Patents

Literature

142results about How to "Increase the burning area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

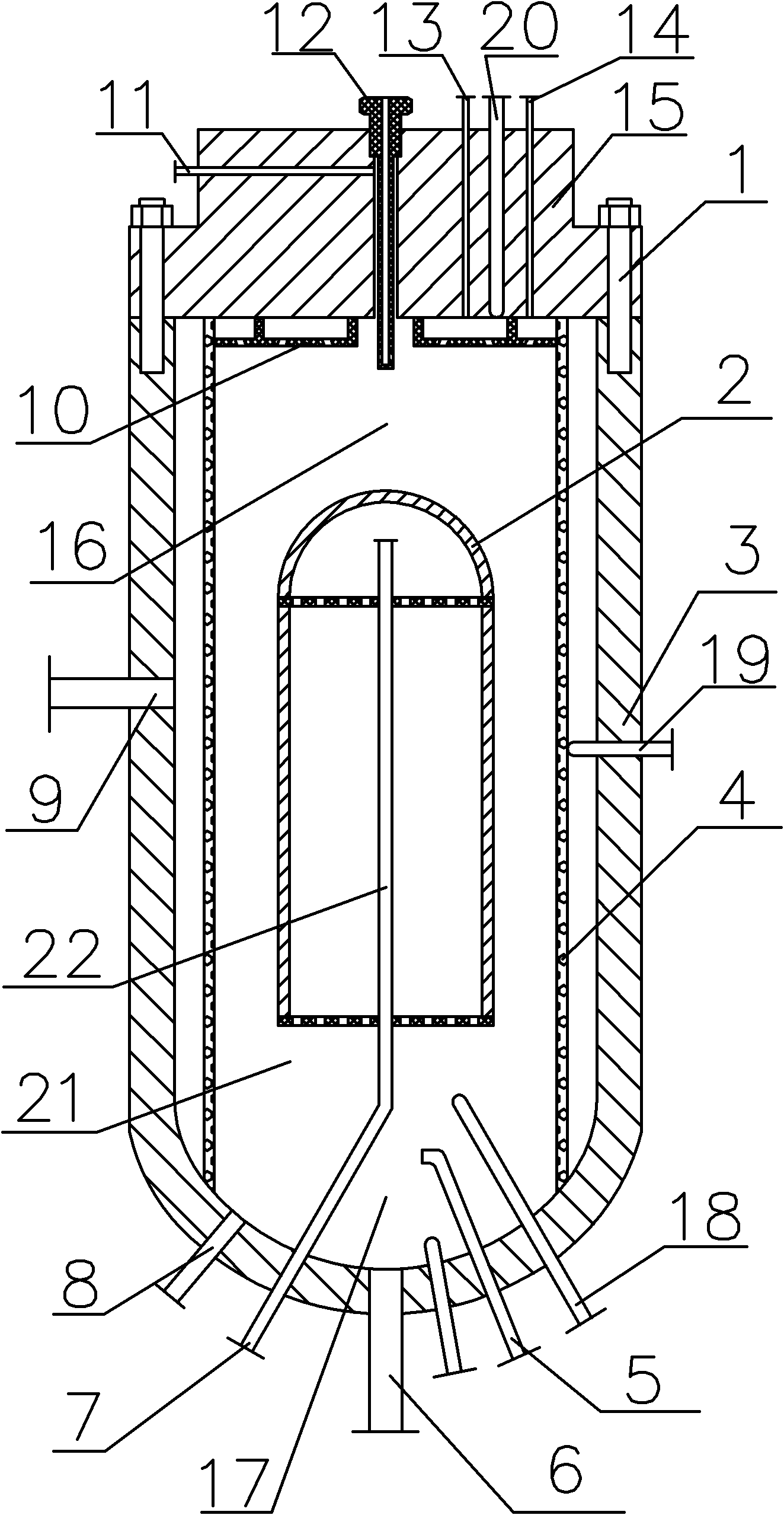

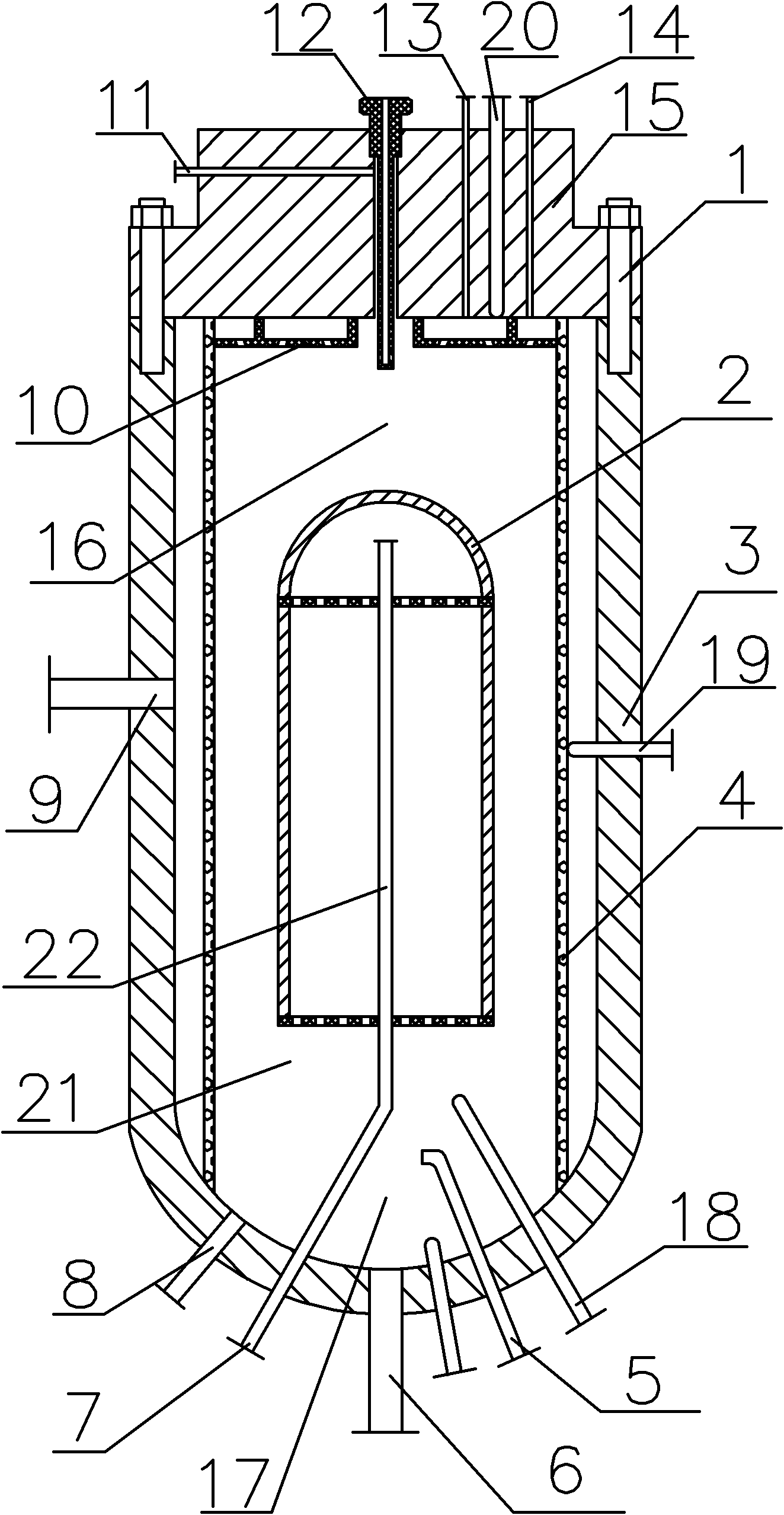

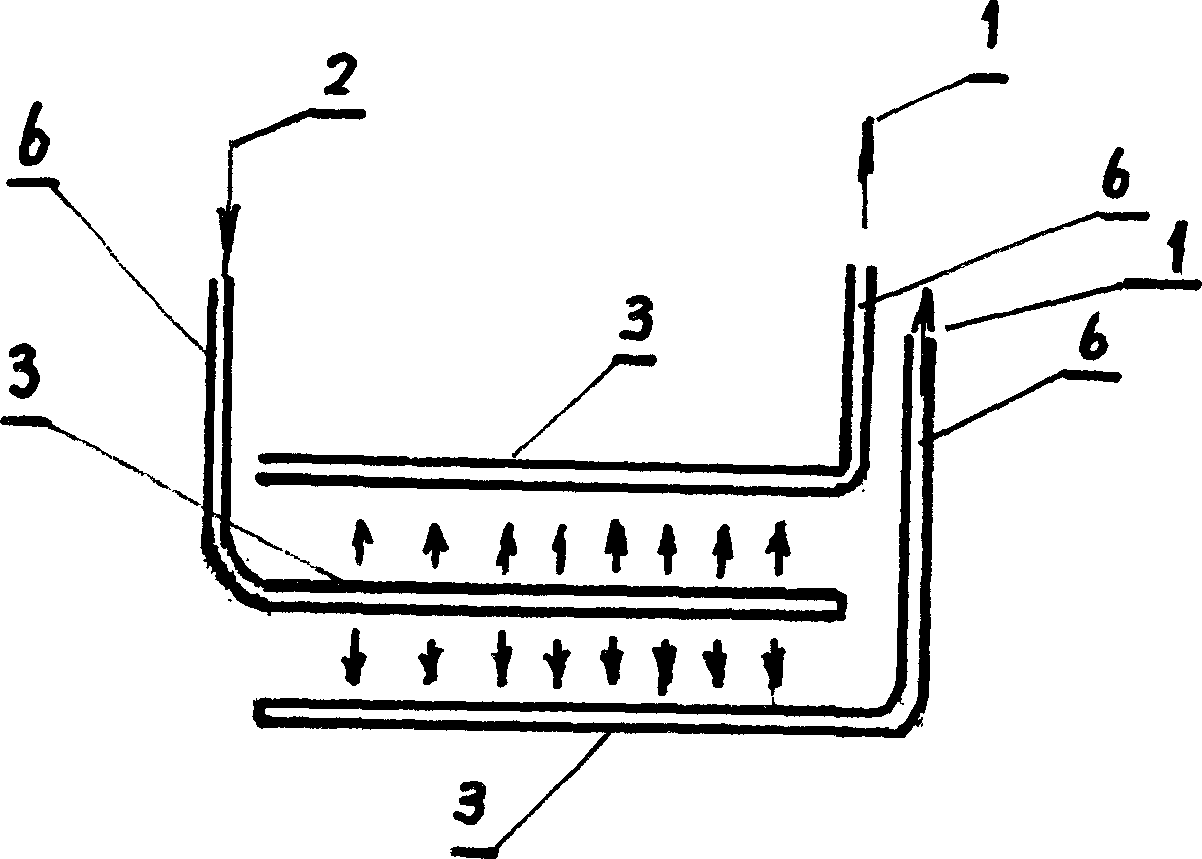

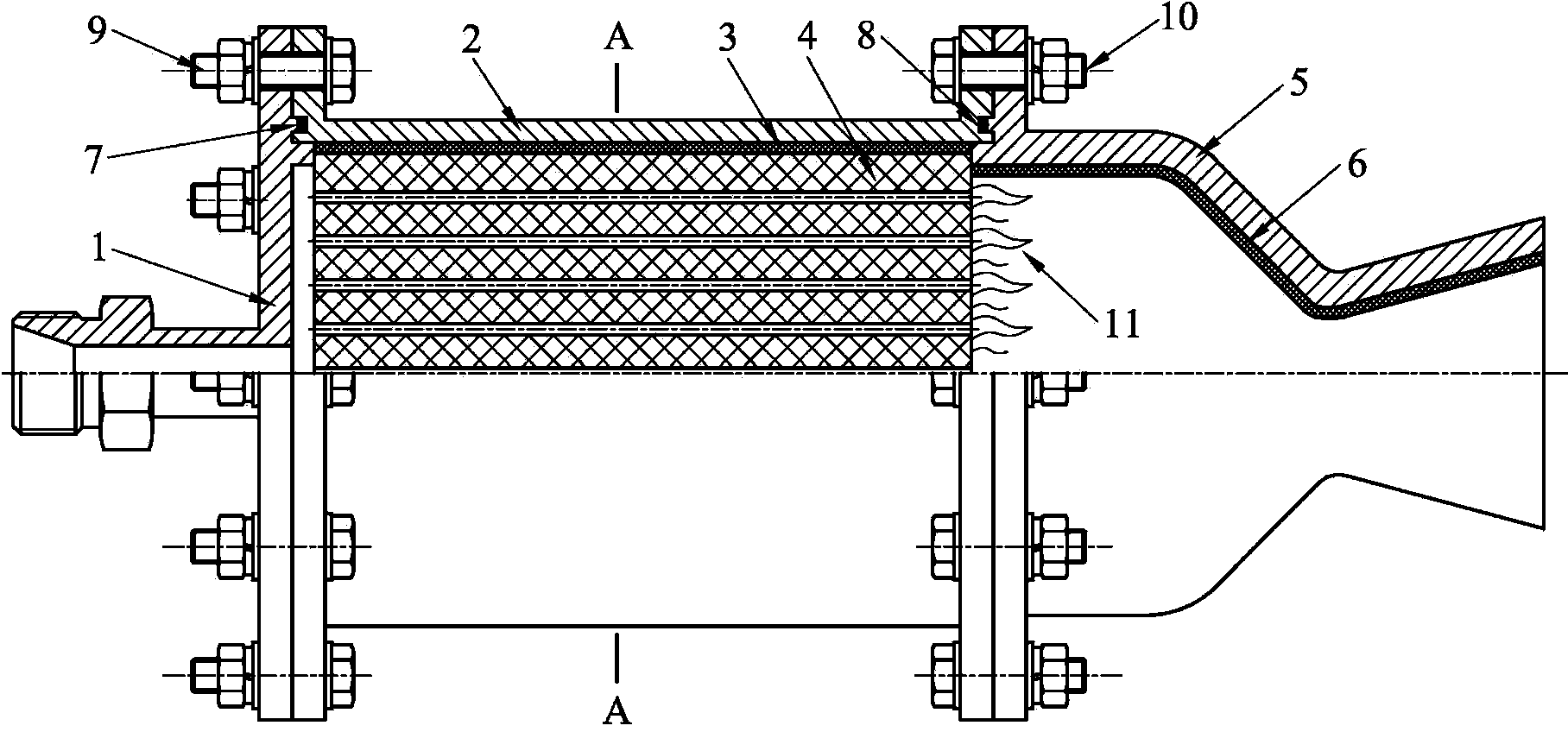

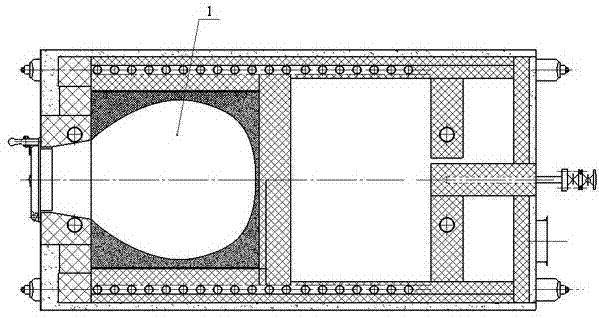

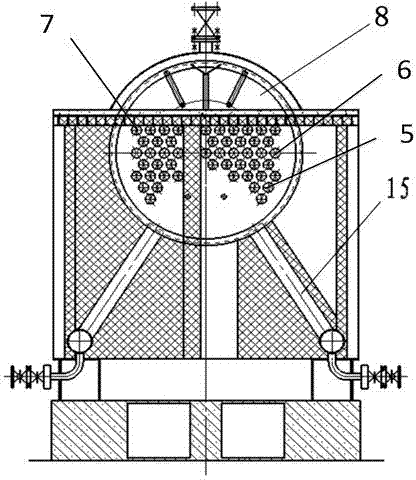

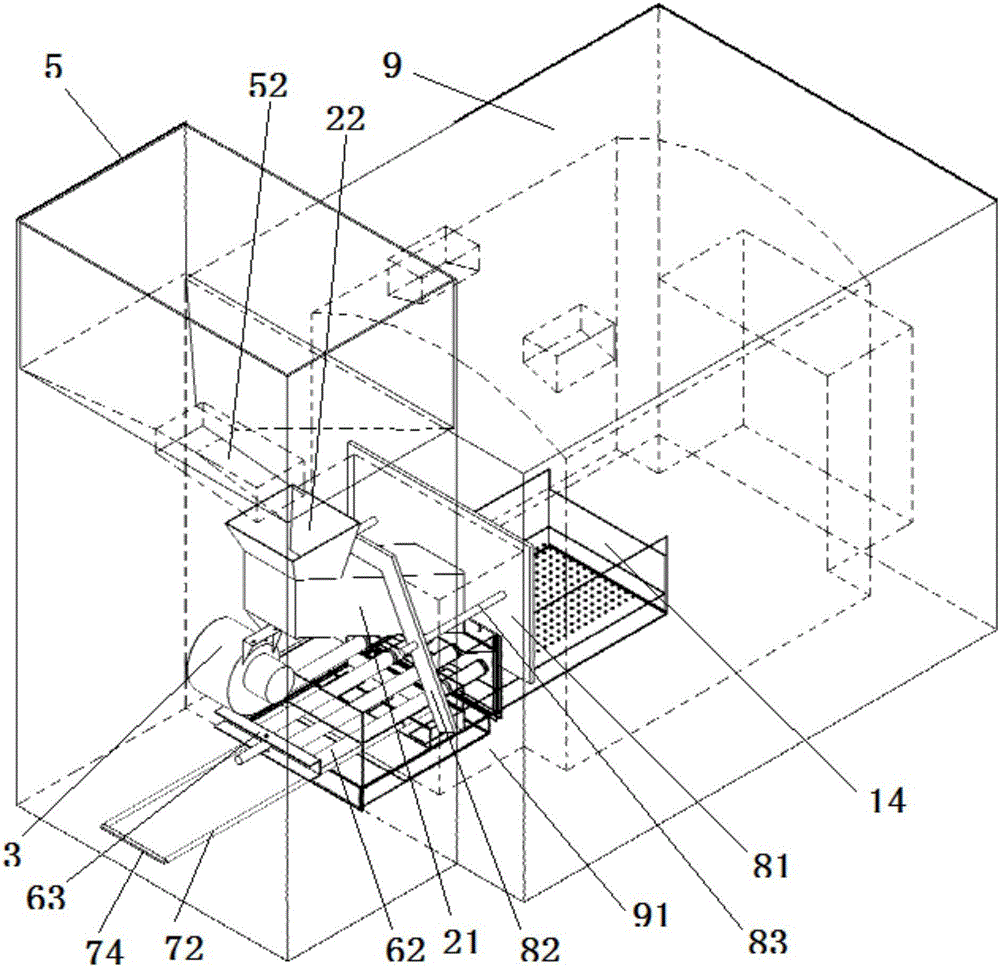

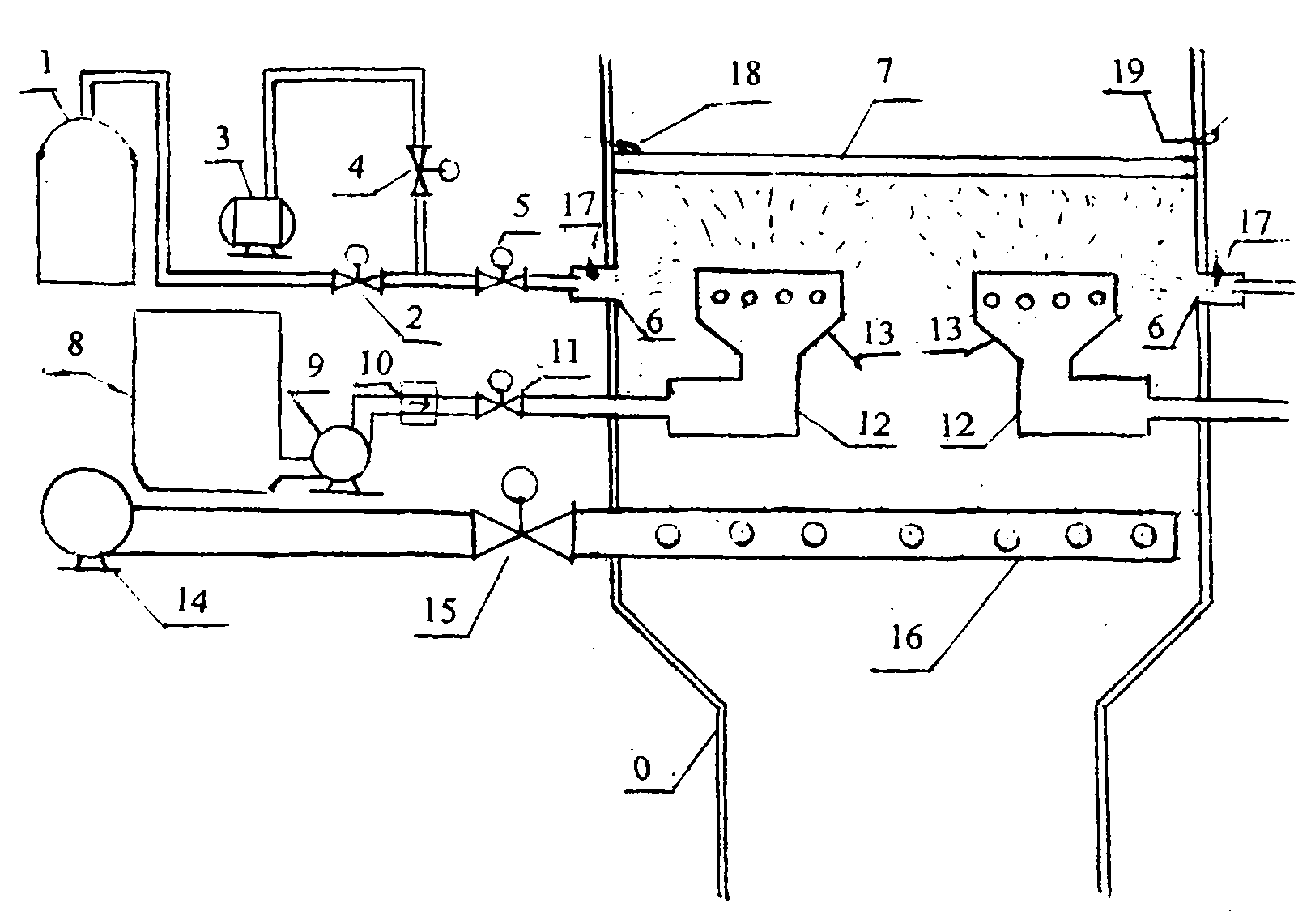

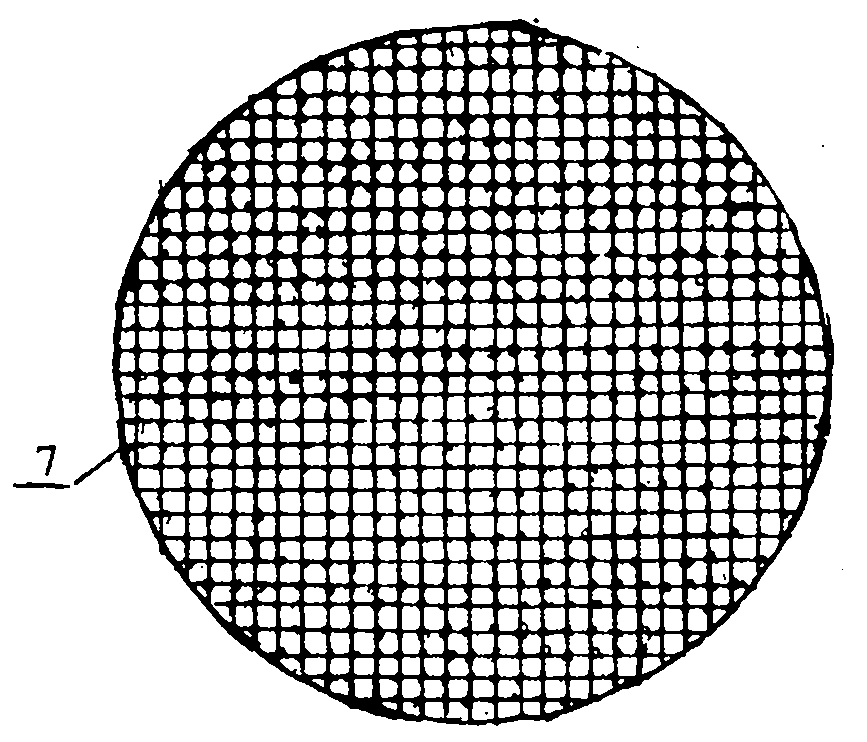

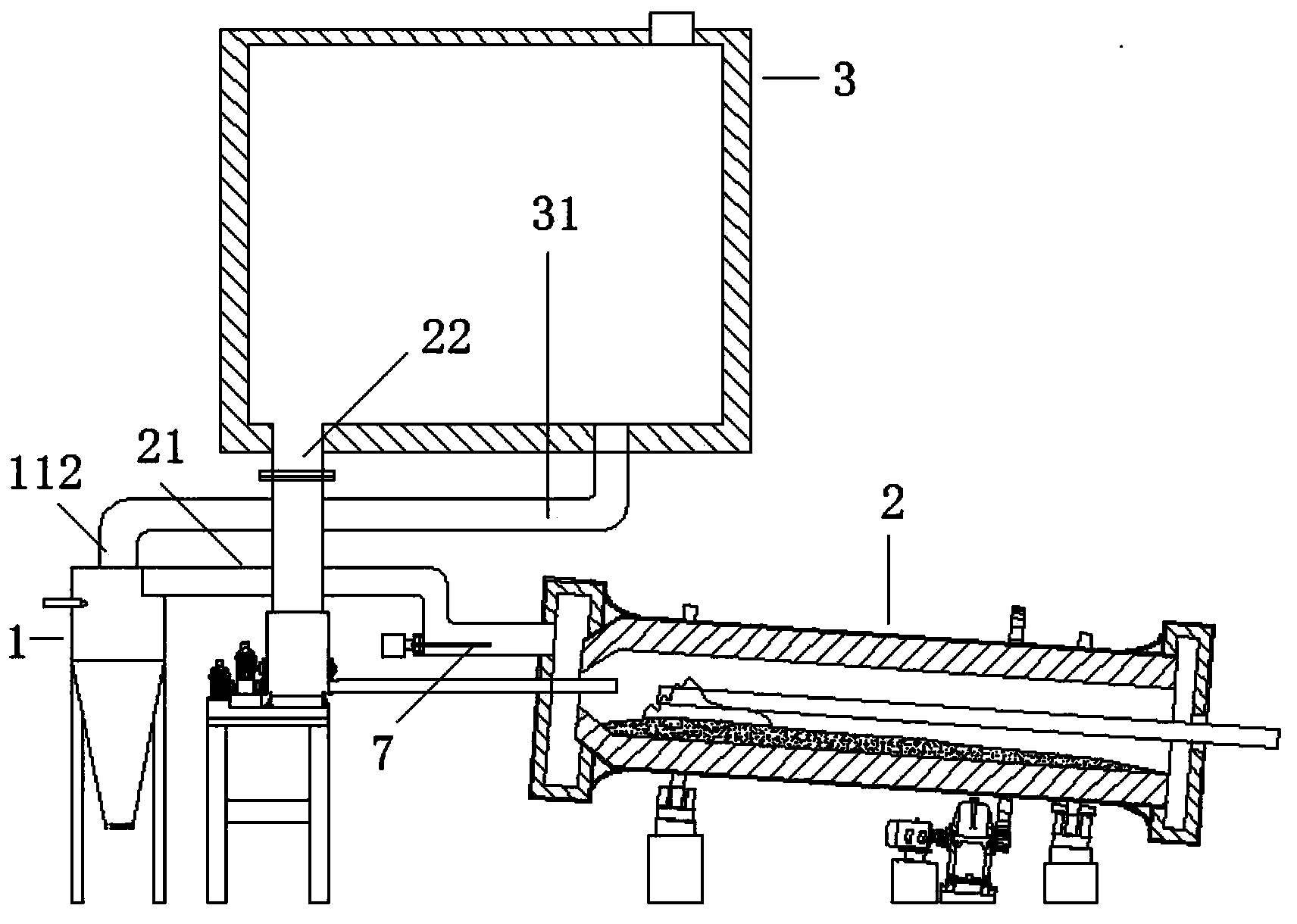

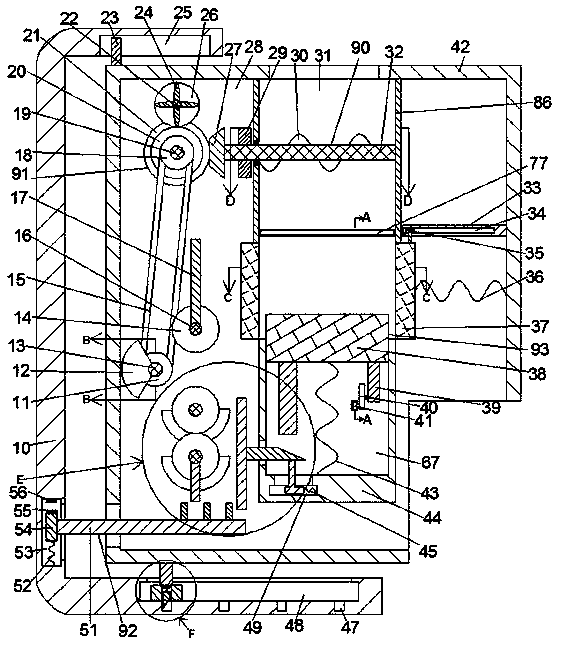

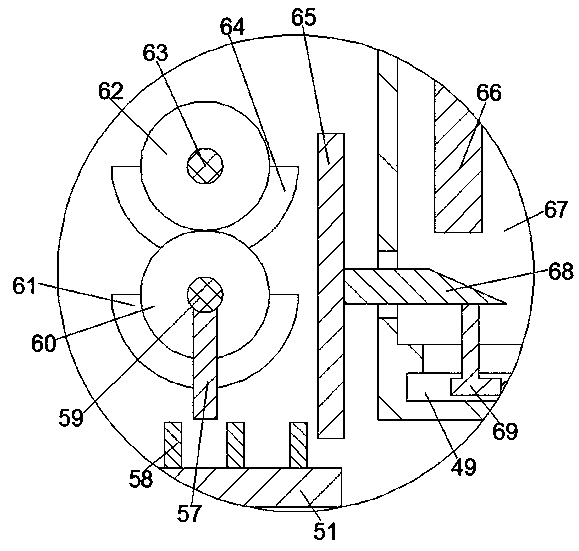

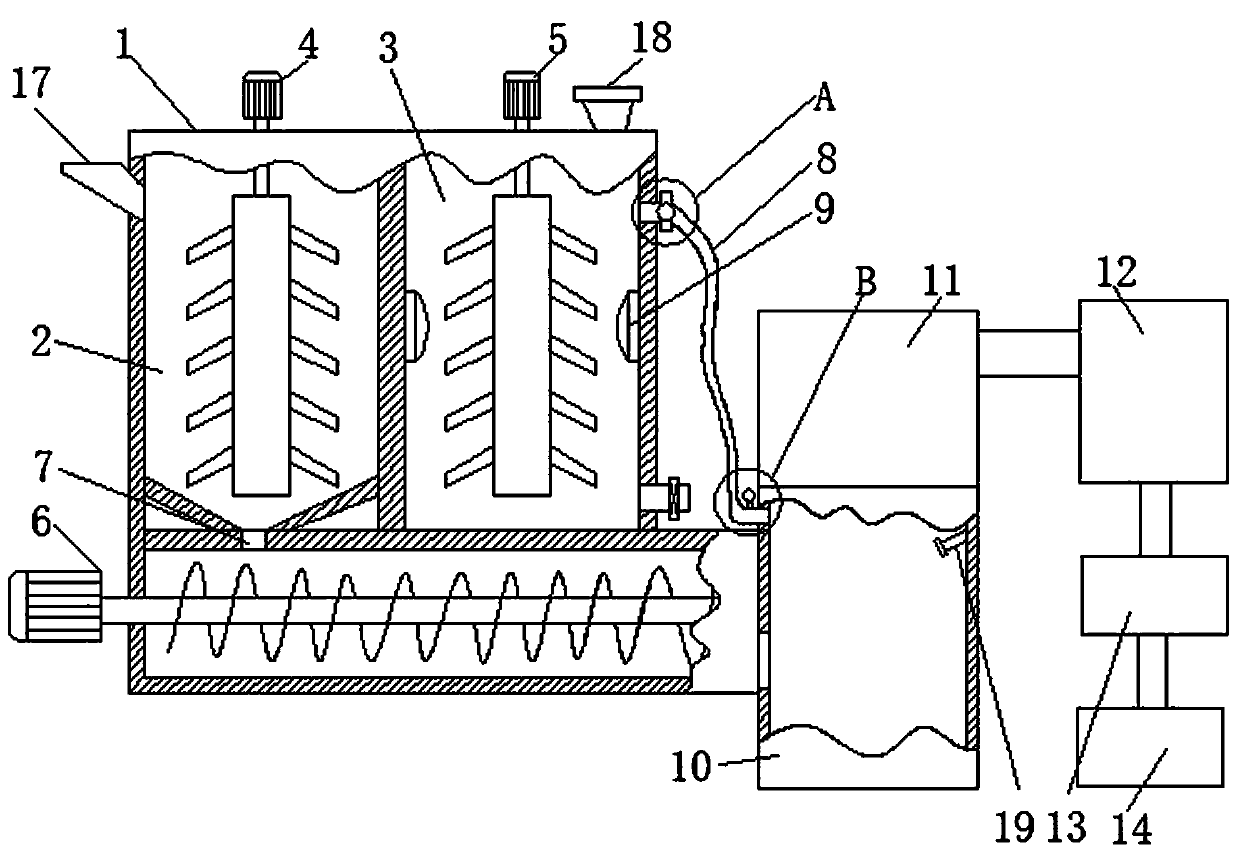

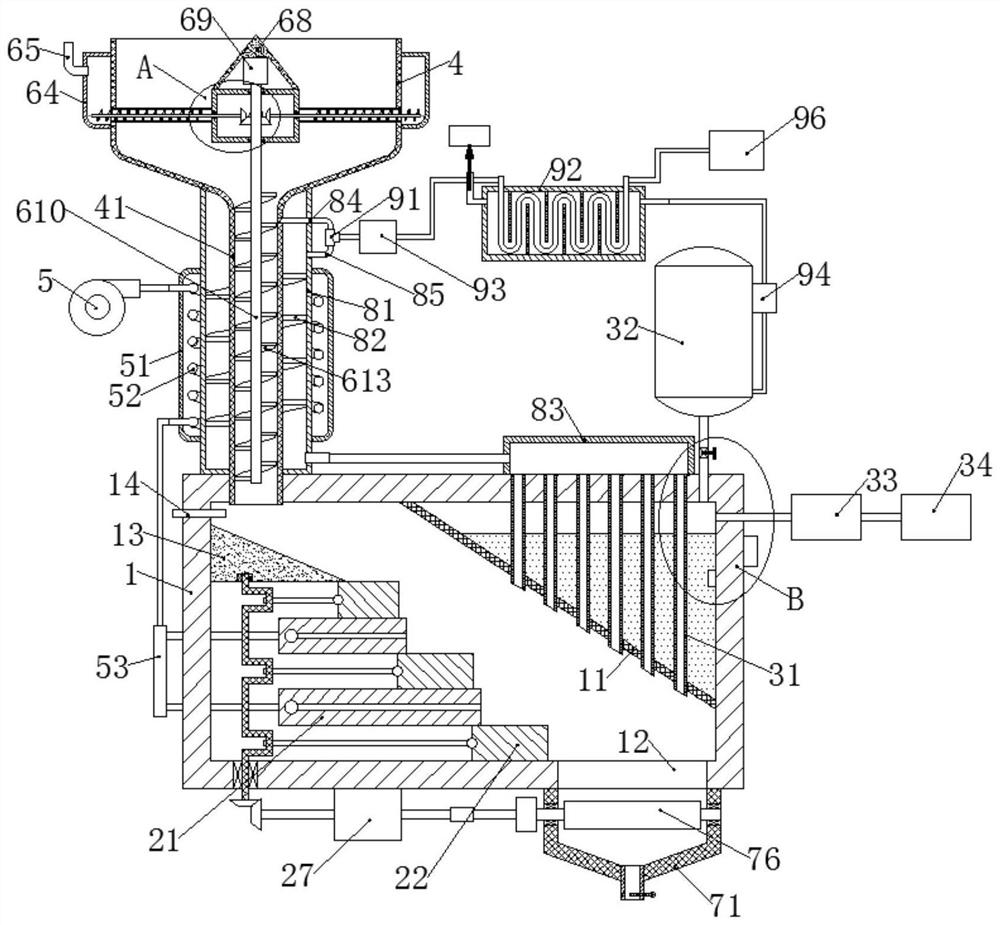

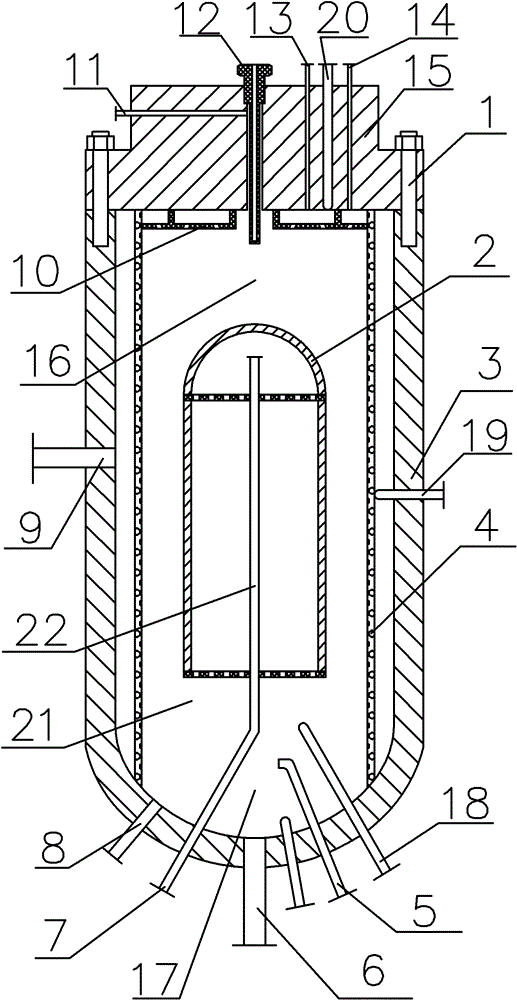

Supercritical water oxidation reactor by using auxiliary fuel for supplying heat

ActiveCN102190363AEfficient mixingEfficient combustionSludge treatmentWater/sewage treatment by oxidationNuclear engineeringOrganic fluid

The invention discloses a supercritical water oxidation reactor by using an auxiliary fuel for supplying heat, the heat required for a reaction can be supplied by using the auxiliary fuel, Material, fuel and an oxidizing agent (air or oxygen) are mixed with a high efficiency through the different directional jets for raising oxidation efficiency. According to the invention, the reactor employs a combination structure of evaporation wall and pot type backflow, the reaction vessel volume is