Patents

Literature

47results about How to "Increase incineration speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering rhodium from rhodium-containing waste liquid

ActiveCN111020200AAvoid direct dischargeAvoid direct discharge of pollutionProcess efficiency improvementFlue gasEnvironmental engineering

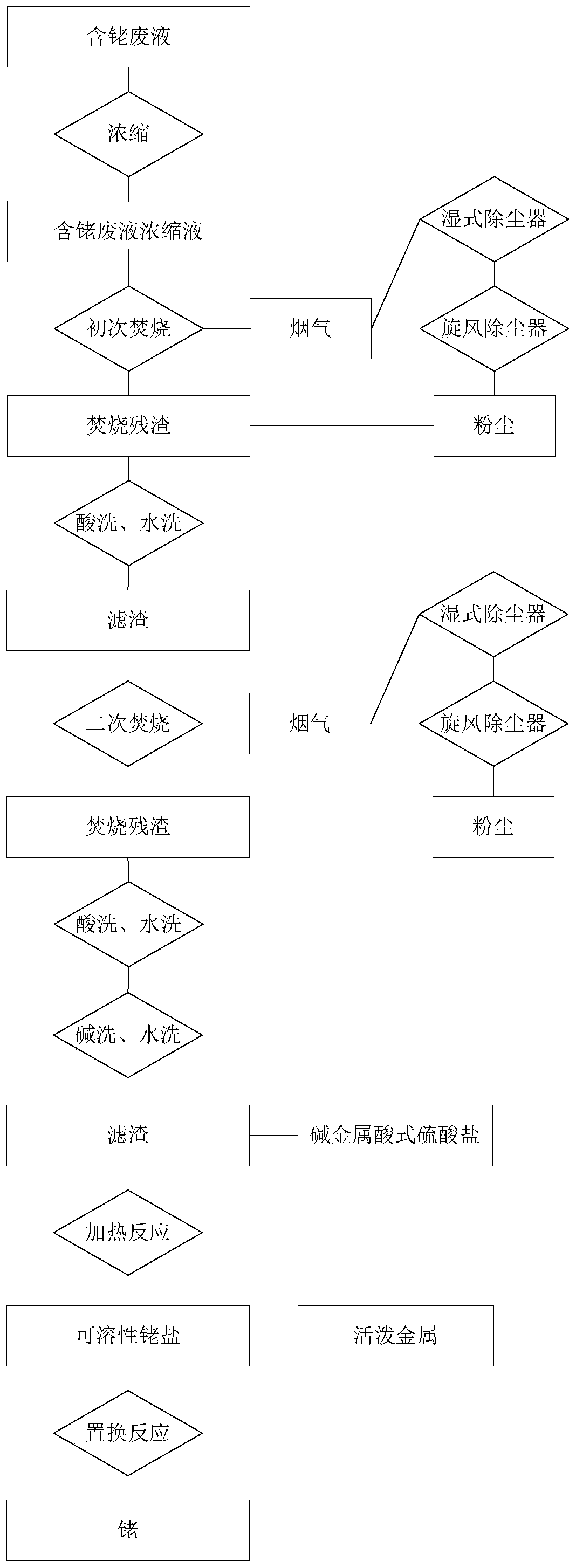

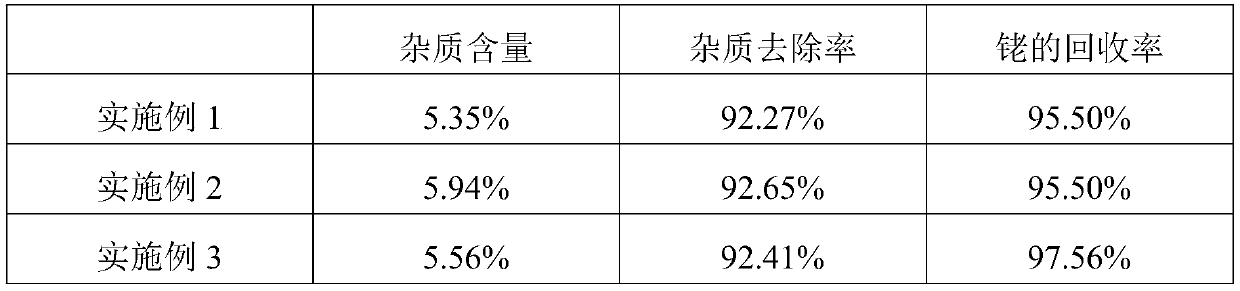

The invention belongs to the field of rhodium recovery, and particularly discloses a method for recovering rhodium from rhodium-containing waste liquid. The method comprises the following steps of concentrating the rhodium-containing waste liquid to evaporate light components, mixing wood chips, carrying out primary incineration on the rhodium-containing waste liquid concentrated solution to obtain rhodium-containing carbon residues, and carrying out acid pickling and water washing; carrying out secondary incineration on the rhodium-containing carbon residues to obtain rhodium-containing ash residues, and carrying out acid pickling, water washing, alkali washing and water washing to completely remove acid-soluble and alkali-soluble impurities; in the primary incineration and secondary incineration processes, enabling flue gas to pass through a wet dust collector and a cyclone dust collector, collecting dust in the flue gas, avoiding direct emission of the flue gas to pollute the environment, and reducing rhodium loss in the incineration process; and combining the dust with incineration residues, reacting with alkali metal acid sulfate to generate soluble rhodium salt, and reactingthe soluble rhodium salt with active metal to obtain rhodium. According to the process, the rhodium loss in the incineration process can be reduced, the rhodium yield can be improved, impurities in the rhodium-containing ash residues can be removed, the rhodium enrichment degree is higher, and the recovery process is simplified.

Owner:山东博苑医药化学股份有限公司

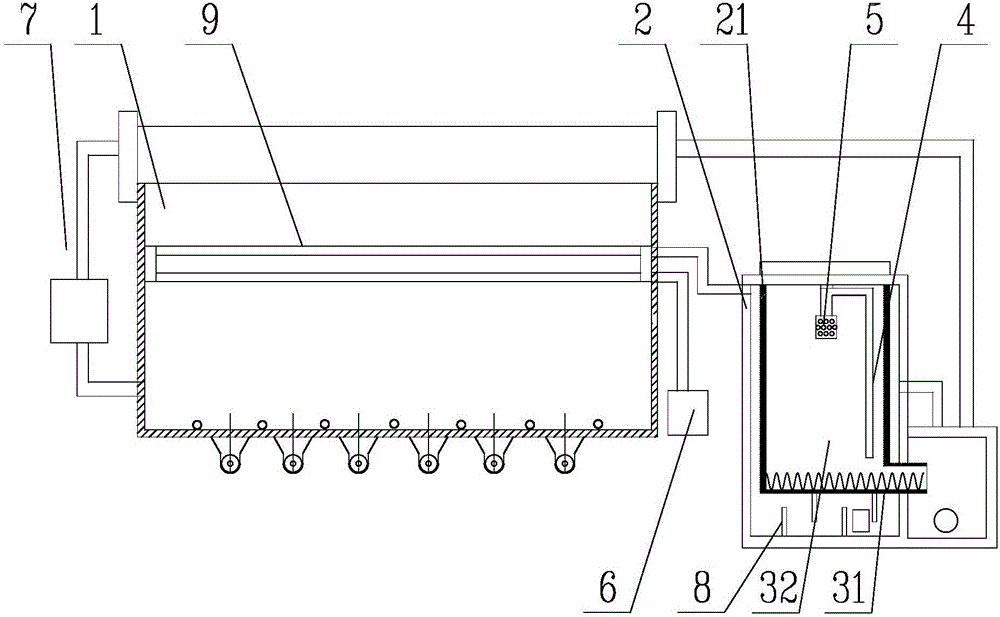

Power generation technique based on pyrolyzation and gasification of refuse derived fuel (RDF) prepared from household refuse and incineration of fuel gas

InactiveCN105351019ACurb emissionsInhibition formationBiofuelsSolid fuelsRefuse-derived fuelElectric generator

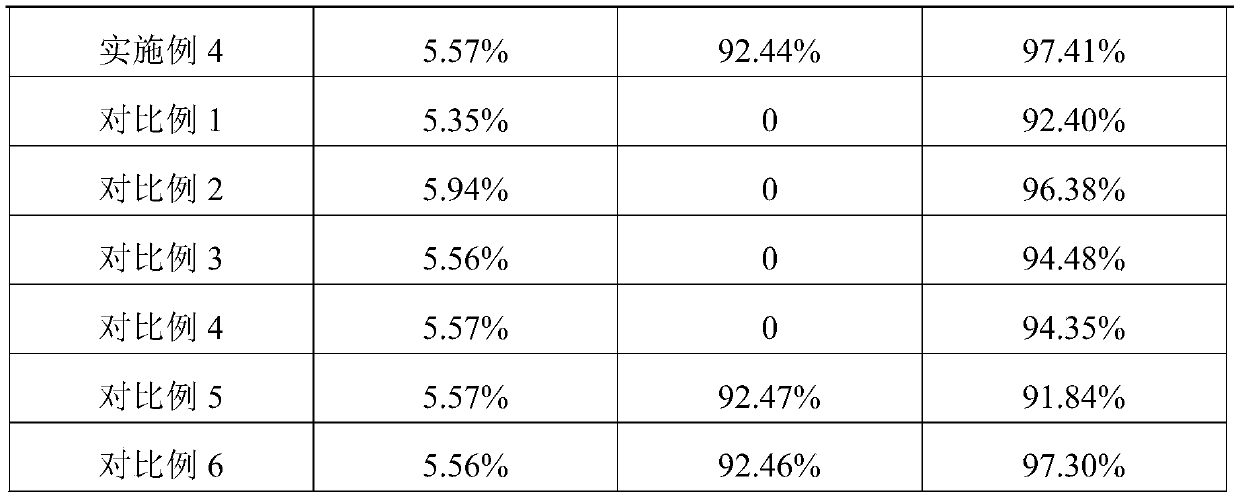

The invention discloses a power generation technique based on pyrolyzation and gasification of refuse derived fuel (RDF) prepared from household refuse and incineration of fuel gas. The power generation method comprises the steps that the household refuse is sorted, pulverized and dried and then is made into the solid RDF; pyrolyzation and gasification are conducted on the solid RDF, so that combustible gas is generated; the combustible gas is incinerated; steam is prepared from hot air obtained through incineration through heat exchange; and the steam is introduced into a steam power generator for power generation. According to the power generation technique based on pyrolyzation and gasification of the RDF prepared from the household refuse and incineration of the fuel gas, the household refuse is made into the combustible solid RDF, and thus formation of dioxin can be effectively restrained; after prepared bars are formed, the moisture content is decreased, the heat value is increased, and the power generation efficiency is improved; the dioxin is completely decomposed by conducting heat-storage incineration of the generated combustible gas through secondary gas at the temperature over 850 DEG C, and waste heat is used for drying the refuse; smoke emission hardly exists under the adsorption action of the pulverized refuse.

Owner:FUJIAN ZHENGREN ENVIRONMENTAL PROTECTION

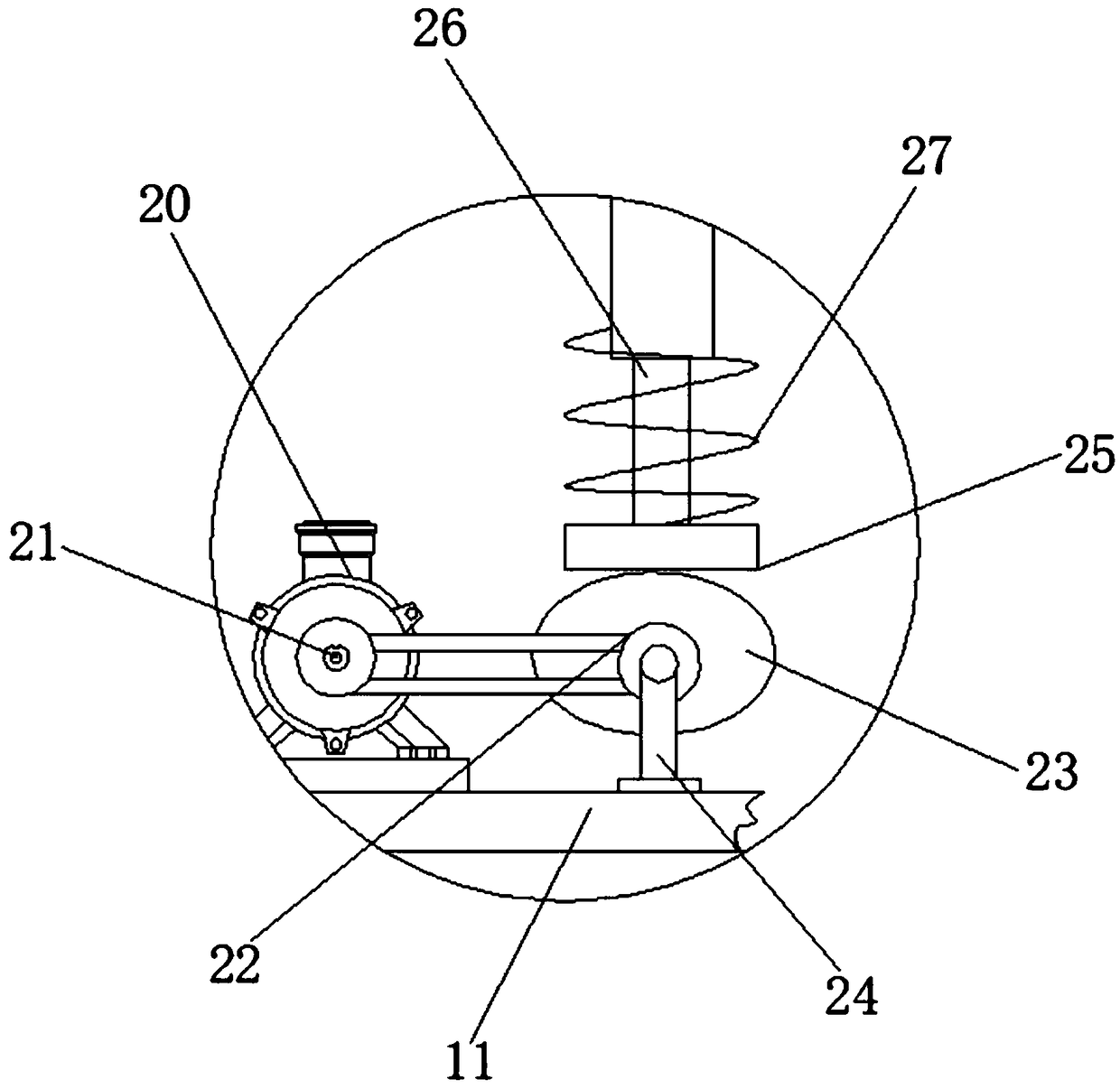

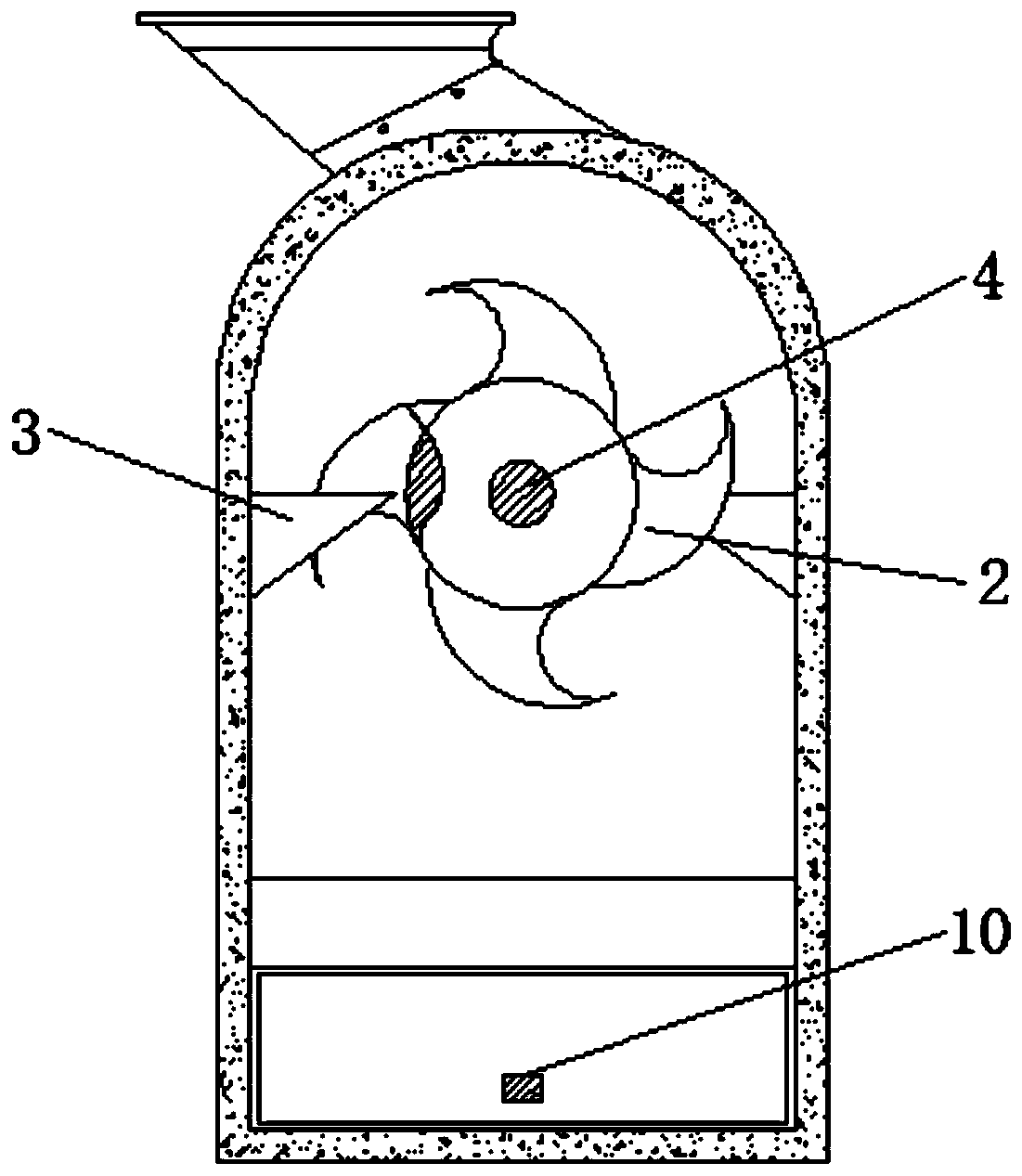

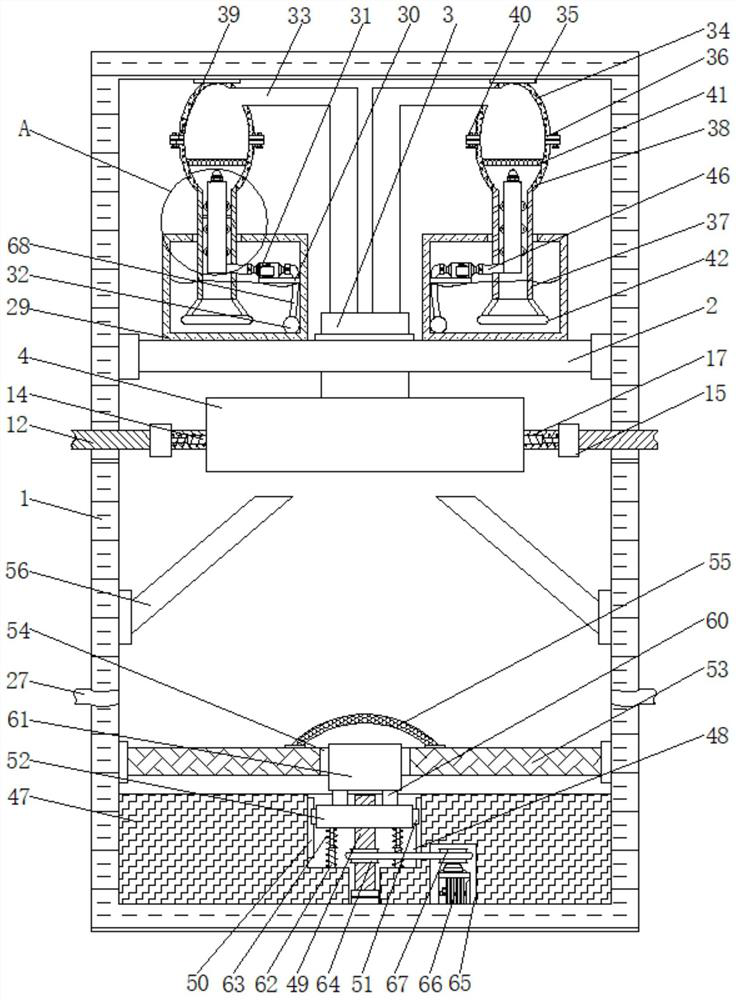

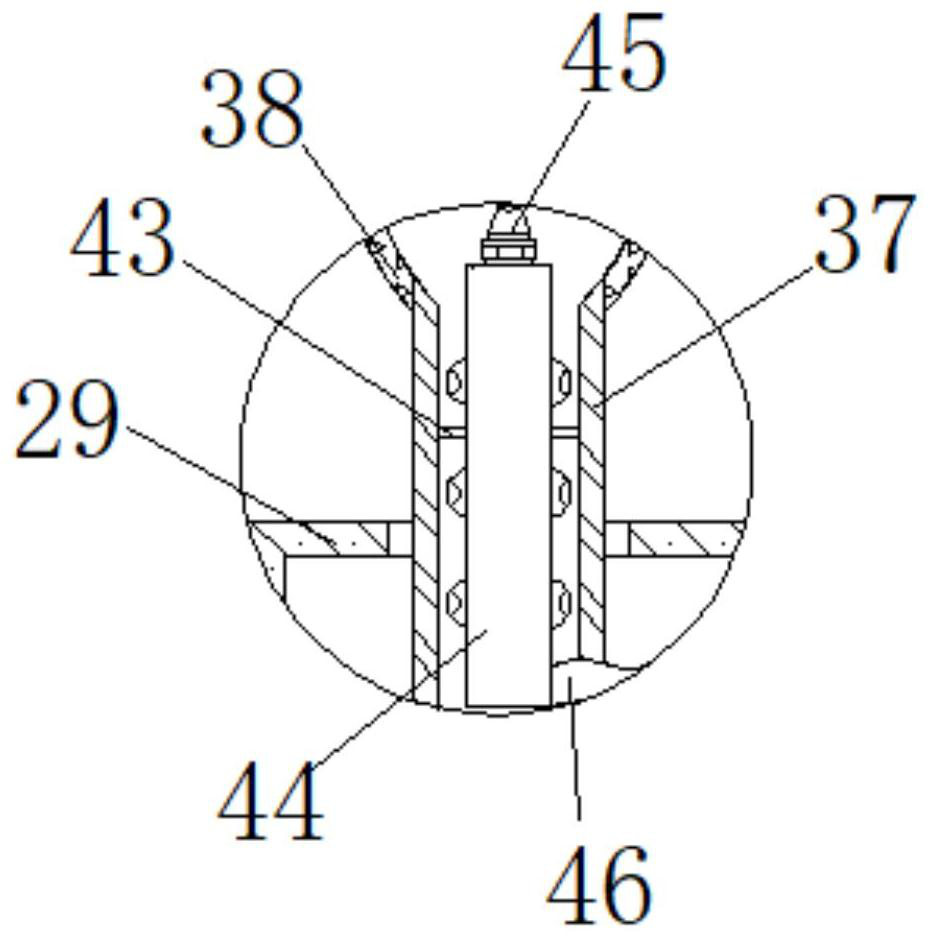

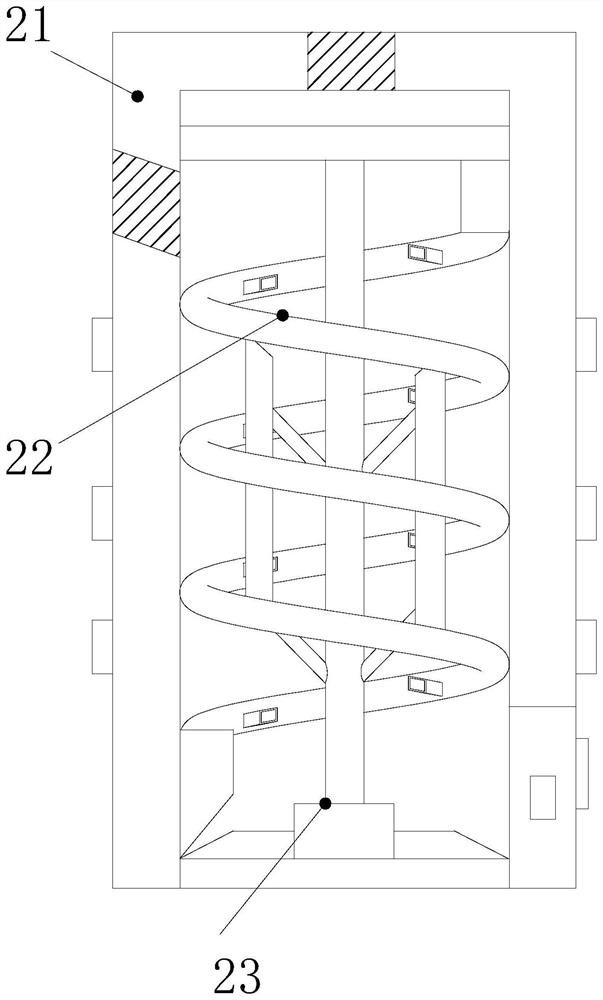

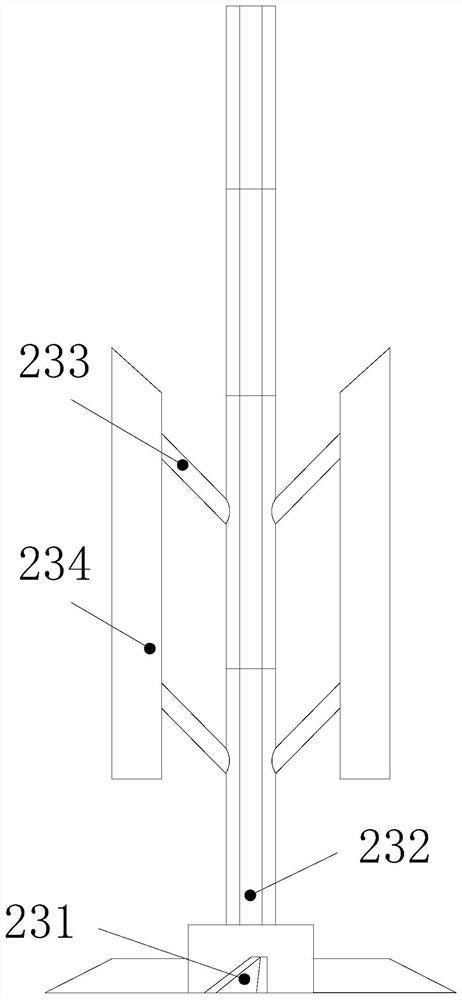

Photothermal medical garbage incinerator

InactiveCN110848710AAchieve the purpose of burningImprove crackingSolar heating energySolar heat collector for particular environmentSlagFuel oil

The invention discloses a photothermal medical garbage incinerator. The photothermal medical garbage incinerator comprises a furnace body and a solar condensing device, the furnace body comprises a furnace shell and a pyrolysis incineration chamber arranged in the furnace shell, a material scattering stand column is arranged at the bottom of the pyrolysis incineration chamber, a spiral buffer material plate is arranged on the material scattering stand column, a solar concentrating port is formed in the bottom of the furnace shell, the solar concentrating port is facing the material scatteringstand column, a solar concentrator is positioned right below the solar concentrating port, a feed port and an exhaust pipe are arranged at the upper part of the pyrolysis incineration chamber, and anair inlet pipe and a slag discharge port are arranged at the lower part of the pyrolysis incineration chamber. According to the method, solar energy is used as a heat source, a medical waste treatmentmethod adopting coal gas and fuel oil as a heat source is replaced, energy consumption is reduced, the photothermal temperature can reach 1600 DEG C instantaneously, waste cracking and incineration speed and completeness are improved, coal gas and fuel oil do not need to be used, and exhaust gas and smoke emission are reduced.

