Patents

Literature

766results about How to "Not easy to spread" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

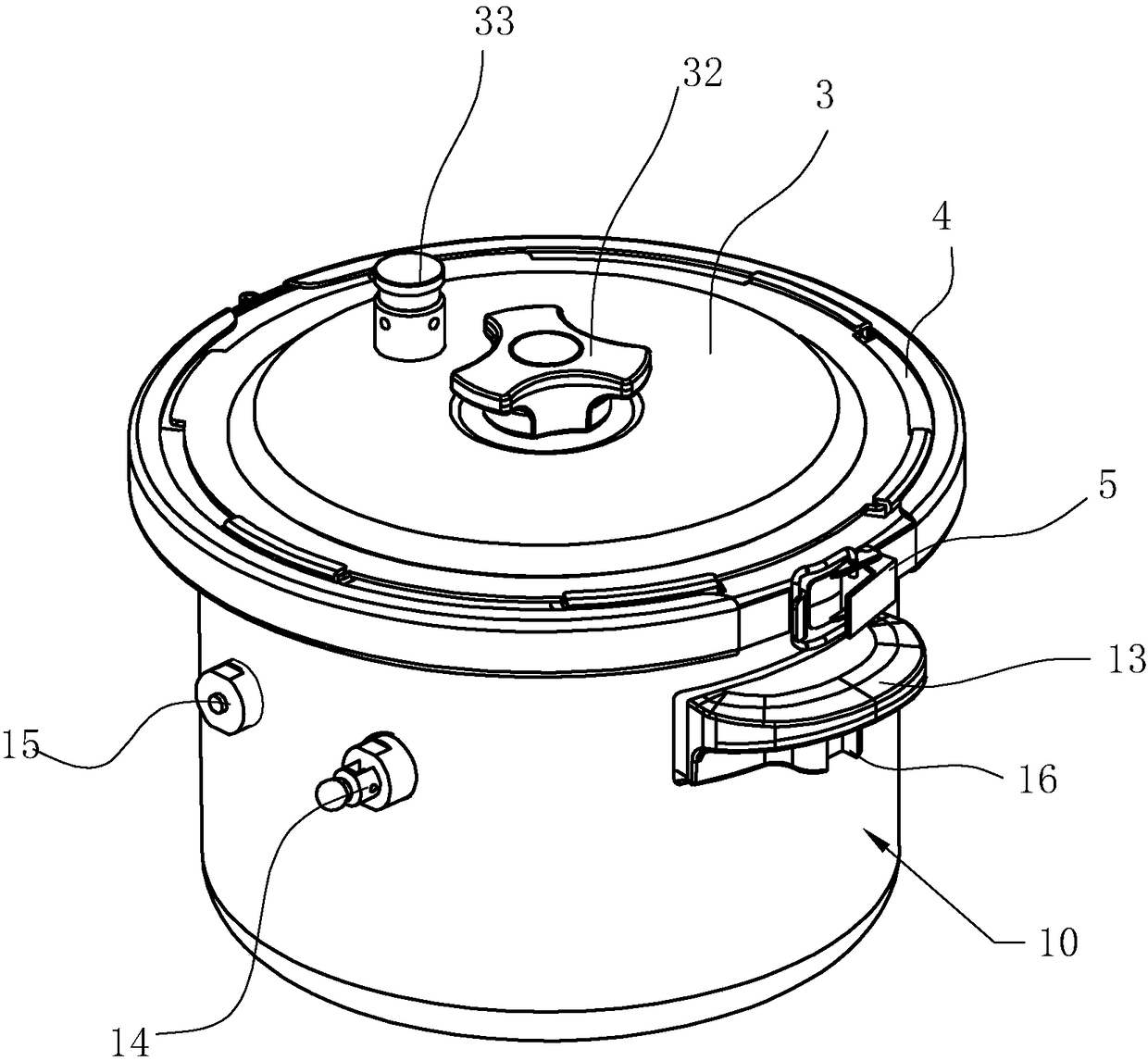

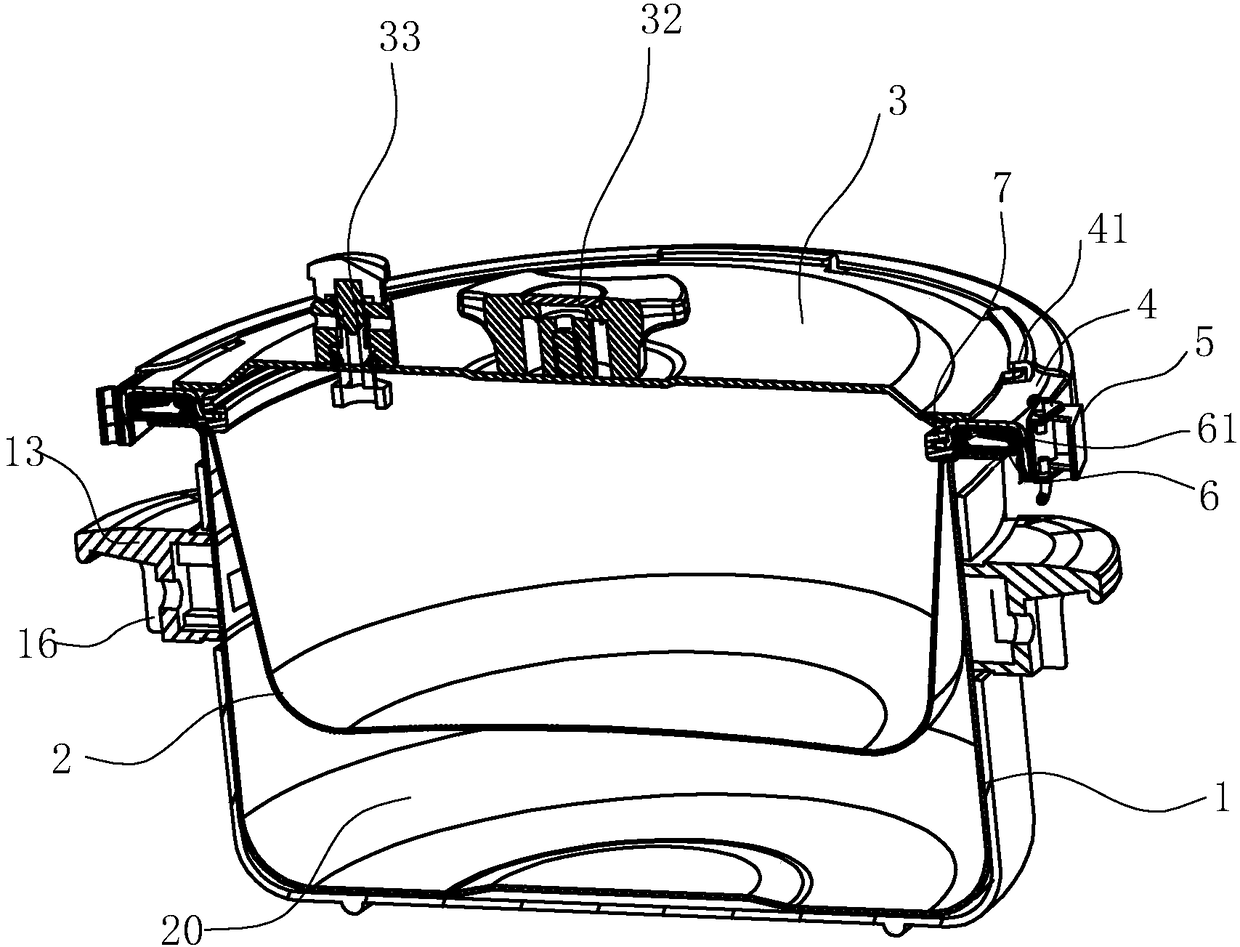

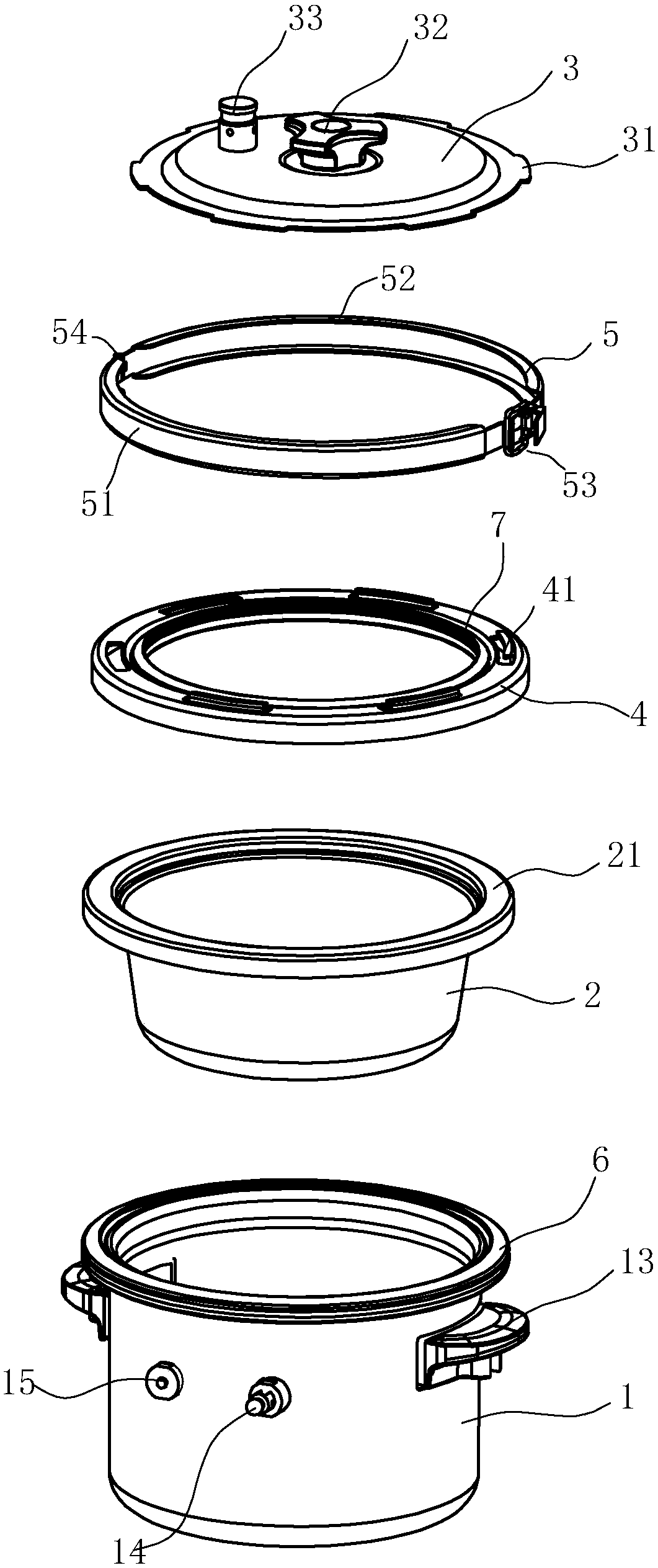

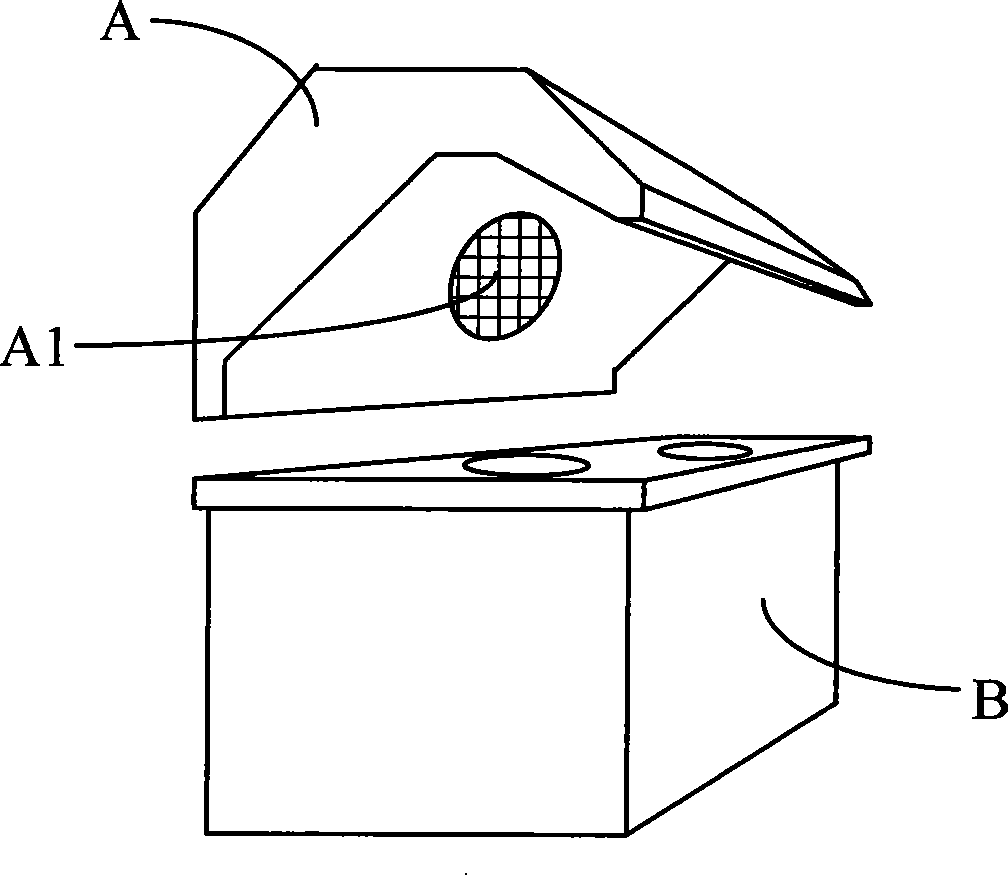

Portable pressure cooker

PendingCN108354444ADisassembly safetyEasy to assemble and disassemblePressure-cookersWarming devicesExhaust valveEngineering

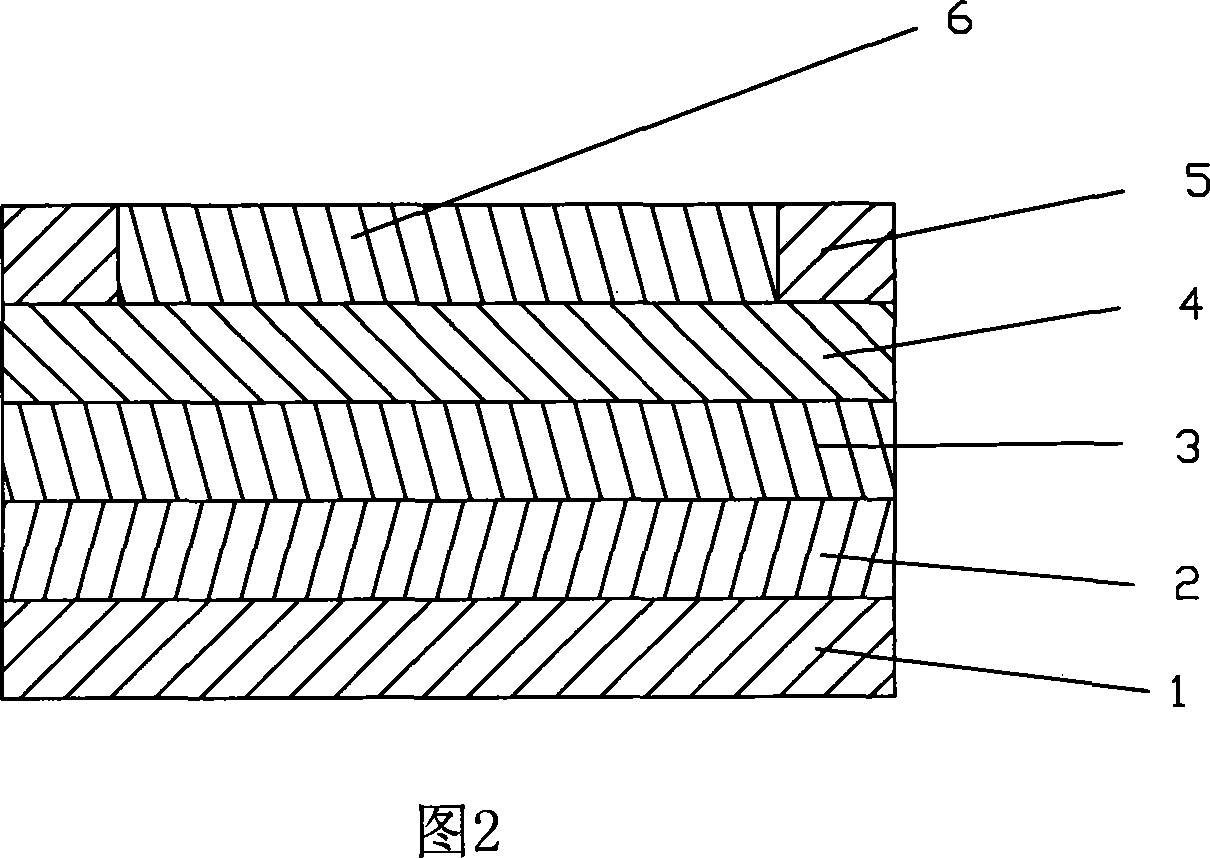

The invention provides a portable pressure cooker. The pressure cooker comprises a cooker body and a cover. The pressure cooker is characterized in that the cooker body comprises an outer cooker bodyand an inner cooker body, the inner cooker body is sleeved with the outer cooker body and connected with the outer cooker body through a cover ring and a clamp ring, a cavity used for placing self-heating materials is formed in the part between the inner cooker body and the outer cooker body, and a pressure limiting valve and / or a safety valve communicated with the cavity is arranged on the side face of the cooker body. By arranging the inner and outer cooker bodies and placing the self-heating materials in the cavity formed in the part between the inner and outer cooker bodies, automatic heating can be conducted by adding in water to cook foods in the inner cooker body, so that the use of the cooker in an environment without heating sources in the field is convenient; by arranging the safety valve on the side of the outer cooker body and arranging an exhaust valve on the cover, the pressure cooker is safe and reliable to use; by fixing the inner cooker body and the outer cooker body through the clamp ring and the cover ring, the disassembly and assembly of the pressure cooker are convenient, and the sealing performance is good; the outer cooker body is divided into two layers, theouter layer is a heat preserving layer, heat does not disperse easily, the heat preserving performance is good, and cooking is faster. The pressure cooker has the advantages of being simple and reasonable in structure, convenient to dismantle and assemble and safe and reliable to use.

Owner:王国海

Iron oxide black granular pigment and preparation method thereof

InactiveCN101691456APollution suppressionSettling fastPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDispersityIron oxide black

The invention belongs to the field of chemical pigments, and in particular relates to an iron oxide black granular pigment and a manufacturing method thereof. The iron oxide black granular pigment comprises a main component iron oxide black (Fe3O4) which is coated with an additive coating layer, and the main component iron oxide black is combined with the additive coating layer to form the granular pigment; and the pigment is prepared by the following steps: firstly preparing aqueous solution of an additive, and performing heating until 30 to 100 DEG C; and sending the iron oxide black into a granulator, evenly spraying the prepared aqueous solution of the additive onto powder, gradually forming small granules, and screening and drying the prepared granules with a vibrating screen to prepare a finished product. The granular pigment prepared by the method is not easy to diffuse so as to effectively prevent dust pollution, has high luster retention, good flowability and dispersity, and low cost, and is suitable to be widely applied in industry.

Owner:HANGZHOU XIAOXIANG PIGMENT CHEM

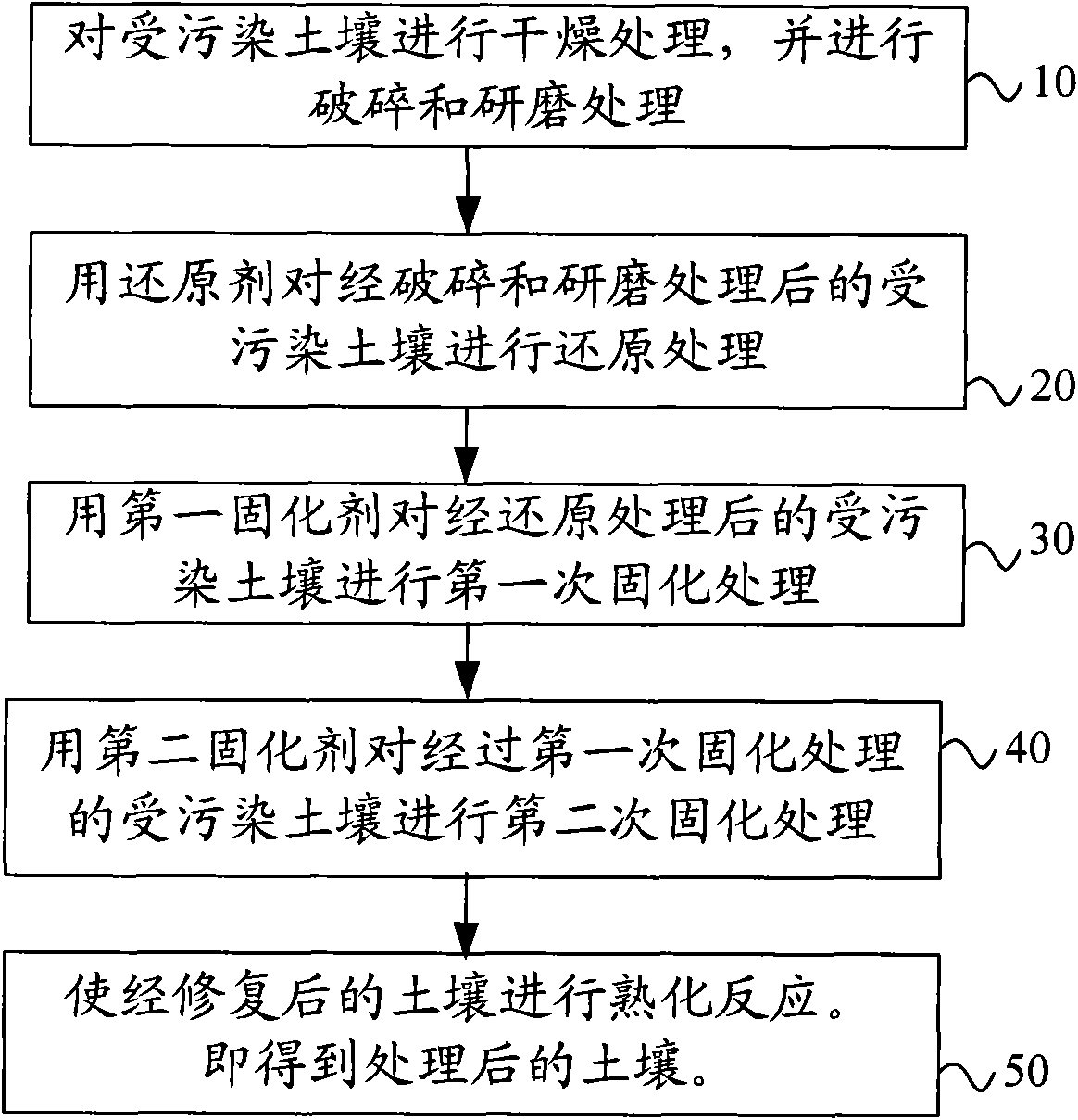

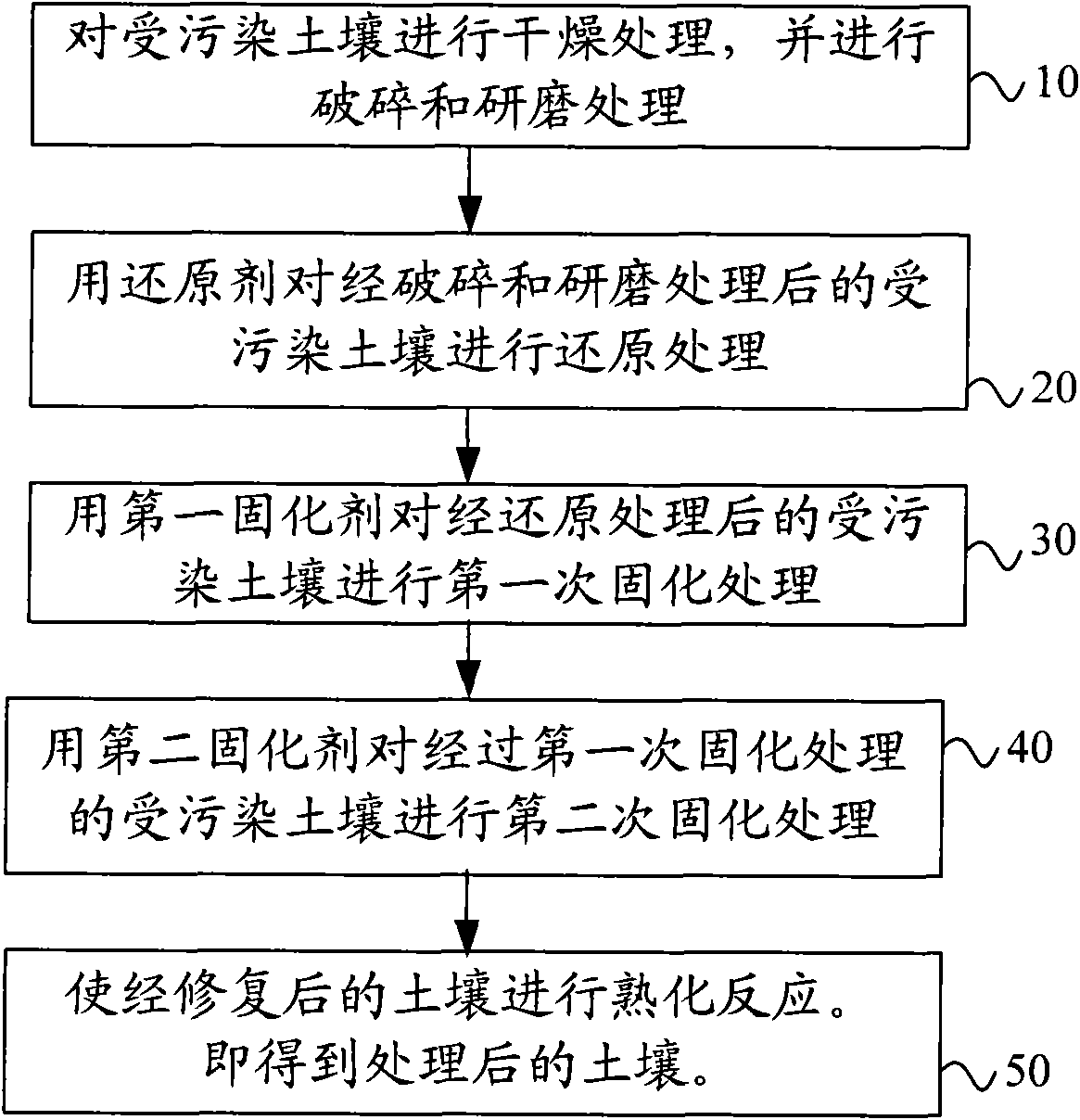

Repairing method of soil polluted by chromium residue

InactiveCN101862749AReduce solubilityNot easy to spreadContaminated soil reclamationReduction treatmentHazardous substance