effectively used and the reaction time is increased, the blockage problem generated by salt deposition can be also prevented, the corrosion problem of the reactor is effectively reduced. The temperature of the reactor bottom can be preciously controlled through a cooling water pipeline at the reactor bottom, thereby the safe operation of equipment is guaranteed. The reactor effectively solves the economic problem of a supercritical water reaction system by using the auxiliary fuel for supplying, the invention has the advantage of easy industrial amplification, and is widely applied to organic liquid such as high density and difficult biodegradation organic waste water / garbage leachate and the like for a harmlessness processing.

Owner:XI AN JIAOTONG UNIV

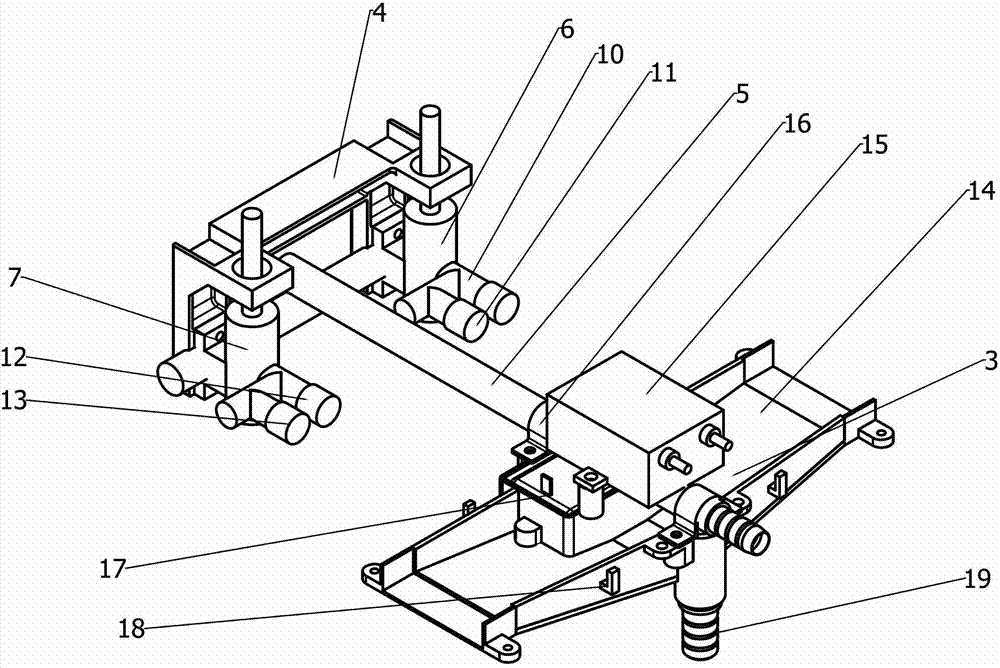

Deep low penetrating oil layer thin oil fire flooding horizontal well gas-injection horizontal well oil production process technology

The present invention relates to a deep-layer low-permeability oil reservoir thin oil combustion drive horizontal well air injection horizontal well oil production technique. It is characterized by that said invention utilizes the heat quantity produced in air injection horizontal well section as firing drive oil reservoir and transfers the heat quantity into the horizontal oil-producing wells distributed at two sides of the air injection horizontal well section so as to make the thin oil be recovered from the oil-producing wells.

