Household garbage incineration treatment equipment

A technology of domestic waste incineration and treatment equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

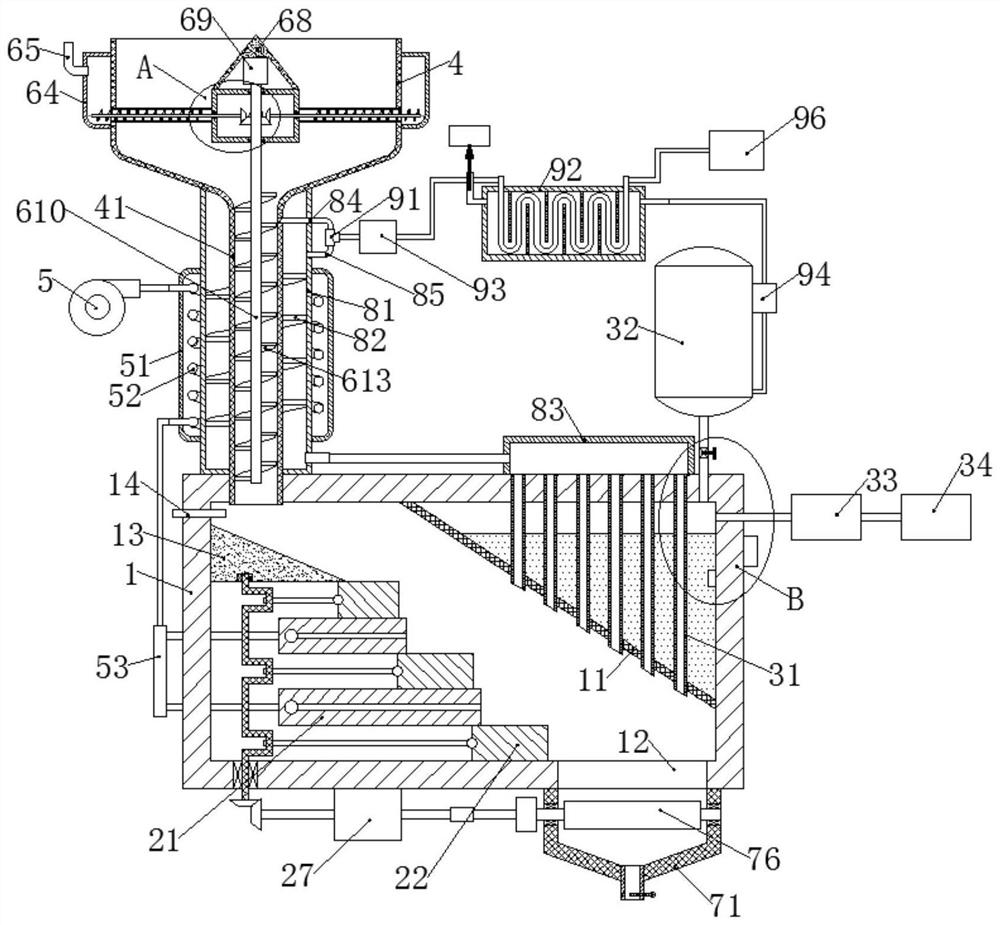

[0058] A domestic waste incineration treatment equipment, including a furnace 1, a fire grate, a power generation device, a hopper 4 and a blower 5;

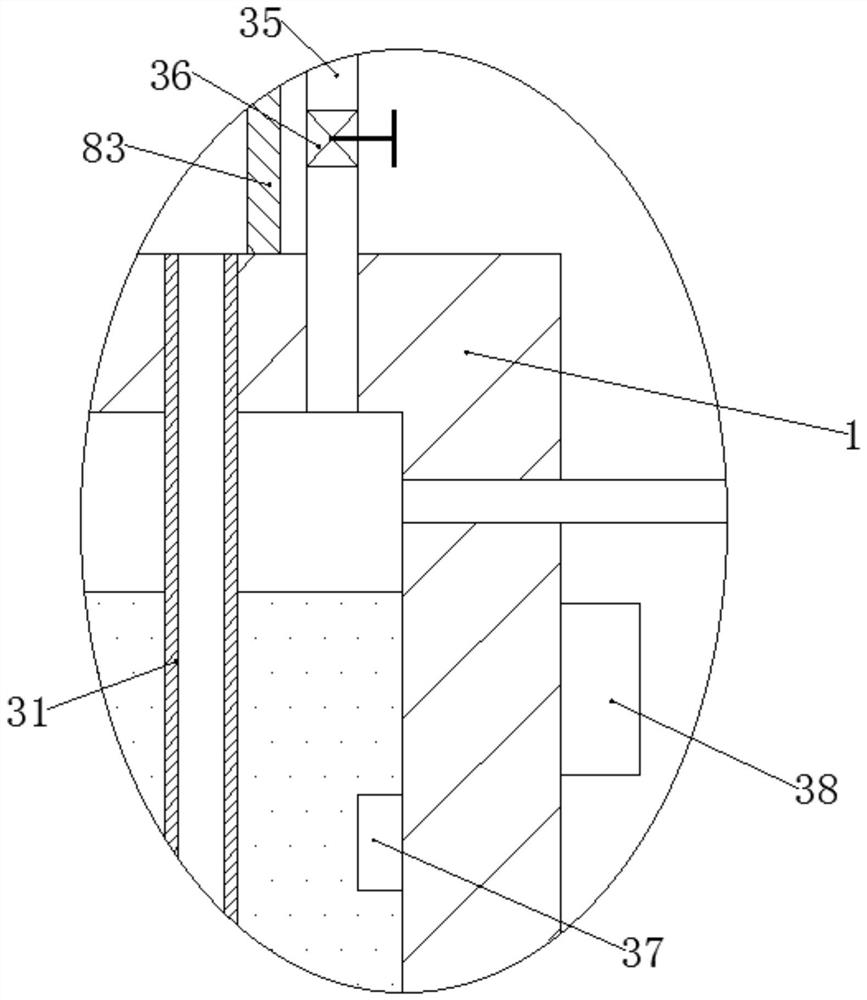

[0059] Furnace 1 is a cuboid cavity structure, and the upper right corner of furnace 1 is fixed with a partition 11, which divides the inner cavity of furnace 1 into a combustion chamber and a steam chamber, and a slag port 12 is provided on the right side of the bottom plate of furnace 1;