The invention relates to a method for repairing and processing the soil polluted by heavy metals such as chromium and the like and semimetal elements such as arsenic and the like, and eliminating the pollution influence. The method mainly comprises the following steps: carrying out the dry treatment on the polluted soil, and carrying out the crushing and grinding treatment; carrying out the reduction treatment by a reducing agent on the polluted soil which is crushed and ground; carrying out a first curing process by a first curing agent on the polluted soil which undergoes the reduction treatment; carrying out a second curing process by a second curing agent on the polluted soil which undergoes the first curing process, thus obtaining the repaired soil. By the processing programs, harmful substances such as the heavy metals and the like in the polluted oil are solidified into the stable state; and the toxicity of the harmful substances is obviously reduced and is not easily diffused.

Owner:刘杰

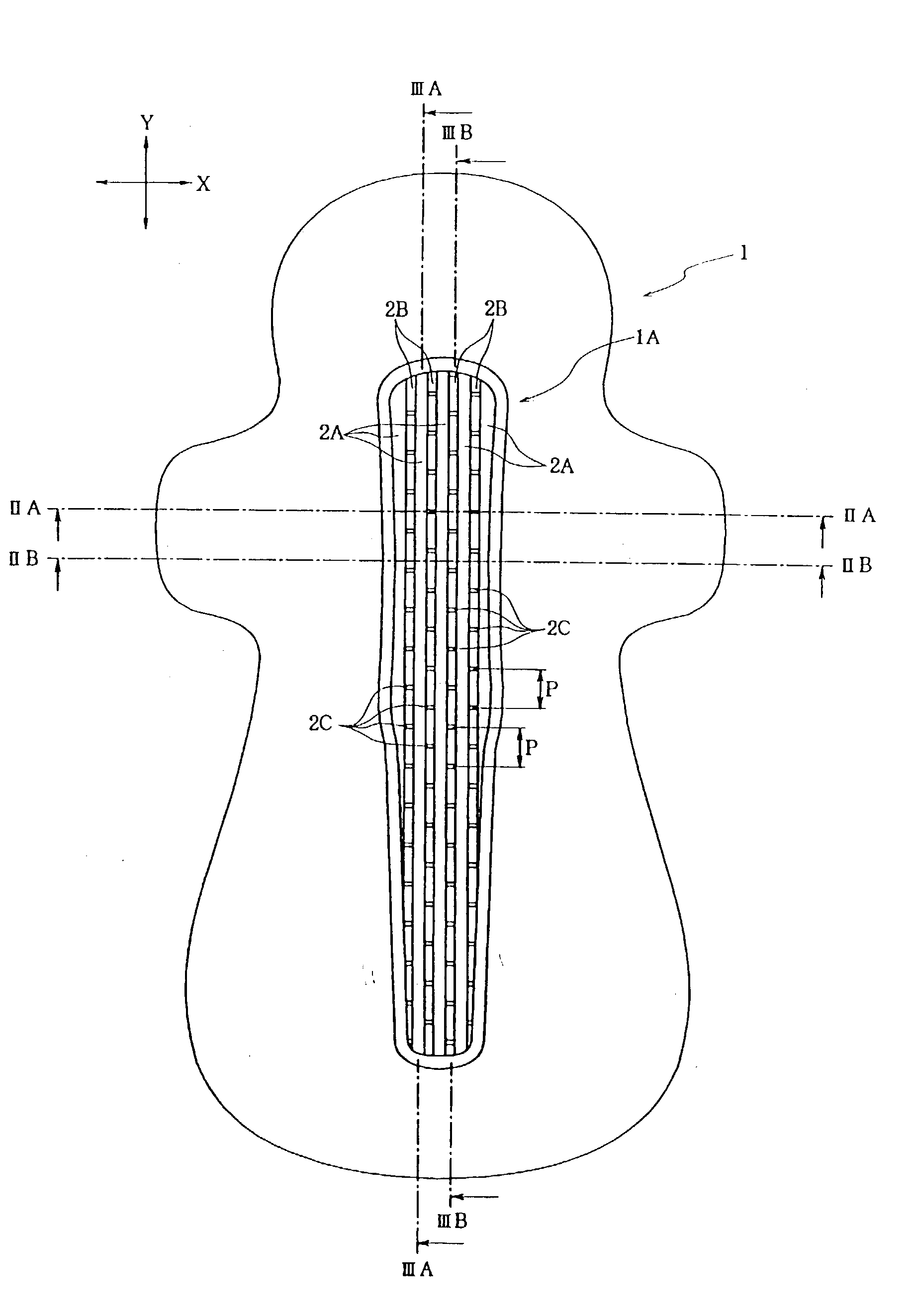

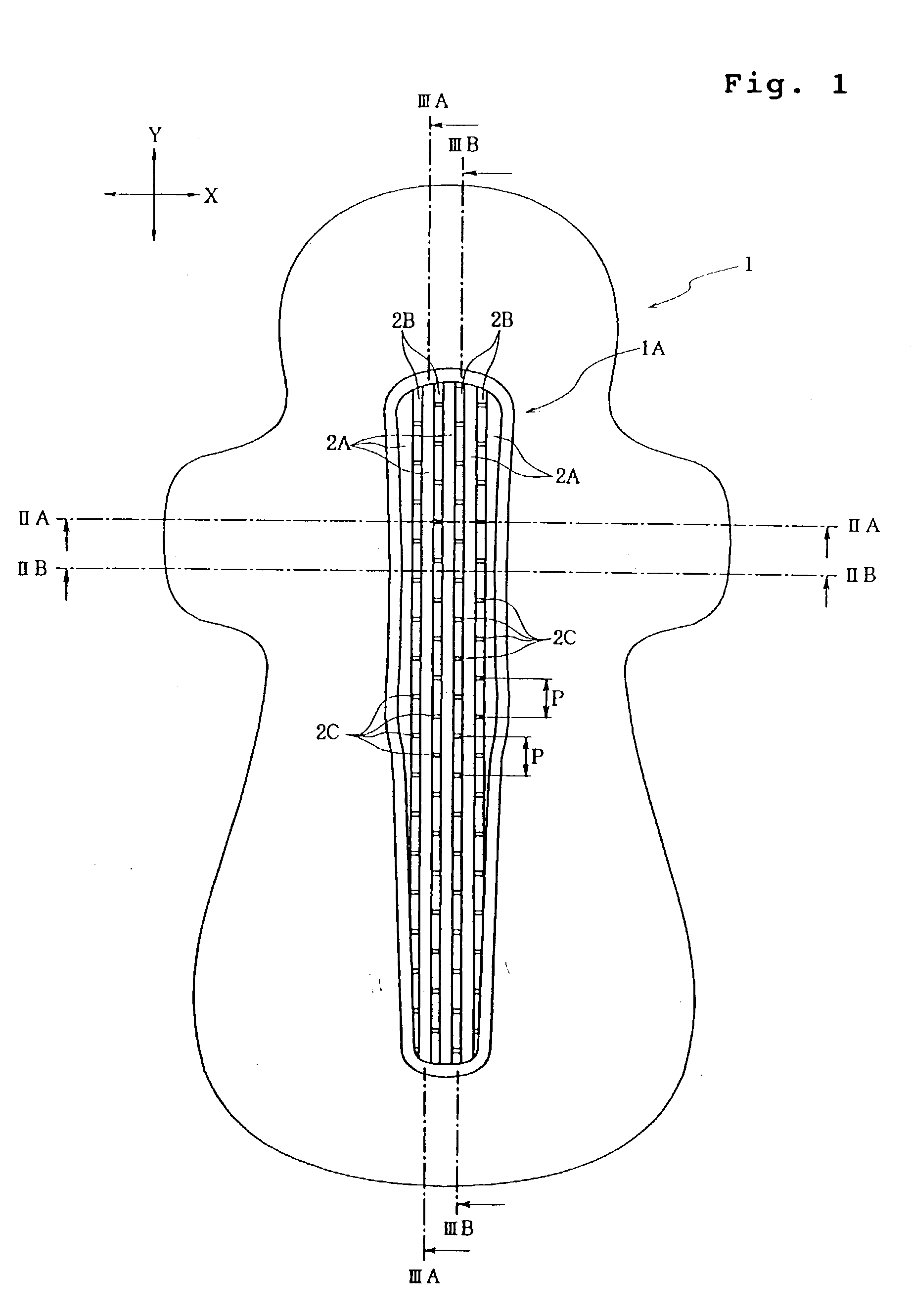

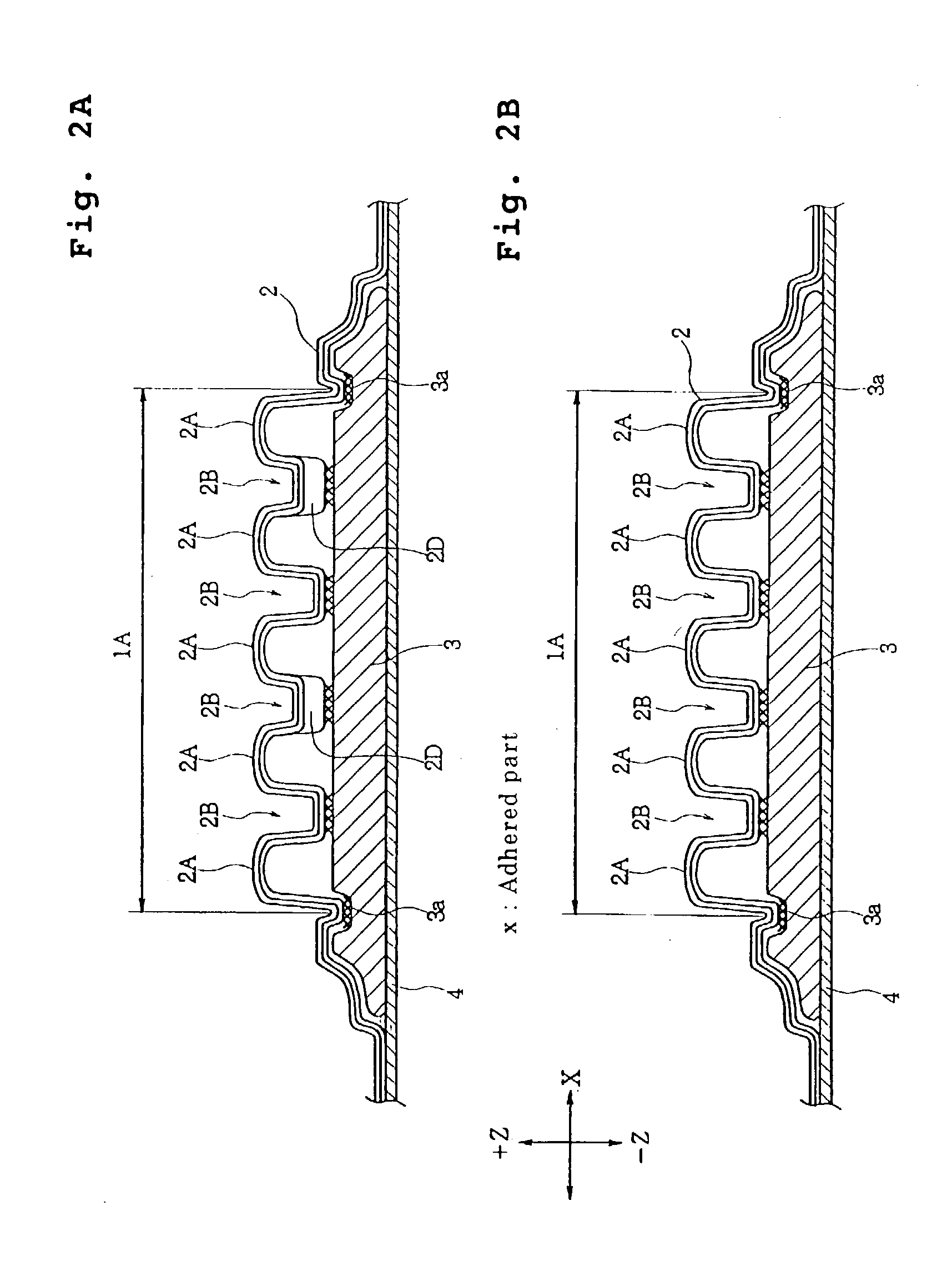

Absorbent article and process for manufacturing the same

InactiveUS20030198784A1Improve the level ofPrevent leakageLayered productsBaby linensEngineeringMechanical engineering

There is disclosed an absorbent article including an absorbent layer and a liquid-permeable surface sheet placed on a liquid-receiving side of the absorbent layer for introducing excreted liquid from the human body to the absorbent layer. The surface sheet is of a corrugated configuration to have valleys and peaks extending in a longitudinal direction of the article and alternately arranged in a transverse direction perpendicular to the longitudinal direction. Each valley has a connecting part raised to connect between two adjacent peaks.