Owner:尤尼斯油气技术(中国)有限公司

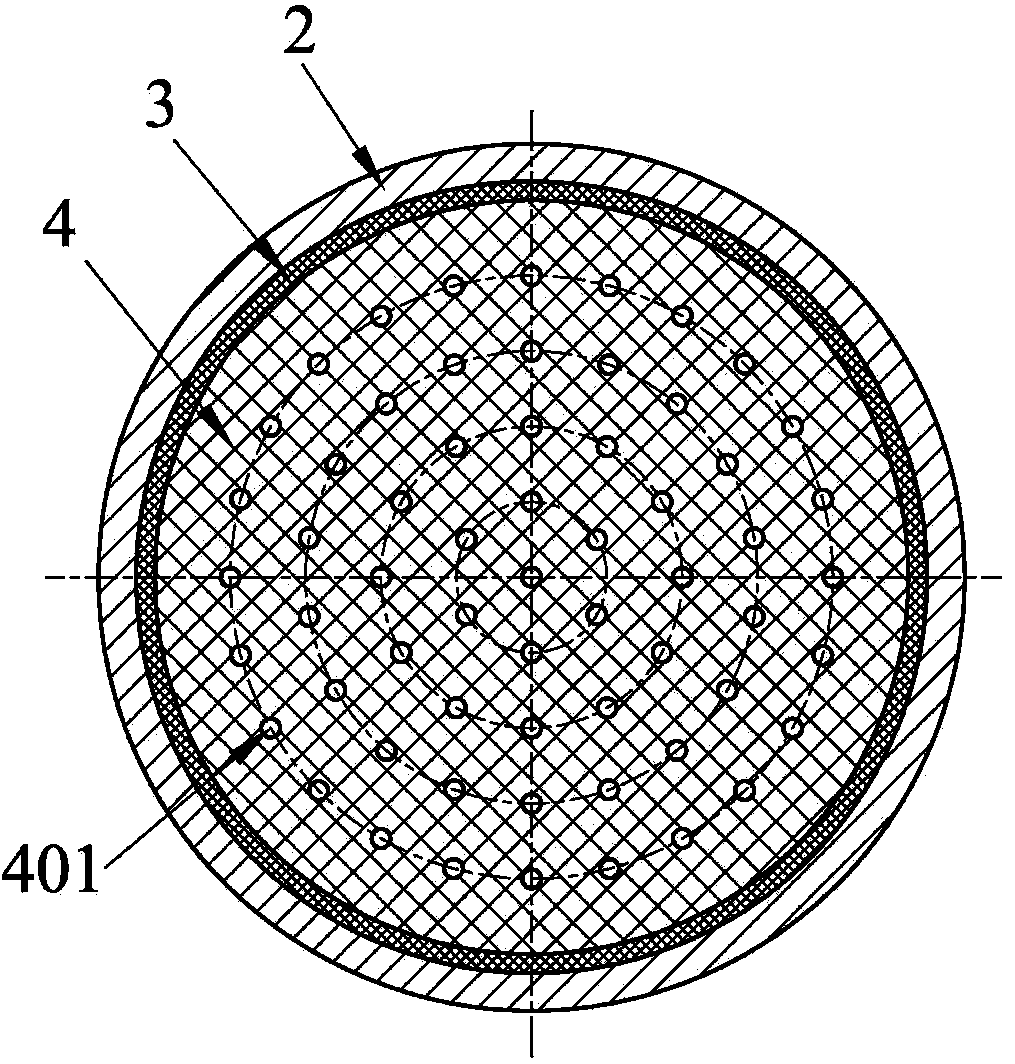

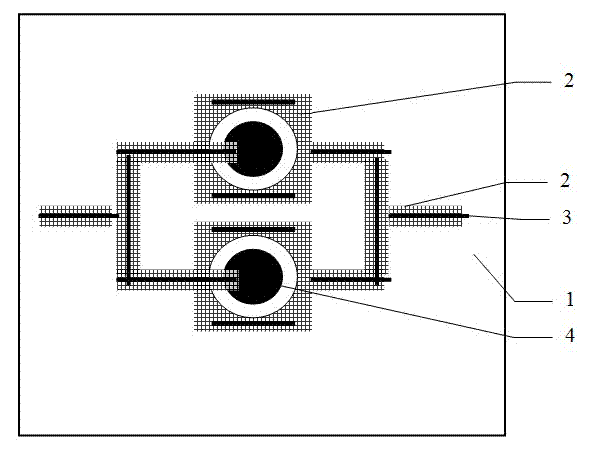

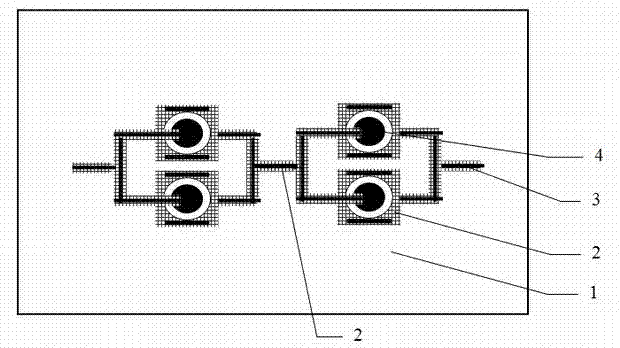

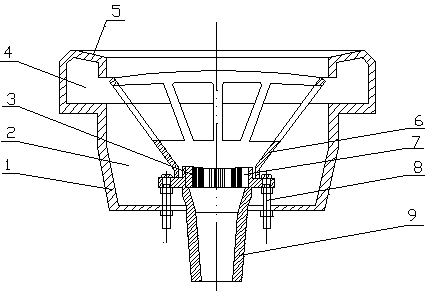

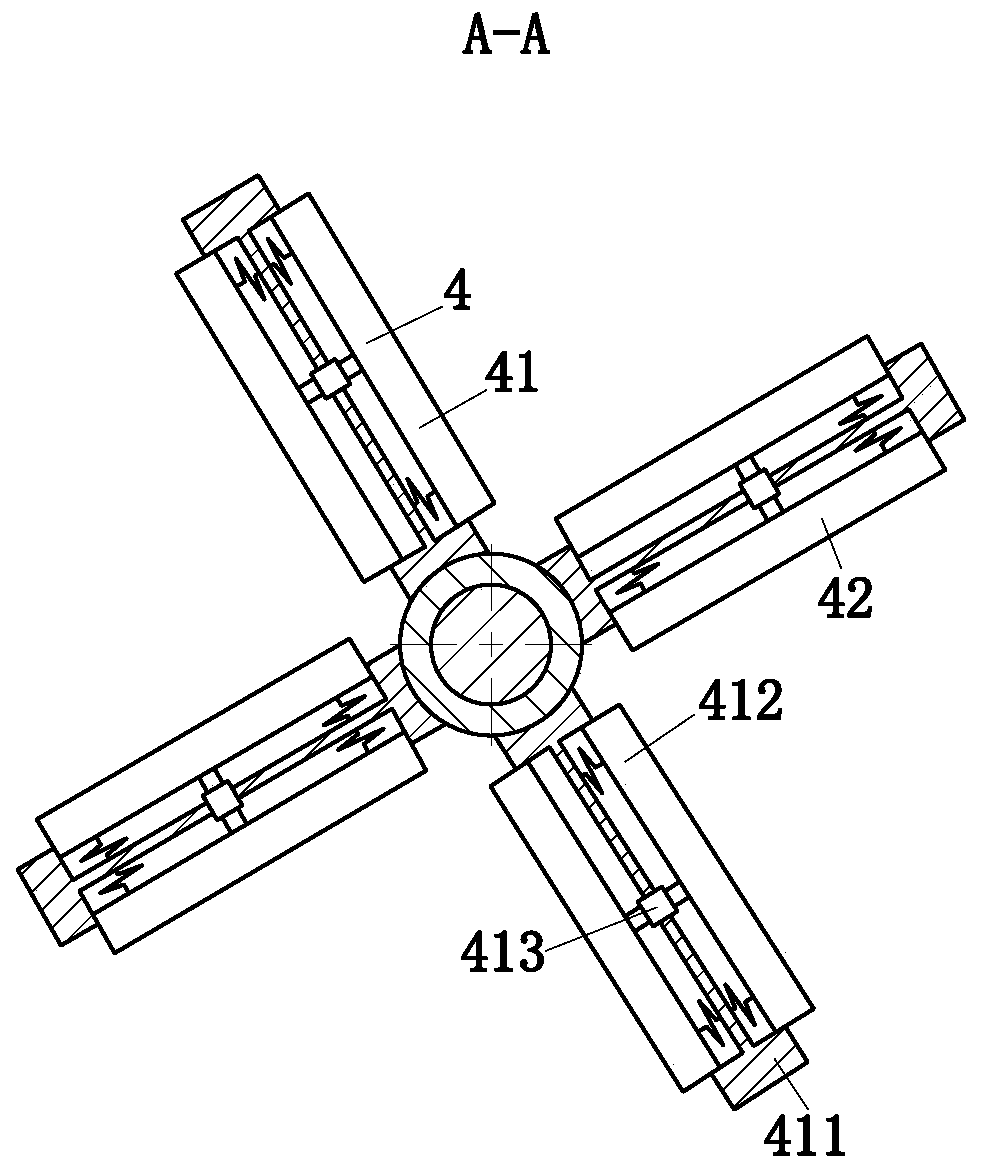

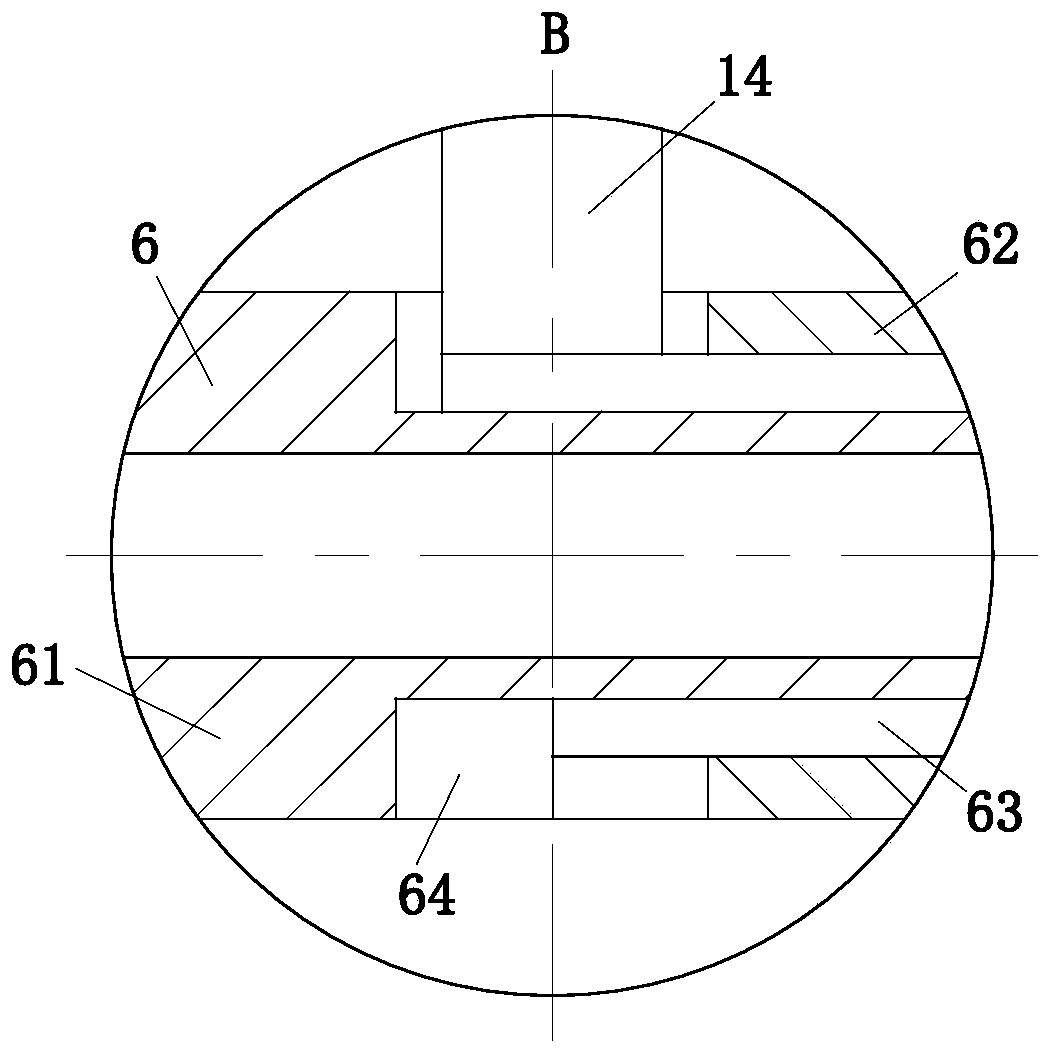

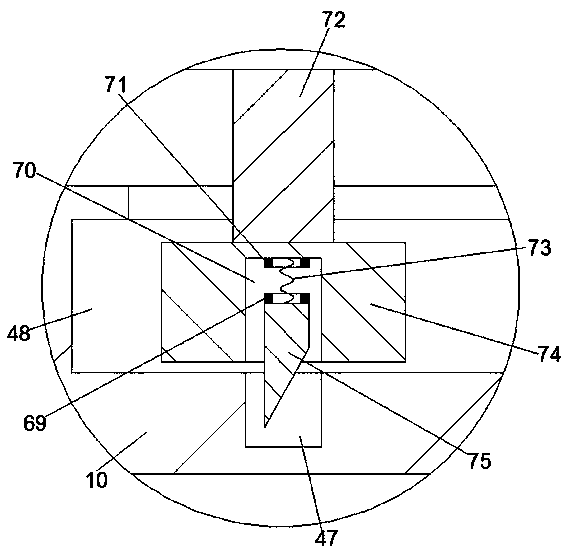

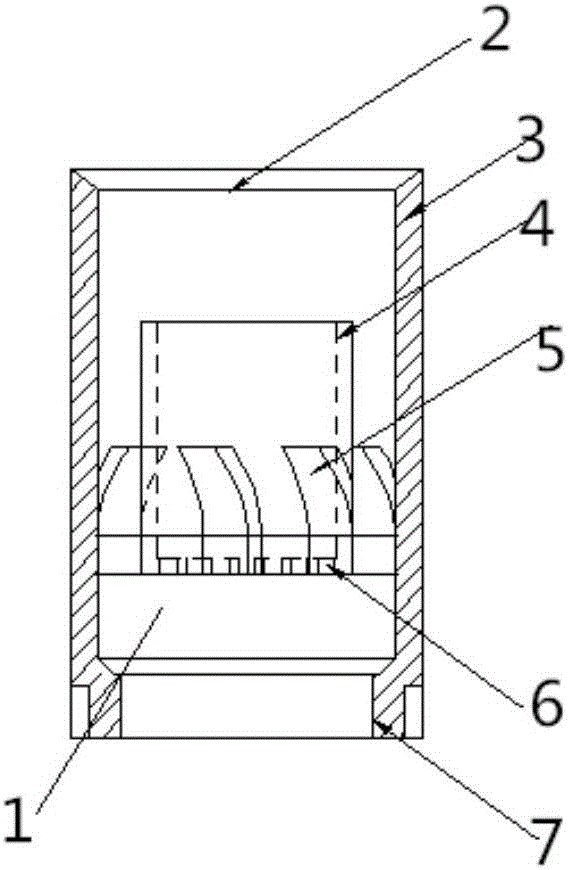

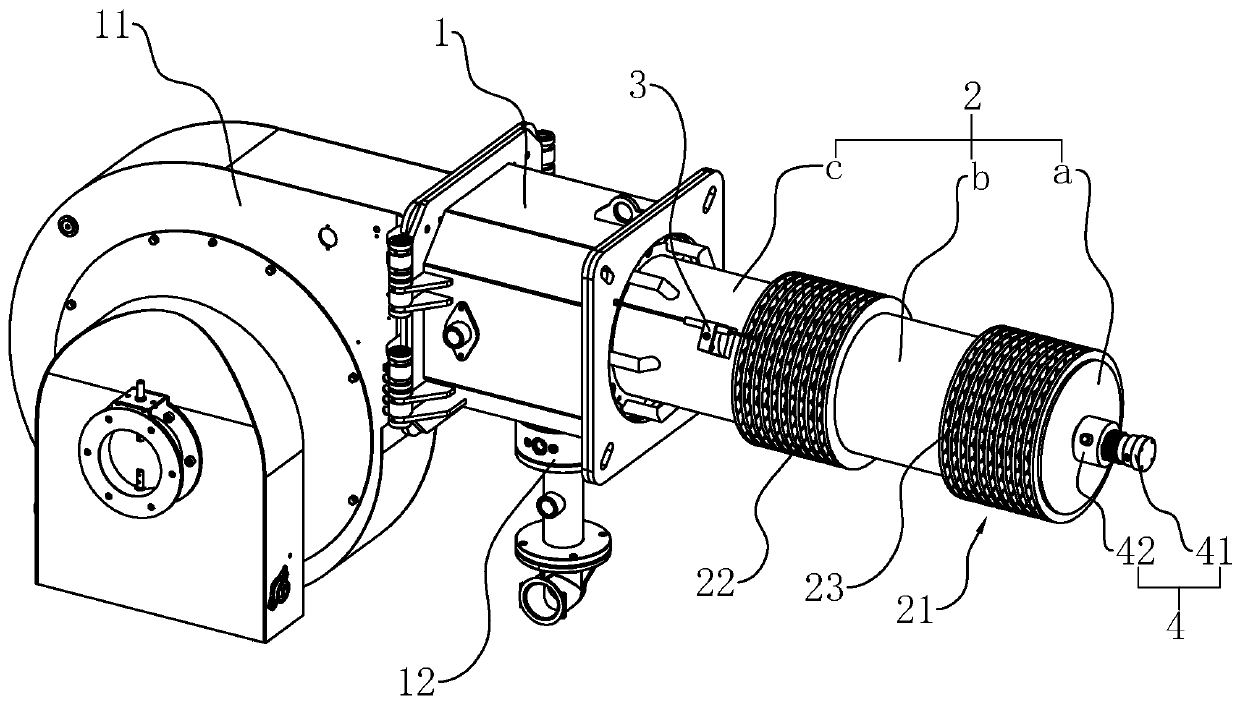

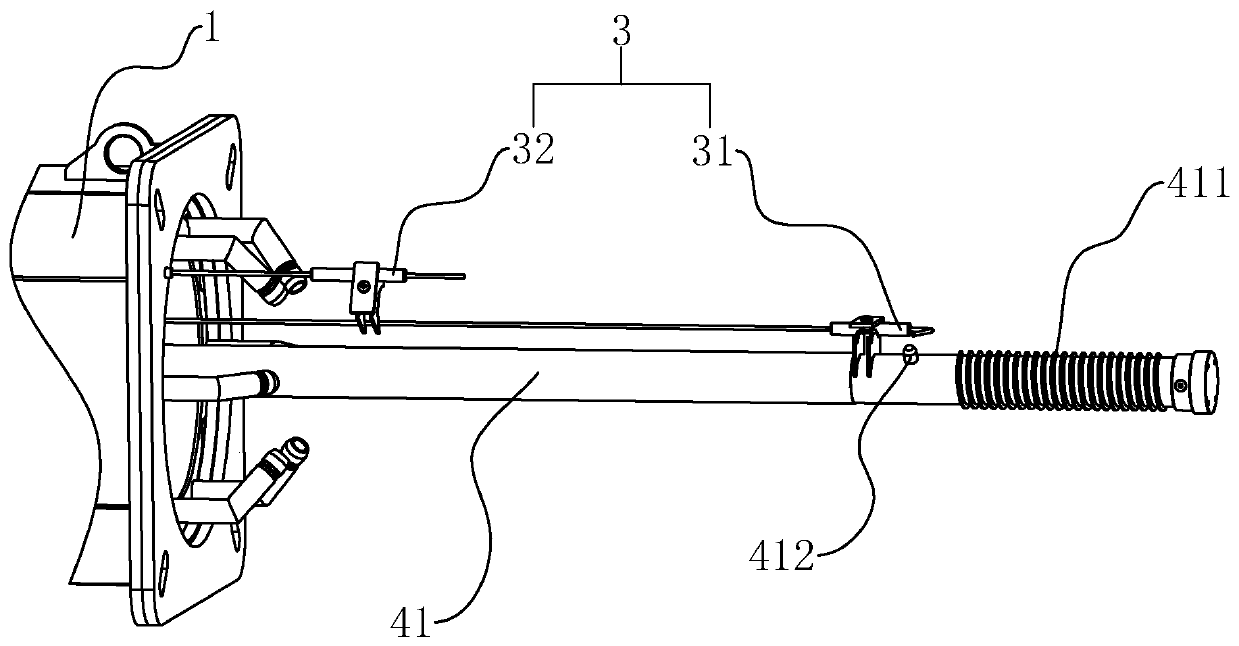

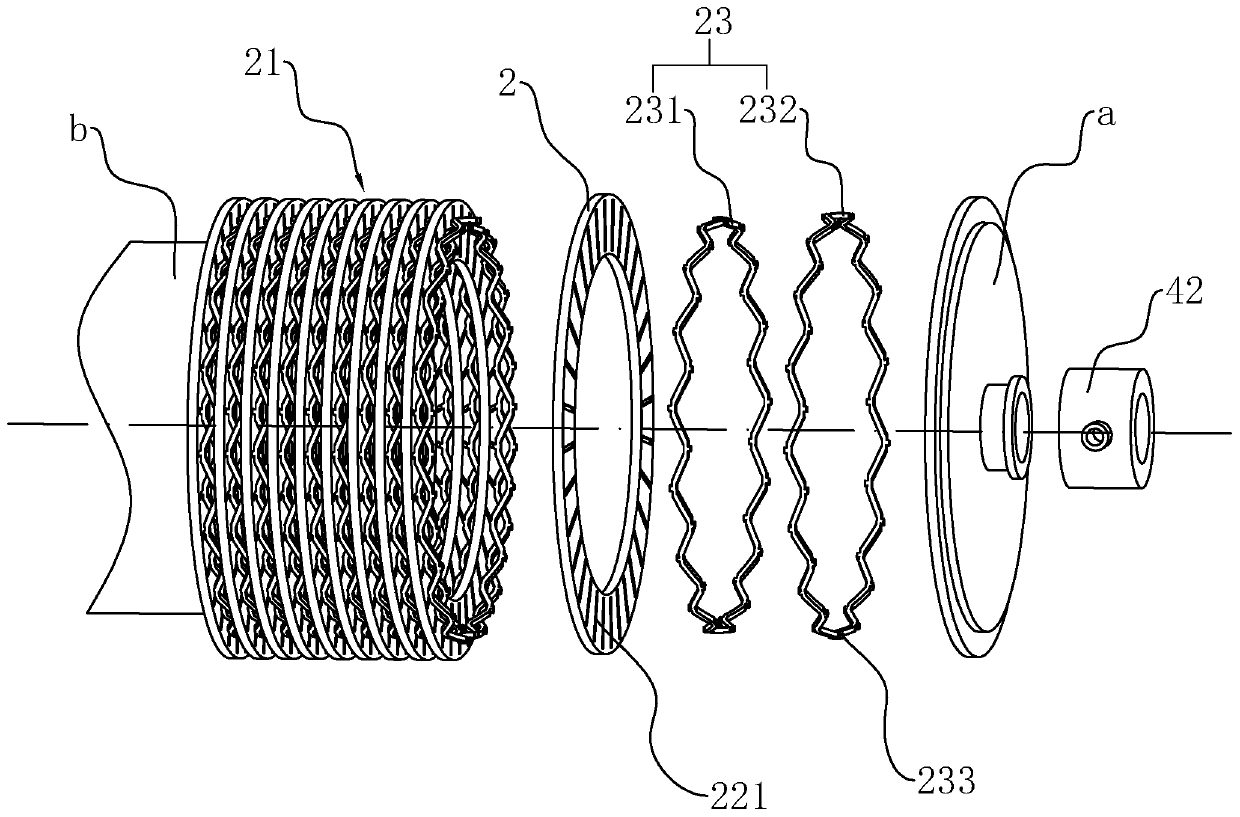

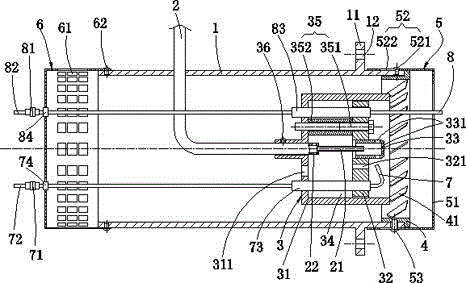

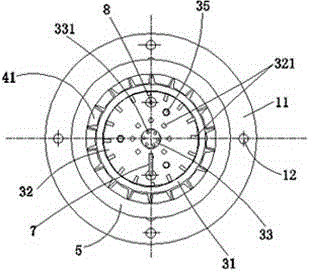

Axial injection end combustion solid-liquid rocket engine structure

ActiveCN103967653AMaintain a constant burning areaMaintain a constant oxygen-fuel ratioRocket engine plantsInlet channelCombustion

The invention discloses an axial injection end combustion solid-liquid rocket engine structure which comprises an engine head cover, a solid propellant shell, a solid propellant heat insulating layer, end combustion solid propellants, a spray pipe shell and a spray pipe heat insulating layer. The engine head cover is mounted at the front end of the solid propellant shell, the spray pipe shell is mounted at the rear end of the solid propellant shell, the engine head cover is provided with an air inlet channel, the end combustion solid propellants are coaxially arranged in the solid propellant shell, a constant volume cavity is formed between the front end faces of the end combustion solid propellants and the rear end face of the engine head cover, each end combustion solid propellant is provided with a plurality of axial injection holes with small diameters, the flow rate of oxidizing agents in the injection holes is high, and combustion reaction only occurs at the end faces of the end combustion solid propellants; the joint between the solid propellant shell and the engine head cover and the joint between the solid propellant shell and the spray pipe shell are respectively provided with a sealing structure, so that air impermeability of an engine is guaranteed; the heat insulating layers are arranged in the solid propellant shell and the spray pipe shell, so that thermal protection performance of the engine during operation is guaranteed. Thus, performance of the engine is improved, meanwhile the filling fraction of the engine is improved, the slenderness ratio of the engine is reduced, and the application rage of engine is widened.

Owner:BEIHANG UNIV

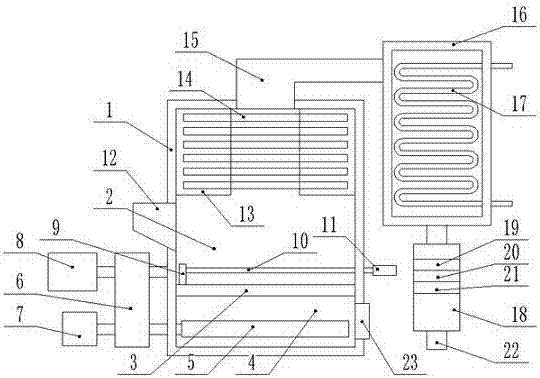

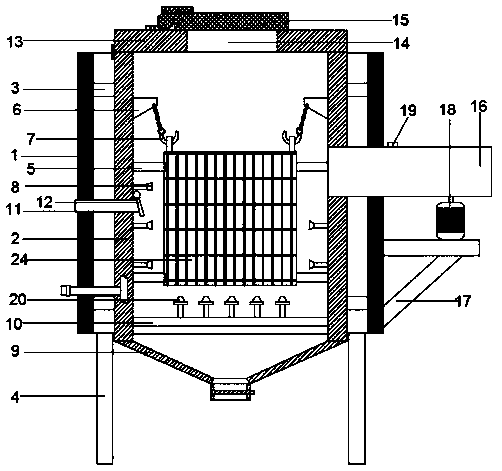

Energy-saving and environment-friendly boiler with preheating function

InactiveCN107421116AIncrease the burning areaBurn fullyCombustion processIndirect carbon-dioxide mitigationCombustionBoiler slag

The invention discloses an energy-saving and environment-friendly boiler with a preheating function. The energy-saving and environment-friendly boiler comprises a shell, a grate, a boiler slag collection trough, a circulating pump and a fan. A vertical material uniformization plate is arranged on the upper surface of the grate. A material passing opening penetrating the two sides is formed in the material uniformization plate. A heat absorption pipe is arranged in the boiler slag collection trough and is located at the bottom of the boiler slag collection trough, and the outer end of the heat absorption pipe communicates with a heat exchanger. Multiple heat conduction columns are horizontally inserted into a water jacket. The other end of a smoke discharging pipe communicates with a waste heat collection box. A heat exchange coiled pipe is mounted in the waste heat collection box. The bottom of the waste heat collection box communicates with a purification box. According to the energy-saving and environment-friendly boiler, the arranged material uniformization plate moves to uniformly pave dye, the combustion area of fuel is large, and contact of the fuel and air is sufficient; and heat in smoke is absorbed by the heat exchange coiled pipe and used for preheating inner heating water, the water temperature increase speed is increased, and the heating efficiency of hot water in the boiler is guaranteed.

