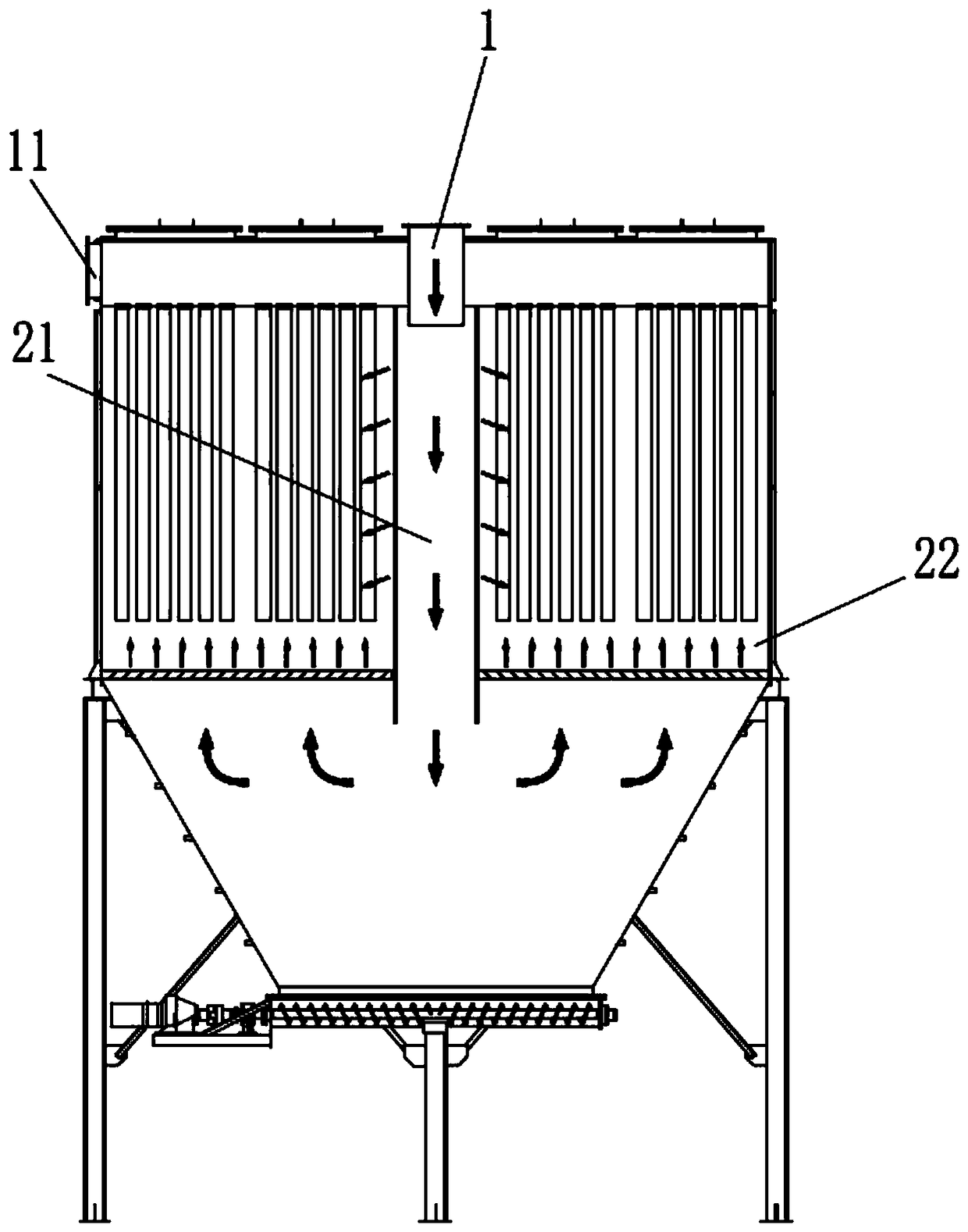

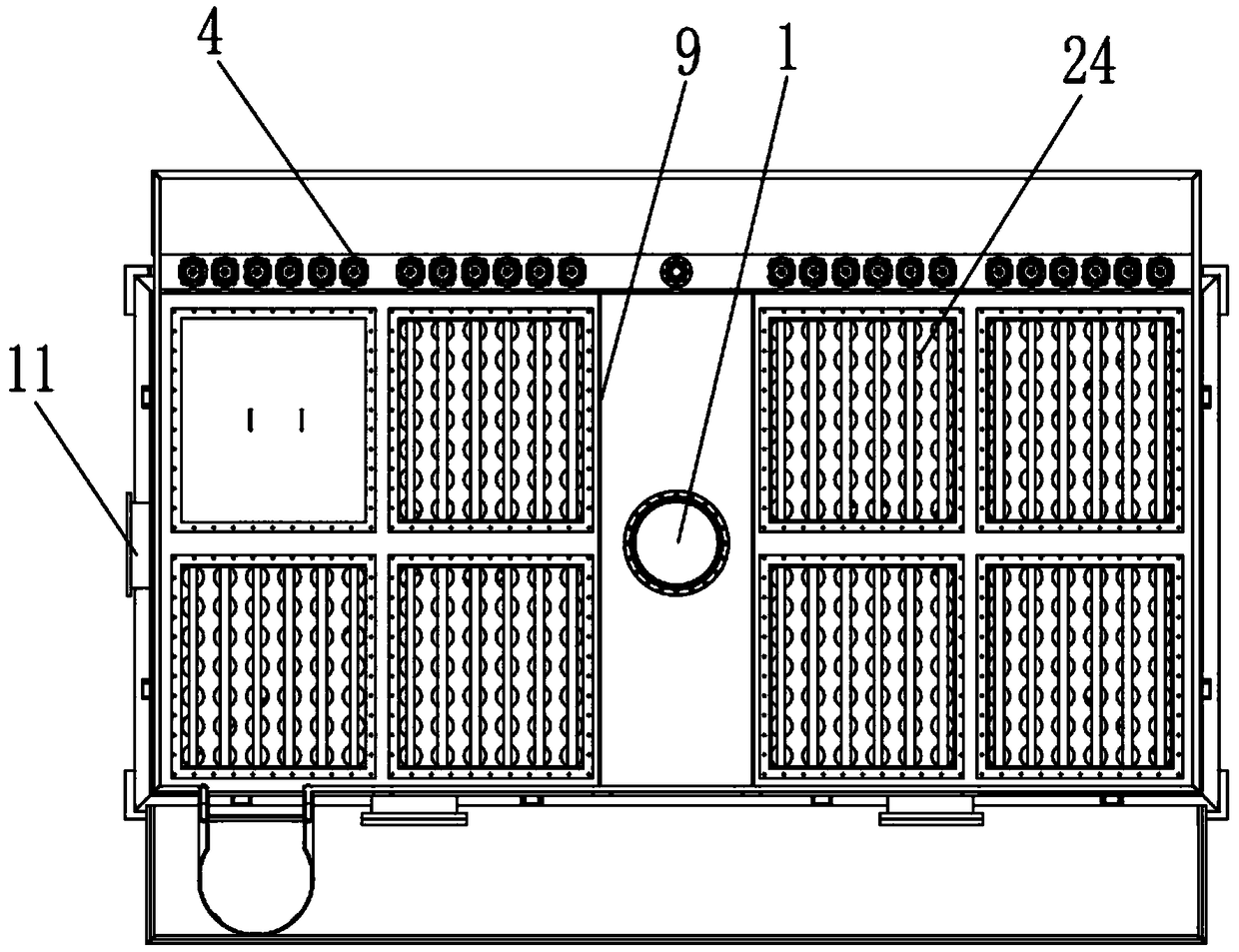

Filter bag dust collector

PendingCN108744766AGuaranteed to passIncrease coverageGas treatmentDispersed particle filtrationEngineeringResidence time

The invention discloses a filter bag dust collector, and belongs to the technical field of dust removal. In view of the problem of uneven distribution of smoke on the surface of a filter bag in an existing filter bag dust collector, the filter bag dust collector comprises a case and a filter plate, the filter plate is provided with the filter bag, the filter plate is installed above the inside ofthe case, two vertical flow passage partition plates are disposed under the filter plate, and the two flow passage partition plates divide the case into a smoke flow passage and two dust removal chambers. The collector increases the smoke flow distance and the residence time through the two flow passage partition plates, adds an airflow uniforming device, makes the smoke flow over to uniformly cover the entire dust removal chambers, and has the advantages of improving the surface area utilization rate of the filter bag, improving the dust removal efficiency and reducing filter bag wear probability.

Owner:KEDA MAS CLEAN ENERGY

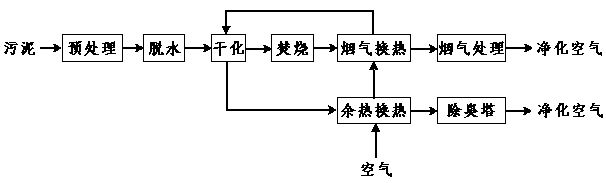

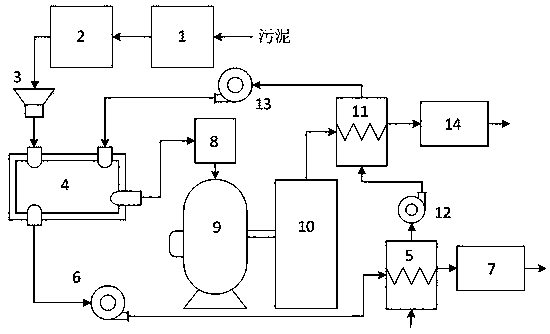

Sludge incineration treatment method and device

PendingCN108692317AAchieve reductionImplement resourcesSludge treatment by de-watering/drying/thickeningIncinerator apparatusCold airFlue gas

The invention provides a sludge incineration treatment method and device. Aiming at the problems that the calorific value of domestic sludge is low, heat energy produced by sludge incineration is low,heat energy required for sludge drying is high, heat energy generated by sludge incineration is not enough to dry the sludge, and the heat energy need to be supplied, the sludge is pretreated, thus the calorific value of the sludge is increased, and the dehydration property of the sludge is improved; the pretreated organic sludge is dehydrated; after dehydration granulation, sludge particles aredried; the dried dry sludge is subjected to incineration treatment; cold air and heat vapor generated in the drying process are subjected to waste heat exchange, and then the cold air and flue gas generated by incineration are subjected to secondary heat exchange; and hot air subjected to heat exchange is used for sludge drying, and sludge drying and incineration heat balance are achieved.

Owner:TIANJIN ENEW ENVIRONMENTAL PROTECTION ENGCO LTD

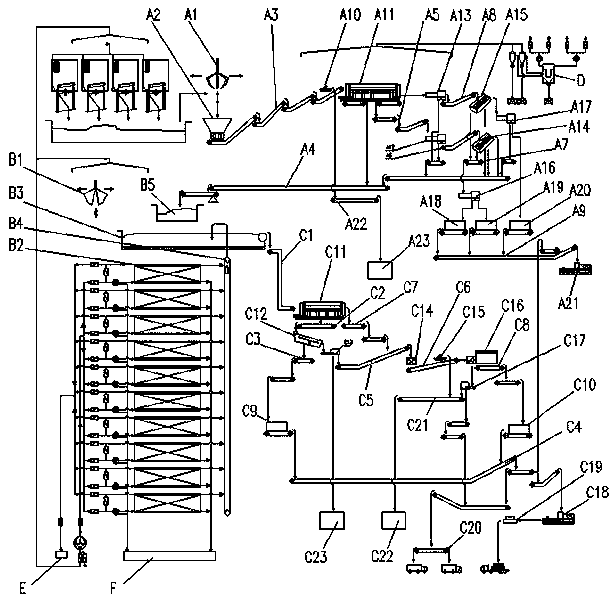

Household waste sorting and drying system

ActiveCN109013662AHigh degree of resource utilizationStable combustionSolid waste disposalTransportation and packagingCircular discLitter

The invention provides a household waste sorting and drying system. The waste heating value can be increased, the moisture content of household waste is decreased, most of recycled items such as metaland plastic can be effectively recycled, the waste resource degree is high, and the waste is changed into fuel with the high heating value. A waste front sorting system comprises a raw waste grab bucket crane, a bag break crusher, a first front sorting conveyor, a second front sorting conveyor, a third front sorting conveyor, a fourth front sorting conveyor, a fifth front sorting conveyor, a sixth front sorting conveyor, a seventh front sorting conveyor, a first magnetic separator, a front sorting drum screen, a first bounce screen, a second bounce screen, a first photometric sorter, a secondphotometric sorter, a third photometric sorter, a fourth photometric sorter, other plastic belt bins, an HDPE plastic belt bin, an LDPE plastic belt bin and a front sorting packing machine; a waste drying system comprises a drying bin grab bucket crane, a drying bin, a first drying conveyor and a drying front temporary-storing bin; and a waste rear sorting system comprises a first rear sorting conveyor, a second rear sorting conveyor, a third rear sorting conveyor, a fourth rear sorting conveyor, a fifth rear sorting conveyor, a sixth rear sorting conveyor, a seventh rear sorting conveyor, aneighth rear sorting conveyor, a first belt bin, a second belt bin, a rear sorting drum screen, a flip-flow screen, a glass sorter, a disc homogenizer, a second magnetic separator, a winnowing machine, an eddy current sorter, a rear sorting packing machine and an outer transportation conveyor.

Owner:CHINA UNITED ENG

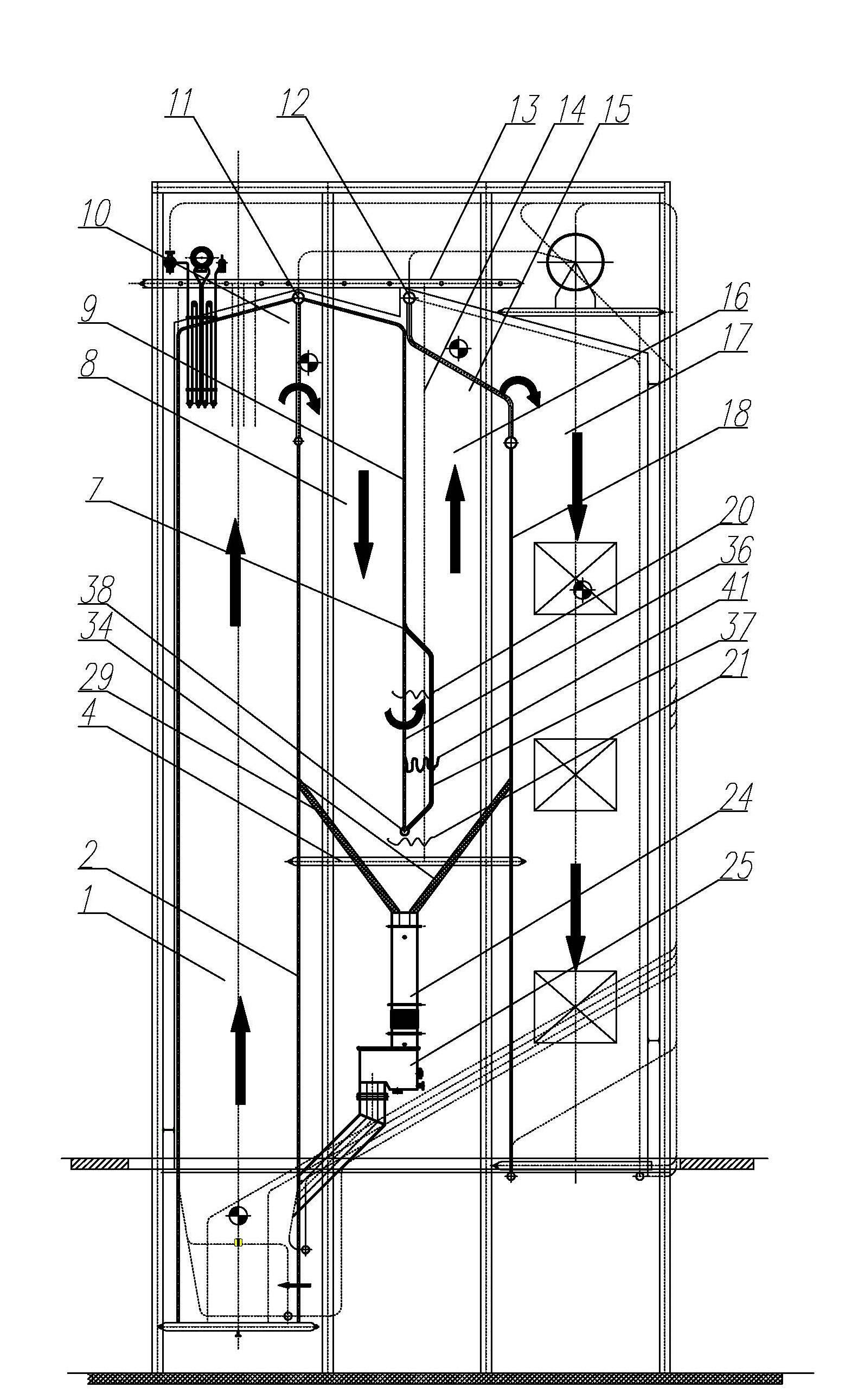

Furnace for combined combustion of methane of garbage leachate and garbage

ActiveCN103471103AImprove combustion efficiencyIncrease contact surfaceIncinerator apparatusSteam boilersCombustion chamberThermodynamics

The invention relates to a furnace for combined combustion of methane of garbage leachate and garbage and belongs to the technical field of combustion equipment. The furnace comprises a steel frame, a furnace grate, a furnace chamber and a tail flue pipe. The furnace chamber is connected with the tail flue pipe, the furnace chamber is made up of a hearth, a combustion chamber and three flue pipes, the furnace grate is arranged on the lower part of the furnace chamber, and a slag and ash discharging device is arranged below the furnace grate. The furnace is characterized in that a methane burner of the garbage leachate is mounted on a side wall of the lower part of the hearth above the furnace grate, and superheaters are arranged in the three flue pipes and the tail flue pipe. Considering the features of various fuels, the methane of the garbage leachate and garbage are burned mixedly, and accordingly the furnace is an energy-saving and environment-friendly comprehensive furnace.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

Rural household waste incineration method and device

ActiveCN108613194AReduce usageReduce disposal costsCombustion technology mitigationIncinerator apparatusAir preheaterFluidized bed

The invention discloses a rural household waste incineration method and device, and belongs to the technical field of waste disposal. The problems of rural household waste disposal at present are solved. The method comprises the steps that a circulating fluidized bed incinerator is used for incinerating dried waste with the moisture content being 15% or below, and water vapor released by waste drying is drawn to be injected into a hearth for cooling in the incineration process. The device comprises the circulating fluidized bed incinerator. A vapor inject-in port is formed in the side wall ofthe hearth of the circulating fluidized bed incinerator. A tubular heat exchanger, a vapor heater, a secondary air preheater and a primary air preheater are sequentially arranged in a tail flue of thecirculating fluidized bed incinerator. A vapor outlet of the vapor heater is connected with a vapor inlet of a rotary kiln roller dryer. The roller wall of the rotary kiln roller dryer is of a hollowrow tube structure. An inlet and an outlet of the tubular heat exchanger communicate with the two ends of the roller wall correspondingly. The rural household waste incineration method and device areused for waste disposal.