Owner:UNI CHARM CORP

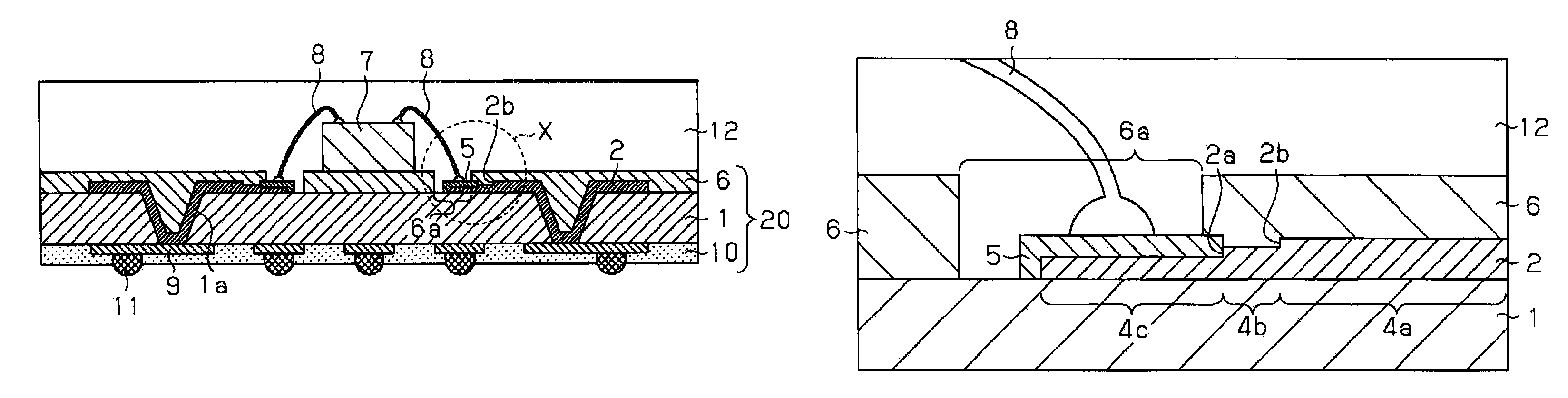

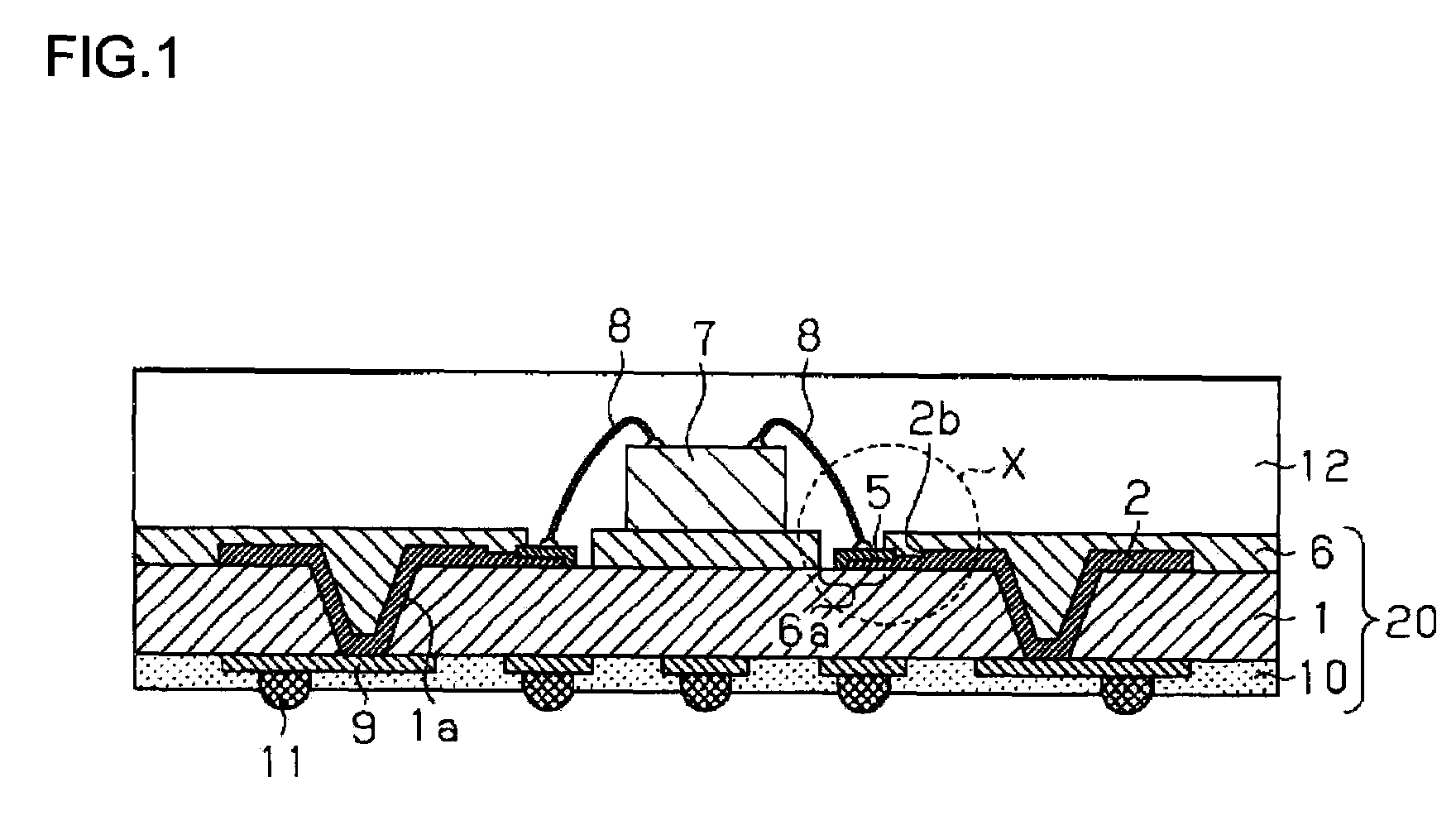

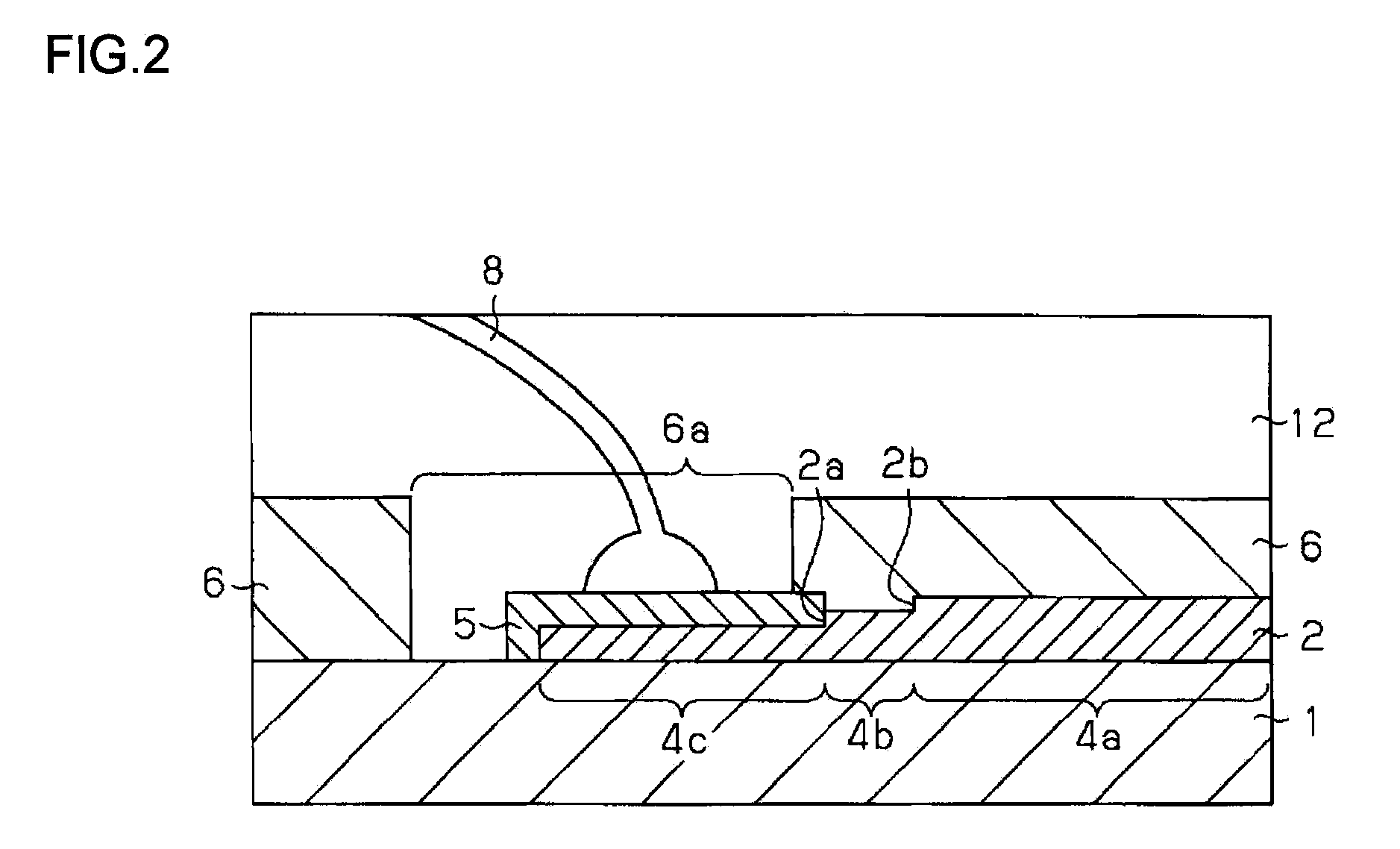

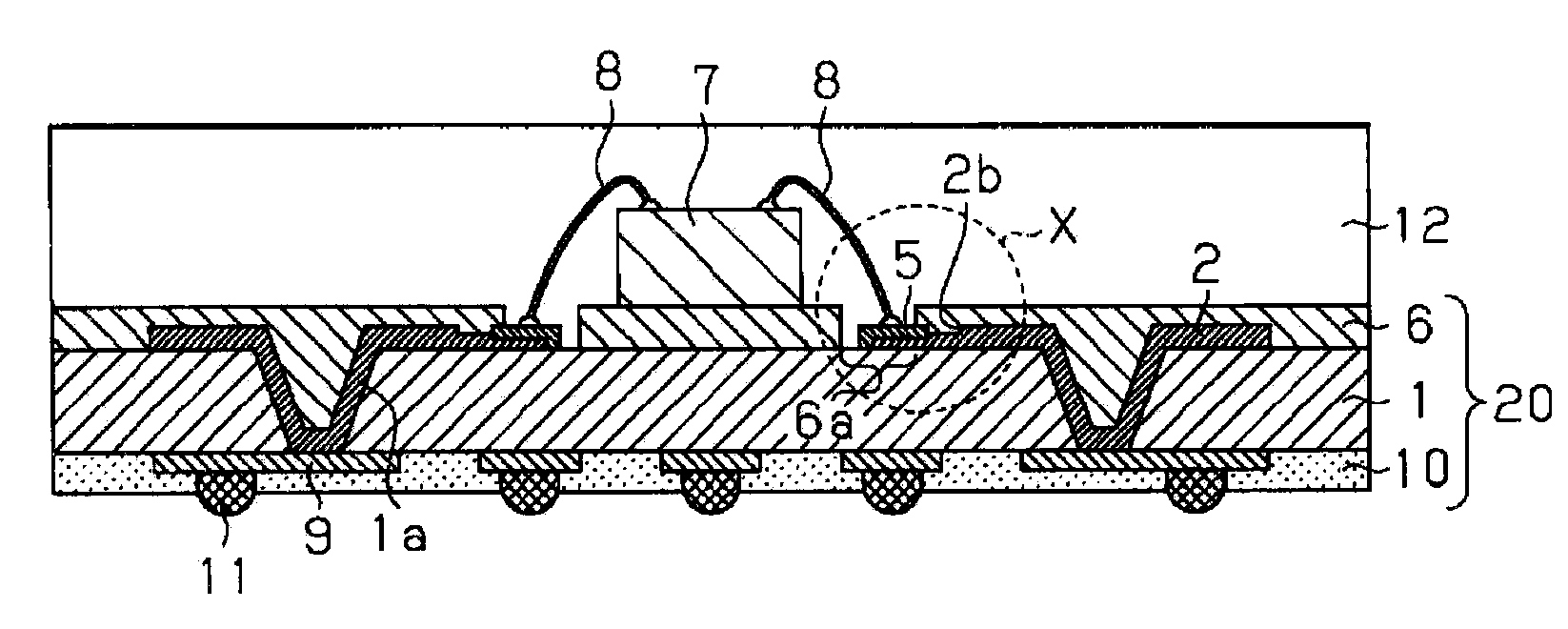

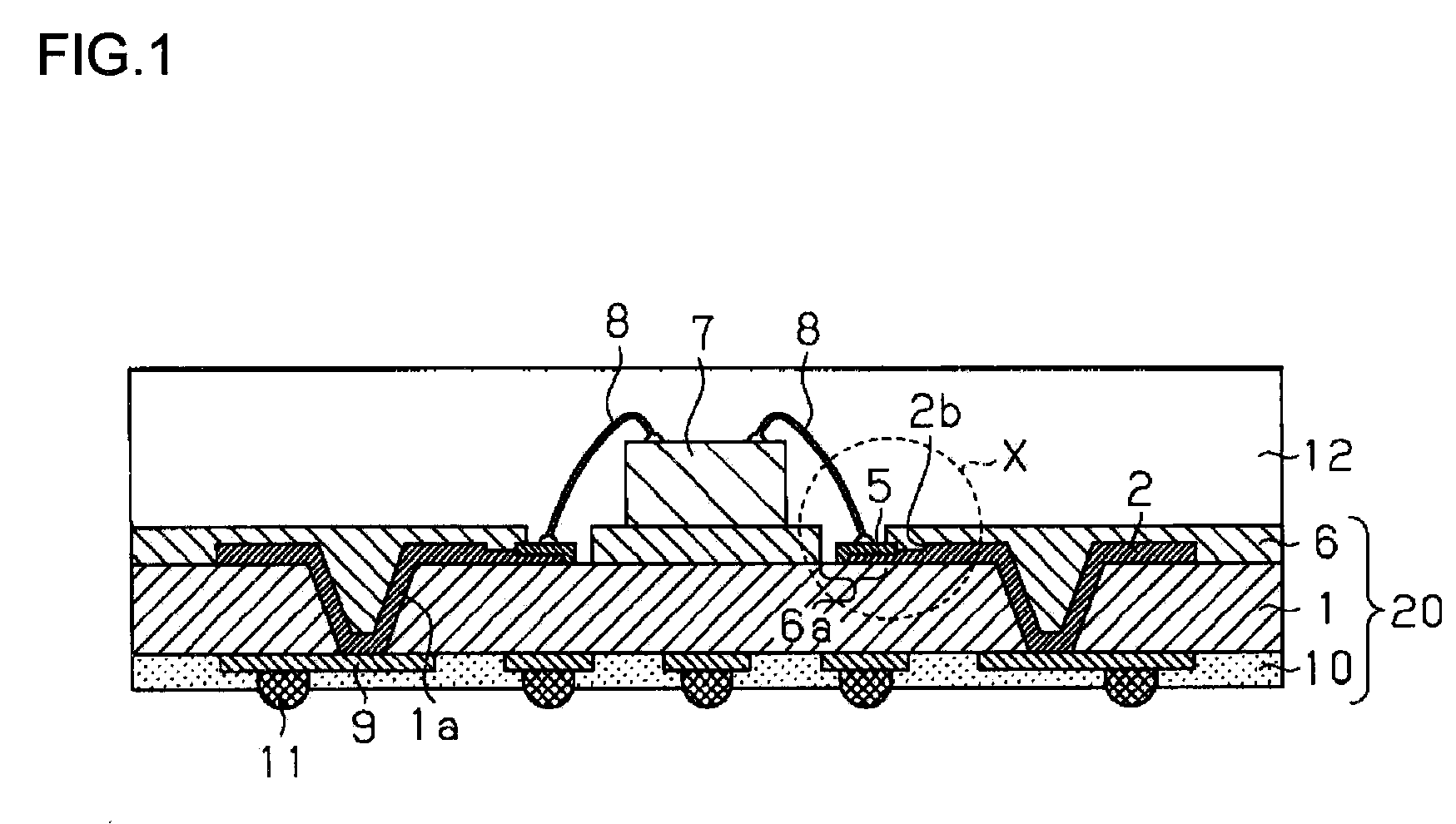

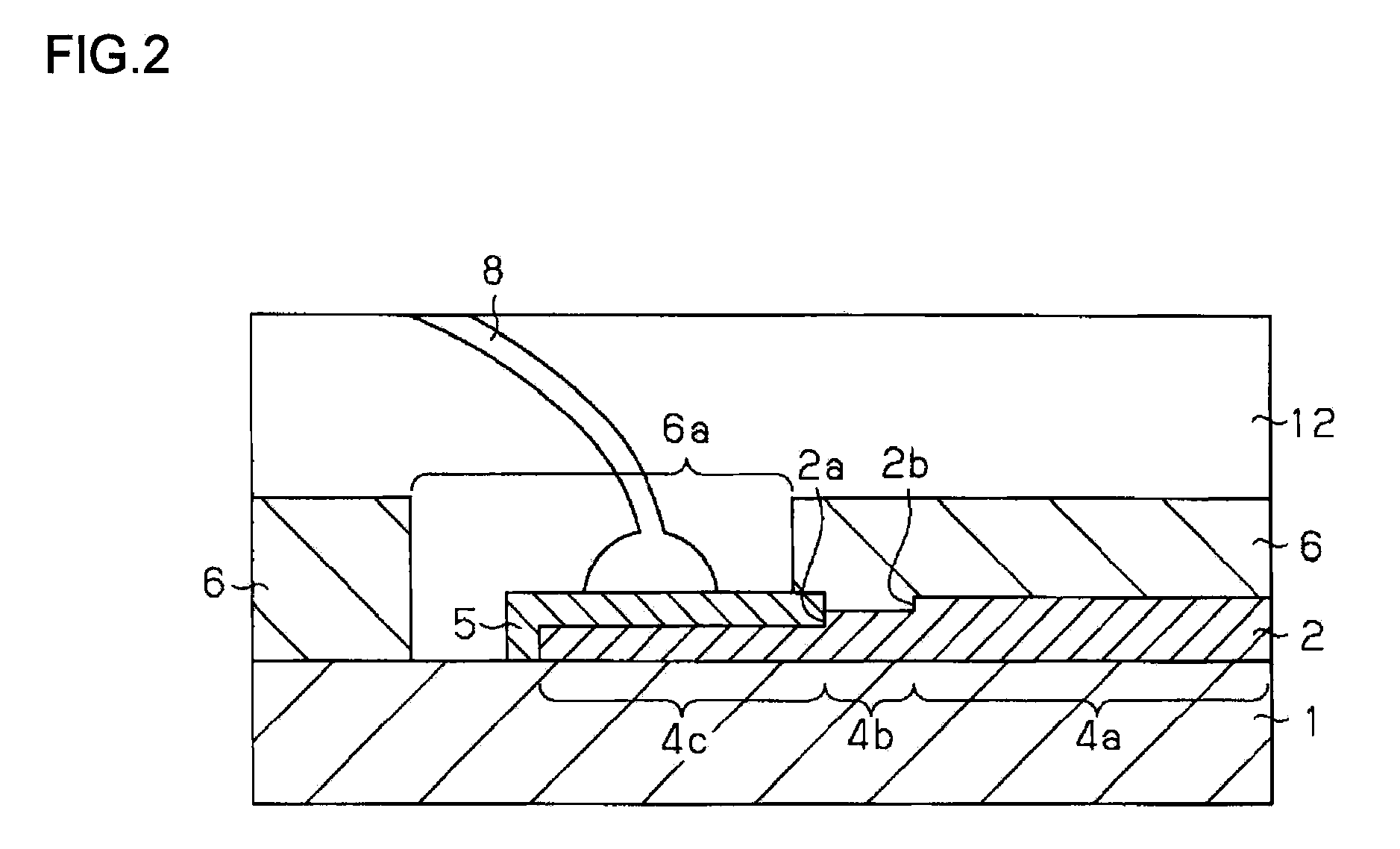

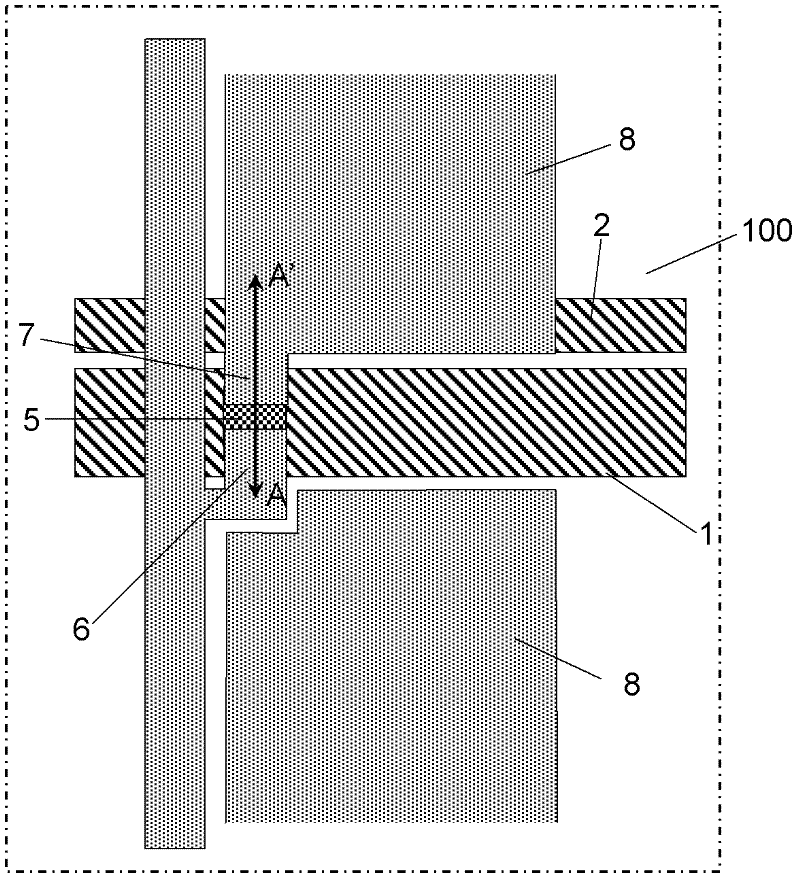

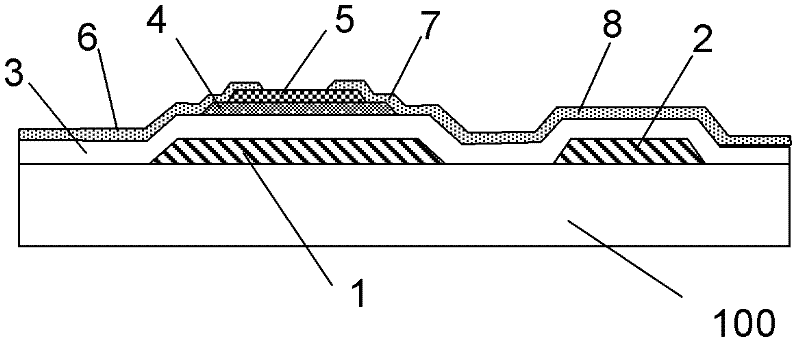

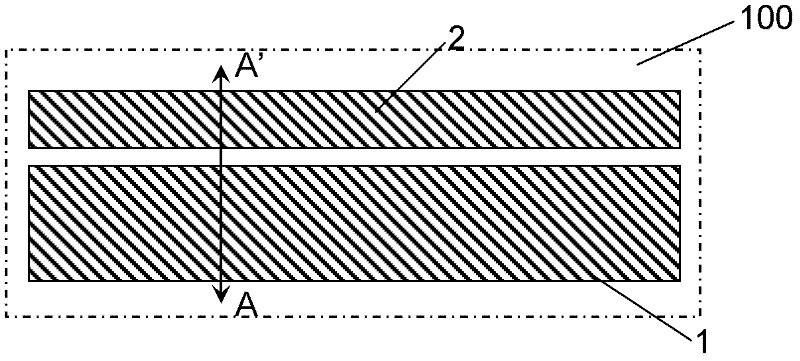

Packaging board and manufacturing method therefor, semiconductor module and mobile apparatus

ActiveUS7595553B2Improve package reliabilityLong distance of spreadingFinal product manufactureSemiconductor/solid-state device detailsResistComputer module

An advantage of the present invention is to suppress moisture infiltrating from a pad electrode portion from spreading over the surface of a wiring pattern and improve the reliability of a packaging board. The wiring pattern of the packaging board is formed on an insulating substrate and includes a wiring region, an electrode region (pad electrode) connected with a semiconductor device, and a boundary region provided between the wiring region and the electrode region. A gold plating layer is provided on the surface of the electrode region of the wiring pattern. The top surface of the boundary region of the wiring pattern is so formed as to be dented from the top surface of the wiring region of the wiring pattern, and there is provided a stepped portion in the boundary region. A solder resist is formed in such a manner as to cover part of the gold plating layer and the wiring pattern corresponding to the boundary region and the wiring region, and the solder resist has a predetermined opening through which to connect to the semiconductor device. A conductive member is connected to the gold plating layer in the electrode region, and a molded resin layer seals the entire semiconductor module.

Owner:III HLDG 12 LLC

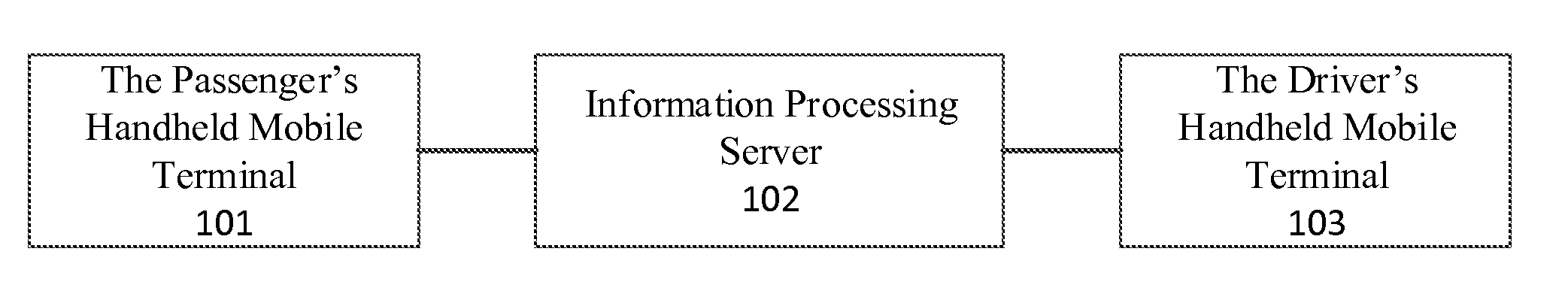

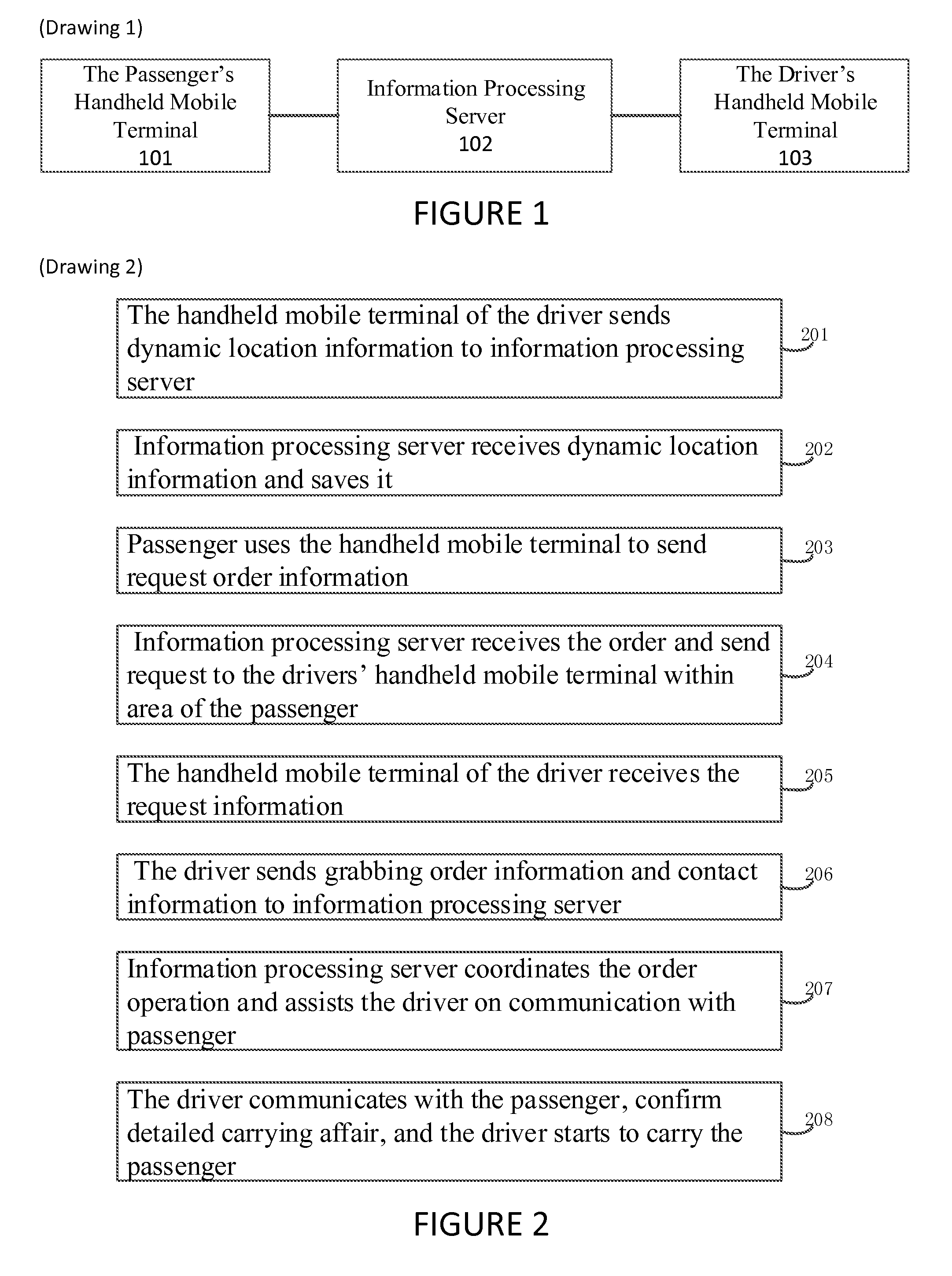

Taxi Calling System and Method Based on Handheld Mobile Terminals

InactiveUS20150012310A1Avoid unnecessary wasteLow costReservationsLocation information based serviceInformation processingHand held

The taxi calling system and methods based on the handheld mobile terminal aims at resolving passengers' difficulty of calling a taxi, waste of traffic resource and the platform promotion of taxi calling system. This system contains the hand-held mobile terminal of the passengers, information processing server and the handheld mobile server of the driver. The information procession server can receive and save the dynamic geographic location information of the driver's hand-held mobile terminal. The passengers use handheld mobile terminal to send order information that includes location information to the information processing server which will send request information to the driver's handheld mobile terminal within the relevant area of the passenger. After the drivers receive the request information, they can grab the request, contact the passenger through voice or symbol communication under the coordination of information processing server, confirm the request affairs and finally provide carrying for the passenger. This system and method is convenient for passengers to lower empty rate of taxis and is easy to promote.

Owner:SHEN ZHE

Packaging board and manufacturing method therefor, semiconductor module and mobile apparatus

ActiveUS20080136033A1Improve package reliabilityLong distance of spreadingFinal product manufactureSemiconductor/solid-state device detailsResistEngineering

An advantage of the present invention is to suppress moisture infiltrating from a pad electrode portion from spreading over the surface of a wiring pattern and improve the reliability of a packaging board. The wiring pattern of the packaging board is formed on an insulating substrate and includes a wiring region, an electrode region (pad electrode) connected with a semiconductor device, and a boundary region provided between the wiring region and the electrode region. A gold plating layer is provided on the surface of the electrode region of the wiring pattern. The top surface of the boundary region of the wiring pattern is so formed as to be dented from the top surface of the wiring region of the wiring pattern, and there is provided a stepped portion in the boundary region. A solder resist is formed in such a manner as to cover part of the gold plating layer and the wiring pattern corresponding to the boundary region and the wiring region, and the solder resist has a predetermined opening through which to connect to the semiconductor device. A conductive member is connected to the gold plating layer in the electrode region, and a molded resin layer seals the entire semiconductor module.