Owner:湖南烁科热工智能装备有限公司

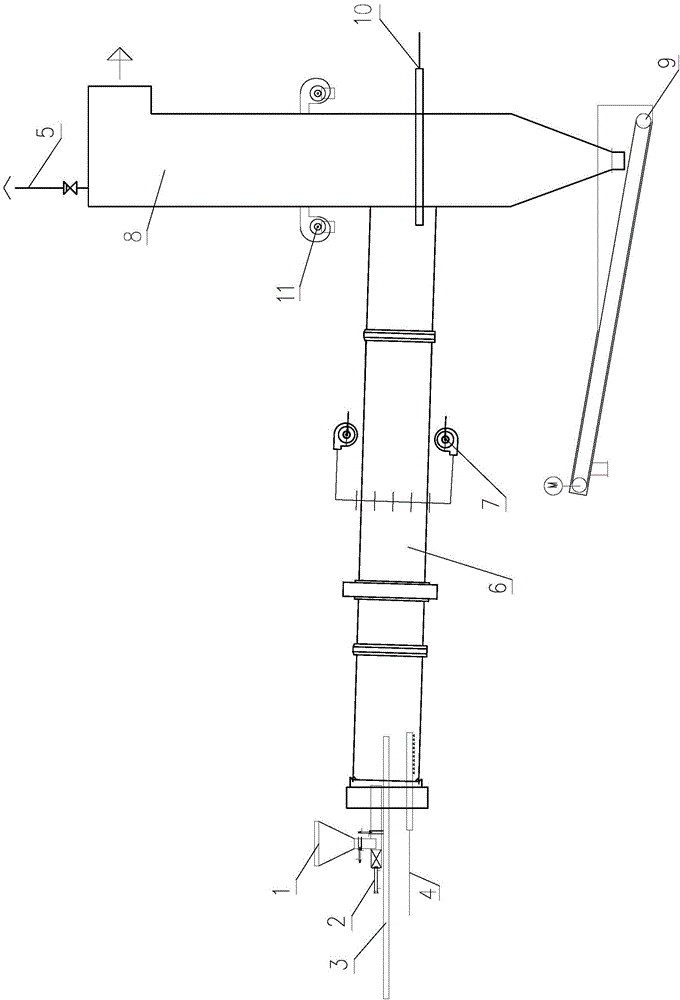

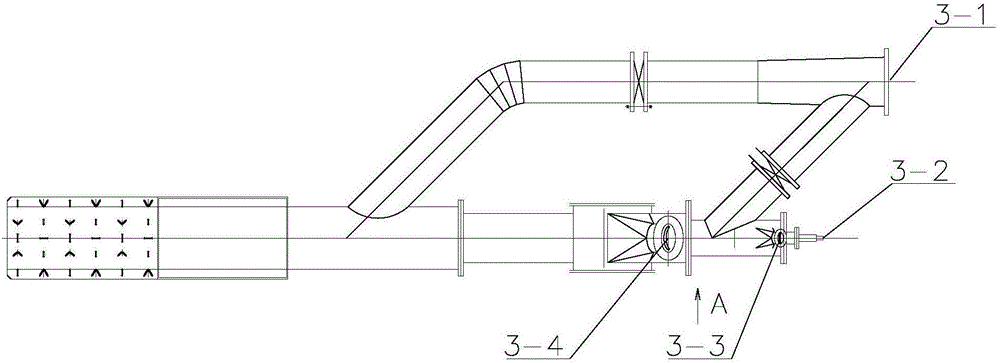

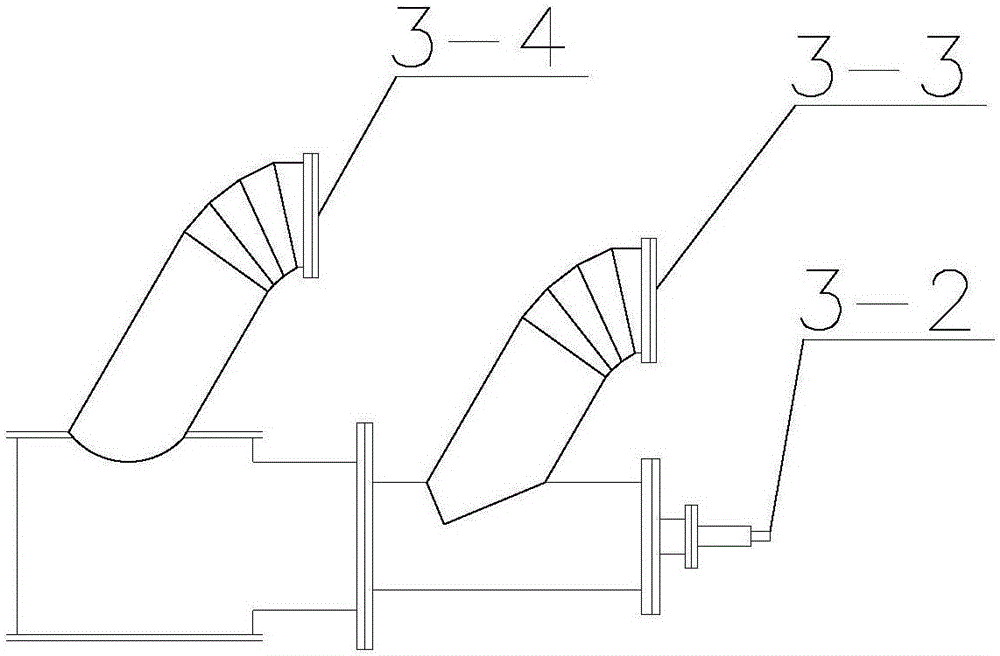

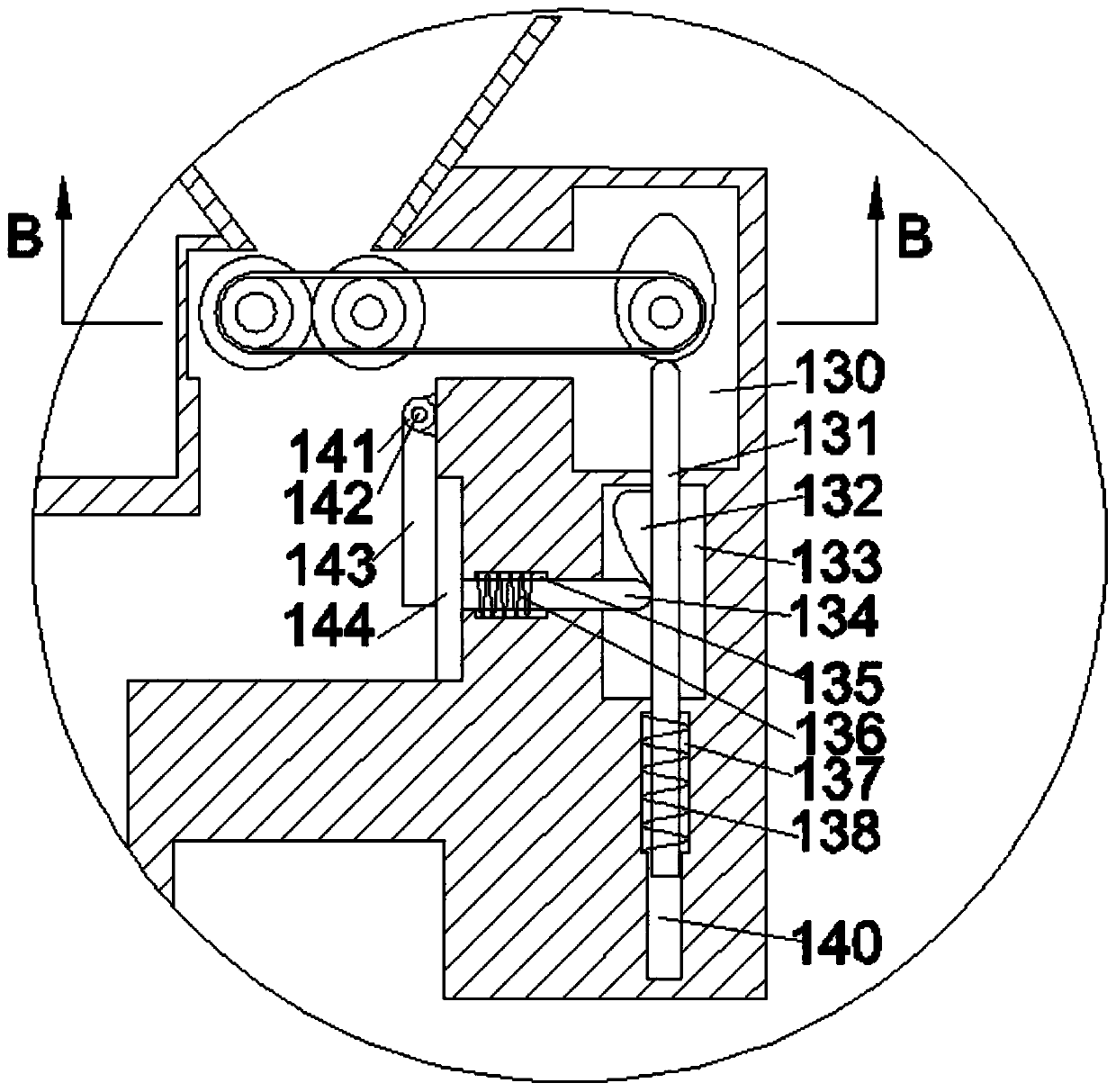

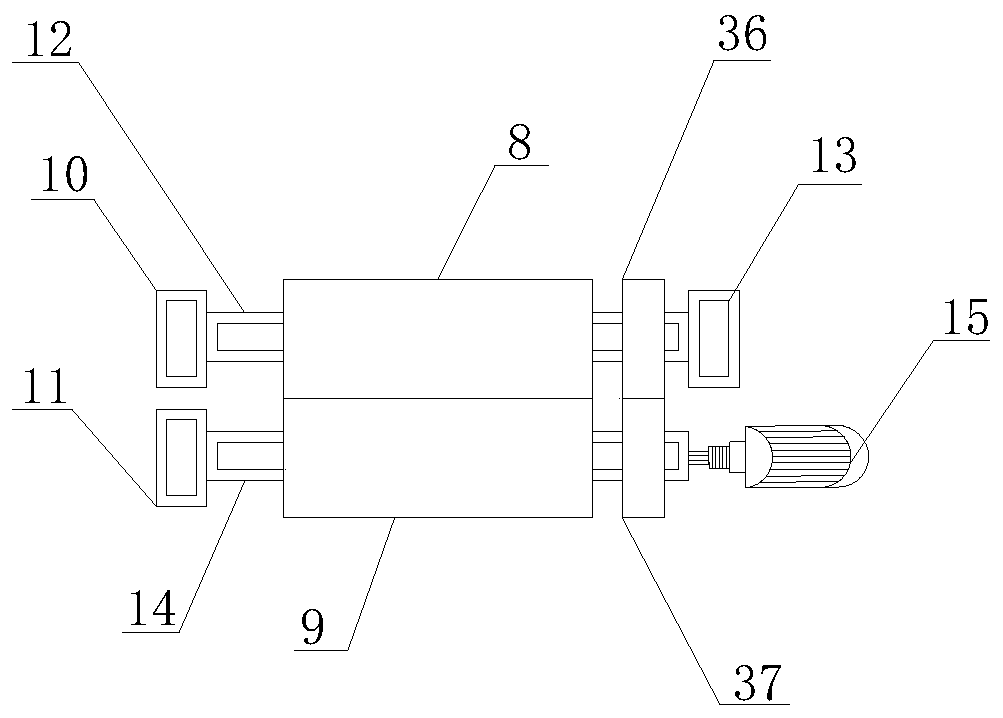

Large-size hazardous waste rotary kiln type incinerator device taking sludge as main target

InactiveCN106402894APromote complete combustionLow oxygenIncinerator apparatusHot blastCombustion chamber

The invention discloses a large-size hazardous waste rotary kiln type incinerator device taking sludge as a main target. The device comprises a receiver bin, a feeder, a multifunctional fuel nozzle, a kiln internal hot blast blowing unit, a rotary kiln, a power suspension unit, a secondary combustion chamber and a scraper slag discharging machine. The feeder, the multifunctional fuel nozzle and the kiln internal hot blast blowing unit are arranged at an inlet of the rotary kiln. The receiver bin is arranged above the feeder. The power suspension unit is arranged in the middle of the rotary kiln. The secondary combustion chamber is arranged at the tail of the rotary kiln. The scraper slag discharging machine is arranged at the lower end of the secondary combustion chamber. Three fuels, namely the solid fuel, the gas fuel, and the liquid fuel can be simultaneously or independently used for providing heat for the incinerator, and steam or nitrogen or water can be used for cooling the fiery furnace under the emergent incinerator shutdown condition. The power suspension unit and the kiln internal hot blast blowing unit are used for increasing the contact area of materials and the gas, so that the heat transferring, drying and combusting effects are improved, and the disposal capacity and efficiency of the kiln type incinerator device are improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

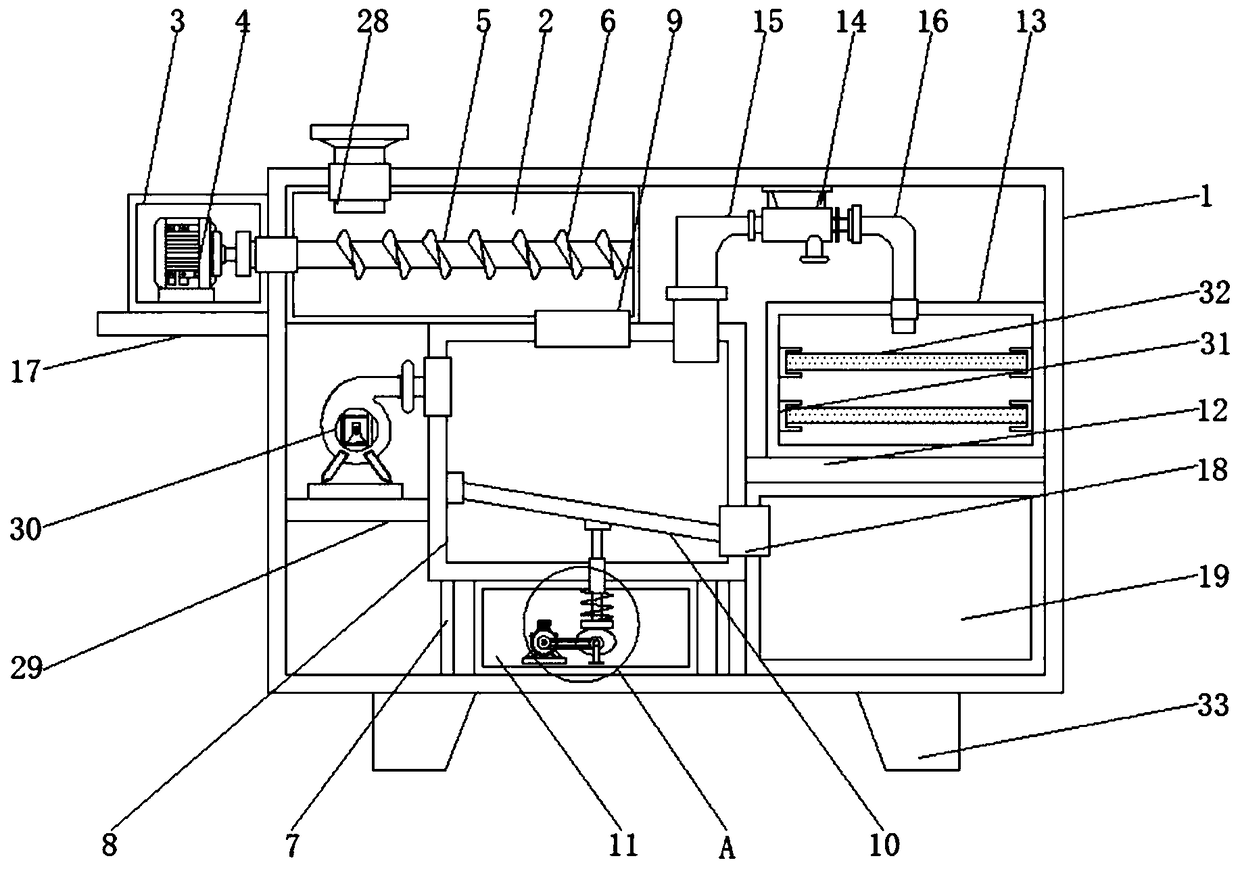

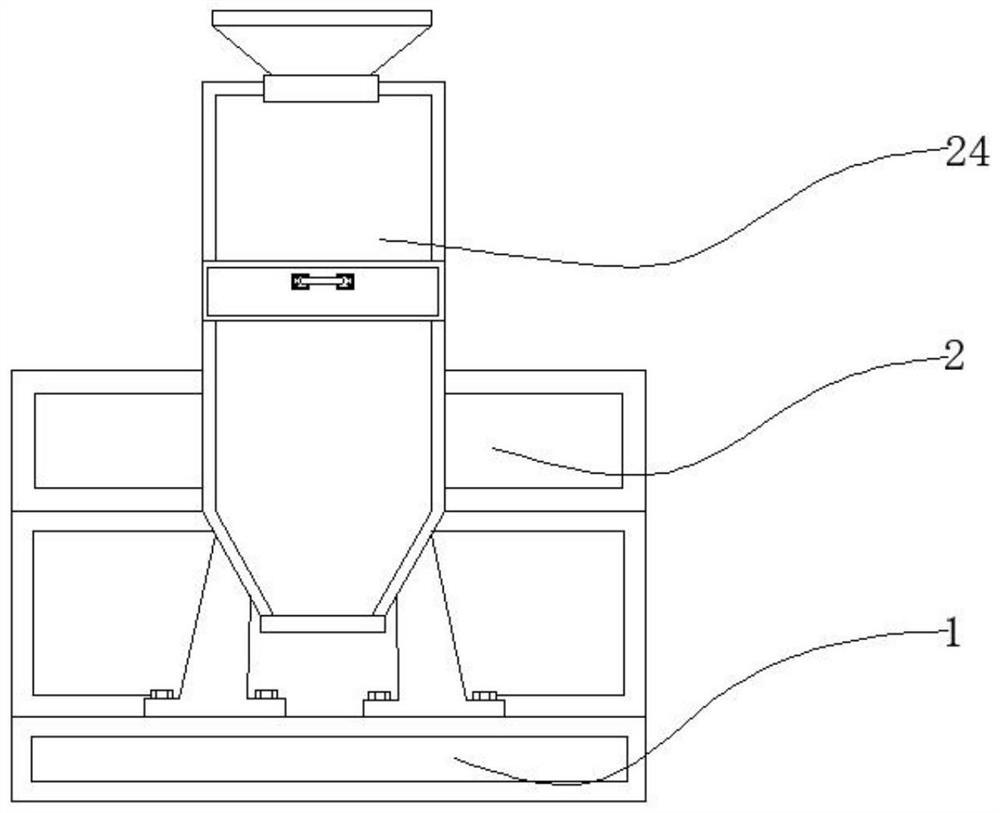

Garbage incineration disposal device used for municipal engineering

InactiveCN108870409AAvoid wastingEnvironmentally friendlyIncinerator apparatusEngineeringIncineration

The invention discloses a garbage incineration disposal device used for municipal engineering and relates to the field of technological municipal engineering equipment. The device includes a main bodybox, a garbage stirring box is fixedly connected to the left side of the top of the inner wall of the main body box, and a discharge port is formed in the right side of the bottom of the garbage stirring box. A machine box is fixedly connected to the left side of the main body box through a fixing plate, a first driving motor is fixedly connected to the bottom of the inner wall of the machine box, a stirring shaft is fixedly connected to an output shaft of the first driving motor, and the right end of the stirring shaft sequentially penetrates through the machine box, the main body box and the garbage stirring box and extends into the garbage stirring box. Garbage is uniformly stirred through the garbage stirring box and then discharged into an incineration box, and therefore the problemsthat the size of the garbage is large and incineration is not complete and uniform are solved. The incineration efficiency is greatly improved, the garbage incineration disposal device has the advantage of being environmentally friendly, residues after incineration can be collected by an ash accumulation box and adopted as fertilizer, and waste of resources is avoided.