Owner:YANCHENG CITY LONG XIANG MACHINERY MFG PLANT

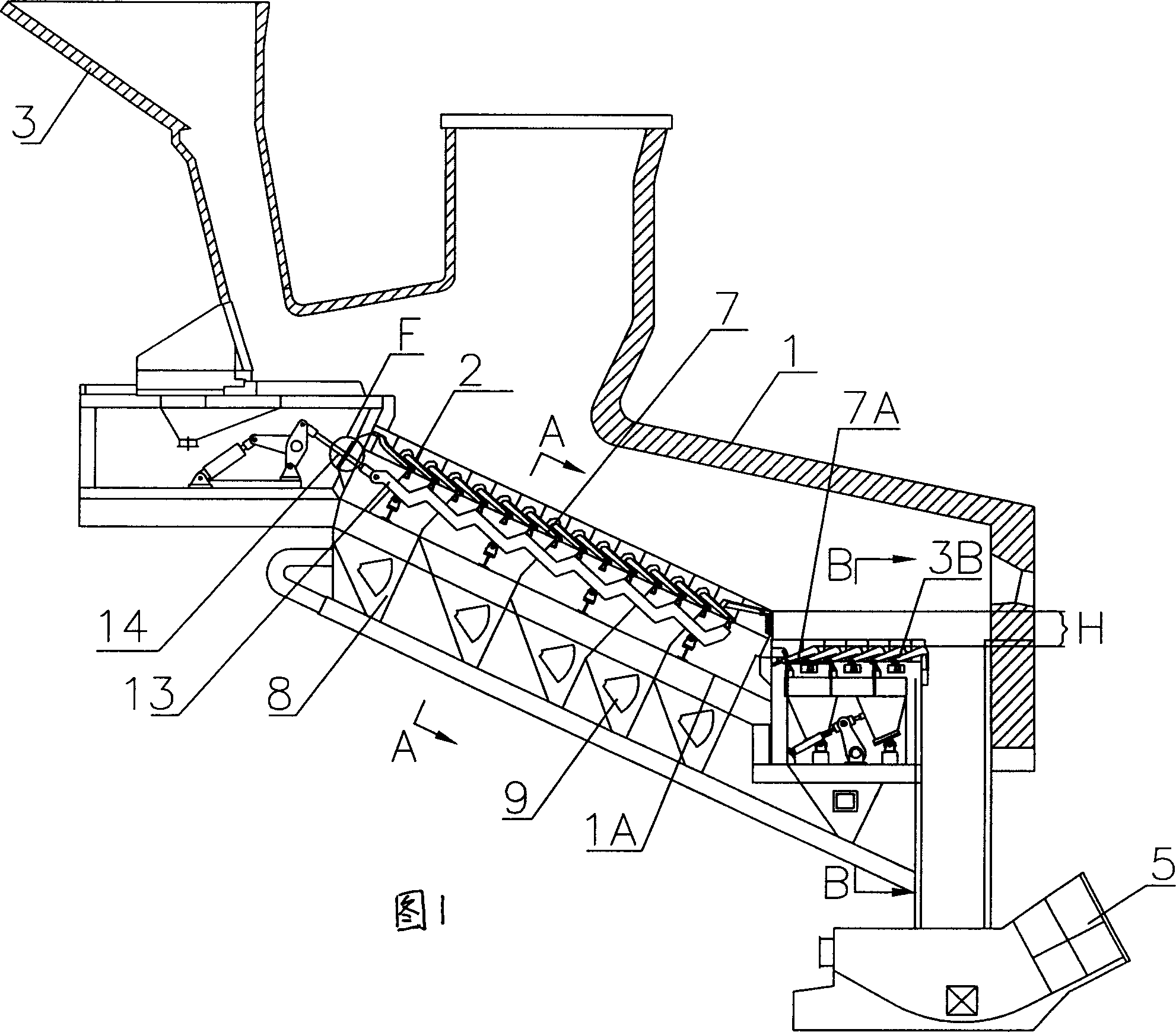

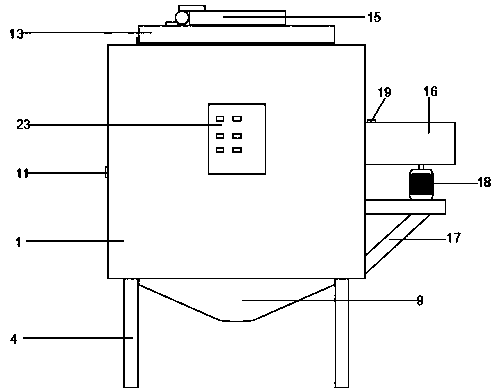

Reciprocating multi-row grate type domestic refuse incinerator

ActiveCN1763429AIncrease in number of columnsAchieve individual controlIncinerator apparatusCombustionAir volume

The invention discloses a domestic refuse incinerator of reciprocal multirow stoker, which comprises the following parts: furnace, stoker rack on the furnace, stoker on the stoker rack, wind room under the stoker, wherein each stoker contains fixing stoker plate, moving stoker plate and moving stoker plate driving system; the moving stoker plate is arranged between two fixing stoker plates with certain gap; the stoker rack contains at least three rows of stoker; the middle closed supplementary device is set on the lateral end of middle stoker in the stokers; multiple groups of separating room is set under the stoker according to the combustion region section along the rubbish moving direction; each separating room contains the same amount as stoker row number to correspond one by one, which concludes ventilator within wind door to adjust air quantity in connection with wind room.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

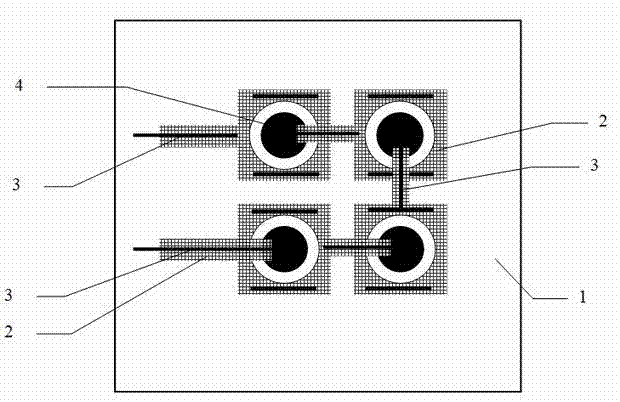

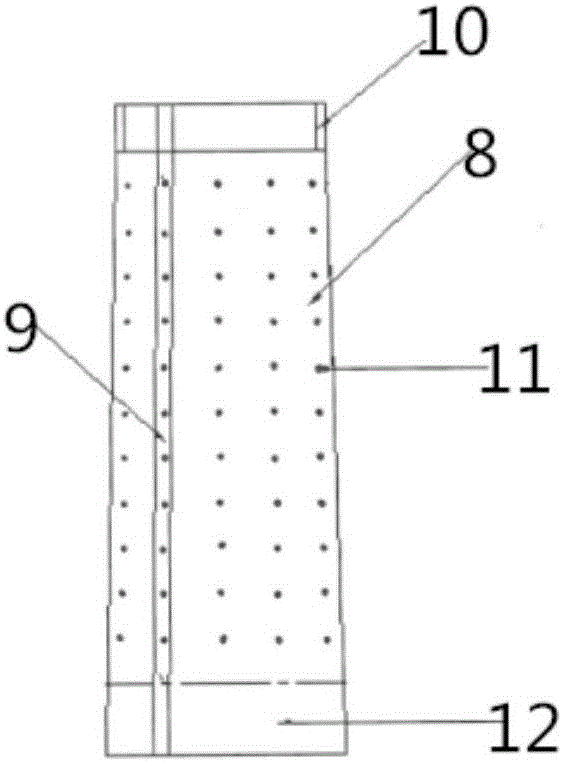

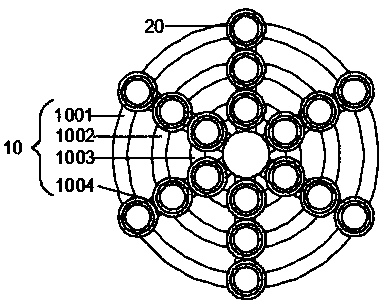

Direct flame type solid oxide fuel battery pack and preparation method thereof

InactiveCN101820075AImprove performanceIncrease the burning areaFuel cells groupingFinal product manufactureThermal energyFuel cells

The invention discloses a direct flame type solid oxide fuel battery pack and a preparation method thereof, and belongs to the field of electrochemical power generation. The preparation method solves the problems that the preparation process of the traditional direct flame type solid oxide fuel battery pack is complex and has high cost. A plurality of holes are arrayed on a heat-resisting insulating thin plate supporter; a conducting net is covered on each hole; a single battery is adhered to the upper surface of each conducting net; a plurality of single batteries are connected in series, in parallel or in series and parallel through leads to form the battery pack; and the cathode and the anode of the battery pack are led out by the leads. The preparation method comprises the following steps of: digging the plurality of holes on the heat-resisting insulating thin plate supporter and covering the conducting net on each hole; adhering the single battery to the upper surface of each conducting net by using conducting slurry and performing heat treatment to cure and stabilize the single battery at the temperature of between 50 and 500 DEG C; and connecting the plurality of single batteries in series, in parallel or in series and parallel through the leads to form the battery pack, and leading the cathode and the anode of the battery pack out through the leads. The direct flame type solid oxide fuel battery pack of the invention is used for providing electric energy and heat energy.

Owner:HARBIN INST OF TECH

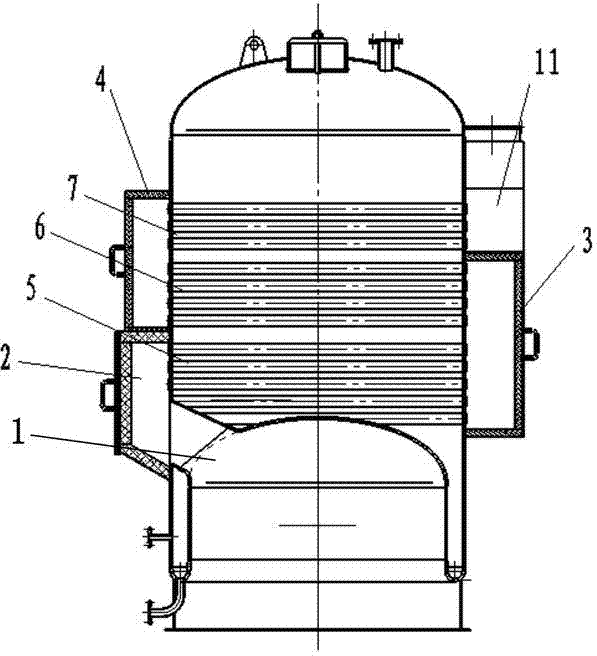

Energy-efficient steam boiler

InactiveCN103486564AHigh heat conversion efficiencyIncrease the heating areaSteam boilersCombustion chamberEngineering

The invention discloses an energy-efficient steam boiler, which belongs to boiler technical field. The energy-efficient steam boiler comprises a boiler body, a furnace body and a chimney. A multi-flue return folded structure is arranged in the boiler body, down pipe is arranged on the lower part of the drum, which is connected with the drum; the cross section of the firebox is oval, which is provided with injected screw feeder whose discharge port inclines upwardly to connect with inlet of firebox. The energy-efficient steam boiler has advantages of high combustion efficiency and heat utilization efficiency, good heat transition effects, easy operation and maintenance.

Owner:GUANGXI SKYRANINBOW BOILER

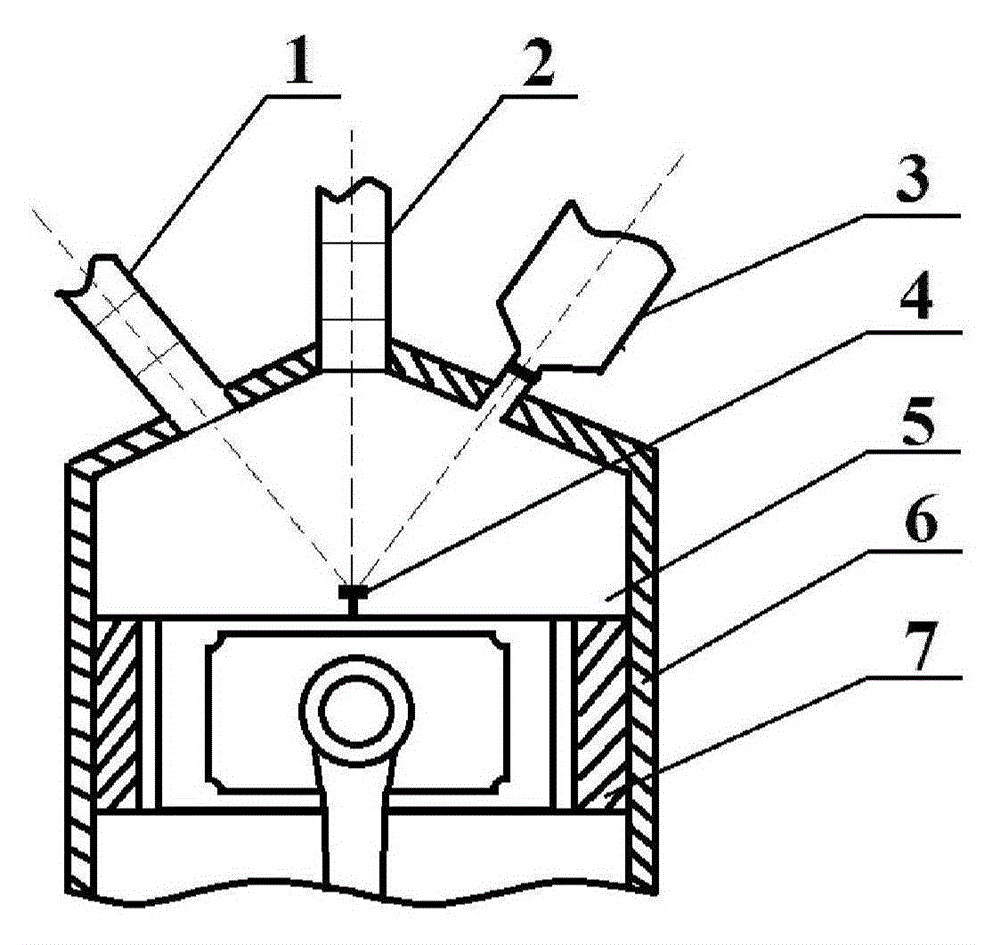

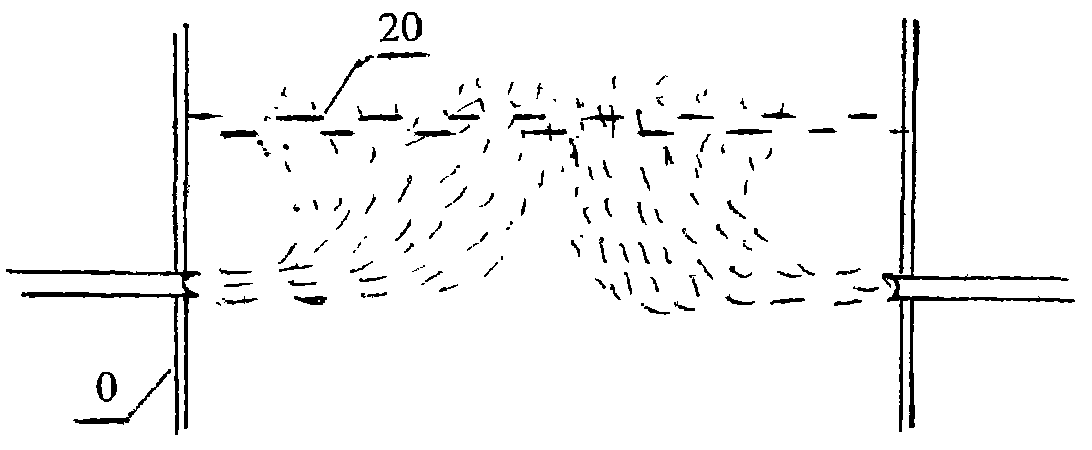

Device and method for ignition through dual-mode lasers in target portion breakdown manner

ActiveCN105134452AFast ignitionImprove combustion efficiencyMachines/enginesEngine ignitionCombustion chamberDual mode

The invention provides a device and method for ignition by plasma sparks generated through continuous and pulsed dual-mode lasers in a target portion breakdown manner. The device is mainly provided with a pulsed laser transmitting end, a continuous laser transmitting end, a fuel injection device, a target portion, a combustion chamber, a cylinder cover, a piston and the like. The laser transmitting end does not stretch into the combustion chamber. According to the device and method for ignition through the continuous and pulsed dual-mode lasers in the target portion breakdown manner, the plasma sparks can always be reliably generated to ignite a fuel-air mixture in the combustion chamber; and the ignition speed can be effectively increased, the ignition adjusting difficulty is lowered, ignition reliability is improved, the combustion area is increased, combustion efficiency can be improved, and fuel can be saved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

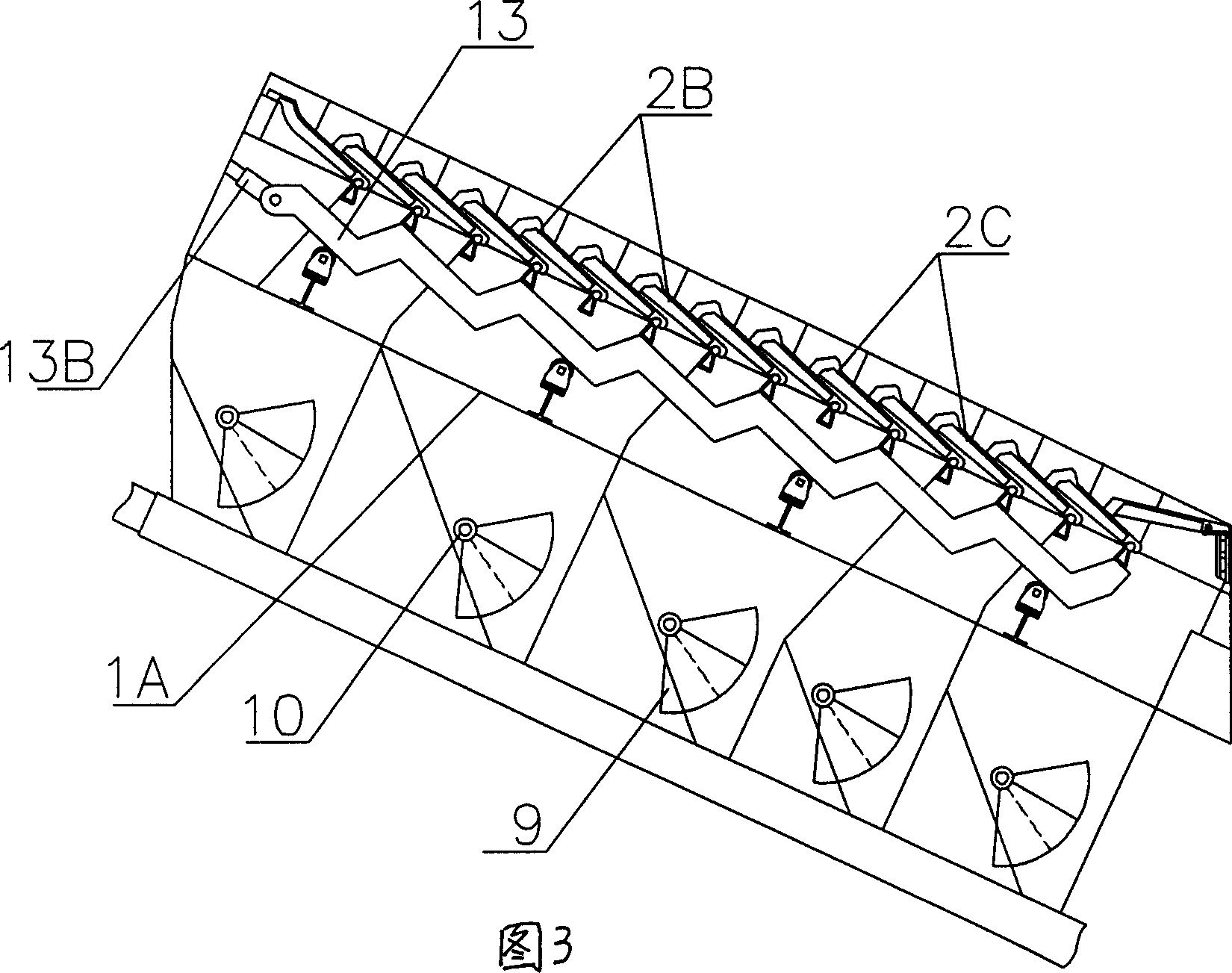

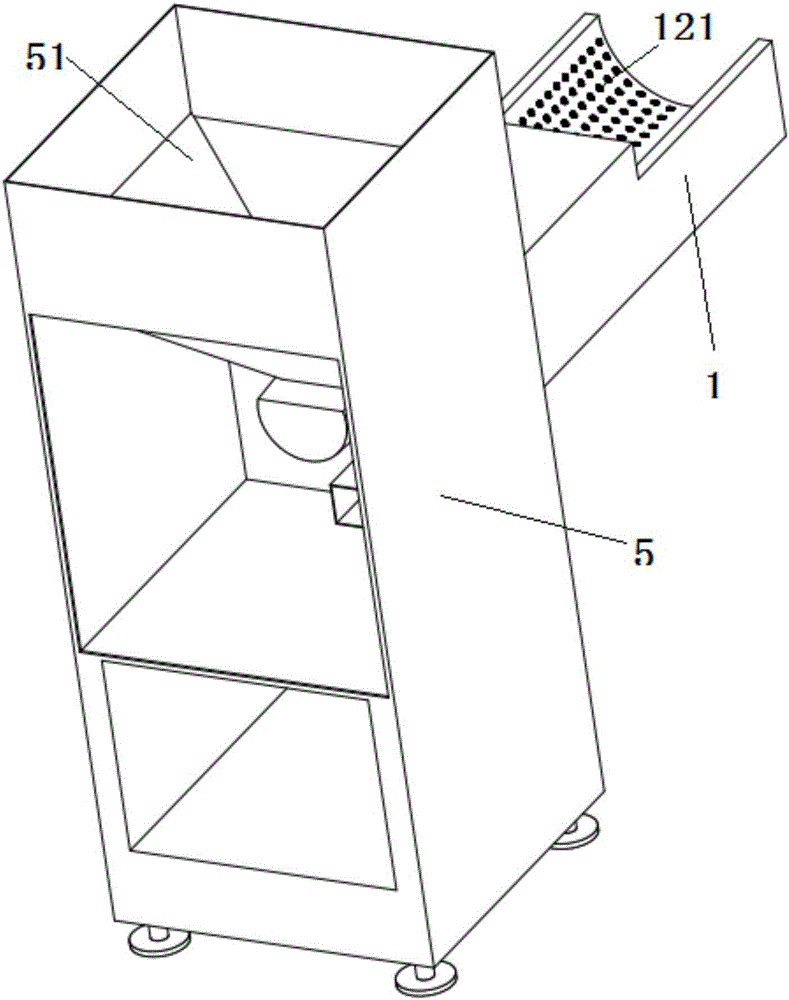

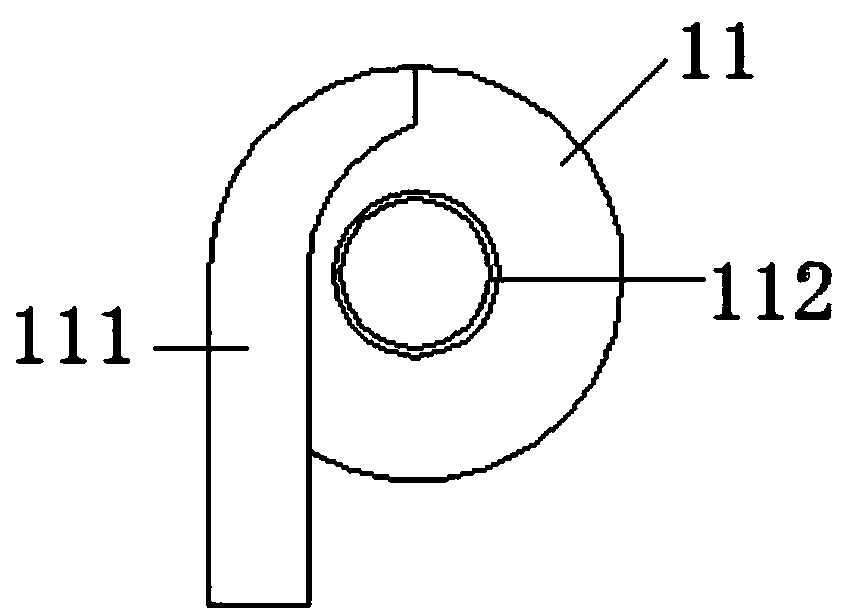

Vibrating feed combustor and control method thereof

ActiveCN106642192ASave man hoursReduce electric powerFuel supply regulationSolid fuel combustionSlagFlue

The invention discloses a vibrating feed combustor, comprising a combustion grate, a feeder, a blower and a controller, wherein the combustion grate comprises a grate enclosure, a first division plate and a second division plate arranged horizontally are arranged in the grate enclosure to divide the space encircled by the grate enclosure into a combustion trough, a combustion trough air flue and a slag receiving chamber, the first division plate is provided with vents, the combustion trough air flue is provided with an air inlet in one side in the horizontal direction, and the blower is communicated with the combustion trough air flue via the air inlet; the feeder is an electric vibrating feeder and comprises a feed pipe, the lower port of the feed pipe is arranged above the combustion trough, a first temperature sensor is arranged in the combustion grate, a second temperature sensor is arranged in a baking room, and the controller is connected with the blower, the electric vibrating feeder, the first temperature sensor and the second temperature sensor and used for controlling the frequency or magnitude of the electric vibrating feeder and the air quantity of the blower according to the temperature in the combustion trough and the difference between the current temperature in the baking room and a preset temperature.

