Fire cover for burner and burner

A burner and fire cover technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of insufficient combustion of gas, low combustion efficiency of fire cover, low combustion efficiency, etc., and achieve large combustion load , large quantity and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

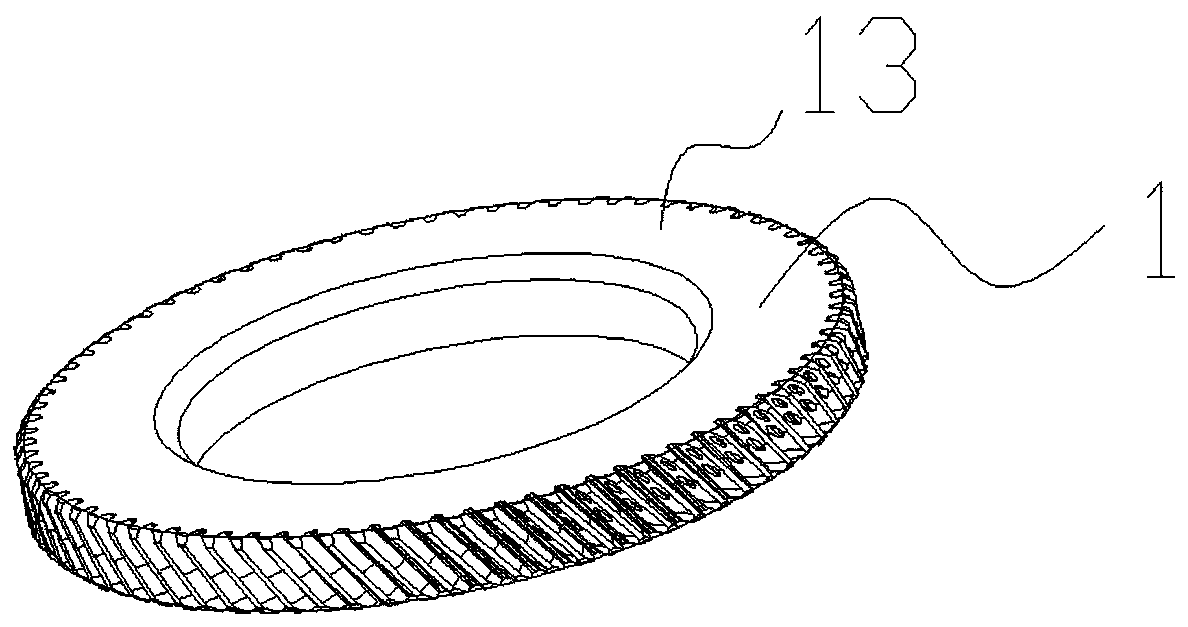

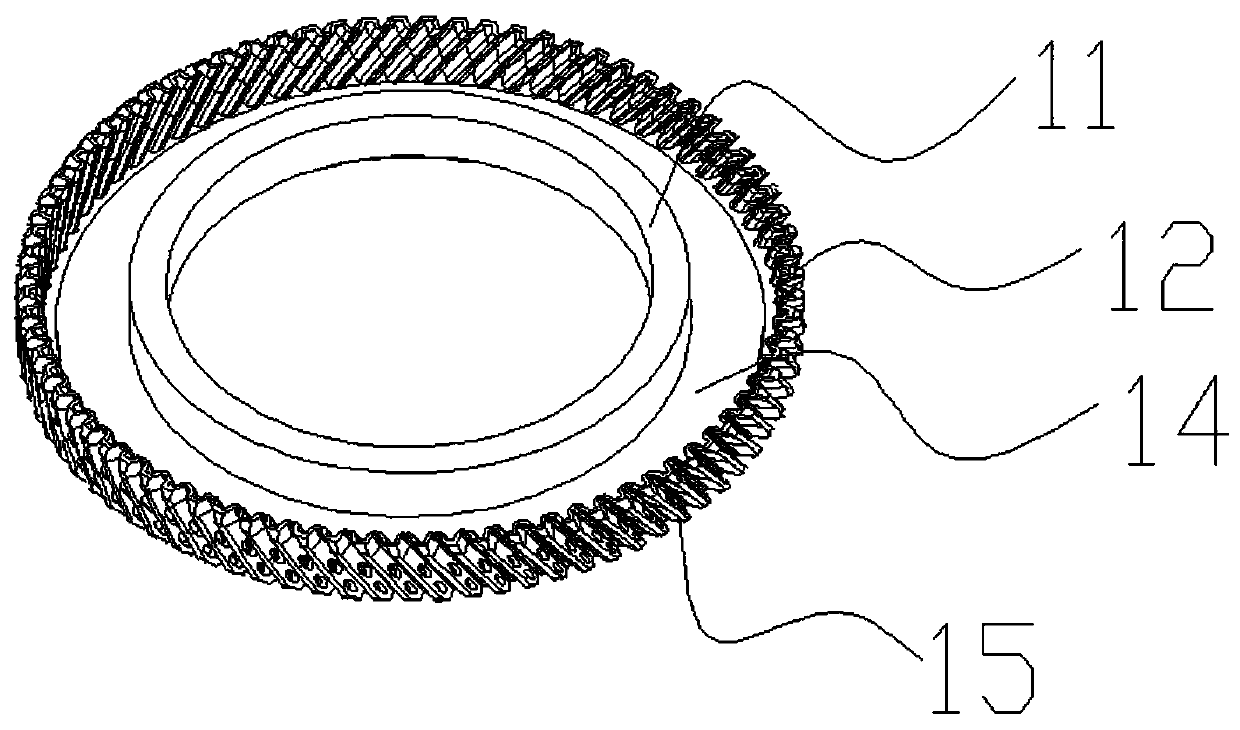

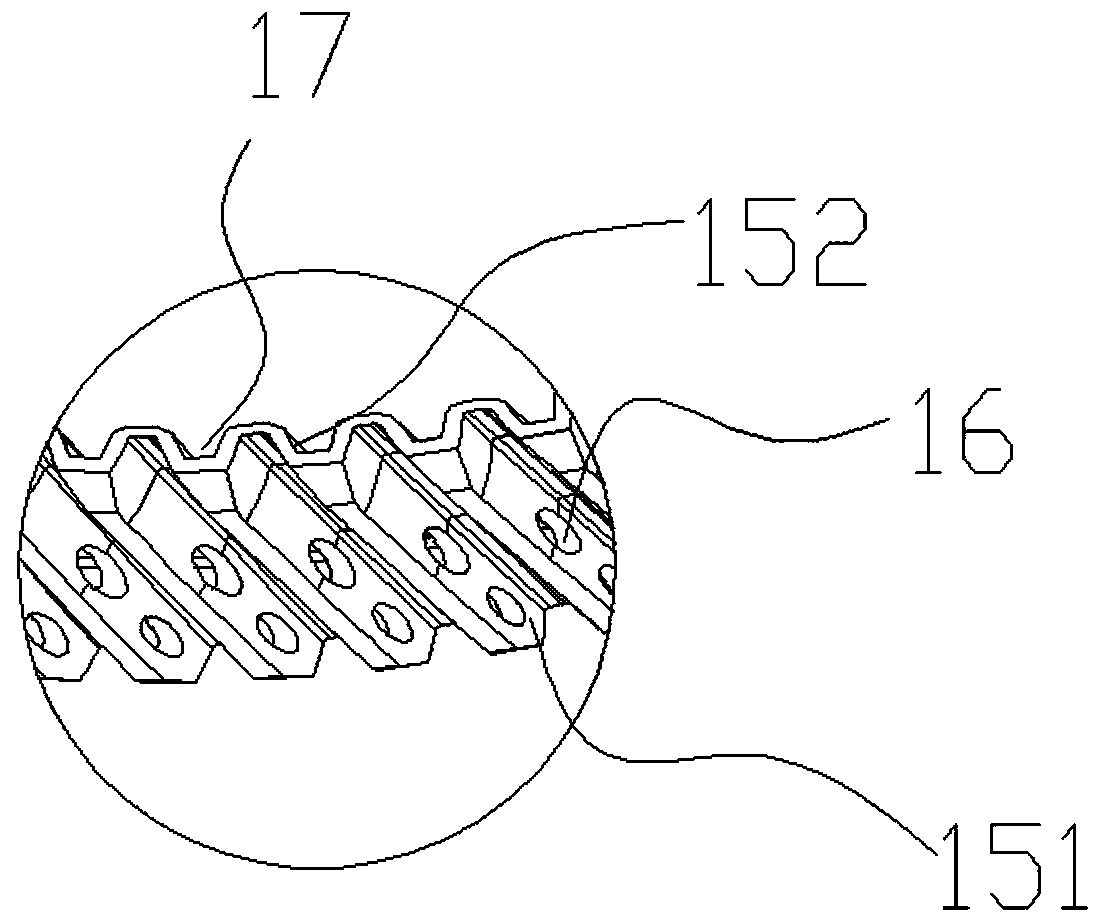

[0025] See attached Figure 1-3 It shows a fire cover for a burner proposed by the present invention, which includes an annular main body 1, and the annular main body 1 includes an inner side wall 11, an outer side wall 12 and a top wall 13, wherein the top wall 13 is connected to the inner side wall Between the top of the wall 11 and the top of the outer wall 12, a gas groove 14 with an opening downward is formed between the inner wall 11, the outer wall 12 and the top wall 13, and it is characterized in that: The outer wall 12 includes a plurality of ribs 15 distributed at intervals in the circumferential direction and connected in sequence. The ribs 15 are arranged obliquely from top to bottom, so that the fire cover forms a gear-like shape, and fire holes are arranged on the ribs 15. 16. The fire hole 16 communicates with the gas groove 14. The convex rib 15 is arranged inclined from top to bottom, and the fire hole 16 is arranged on the convex rib 15. The shape of the po...

Embodiment 2

[0030] See attached Figure 4 A burner shown includes the above-mentioned fire cover. The burner is provided with a fire cover, and the outer wall 12 of the fire cover includes a plurality of convex ribs 15 distributed at intervals in the circumferential direction and connected in sequence. A fire hole 16 is provided on the rib 15 , and the fire hole 16 communicates with the gas groove 14 . The burner is provided with an inclined rib 15, and a fire hole 16 is arranged on the rib 15. When the burner is turned on, the burning flame rotates in a certain direction, so that the combustion area is large and the combustion efficiency is high. The convex ribs 15 are equidistantly distributed in the circumferential direction of the fire cover, and the flame distribution is even when burning. Two fire holes 16 are arranged on the convex ribs 15. The number of the flame holes 16 increases, and the combustion load increases, which meets the needs of people.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com