Owner:芜湖芬特勘测服务有限公司

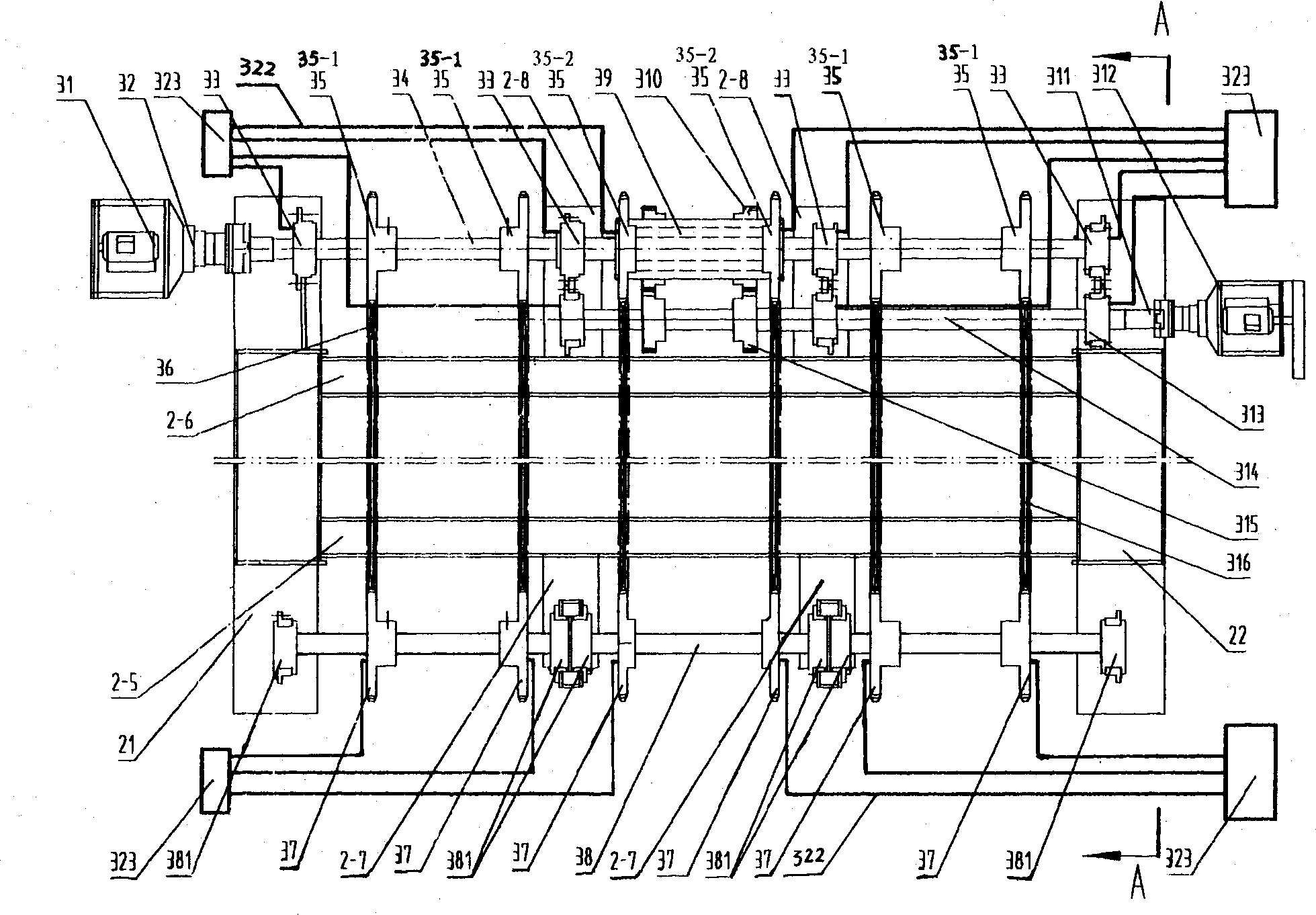

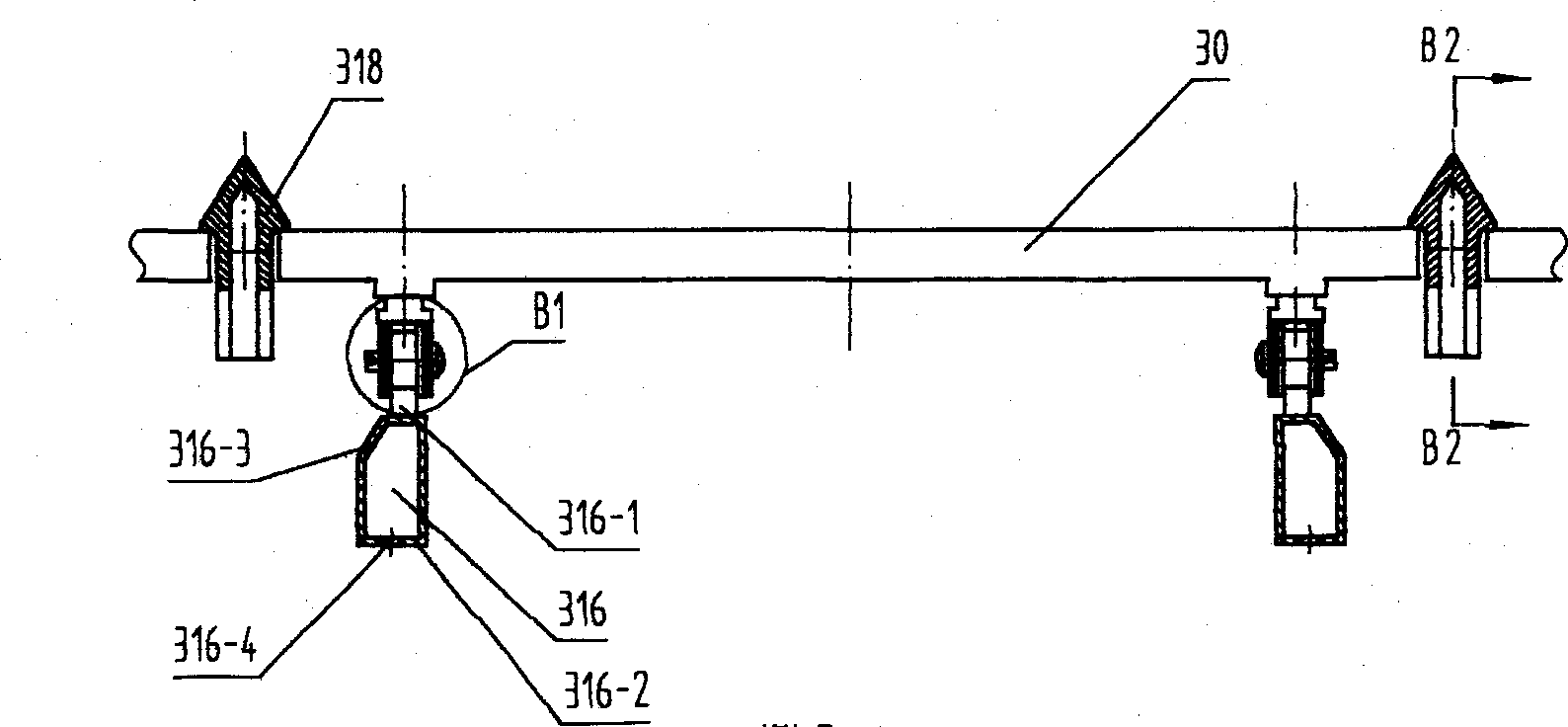

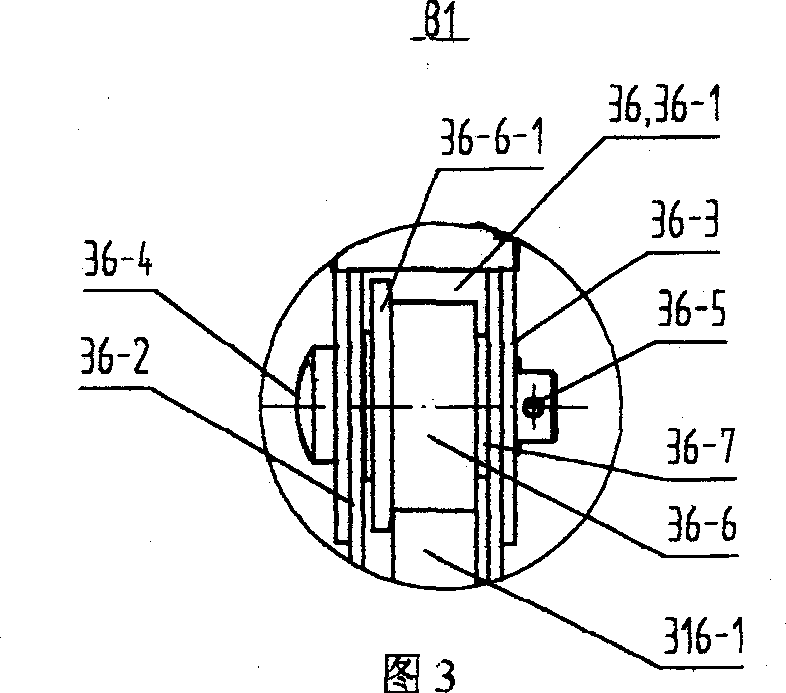

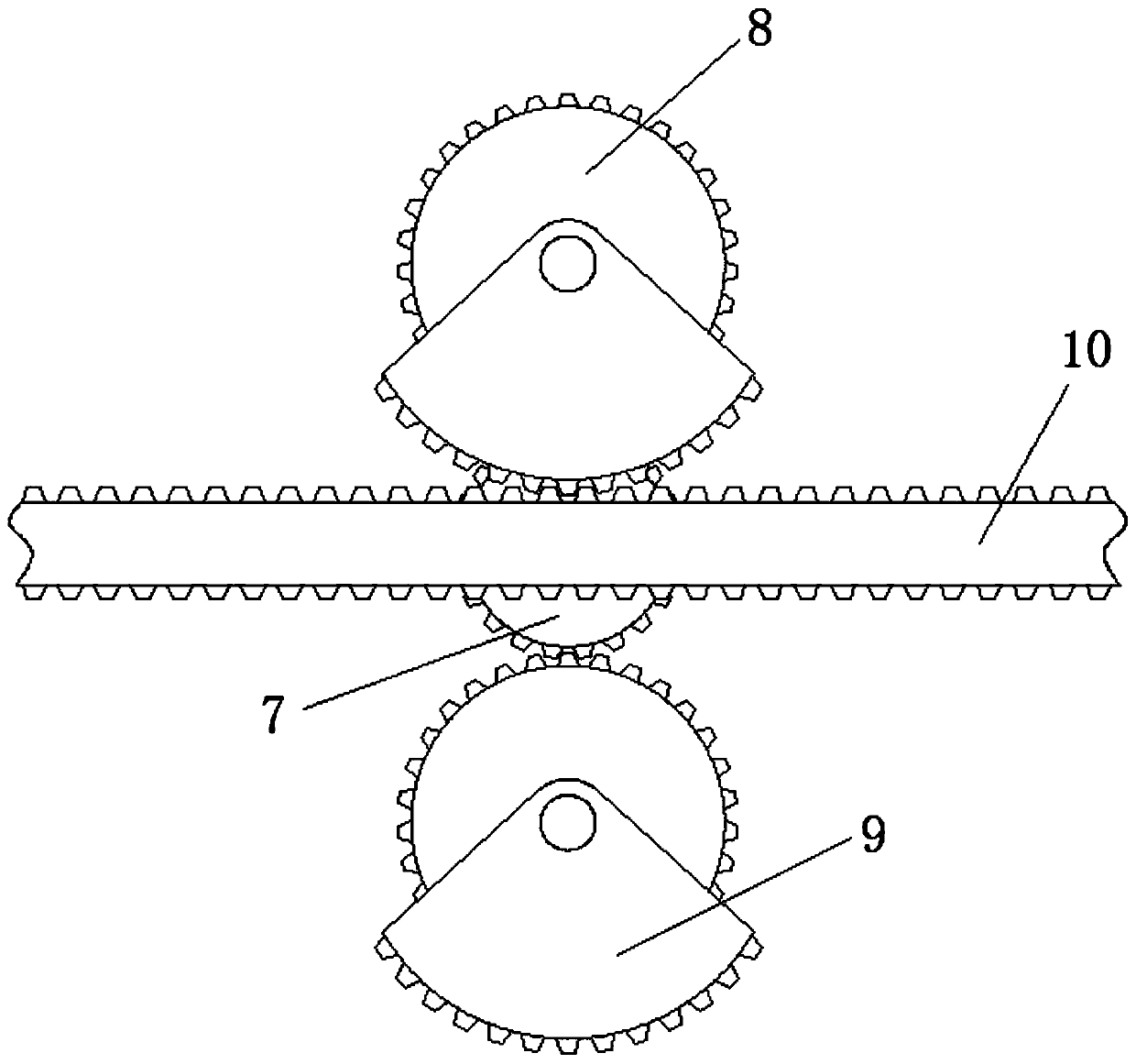

Main body and grate running unit of life garbage incinerator

InactiveCN1330246AGuaranteed uptimePrevent fallingTravelling grateIncinerator apparatusCombustionGear wheel

A main body and grate unit of life garbage incinerator features that its grate unit is divided into left, central and right subgrates, said left and right subgrates have drive chain wheels fixed to the drive axle for directly driving them, the drive chain wheel of central subgrate is fixed to the sleeve axle arranged in central part of drive axle and is driven by secondary drive axle via gear, chain wheel and chain, and a differentiating movement between left-right subgrates and central subgrate is formed for high combustion speed and full combustion of garbage. Said main body is composed of feeder, base, furnace body, blower and dreg crusher besides said grate unit.