Owner:湖南驱动源电气技术有限公司

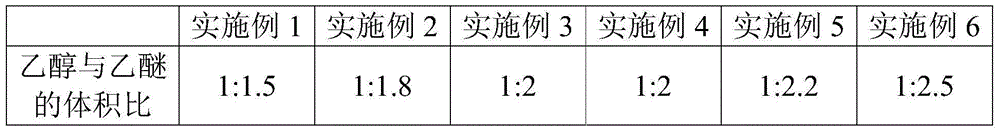

Coal economizing agent

InactiveCN106753681AImprove combustion efficiencyImprove efficiencySolid fuelsFuel additivesCombustionNon compliance

The invention belongs to the technical field of coal combustion additives, and in particular relates to a coal economizing agent. The invention solves the problems of unobvious coal economizing effect, high addition level, pollution of the environment and non-compliance of Green blackness of the existing coal economizing agents. The coal economizing agent is prepared from the components in parts by weight: 22-26 parts of a combustion adjuvant, 28-41 parts of a mixed type strong oxidizer, 18-26 parts of a dispersing agent, 2-5 parts of a catalyst and 15-25 parts of a compound sulfur-fixing agent. The coal economizing agent disclosed by the invention can improve the combustion conditions of a furnace body and increase the air permeability of a coal layer, thus enabling sufficient combustion of coal, improving the coal-burning heat efficiency, reducing discharge amount of smoke, improving the thermal conduction efficiency, fixing sulfur to reduce smoke, reducing emission of CO, SO2 and the like, reducing environmental pollution, and achieving the purposes of combustion supporting, sulfur fixing, energy saving and desulfurization.

Owner:GUANGZHOU AUSPICIOUS CHEM

Incinerator for processing smoke gas generated by waste incineration by utilizing incineration method

The invention discloses an incinerator for processing smoke gas generated by waste incineration by utilizing an incineration method. The high-temperature smoke gas generated by the waste incineration passes through a gas duct; after being pumped by an oil pump, fuel oil in an oil tank flows into a gasification pipe after passing through a fuel oil electric regulating valve; and the fuel oil is heated to be gasified by the high-temperature smoke gas, the gasified fuel oil gas is sprayed from a fuel oil spray head.; after the fuel gas outputting from a fuel gas storage tank is mixed with the compressed air from an air compressor, the mixed gas is ignited by a spark plug after being sprayed from a fuel gas spray nozzle through the electric regulating valve of the mixed gas; the fuel gas flame ignites the fuel oil gas sprayed from the fuel oil spray head; the wind blown by an air blower passes through the electric regulating valve and is blown out from an air outflow pipe, thereby supporting the ignition of the fuel oil gas; the red flame of the fuel oil gas ignited for the first time is horizontally laid to enter small holes of a honeycomb ceramic plate, thereby forming the blue flame of the fuel oil gas ignited for the second time; and when entering the small holes of the honeycomb ceramic plate, inflammable matters comprising dioxin in the smoke gas are ignited and incinerated by the blue flame of the fuel oil gas ignited for the second time.

Owner:张英华

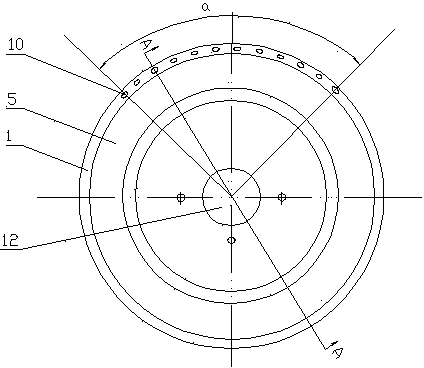

Burner of energy-saving stove

Provided is a burner of an energy-saving stove. The burner is widely applied to the energy-saving stove in the foodservice industry. The burner is structurally composed of a cast iron ring, a gas inlet, a gas outlet channel, a mixing air cylinder, an iron cake, a heat collecting plate, an ignition device and the like. Fire nozzles are formed in the iron cake, and ceramic cores with fire holes are arranged in the fire nozzles. The burner is mainly characterized in that a support for supporting the heat collecting plate is additionally arranged on the mixing air cylinder so as to prevent the weathered heat collecting plate from breaking under the action of dead weight; the structure of the gas outlet channel is improved; a 90-degree arc-shaped groove in the upper periphery of the cast iron ring is replaced with evenly-distributed arc-shaped gas outlet holes so that material stress can be reduced, the cast iron ring is prevented from cracking in the use process, and the function of reducing the weathering speed of the heat collecting plate is achieved; the outer circle of the iron cake is designed to be in a step shape allowing the iron cake to be taken easily with the fingers, and the fire nozzles of the iron cake are designed to be of an inclined structure; and meanwhile, the other structures of the burner are correspondingly improved to improve heat efficiency. Therefore, the improved structure has the advantages of being ingenious in design, easy to mount and dismount, large in burning area and longer in service life.

Owner:KUNSHAN FULING ENERGY USE

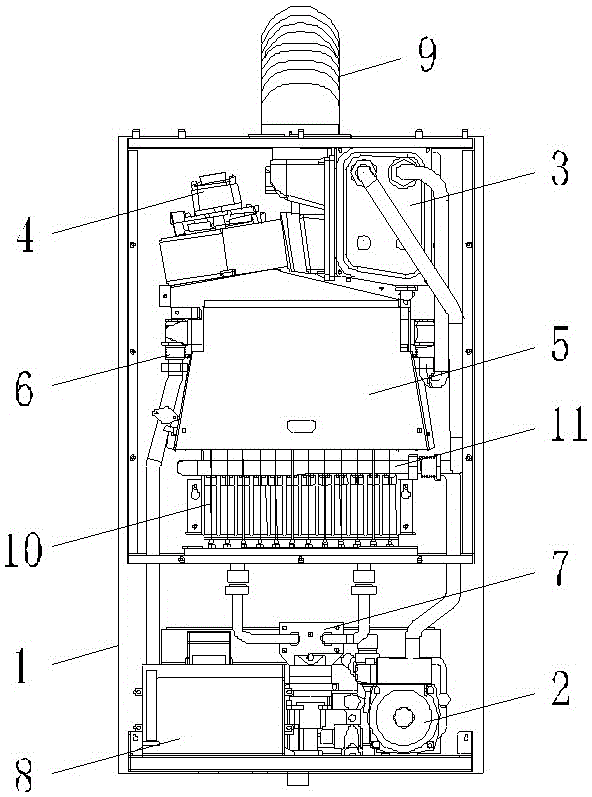

Segmental-control secondary heat exchange condensation type gas heating water heater

InactiveCN106440334AEmission reductionIncrease the burning areaWater heatersCombustion chamberEngineering

Owner:FOSHAN SHUNDE DISTRICT YICHENG ELECTRIC APPLIANCE CO LTD

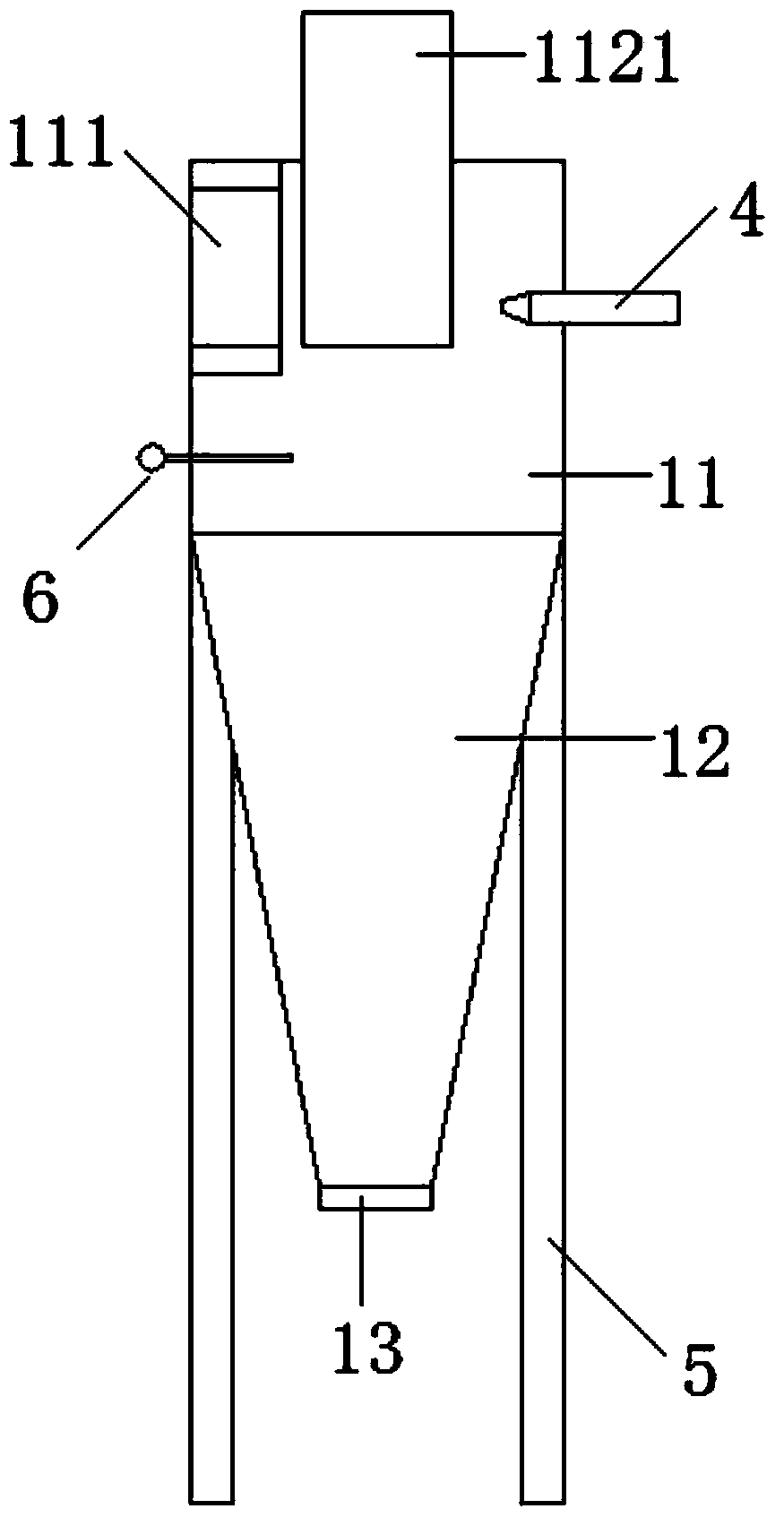

Secondary combustion system

ActiveCN104235858AIncrease the burning areaReasonable timeIncinerator apparatusSlagCombustion chamber

The invention discloses a secondary combustion system, which aims at providing a secondary combustion device with the advantages that hot smoke gas can be purified, high-temperature volatile matters and dioxin in the smoke gas can be sufficiently cleared, dust and iron slag can be conveniently and efficiently recovered, and in addition, the energy sources can be effectively saved. The secondary combustion system comprises a secondary combustion chamber and a hot smoke gas backflow pipe, wherein a rotary kiln is connected to a drying chamber, a smoke inlet part and a burner are arranged on the secondary combustion chamber, the secondary combustion chamber comprises a main combustion cavity and a deposition recovery cavity, the top center of the main combustion cavity is provided with an air outlet part, the lower end of the air outlet part extends into the secondary combustion chamber, the air outlet part is connected with an air outlet passage, the air outlet passage is communicated to the drying chamber, the smoke inlet direction of the smoke inlet part is parallel to the tangent line direction at the outer side of the main combustion cavity, and the smoke inlet part and the horizontal plane form an angle being 10 to 30 degrees. The secondary combustion system has the beneficial effects that harmful substances can be burnt again and can be sufficiently and thoroughly burnt, additional devices are not needed, in addition, the dust separation effect is obvious, the purified smoke gas can be cyclically reused again, and the environment protection effect is good.

Owner:ZHEJIANG SANLIAN ENVIRONMENT MACHINERY EQUIP

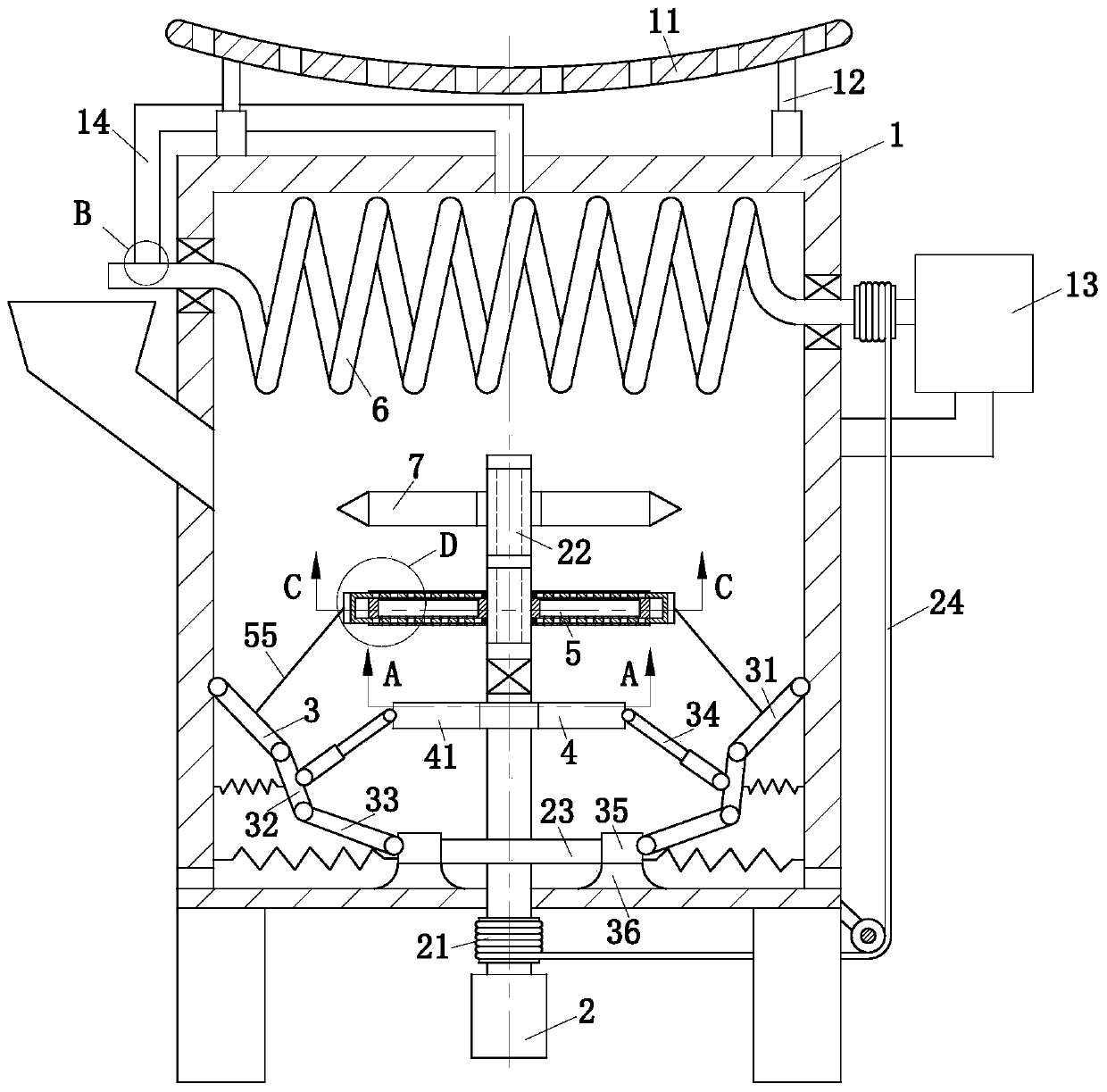

Environment-friendly heating furnace based on solar energy

ActiveCN109751591AReduce manufacturing costEasy to usePhotovoltaic supportsRenewable energy machinesAir volumeEngineering

The invention belongs to the technical field of heating furnaces, and particularly relates to an environment-friendly heating furnace based on solar energy. The environment-friendly heating furnace comprises a box body, and further comprises a driving unit, a swing unit, a crushing unit, an aeration unit, a spiral coil, a crushing plate, a solar panel, a first column, an air volume control room and a controller. Through rotation of a cam, two sliders intermittently slide to the two sides, so that a first rod, a second rod and a third rod which are hinged together fluctuate and swing, air flowin the box body is accelerated, a telescopic rod, a first crushing knife and a second crushing knife are matched with each other to shear and crush straw, and the straw burning area is increased; andmeanwhile, the first rod, a rigid rope, a circular arc plate and a clamping plate are matched with each other to makes oxygen in a first area to expose, straw burning is accelerated, and the straw burning effect is improved.

Owner:庆阳新泰工程技术有限公司

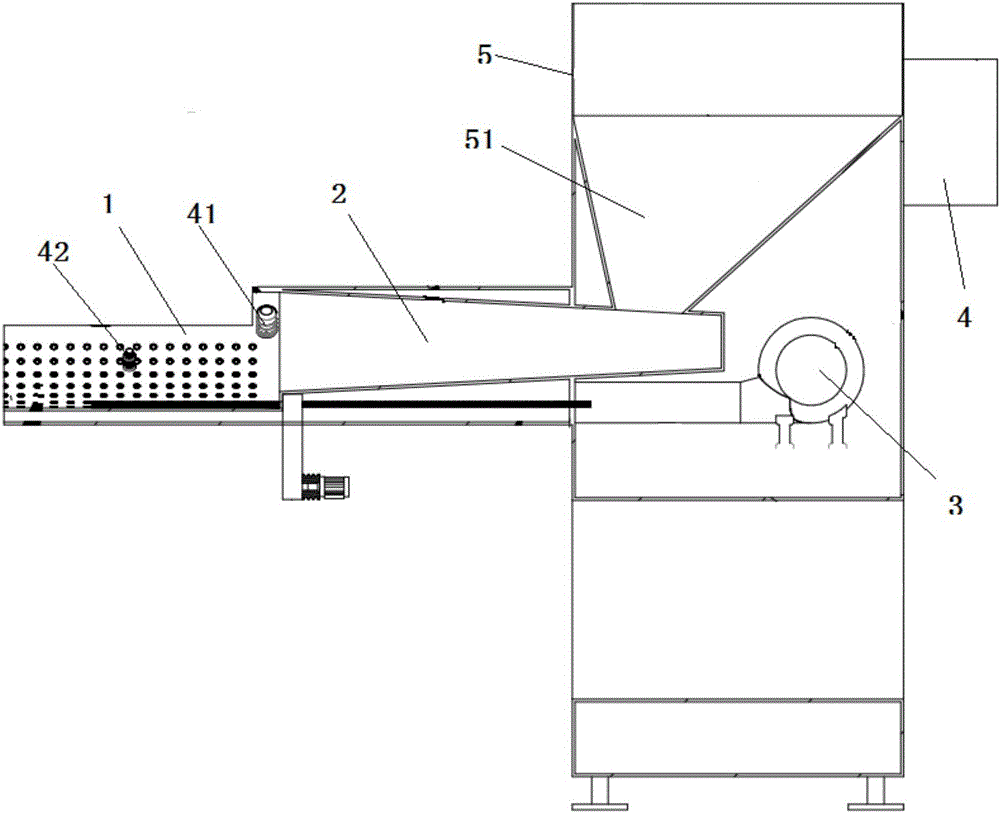

Environment-friendly auxiliary system for assisting efficient combustion of biomass in combustion equipment

ActiveCN110102562AEasy to carryReduce pollutionSolid waste disposalTransportation and packagingBiomassCombustion

The invention discloses an environment-friendly auxiliary system for assisting efficient combustion of biomass in combustion equipment. The auxiliary system comprises a biomass processing box, whereina processing tank opening downwards to the right is formed in the biomass processing box; a driving mechanism is fixedly arranged in the processing tank; a feeding block is fixedly arranged on the rear end wall of the processing tank; a crushing mechanism for crushing the biomass is arranged in the feeding block; the crushing mechanism is powered by the driving mechanism; and a processing mechanism used for quantitatively compressing and discharging the crushed biomass is arranged at the lower side of the driving mechanism. According to the auxiliary system, it is convenient to carry, large biomass materials can be crushed and quantitatively compressed into blocks to be discharged, the pollution generated by combustion of the biomass materials is reduced; the biomass materials are compressed into square blocks, so that the combustion is carried out more conveniently, the combustion area the increased, and the combustion efficiency is improved; and the inlet air can be increased duringcombustion, so that the combustion efficiency is further improved.

Owner:浙江特富炜业热能设备有限公司

Strip-shaped stove combustor

PendingCN107741034AEven gas distributionNormal burningDomestic stoves or rangesCooking fumes removalCombustion chamberCombustor

The invention discloses a strip-shaped stove combustor. The strip-shaped stove combustor comprises a bottom cup with a top opening, a fire distributor and a combustor cap; the bottom cup comprises anair inlet channel, a flange, an ignition needle seat, a thermocouple seat and a spraying nozzle; an air inlet connector is arranged at an air inlet end of the air inlet channel; an air outlet end of the air inlet channel is positioned in the centre of the bottom plate of the bottom cup; the fire distributor comprises a combustion chamber with an upper opening, an injection pipe which communicateswith the combustion chamber and a bracket which is positioned on a lower surface; a combustion groove is formed in the wall of the combustion chamber; the bottom cup, the fire distributor and the combustor cap have length and width and are strip-shaped; an annular groove is formed in the lower surface of the combustor cap; flow division bumps are formed in the bottom plate of the combustion chamber; the flow division bumps extend to the two sides of the length direction by taking the centre in the length direction of the combustion chamber as a starting point; gaps between the flow division bumps and the combustor cap are increased gradually; the upper end of the combustion chamber extends into the annular groove. Gas in the combustion chamber is distributed uniformly and can combust normally; moreover, the combustion area is large; and the fire is strong.

