Deep low penetrating oil layer thin oil fire flooding horizontal well gas-injection horizontal well oil production process technology

A process technology and a technology for horizontal wells, which are applied in the technical field of thin oil fire flooding horizontal wells in deep low permeability oil layers, gas injection horizontal wells, and oil production technology fields, and can solve the problems of limited exploitation, unproducible performance, poor permeability, and difficulty in thin oil development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

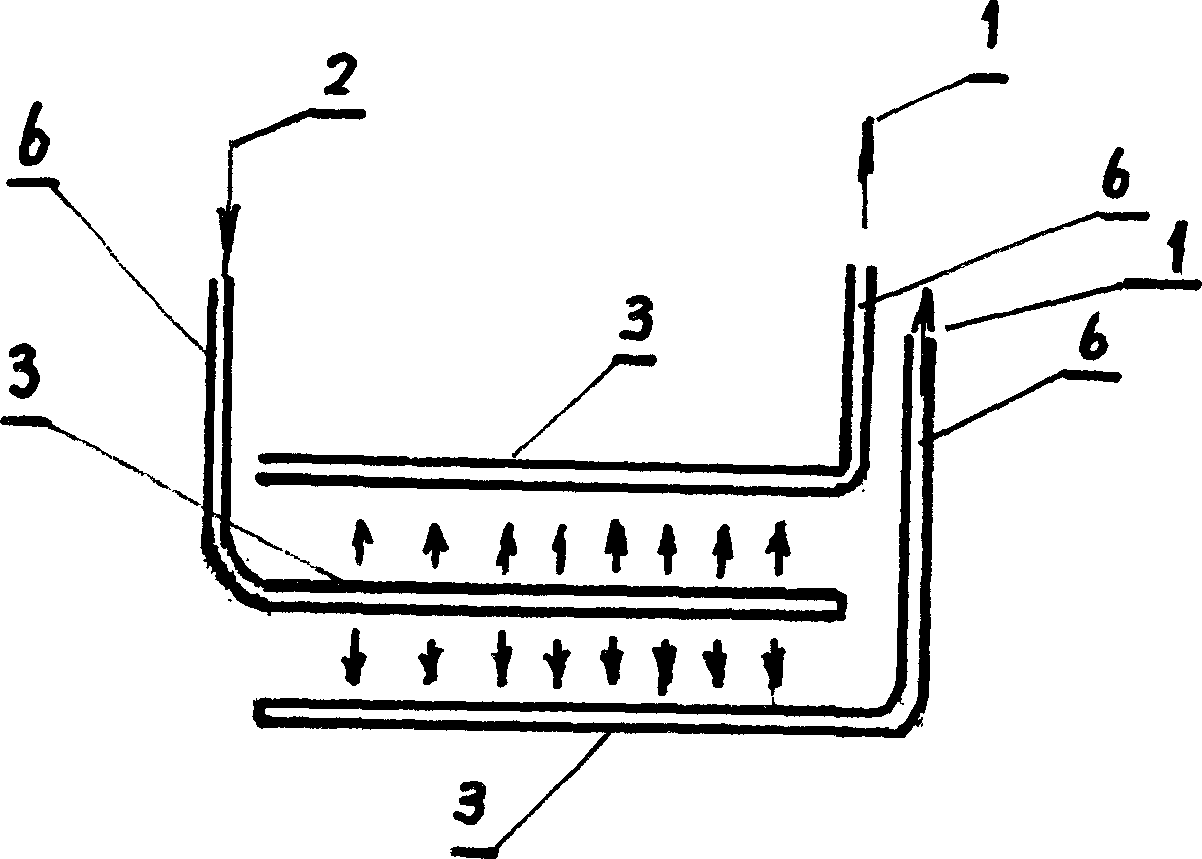

[0025] figure 1 Among them, the design depth of oil production well 1 and gas injection well 2 are both rock formations below 2000 meters, their permeability is less than 30DM, the viscosity of thin oil is 20-100MP.S at 50°C, it can flow below 75°C, and the density of thin oil is 0.9g / cm 3 Below, the lithology is sandstone body or ancient buried hill fracture reservoir. After the above conditions are met, the fire flooding horizontal oil production well section can be drilled.

[0026] Determine the position of the ignition layer in the gas injection well after completion:

[0027] 1. The ignition layer, that is, the fire displacement oil layer, should be selected within the horizontal section 3 of the horizontal gas injection well 2, because in the ignition well, only the oil reservoir in the horizontal well section has the largest exposure surface, and in general, the oil layer exposure layer is proportional to the horizontal well depth distance , which can increase the oi...