Owner:HARBIN INST OF TECH

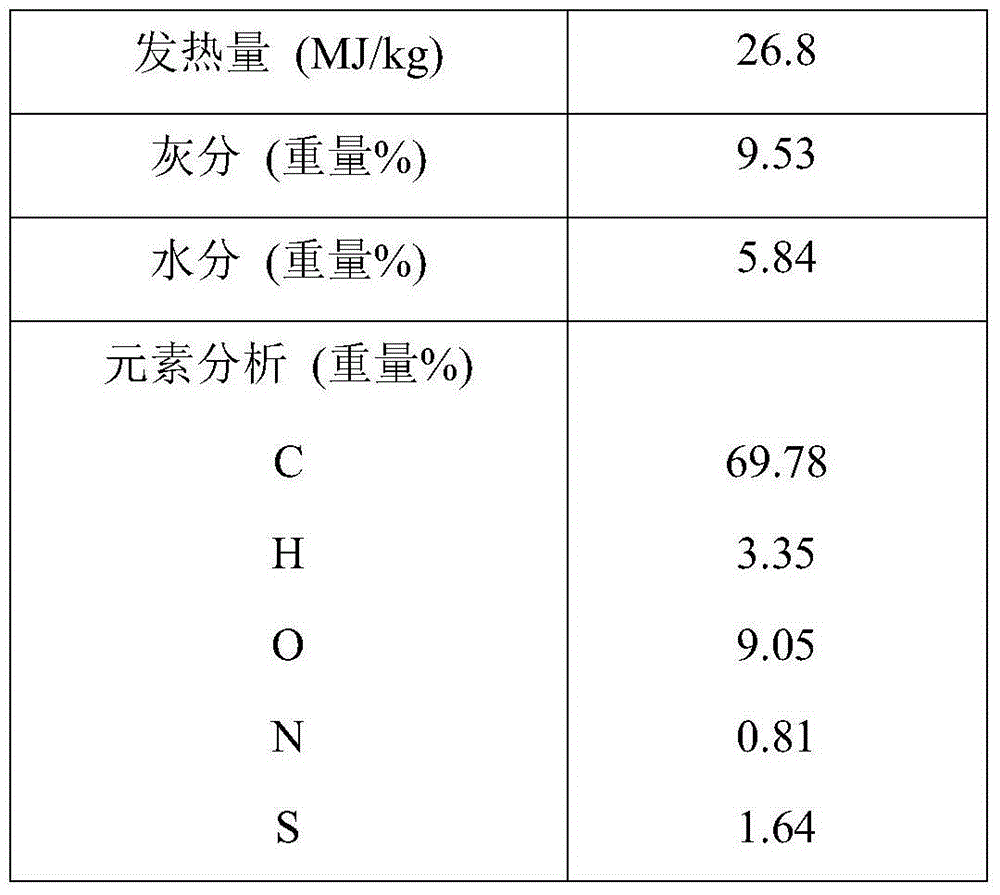

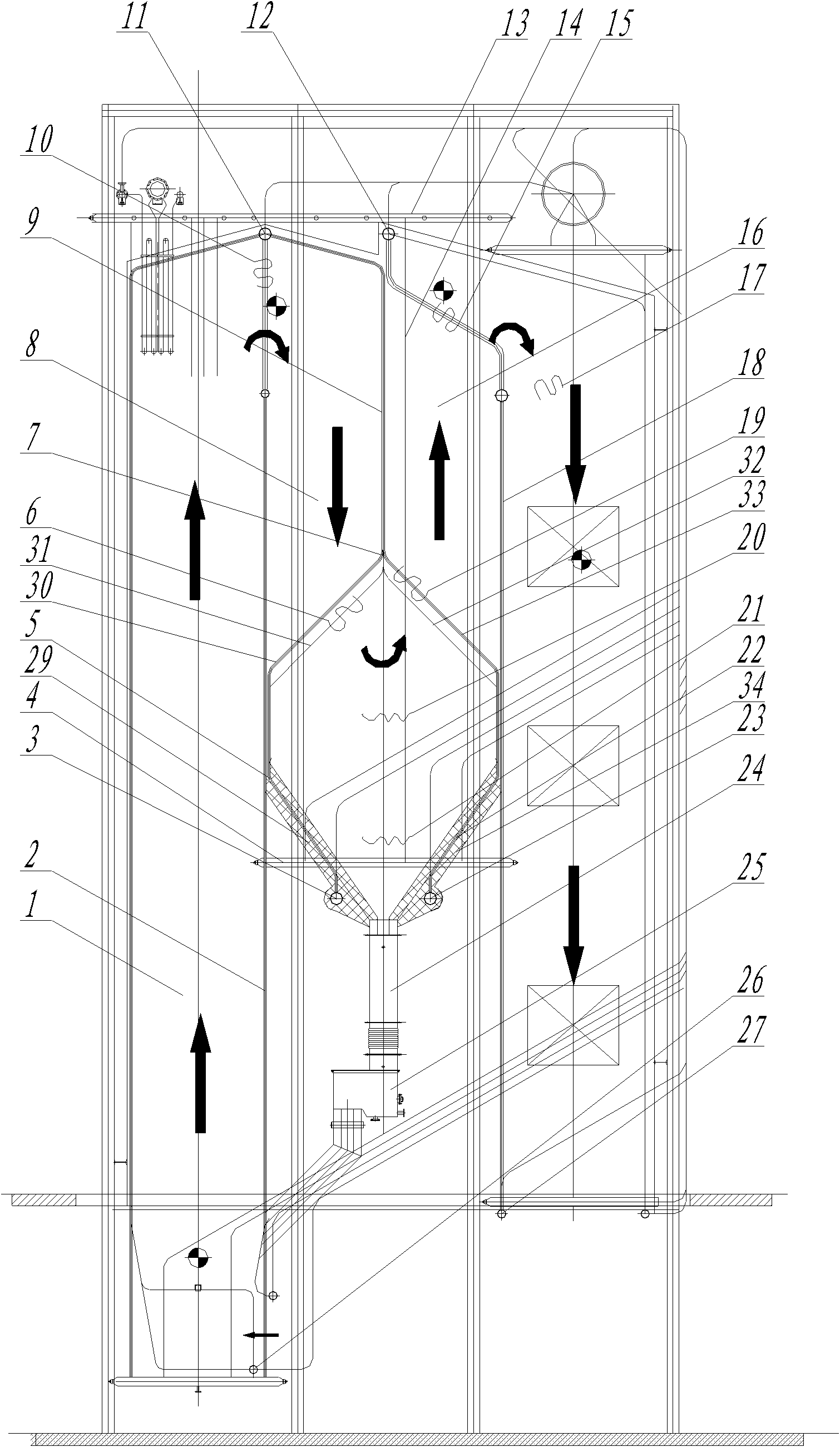

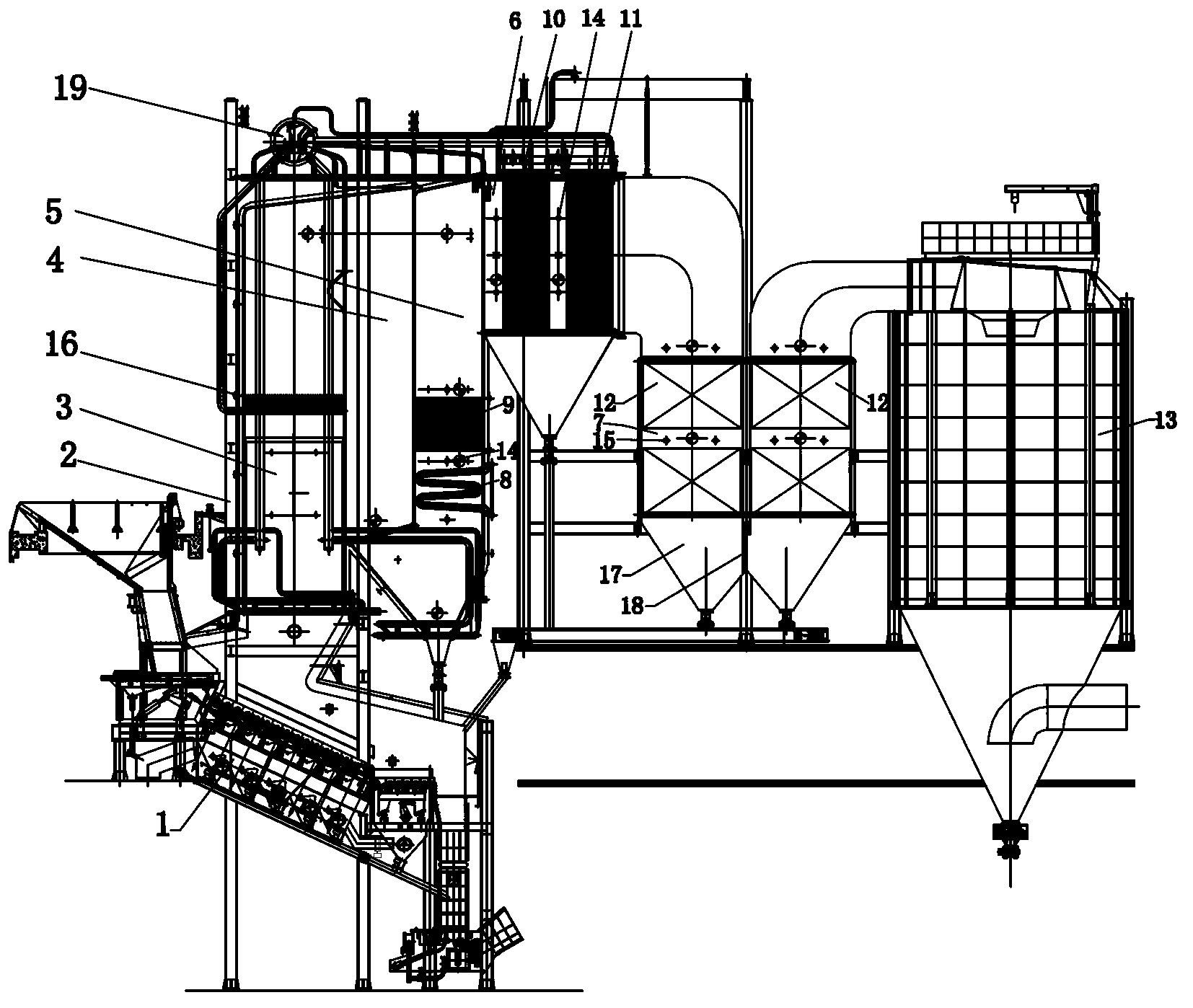

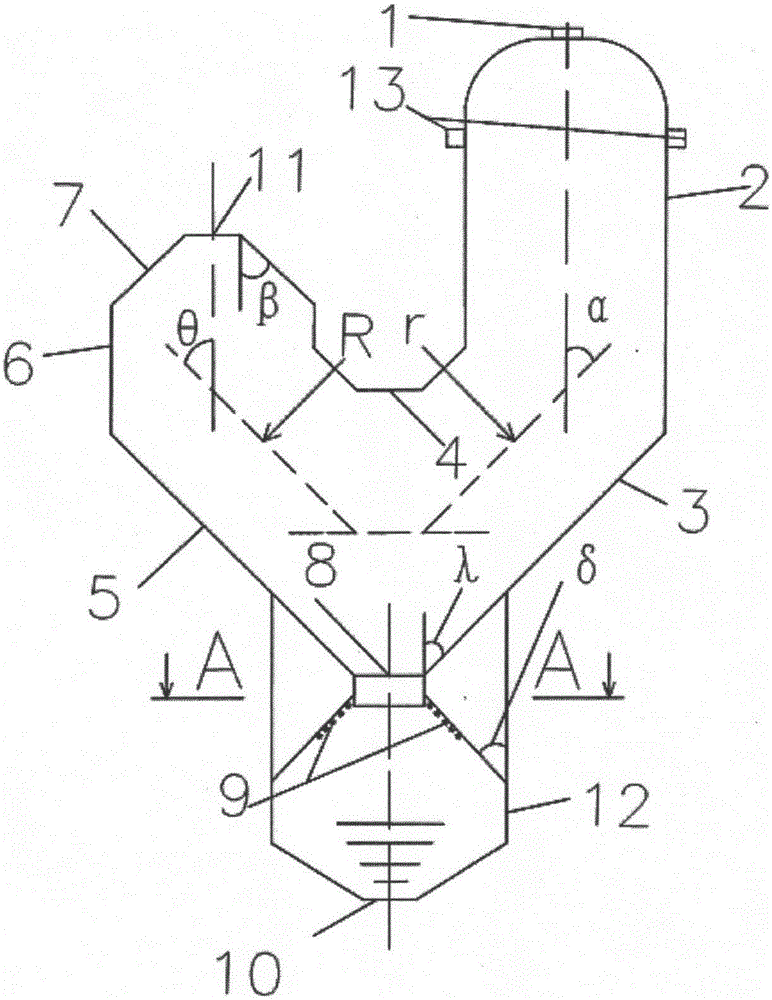

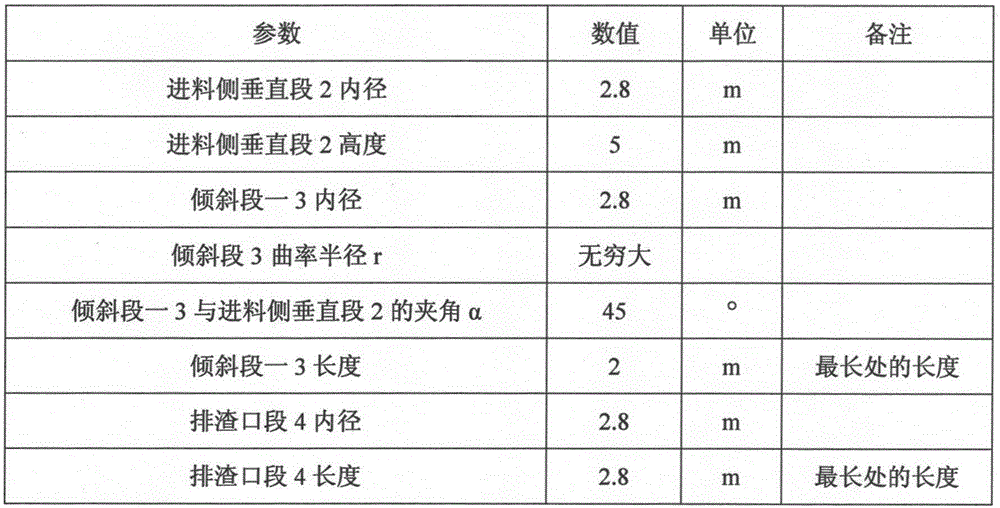

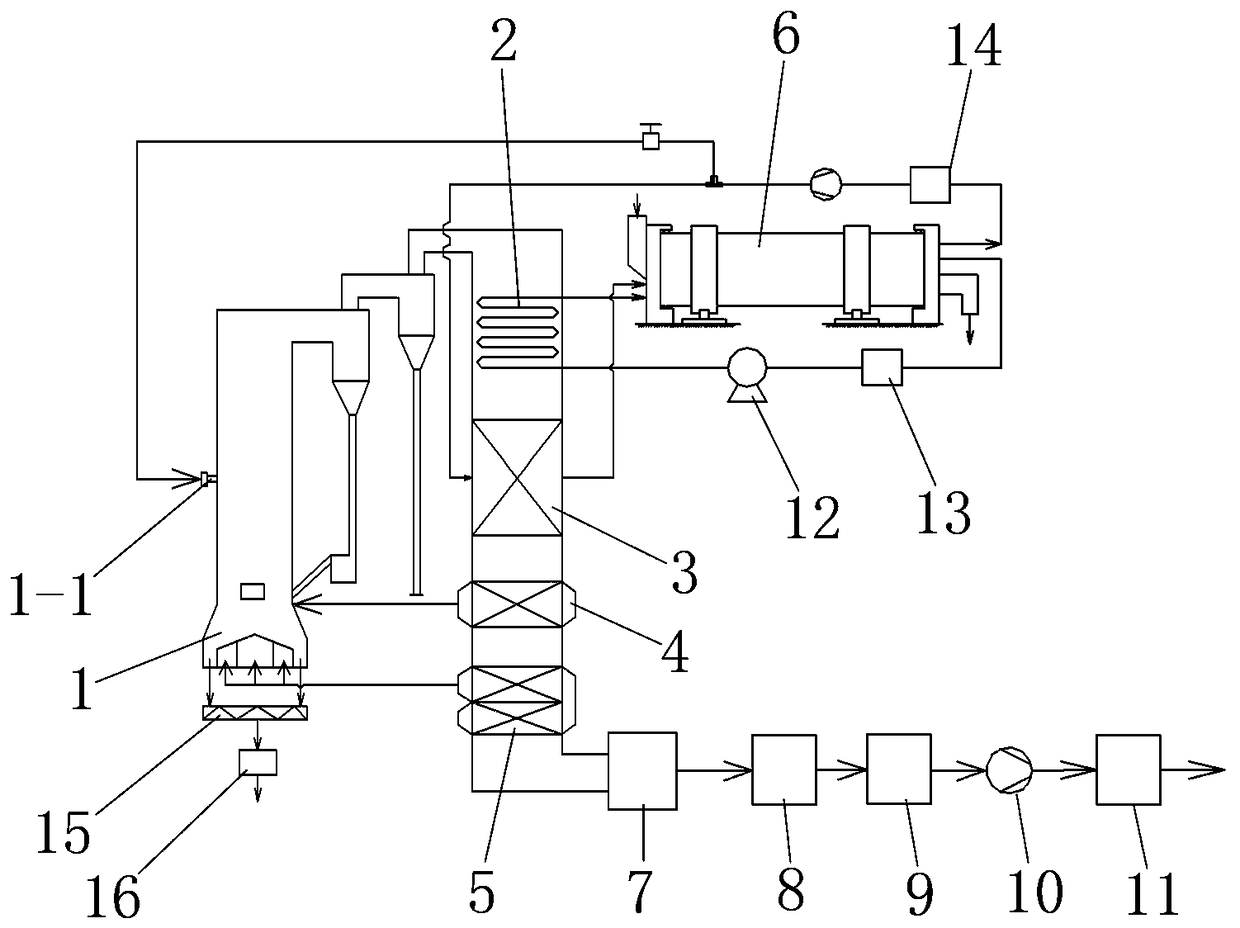

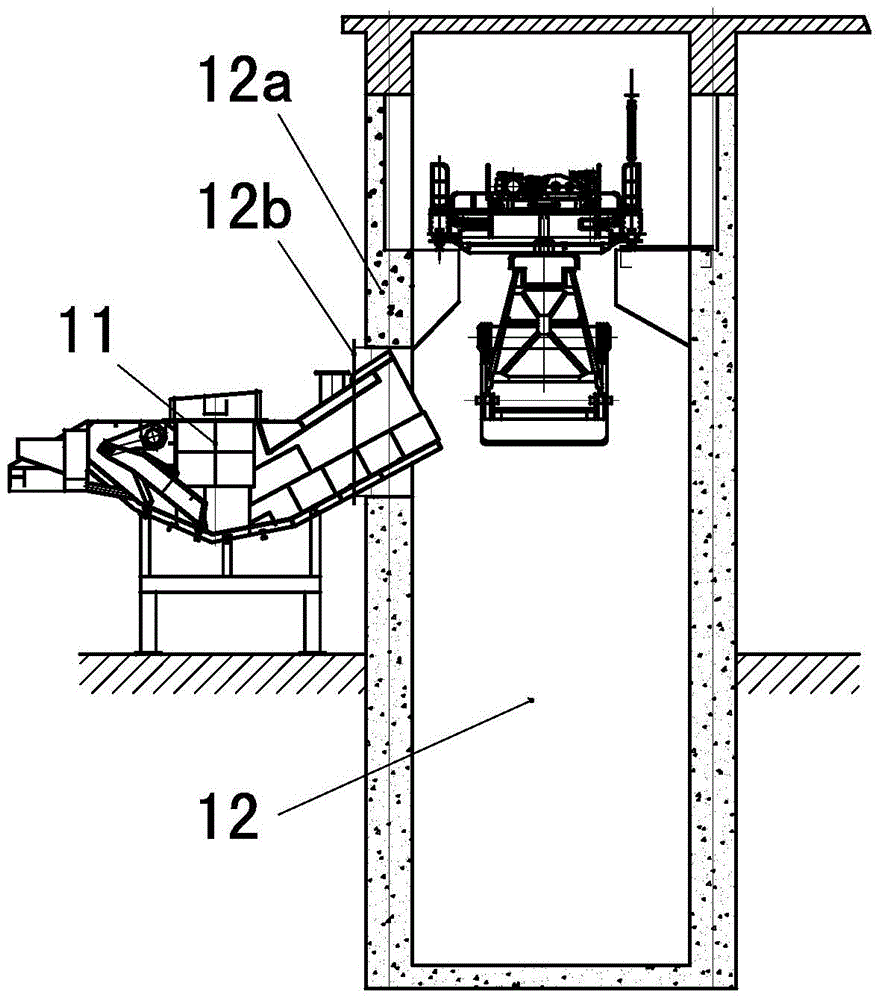

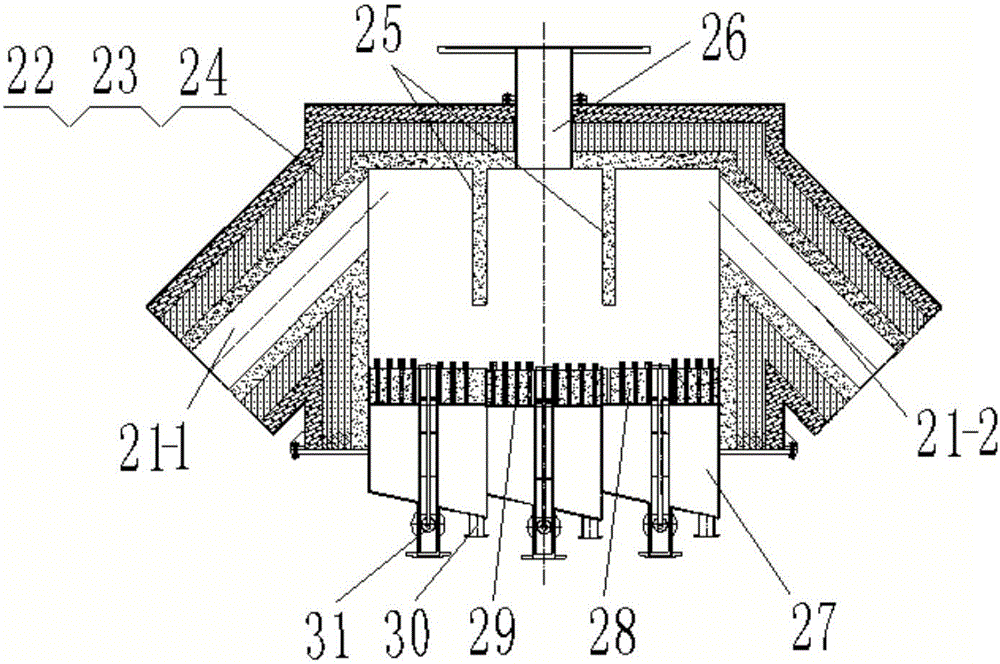

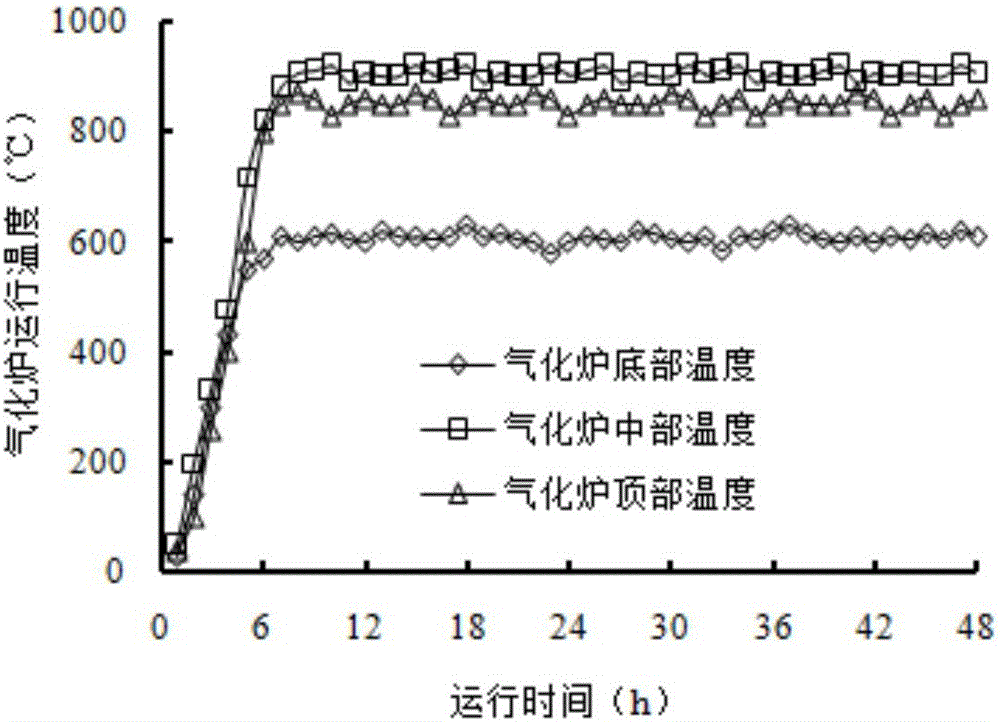

U-shaped coal gasification reaction device and process for coal gasification by using device

InactiveCN107099337AImprove slag collection efficiencyReduce the amount of fly ashChemical industryGasification processes detailsFlueSlag

The invention relates to a U-shaped coal gasification reaction device and a process for coal gasification by using the device, and aims to solve the problems of large flying ash generation amount, high flying ash carbon content, low carbon conversion rate and low energy utilization rate of an existing entrained flow gasifier. The U-shaped coal gasification reaction device consists of a gasifier body, a horizontal flue and a waste pan, wherein the gasifier consists of a gasifier nozzle, a gasifier hearth, a water cooling wall pipe and a slag basin; the waste pan is divided into a radiation heat exchange chamber and a convection heat exchange chamber through a middle furnace wall; the gasifier body, the horizontal flue and a second gasification chamber form a U-shaped coal gasification reaction region. The U-shaped coal gasification reaction device is used for coal gasification.