[0060] The upper part of the inner wall of the left side plate of the furnace 1 is fixedly connected with a material guide seat 13, and the upper surface of the material guide seat 13 is arranged obliquely. below seat 13;

[0061] The power generation device includes an aluminum smoke pipe 31, a water tower 32, a steam turbine 33 and a generator 34; the top of the aluminum smoke pipe 31 is fixedly connected to the top plate of the furnace 1, and a plurality of aluminum smoke pipes 31 are uniformly arranged horizontally, and each aluminum smo...

Embodiment 2

[0069] The difference from Example 1 is that it also includes the following:

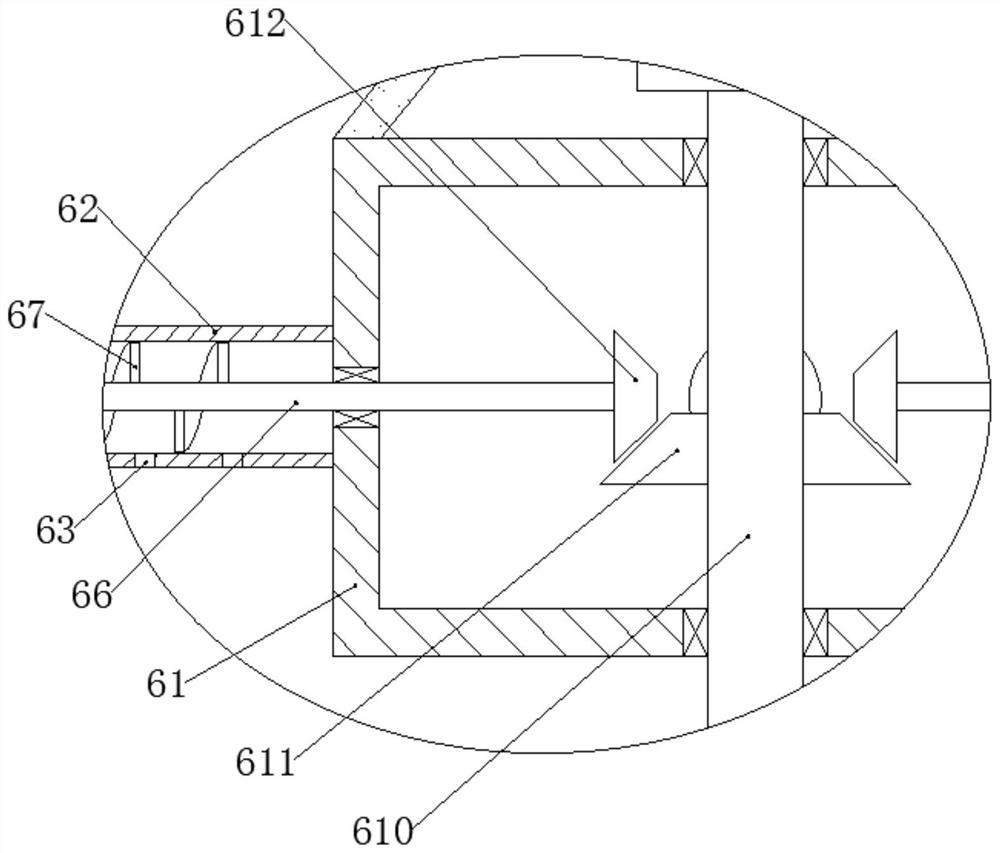

[0070] The center of the hopper 4 is provided with a transmission bin 61, the outer wall of the arc-shaped side plate of the transmission bin 61 is evenly fixed with a delivery pipe 62, the head of the delivery pipe 62 is fixedly connected with the side plate of the hopper 4, and the bottom of the delivery pipe 62 is densely covered with The discharge port 63 is fixedly connected with the outer wall of the side plate of the hopper 4 with an annular silo 64, the silo 64 covers the conveying pipes 62 in it, and the upper part of the silo 64 is fixedly connected with an adding pipe 65, which also includes a conveying shaft 66, the conveying shaft 66 is set coaxially with the conveying pipe 62 and is connected with the arc-shaped side plate of the transmission bin 61. One end of the conveying shaft 66 extends into the material bin 64, and the other end of the conveying shaft 66 extends into the transmiss...

Embodiment 3

[0075] The difference from Example 2 is that it also includes the following:

[0076] The fire grate includes a fixed fire grate 21 and a movable fire grate 22. The fixed fire grate 21 is fixedly connected between the front and rear side plates of the furnace 1 and arranged at vertical intervals. A moving grate 22 is slidably connected between adjacent fixed grates 21 and between the bottommost fixed grate 21 and the bottom plate of the furnace 1, and a shaft is rotatably connected between the bottom of the material guide seat 13 and the bottom plate of the furnace 1. Rod 23, the position corresponding to each movable fire grate 22 on the shaft rod 23 is all provided with U-shaped crankshaft 24, is hinged with connecting rod 25 between crankshaft 24 and corresponding mobile fire grate 22, and the bottom of shaft rod 23 is fixedly connected with the first Two driven bevel gears 26, the lower surface of the bottom plate of the furnace 1 is fixedly connected with a double-headed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com