Owner:III HLDG 12 LLC

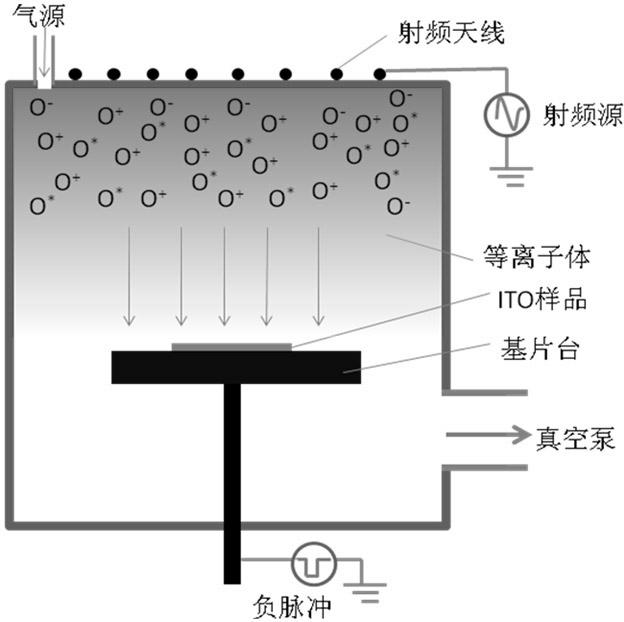

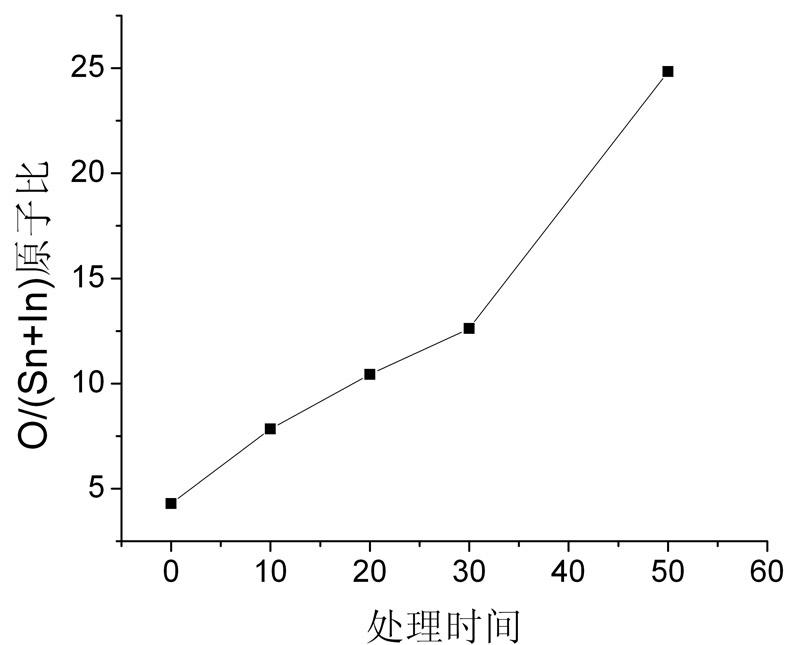

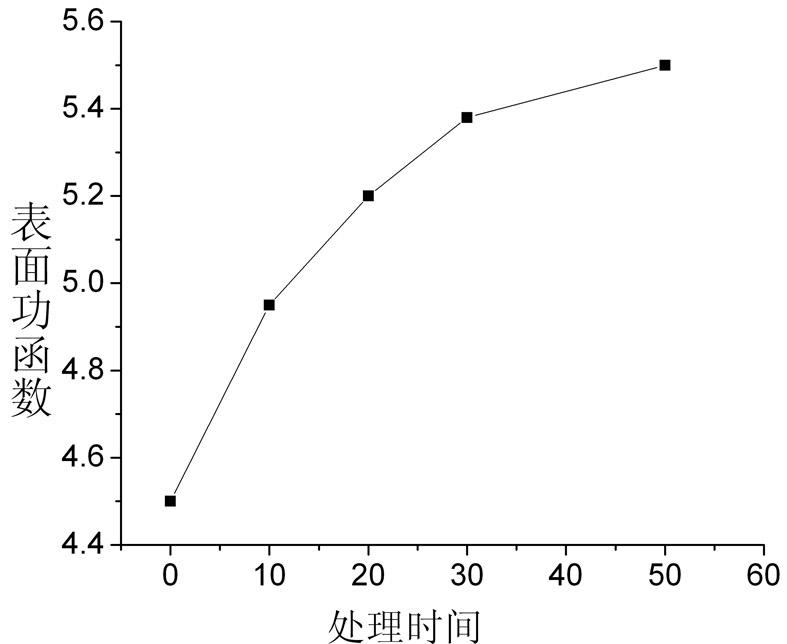

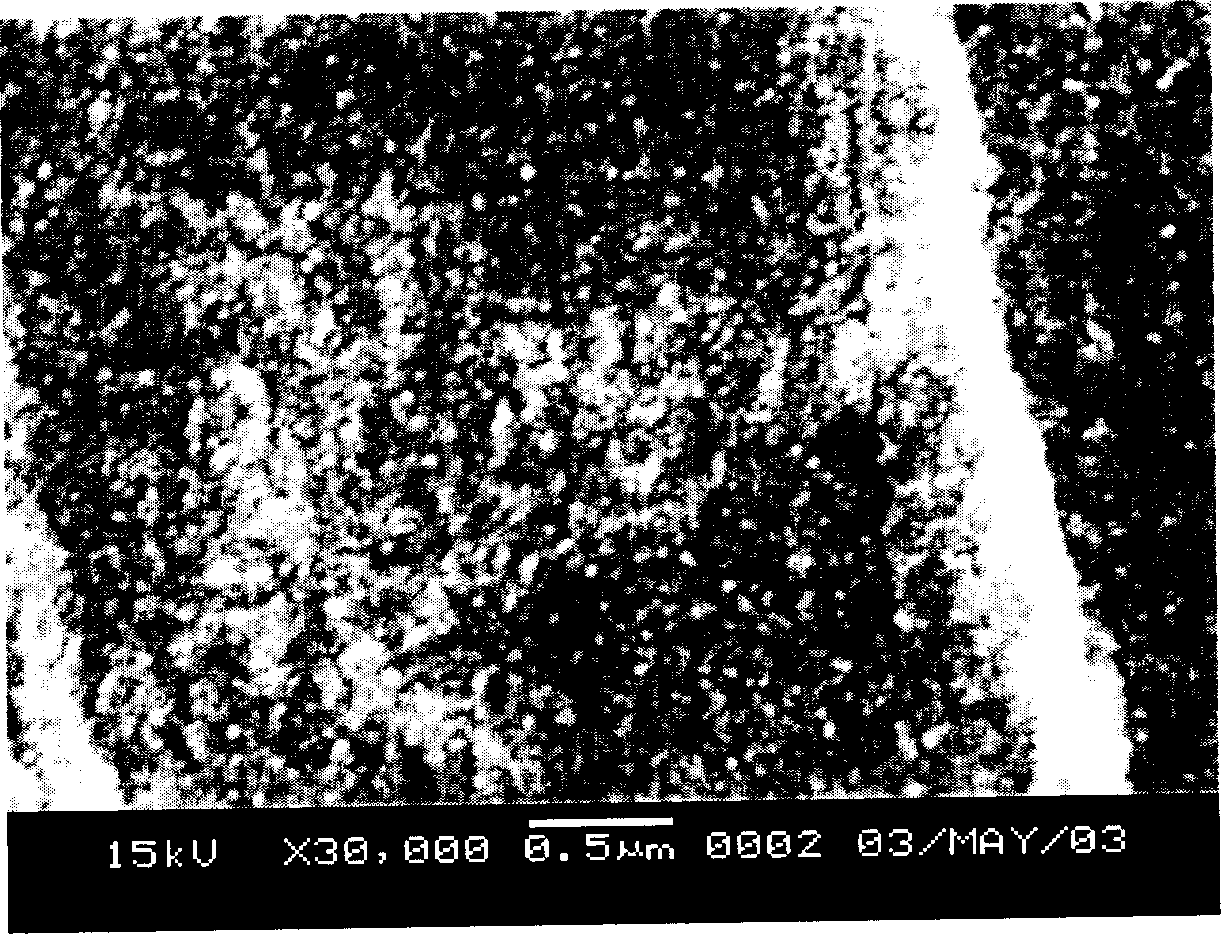

Surface modifying method for improving surface power function of indium tin oxide transparent conductive film

InactiveCN102610765AHigh surface work functionDoes not degrade surface finishSolid-state devicesSemiconductor/solid-state device manufacturingHigh energyOxygen ions

The invention belongs to the technical filed of conductive thin films, in particular relates to a surface modifying method for improving the surface power function of an indium tin oxide transparent conductive film. The surface modifying method comprises the following steps: a large volume of plasma, containing oxygen, chlorine, or fluorine strong electric negative elements, is generated in a vacuum chamber in a radio frequency or microwave discharge excitation way; sheet glass coated with an indium tin oxide (ITO) thin film is placed on a metal substrate bench which is dipped in the plasma; high voltage negative pulses are applied on the substrate bench, thus forming a negative voltage sheath layer between the ITO thin film and the plasma; oxygen ions are accelerated by an electric field to move toward the surface of the ITO thin film in the sheath layer; and high-energy oxygen ions are injected to the surface of the ITO thin film and reserved in a surface layer of the ITO thin film, so that O / (Sn+In) atom proportion of the surface of the ITO thin film is increased, and then the surface power function of the ITO thin film is improved. The ITO thin film modified by the surface modifying method provided by the invention is applied as an anode of an organic light emitting diode (OLED), in this way, the drive voltage of a component is reduced greatly, the current stability of the component is improved, the light efficiency and brightness are enhanced, and the service life of the component is prolonged.

Owner:FUDAN UNIV

Method for preparing nano particle modified chemical fibre

The method of preparing nano particle modified chemical fiber features that nano particles after surface treatment in certain proportion is added into and dispersed in solidifying bath, preheating bath or extracting bath for wet spinning or wet-dry spinning via high speed stirring to form bathing liquid with homogeneously dispersed nano particles. After eliminating solvent and drawing, nano particles are diffused into fiber pores, and the nano particle modified chemical fiber possesses raised drawing performance. The said method is simple, low in cost and suitable for industrial production.

Owner:DONGHUA UNIV

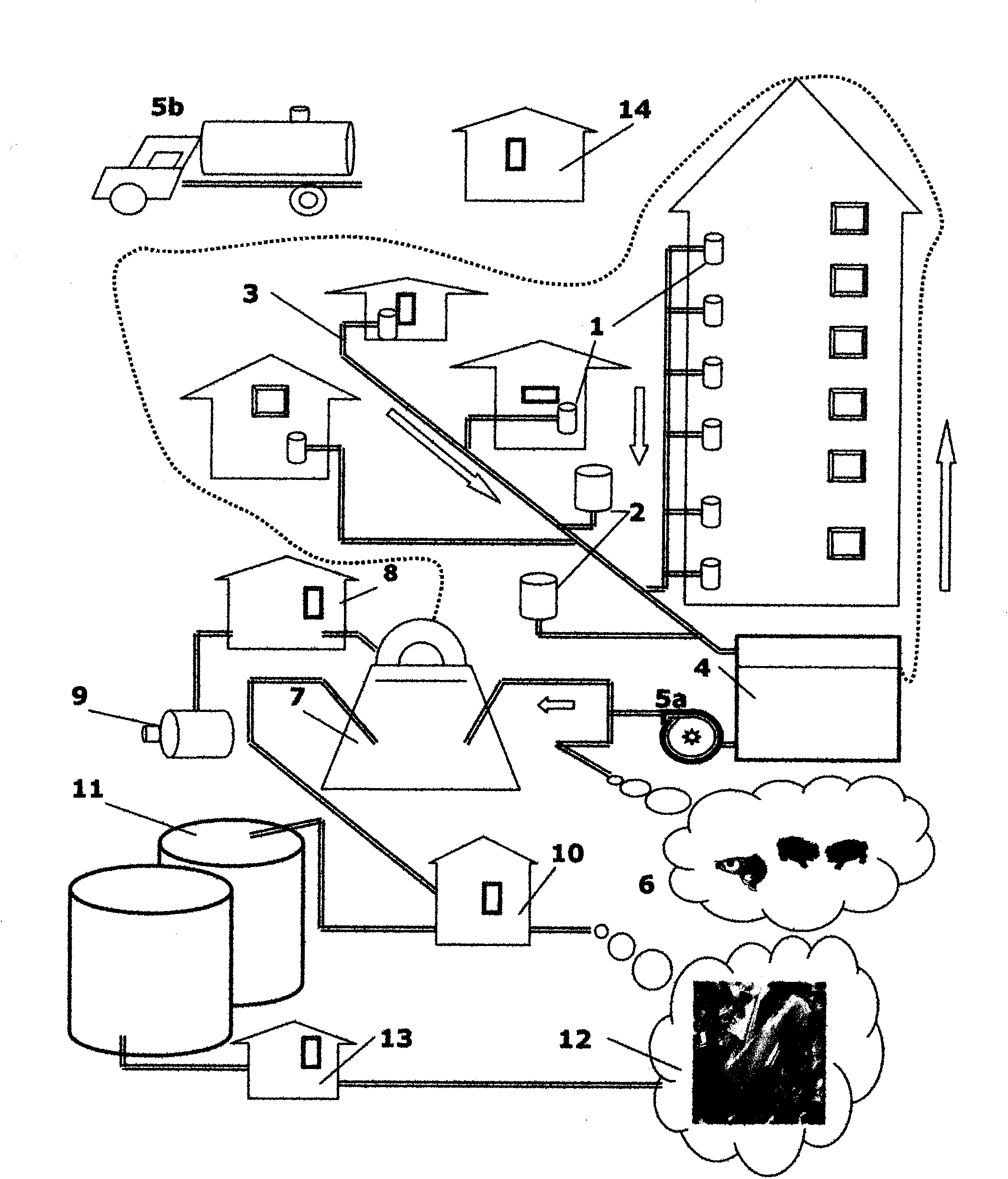

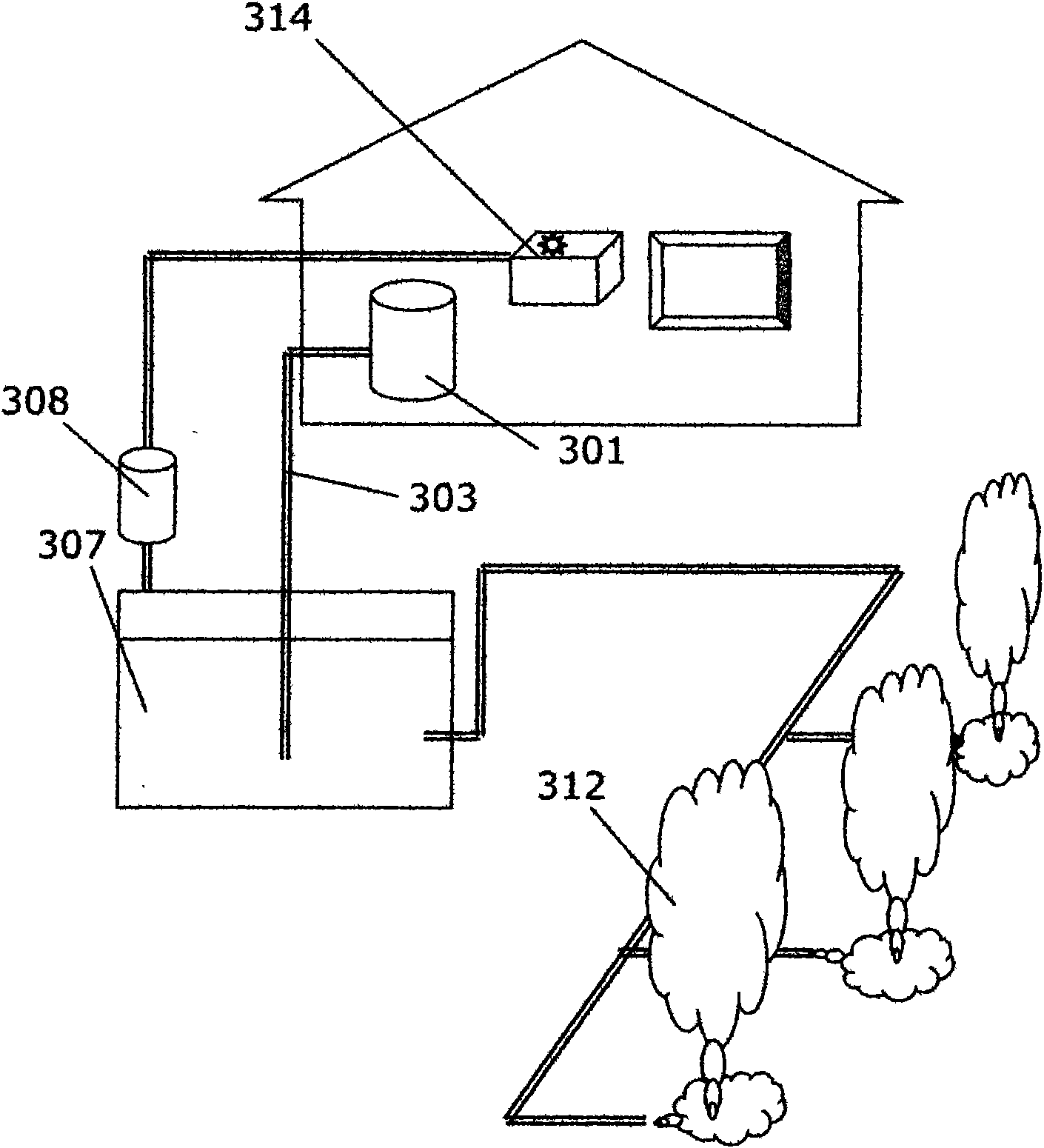

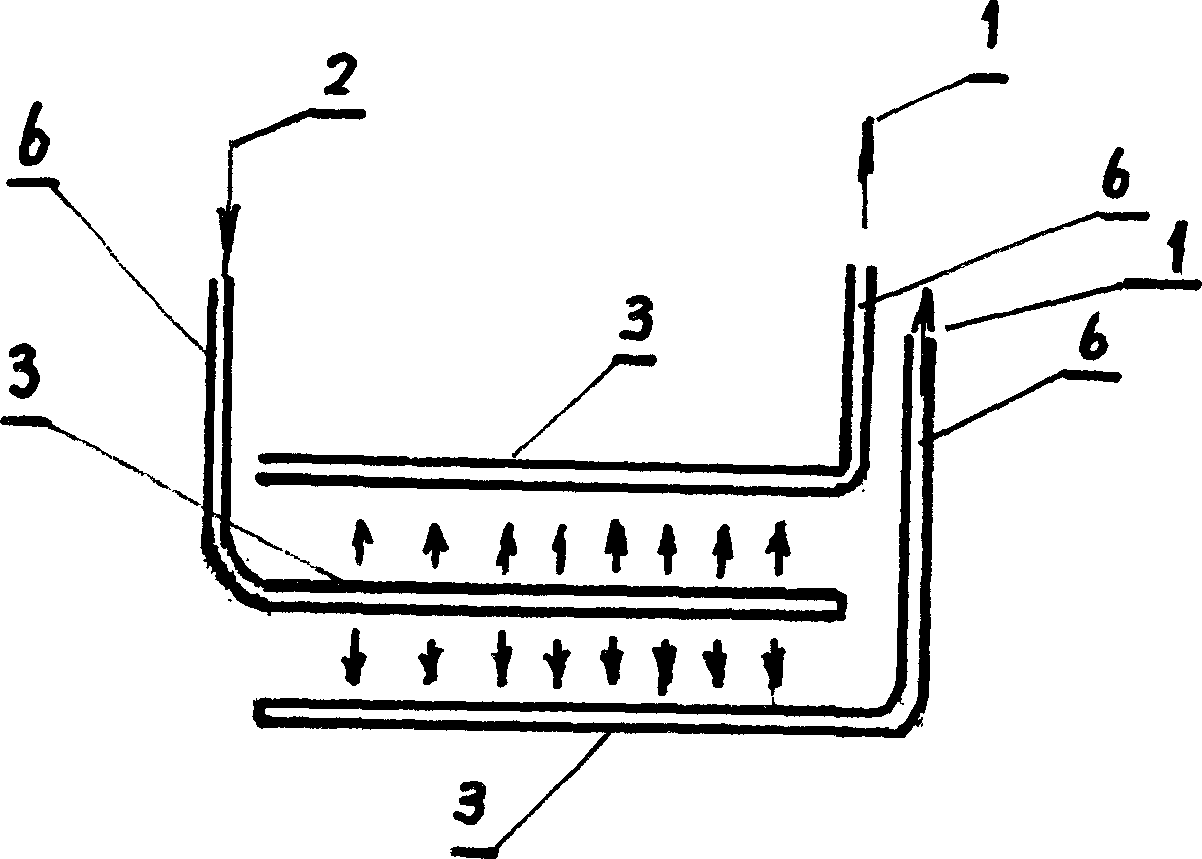

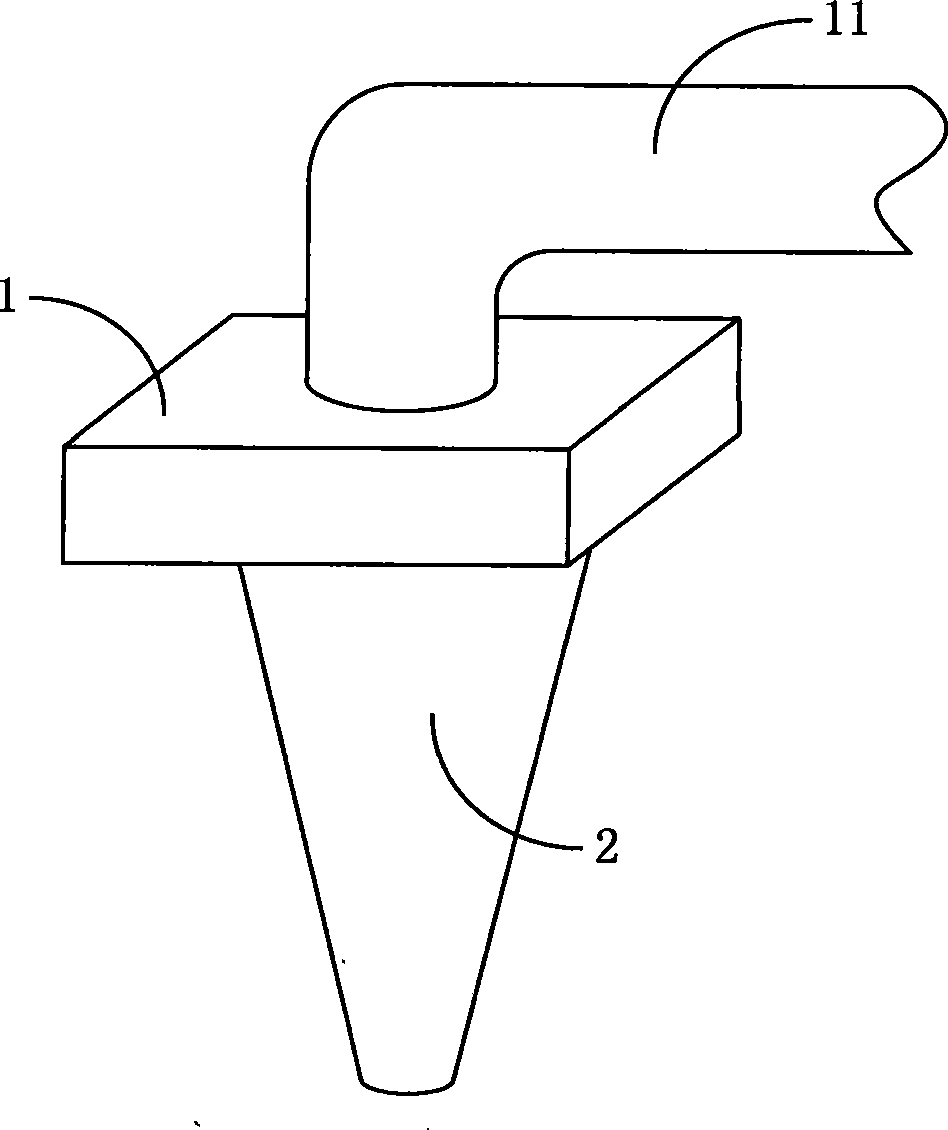

Method and apparatus for totally-closed garbage emission and transmission atomization and comprehensive utilization

ActiveCN101844144ARealize resource utilizationAchieve cleanupProductsBio-organic fraction processingLiquid stateSewage

The invention relates to a method and an apparatus for totally-closed garbage emission and transmission atomization and comprehensive utilization, in particular to the field of a method, an apparatus, a container and a facility for realizing the automation of totally-closed garbage emission, collection, concentration and transportation, no bag and comprehensive utilization. The method comprises the following steps: pulping the garbage thrown into a can with water in a certain proportion by utilizing an auto pulping liquid-state garbage can 1-2; collecting the pulped garbage into a concentrating pool 4 by utilizing a pipeline 3; transmitting the pulped garbage to a feeding farm 6 and a methane fermenting pool 7 by utilizing a water pump 5a and a carrier vehicle 5b; utilizing a purification workshop 4 and a methane recovering pipeline 9 to recover the methane; utilizing a disinfection workshop 10 and a biogas dreg dewatering device 11 to prepare the biogas dregs into organic fertilizer and fuel and discharge to be discharging into a crop irrigation and drainage land 12; purifying the sewage by utilizing a purification workshop 13 and discharging the purified sewage water; and systematically blending by utilizing a control center 14. Therefore, the invention realizes automation for totally-closed garbage emission, collection, concentration and transportation and comprehensive cyclic utilization of the garbage, and thoroughly eliminates garbage pollution caused by high polymer materials such as plastic and the like.