Owner:HARBIN INST OF TECH

Boiler for derived fuel RDF, waste plastics RPF and waste wood of combustion of refuses

ActiveCN101852422AAvoid cokingHigh volatile contentCasings/liningsSteam boilersRefuse-derived fuelSocial benefits

The invention discloses a boiler for derived fuel RDF, waste plastics RPF and waste wood of combustion of refuses, mainly comprising a hearth, a burnout chamber, a superheater chamber and a rear flue duct, wherein the burnout chamber, the superheater chamber and the rear flue duct are successively connected behind the hearth; a drum is arranged above the hearth, and a reverse chain fire grate is arranged on the lower part of the hearth; slag trapping and ash discharging equipment is arranged below the reverse chain fire grate; the front wall of the lower part of the hearth is provided with a waste wood spray seeding device and a refuse derived fuel RDF and waste plastics RPF spray seeding device which are communicated with the inner part of the hearth, and the waste wood spray seeding device is arranged below the refuse derived fuel RDF and waste plastics RPF spray seeding device. In the invention, the steam produced by using refuse derived fuel RDF, the waste plastics RPF and the waste wood to be combusted in a boiler is used for generating electricity and supplying steam. The invneiton has the social benefit of saving energy and reducing environmental pollution and has favourable economic benefit.