Owner:中山市沙贝特科技有限公司

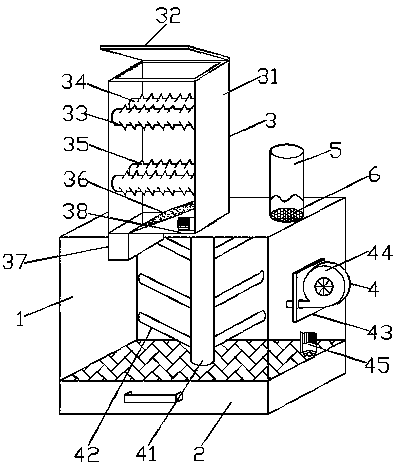

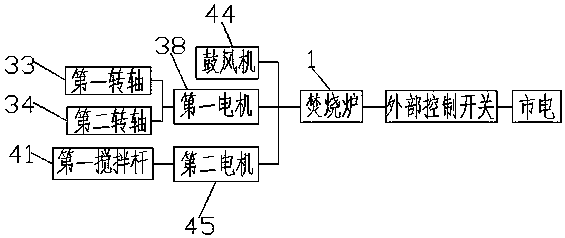

Combustion system for inorganic garage disposal equipment

The invention relates to a combustion system for inorganic garage disposal equipment. The combustion system for the inorganic garage disposal equipment comprises an incinerator, a slag leakage cabin is installed at the bottom end of the incinerator, and a smashing device is fixed to one side of the top end of the incinerator. The smashing device comprises an outer shell, a top cover, a first rotary shaft, a second rotary shaft, smashing blades, a guide plate discharging opening and a first motor, the first rotary shaft is installed on one side of the interior of the outer shell, the second rotary shaft is installed on the other side of the interior of the outer shell, the smashing blades are fixed to the outer sides of the first rotary shaft and the second rotary shaft, and a guide plate is fixed to the bottom end of the interior of the outer shell. A discharging opening is formed in one side of the bottom end of the outer shell, the first motor is installed between the outer shell andthe guide plate, a combustion supporting device is installed in the incinerator, and the combustion supporting device comprises a first stirring rod, a second stirring rod, a fixed plate, an air blower and a second motor. The combustion system for the inorganic garage disposal equipment has the advantages of high working efficiency and thorough incineration.

Owner:济源市众帮环境保洁有限公司

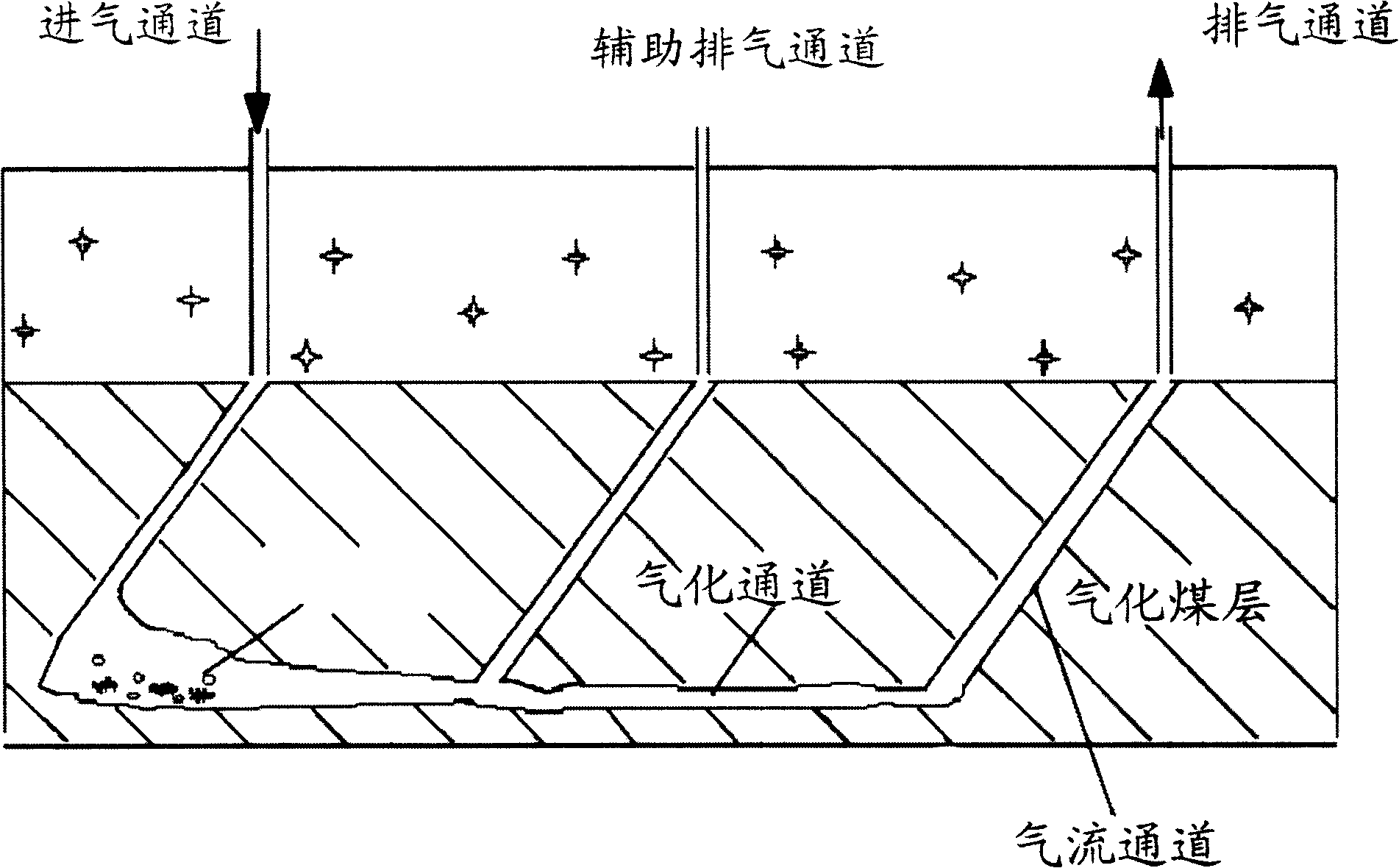

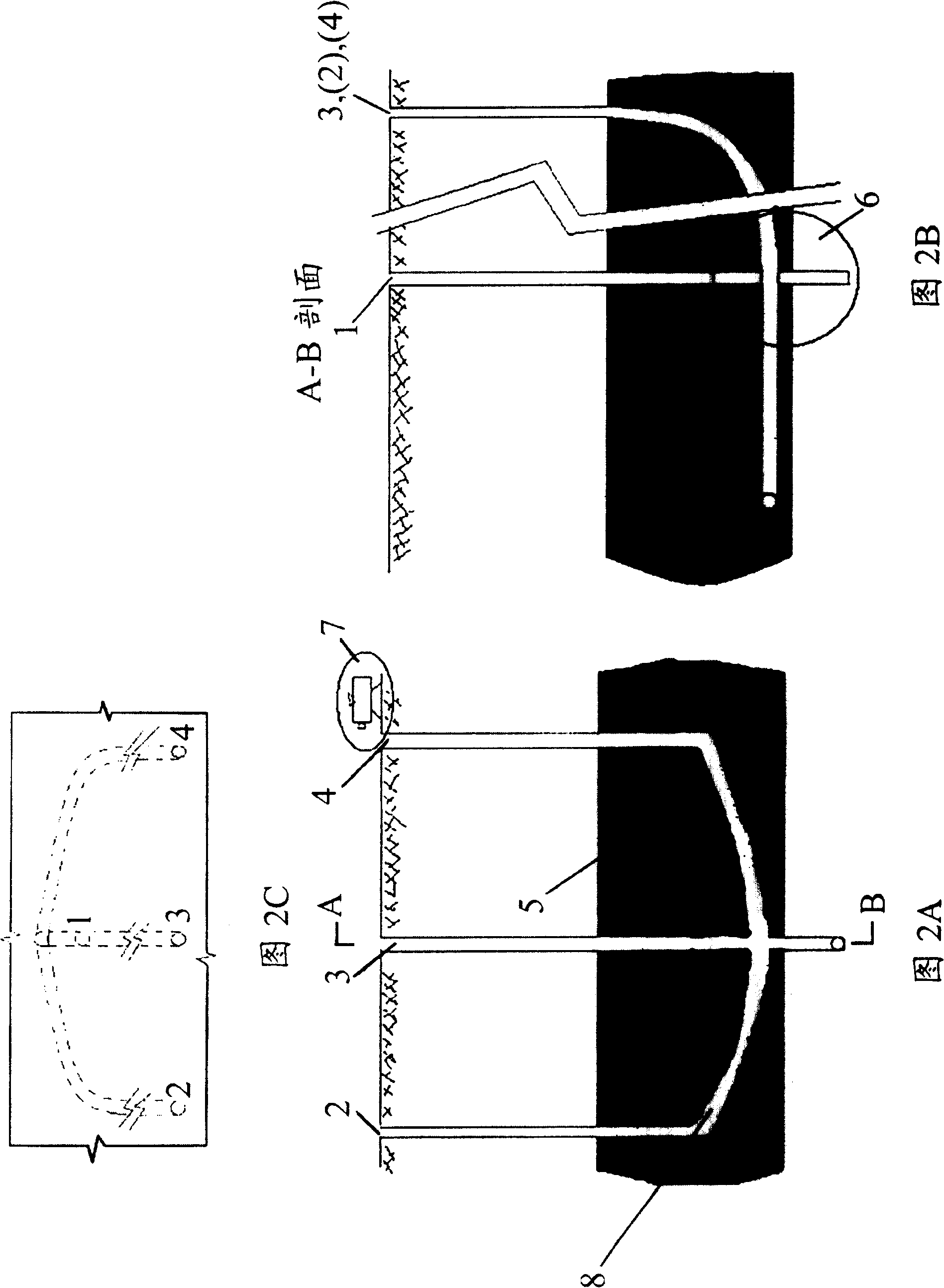

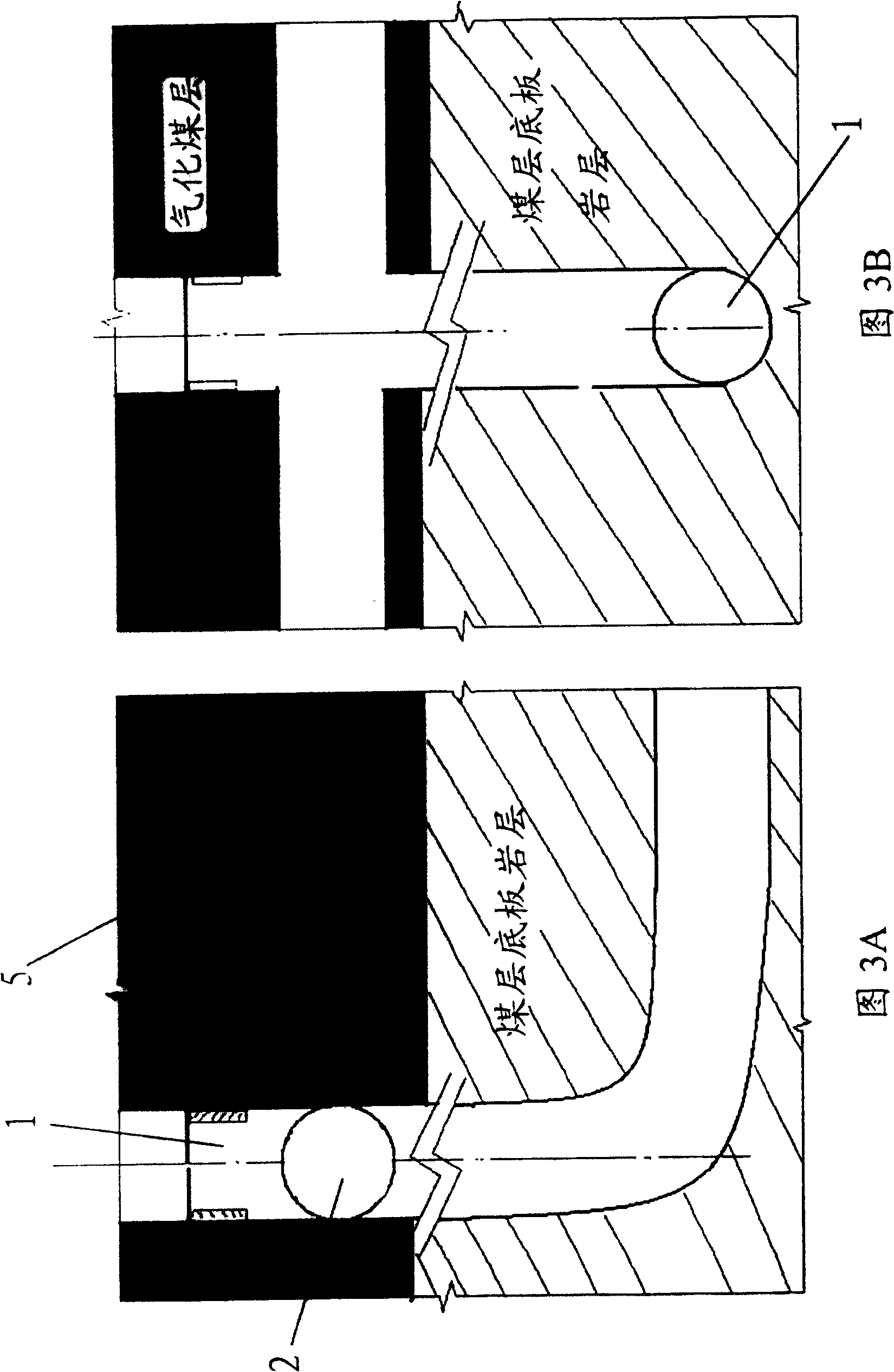

Underground coal gasification

ActiveCN100420824CReduce manufacturing costImprove efficiencyConstructionsFluid removalProcess engineeringCoal fired

A coal gasification process of coal bed deep underneath includes a gasification furnace in the coal bed, a gas let in canal linking one end of the furnace to ground, a gas let out canal linking the other end of the furnace to ground. Gas generated by coal burning in the furnace is collected. A drain system links a drain outlet over 10 meters below the furnace to the ground.

Owner:ENN SCI & TECH DEV

Industrial gas ultralow-nitrogen energy-saving spiral combustion head and combustor

The invention discloses an industrial gas ultralow-nitrogen energy-saving spiral combustion head and belongs to the technical field of gas combustion devices. The spiral combustion head comprises an outer cylindrical wall; an inner cylindrical wall is sleeved inside the outer cylindrical wall; the outer cylindrical wall and the inner cylindrical wall are connected into an integrated structure through a spiral bulge; air outlet holes are uniformly distributed in the bottom of the inner cylindrical wall; a fire outlet hole is formed in the top of the outer cylindrical wall; and the bottom of the outer cylindrical wall is provided with a combustion head connecting section. The invention also discloses a combustor comprising the spiral combustion head. By using the spiral combustion head disclosed by the invention, a flame rotates in a fixed direction, so that the heat exchange efficiency is increased, and the utilization ratio of heat energy is increased; meanwhile the combustion speed of the flame is stabilized, so that flame lifting and backfire are avoided; by using the combustor comprising the spiral combustion head, the radiated heat energy can be increased, so that a nitrogen reducing effect is achieved; and air and gases are sufficiently and uniformly stirred in a mixing pipe, so that an air / fuel ratio approaching to a theoretical value is achieved.

Owner:江苏弗雷姆环境科技有限公司

Multi-path garbage power generation device

InactiveCN109724089AImprove resource utilizationThe fermentation process is simpleSteam generation using pressureSteam useResource utilizationEngineering

The invention discloses a multi-path garbage power generation device, comprising a box body, wherein a first treatment chamber and a second treatment chamber are respectively arranged in the box body;a first stirring device is installed in the first treatment chamber, a second stirring device is installed in the second treatment chamber, a conveying device is installed at the bottom end of the box body, a discharging opening is formed between the conveying device and the first treatment chamber, an electric heater is arranged on the inner wall of the second treatment chamber, and an incinerator is arranged on one side of the conveying device. And through the arrangement of the conveying device, the combustible garbage fragments are conveyed to the incinerator. By arranging the electric heater, the fermentation speed of the organic garbage in the second treatment chamber is increased, the biogas valve ensures that the internal biogas can be safely used by the incinerator, the pressuregauge detects the pressure of the biogas in the pipeline, the whole device can effectively utilize combustible garbage and the organic garbage to assist in power generation, and the garbage resource utilization rate is increased.

Owner:韦健宁

Environment-friendly coal-saving agent

InactiveCN104877730ASignificant coal saving effectReduce consumptionSolid fuelsSocial benefitsCombustion

The invention relates to the field of fire coal additive, in particular to environment-friendly coal-saving agent. The environment-friendly coal-saving agent includes 10 to 20 parts of combustion improver, 10 to 20 parts of oxygen supplier, 5 to 15 parts of catalyst, 0.8 to 1.6 parts of penetrating agent, 0.5 to 1.2 parts of dispersing agent, 1.6 to 3.2 parts of purificant and 0.8 to 3.2 parts of sulfur-fixing agent by weight. The environment-friendly coal-saving agent is obvious in coal saving effect, the coal saving effect can arrive at 24.35%, the coal consumption is reduced, the emission of carbon dioxide and the like harmful gas is greatly reduced, and the economical benefit and social benefit are high; the harmful gas is reduced by more than 70%, and the Greenman blackness is less than 1 grade.