Owner:邱泽国

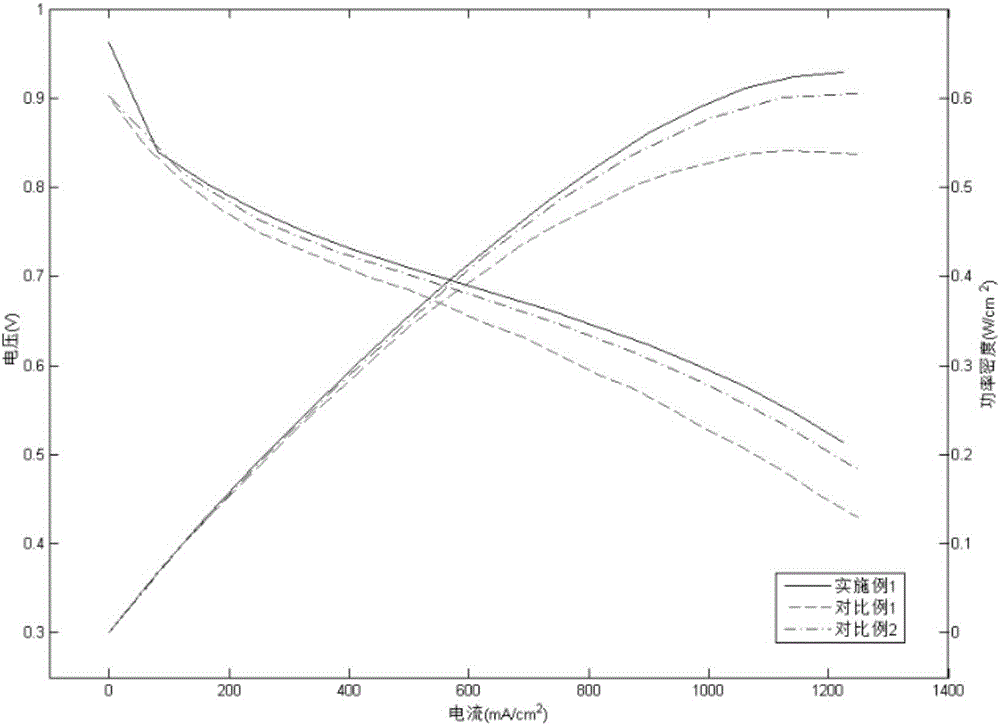

Preparation process of hydrogen fuel battery membrane electrode

ActiveCN106784944AIncrease profitReduce utilizationFinal product manufactureFuel cellsHydrogen fuel cellSlurry

The invention discloses a preparation process of a hydrogen fuel battery membrane electrode, and belongs to the field of battery membrane electrodes. The membrane electrode is prepared by the aid of an ultrasonic spraying process and a heat transfer printing process. The preparation process includes the steps: firstly, sequentially spraying a transfer printing medium with carbon powder slurry, electric catalyst slurry and binding agent slurry by the aid of the ultrasonic spraying process; secondly, loading a catalyst layer on a proton exchange membrane by the aid of the heat transfer printing process; finally, performing hot-pressing for self-made diffusion layers by the aid of the ultrasonic spraying process to obtain the membrane electrode. According to the preparation process, the diffusion layers are closely combined by the aid of actions among Nafion slurry, the proton exchange membrane and carbon powder slurry and the diffusion layers, electrochemical performance of the membrane electrode is greatly improved by the aid of the heat transfer printing process, the service life of the membrane electrode is prolonged, the problems such as wrinkle and swelling of the proton exchange membrane are solved, a lot of time for paving and treating the membrane is saved, and mass production of the membrane electrode is facilitated.

Owner:KUSN INNOVATION INST OF NANJING UNIV

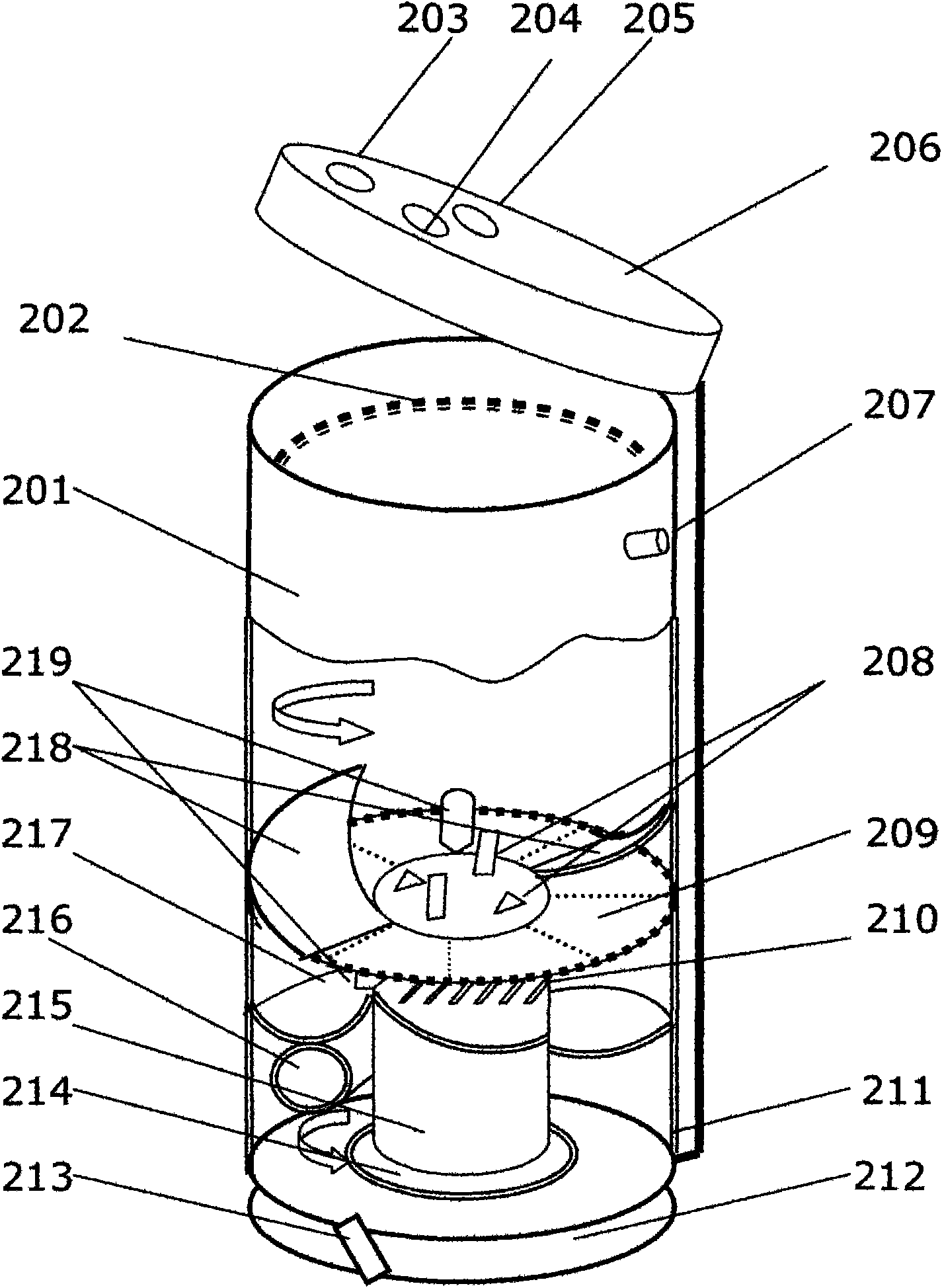

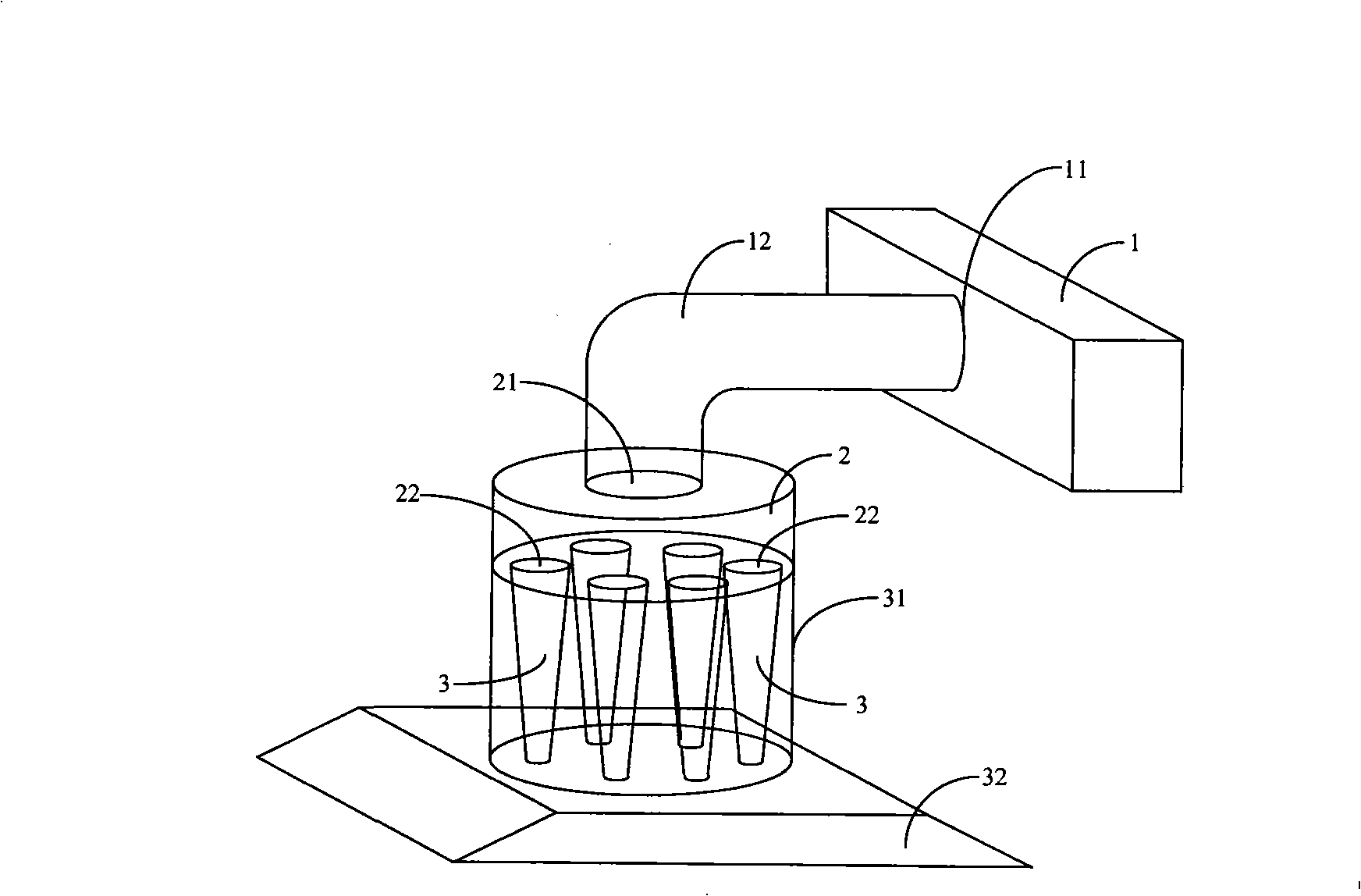

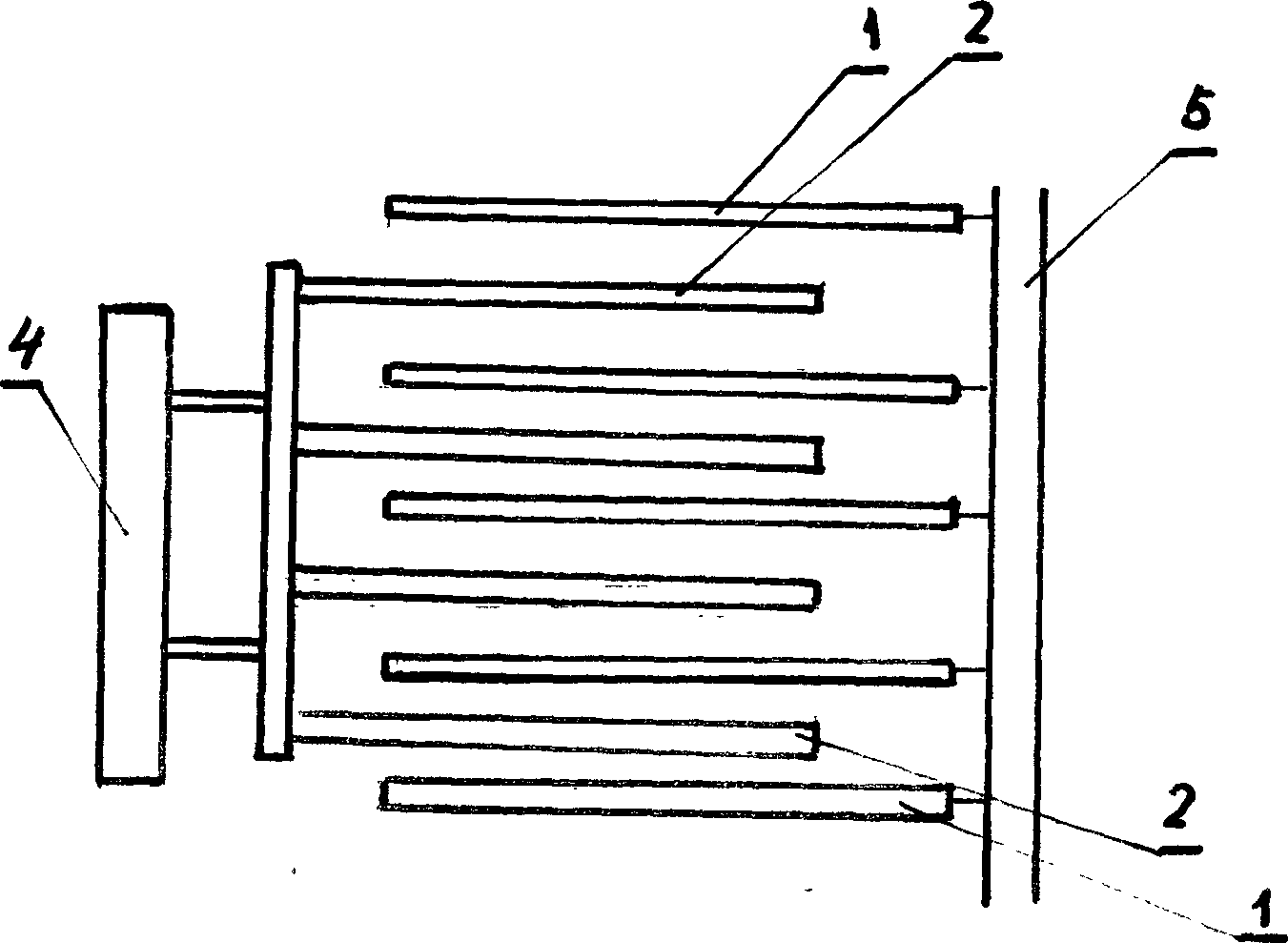

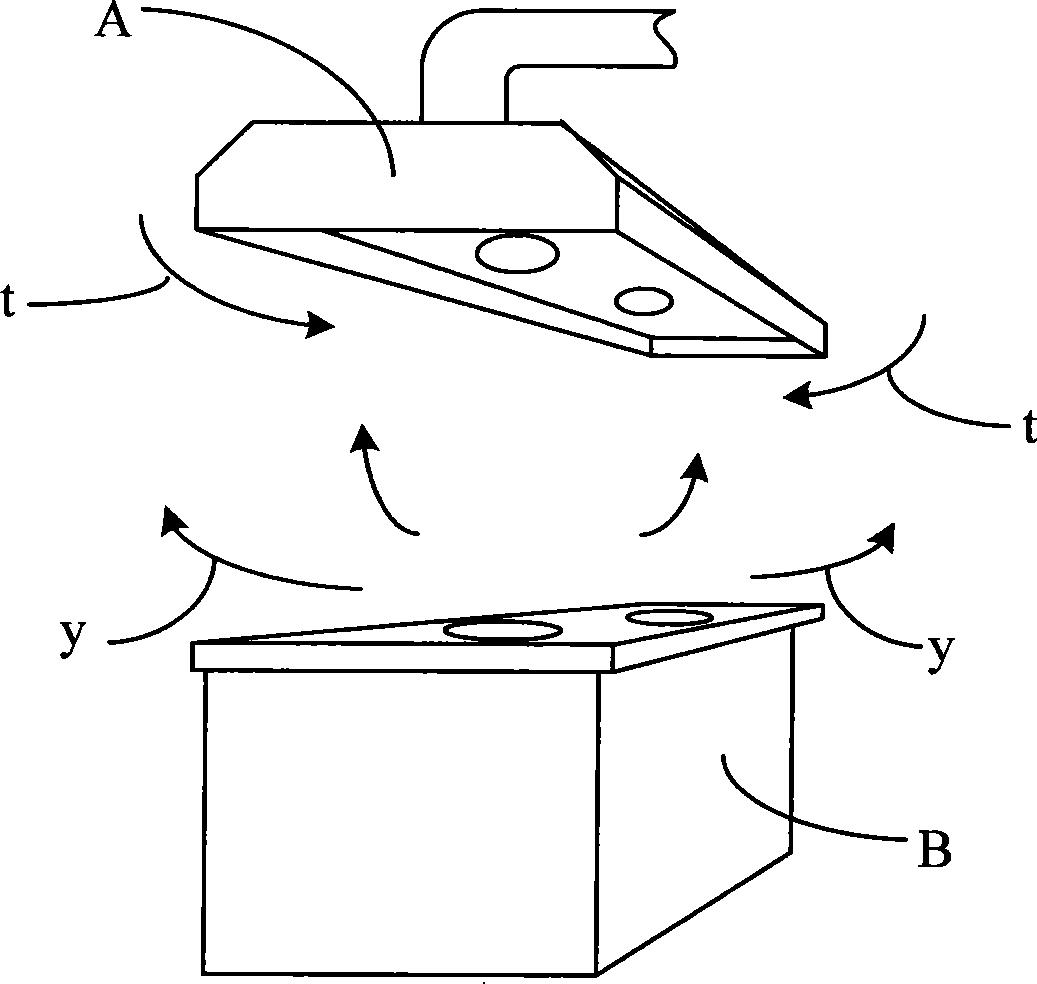

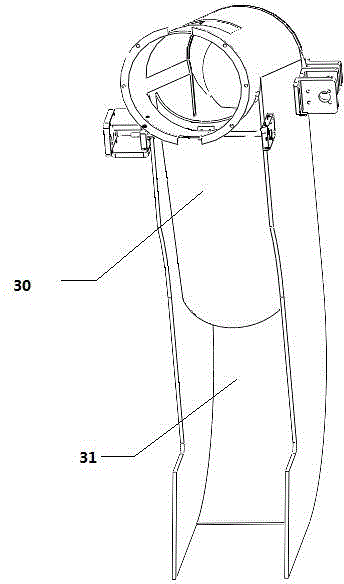

Oil smoke cleanse extraction device

InactiveCN101254382ANot easy to spreadQuick exclusionDomestic stoves or rangesLighting and heating apparatusCycloneProduct gas

The invention relates to a oil-smoke purification and discharging device, which comprises a fan used for discharging gas to outside, and the inlet of the fan is connected with the outlet of a box-shaped gas flow controller; a plurality of air inlets are opened on the gas flow controller, and are respectively and correspondingly connected with the larger diameter ends of a plurality of conical cyclone tubes. Through the conical cyclone tubes, the invention can form a stronger air negative-pressure area, and can fast absorb the oil-smoke gas of a large area into the cyclone tubes, then the oil-smoke gas can fast rotate for purification and fast flow for discharging through the effective control of the gas flow controller without any noise, and the oil-smoke gas entering into the cyclone tubes undergoes the purification treatment, thereby enabling the discharged oil-smoke gas not to pollute the surrounding air environment, eliminating the pollution to the kitchen facilities caused by the large amount of oil-smoke during the cooking, and having the capability of fast and silently processing the oil-smoke.

Owner:王君

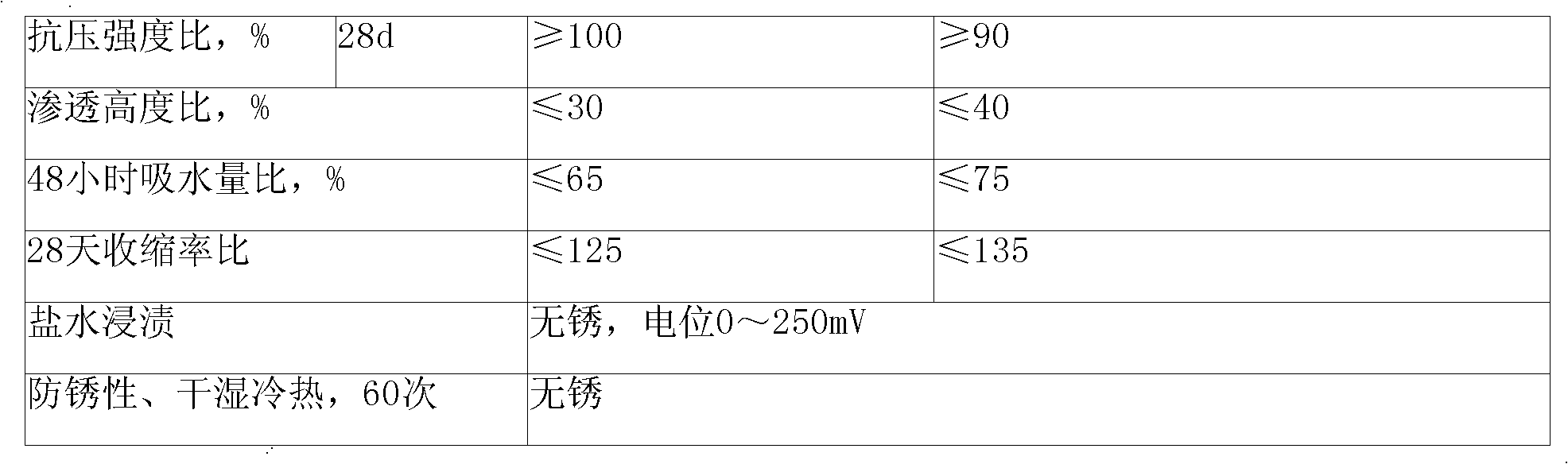

Water-proof corrosion inhibitor and preparation method thereof

The present invention discloses a water-proof rust-resistant agent with the ingredients by the following weight percent: 10 to 20 percent of modified organosilicone, 10 to 30 percent of alkamine, and 60 to 70 percent of water. The modified organosilicone is alkyl alkaoxy silane with the chemical formula of R'Si(OR3)3, wherein, R' and R represent the alkyl. The present invention is free from negative influence on the condensation time and the strength of the concrete, and has the advantages of low consumption volume and high rust-resistant performance. The present invention has remarkable functions on the self water prevention of the concrete structure and the rusty corrosion of the steel bar, and also has the functions such as water reduction, air introduction, plasticity preservation and corrosion prevention, thereby can be used as the additive for the concrete pumping agent, the water-proof agent and the rust-resistant agent.