Owner:ZHEJIANG WEIMING ENVIRONMENT PROTECTION

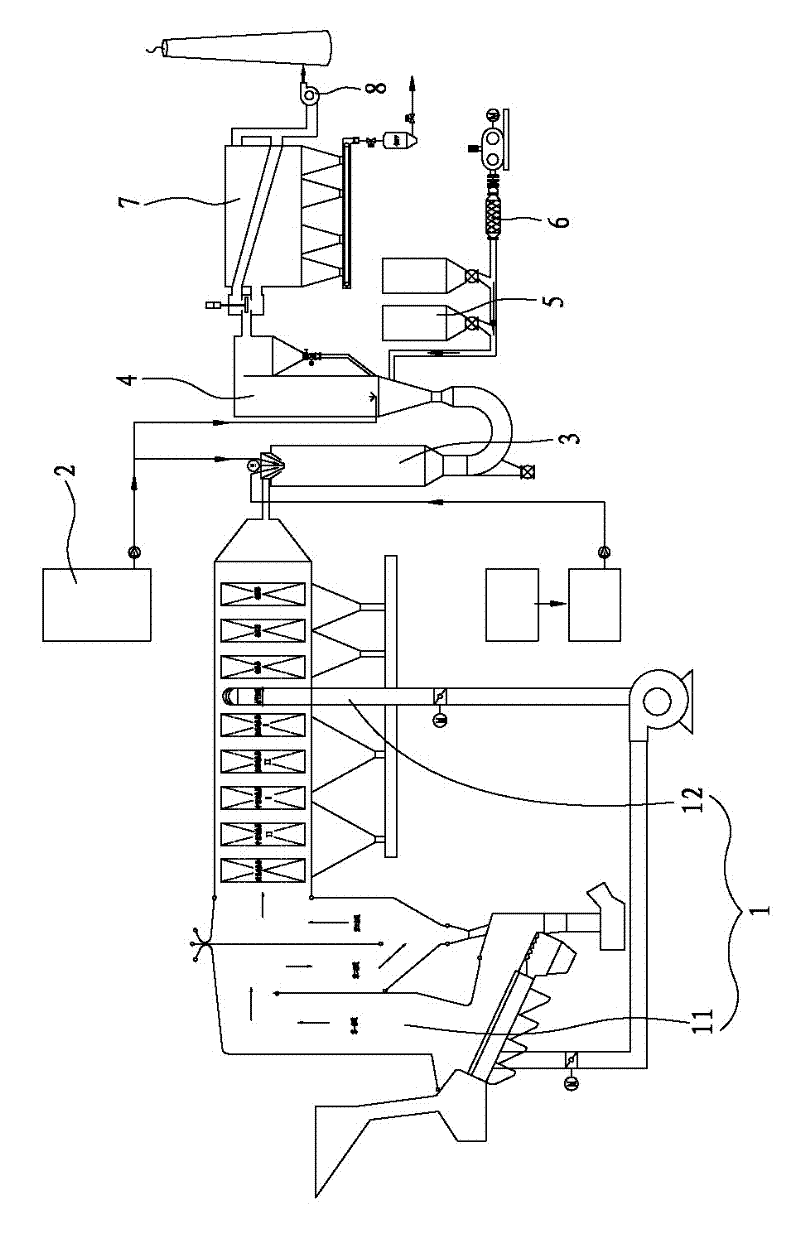

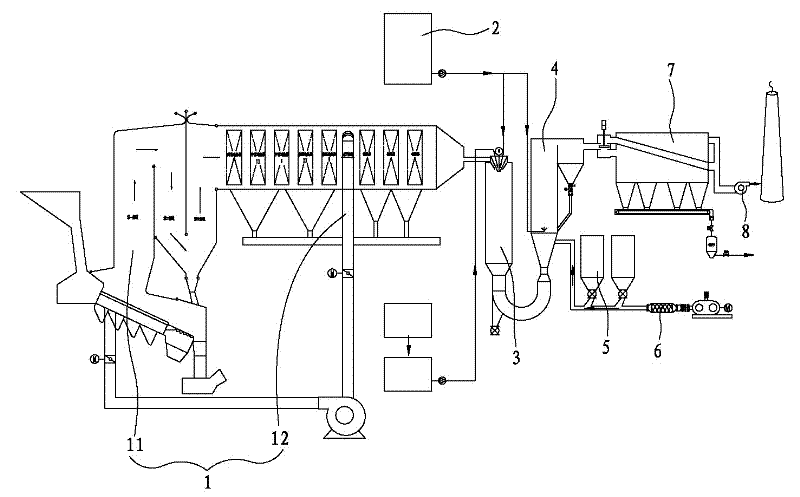

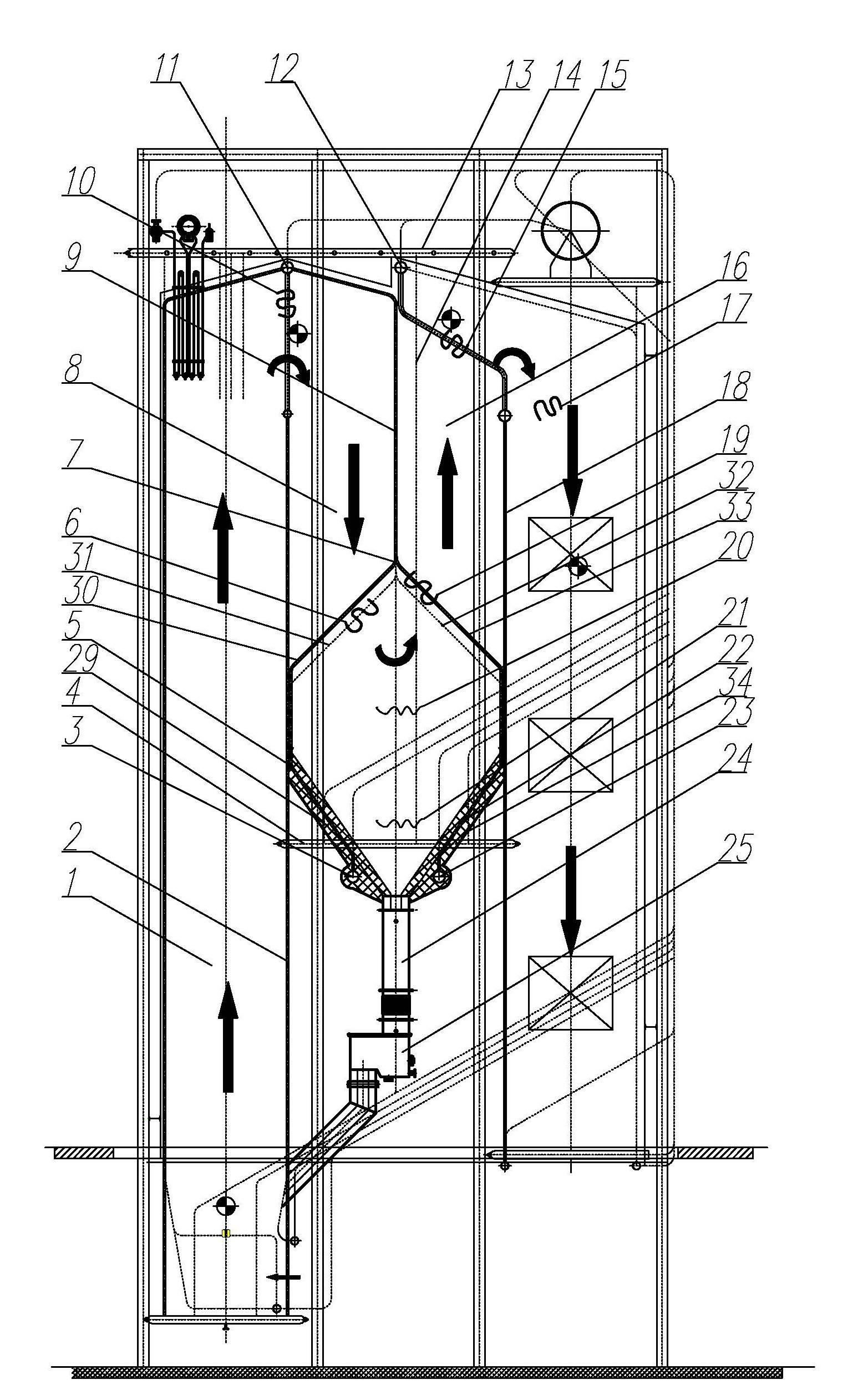

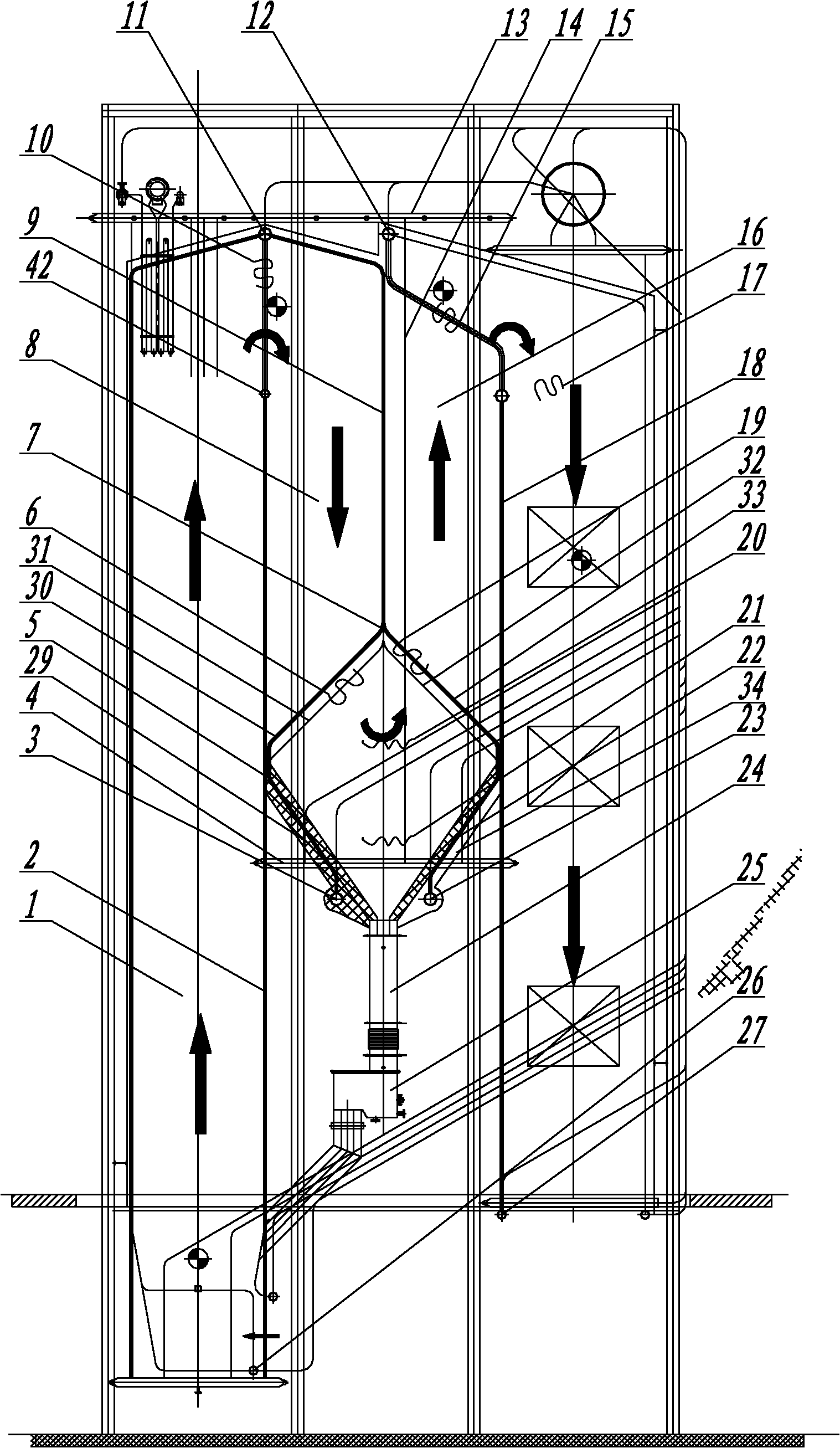

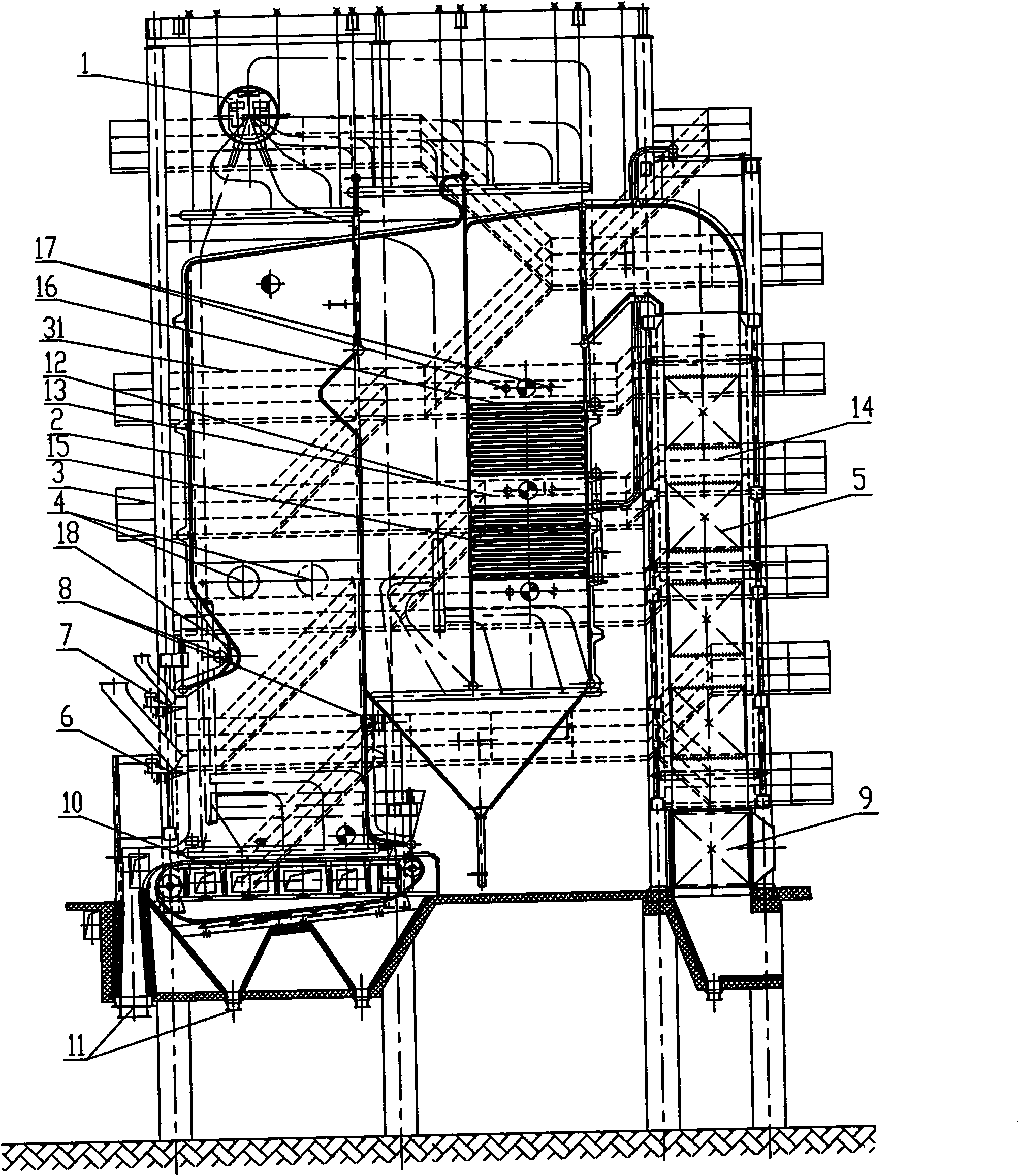

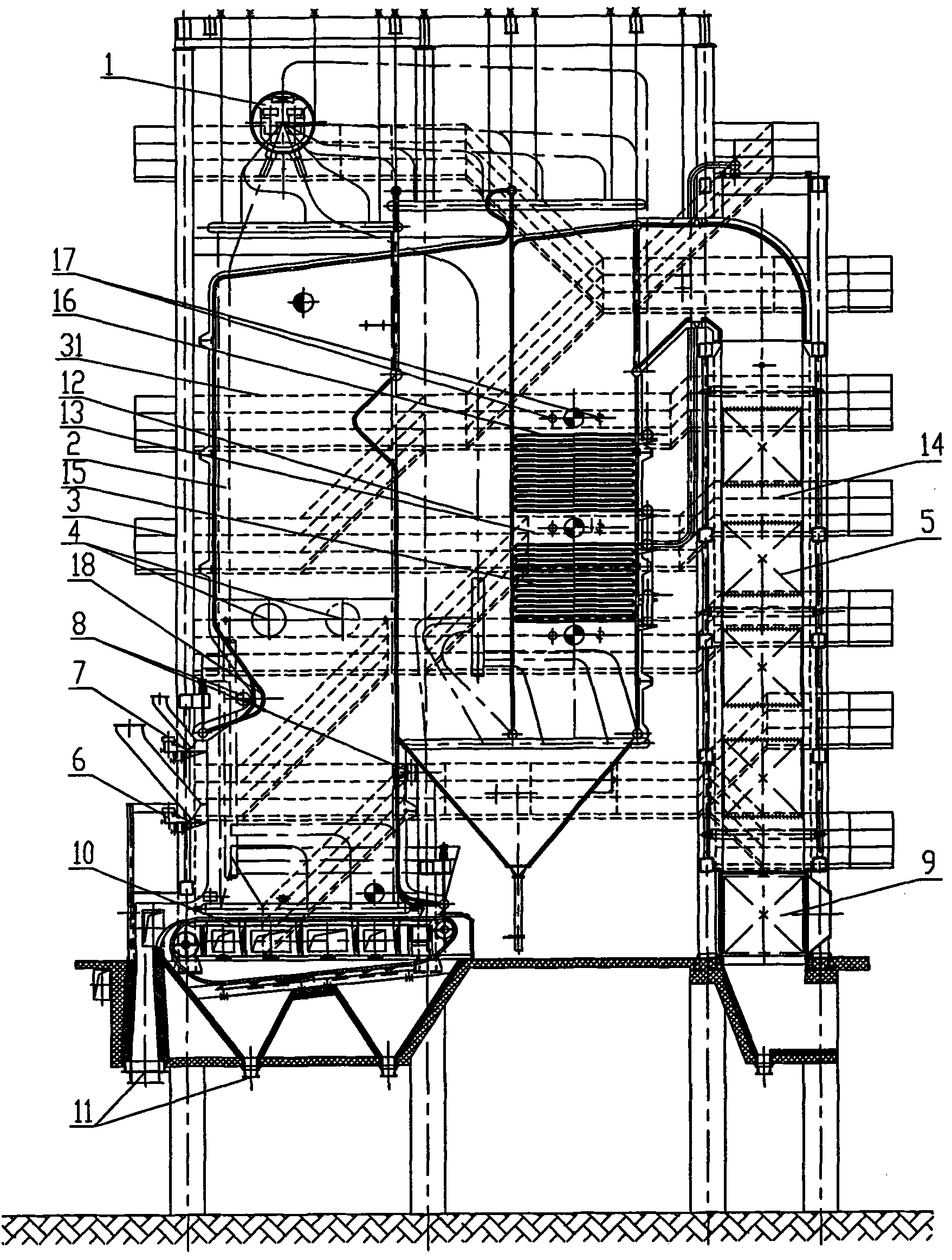

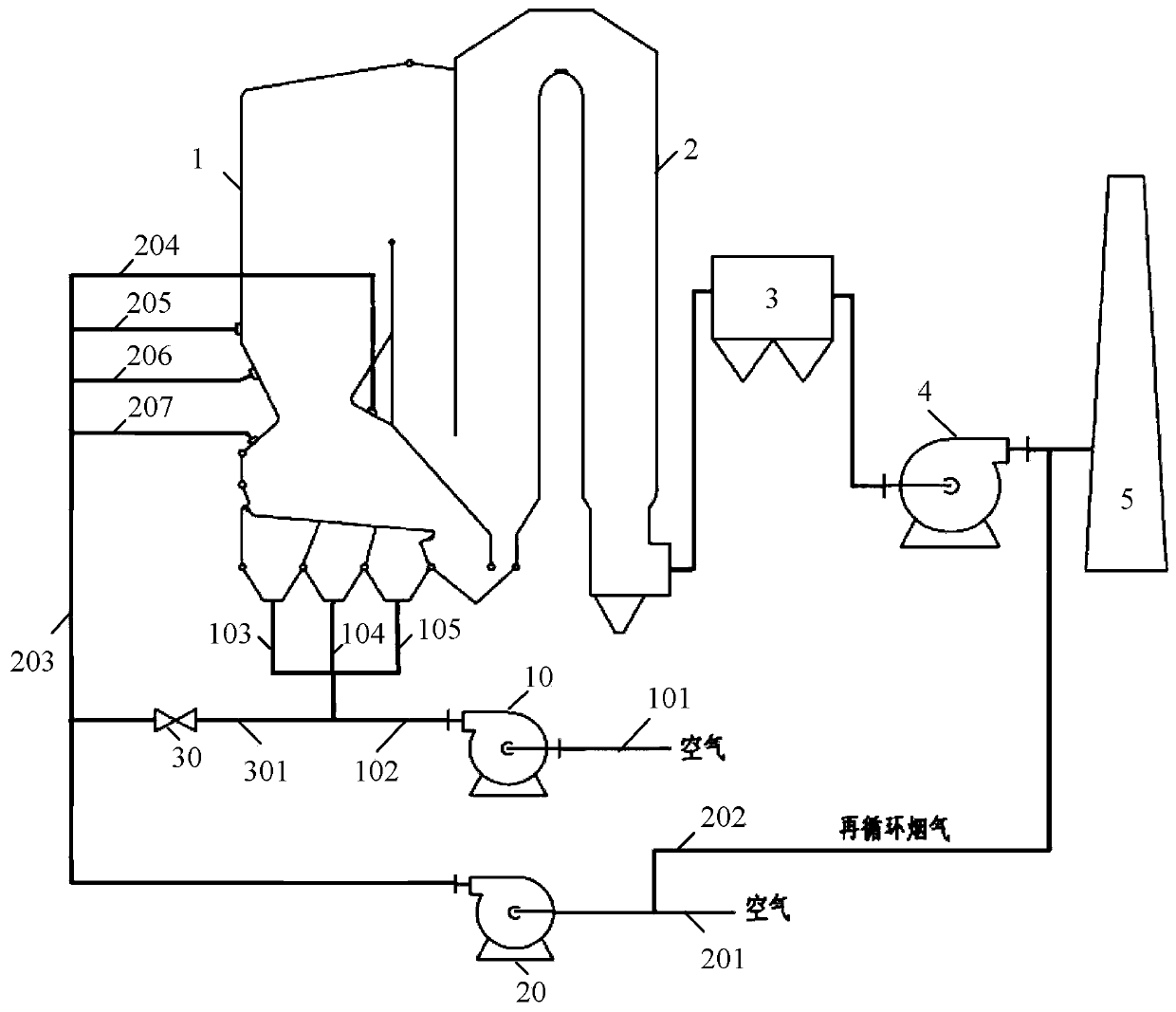

Smoke recycling rubbish incineration boiler

The invention relates to a smoke recycling rubbish incineration boiler. The smoke recycling rubbish incineration boiler comprises a boiler steel frame and a furnace arranged on the boiler steel frame. A grate mounting frame is arranged under the furnace, and a reciprocating machinery grate is arranged on the grate mounting frame. The rear part, of a smoke outlet, on the top of the furnace is provided with a first shaft flue, a second shaft flue, a third shaft flue, a horizontal flue, a first vertical rear flue and a second vertical rear flue which are connected in order. A smoke outlet A formed in the upper portion of the second vertical rear flue is connected with the smoke recycling nozzles arranged on the back wall and the front wall of a furnace exit through a smoke recycling system. A precipitator is arranged between the exit of the first vertical rear flue and the entrance of the second vertical rear flue. The smoke recycling rubbish incineration boiler has the advantages that the drying sludge can be burned at the time of rubbish incineration disposal, the heat loss due to exhaust gas of the boiler is decreased by more than 15%, the heat efficiency is increased by more than 2.2%, the dust capacity of the smoke in the exit of the boiler is decreased by more than 90%, the continuous running time is long, and effects of high efficiency, energy conservation and emission reduction can be achieved.