Owner:江苏三信环保设备有限公司

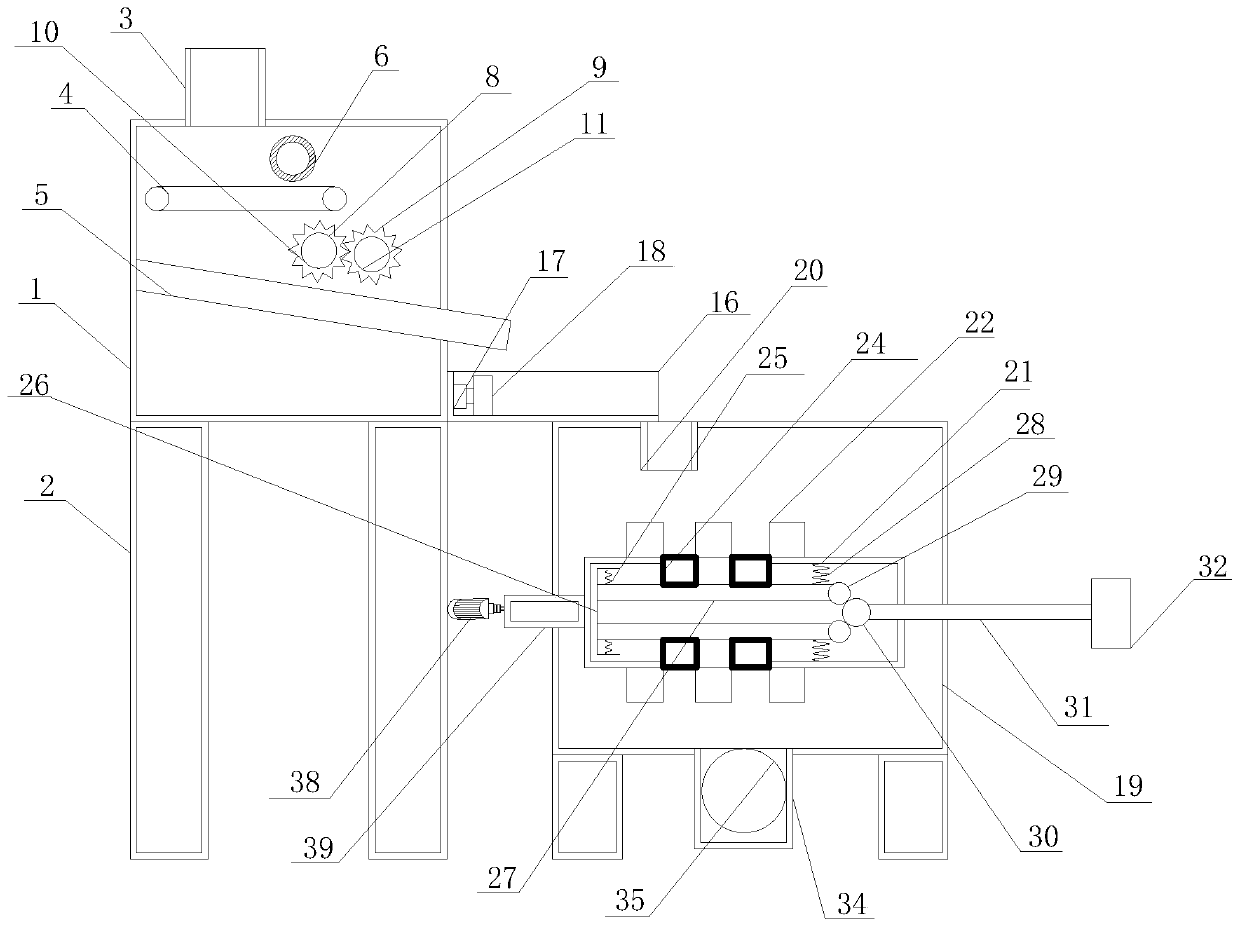

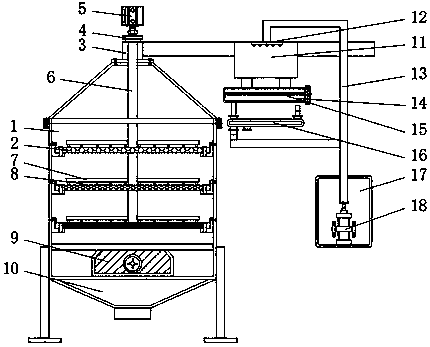

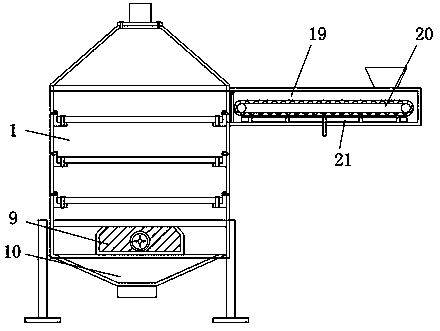

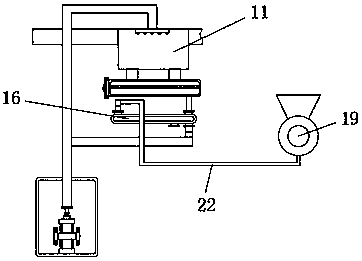

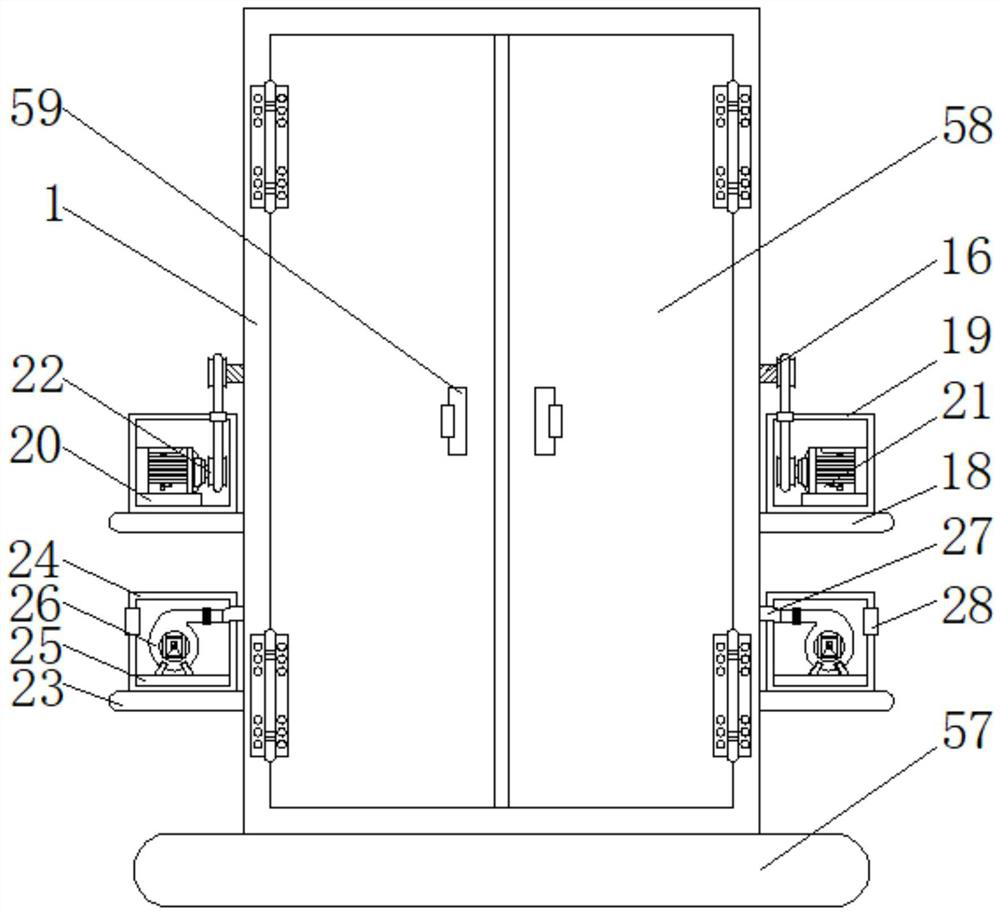

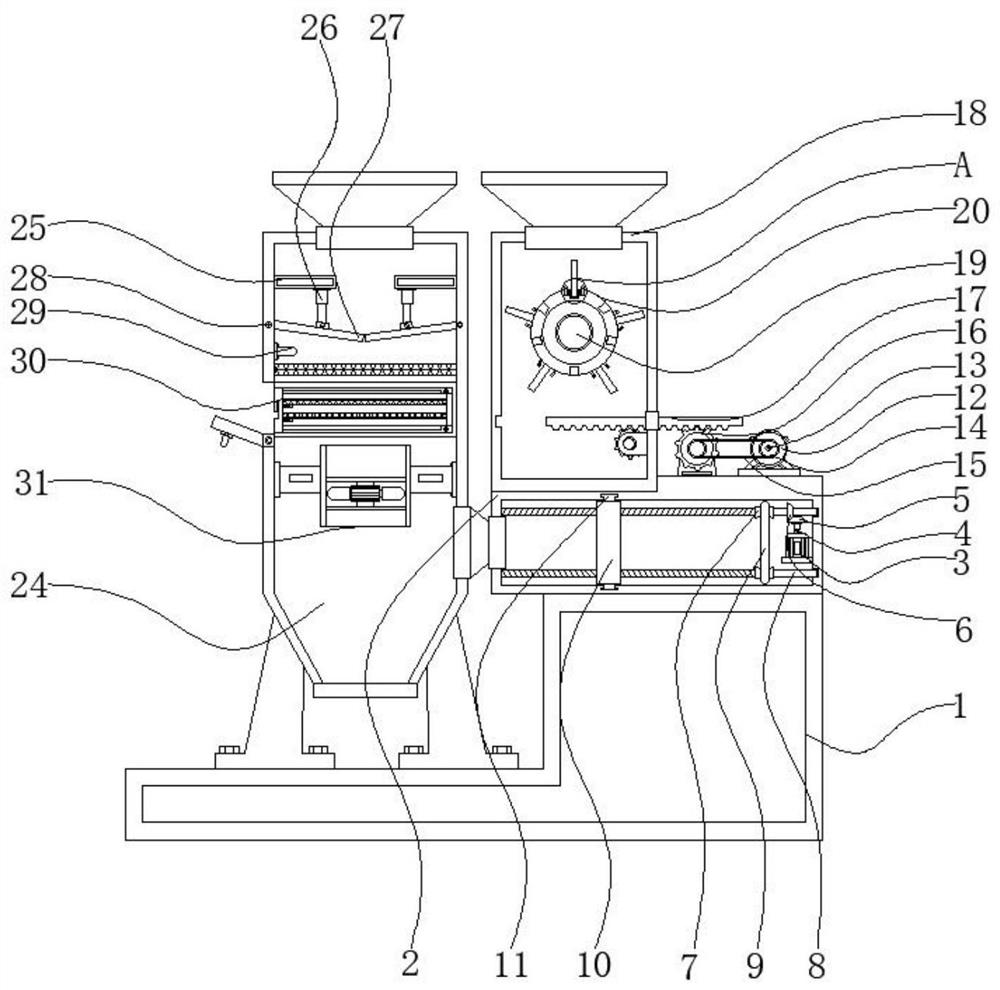

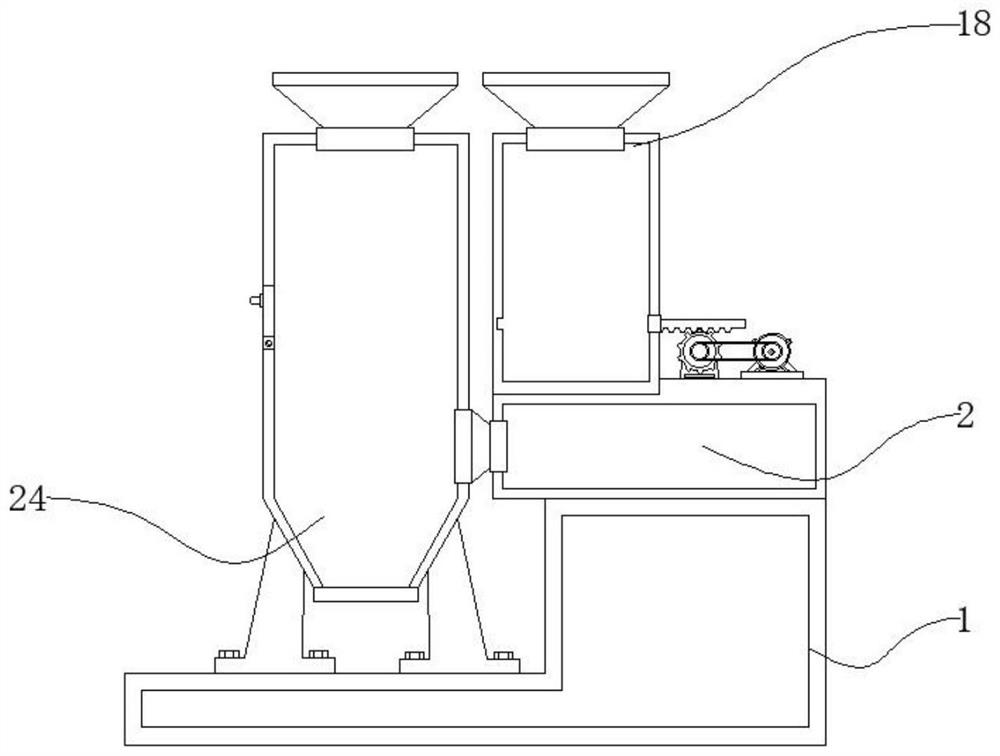

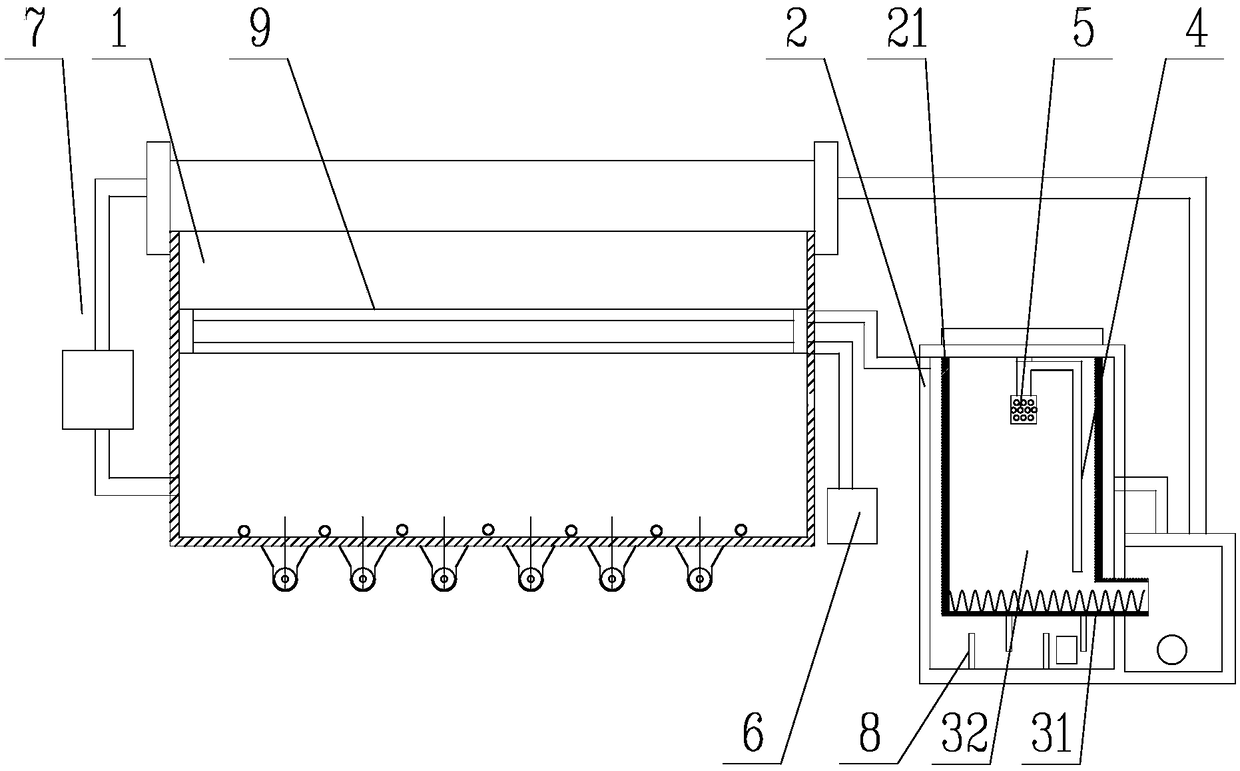

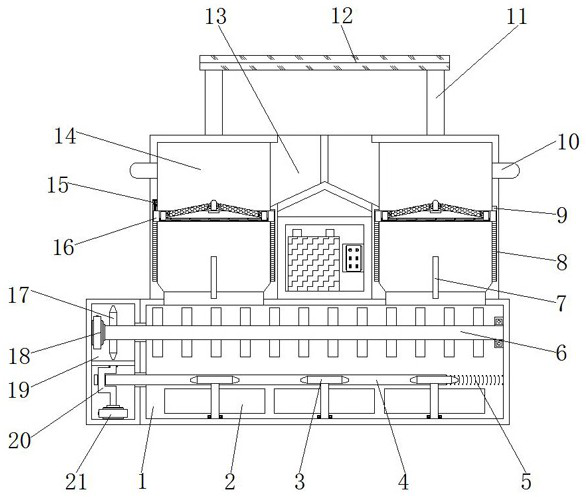

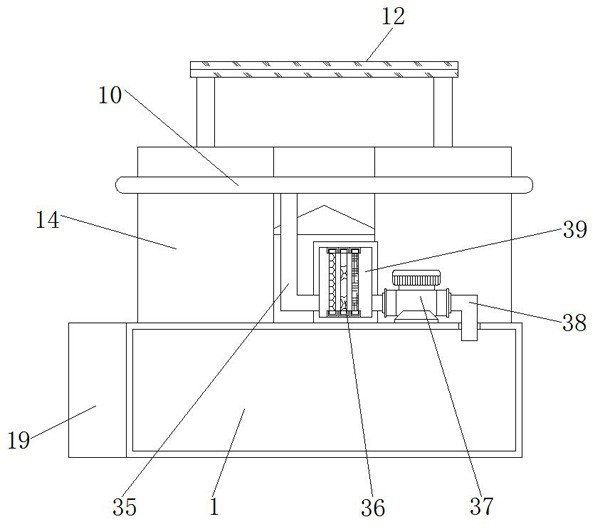

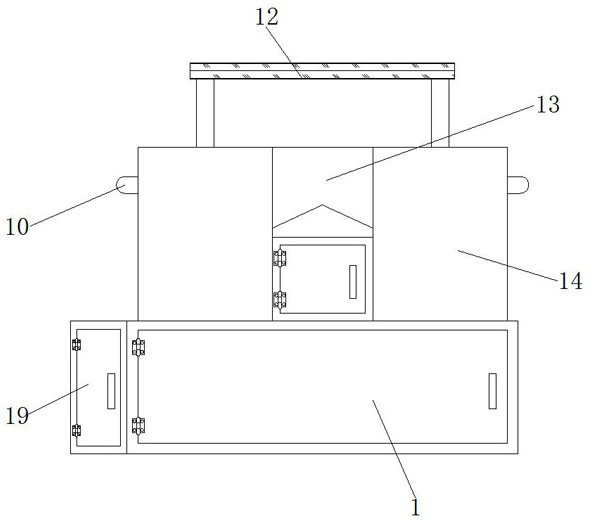

Garbage incineration device with pre-drying and metal waste removing functions

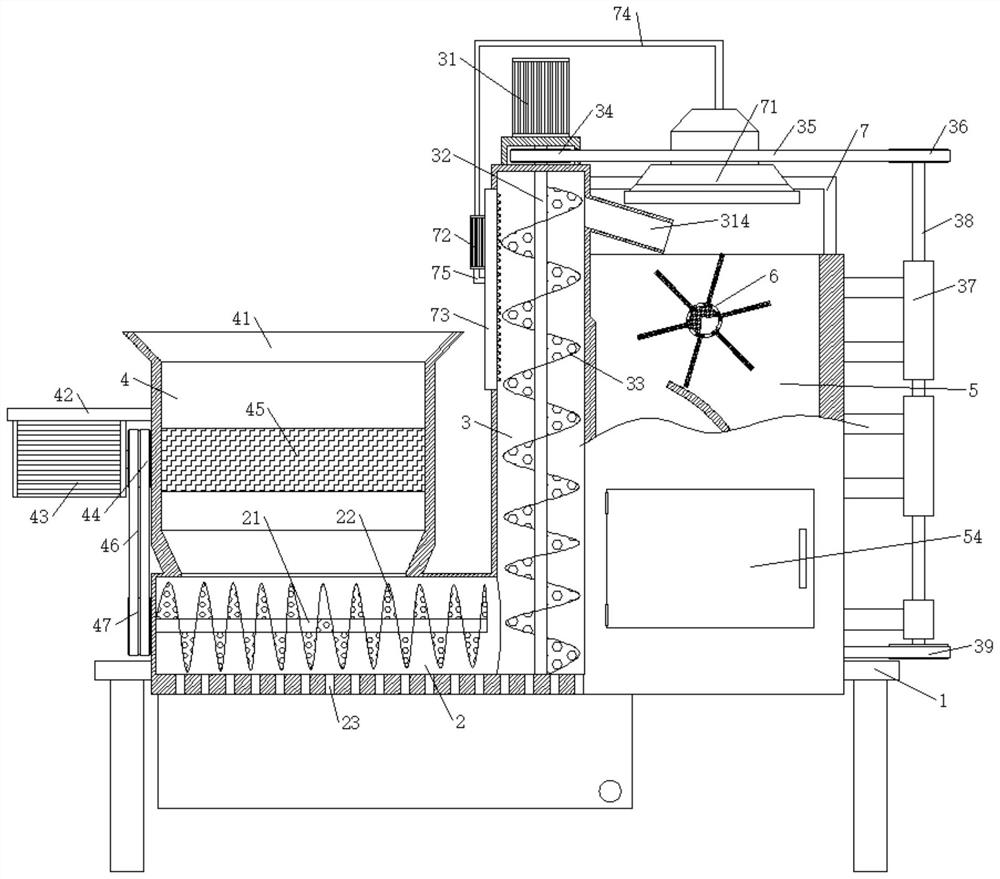

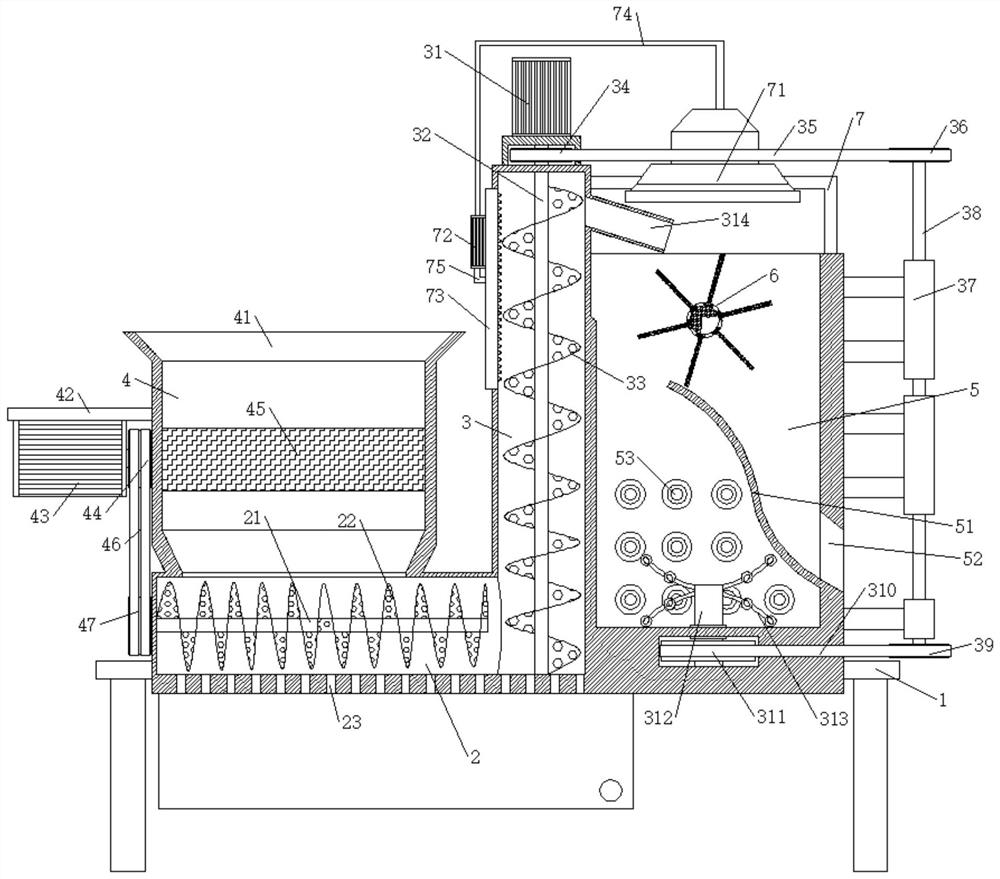

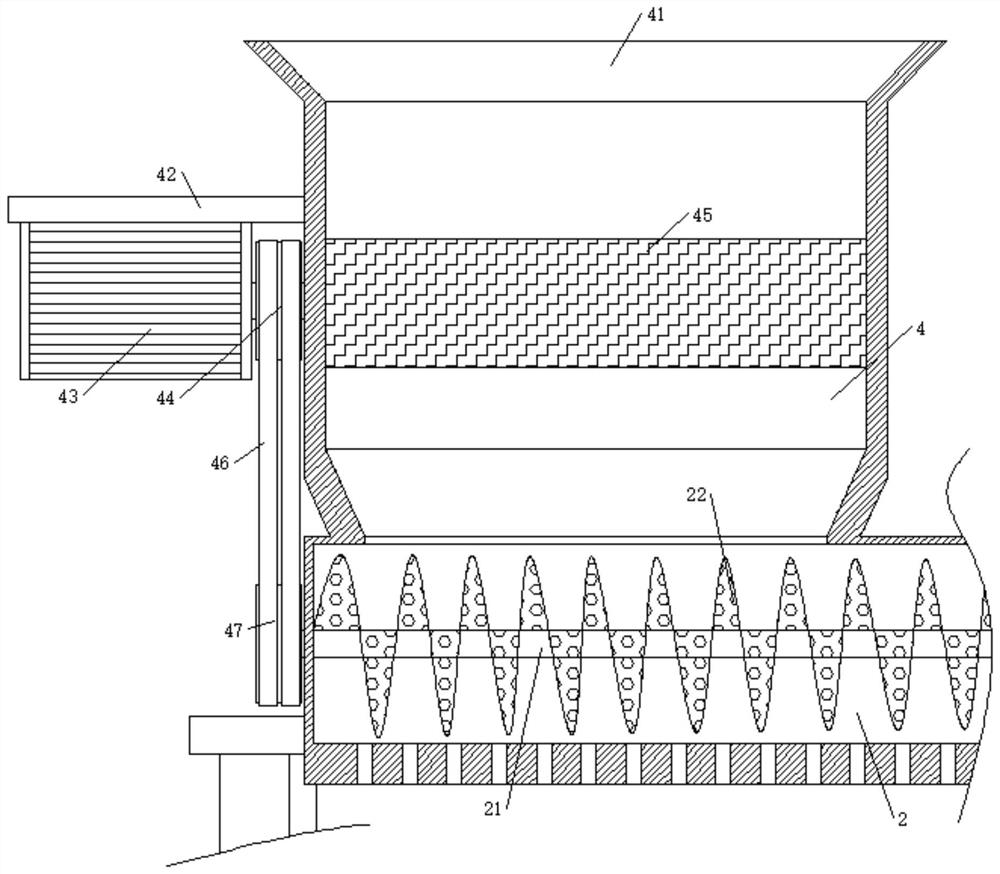

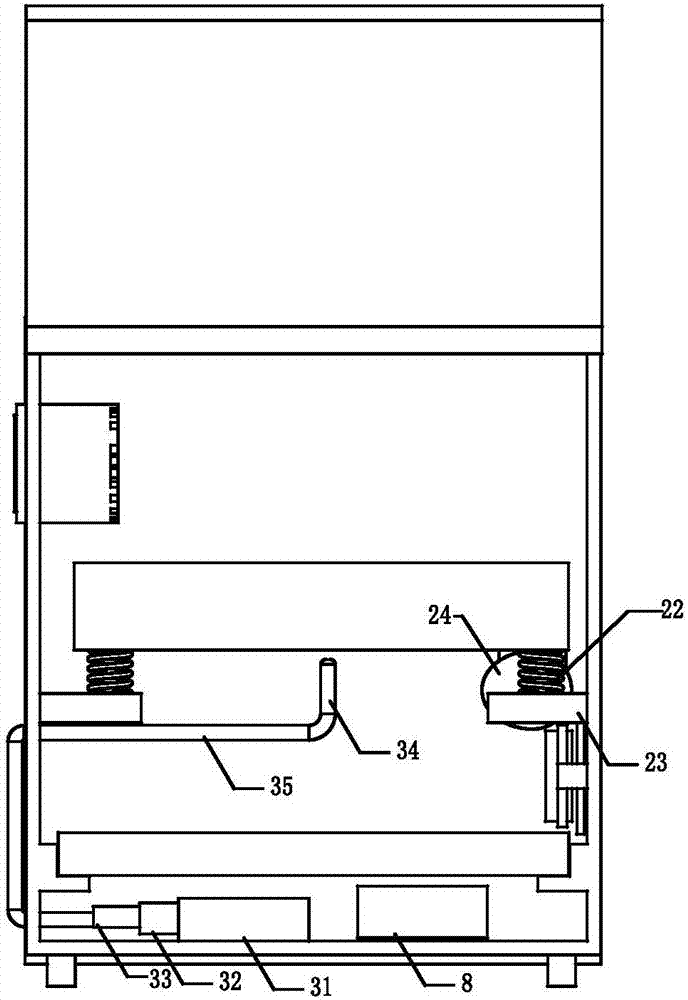

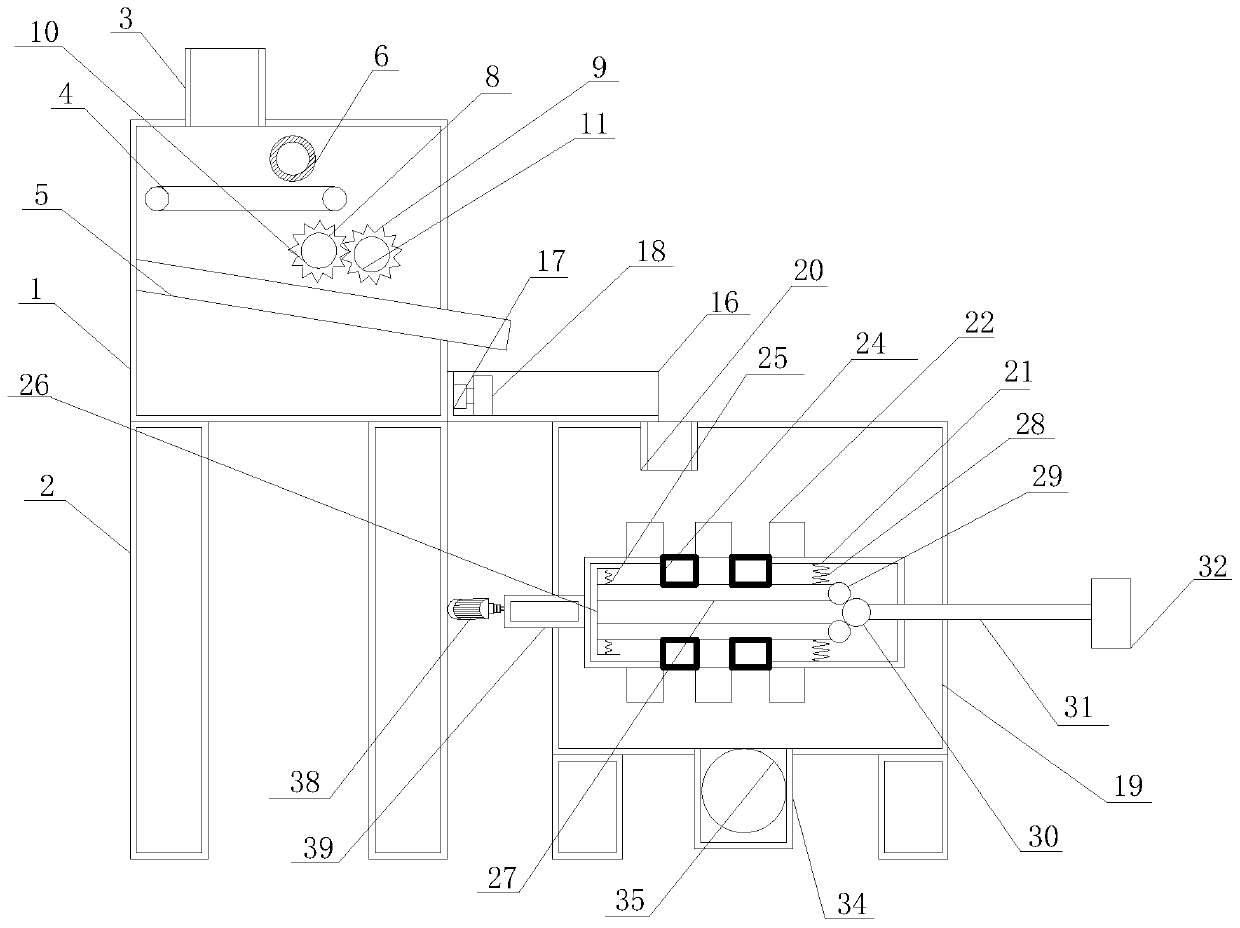

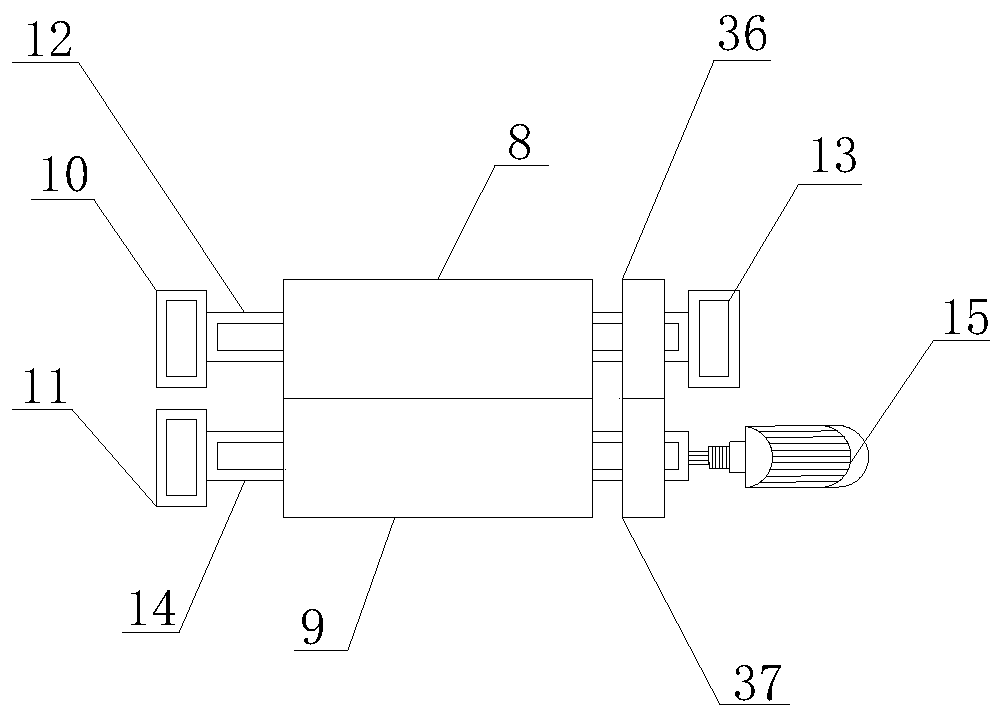

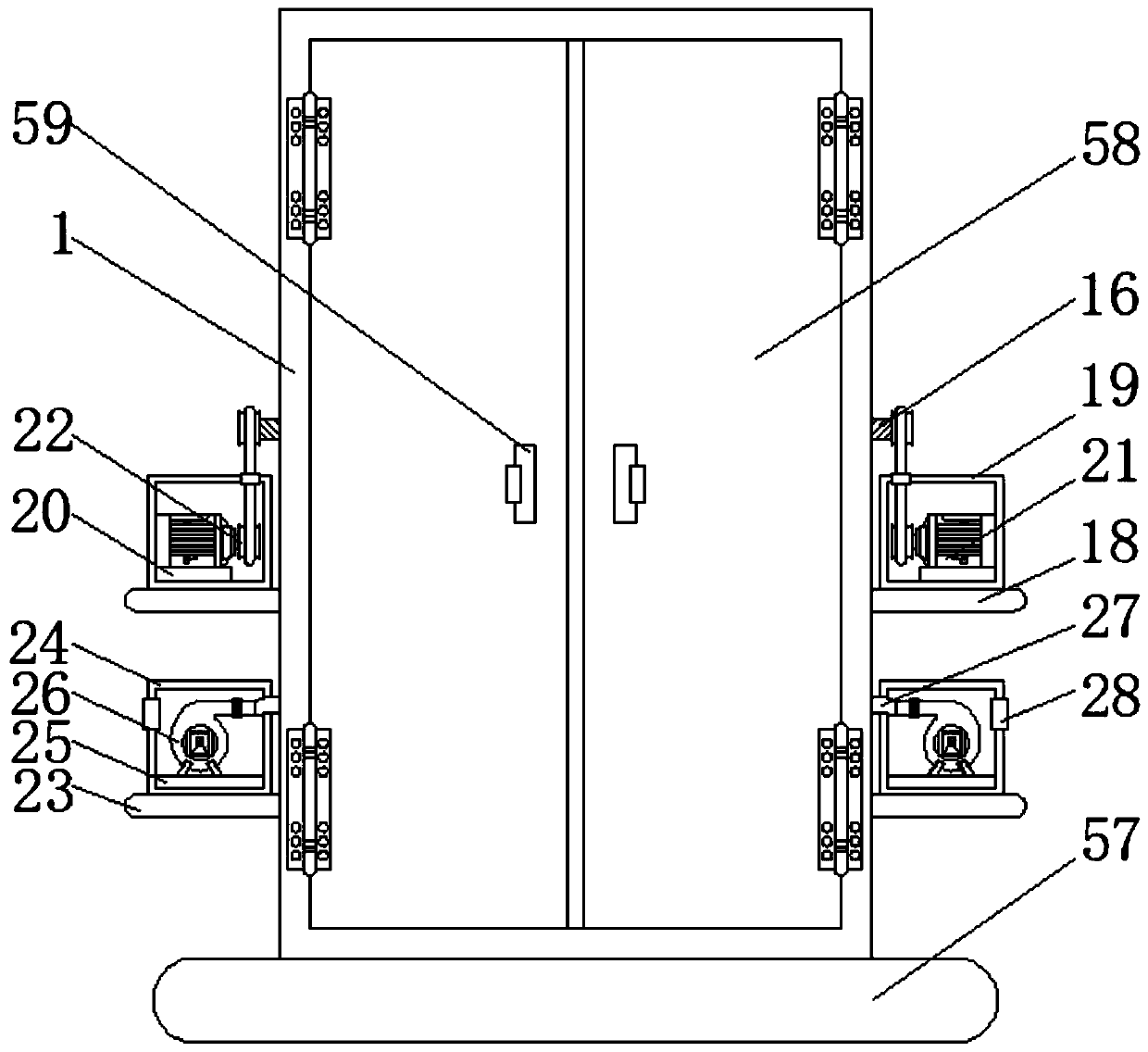

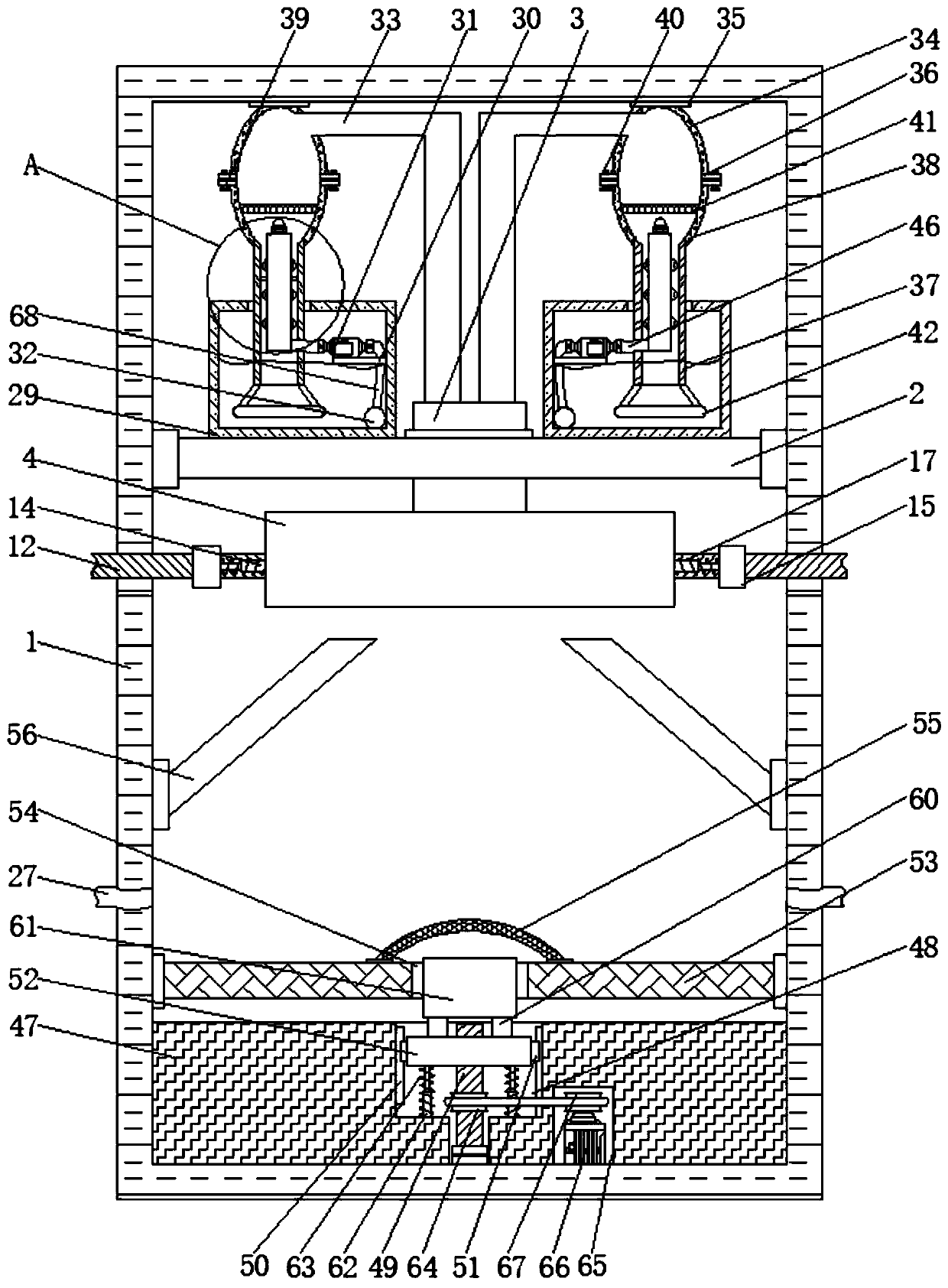

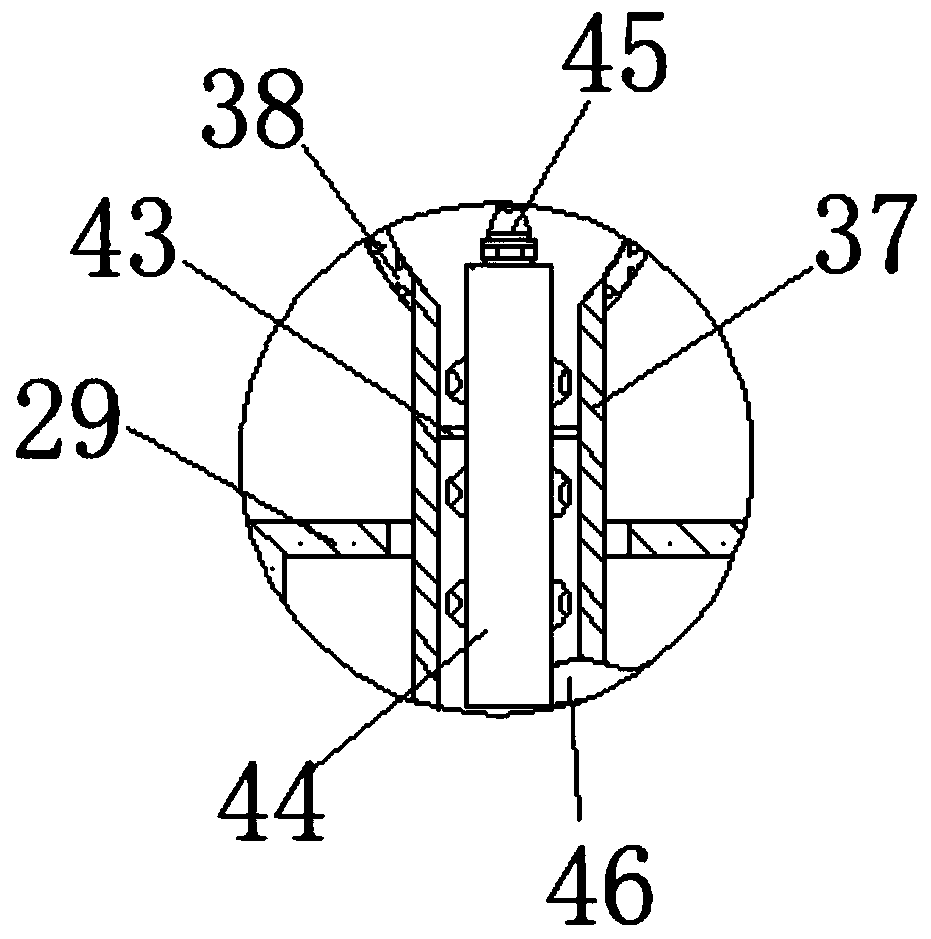

PendingCN112228879AIncrease incineration speedImprove work efficiencyIncinerator apparatusMetallic materialsProcess engineering

The invention discloses a garbage incineration device with pre-drying and metal waste removing functions. The garbage incineration device comprises a base, a crushing box, a first conveying box, a second conveying box and an incineration box; and a feeding port is formed in the top of the crushing box, a crushing mechanism is arranged in the crushing box, a first conveying mechanism and a second conveying mechanism are connected in the first conveying box and the second conveying box correspondingly, an incineration part is arranged in the incineration box, a material distribution plate is arranged in the incineration box, the material distribution plate divides the incineration box into an incineration cavity and a discharging cavity, a material distribution mechanism is connected above the material distribution plate, and a box door is connected to the incineration box in a sealed and rotating mode. According to the garbage incineration device, garbage can be crushed in advance before incineration, water control is carried out on the crushed garbage when the crushed garbage is conveyed, and meanwhile, heat generated in the incineration box can be absorbed to carry out water drying on the conveyed garbage, when the crushed garbage enters the incineration box, the material distribution mechanism is electrified to electromagnetically adsorb metal materials in the garbage, so that the metal and the non-metal are separated, the incineration speed is increased, and the working efficiency is improved.

Owner:普刚

Waste incineration device

The invention discloses a waste incineration device. The waste incineration device comprises a fixed box and a fixed box cavity arranged in the fixed box and communicating up and down, wherein an incineration mechanism is rotationally connected in the fixed box cavity, a stirring assembly is arranged in the incineration mechanism, the stirring assembly is used for stirring waste, the contact areabetween waste and air is increased, the incineration speed is accelerated, the upper side of the incineration mechanism is fixedly connected with a feeding mechanism, the feeding mechanism comprises afeeding assembly and a pushing assembly, the pushing assembly can intermittently convey the waste to the incinerating mechanism and make the feeding assembly stop feeding, and sufficient combustion of the waste in the incineration mechanism is guaranteed. According to the waste incineration device, crushed garbage is conveyed into an incinerator intermittently, so that the phenomenon that incineration is not sufficient due to the fact that too much garbage is incinerated in one-time incineration is avoided.