Owner:ZHANGJIAGANG WUHU NEW MATERIAL TECH DEV

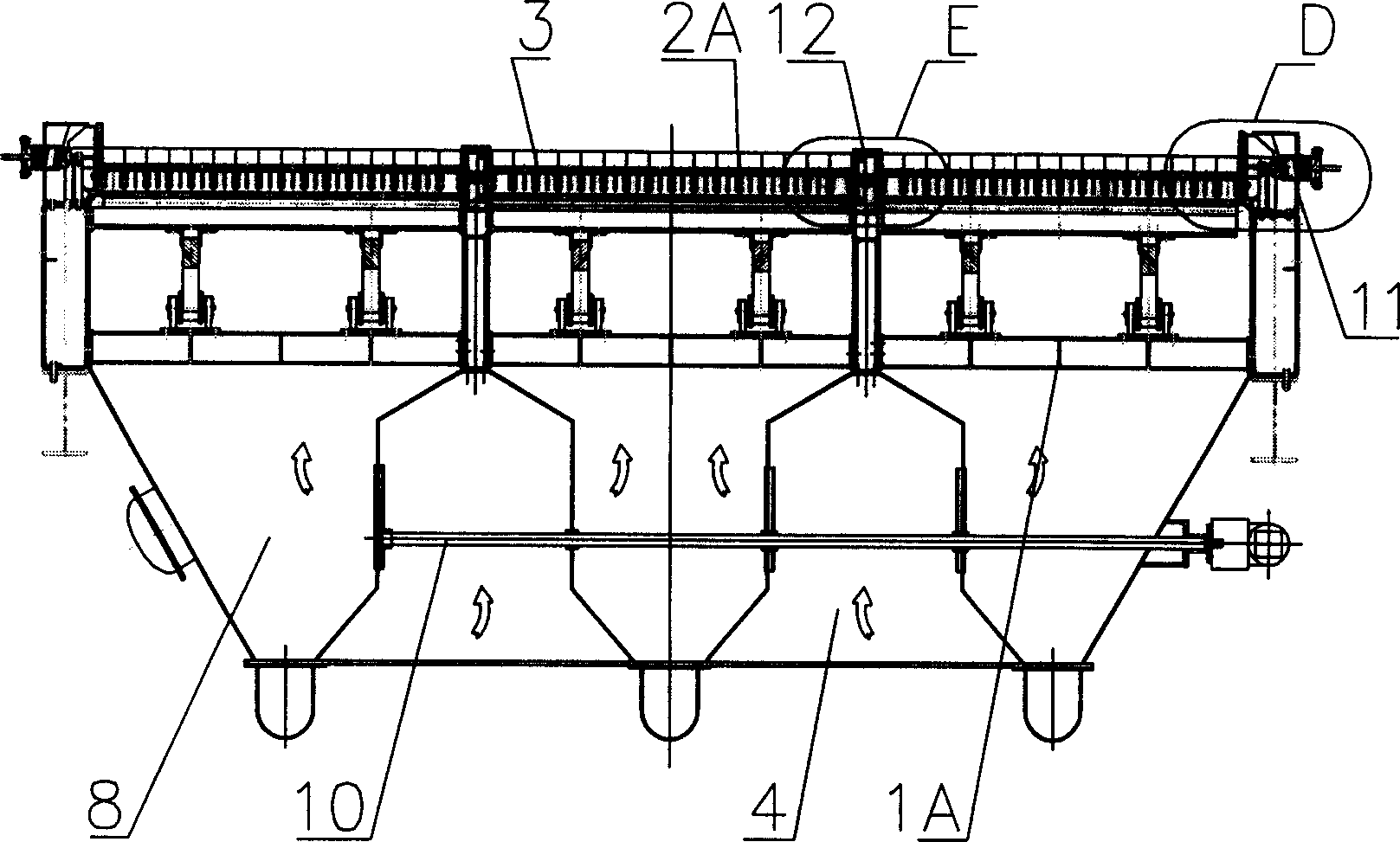

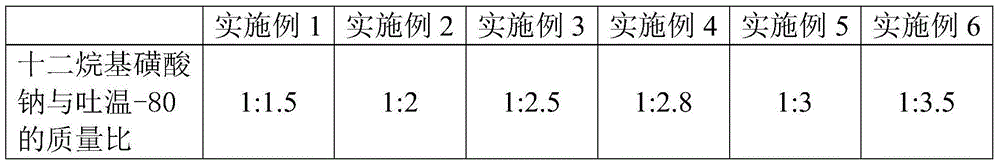

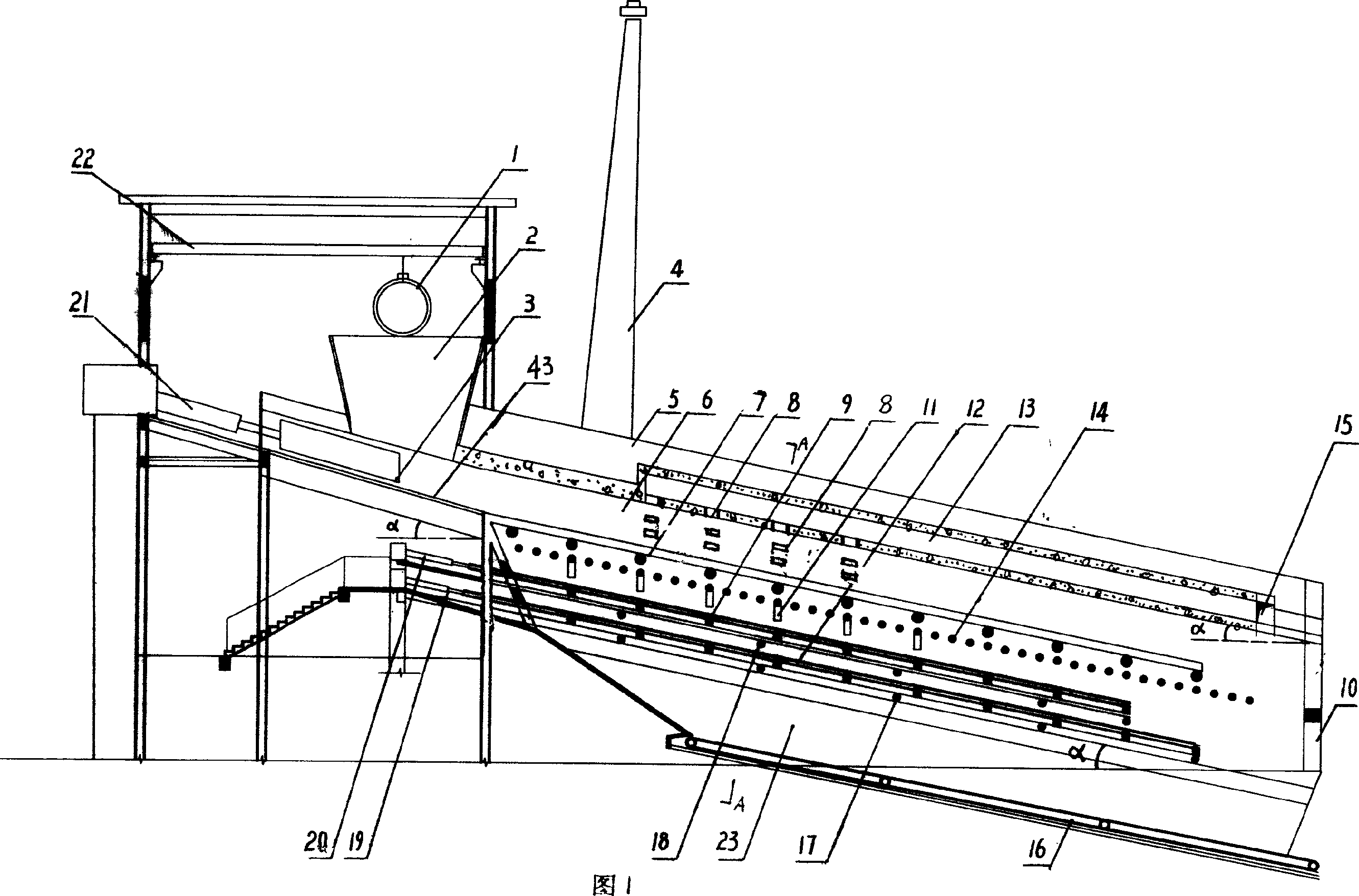

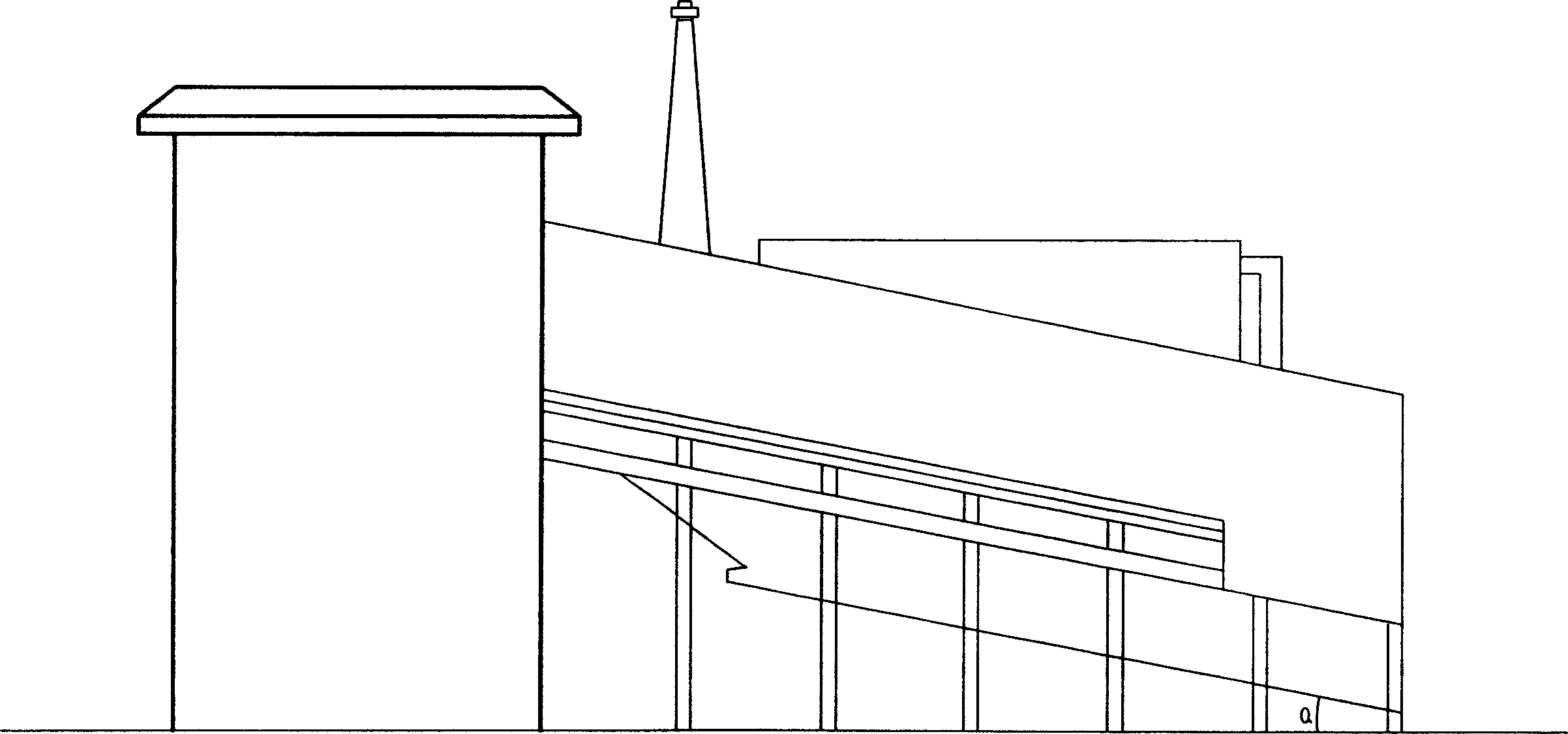

Automatic refuse burning furnaces with multiple inclined verticle grates

InactiveCN1644991AEasy to dryImprove automationSolid fuel combustionIncinerator apparatusEngineeringHearth

This invention is a sloping standing automatic garbage-burning furnace of multi-grate mode. The furnace consists of furnace body, hearth, grates installed in hearth, inlet of garbage and outlet of ash. Its characteristic is the sloping setting of hearth and grate installed in hearth, the angle with horizontal plane is 5deg<alpha<50deg, the best value is 10deg<alpha<30deg. There are three tiers or more tiers of sloping standing grates in sloping standing hearth; there is an inlet at the up end of sloping standing hearth; there is an outlet of lime-ash at low end of the hearth; there is an inlet of air at low end of the hearth. This invention has advantages of low operation cost, completeness of garbage burning, no secondary pollution.

Owner:陈祖焕 +1

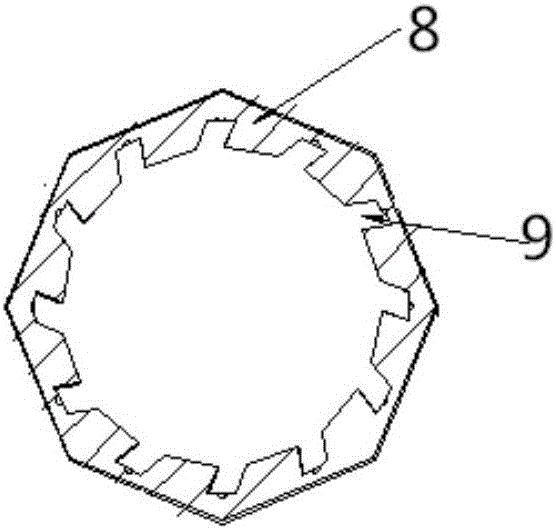

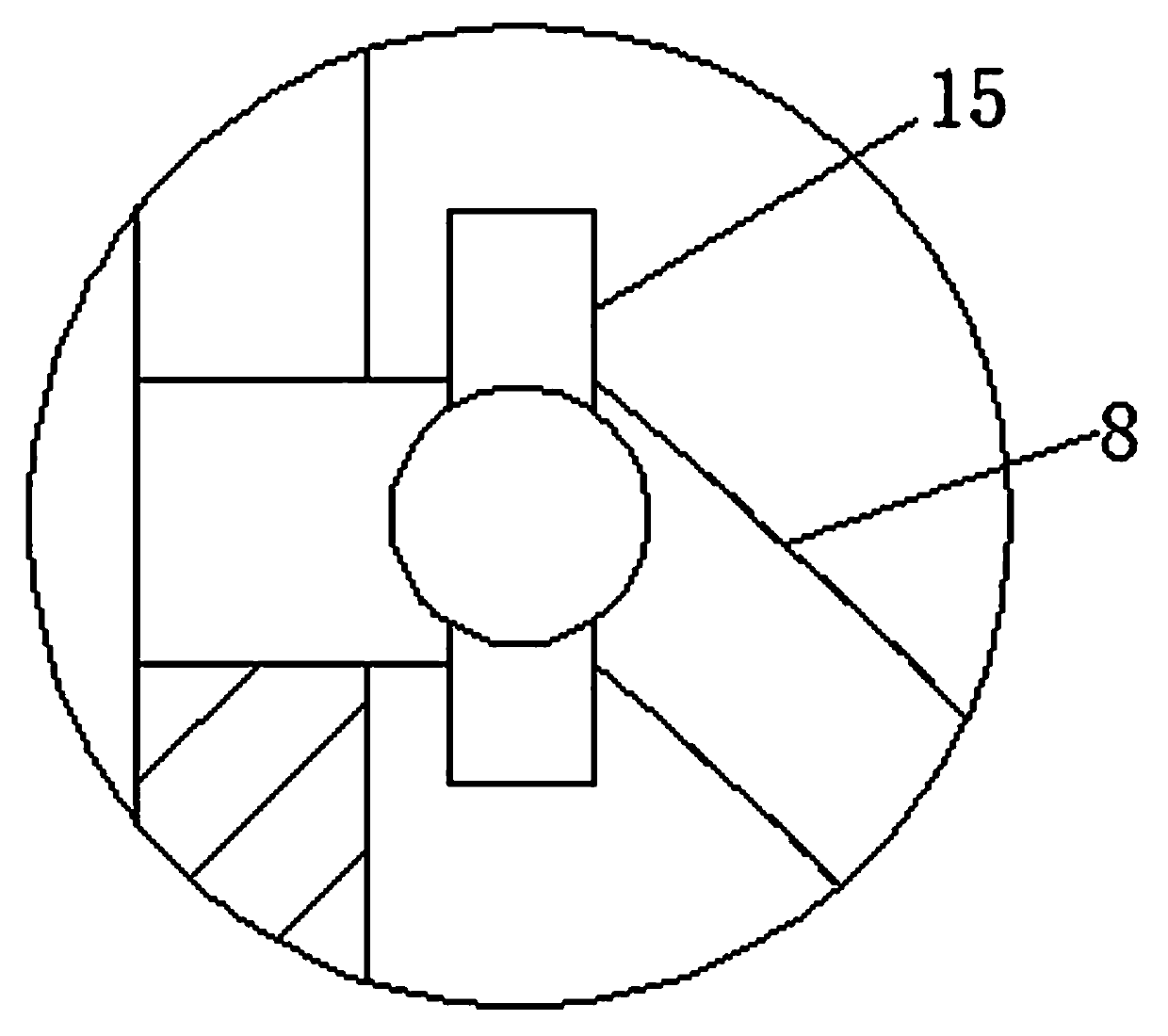

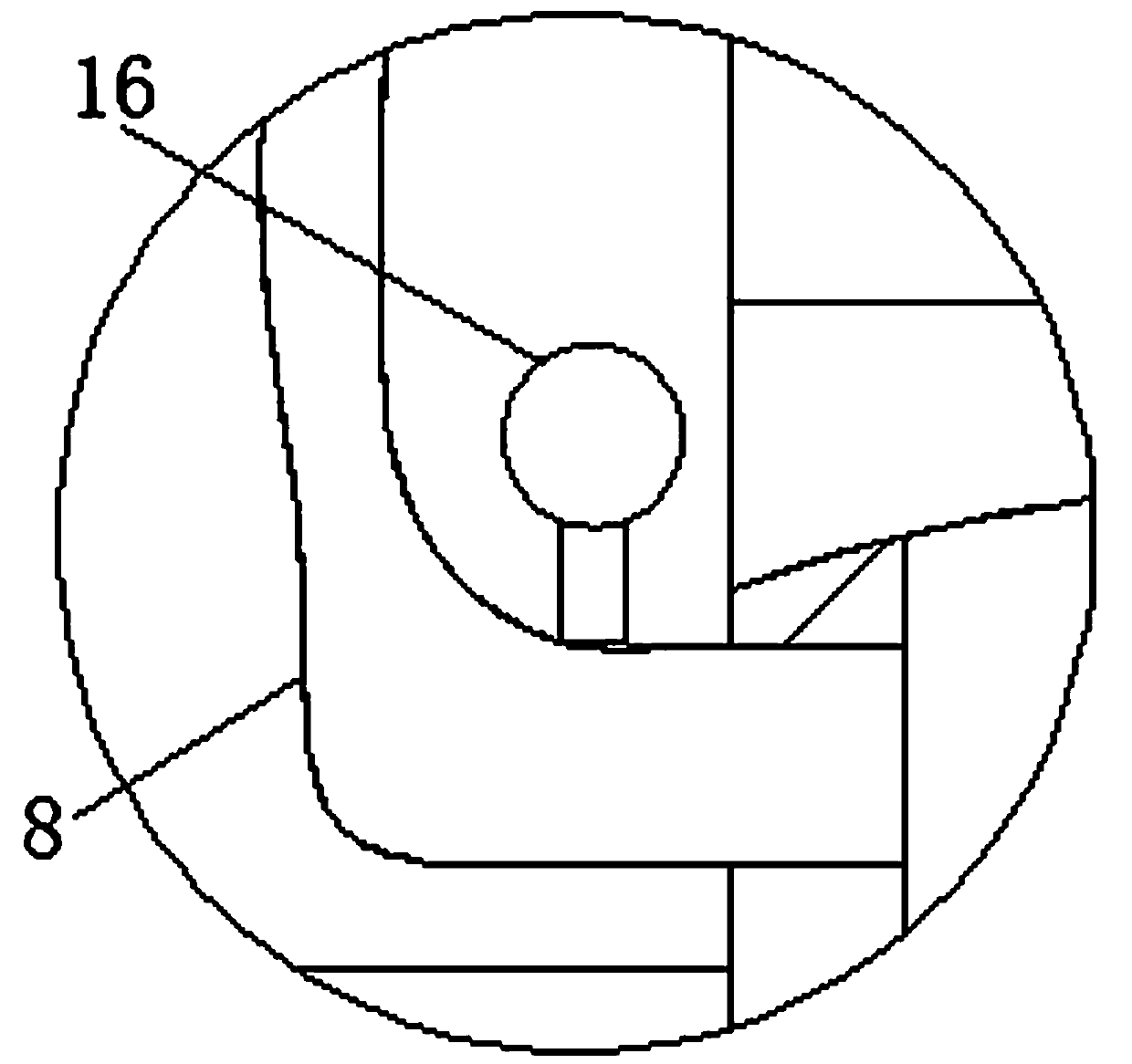

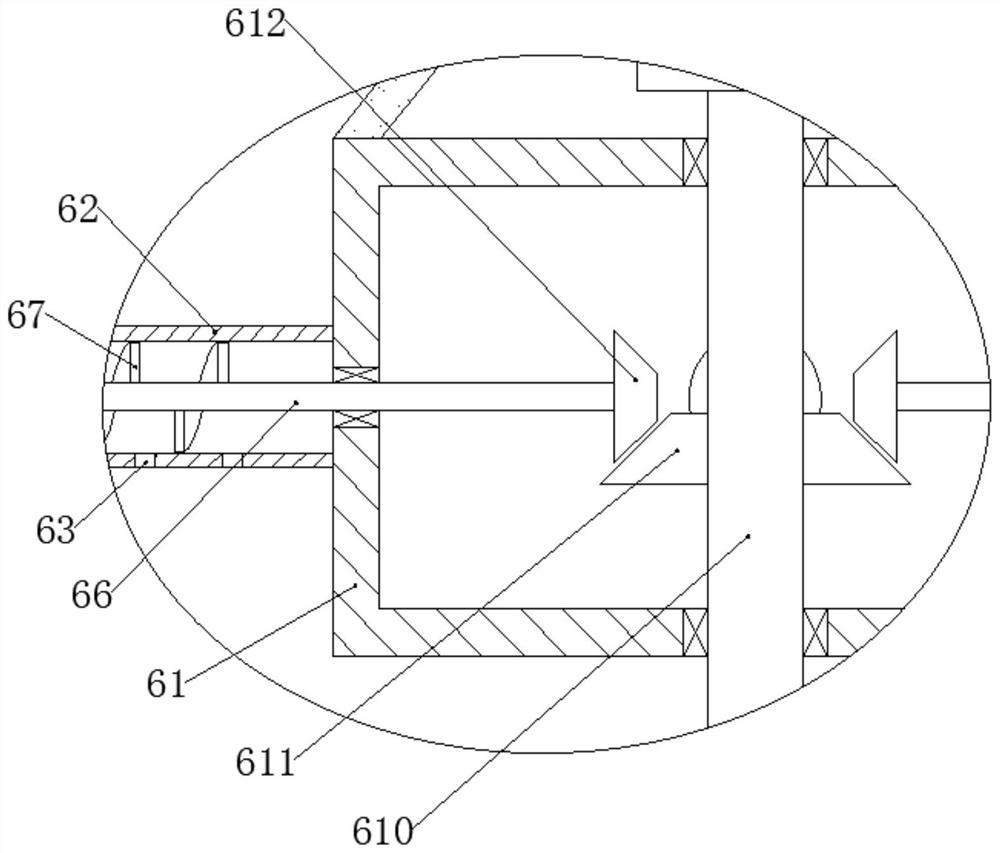

Side-spraying combustor

ActiveCN111578294AIncrease the burning areaBurn fullyPilot flame ignitersIncinerator apparatusCombustorEngineering

The invention relates to the technical field of combustors, and aims to provide a side-spraying combustor. The side-spraying combustor comprises a combustor body, wherein a combustion cylinder is arranged at one end of the combustor body, and an air inlet device and a gas valve set are arranged at the other end of the combustor body; an ignition device for igniting fuel gas is arranged on the combustion cylinder; the front end of the combustion cylinder is closed, and combustion openings formed in the circumferential direction in a surrounding mode is formed in the side wall of the combustioncylinder. According to the side-spraying combustor, gas and air are introduced into the combustion cylinder through the air inlet device and the gas valve set, and then the gas and the air are jettedtowards the periphery in the radial direction through the combustion openings, so that the atomized test solution in the large area around the combustion cylinder is combusted through ignited flame, the combustion area is large, and combustion is more sufficient.

Owner:浙江亿得利燃烧器有限公司

Environmentally-friendly incinerator for solid waste product disposal

InactiveCN109000260AIncrease the range of incinerationIncrease incineration speedIncinerator apparatusEnvironmentally friendlyWaste product

The invention provides an environmentally-friendly incinerator for solid waste product disposal. The environmentally-friendly incinerator for the solid waste product disposal comprises a protective barrel, a control box and a storage basket. Four supporting columns are welded to the bottom end face of the protective barrel in a ring array. A motor support is welded to a position close to the rightside of the outer wall of the protective barrel. Top end faces of spraying heads are distributed in a circular array, and four iron cylinders are welded to the top end faces of the spraying heads. Aspraying head protecting cover is arranged at the top end of each iron cylinder. When air is exhausted by an exhausting fan, the air inside a combustion barrel is pumped out. An air inlet door can bepushed open through an air input pipe, and the air outside the combustion barrel enters the interior of the combustion barrel. When the exhausting fan stops rotating, the air inlet door closes automatically under the influence of gravity. Therefore, the exhausting fan and the air inlet door are arranged in a cooperating manner, and the air input manner and air output manner are optimized; a spraying head seat is arranged, on the one hand, the litten area and combustion area are enlarged, and on the other hand, falling of carbon dust generated after combustion can be avoided and obstructed; andbottom spraying head structures are optimized.

Owner:赵瑞霞

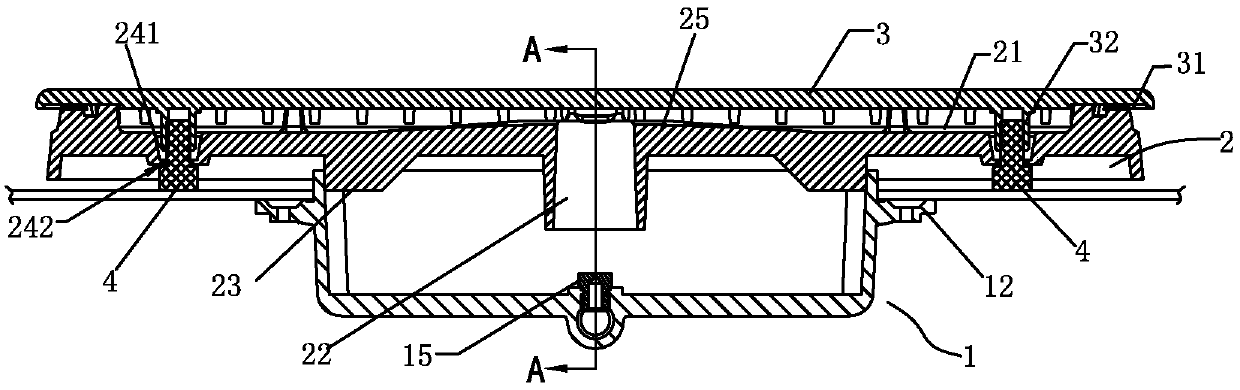

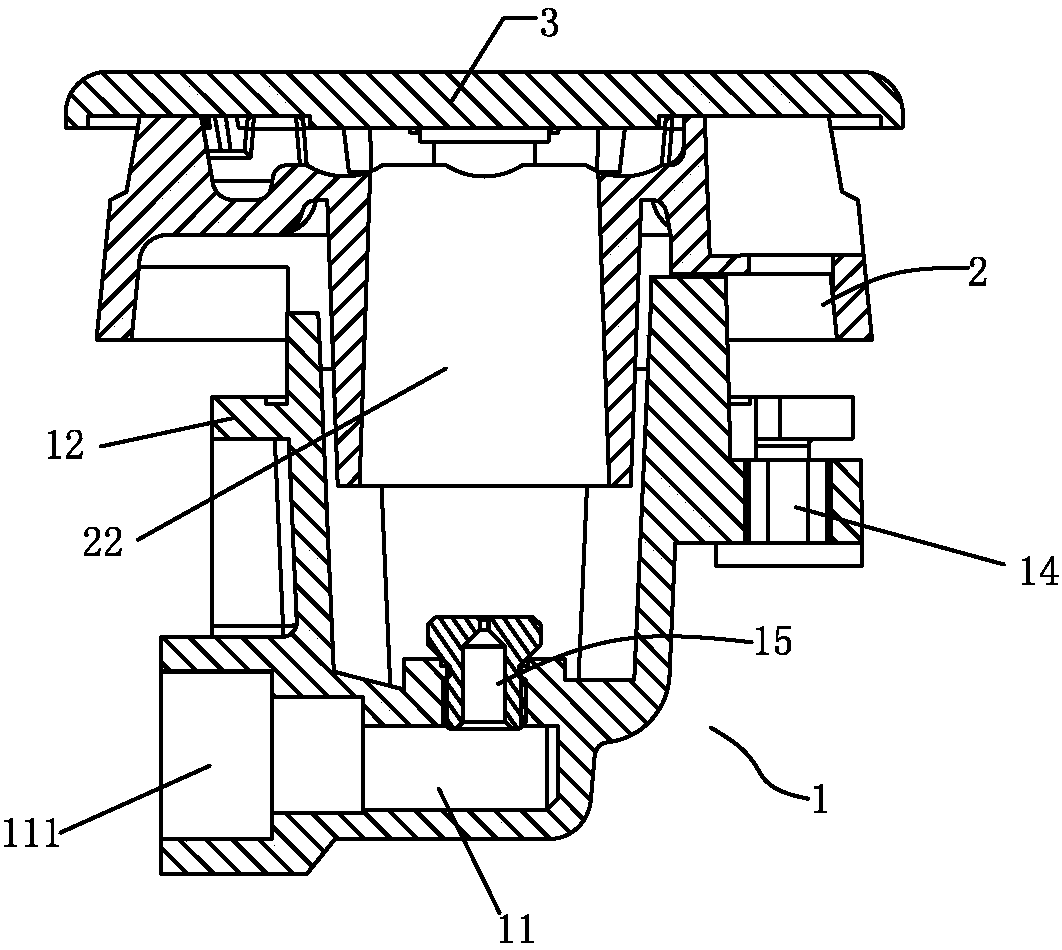

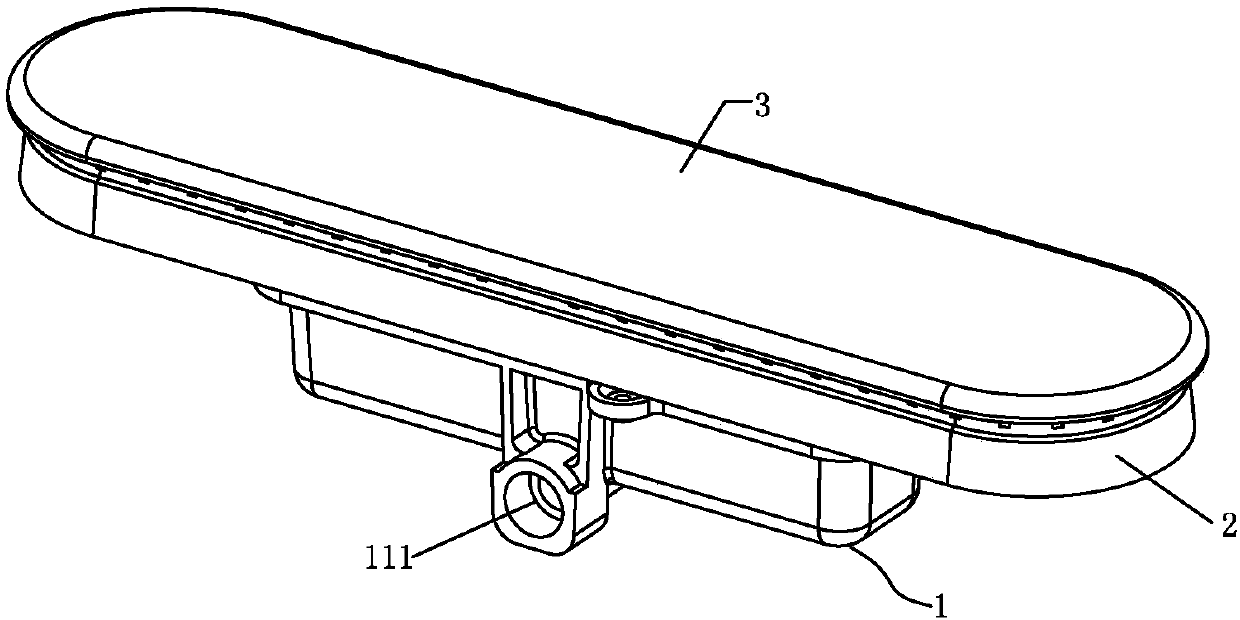

Household garbage incineration treatment equipment

ActiveCN113464958ABurn fullyIncrease the burning areaIncinerator apparatusCombined combustion mitigationFresh airEngineering