Owner:潘韬任

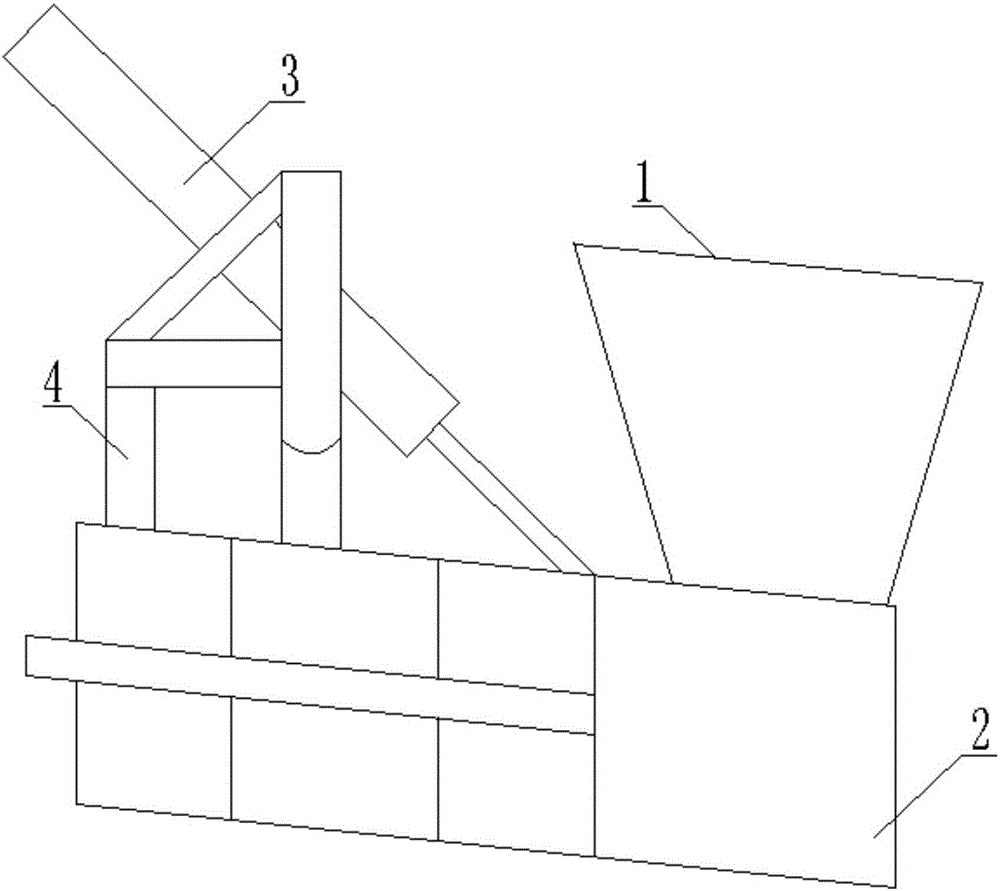

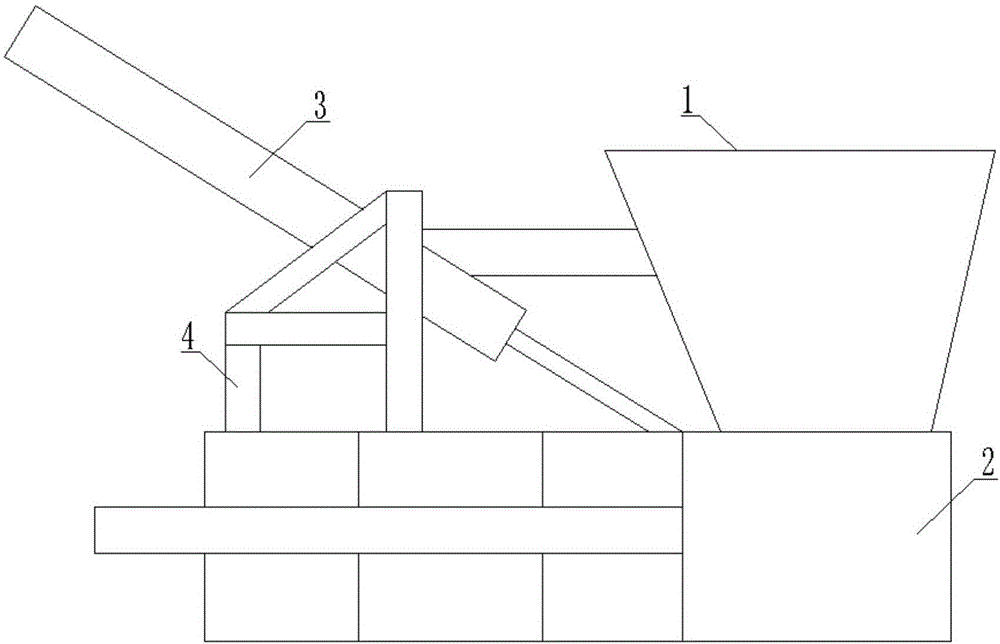

Quantitative compressing device for fly ash solidification

ActiveCN106239964APromotion falls intoReduce the amount of fly ashPressesEngineeringVolumetric Mass Density

The invention discloses a quantitative compressing device for fly ash solidification, and belongs to the technical field of waste incineration. The quantitative compressing device comprises a scale hopper, a compressing box, a power mechanism and a supporting mechanism. The scale hopper is mounted on a feed inlet of the compressing box. The compressing box is mounted on the supporting mechanism. Opening and closing of the compressing box and dynamic extending and contracting movement of the supporting mechanism are powered by the power mechanism. A bottom panel of the compressing box is oblique in the initial state. One end of the compressing box is a material compressing end, the other end of the compressing box is a motion end of a compressing rod of the power mechanism, and the initial height of the motion end is greater than that of the material compressing end. The scale hopper is arranged on the compressing box, the material extrusion quantity each time of the compressing box and the size of the compressing box are controlled, the problem that solidification blocks in the fly ash solidification process are different in size is solved, and the quantitative compressing device for fly ash solidification has the advantages that materials are input quantitatively, and solidification blocks equal in density are output.

Owner:安徽智崎环保设备有限责任公司

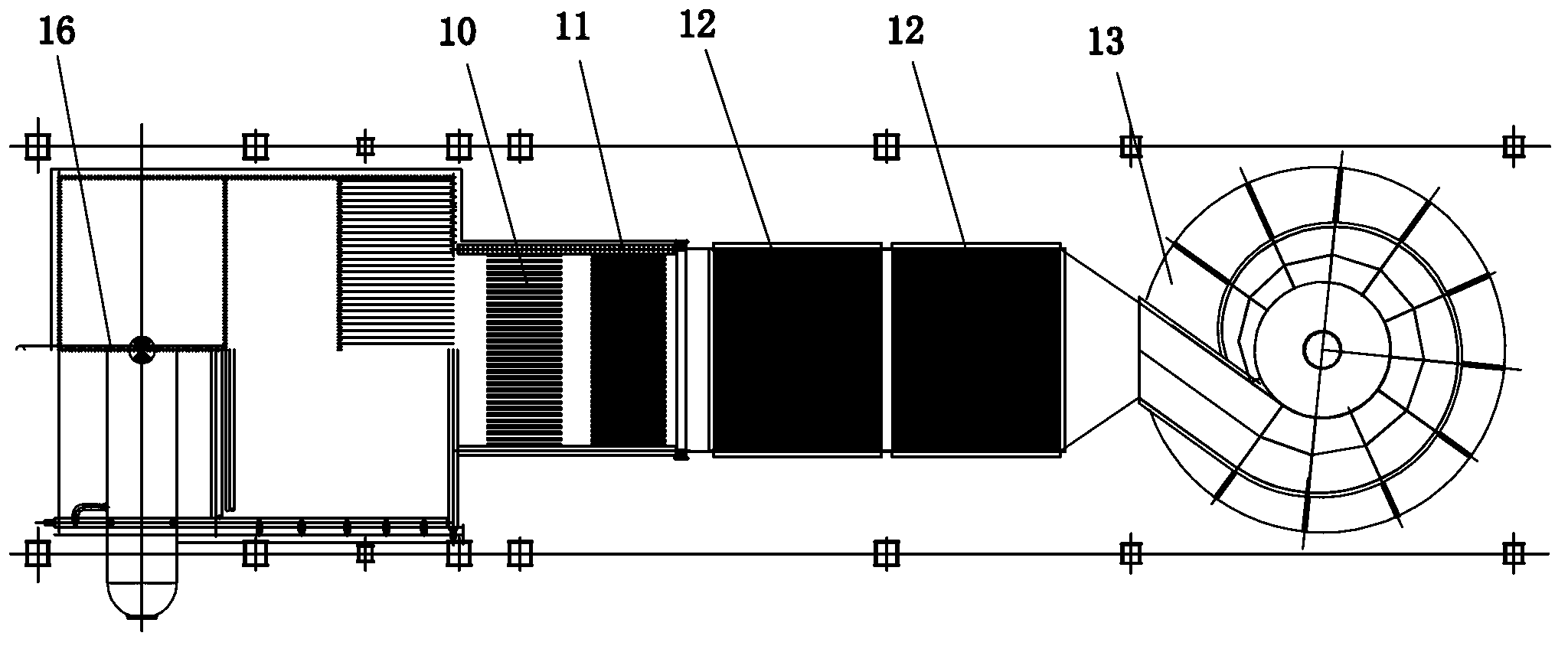

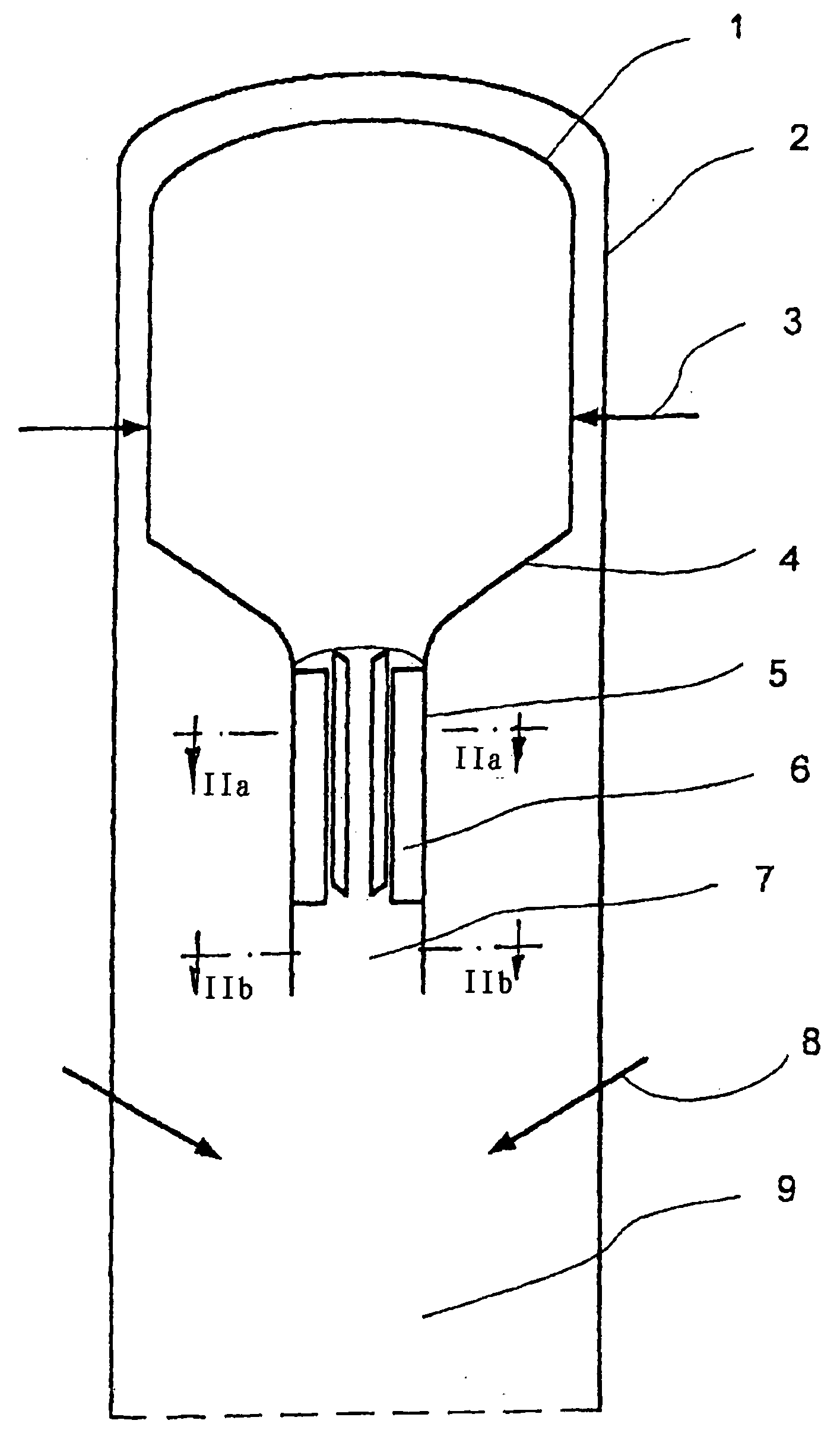

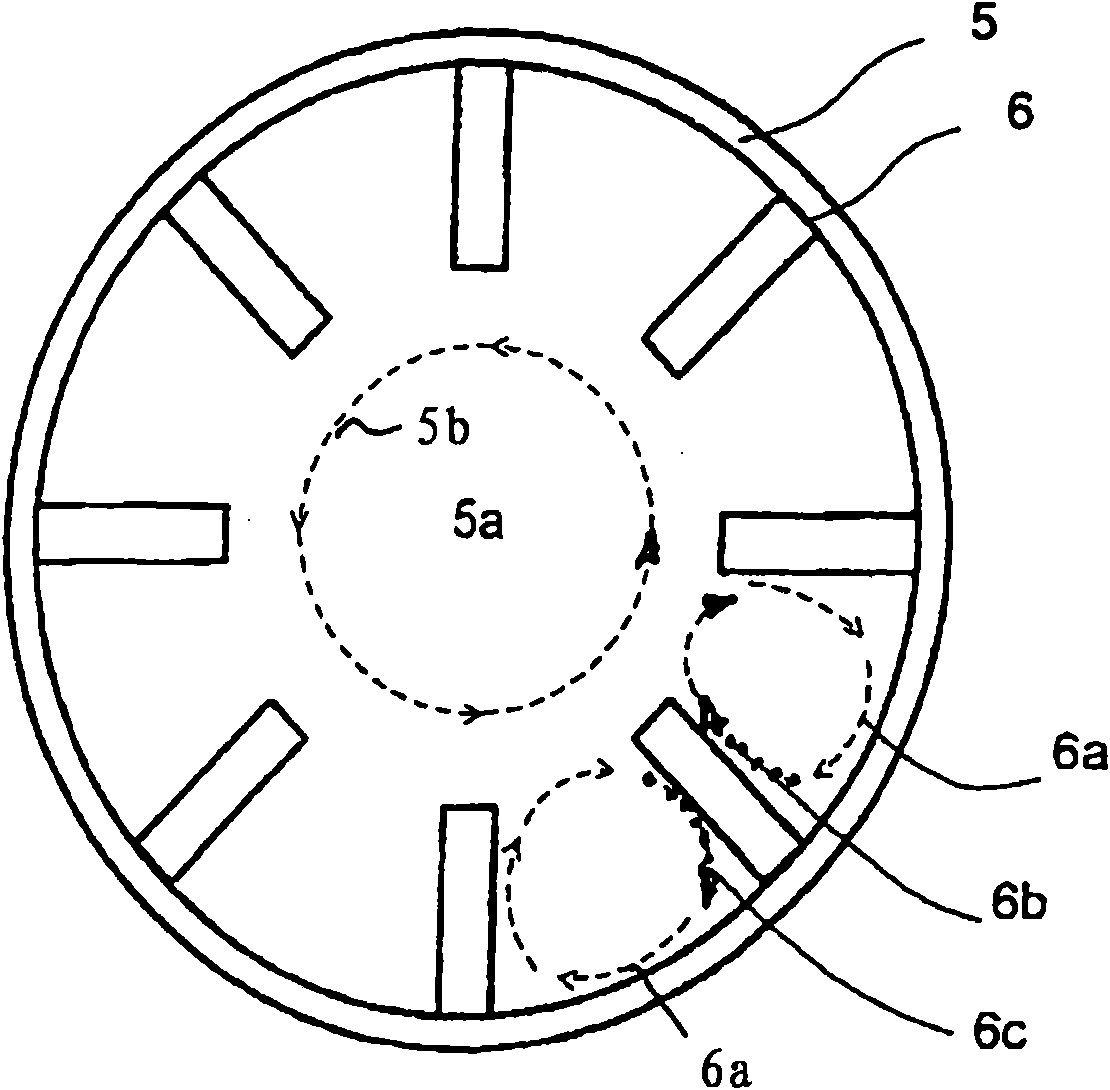

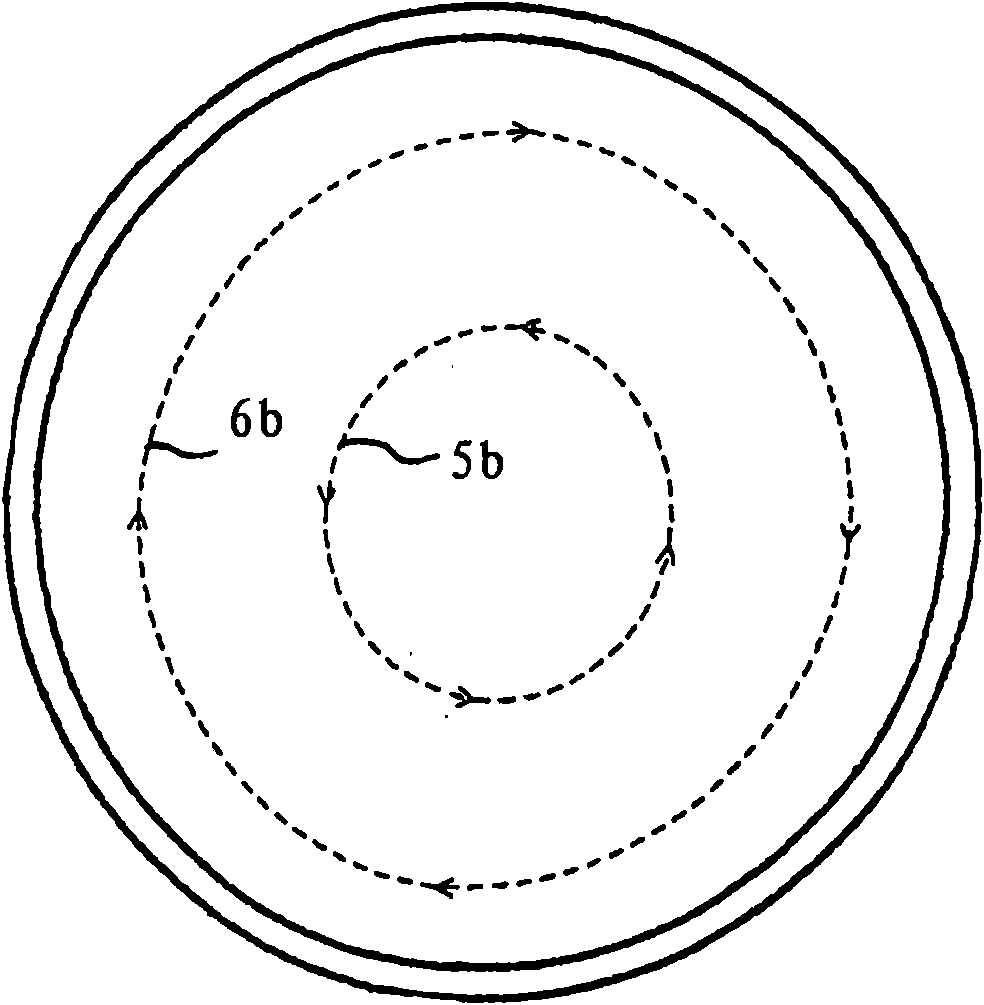

Device for producing synthesis gas with a gasification reactor and connecting quenching chamber