Owner:安徽天盛新材料科技有限公司

Ecological environment-friendly garbage treatment method

InactiveCN111533536AAdd follow-up processingAchieve re-useIncinerator apparatusCeramic materials productionEcological environmentElectric machine

The invention discloses an ecological environment-friendly garbage treatment method. Garbage can be conveyed through a conveying device; the garbage is flattened through a pressing roller; the garbagecan be crushed through a left crushing roller and a right crushing roller, a column body rotates through a third driving motor so that a stirring rod rotates along with the column body, the incineration speed is increased, and after incineration is finished, a push rod is pushed to enable a second sphere block to enter the position between two connecting rods so that a brush is exposed out of a through opening, and one side of the stirring rod is cleaned. The subsequent treatment procedure of the incinerated materials is added on the basis of the prior art, waste utilization is achieved, andupdating and upgrading of ceramsite products are achieved.

Owner:山东瑞泓智能科技有限公司

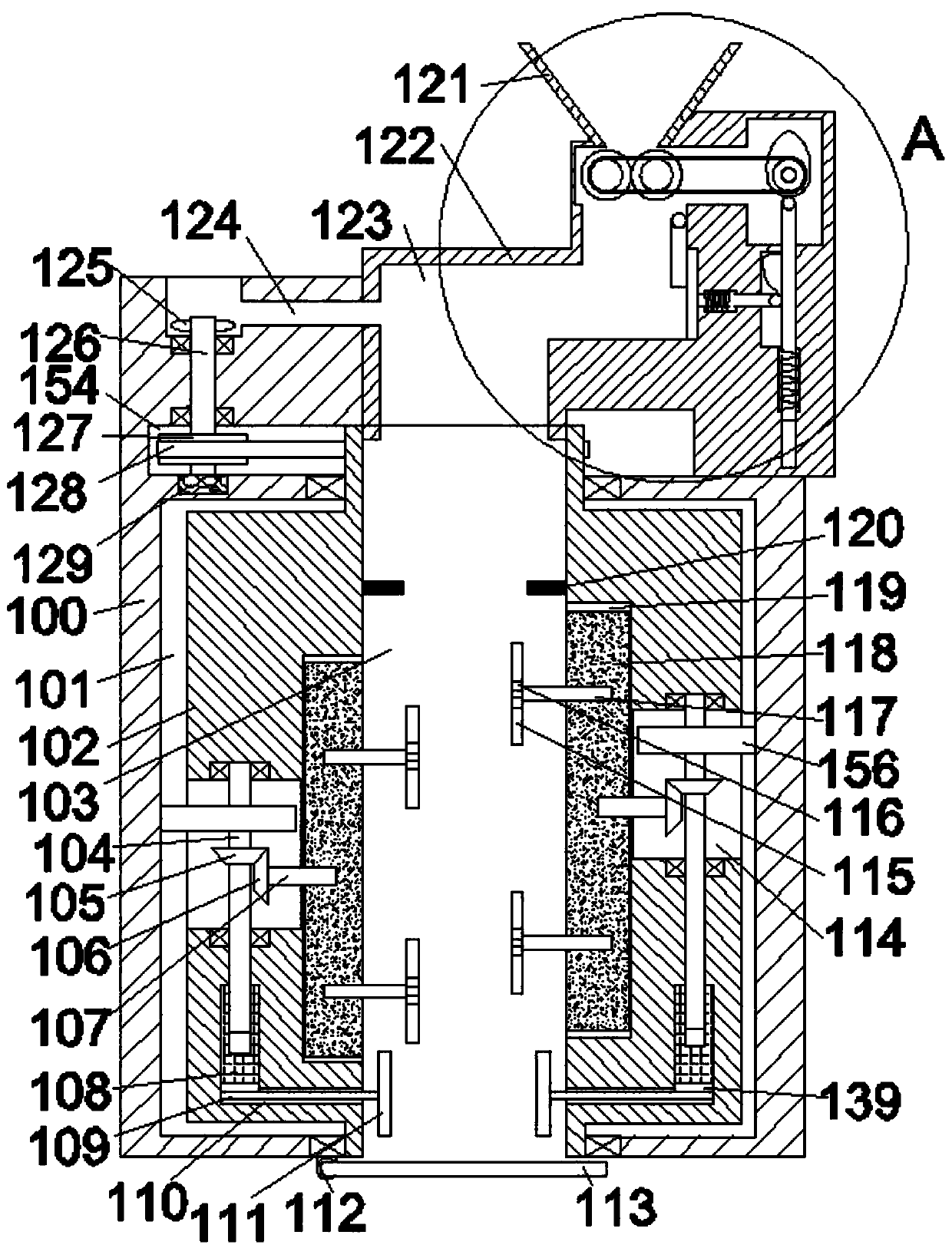

Garbage incinerator

The invention discloses a garbage incinerator. The garbage incinerator at least comprises two incinerator bodies attached to each other. Each incinerator body is provided with a feeding hopper and a hearth, wherein the feeding hopper is arranged on the top of the incinerator body, and a discharger is arranged in the feeding hopper. The hearths are communicated through smoke outlets formed in the upper portions of the side walls of the incinerator bodies, the smoke outlet of the last incinerator body is connected with an inlet of a smoke header pipe, an outlet of the smoke header pipe passes through a waste heat device and then is connected with an inlet of a filtering device, and an outlet of the filtering device is connected with an exhaust pipe. The garbage incinerator has the advantages of being simple in structure, high in incinerating speed, capable of saving energy and environmentally friendly.

Owner:GUILIN TECH ENTERPRISE DEV CENT

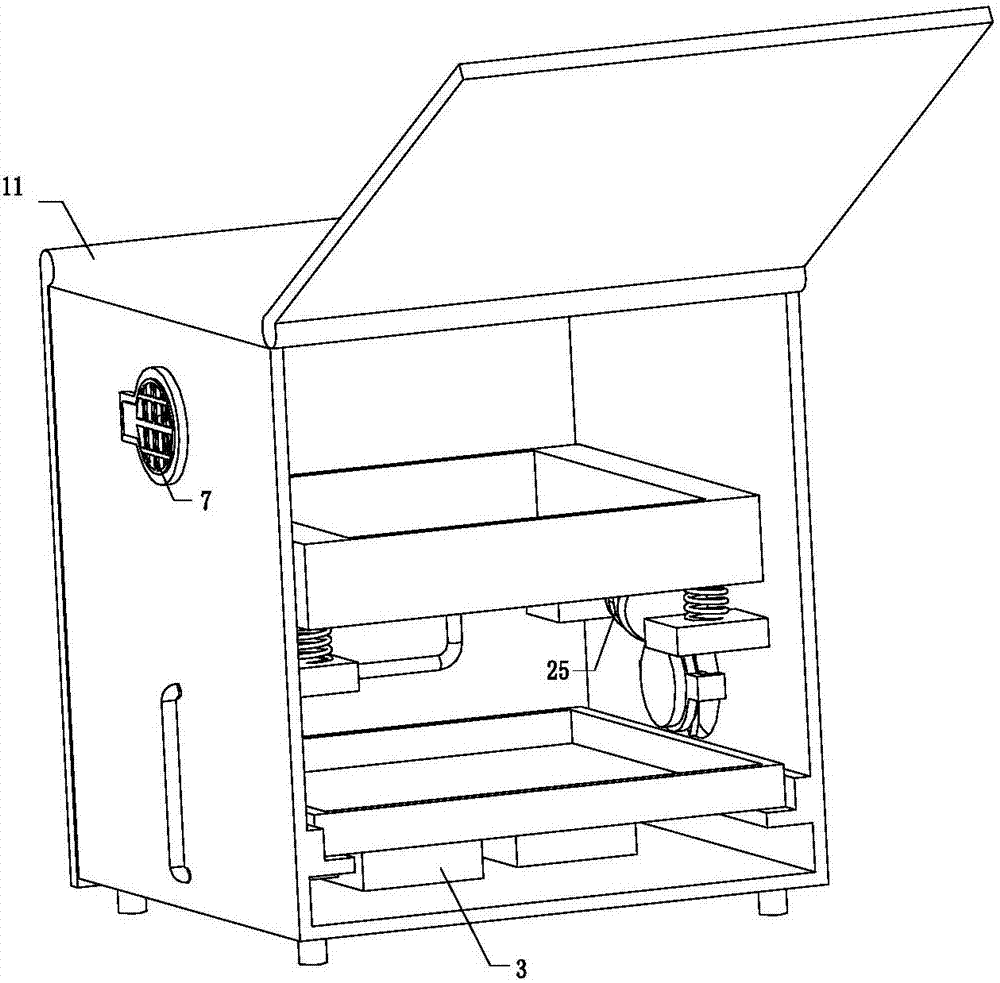

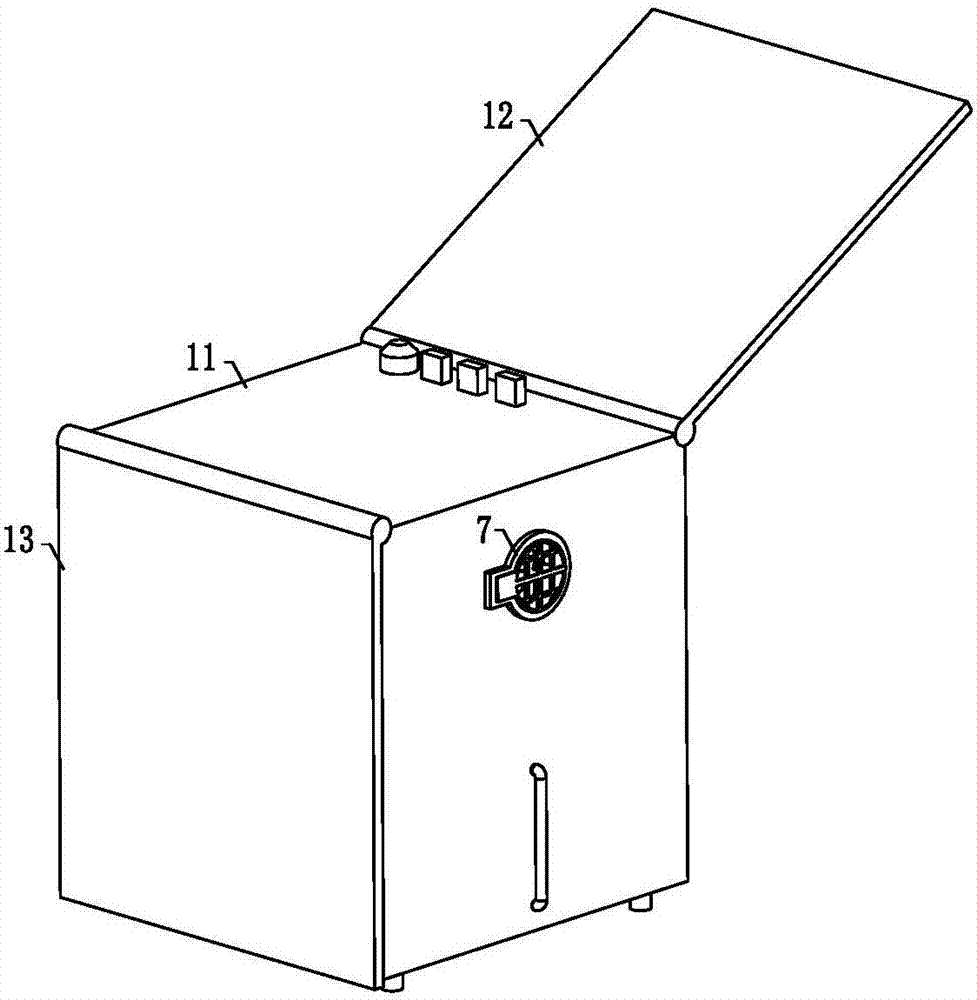

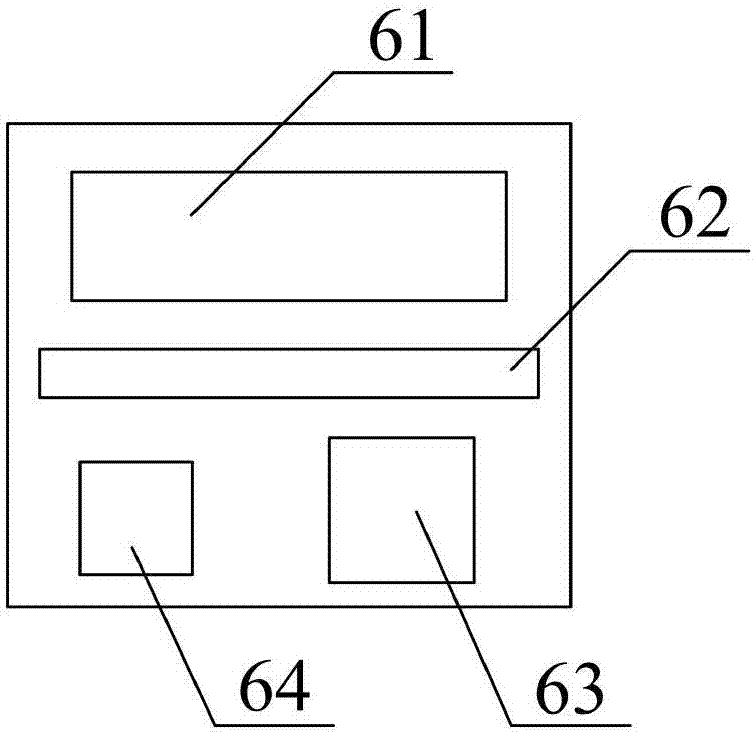

Sacrifice incineration box for security and protection

ActiveCN106983343AAvoid ignitionEliminate potential safety hazardsReligious equipmentCombustorEngineering

The invention relates to the field of folk products, in particular to a sacrifice incineration box for security and protection. The sacrifice incineration box comprises a shell for preventing comburent from being blown away and igniting surrounding inflammable, a vibration screen for increasing combustion speed, a combustor for carrying out ignition and increasing the combustion speed, a water basin for extinguishing ash falling from the vibration screen, an air inlet device for increasing the combustion speed, an air outlet for exhausting air and filtering the comburent to prevent the comburent from being blown out, a filtering cup for filtering polluted gas, a control circuit, and a storage battery for providing a power source. According to the sacrifice incineration box for security and protection, combustion fragments can be prevented from igniting near inflammable under the action of wind, the combustion speed can be increased, and meanwhile the function of filtering the polluted gas is achieved.

