Fly ash smelting pre-treatment system and fly ash treating method

A pretreatment and fly ash technology, which is applied in the field of pretreatment system in the fly ash melting and pyrolysis technology, can solve the problems of incomplete treatment, small fly ash particle size, blockage of subsequent pipelines, etc., to reduce the number of equipment used, Improved melting efficiency and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

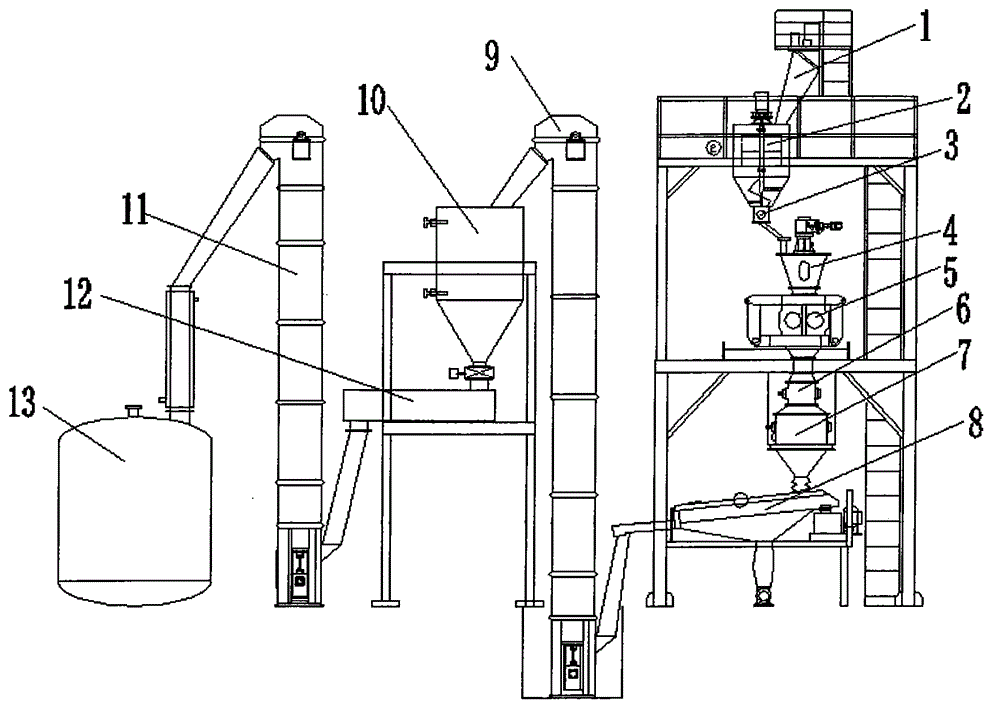

[0029] Such as figure 1 As shown, a fly ash melting pretreatment system of the present invention includes a raw material storage bin 2, granulation equipment, and a melting furnace 13. The rear part of the raw material storage bin 2 is connected to the granulation equipment, and the rear part of the granulation equipment is connected to a The first hoist 9, the finished product warehouse 10 is connected to the rear of the first hoist 9, the second hoist 11 is connected to the rear of the finished product warehouse 10, and the melting furnace 13 is connected to the second hoist 11 rear, The granulation equipment includes a forced feeder 4 connected to the raw material storage bin 2, the rear of the forced feeder 4 is connected with a flaking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com