Owner:北京东方建宇混凝土科学技术研究院有限公司 +1

Silver-containing silicon-based mesoporous antibacterial agent and preparation method thereof

InactiveCN101744001AEasy to spreadImprove antibacterial propertiesBiocideDisinfectantsMesoporous materialSilver ion

The invention discloses a silver-containing silicon-based mesoporous antibacterial agent and a preparation method thereof. The method comprises the following steps: mixing structure-directing agent of polyethylene glycol-polypropylene glycol-polyethylene glycol block copolymer, deionized water and acid, adding silicon source and silver source, then heating, continuously stirring to obtain sol-gel, drying sol-gel in vacuum, then washing with ethanol, drying in vacuum; and roasting the product of vacuum drying in protective gas. The antibacterial active silver is added during the preparation process of the mesoporous material, so that the silver ion can be deposited on the hole wall of mesoporous, then a physical or chemical method is used to remove the structure-directing agent of mesoporous and finally the silver-containing mesoporous inorganic antibacterial agent is prepared. The antibacterial agent is characterized in that the content of the antibacterial active body is easy to control, the preparation method is easy, the antibacterial property is strong and stable, the antibacterial effect can last for long time, the color of the antibacterial agent is not easy to change, the antibacterial agent is nontoxic, etc. The antibacterial agent can be widely used in fields such as ceramics, plastics, textile, coatings, water treatment and the like.

Owner:ZHEJIANG SCI-TECH UNIV

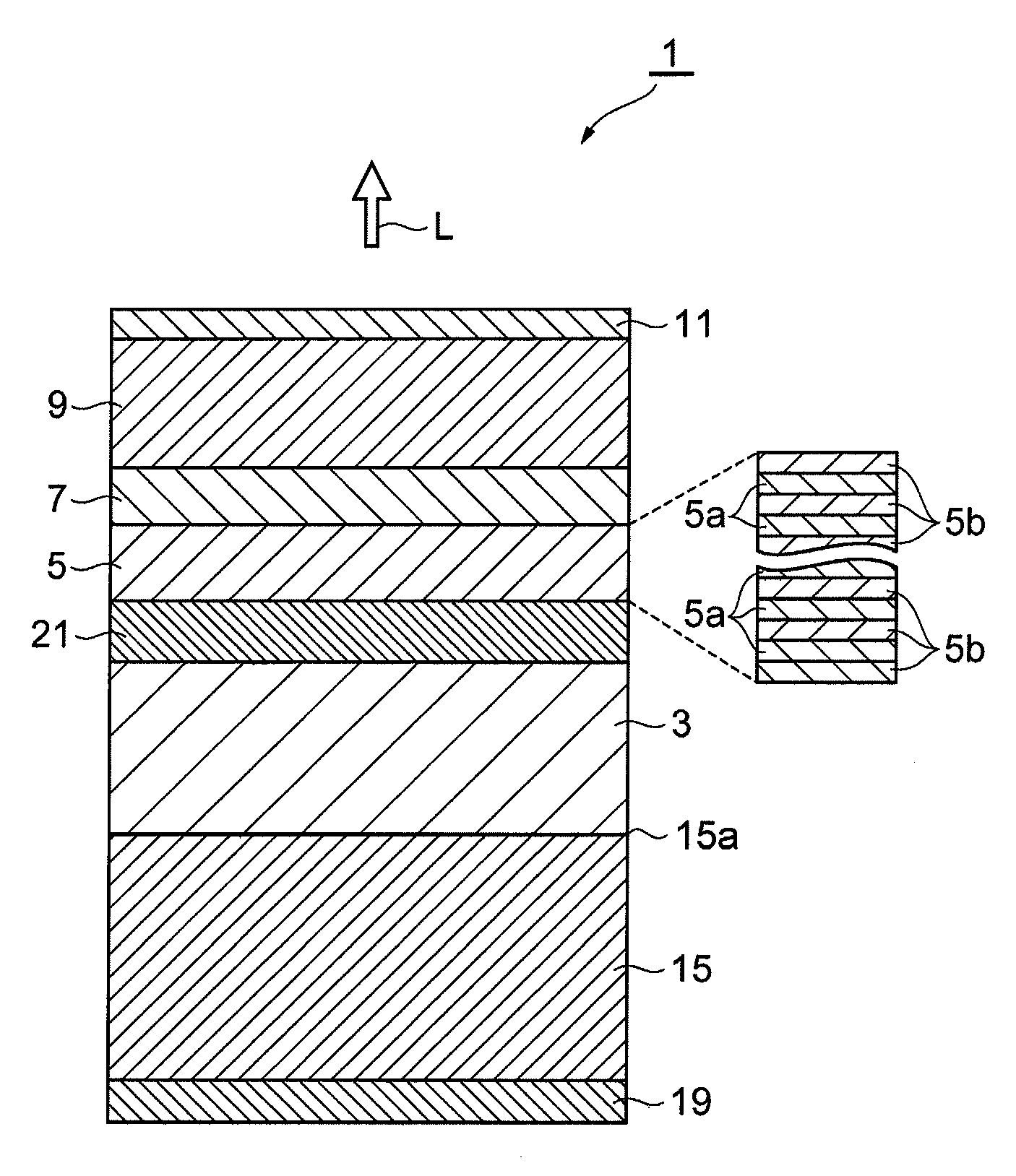

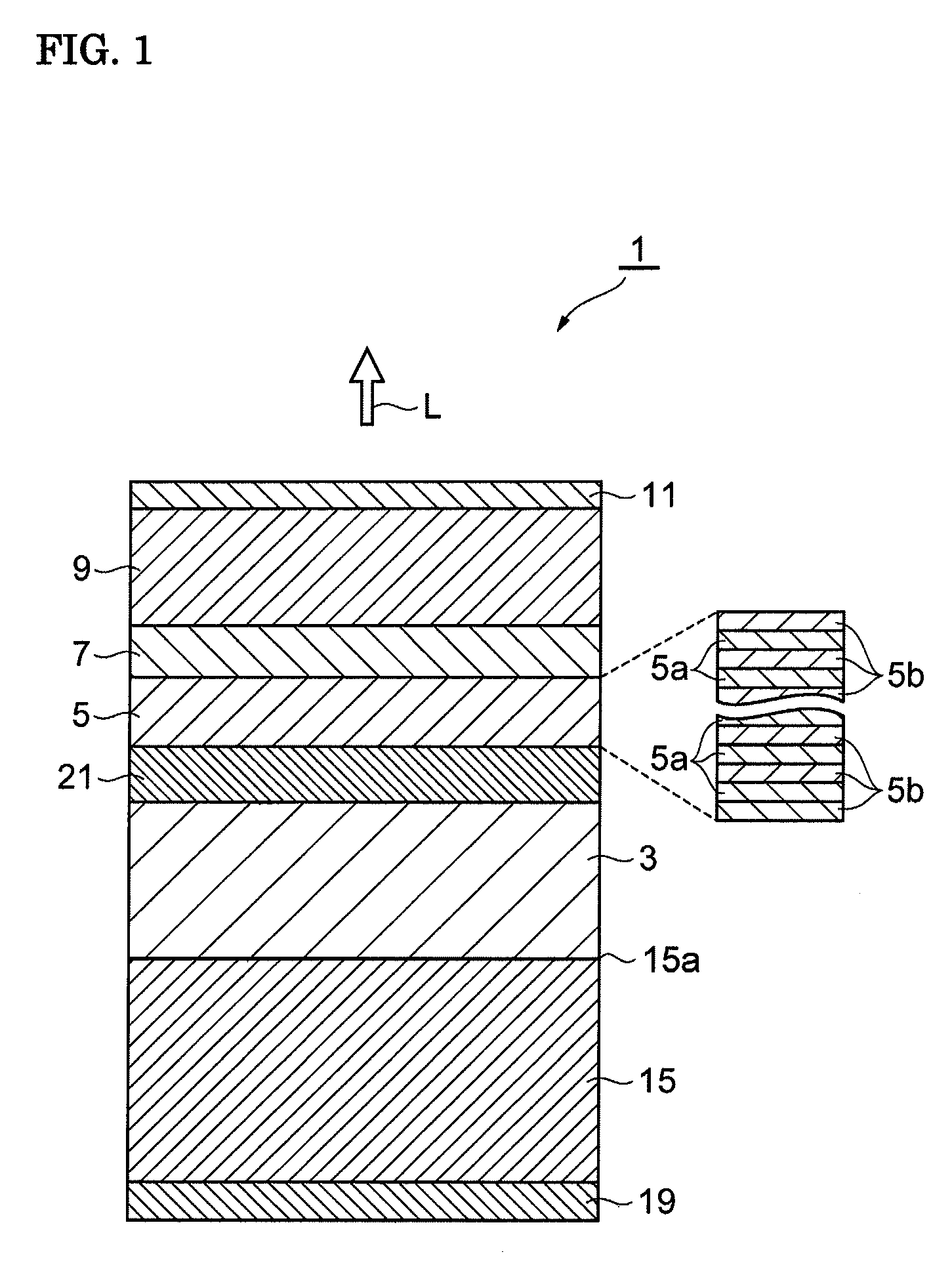

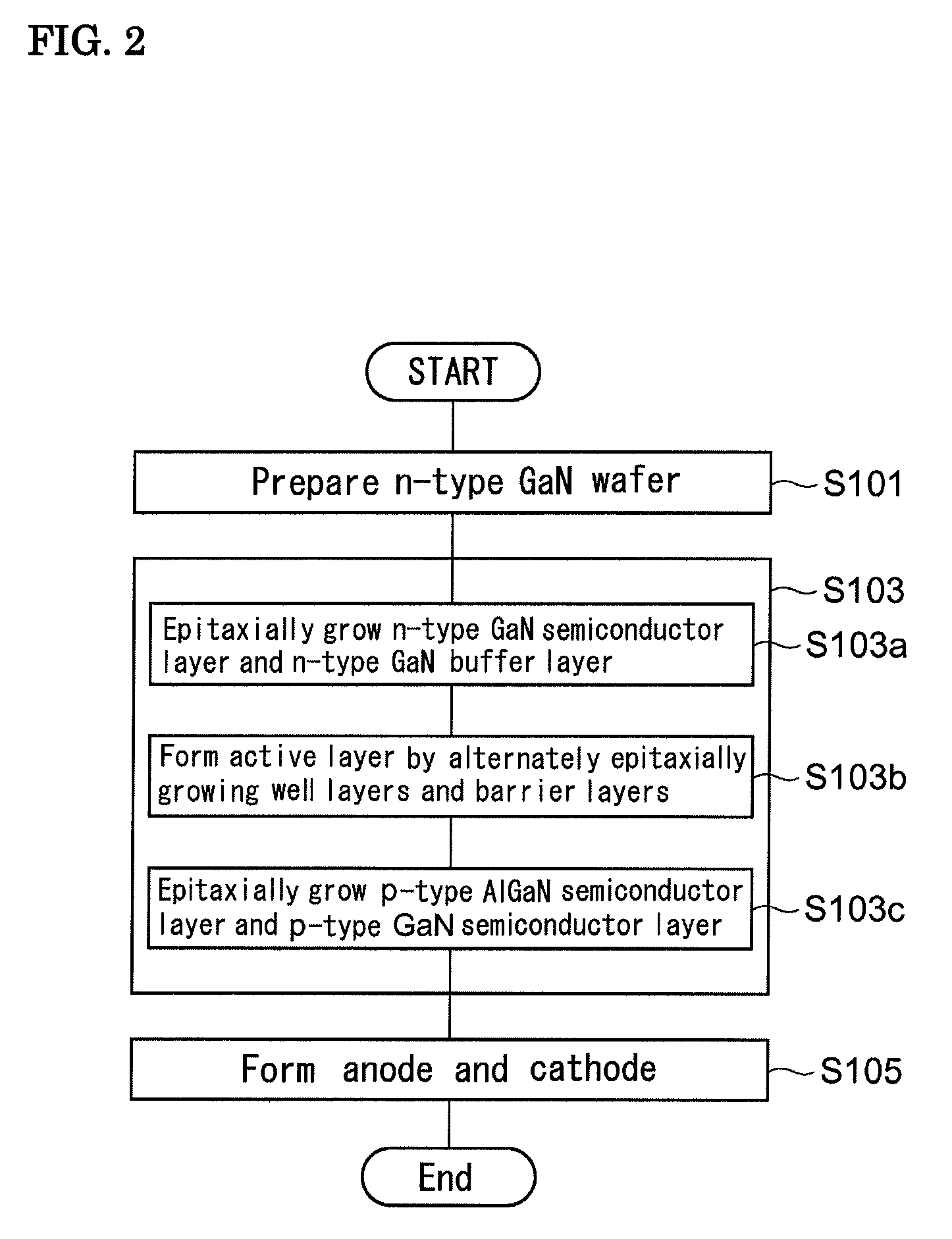

Method for forming quantum well structure and method for manufacturing semiconductor light emitting element

ActiveUS20090258452A1Reduce variationVariation in compositionNanoinformaticsSemiconductor/solid-state device manufacturingQuantum wellProduct gas

A method for forming a quantum well structure that can reduce the variation in the In composition in the thickness direction of a well layer and a method for manufacturing a semiconductor light emitting element are provided. In a step of forming a quantum well structure (active layer) by alternately growing barrier layers and well layers on a primary surface of a GaN substrate, the well layers are each formed by growing InGaN, the barrier layers are each grown at a first temperature, the well layers are each grown at a second temperature which is lower than that of the first temperature, and when the well layers are each formed, before a starting material gas for Ga (trimethylgallium) is supplied, a starting material gas for In is supplied.

Owner:SUMITOMO ELECTRIC IND LTD

LED epitaxial layer growing method and LED epitaxial layer

InactiveCN103996759AImprove crystal qualityIncrease contactSemiconductor devicesDelta dopingTotal thickness

The invention provides an LED epitaxial layer growing method and an LED epitaxial layer. The method for growing a P-type GaN layer comprises the steps that A, NH3 and Cp2Mg are introduced in a reaction chamber at the temperature of 900 DEG C to 950 DEG C, wherein pressure of a reaction cavity ranges from 200 mbar to 600 mbar, TMGa is closed, and pretreatment of doping Mg is carried out for 10 minutes-20 minutes; B, TMGa is introduced, Cp2Mg is closed, a GaN layer grows for 20 minutes-40 minutes, and the thickness of GaN is 5 nm-10 nm; the step A and the step B are repeated ten to twenty times until the total thickness of the P-type GaN layer is 80 nm-200 nm. According to the method, delta doping is used for growing the P-type GaN layer, the crystal quality of the P-type GaN layer is improved, the dislocation density is reduced, and hole concentration and the migration rate of P-type GaN are improved; more hole-electron pairs can be provided for light-emitting active areas of an LED device, the composite probability is improved, the brightness is promoted, and therefore photoelectric property of the LED device is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Pig feed and preparation method thereof

The invention provides a pig feed and a preparation method of the pig feed, and belongs to the feed field. The pig feed comprises the following raw materials in parts by weight: 650-720 parts of corns for pigs, 25-40 parts of oil bran, 200-250 parts of high-temperature bean pulp, 5-10 parts of mountain flour, 6-10 parts of calcium hydrophosphate, 1-5 parts of table salt, 0.5-3 parts of baking soda, 0.5-2 parts of choline chloride, 1-3 parts of a mildew preventive, 0.1-0.5 part of an antioxidant and 25-35 parts of a core material. The pig feed is reasonable in formulation and complete in nutrition; due to the reasonable combination of energy substances, vitamins, mineral substances and Chinese herbal medicines and the optimization for the preparation method, the metaboilic level of the pigs can be improved, and the digestibility of the feed can be increased; and therefore, the utilization rate of the feed is greatly increased, the shelf life of the feed is prolonged, the loss of the feed is reduced, and the feed cost is lowered.

Owner:广西康佳龙农牧集团有限公司

Deep low penetrating oil layer thin oil fire flooding horizontal well gas-injection horizontal well oil production process technology

The present invention relates to a deep-layer low-permeability oil reservoir thin oil combustion drive horizontal well air injection horizontal well oil production technique. It is characterized by that said invention utilizes the heat quantity produced in air injection horizontal well section as firing drive oil reservoir and transfers the heat quantity into the horizontal oil-producing wells distributed at two sides of the air injection horizontal well section so as to make the thin oil be recovered from the oil-producing wells.

Owner:尤尼斯油气技术(中国)有限公司

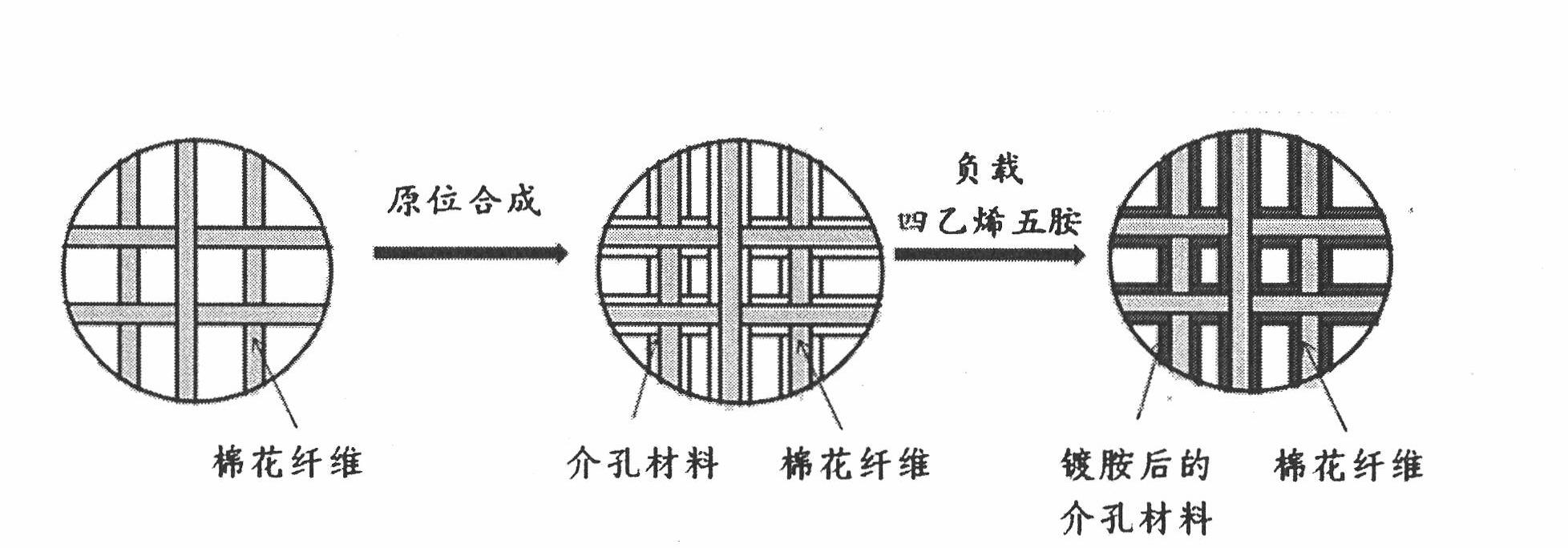

Formed carbon dioxide absorbing material and preparation method thereof

InactiveCN101804327AImprove adsorption capacityNot easy to spreadOther chemical processesFibre treatmentMolecular sieveFiber

The invention relates to a formed carbon dioxide absorbing material. Cotton fiber is taken as carrier, in situ synthesis is carried out to obtain mesoporous molecular sieve-cotton fiber composite material, and then organic amine is coated, thus obtaining organic amine-mesoporous molecular sieve-cotton fiber formed composite material, namely the formed carbon dioxide absorbing material. In the organic amine-mesoporous molecular sieve-cotton fiber formed composite material of the invention, larger space is kept between cotton fibers, the mesoporous molecular sieves dispersed on the cotton fiber can not be extruded together and further carbon dioxide is difficult to be diffused into interior particle, thus carbon dioxide absorption can be effectively carried out. The organic amine-mesoporous molecular sieve-cotton fiber composite material formed carbon dioxide absorbing material of the invention has the characteristics of high efficiency and high stability. The invention also discloses a preparation method thereof.