Owner:湖北景维环保科技有限公司

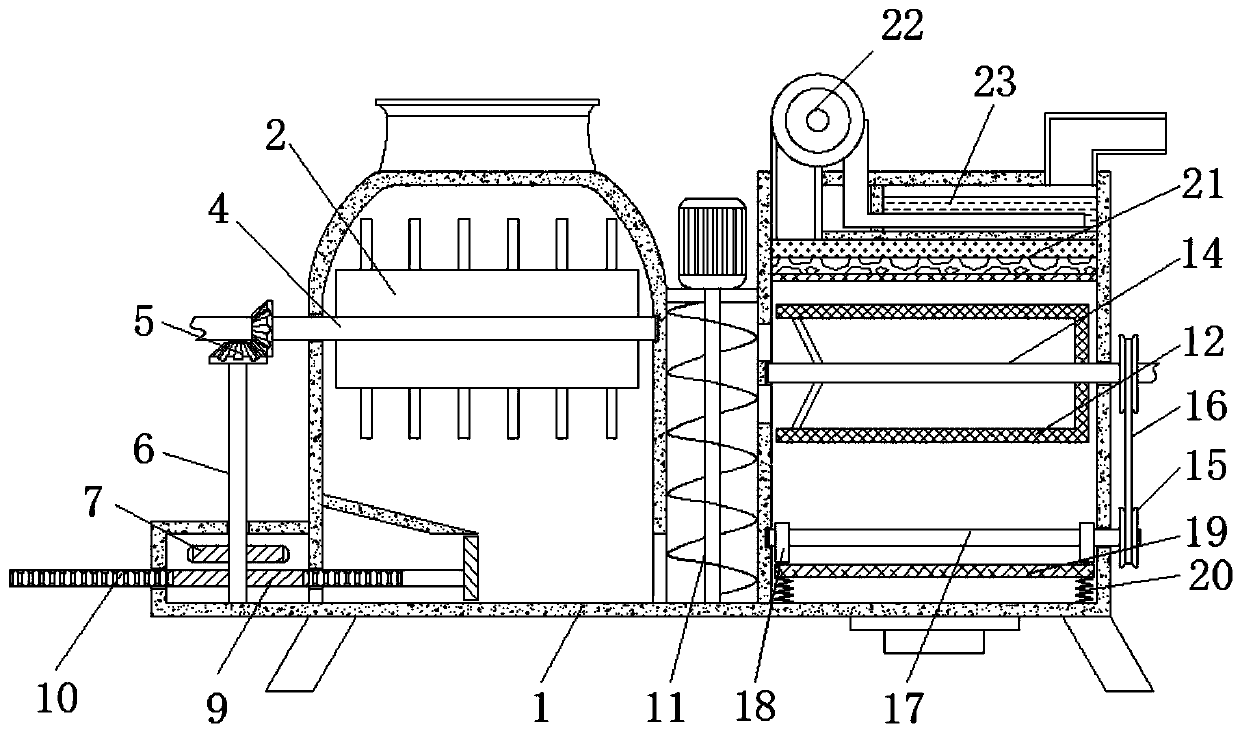

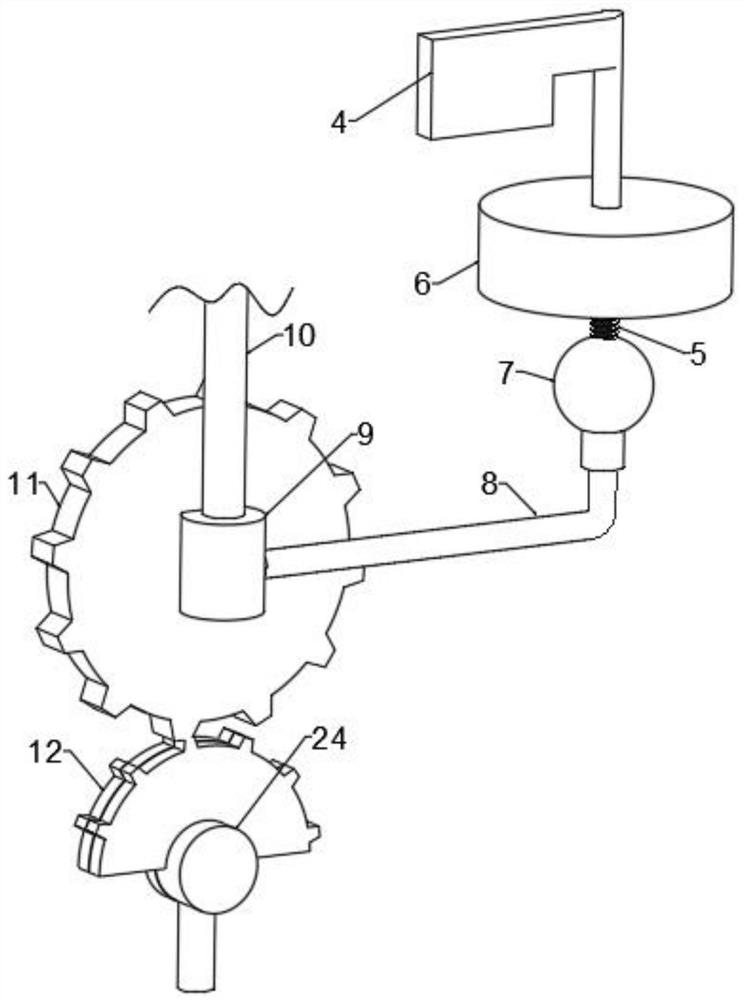

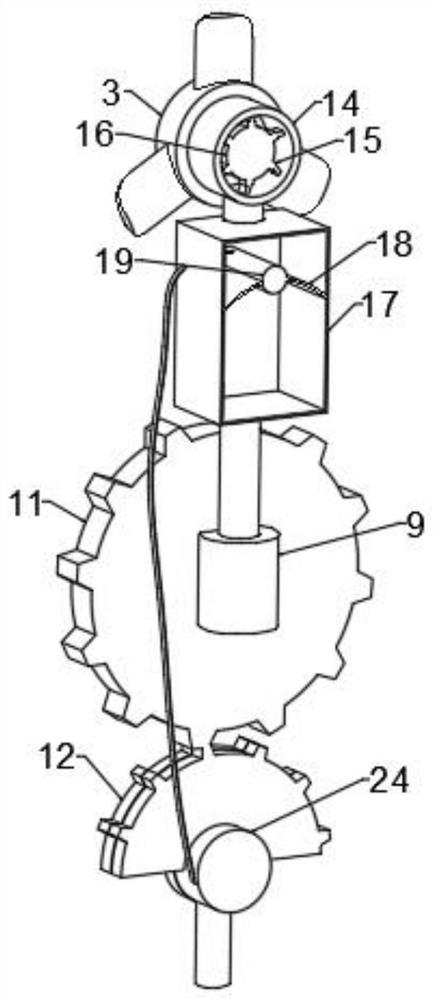

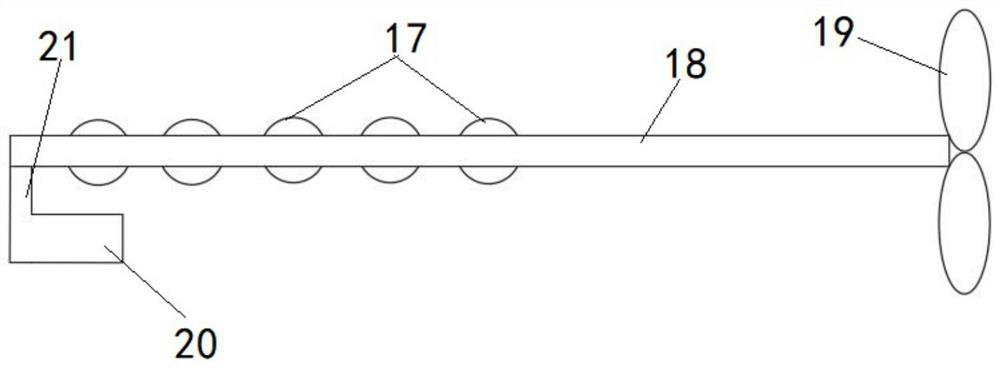

Straw incineration device based on special-shaped gear transmission principle

PendingCN111457386AAchieve primary crushingImprove incineration effectIncinerator apparatusSteering wheelGear wheel

The invention relates to the technical field of environmental protection, and discloses a straw incineration device based on a special-shaped gear transmission principle. The straw incineration devicecomprises a frame body, a material guide wheel is movably connected in the frame body, a cutting knife is movably connected to the outside the material guide wheel, a material guide rod is fixedly connected in the material guide wheel, a steering wheel is fixedly connected to the outside of the material guide rod, a connecting rod is fixedly connected to the outside of the steering wheel, a maingear is fixedly connected to the outside of the connecting rod, a connecting gear is connected to the outside of the main gear in an engaged manner, and a sector gear is fixedly connected to the outside of the connecting gear. Through cooperative use of the material guide wheel, the cutting knife, the main gear, the connecting gear, the sector gear and a straight toothed bar, straw is preliminarily crushed, the straw incineration effect is improved, the straight toothed bar pushes the straw so as to guarantee that the straw can smoothly enter an incineration chamber, the straw is prevented from being stuck, and therefore smooth operation of the equipment is guaranteed.

Owner:伍冬秋

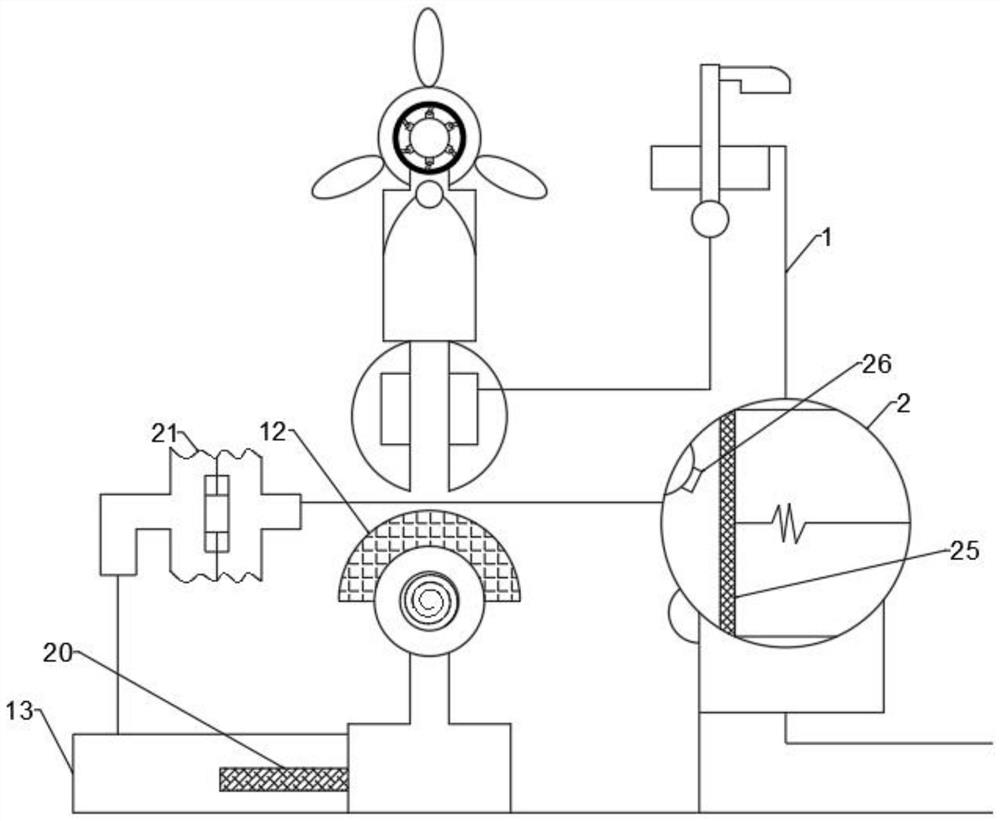

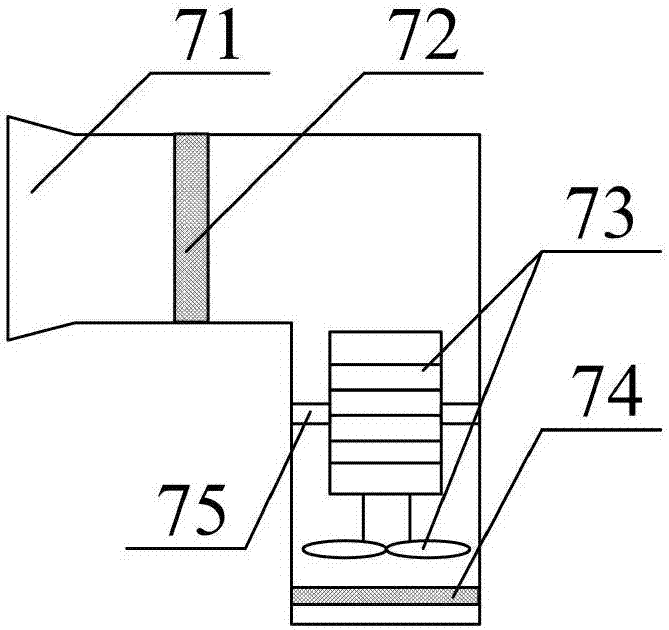

Wind vane for generator based on dry-wet separation

PendingCN113293399AIncrease incineration speedCombustion preventionCellsWind energy with garvitational potential energyElectrolysisThermodynamics

The invention discloses a wind vane for a generator based on dry-wet separation, the wind vane comprises a shell, an incinerator is fixed in the shell, the generator is fixed at the bottom of the middle of the shell, a fan is in gear connection with the upper part of the generator, the wind vane is arranged on the right side of the fan, and the wind vane is in threaded connection with the upper part of the shell. An electrolysis box is fixed to the left side of the generator, the right side of the incinerator is connected with an air opening through a pipeline, the middle bearing of the weather vane is connected with a threaded rod, the bottom end of the threaded rod is in threaded connection with a nut, the nut is fixedly connected with the inner wall of the upper end of the shell, a ball is fixed to the bottom end of the threaded rod, and a fixing rod is connected to the lower portion of the ball through a bearing. A sleeve is fixed to the left end of the fixing rod, a sliding rod is connected to the middle of the sleeve in a sleeving mode, the sliding rod is fixedly connected with the inner wall of the shell, and a gear disc is connected to the front side of the sleeve through a bearing. The wind vane can automatically change the engine power and adjust the combustion support degree.

Owner:朱荣飞

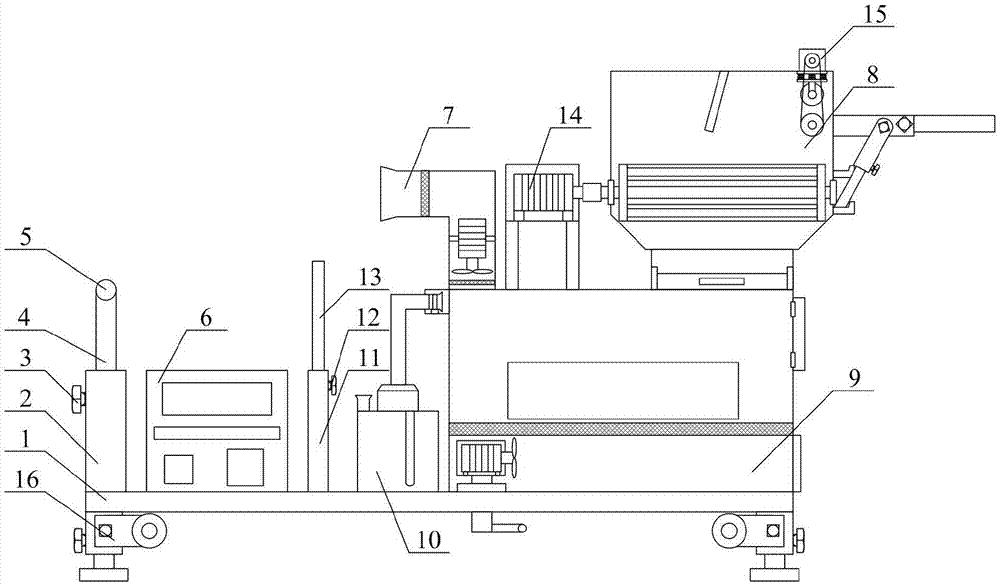

Incineration device for agriculture

ActiveCN107401745AEasy to moveSolve the inconvenience of movingIncinerator apparatusEngineeringCrusher

The invention provides an incineration device for agriculture. The incineration device comprises an installing plate, a first-level sleeve, a first-level locking bolt, a first-level loop bar, a hand pushing rod, a control cabinet, a waste gas treating machine device, a material pulverizing box device, a dust treating machine device, a cleaning pump device, a first-level baffle, a second-level locking bolt, a second-level baffle, a beating crusher device, a feeding wheel device, an adjusting supporting base device, a drainage pipe and a manual control valve. The first-level sleeve is welded to the upper left portion of the installing plate. Universal wheels are specifically adopted as movable wheels, the multiple movable wheels are arranged, so that an operator conveniently moves the incineration device for agriculture, and the problem that an existing incineration device for agriculture is not convenient to move is solved. Through the arrangement of the dust treating machine device, the operator conveniently treats dust, meanwhile, the labor intensity of the operator is relieved, accordingly, the practicability of the incineration device for agriculture is improved, and the problem that dust of the existing incineration device for agriculture is not convenient to treat is solved.

Owner:姚琴妹

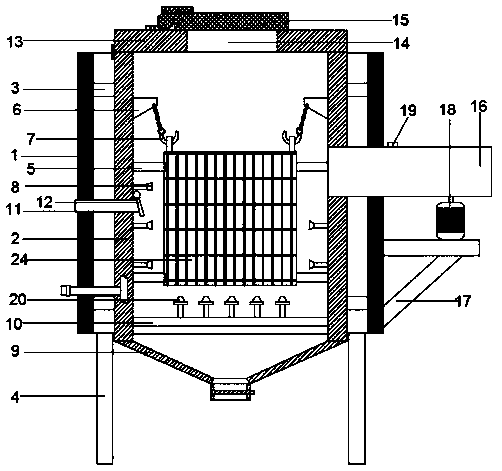

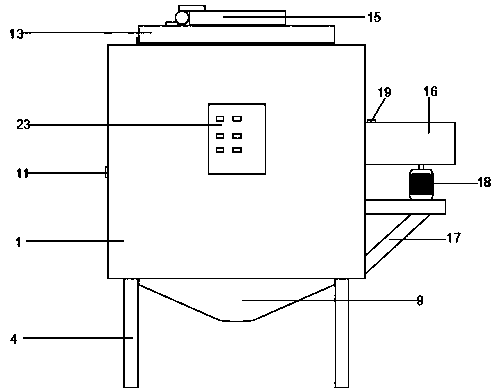

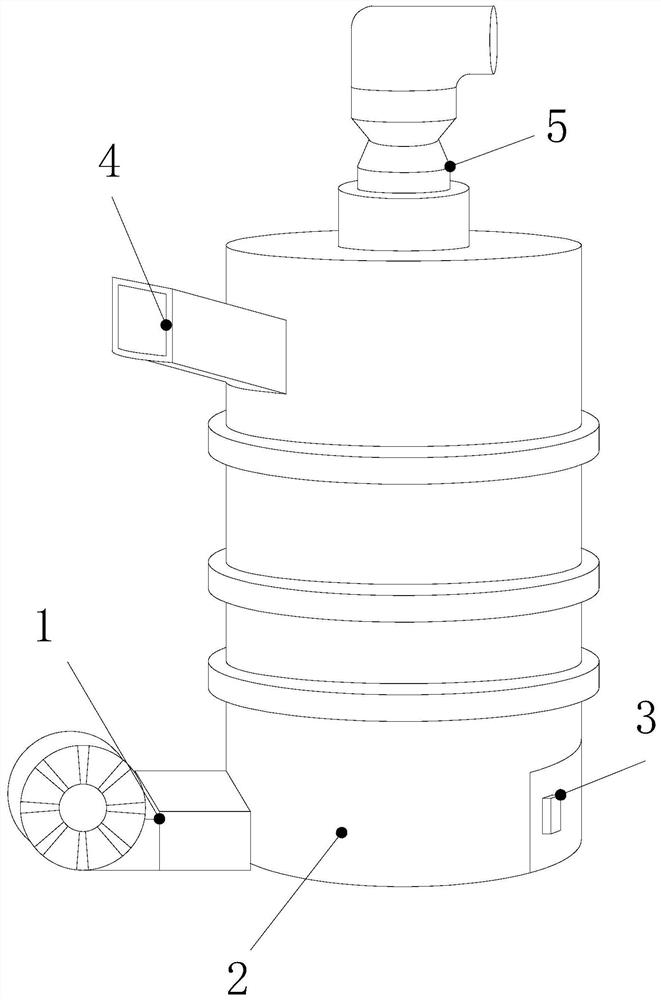

Environmentally-friendly incinerator for solid waste product disposal

InactiveCN109000260AIncrease the range of incinerationIncrease incineration speedIncinerator apparatusEnvironmentally friendlyWaste product

The invention provides an environmentally-friendly incinerator for solid waste product disposal. The environmentally-friendly incinerator for the solid waste product disposal comprises a protective barrel, a control box and a storage basket. Four supporting columns are welded to the bottom end face of the protective barrel in a ring array. A motor support is welded to a position close to the rightside of the outer wall of the protective barrel. Top end faces of spraying heads are distributed in a circular array, and four iron cylinders are welded to the top end faces of the spraying heads. Aspraying head protecting cover is arranged at the top end of each iron cylinder. When air is exhausted by an exhausting fan, the air inside a combustion barrel is pumped out. An air inlet door can bepushed open through an air input pipe, and the air outside the combustion barrel enters the interior of the combustion barrel. When the exhausting fan stops rotating, the air inlet door closes automatically under the influence of gravity. Therefore, the exhausting fan and the air inlet door are arranged in a cooperating manner, and the air input manner and air output manner are optimized; a spraying head seat is arranged, on the one hand, the litten area and combustion area are enlarged, and on the other hand, falling of carbon dust generated after combustion can be avoided and obstructed; andbottom spraying head structures are optimized.

Owner:赵瑞霞

A sacrificial offering incineration box for security

ActiveCN106983343BAvoid ignitionEliminate potential safety hazardsReligious equipmentCombustorEngineering

The invention relates to the field of folk products, in particular to a sacrifice incineration box for security and protection. The sacrifice incineration box comprises a shell for preventing comburent from being blown away and igniting surrounding inflammable, a vibration screen for increasing combustion speed, a combustor for carrying out ignition and increasing the combustion speed, a water basin for extinguishing ash falling from the vibration screen, an air inlet device for increasing the combustion speed, an air outlet for exhausting air and filtering the comburent to prevent the comburent from being blown out, a filtering cup for filtering polluted gas, a control circuit, and a storage battery for providing a power source. According to the sacrifice incineration box for security and protection, combustion fragments can be prevented from igniting near inflammable under the action of wind, the combustion speed can be increased, and meanwhile the function of filtering the polluted gas is achieved.