ActiveCN101981164AReduce eddy currentSuppress eddy currentGasification processes detailsChemical/physical processesForming gasSlag

The invention relates to a device for producing a crude gas containing CO or H2 by gasification of an ash-containing fuel with oxygen-containing gas at temperatures above the fusion temperature of the ash in a gasification reactor and with a connected gas cooling chamber and a tapered connecting channel running from one chamber to the other. The aim of the invention is avoiding known problems and reducing the amount of fly ash and the amount of ungasified fuel, wherein a weak eddy is achieved in the inlet to the subsequent apparatuses in order to avoid deposits there with a very compact device, wherein the risk of solidification of the slag in the outlet is also avoided. The aim is achieved, wherein in the tapered connection channel (5) eddy reducing or eliminating wall surfaces (6) running over only a part of the cross-section of the connection channel are provided.

Owner:UHDE GMBH

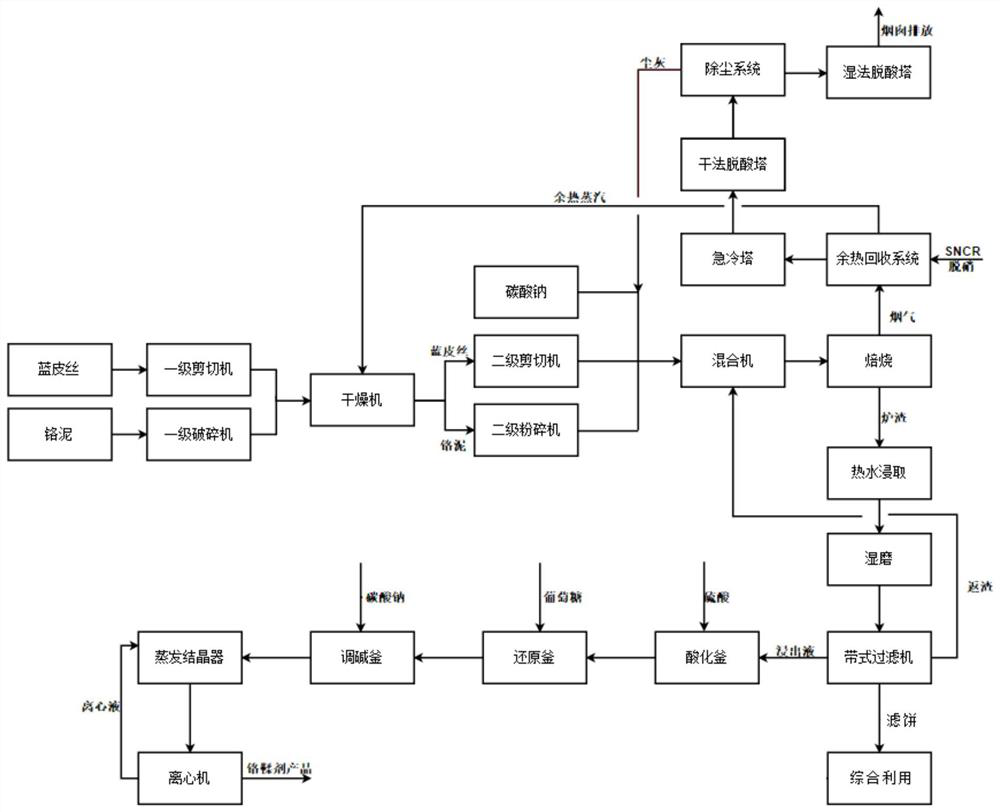

Leather tanning chromium-containing waste treatment method

The invention discloses a leather tanning chromium-containing waste treatment method, which aims to solve the problems that hazardous wastes including chromium leather shavings and chromium mud can be generated during leather tanning, a small amount of trivalent chromium is converted into hexavalent chromium due to direct incineration of the chromium leather shavings, the toxicity of waste residues after combustion is increased, the treatment difficulty is increased, the nitrogen content of the chromium leather shavings is high, the nitric oxide content in combustion smoke is high, and the smoke treatment cost is high. The chromium leather shavings and chromium mud are treated through the four working stages of pretreatment, roasting, post-treatment and smoke treatment, the problem existing in landfill after direct incineration or direct landfill of the chromium leather shavings is solved, and recycling of waste resources is achieved,. The leather tanning chromium-containing waste treatment method has good environmental benefits and economic benefits.

Owner:丁吉东

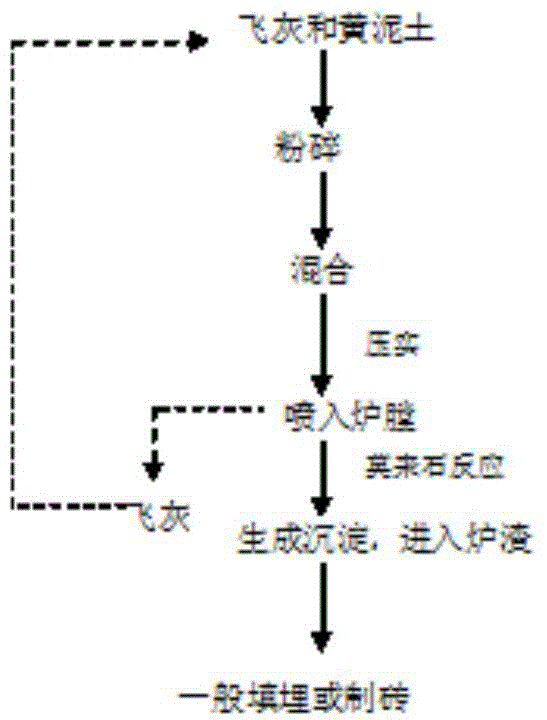

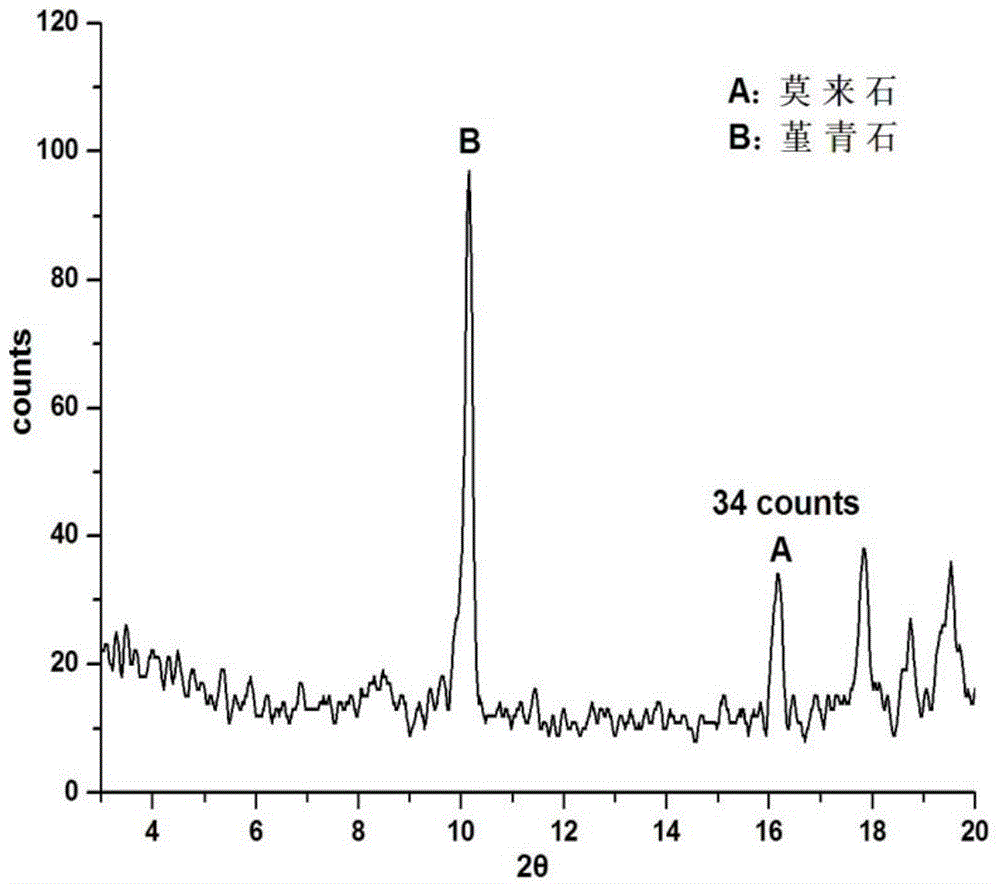

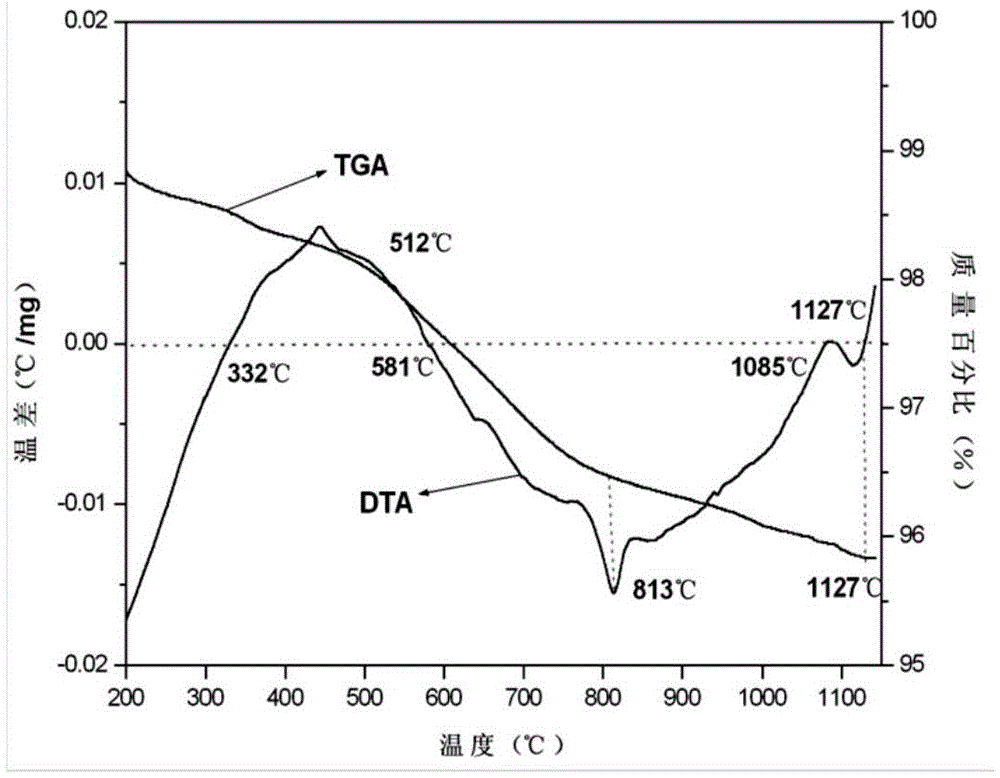

Method for lowering quantity and toxicity of flying ash of household garbage incineration plant

ActiveCN104676595AAchieve detoxificationAchieve fixationAluminium silicatesEnergy inputSlagEngineering

A method for lowering the quantity and toxicity of the flying ash of a household garbage incineration plant is characterized by including the steps of firstly, mixing cream-colored mud and existing flying ash of the household garbage incineration plant according to a certain proportion, smashing to reach a certain particle size, mixing with fine grinding media according a certain proportion, and performing fine grinding with a stirring ball mill; secondly, pressing the finely-ground flying ash and cream-colored mud into cylindrical samples under certain pressure; thirdly, during household garbage incineration, putting the samples into an incineration hearth at a certain speed, and fully utilizing the waste heat generated by the incineration to perform fast mullite reaction so as to allow generated substances containing mullite to settle to a slag system, to lower the flying ash quantity during the incineration to 40% of the original quantity, and to reduce heavy metal contents in the flying ash. The method has the advantages that the temperature of a household garbage incineration furnace is fully utilized, the method is simple in process, low in cost and free of pollution, subsequent flying ash processing cost and difficulty are lowered, and good economic and social benefits are achieved.