Owner:NANJING UNIV

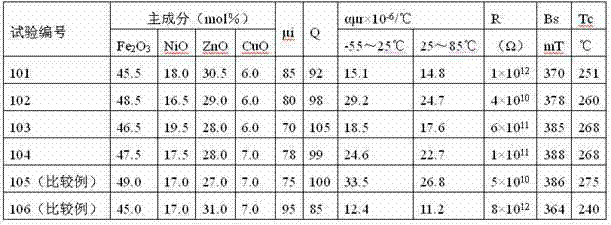

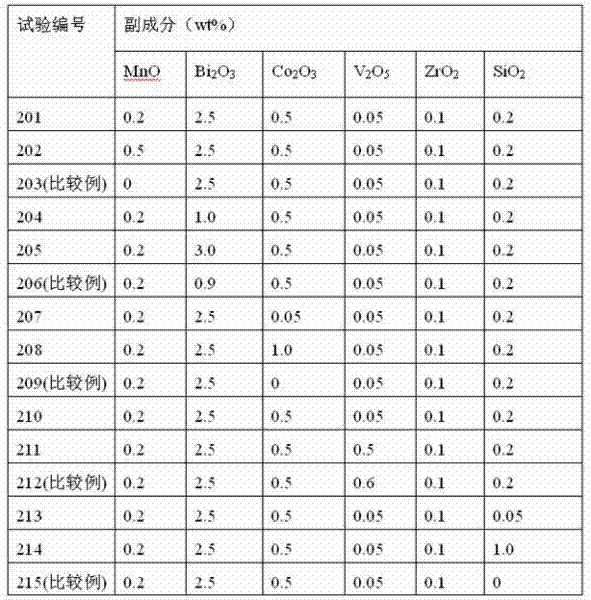

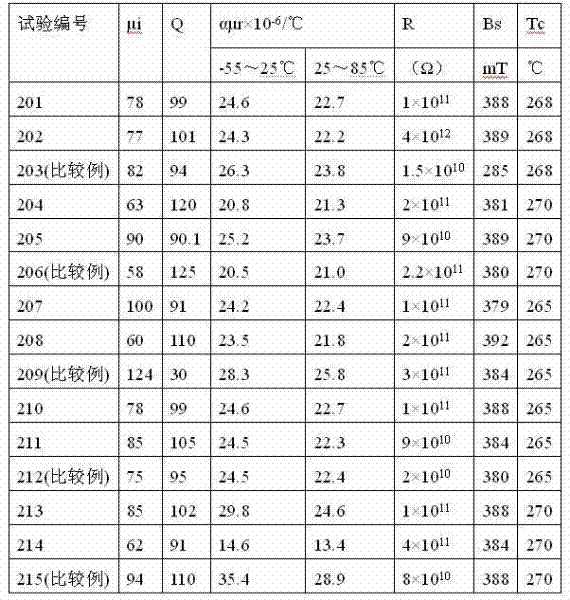

NiCuZn soft magnetic ferrite material used for low temperature co-sintering and preparation method thereof

The invention belongs to the field of soft magnetic ferrite materials, and in particular, relates to a NiCuZn soft magnetic ferrite material used for low temperature co-sintering. The material comprises major constituents and accessory constituents, wherein: the major constituents consist of ferric oxide, nickel oxide, zinc oxide and copper oxide, the molar percentage content of each major constituent being Fe2O3 45.5-48.5 mol%, NiO 16.5-19.5 mol%, ZnO 28.0-30.5 mol% and CuO 6.0-8.0 mol%; the accessory constituents comprise manganic oxide and bismuth oxide, compared with the gross weight of the major constituents, the weight percentage gross of the accessory constituents being 1.1-3.5 wt% calculated by taking MnO and Bi2O3 as standard. The invention also provides a preparation method for the ferrite material. When used for preparing MLCI devices under high frequency usage, the material of the invention has advantages in that: the material has a relatively low sintering temperature and metallic silver is not easy to diffuse during co-sintering; and the material ensures that the MLCI devices can obtain excellent magnetic properties and have a relatively good consistency.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

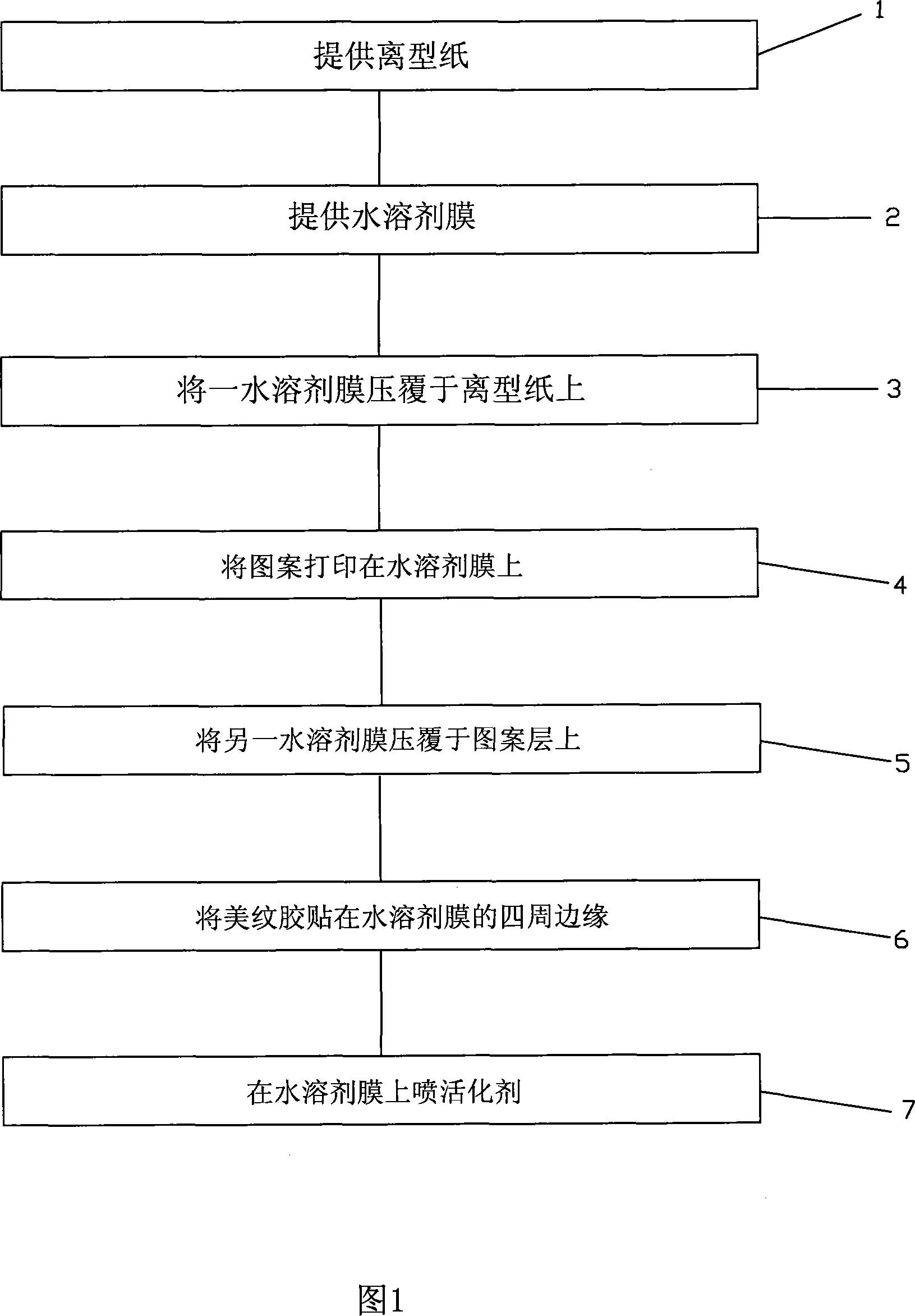

Method for making water-transfer printing paper by using printer to make pattern

InactiveCN101125499AUniform thicknessEasy to printDecorative surface effectsSynthetic resin layered productsPulp and paper industrySolvent

The present invention relates to a preparation method of water transfer paper which makes picture by utilizing printer. The method comprises the steps as follow: a release paper is provided; a hydrosolvent membrane is provided; the hydrosolvent membrane is pressed on the release paper; the picture is printed on the hydrosolvent membrane; another hydrosolvent membrane is pressed on the picture layer; masking glue is adhered at the edges of the hydrosolvent membrane; and an activator is coated on the hydrosolvent membrane. The picture of the water transfer paper made by the present invention has the advantages of clarity, flat, being hard for diffusing, good stability, being convenient for amending and adjusting the picture by utilizing computer and printer for making picture, thus effectively saving the picture production time and cost. The present invention is suitable to small lot production.

Owner:林其武

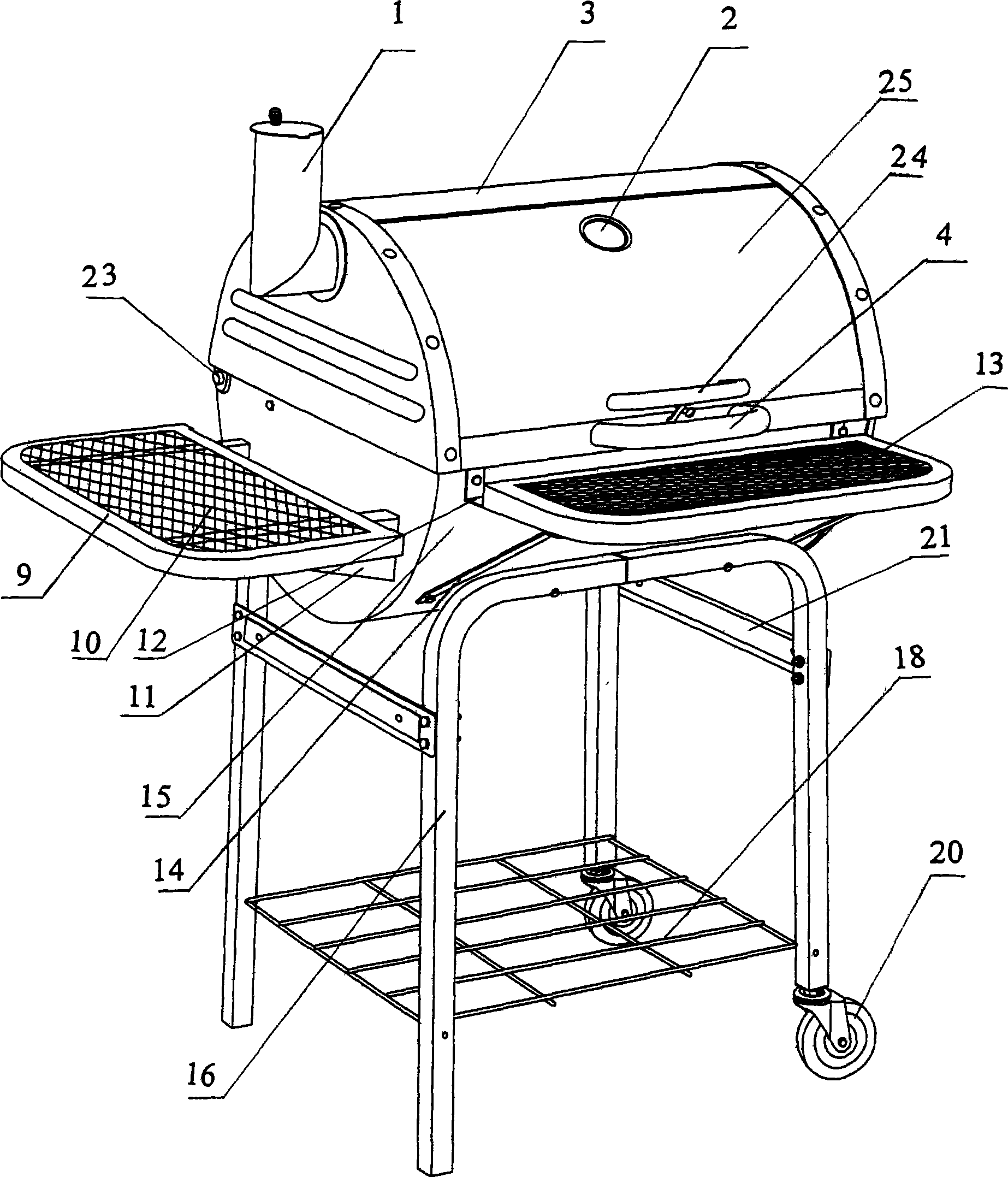

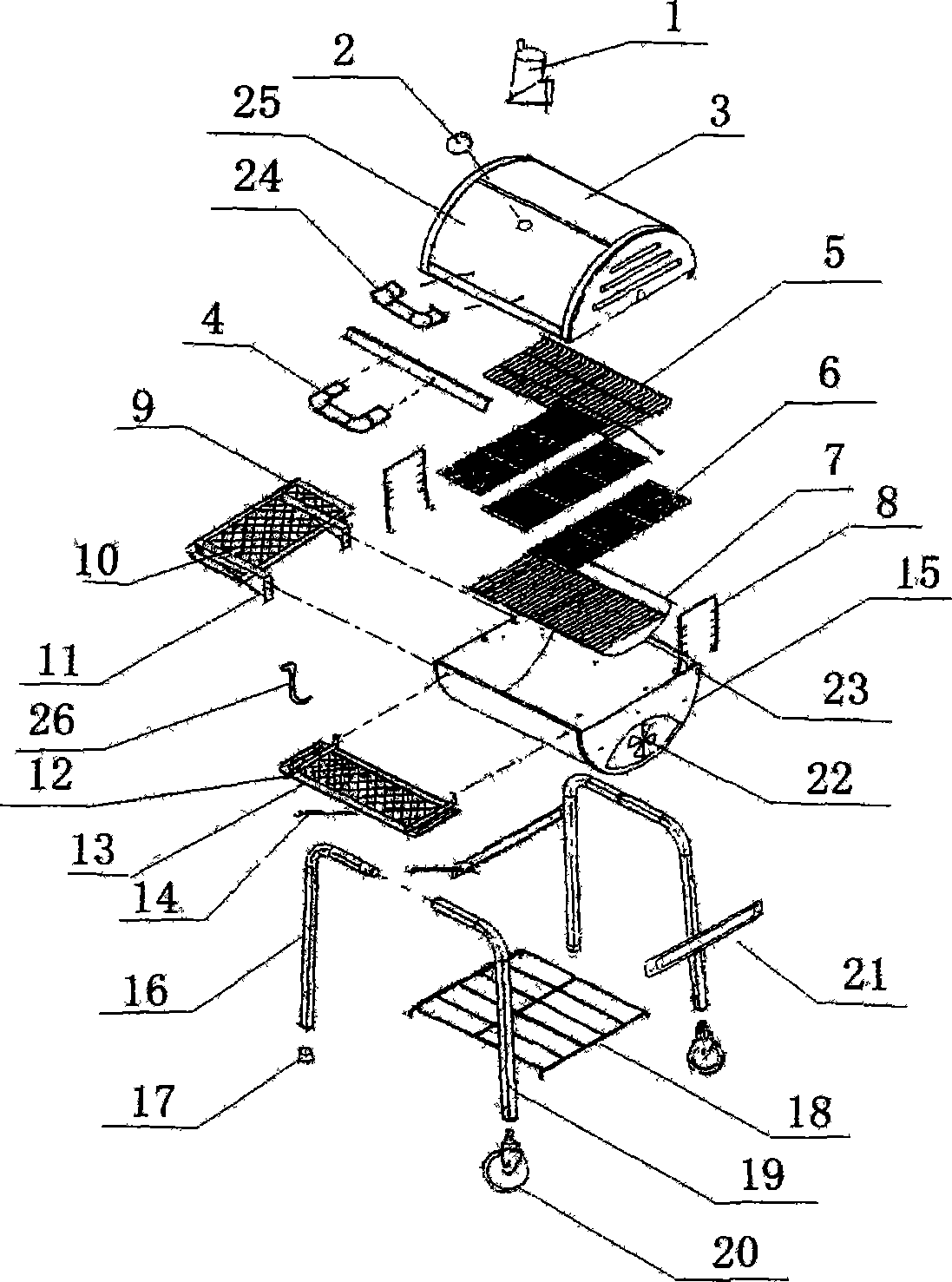

Barbecue furnace with cover

The invention relates to an oven with a cover cap, and belongs to the technical field of food processing and domestic instant food processing. The oven is characterized in that an oven hearth consists of a lower semicircular cylinder which is arranged transversely and has an upward opening and two ends connected to a fixed semicircular wall, and an upper semicircular cylinder connected with a cylinder edge by a shaft; two ends of the oven hearth fixed at the edges inside the upper semicircular cylinder on the circumferential wall are provided with calking grooves along a semicircle, the calking grooves are embedded into the edges of an arc moving door at one-quarter opening of an upper semicircular cover, and the middle of the upper semicircular cylinder is provided with a dial thermometer for measuring temperature of the oven hearth; three racks are arranged in the oven hearth, namely, a bottom layer, an upper rack and a middle rack; a cylindrical oven body is arranged on a bracket; and the oven is provided with a chimney, an air door and a shelf. The oven has the advantages as follows: because barbecue is roasted closely, heat is not easy to diffuse, roasting strength can be adjusted, the oven not only improves roasting efficiency and does not pollute environment, but also heat food evenly, shortens roasting time, and can supply enough smudging roasted food.

Owner:SHANGHAI YUQIANG OUTDOOR PROD CO LTD

Array substrate, array substrate preparation method and display device

The invention relates to display technologies and discloses an array substrate. In a pixel structure of the array substrate, a leakage electrode is connected with a pixel electrode in electrical conductivity, and the pixel electrode, or a source electrode and the leakage electrode, or the pixel electrode, the source electrode and the leakage electrode are made from graphene. The invention also discloses an array substrate preparation method, and specifically, patterning graphene films are prepared from a graphene oxide solution. According to the array substrate, the electrodes prepared from the graphene films are high in chemical stability, good in flexibility and not easy to be subjected to ion diffusion, the cost can be reduced substantially, and the product competiveness is improved; according to the array substrate reparation method, the electrodes made from the graphene do not damage substrates, thus being suitable for various substrates such as flexible substrates; in addition, the whole technological operation is simple, the capitalized cost on equipment is reduced as expensive equipment is not needed, the large-area graphene films can be prepared, and the array substrate can be used in a large scale.

Owner:BOE TECH GRP CO LTD

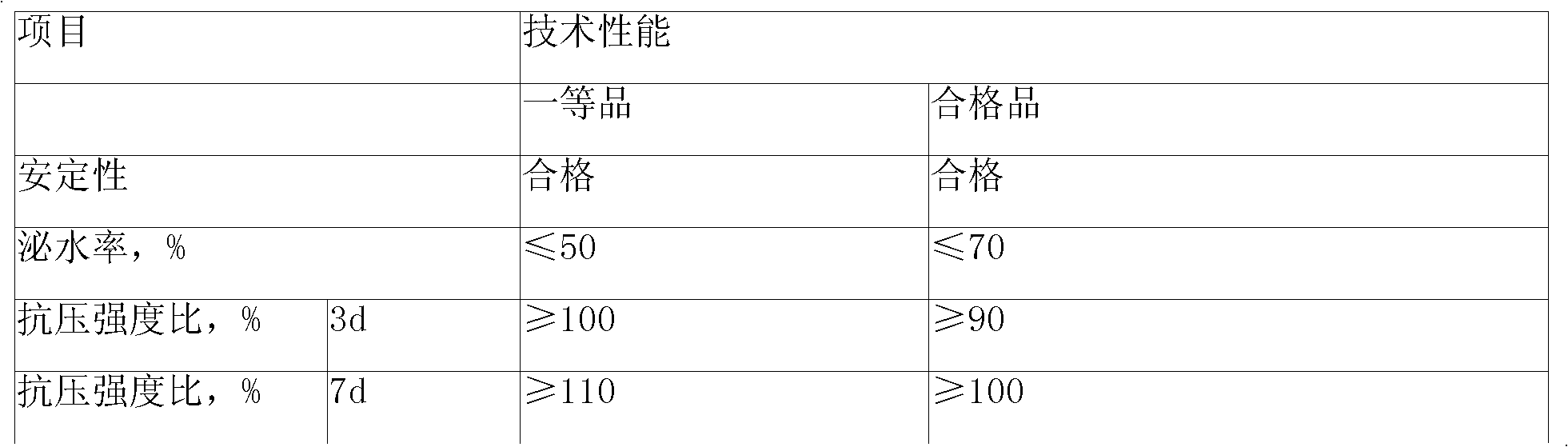

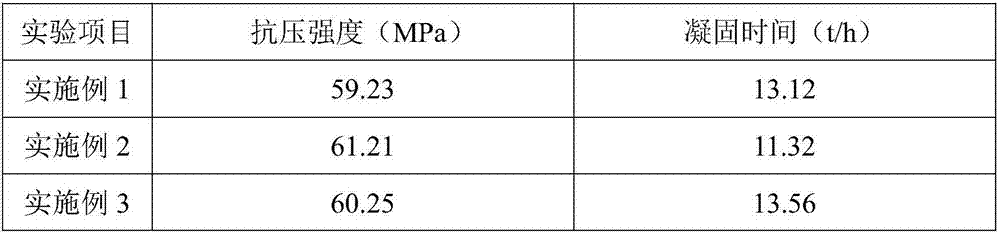

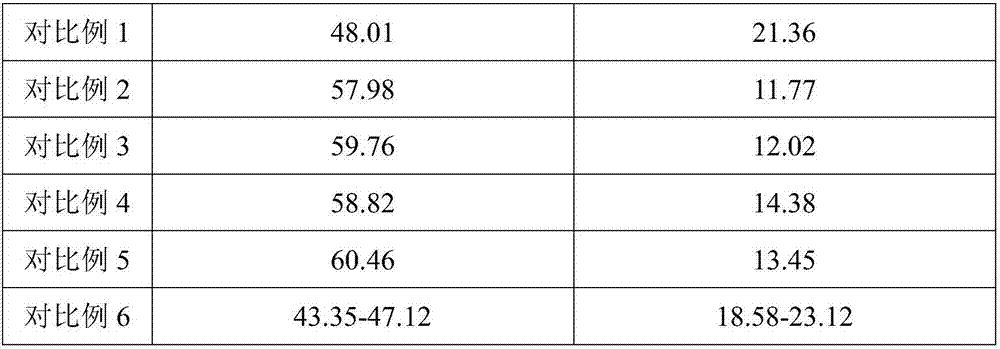

Soil curing agent

ActiveCN107973571AImprove setting timeGood comprehensive effect of compressive strengthFirming agentSoil texture

The invention discloses a soil curing agent, which belongs to the technical field of building materials. The soil curing agent comprises the following raw materials: common silicate cement, solid sulphur ash, an excitant, an early strength agent, silica fume, quick lime, polyacrylamide, water, polyvinyl butyral, calcium lignosulphonate, 3-amino propyl trialkoxysilane and polyvinylpyrrolidone. Theabove soil curing agent is prepared through the steps of carrying out material modification, mixing, vacuum preparation and the like. The soil curing agent has a simple preparation technology. When the soil curing agent is adopted, the solidification time of a roadbed can be obviously shortened, the compressive strength of the roadbed is improved, time limit for construction are shortened, and thesoil curing agent can be applied to the soil solidification of different soil textures.