Owner:湖北景维环保科技有限公司

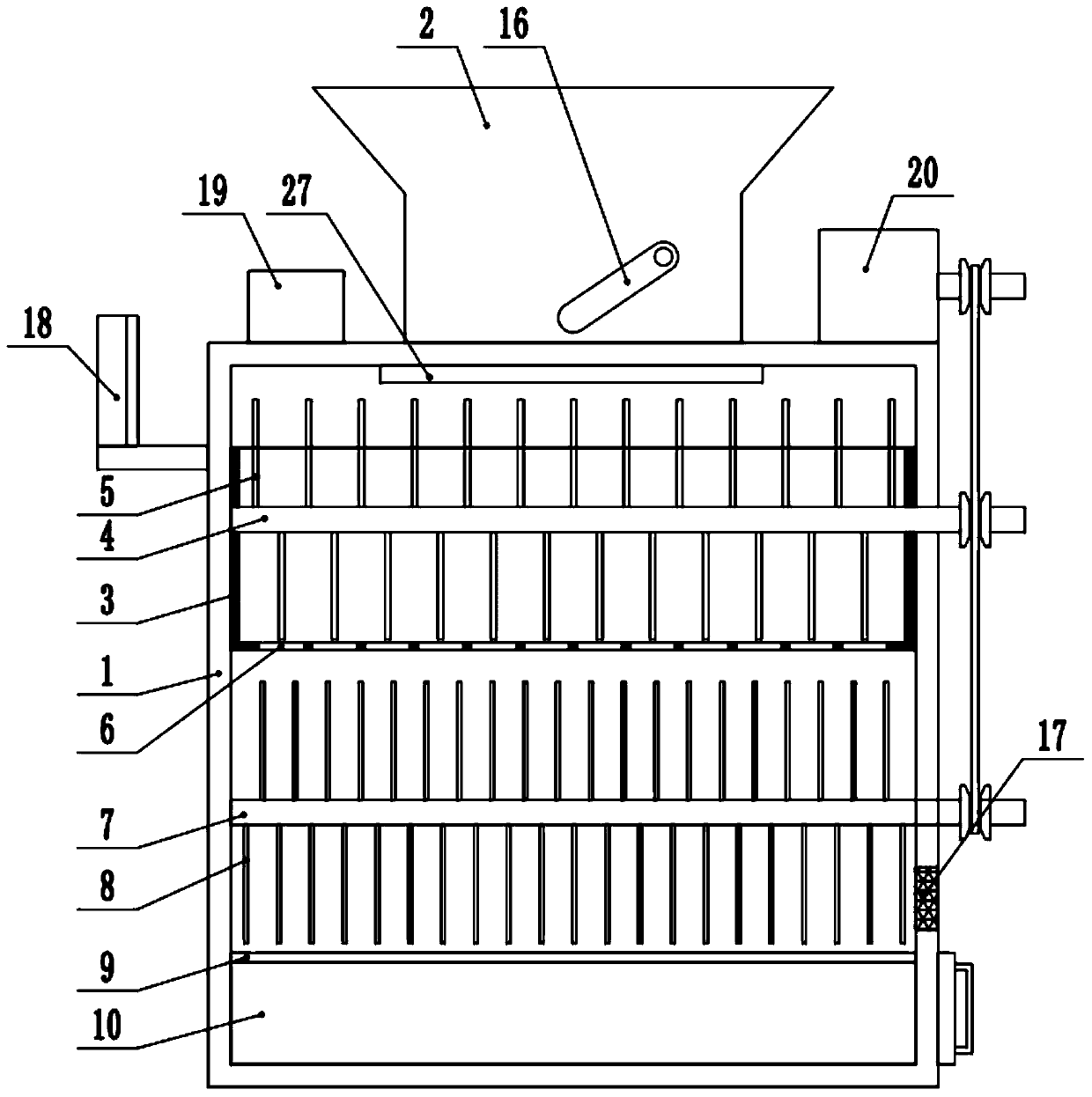

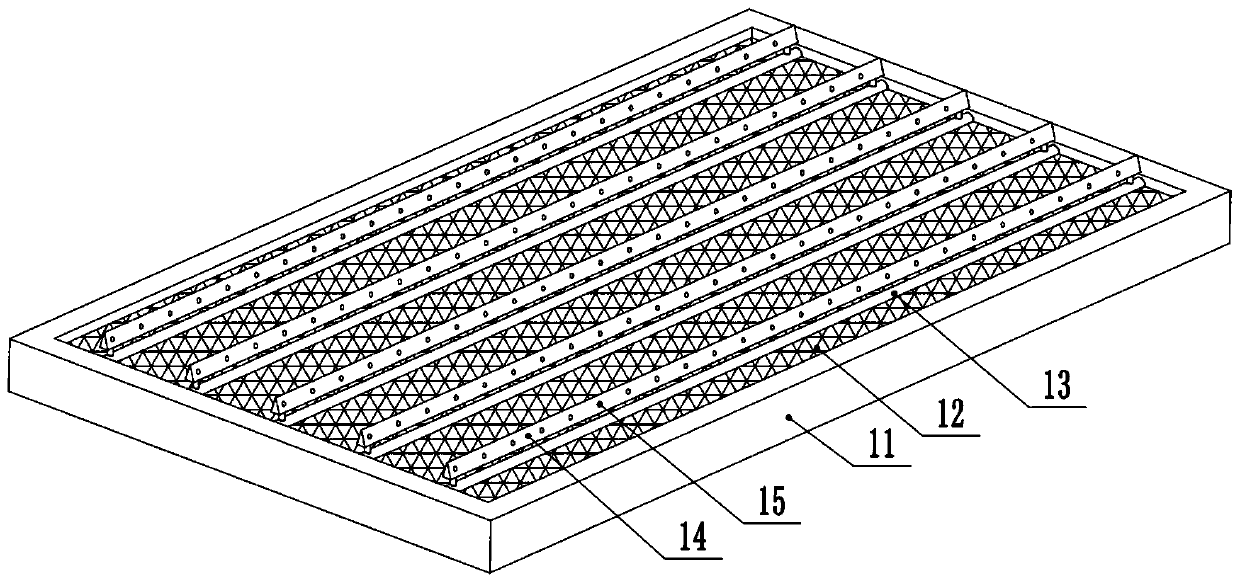

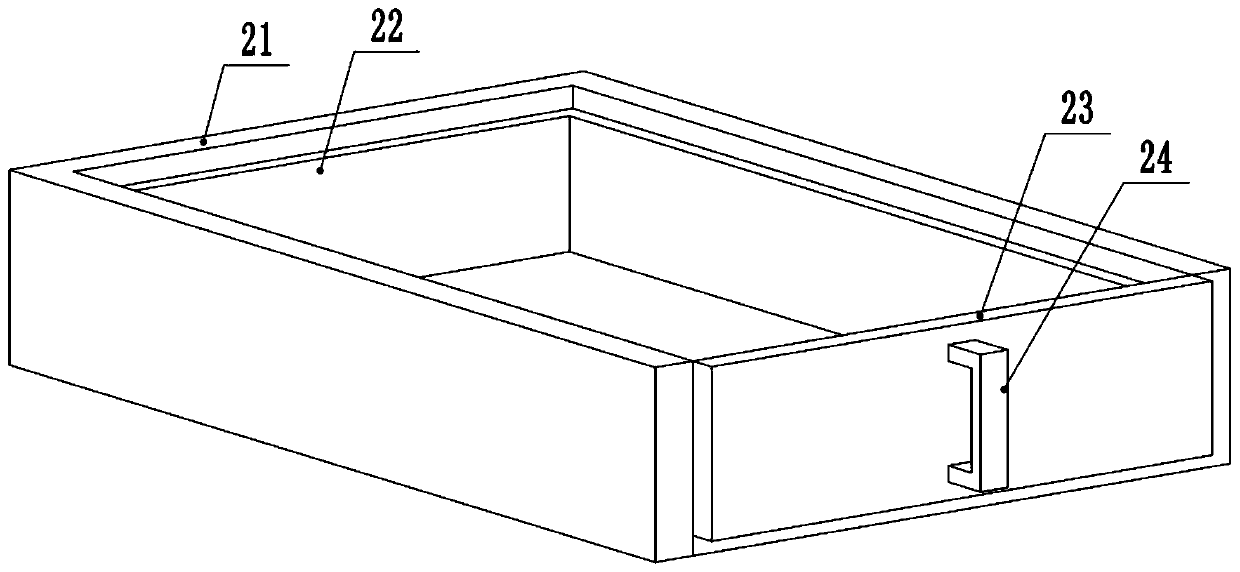

Convenient-to-clean environmentally-friendly type incinerator furnace with waste heat of garbage incineration utilizable

InactiveCN109282292AThe incineration effect is not completeHelp passIncinerator apparatusIncinerationEnvironmentally friendly

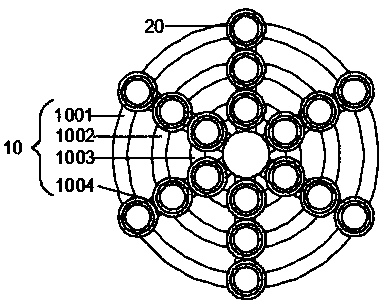

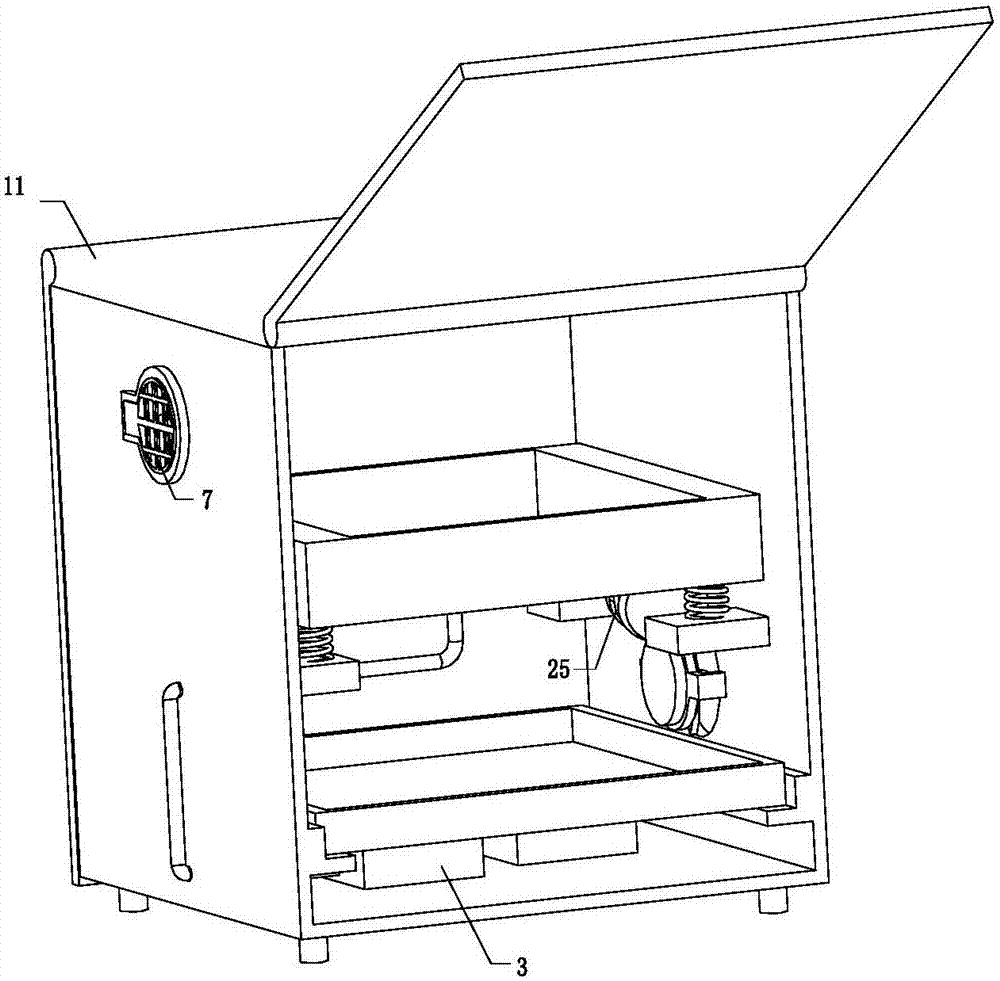

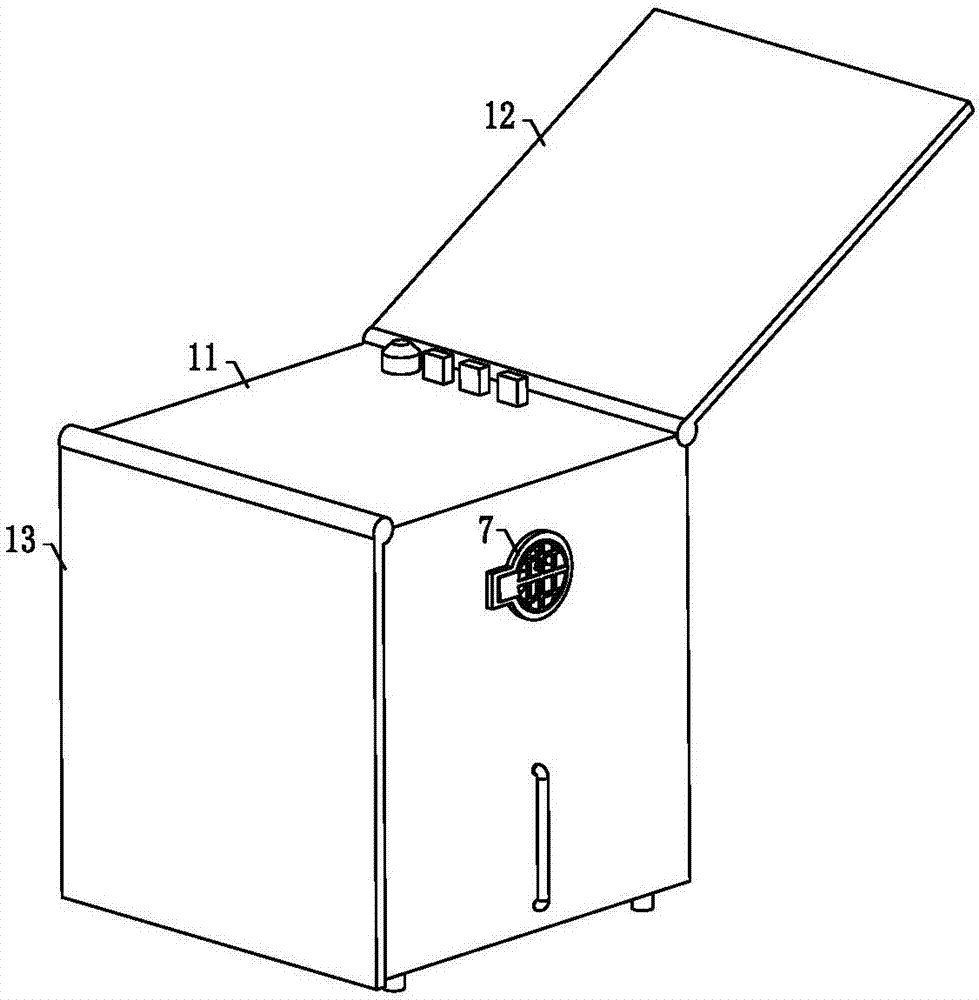

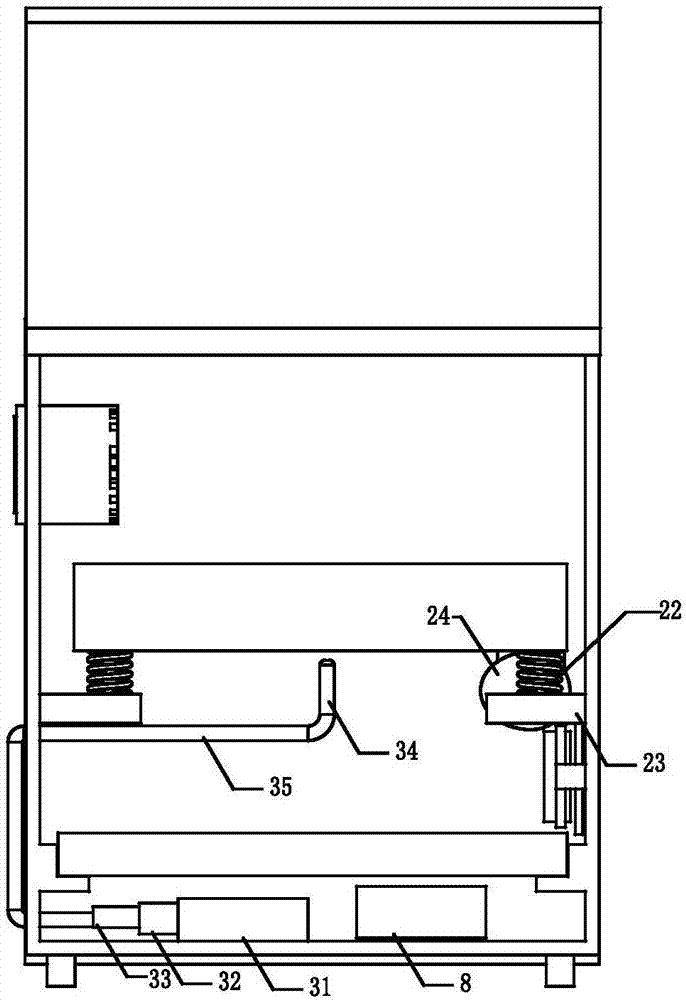

The invention discloses a convenient-to-clean environmentally-friendly type incineration furnace with waste heat of garbage incineration utilizable. The incineration furnace comprises a furnace body and an air supply valve. Incineration nets are arranged inside the furnace body, and an air output pipeline is arranged at the upper end of the furnace body. The incineration nets are connected with the furnace body through bolts. A rotary shaft is inset into the upper end of the air output pipeline, and an electromotor is connected to the upper end of the rotary shaft. A connecting shaft is installed at the lower end of the rotary shaft, and connecting rods are fixed to two sides of the connecting shaft. Fixing blocks are arranged at the lower ends of the connecting rods. The fixing blocks arein welded connection with the connecting rods, and the connecting rods are in welded connection with the connecting shaft. According to the convenient-to-clean environmentally-friendly type incinerator with the waste heat of garbage incineration utilizable, the incineration nets are arranged inside the furnace body from up to down; mesh diameters of the incineration nets decrease from up to down;thus classified incineration can be conducted on garbage; garbage with bigger volume is located at the upper end, and garbage with smaller volume is located at the lower end; and heat transfer from down to up is benefited.

Owner:海数(青岛)医学科技有限公司

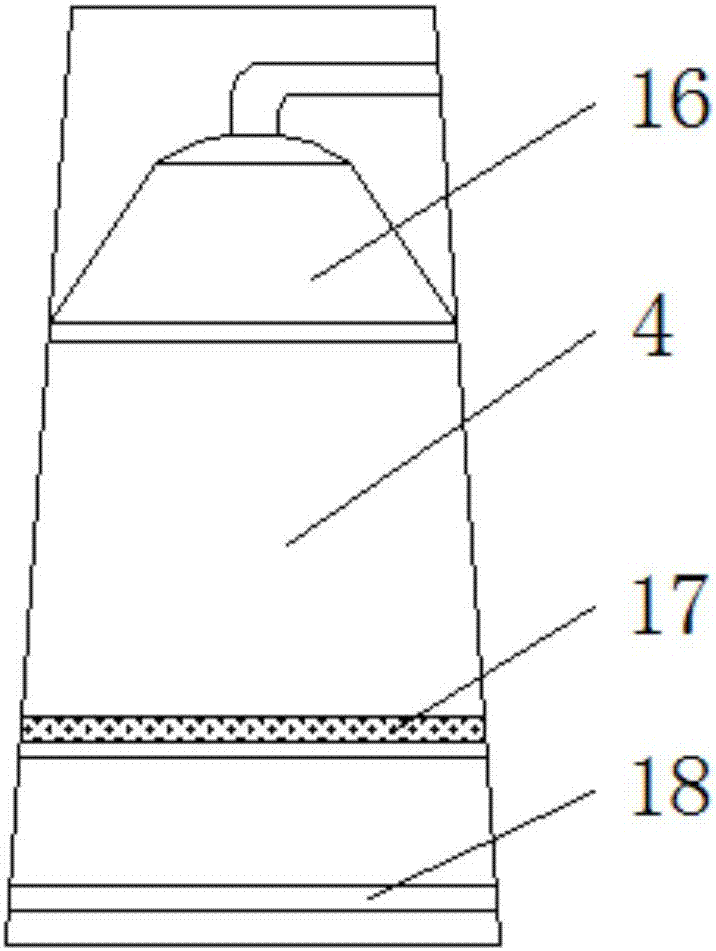

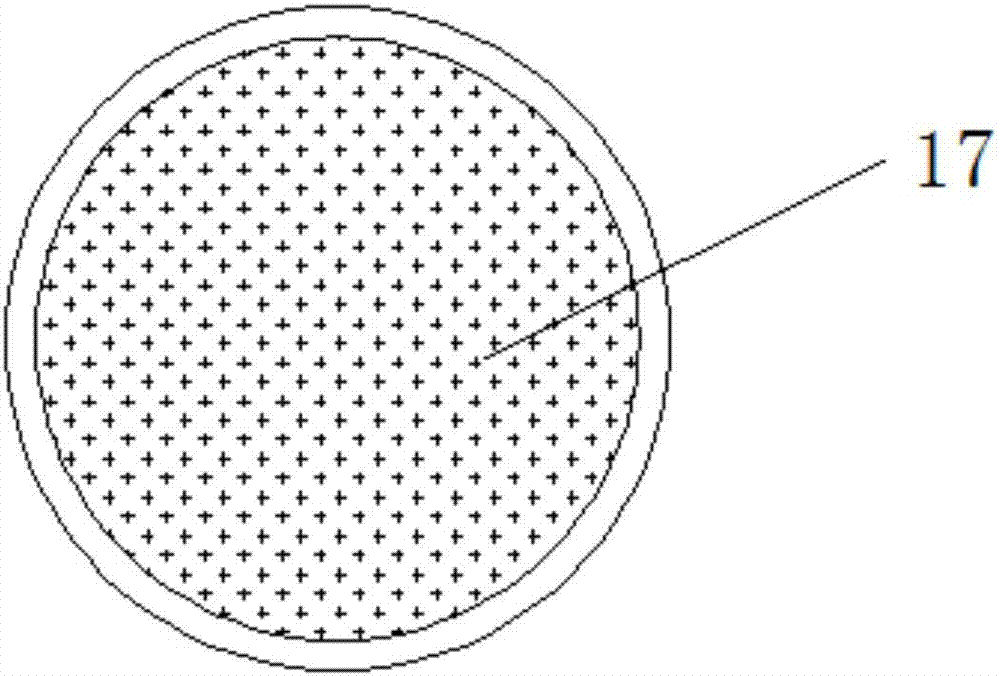

Upper arch cover incinerator

InactiveCN107202330AIncrease incineration speedImprove incineration efficiencyIncinerator apparatusCombustionBulk polymerization

The invention discloses an incinerator with an upper arched cover, which comprises an incinerator body, an ash outlet is arranged on the front surface of the incinerator body, an arched cover is arranged on the top of the incinerator body, and one side of the arched cover A handle for opening the cover is provided, and an overhead floor is provided below the interior of the incinerator body, and a fan is connected to the upper part of the overhead floor through an air duct, and a ventilation plate is clamped at the center of the interior of the incinerator body. In the present invention, the device is provided with a gas-gathering hood inside the incinerator body, one end of the gas-gathering hood is connected to a gas washing box through a flue, and a filter screen is clamped inside the gas washing box, and one side of the filter screen is provided with a The adsorption net makes the device have the function of preliminary purification and dust removal of the flue gas produced by incineration, which enhances the practicability of the device. The device is equipped with a fan on one side of the incinerator body, and the fan passes through the air duct to the incinerator. Air is blown into the main body to increase the burning speed and burning efficiency inside the incinerator main body.