Owner:SHANGHAI JIAO TONG UNIV

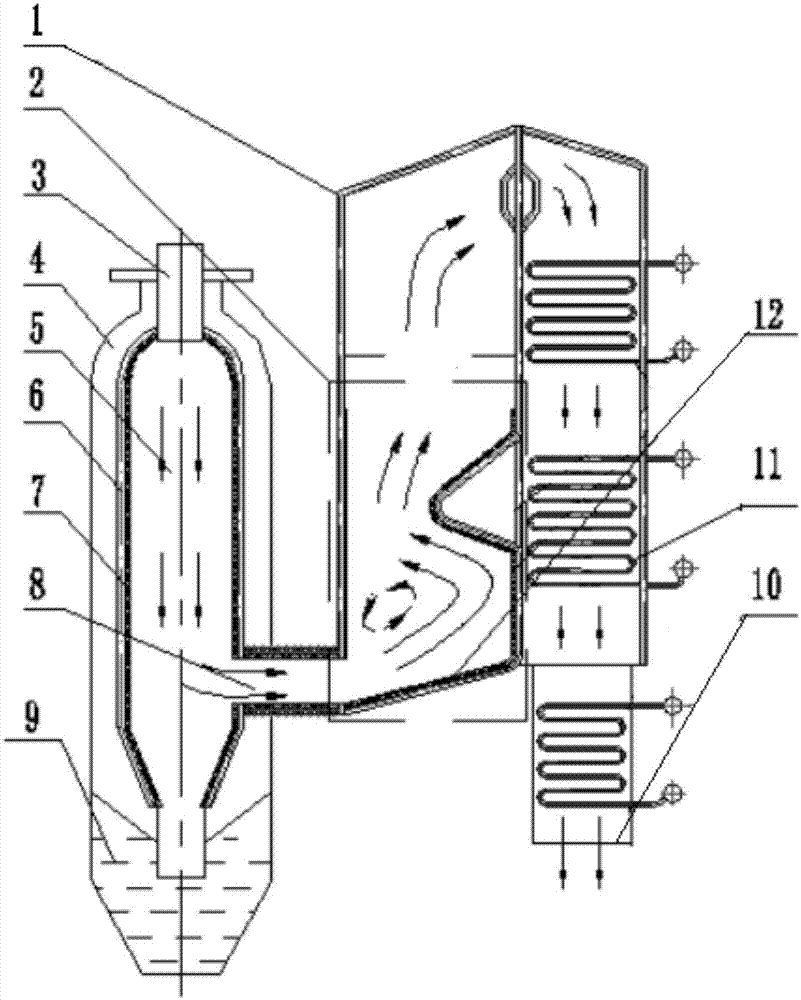

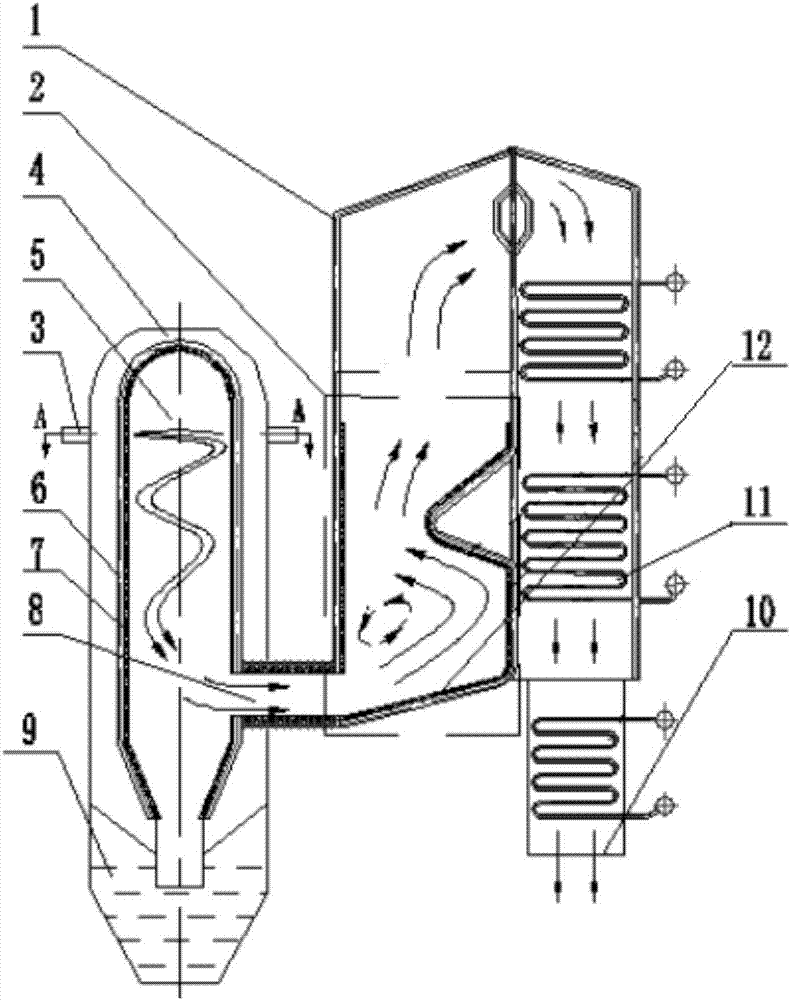

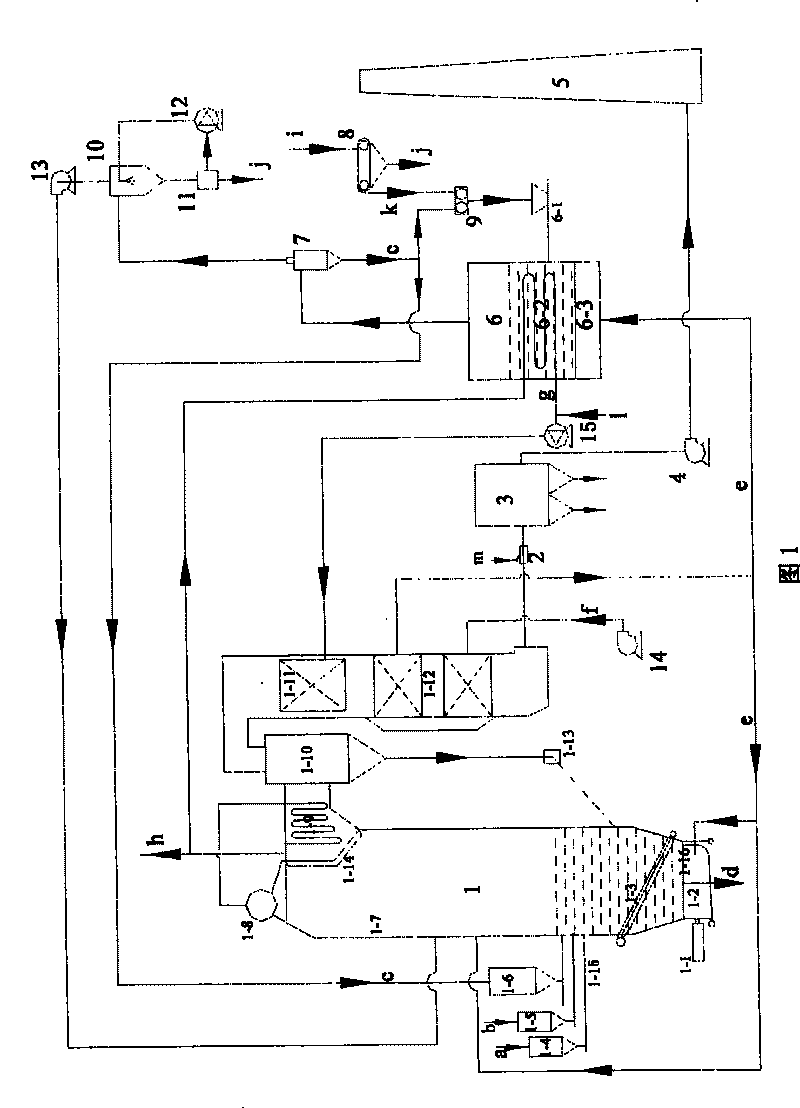

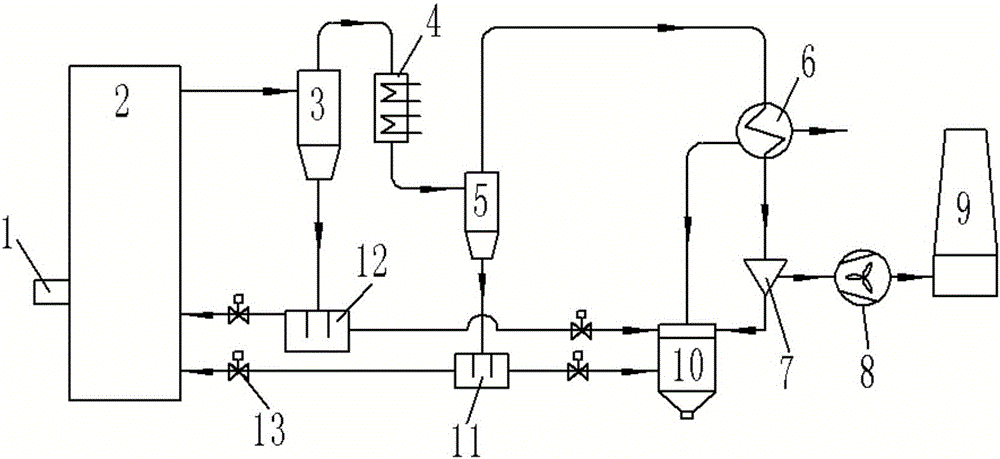

Sludge drying burning combination treatment method

ActiveCN101265008BStable combustionImprove thermal efficiencySludge treatment by de-watering/drying/thickeningIncinerator apparatusFluidized bed dryingPollutant emissions

The invention relates to a sludge drying and incineration combined treatment method with good treatment effect, wide sludge adaptability, and safe and stability system. To avoid agglomeration of mechanically dewatered sludge (k) in a fluidized bed dryer (6), a part of dried sludge (c) is premixed with the mechanically dewatered sludge (k) and then fed into the fluidized bed dryer (6). The dried sludge (c) is incinerated into a circulating fluidized bed incinerator (1) to generate superheated vapor. The superheated vapor is condensed to hot water in a heat exchange tube (6-2) of the fluidized bed dryer (6) and then recycled to the circulating fluidized bed incinerator (1). The arrangement of buried pipes (1-3) and fractional air supply inside the circulating fluidized bed incinerator (1) can effectively control the lower temperature of the circulating fluidized bed incinerator (1) to prevent deflagration of dried sludge. The entire system has no emission of pollutants such as unpleasantodor, acidic gases, heavy metals and dioxin; is safe and reliable; and can operate for a long time.

Owner:JIANGSU JINSHAN SOLID WASTE RESOURCE TECH

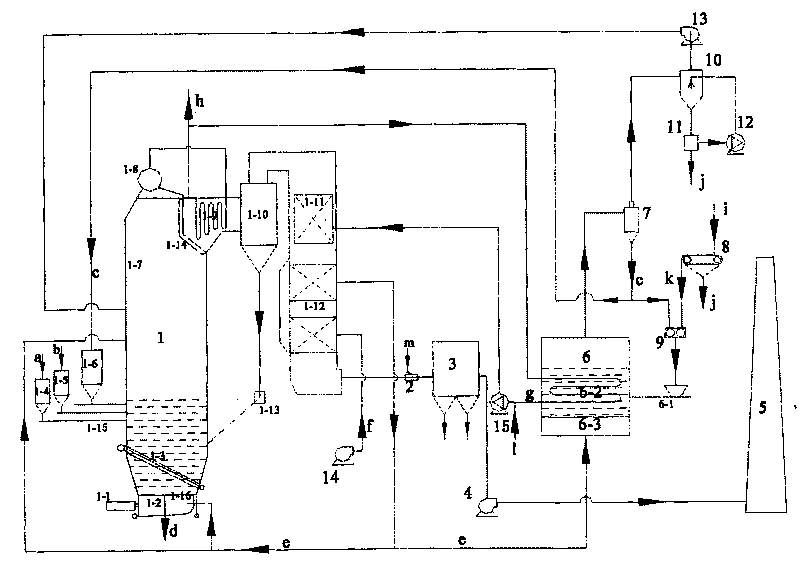

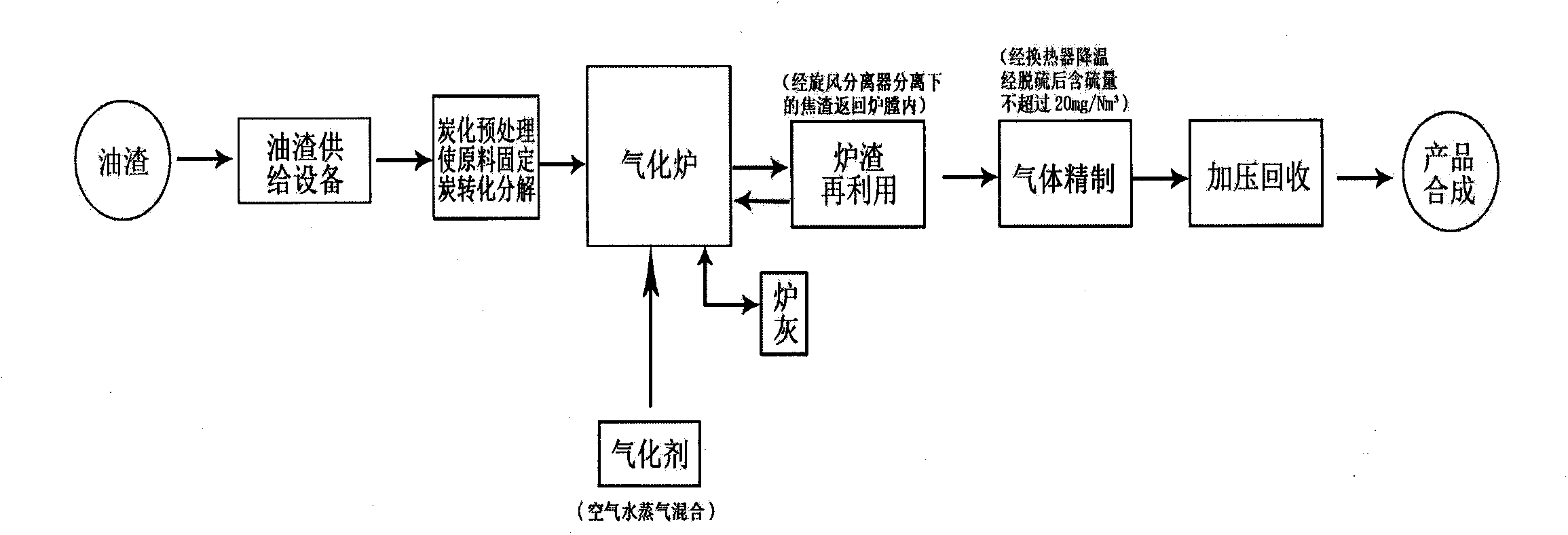

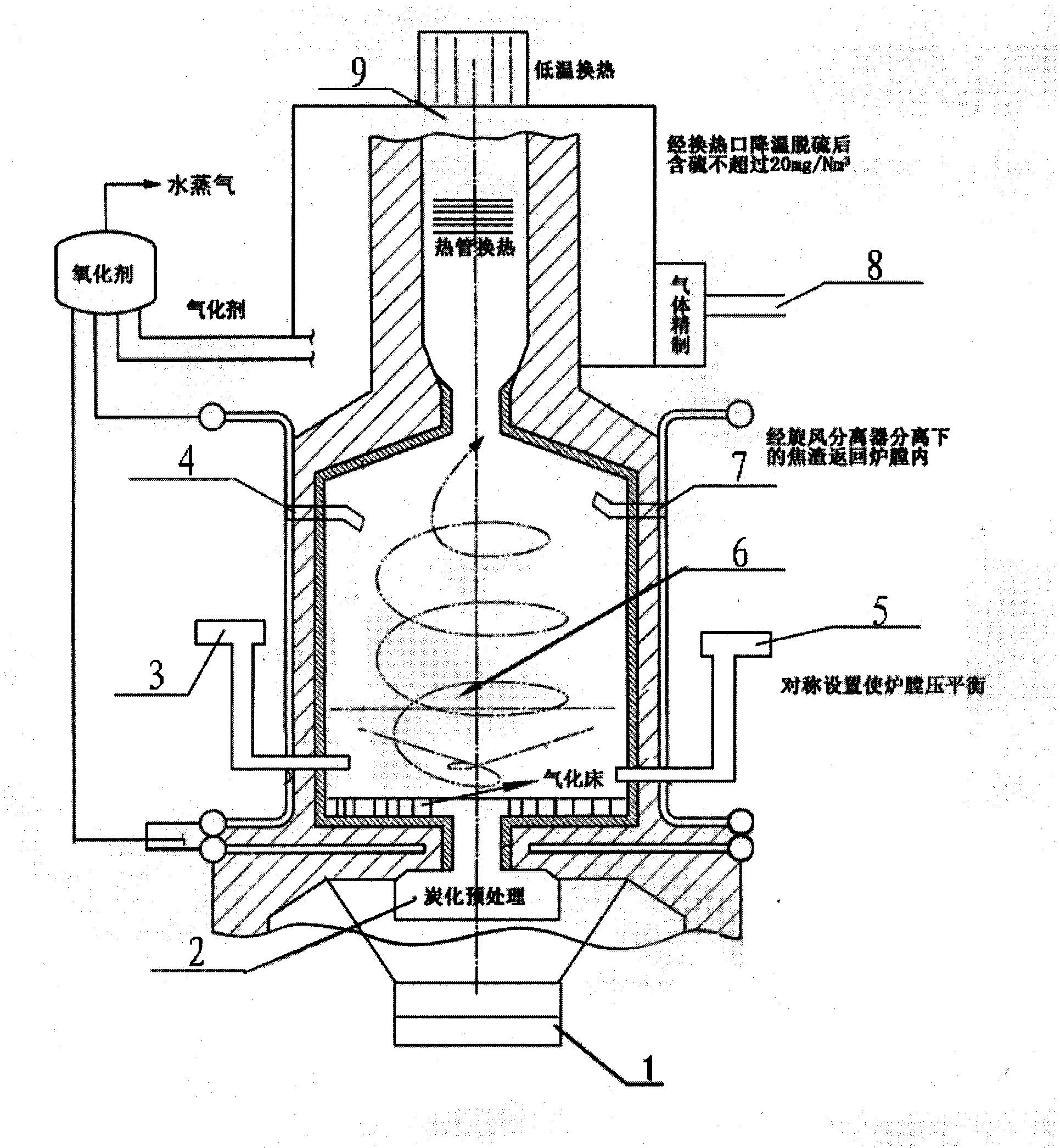

Secondary gasification treatment method for oil residue caused in gas production

The invention discloses a secondary gasification treatment method for oil residue caused in gas production. The secondary gasification treatment method for oil residue caused in gas production comprises the following steps: delivering an oil residue raw material with the particle diameter of 10mm below to an oxygen carbonizing furnace for carbonizing treatment, further gasifying the oil residue raw material, then transmitting the mixture gas into a cone section at the bottom of a gasification furnace so as to react with a gasifying agent, wherein the temperature of the gasifying agent is 750 DEG C, the pressure and temperature of the top of a gas furnace are respectively 15Kpa and 98 DEG C; flowing the gas out to enter a primary cyclone separator, returning the separated residue ash back to the hearth of the gasification furnace through a return pipe, and entering the gas into a dry type dust collection system after being subjected to dust collection treatment by a secondary cyclone separator, then cooling the gas again by a heat pipe exchanger, and recovering the desulfurized gas in a pressurization system. According to the secondary gasification treatment method, the gasification efficiency is high, the fluidization quality is improved, the flying ash quantity, flying as carbon content, ash slag carbon content in the gas can be greatly reduced, and the effective utilization rate and gasification efficiency of the oil residues can be improved.

Owner:杜维兴

Double-circuit gasification and combustion system based on circulating fluidized bed and method and application thereof

ActiveCN106402911AGuaranteed pressure balanceAvoid running unstableLighting and heating apparatusGasification processes detailsCombustion systemFluidized bed

The invention discloses a double-circuit gasification and combustion system based on a circulating fluidized bed and a method and application thereof. The double-circuit gasification and combustion system comprises a gasifier, a primary separator, a heat exchanger, a secondary separator, a boiler and an ash bin, wherein the inlet of the primary separator communicates with the outlet of the gasifier; the gas outlet of the primary separator communicates with the heat medium inlet of the heat exchanger; the heat medium outlet of the heat exchanger communicates with the inlet of the secondary separator; gas subjected to primary separation is subjected to heat exchange for cooling in the heat exchanger; the gas outlet of the secondary separator communicates with the boiler; the solid outlet of the primary separator communicates with the inlet of a first material return valve; one side outlet of the first material return valve communicates with a first material return opening of the gasifier, and the other side outlet of the first material return valve communicates with the ash bin; the solid outlet of the secondary separator communicates with the inlet of a second material return valve; and one side outlet of the second material return valve communicates with a second material return opening of the gasifier, and the other side outlet of the second material return valve communicates with the ash bin.