Embodiment 2

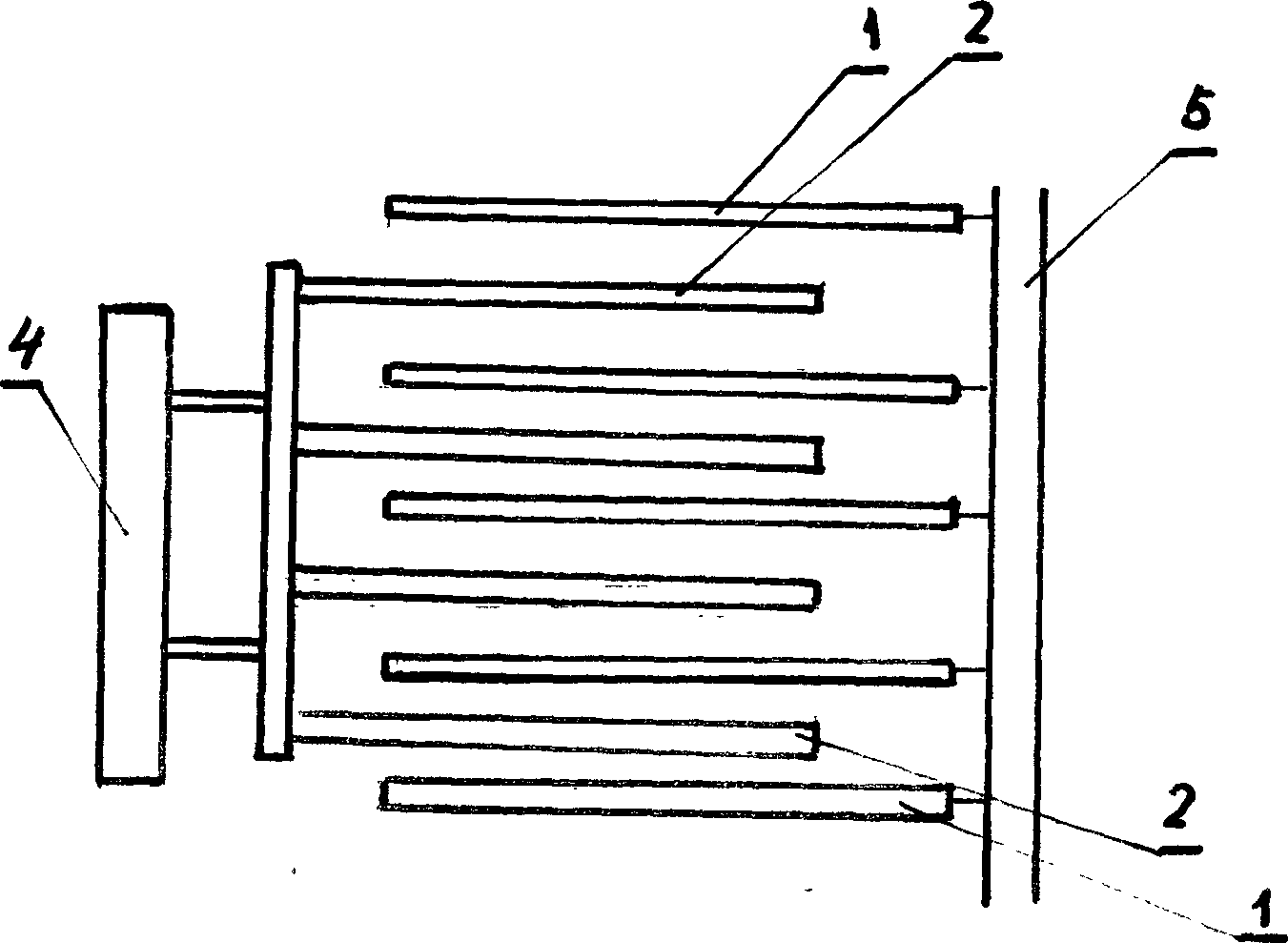

[0034] When the conditions in Example 1 are met, the exposed single horizontal section oil layer in the gas injection well 2 can be injected with high-pressure air by a WV-12 type compressor to implement ignition and drive the horizontal section oil layer, and produce in the oil production well 1 , if a large area of oil production area is required, it can also be figure 2 The well layout method uses the multi-stage compressor unit 4 and the parallel horizontal oil production well 1 and horizontal gas injection well 2 to ignite in the horizontal section of the gas injection well 1 as described above, and the thin oil is produced in the horizontal section of the oil production well 2. crude oil is sent out through oil pipeline 5, like this, will improve the recovery degree of thin oil to a greater extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com