The invention discloses household garbage incineration treatment equipment which comprises a hearth, fire grates, a power generation device, a hopper and an air blower. The fire grates comprise the fixed fire grate and the movable fire grate, the power generation device comprises an aluminum smoke pipe, a water tower, a steam turbine and a power generator, a material pipe is fixedly connected to the bottom of the hopper, a heat exchange bin is fixedly connected to the material pipe, a cover bin is fixedly connected to the outside of the heat exchange bin, and a heat exchange pipe is fixedly connected into the cover bin. The equipment further comprises a waste heat recycling bin. Household garbage is conveyed to the fire grates in the hearth through a hopper and a material pipe to be combusted, steam is generated by energy generated during combustion, then power is generated through the power generation device, and external fresh air is conveyed into the hearth through the air blower to support combustion; and by adding pulverized coal, garbage combustion is more sufficient, garbage can be dried and fresh air can be preheated through the heat exchange bin, ash residues obtained after combustion can be smashed through a smashing roller, and waste heat can be further recycled through the waste heat recycling bin.

Owner:甘肃振毓新能源科技发展有限公司

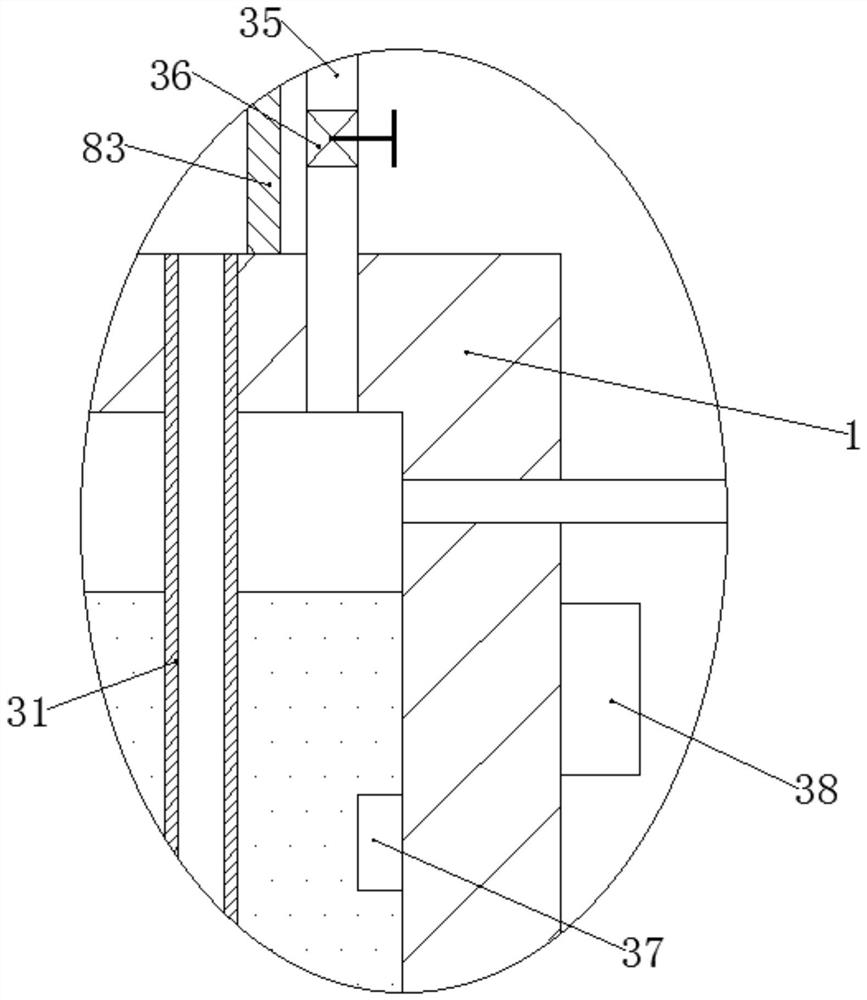

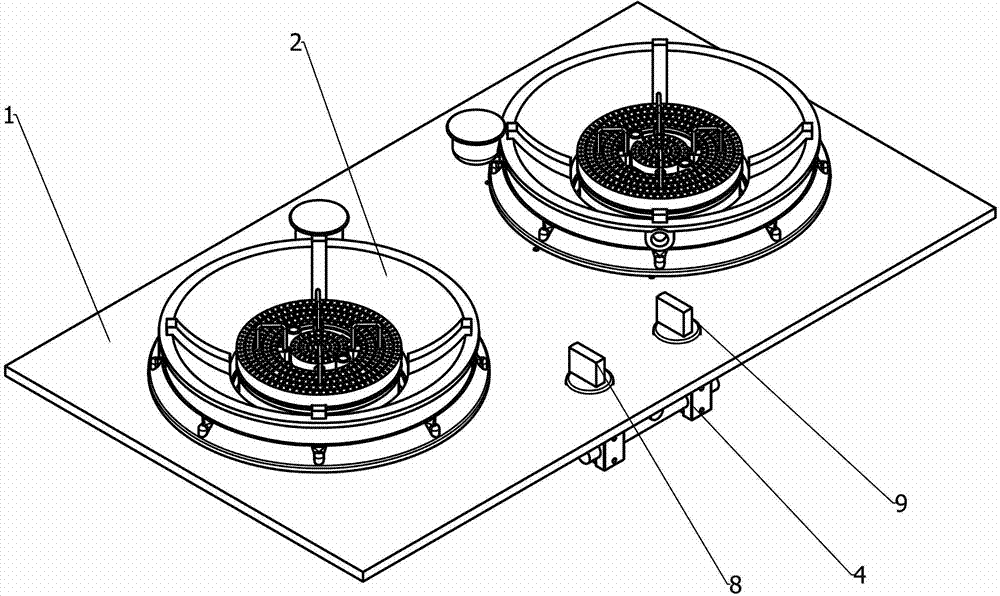

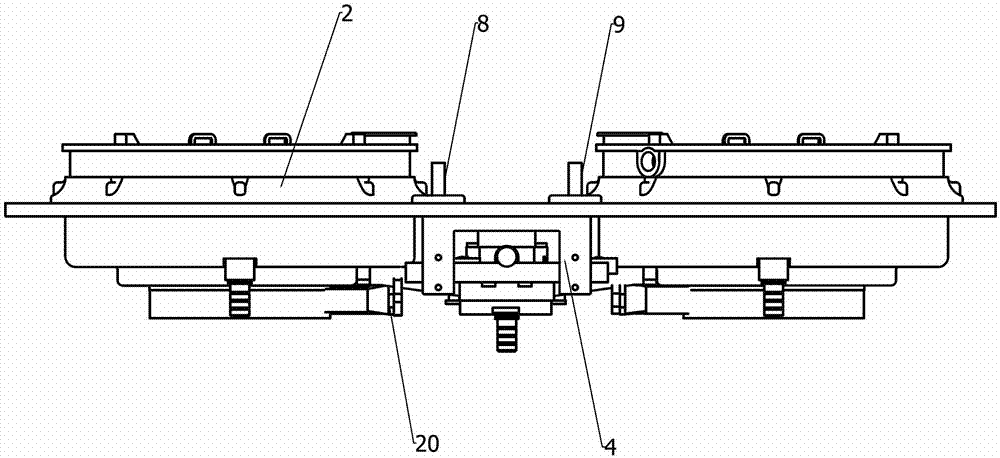

Steam wet combustion total heat type lifting energy-saving stove

InactiveCN103047688ABurn fullyBulk volumeWater heating stoves/rangesCooking fumes removalWater storageCombustion

The invention relates to a steam wet combustion total heat type lifting energy-saving stove, which belongs to the technical field of gas stoves, and includes a panel, cooking ranges, a gas supply bracket, a gas supply pipe, a first gas valve, a second gas valve, a main plate, igniters, a pressing plate, a battery holder and a main plate water outlet, wherein each cooking range includes a mixer, a pivot disk, a water storage hearth bottom disk, water storage hearths, a wet combustion back pressure fire cover, a lifting disk, a connecting bracket and bent wanes; the upper end edges of the pivot disks are fixed on the panel through bolts; water storage disk bodies are arranged at the bottom centers inside the pivot disks; the lower ends of the water storage hearths are connected with the water storage hearth bottom disks; communicated lifting disk accommodating holes are arranged at the centers of the water storage hearths and the water storage hearth bottom disks; the lifting disks are positioned inside the lifting disk accommodating holes; and the upper ends of the lifting disks are connected with the wet combustion back pressure fire covers. The steam wet combustion total heat type lifting energy-saving stove is easy to dismount, convenient to clean, has no sanitary dead space, enlarges the combustion area and saves energy source as water vapor in appropriate amount changes the flame structure during combustion, avoids hidden danger caused by bottom combustion of the stoves, and can be suitable for various pot shapes.

Owner:李欣欣

Industrial gas burner

InactiveCN102721057APromote combustionIncrease the burning areaGaseous fuel burnerIndustrial gasEngineering

The invention relates to an industrial gas burner. The industrial gas burner comprises a cylindrical housing, and a gas guide pipe arranged in the housing, wherein a burning head is arranged in the front end of the housing and adjustably sleeved on the gas guide pipe; a swirler is arranged at the front end of the housing, and an air guide blade inclined to an axis of the housing is fixed onto the swirler; a front cover is also arranged at the front end of the housing, with the front end contracted inwards to form a circular opening, and the inside diameter of the opening is more than the outside diameter of the burning head. According to the industrial gas burner, the swirler is arranged outside the burning head, which can further promote the gas burning during burning under gas, and moreover, the flame in burning can be spread to the outside by means of rotating through the swirler, therefore, the burning area of the flame is expanded. The front cover is arranged at the front end of the burning head, and the edges of the flame in burning are baffled by the front cover, thus, the edges are forcibly close to centre of the flame, and spewed out from the opening at the front cover, and the flame in burning is collected and extended, and the full burning is achieved, the emission of CO and NOx is reduced, and the stability of the flame is improved.

Owner:潘育坛

Supercritical water oxidation reactor by using auxiliary fuel for supplying heat

ActiveCN102190363BEfficient mixingEfficient combustionSludge treatmentPressure vessels for chemical processNuclear engineeringOrganic fluid

The invention discloses a supercritical water oxidation reactor by using an auxiliary fuel for supplying heat, the heat required for a reaction can be supplied by using the auxiliary fuel, Material, fuel and an oxidizing agent (air or oxygen) are mixed with a high efficiency through the different directional jets for raising oxidation efficiency. According to the invention, the reactor employs a combination structure of evaporation wall and pot type backflow, the reaction vessel volume is effectively used and the reaction time is increased, the blockage problem generated by salt deposition can be also prevented, the corrosion problem of the reactor is effectively reduced. The temperature of the reactor bottom can be preciously controlled through a cooling water pipeline at the reactor bottom, thereby the safe operation of equipment is guaranteed. The reactor effectively solves the economic problem of a supercritical water reaction system by using the auxiliary fuel for supplying, the invention has the advantage of easy industrial amplification, and is widely applied to organic liquid such as high density and difficult biodegradation organic waste water / garbage leachate and the like for a harmlessness processing.

Owner:XI AN JIAOTONG UNIV

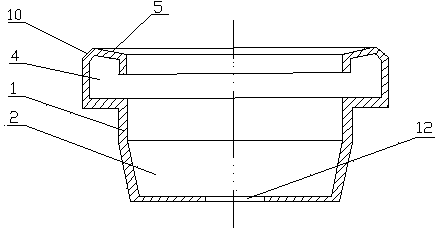

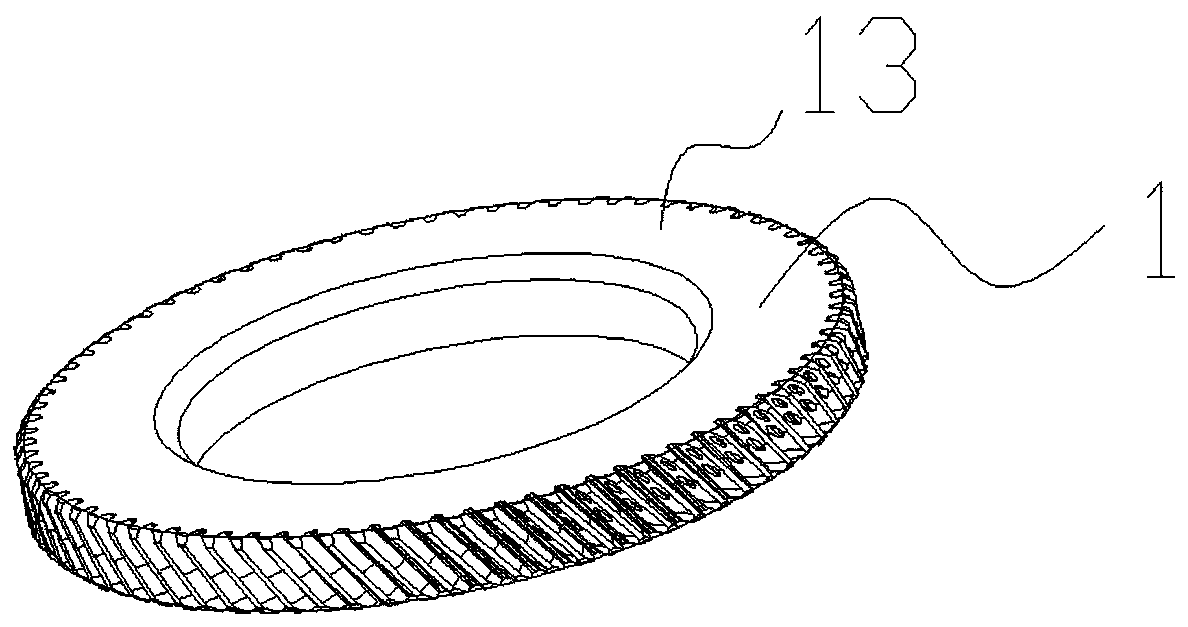

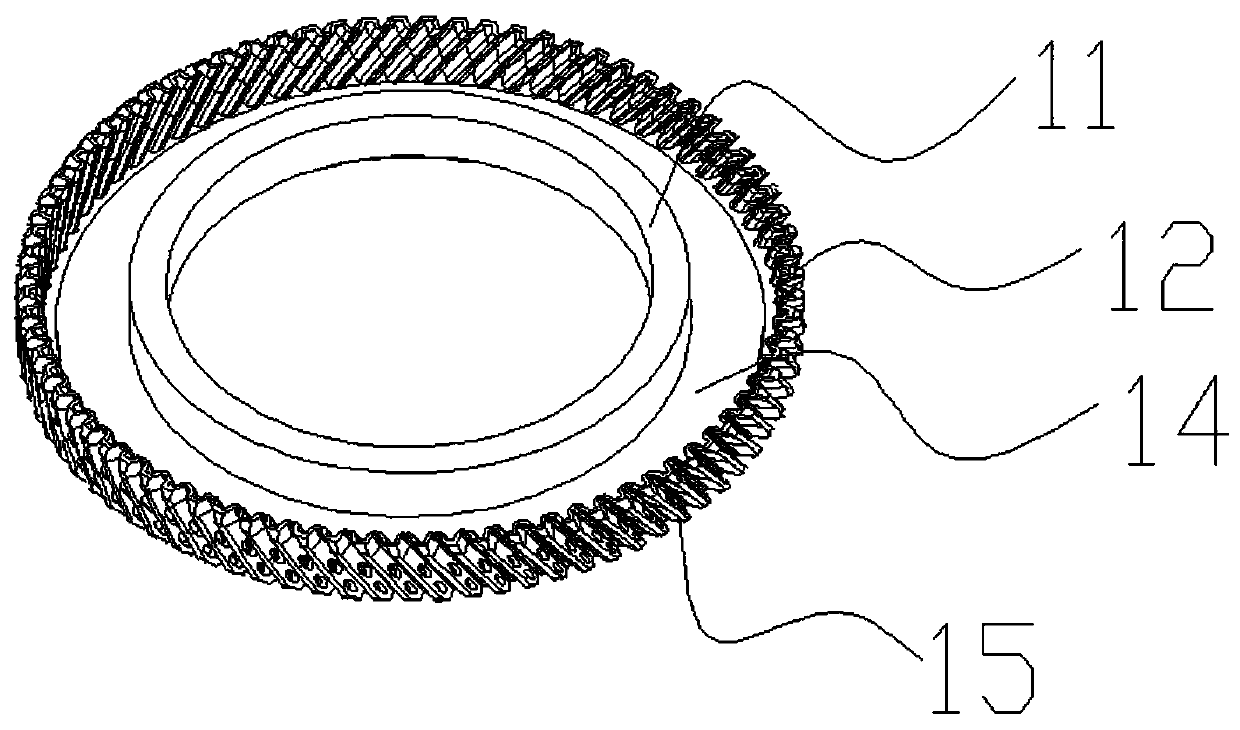

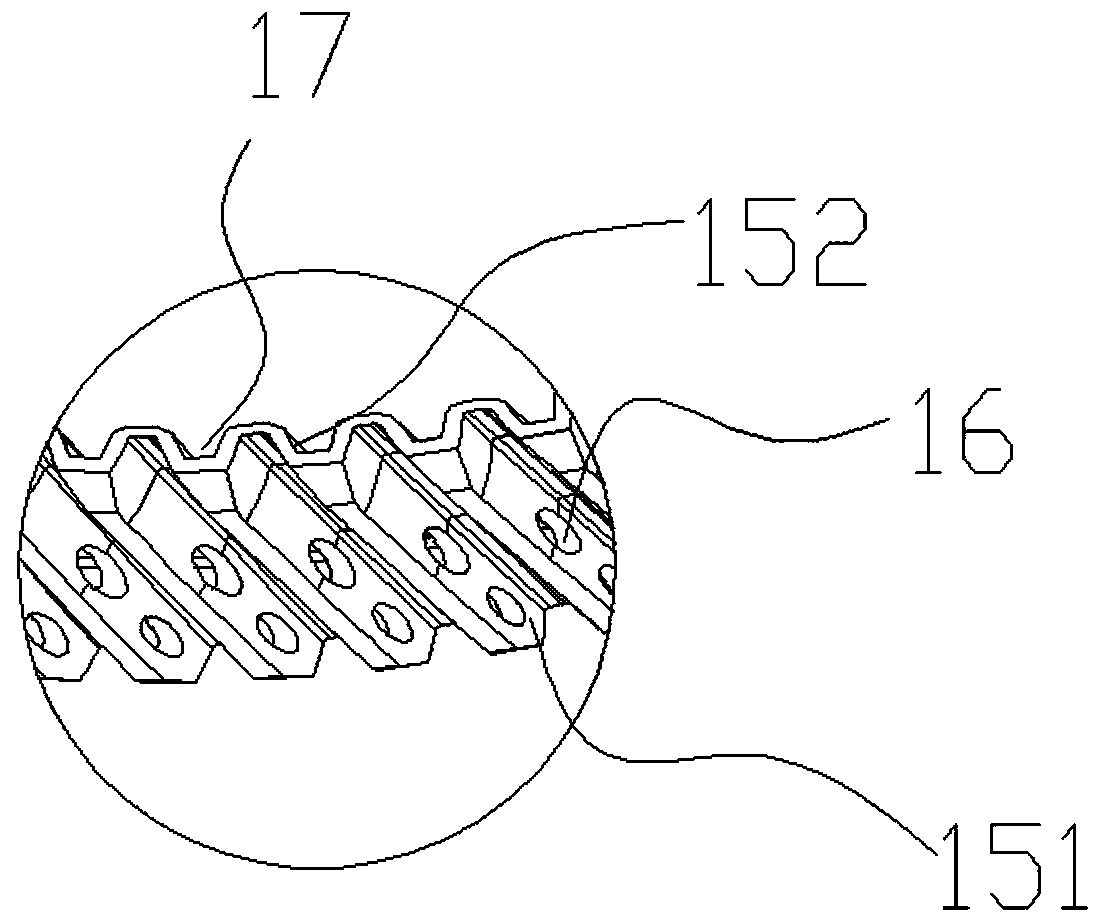

Fire cover for burner and burner

PendingCN110848691AIncrease the burning areaImprove combustion efficiencyGaseous fuel burnerCombustorEngineering

The invention discloses a fire cover for a burner and a burner. The fire cover comprises annular bodies, the annular bodies each include an inner side wall, an outer side wall and a top wall, whereinthe top walls are connected between the tops of the inner side walls and the tops of the outer side walls, and gas grooves with downward openings are formed in the positions between the inner side walls, the outer side walls and the top walls. The fire cover is characterized in that the outer side walls each include a plurality of convex ribs which are distributed at intervals in the circumferential direction and are connected in sequence, the convex ribs are arranged obliquely from top to bottom, fire holes are formed in the convex ribs, and the fire holes are in communication with the gas grooves. The combustion efficiency is high and the combustion load is large.

Owner:VATTI CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com