Owner:江苏路业建设有限公司

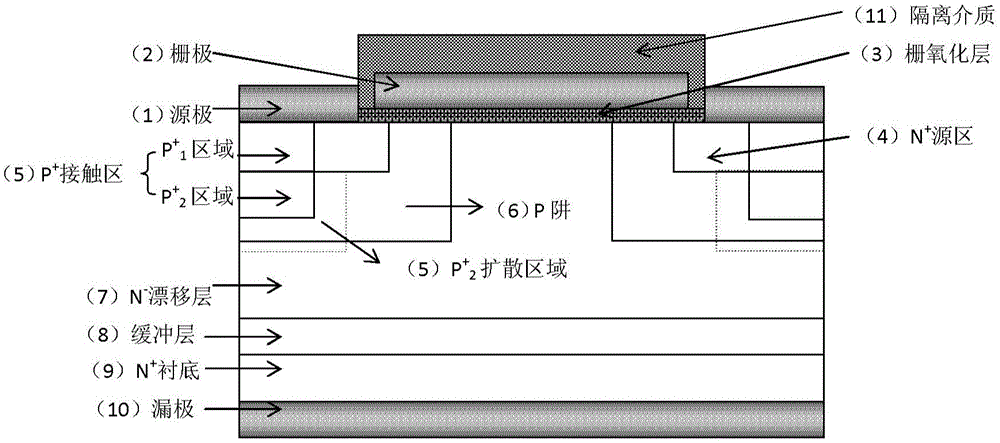

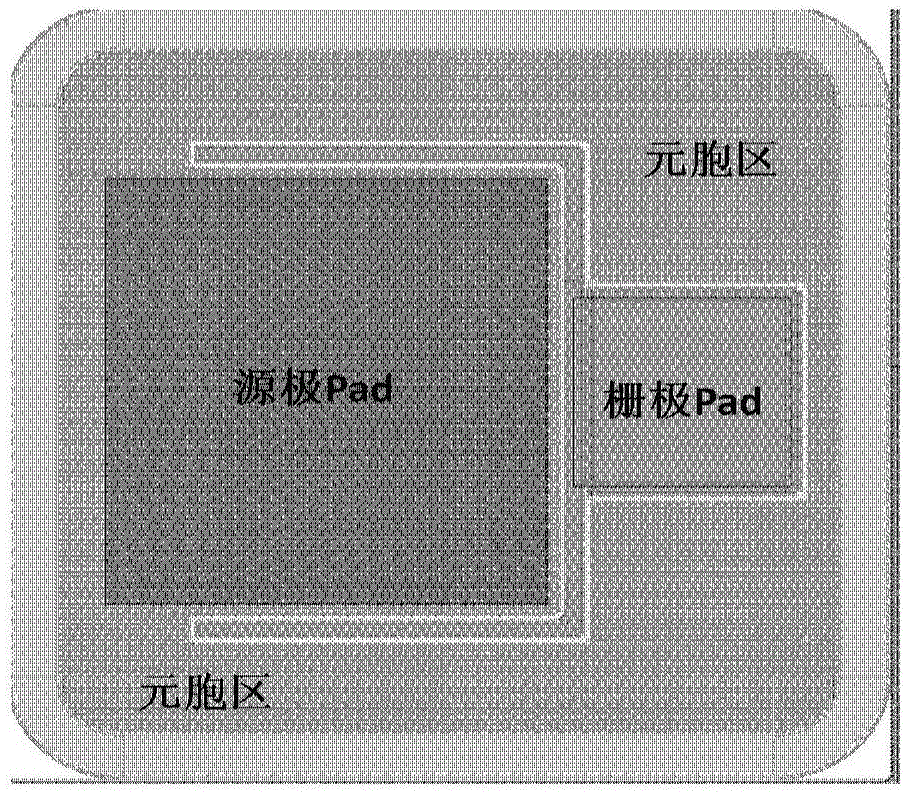

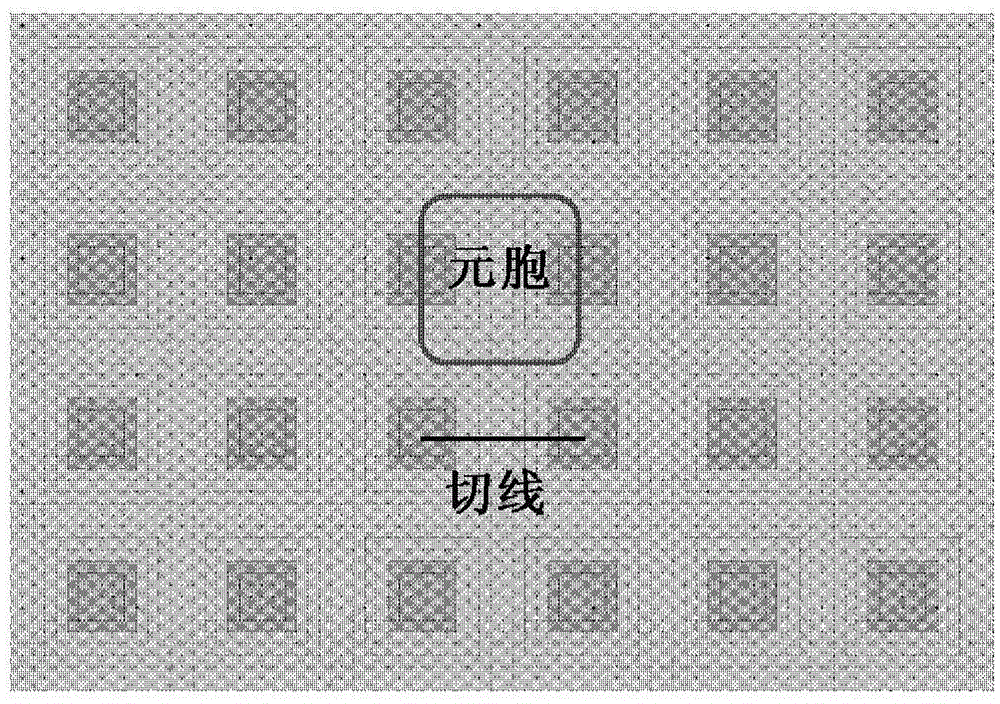

Silicon carbide metal-oxide-semiconductor field-effect-transistor (MOSFET) device and fabrication method thereof

ActiveCN105161539AAvoid avalanche breakdownGood source ohmic contactSemiconductor/solid-state device manufacturingSemiconductor devicesField-effect transistorPower MOSFET

The invention discloses a self-aligned silicon carbide metal-oxide-semiconductor field-effect-transistor (MOSFET) device with an optimized P<+> region and a fabrication method of the self-aligned silicon carbide MOSFET device. The self-aligned silicon carbide MOSFET device is formed by connecting a plurality of same cells in parallel, and the cells of the silicon carbide MOSFET device are uniformly arranged. Each cell of the silicon carbide MOSFET device comprises two sources, a grid, a grid oxide layer, two N<+> source regions, two P<+> contact regions, two P pits, an N<-> drift layer, a buffer layer, an N<+> substrate, a drain and an isolation dielectric layer. By optimizing the P<+> region, favorable source ohmic contact is formed, the on resistance is reduced, meanwhile, the source and the P pits are in short connection, parasitic negative-positive-negative (PNP) and a parasitic transistor effect of PiN are prevented, the conduction property and the breakdown property of the device can be compatible, and the device can be used in a high-voltage and high-frequency silicon carbide MOSFET device. A self-aligned fabrication method is adopted by the invention, the process is simplified, the channel size is accurately controlled, and a transverse or longitudinal power MOSFET can be fabricated.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

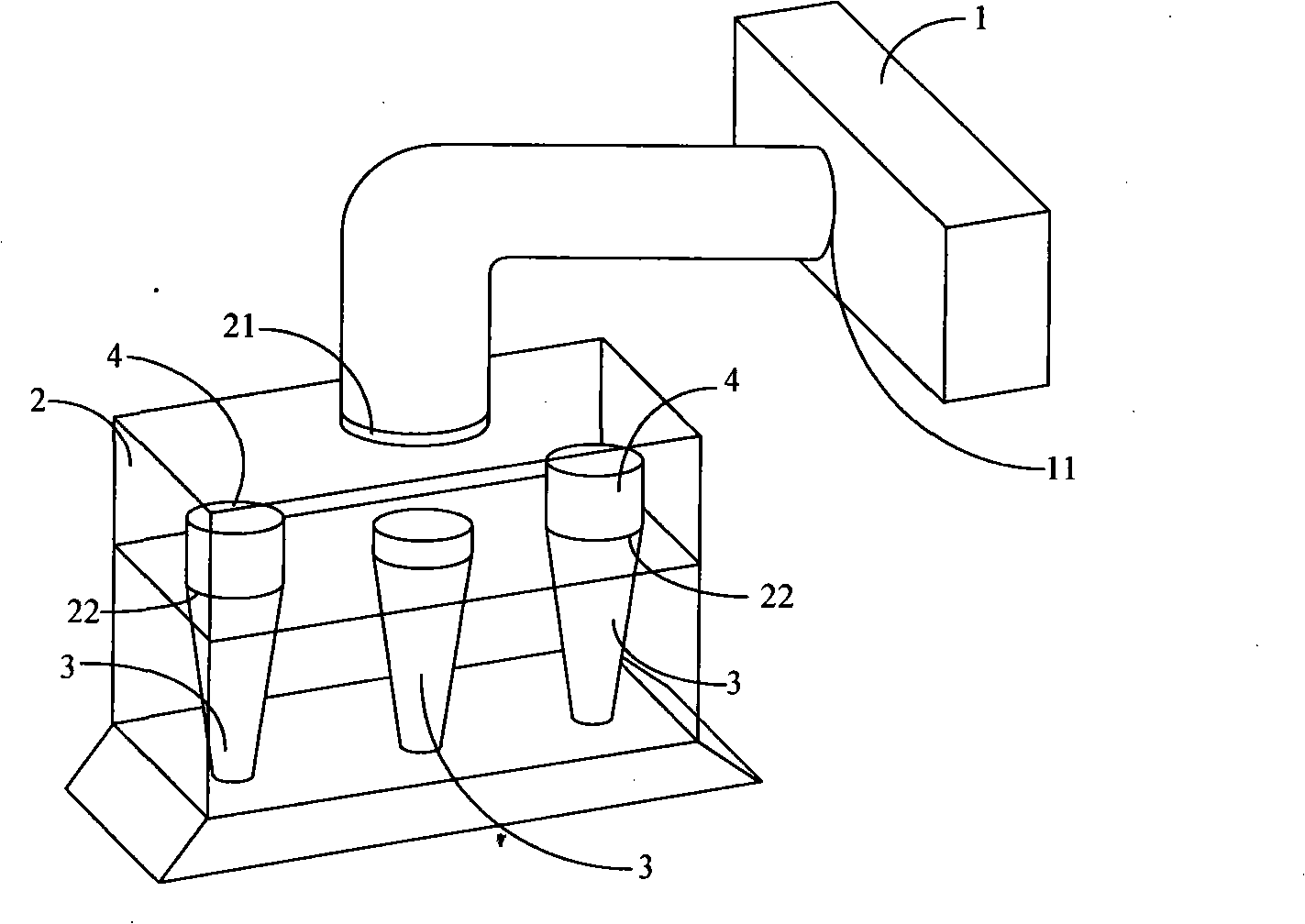

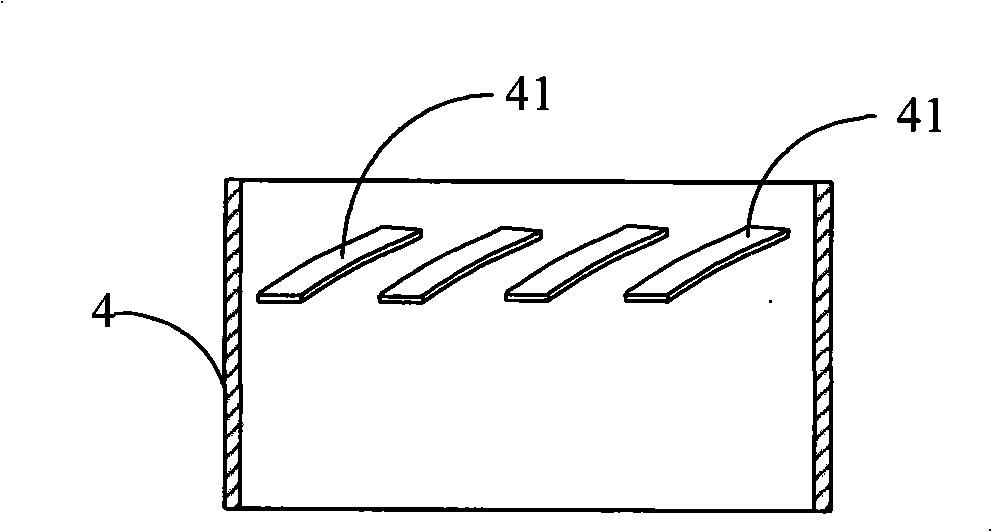

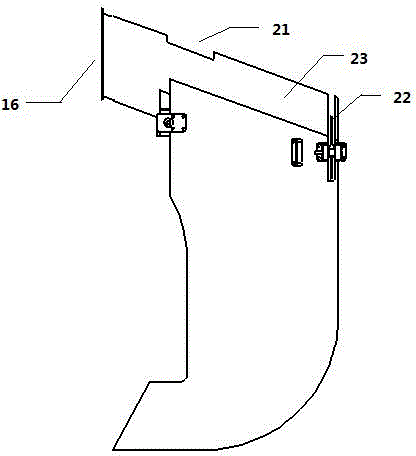

Cooking fume purifier

InactiveCN101249353ANot easy to spreadSprawl eliminationDispersed particle separationCyclonePetroleum engineering

The invention relates to an oil fume purification device, including a fan which exhausts the gas to the outside and a conical cyclone tube, one end with larger diameter of the cyclone tube is connected with an air inlet of the fan; the interior of the cyclone tube is provided with a spiral fluctuation structure which guides the air to rotator and a purification part which carries out the purification treatment of the passing oil fume. The oil fume purification device separates the oil fume granules in the oil fume which is sucked in the cyclone tube by the cyclone structure and the purification treatment structure so as to ensure that the exhaust gas contains no environmental pollution oil fume; at the same time, a pipeline is adopted to arrange the cyclone pipe and the fan separately, thus, when a kitchen exhausts the oil fume, the oil fume purification device is capable of rapidly and quietly removing the oil fume without noise.

Owner:王君

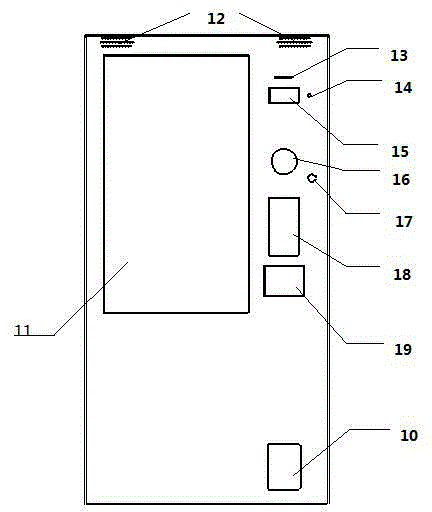

Intelligent beverage bottle recycling terminal

InactiveCN104637161AImprove efficiencyImplementation unit burden reductionReturnable containers actuationProcess engineeringSoftware modules

The invention provides an intelligent beverage bottle recycling terminal. The intelligent beverage bottle recycling terminal comprises a channel module, a compressor module, a storage bin module, an advertising lamp box module, a peripheral assembly module and a shell. A software module runs inside the terminal. The software module has the donation running mode and the paid recycling mode. The intelligent beverage bottle recycling terminal has the advantages that the lamp box advertising function is added on the environment-friendly recycling equipment, the free donation function is created originally, and the using efficiency of the environment-friendly recycling machine is effectively improved; plastic bottle environment-friendly recycling and commercial shopping integration are tightly combined, and the waste water separation technology is created originally on a storage bin.

Owner:GUANGZHOU GAIWANGTONG ELECTRONICS EQUIP CO LTD

Iron oxide yellow granular pigment and manufacturing method thereof

InactiveCN101691455APollution suppressionSettling fastPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsAqueous solutionDust pollution

The invention belongs to the field of chemical pigments, in particular to an iron oxide yellow granular pigment and a manufacturing method thereof, the related iron oxide yellow granular pigment comprises a main component of iron oxide yellow, an additive coating layer is arranged outside the main component of the iron oxide yellow, and the main component of the iron oxide yellow and the coating layer are combined together for constituting the granular pigment; and the pigment is realized by the following steps: firstly preparing additive water solution, heating to 30-100 DEG C, sending the iron oxide yellow into a granulator, evenly spraying the prepared additive water solution on powder materials, gradually forming small grains, further sieving the prepared grains by using a vibration sieve and drying, thereby preparing a finished product. The prepared granular pigment is difficult to diffuse, thereby effectively preventing dust pollution, having the advantages of high color retaining performance, good fluidity, good dispersion and low cost, and being applicable to extensive application on the industry.

Owner:HANGZHOU XIAOXIANG PIGMENT CHEM

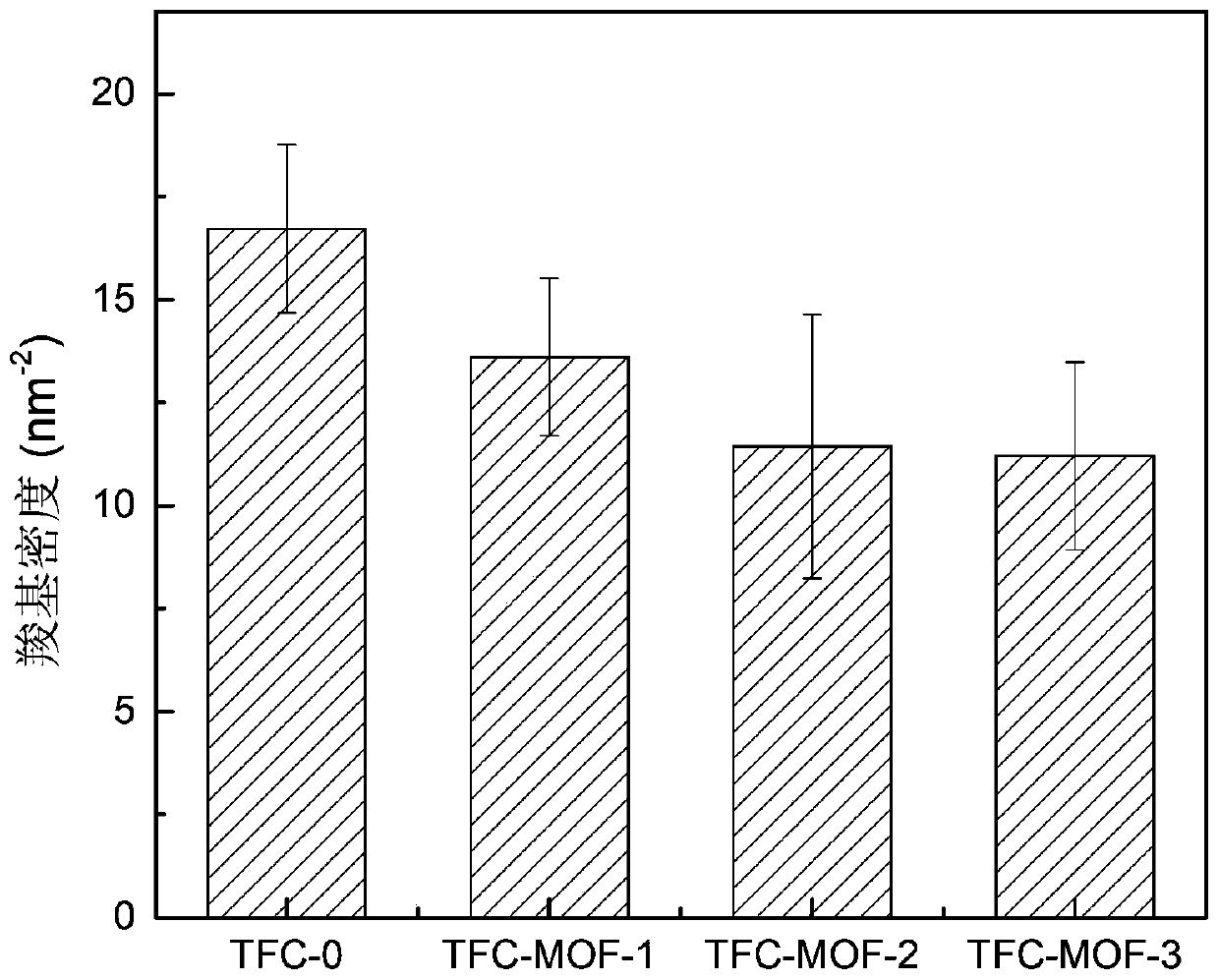

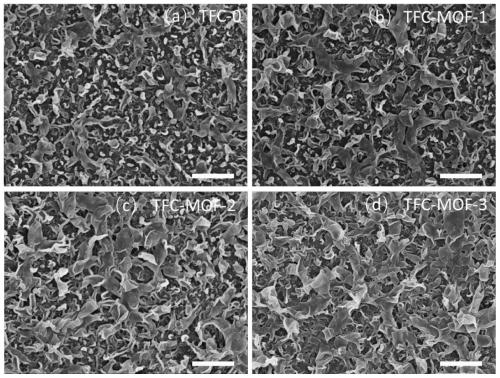

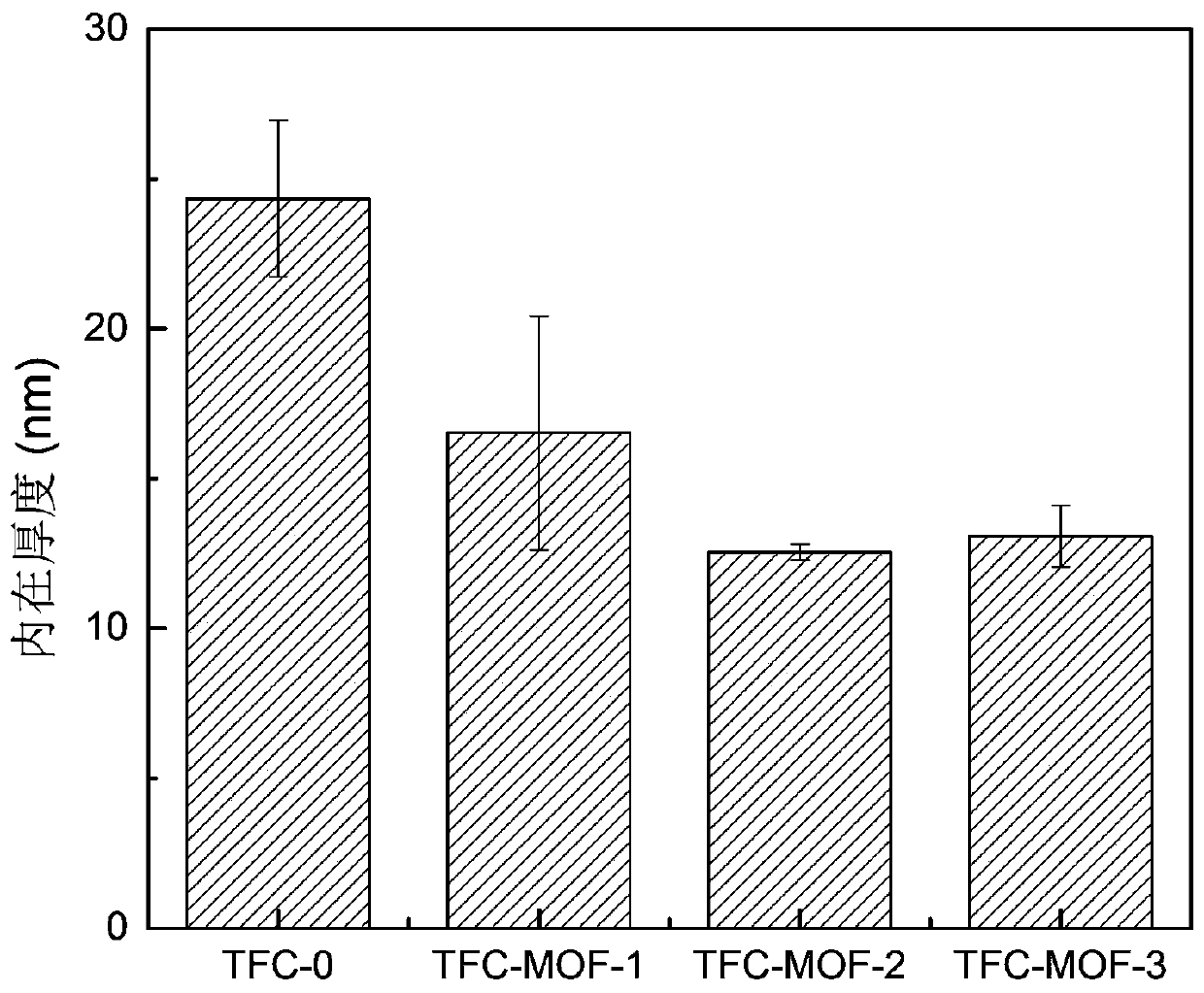

Polyamide thin-layer composite reverse osmosis membrane and preparation method and application thereof

InactiveCN111249920AImprove performanceChange the morphologySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer scienceReverse osmosis

The invention provides a polyamide thin-layer composite reverse osmosis membrane as well as a preparation method and application thereof. The preparation method comprises the steps: preparing an ultrathin metal organic framework nanosheet zinc-meso-tetra(4-carboxyphenyl)porphin; ultrasonically dissolving the ultrathin metal organic framework nanosheet zinc-meso-tetra(4-carboxyphenyl)porphin in alcohol, performing filter pressing on a polyethersulfone ultrafiltration membrane through a filter pressing method to prepare an ultrathin middle layer, and soaking the composite membrane in a resorcinol aqueous solution and a n-hexane solution containing polybenzoyl chloride to form the polyamide thin-layer composite reverse osmosis membrane. The middle layer of the metal organic framework nanosheet can be used as a water permeation channel, so that the geometric resistance of water molecules infiltrating from a polyamide membrane to a polyether sulfone membrane is reduced, and the permeation rate of water in a polyamide thin-layer composite reverse osmosis membrane is increased; the ultrathin middle layer provides a good reaction container for formation of interfacial polymerization reaction, the surface area and crosslinking degree of the prepared polyamide membrane are increased, the internal thickness of the polyamide membrane is reduced, and the salt rejection rate is also improvedwhile the membrane flux is greatly increased.

Owner:TONGJI UNIV

Halogen-free high temperature resistant flame-proof fibre

InactiveCN101161875AReduce burnEasy to spreadFlame-proof filament manufactureMonocomponent polypropylene artificial filamentChemical compositionCombustion

The present invention provides a novel halogen-free high temperature preventing flame-retardant fiber. The present invention is realized in the following way: a certain proportion of silicate nanometer particles are added into spinning melt to be mix fully, and the production is executed according to common chip spinning or melt spinning production flow to prepare the present invention; or the silicate nanometer particles and common high polymer chips are mixed and then mutually melted into flame-retardant master batch under certain temperature, and the present invention is prepared by executing twin-screw spinning to the master batch and high polymer having the same composition with master batch carrier. As the present invention adopts halogen-free compounds as flame-retardant composition, no poisonous gas can be produced during combustion; meanwhile, due to the special chemical composition of silicate, the present invention can combine a large amount of combined water, and leads the burning rate of the fiber to be slower during the process of releasing the combined water, so as to play a role in preventing high temperature. The technique is also characterized in green environmental protection.

Owner:SHENGHONG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com