Owner:山东百川同创能源有限公司

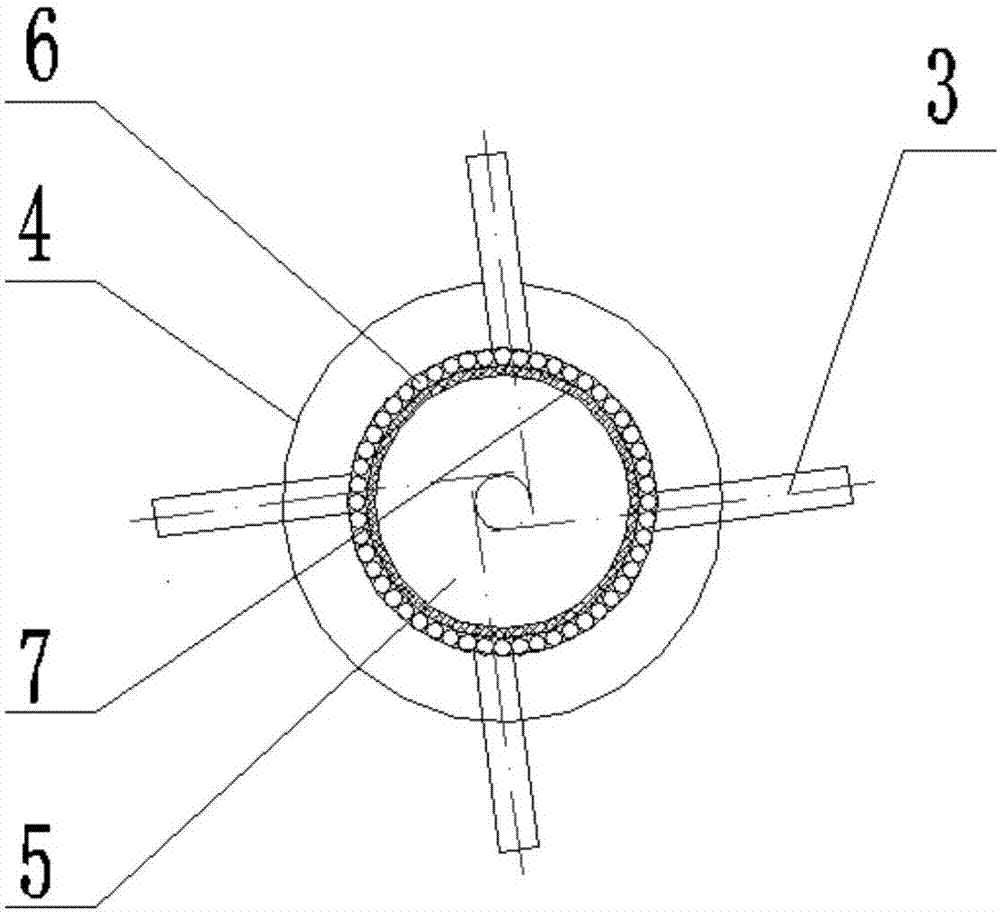

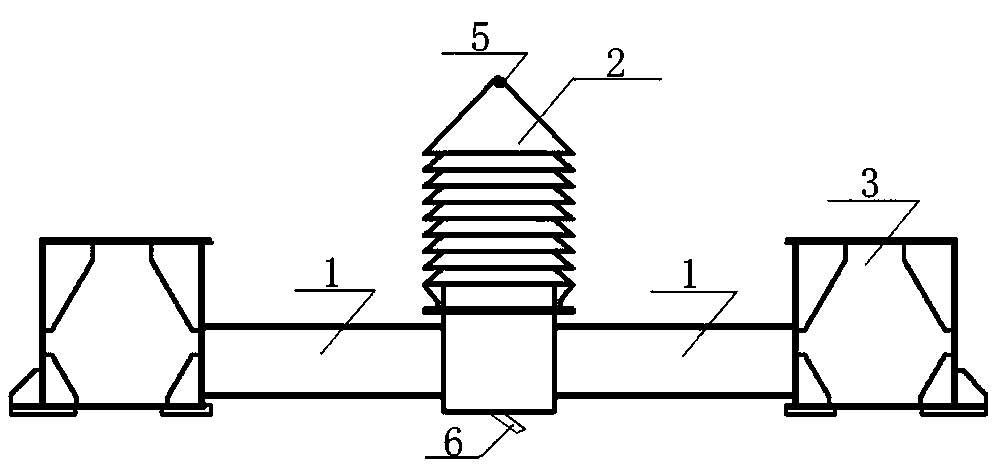

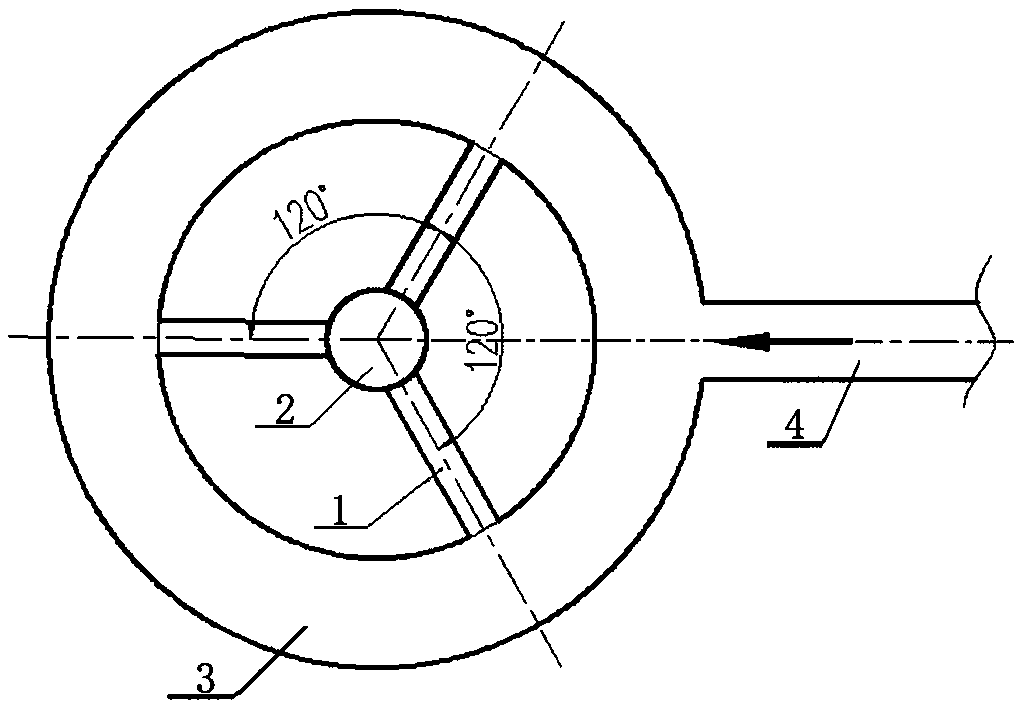

Air supply system for lime kiln

The invention relates to the technical field of the lime kiln and discloses an air supply system for the lime kiln. The air supply system comprises an exhaust fan, an air supply pipeline and an air collection tank, the exhaust fan is fixedly connected with the air supply pipeline, the air collection tank is ring-shaped, the air collection tank and the air supply pipeline are fixedly connected, three air supply branch pipes are formed in the ring-shaped inner wall of the air collection tank, the included angles among the three air supply branch pipes are 120 degrees, and an air cap is arrangedon the intersection part of the other ends of the three air supply branch pipes. The air cap is in a tower-shaped structure, the diameters of the multiple layers of the tower-shaped structure are thesame, a plurality of air supply holes are evenly distributed at each periphery of each layer of the air cap, and a plurality of air outlets are evenly distributed at the periphery of each layer of theair cap. The air cap is in the tower-shaped structure, and the diameters of the ten layers of the tower-shaped structure are the same. A dust falling groove is distributed at the top part of the aircap, and a dust leading pipe is distributed at the lower part of the air cap. The air supply system overcomes the defect of uneven air supply of the lime kiln existing for a long period of time.

Owner:HENAN ZHONGHENG IND FURNACE ENG TECH

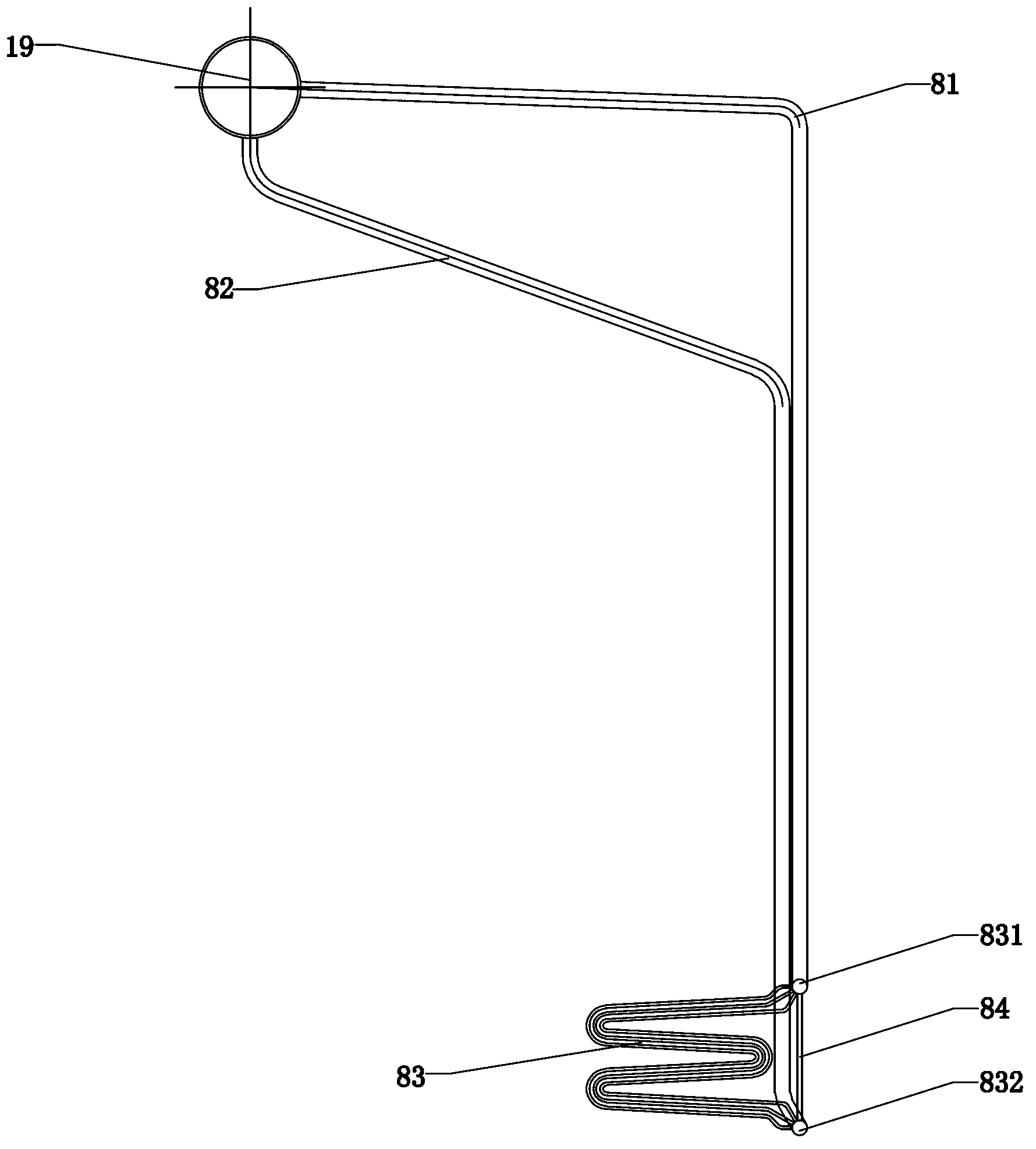

Smoke recirculation device for separating primary air and secondary air

PendingCN110657439AReduce unit consumptionReduce the amount of fly ashAir supply regulationIndirect carbon-dioxide mitigationCombustionEnvironmental engineering

The invention provides a smoke recirculation device for separating primary air and secondary air. The smoke recirculation device comprises an incinerator, a smoke purification device, a primary fan and a secondary fan. The incinerator is configured to incinerate biomass to generate smoke. The smoke purification device is configured to purify the smoke, and one part of purified smoke discharged bythe smoke purification device serves as recirculation smoke. The primary fan is configured to drain air, so that the air serves as primary air of the incinerator. The secondary fan is configured to drain air and the recirculation smoke, and the air and the recirculation smoke serve as secondary air of the incinerator. According to the provided smoke recirculation device for separating the primaryair and the secondary air, the primary fan drains the air as the primary air, the secondary fan drains the air and the recirculation smoke as the secondary air, thus the flying ash quantity and the flying ash carbon content are lowered, fuel unit consumption is lowered, high-temperature corrosion is reduced, and the combustion condition is optimized.

Owner:光大绿色环保管理(深圳)有限公司

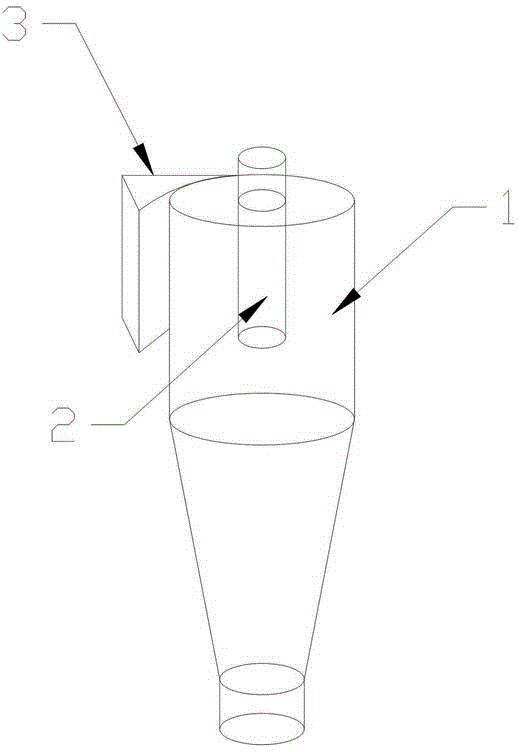

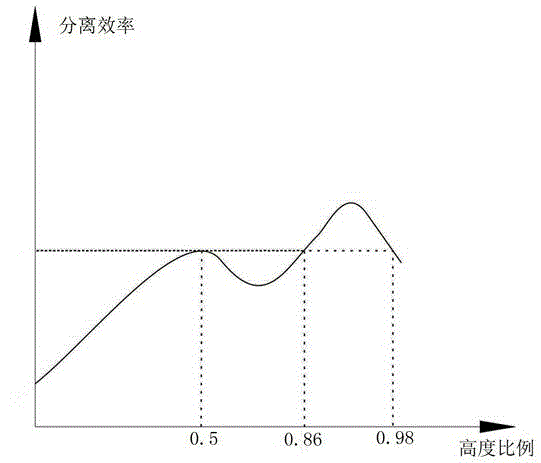

CFB (circulating fluidized bed) waste incineration boiler gas-solid separation method

InactiveCN104534480AReduce the amount of fly ashReduce wearFluidized bed combustionDispersed particle separationGas solidFluidized bed

The invention discloses a CFB (circulating fluidized bed) waste incineration boiler gas-solid separation method which is characterized by including the steps: 1 setting the fluidizing velocity of a section in a hearth to be 4-4.5 meters / second; 2 performing gas-solid separation for flue gas by a cyclone separator; 3 setting an empty flue behind the cyclone separator, and setting a 180-degree upward turn at the tail of the flue. High circulating ash concentration and efficient heat transfer in the boiler are ensured, tail fly ash quantity is decreased, fly ash particle sizes are effectively controlled within a proper range, and abrasion of a tail convection heating surface is reduced.

Owner:CHINA WESTERN POWER INDAL

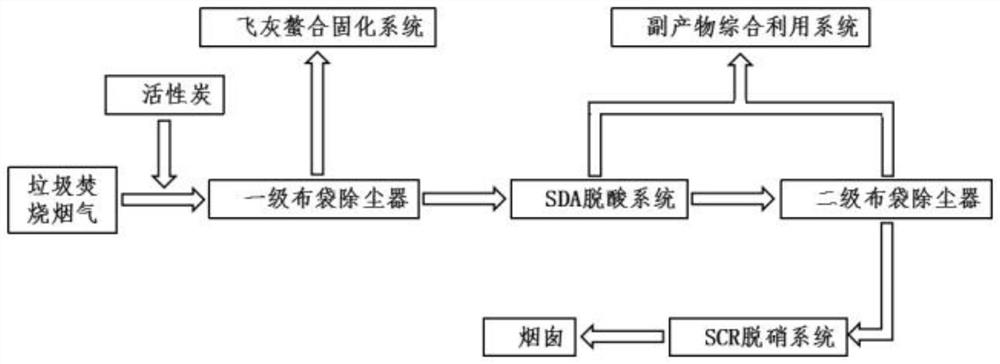

Household garbage incineration fly ash grading treatment system

PendingCN112594728AIncrease profitReduce the difficulty of disposalIncinerator apparatusActivated carbonFlue gas

The invention discloses a household garbage incineration fly ash grading treatment system which comprises a first-stage bag-type dust collector, an SDA deacidification system, a second-stage bag-typedust collector, an SCR denitration system, a chimney, a fly ash chelating and curing system and a byproduct comprehensive utilization system. Waste incineration flue gas sequentially passes through the first-stage bag-type dust collector, the SDA deacidification system, the second-stage bag-type dust collector and the SCR denitration system and is finally discharged through the chimney; activatedcarbon is sprayed into a connecting pipeline before the waste incineration flue gas enters the first-stage bag-type dust collector; the fly ash filtered by the first-stage bag-type dust collector enters the fly ash chelating and curing system; in the actual production process, the flue gas firstly reacts with the activated carbon to remove dioxin contained in the flue gas, then the flue gas is further purified by a dust collection device, a deacidification device and a denitration device, and finally the flue gas is discharged after reaching the standard through the chimney. One part of the filtered fly ash can be intensively treated through the chelating and curing system, and the other part of the fly ash can pass through a treatment system, so that the comprehensive utilization of byproducts is realized, and the fly ash treatment cost is reduced.

Owner:ANHUI XINCHUANG ENERGY SAVING & ENVIRONMENTAL PROTECTION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com