Combustion system for inorganic garage disposal equipment

A technology of processing equipment and combustion system, which is applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of complicated and difficult garbage disposal, affecting the living environment, and insufficient incineration, and achieves simple structure, increased combustion area, The effect of high incineration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

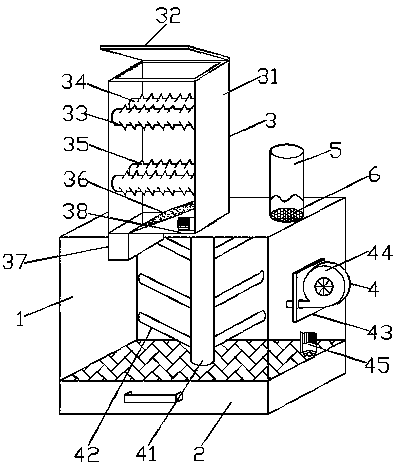

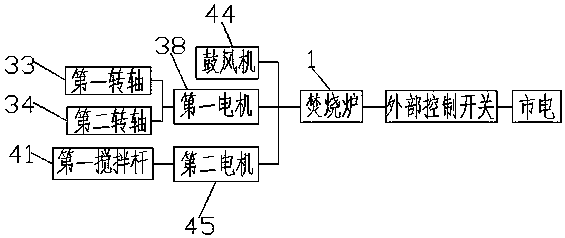

[0018] Such as Figure 1-3 As shown, a combustion system for inorganic waste treatment equipment includes an incinerator 1, a slag leakage bin 2 is installed at the bottom of the incinerator 1, and a crushing device 3 is fixed on the top side of the incinerator 1. The crushing device 3 includes a casing 31, a top cover 32, a first rotating shaft 33, a second rotating shaft 34, a crushing blade 35, a deflector 36, a discharge port 37 and a first motor 38, and the top side of the casing 31 is A top cover 32 is hinged, a first rotating shaft 33 is installed on one side of the housing 31, a second rotating shaft 34 is installed on the other side of the housing 31, and the first rotating shaft 33 and the second rotating shaft 34 are outside All are fixed with crushing blades 35, the inner bottom of the shell 31 is fixed with a deflector 36, and one side of the bottom of the shell 31 is provided with a discharge port 37, between the shell 31 and the deflector 36 A first motor 38 is...

Embodiment 2

[0027] Such as Figure 1-3As shown, a combustion system for inorganic waste treatment equipment includes an incinerator 1, a slag leakage bin 2 is installed at the bottom of the incinerator 1, and a crushing device 3 is fixed on the top side of the incinerator 1 to crush The device 3 first crushes the rubbish that needs to be burned to increase the burning area of the rubbish, making it burn faster. The crushing device 3 includes a casing 31, a top cover 32, a first rotating shaft 33, a second rotating shaft 34, and a crushing blade 35. The deflector 36, the discharge port 37 and the first motor 38, the top side of the shell 31 is hinged with a top cover 32, the inner side of the shell 31 is equipped with a first rotating shaft 33, the shell 31 The other side of the inside of 31 is equipped with a second rotating shaft 34, the outside of the first rotating shaft 33 and the second rotating shaft 34 are fixed with crushing blades 35, and the inner bottom of the shell 31 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com