Owner:成都尚智恒达科技有限公司

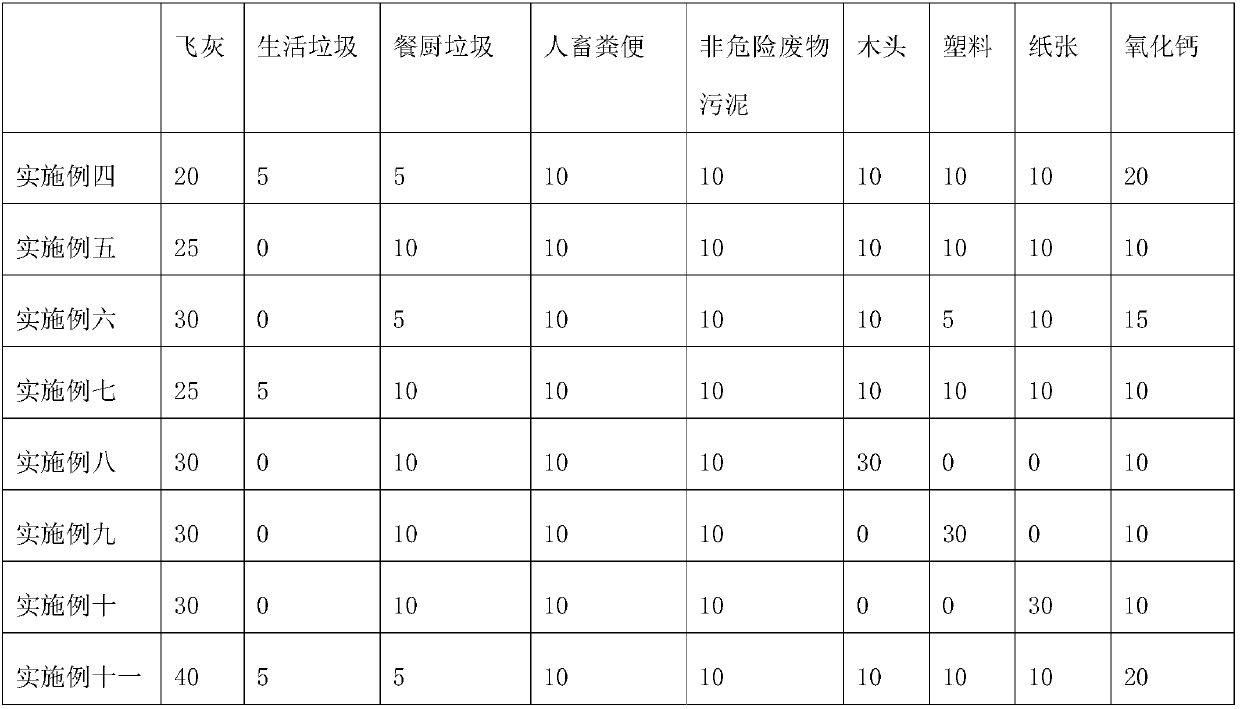

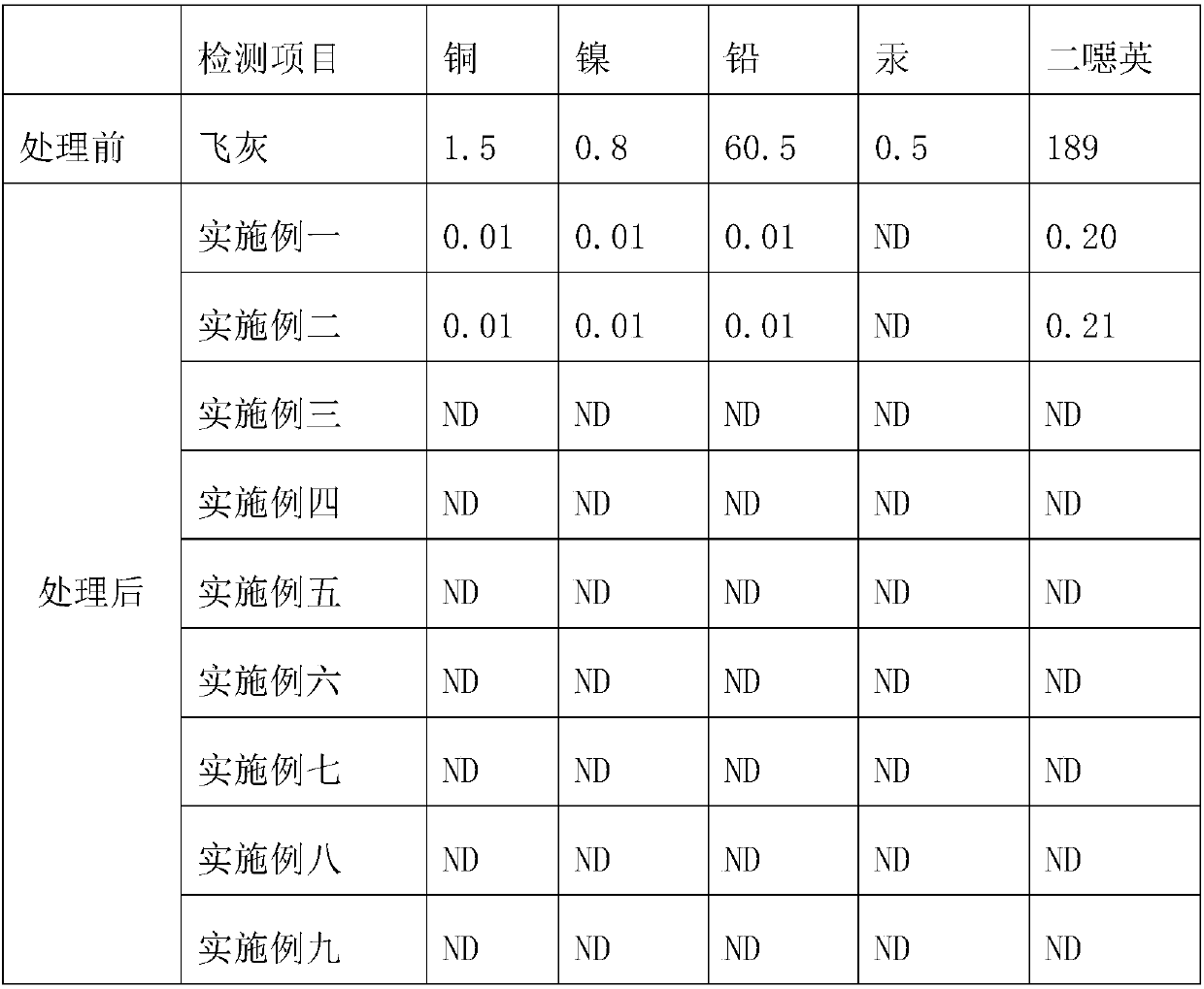

Safe treatment method for fly ash

ActiveCN110631021AIncrease incineration speedRealize harmless treatmentIncinerator apparatusLivestock manureAdhesive

The invention belongs to the technical field of stable treatment of waste incineration fly ash, and particularly relates to a safe treatment method for the fly ash. The method comprises the followingsteps of uniformly mixing the fly ash, an adhesive and a chlorinating agent to obtain a mixture, carrying out drying treatment on the mixture, and then performing incineration at high temperature so as to obtain a harmless product, wherein the adhesive is one or a mixture of household garbage, kitchen waste and human and livestock manure. The safe treatment method for the fly ash has the beneficial effects that harmless treatment on the fly ash can be achieved by mixing and burning the fly ash with various waste materials and the chlorinating agent, and meanwhile the treatment cost of variousother wastes is reduced, so that the cost on environmentally friendliness, investment and operation is low, and higher economic benefits and environmental benefits can be achieved.

Owner:汤广武

Solid waste garbage disposal method

InactiveCN111520726AAdd follow-up processingAchieve re-useIncinerator apparatusGrain treatmentsElectric machineryProcess engineering

The invention discloses a solid waste garbage disposal method. Garbage can be conveyed through a conveying device, pressed flat by a pressing roller and smashed by a left smashing roller and a right smashing roller, a column body is rotated through a third driving motor, and therefore a stirring rod is accordingly rotated, the incineration speed is increased, after incineration ends, a second sphere block enters the space between two connecting rods after a push rod is pushed, a brush is exposed out of a through port, and one side of the stirring rod is cleaned.

Owner:山东瑞泓智能科技有限公司

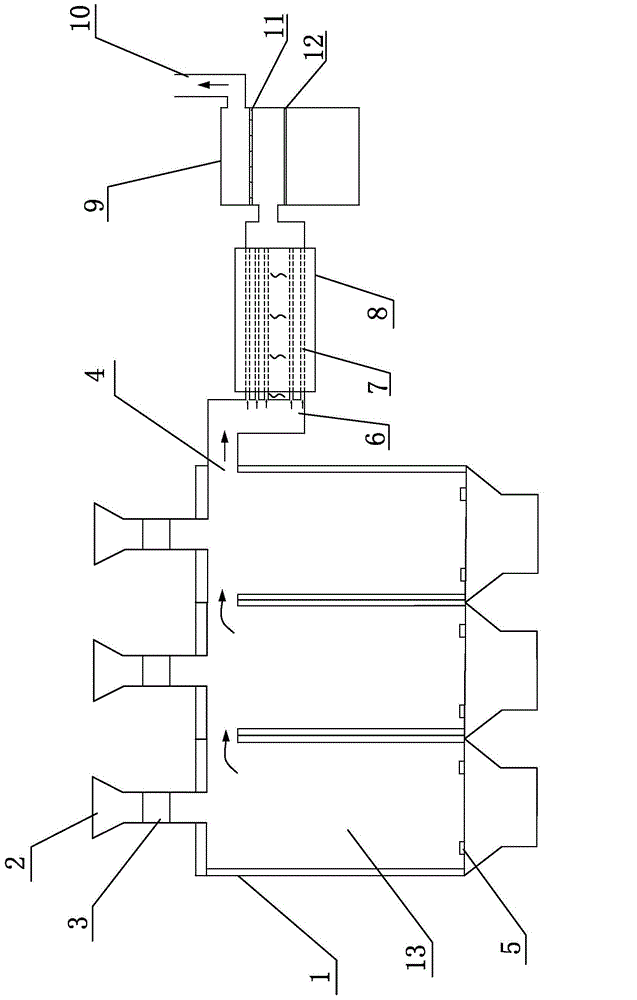

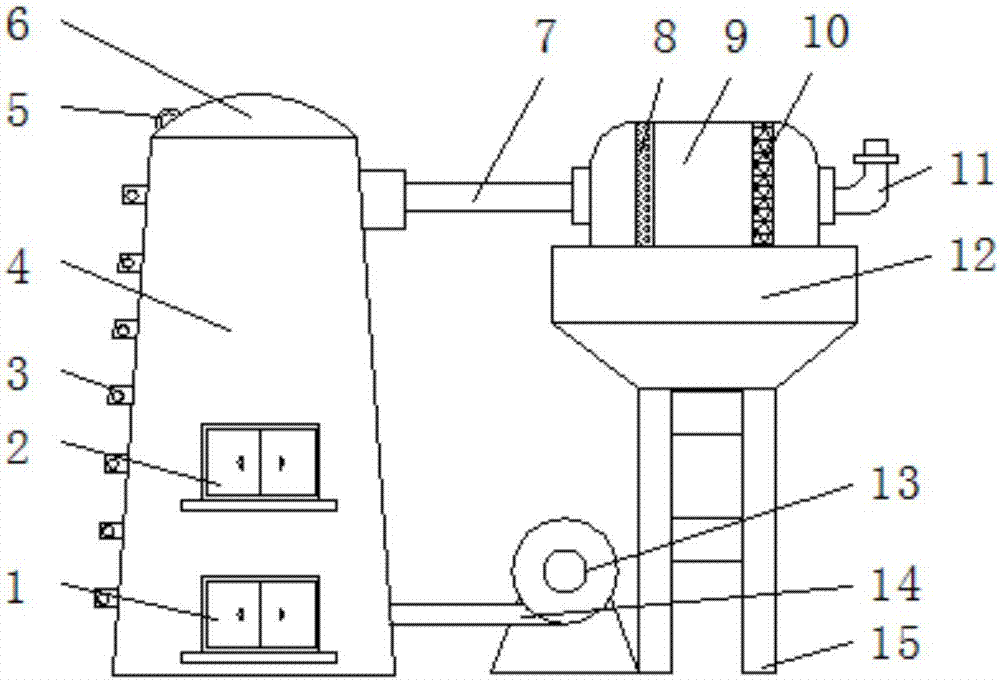

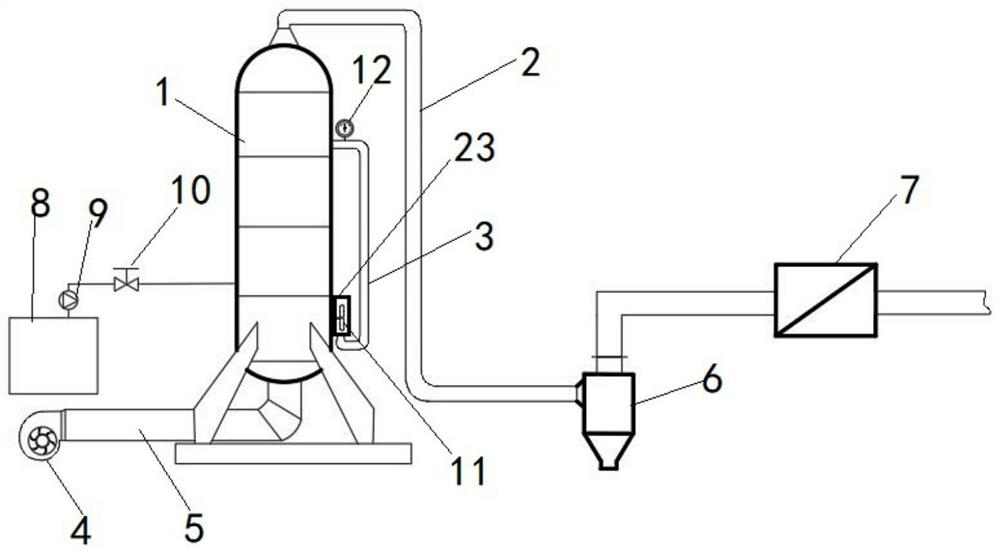

Refuse incineration system efficient in energy utilization

InactiveCN106765149AImprove combustion efficiencyIncrease incineration speedIncinerator apparatusEngineeringIncineration

The invention discloses a refuse incineration system efficient in energy utilization. An auxiliary fine incinerator is arranged for a main incinerator, during a reaction, the drying and reduction process of the refuse is isolated from the combustion process of the refuse in the auxiliary fine incinerator, and therefore the combustion efficiency in the auxiliary fine incinerator is greatly improved. On one hand, circulating gas enters a high-temperature combustion cavity and is fully combusted, so that the environmental pollution caused by tail gas is reduced; on the other hand, the circulating gas has the combustion supporting function on the high-temperature combustion cavity, so that the combustion effect of the high-temperature combustion cavity is further improved; in addition, high-temperature tail gas in the high-temperature combustion cavity enters an auxiliary heating pipe in the main incinerator and conducts auxiliary heating on the refuse, so that the combustion speed of the refuse in the main incinerator is improved; and the drying and reduction process is accelerated before the refuse is combusted, and therefore the combustion efficiency of the main incinerator is further improved.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

An outdoor straw incineration device and method for easy cleaning

ActiveCN110864303BImprove cleanlinessImprove efficiencyDispersed particle filtrationTransportation and packagingProcess engineeringMechanical engineering

The invention discloses an outdoor straw incineration device which is convenient for dust removal, which comprises an incinerator body, a top plate is fixedly connected between the tops on both sides of the inner wall of the incinerator body, and a thick pipe is fixedly connected to the inside of the top plate. The bottom end of the thick pipe is connected with a filter chamber, the inside of which is fixedly connected with a first filter net, and slide bars are fixedly connected between the top and the bottom of the inner wall of the filter chamber. The present invention relates to straw incineration equipment technology field. The outdoor straw incineration device that is easy to clean dust is arranged through the cooperation of the brush plate, the brush, the top plate, the moving plate, the first threaded rod and the stable plate, so that the brush plate can drive the brush to move to the bottom of the first filter net Dust removal solves the problem that dust is not easy to be removed from the mesh of the filter, improves the efficiency of the incinerator body, ensures the normal use of the filter, and facilitates the subsequent use of the straw incineration device.

Owner:威海君祥企业管理咨询有限公司

Outdoor stalk incineration device and method convenient for clearing dust

ActiveCN110864303AImprove cleanlinessImprove efficiencyDispersed particle filtrationTransportation and packagingMechanical engineeringIncineration

The invention discloses an outdoor stalk incineration device convenient for clearing dust. The outdoor stalk incineration device convenient for clearing dust comprises an incineration furnace body, wherein a top plate is fixedly connected between tops of two sides of the inner wall of the incineration furnace body; the inner part of the top plate is fixedly connected with a thick tube; the bottomend of the thick tube communicates with a filter cavity; a first filter screen is fixedly connected inside the filter cavity; and slide rods are fixedly connected between tops and bottoms of the two sides of the inner wall of the filter cavity. The invention relates to the technical field of stalk incineration equipment. According to the outdoor stalk incineration device convenient for clearing dust disclosed by the invention, a brush plate, a brush, a top plate, a movable plate, a first threaded rod and a stable plate are matched, so that the brush plate can drive the brush to perform dust clearing on the bottom of the filter screen, the problem that dust is adsorbed into mesh holes of the filter screen and is not liable to take out is solved, use efficiency of the incineration furnace body is improved, normal use of the filter screen is guaranteed, and follow-up use of the stalk incineration device is more convenient.

Owner:威海君祥企业管理咨询有限公司

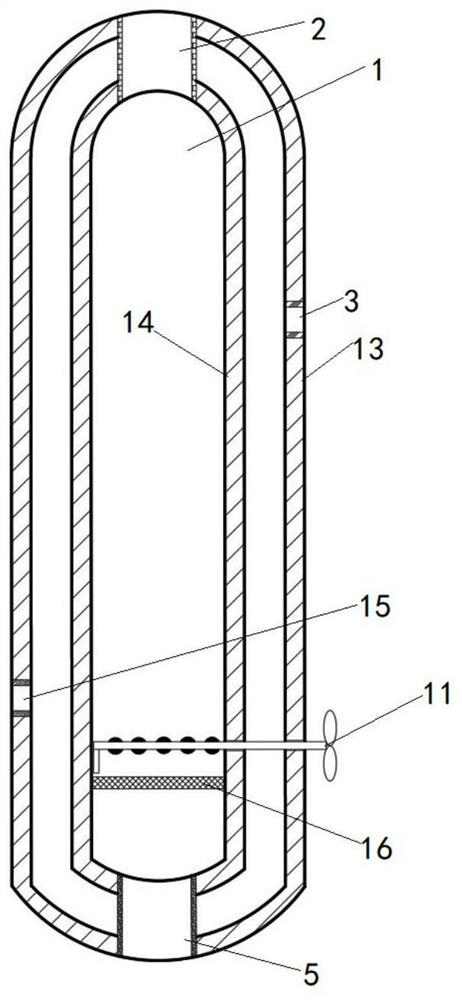

Garbage pyrolysis cyclone incinerator

InactiveCN112013400AReduce the difficulty of cleaning slagIncrease air contentIncinerator apparatusPyrolysisMechanical engineering

The invention discloses a garbage pyrolysis cyclone incinerator. The garbage pyrolysis cyclone incinerator structurally comprises an air blower, an incineration chamber, a clearing opening, a feedingopening and an exhaust opening; the air blower is in bolt connection with the left side, and the right side of the incineration chamber is connected with the outer side of the clearing opening in a hinged mode; and the feeding opening is connected with the left side of the upper end of the incineration chamber in a built-in mode. During disturbance, a shifting base turns middle-lower garbage outwards, a disturbance rod is driven by a power plate connected with a connecting plate to rotate to spread the outer side to disturb airflow in the center, and secondary combustion of waste residue whichis not fully combusted is facilitated, so that the quality of slag is reduced, and the slag clearing difficulty is reduced; and a disturbance plate on the outer side of a fixing block is blown to outwards rotate by a certain angle to be clamped by a main block, then the disturbance plate drives airflow on the outer side into the interior, resetting can be conducted through an elastic rod after completion, the content of air in the middle of cyclone is increased, the middle garbage incineration speed is increased advantageously, thus combustion is more sufficient, and the generation amount oftoxic gas is decreased.

Owner:朱四海

Anti-clogging waste incineration purification device with dust collection function

InactiveCN112781057AImprove stabilityIncrease motivationIncinerator apparatusToxic gasEnvironmental engineering

The invention discloses an anti-clogging waste incineration purification device with a dust collection function, and relates to the technical field of waste incineration purification devices, in particular to the anti-clogging waste incineration purification device with the dust collection function. The anti-clogging waste incineration purification device comprises a base and a driven wheel, a working cabin is fixedly connected to the upper part of the base, a motor is installed in the working cabin, a movable rod is movably connected to the upper portion of the motor, a transmission wheel is movably connected to the upper portion of the movable rod, the driven wheel is located on the left side of the transmission wheel, and a main threaded rod is installed in the driven wheel. According to the anti-clogging waste incineration purification device with the dust collection function, after waste incineration is completed, and after gas is qualified through the detection of a filter and a smoke and dust detector, a telescopic rod can be started to drive a baffle to move upwards to discharge purified gas, through the design, the leakage of unpurified poisonous gas can be avoided, and the safety of the device is improved.

Owner:CHAOHU ZHENGDE MECHANICAL ENVIRONMENTAL PROTECTION ENG

Thermodynamic cycle accumulation-free efficient incineration boiler

PendingCN112113227AAvoid concentrated accumulationSave drive energyRotary stirring mixersTransportation and packagingProcess engineeringIncineration

The invention discloses a thermodynamic cycle accumulation-free efficient incineration boiler. The efficient incineration boiler comprises an incineration cavity, an air blowing pipe, a fan and a stirring device, wherein an air outlet of the air blowing pipe is connected to the bottom of the incineration cavity, the fan is connected with the air blowing pipe and blows air into the air blowing pipe, and the stirring device is arranged at the lower end inside the incineration cavity and used for stirring garbage in the incineration cavity; and the incineration cavity comprises a double-layer wall, wherein the side face of the double-layer wall is connected with an air collecting pipe, and the air collecting pipe collects flowing gas between the double-layer wall of the incineration cavity todrive the stirring device to rotate. According to the thermodynamic cycle accumulation-free efficient incineration boiler, incinerated garbage in the incineration boiler can be fully dispersed, accumulation is avoided during incineration, combustion is sufficient, and meanwhile hot gas outside the incineration cavity can be collected and utilized, so that the incinerated garbage is further fullydispersed.

Owner:江阴市锦绣江南环境发展有限公司

A Waste Incineration System with Efficient Energy Utilization

InactiveCN106765149BImprove combustion efficiencyIncrease incineration speedIncinerator apparatusEngineeringIncineration

The invention discloses a refuse incineration system efficient in energy utilization. An auxiliary fine incinerator is arranged for a main incinerator, during a reaction, the drying and reduction process of the refuse is isolated from the combustion process of the refuse in the auxiliary fine incinerator, and therefore the combustion efficiency in the auxiliary fine incinerator is greatly improved. On one hand, circulating gas enters a high-temperature combustion cavity and is fully combusted, so that the environmental pollution caused by tail gas is reduced; on the other hand, the circulating gas has the combustion supporting function on the high-temperature combustion cavity, so that the combustion effect of the high-temperature combustion cavity is further improved; in addition, high-temperature tail gas in the high-temperature combustion cavity enters an auxiliary heating pipe in the main incinerator and conducts auxiliary heating on the refuse, so that the combustion speed of the refuse in the main incinerator is improved; and the drying and reduction process is accelerated before the refuse is combusted, and therefore the combustion efficiency of the main incinerator is further improved.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

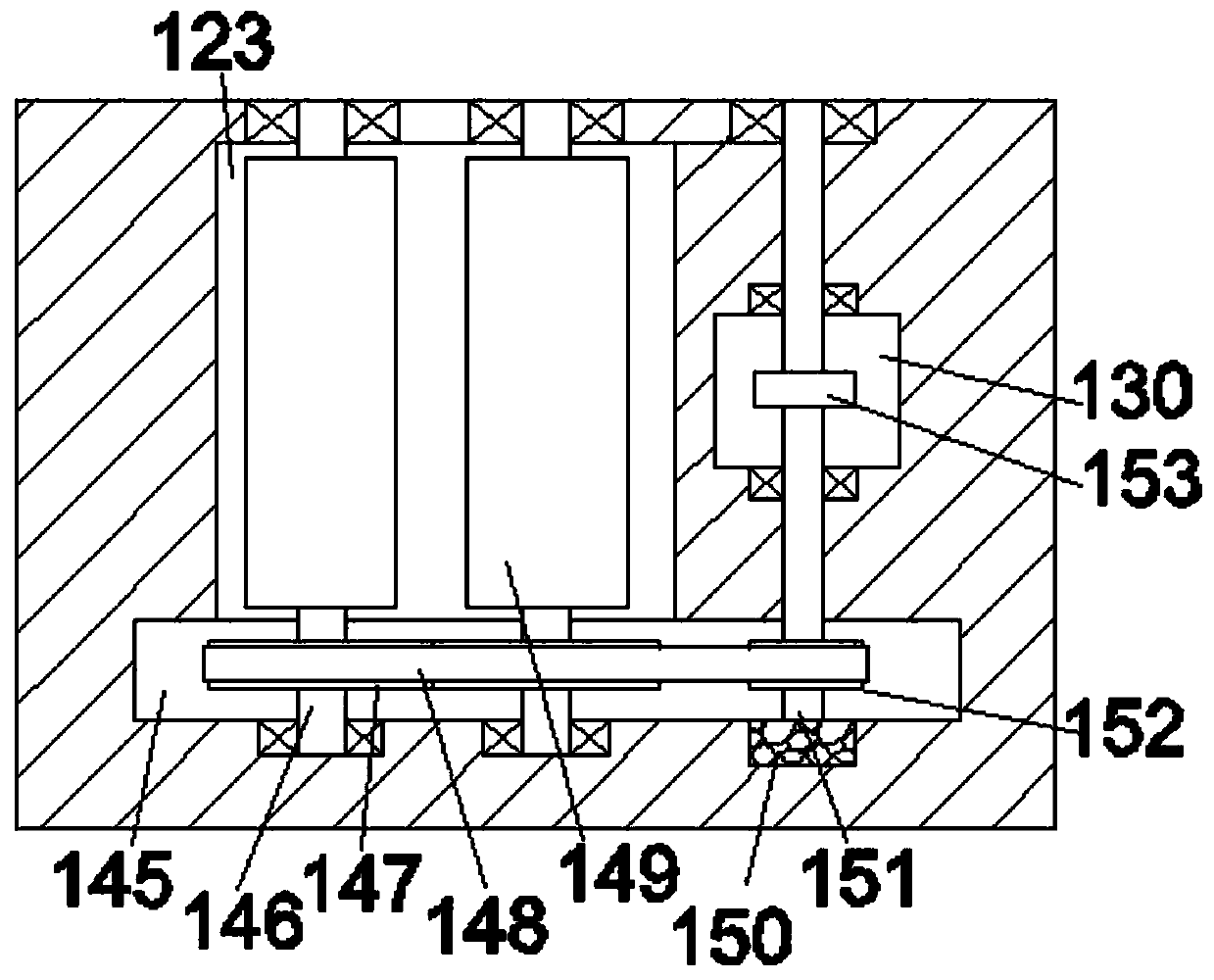

Environment-friendly multifunctional garbage treatment equipment based on garbage classification

InactiveCN113685825ARealize automatic feeding functionRealize crushing workIncinerator apparatusAir pumpEnvironmental engineering

The invention discloses environment-friendly multifunctional garbage treatment equipment based on garbage classification, comprising an incineration bin. A mounting bin is arranged on one side of the incineration bin, an overturning assembly is arranged at the inner bottom of the incineration bin, crushing rods extending into the mounting bin are symmetrically arranged at one end of the front face of the inner top of the incineration bin, the two groups of crushing rods are matched with each other, and meshed gears B are arranged on the sides, close to the mounting bin, of the outer parts of the two groups of crushing rods. Through mutual cooperation of an air pump, a garbage bin, an air inlet pipe, a connecting pipe, a filter bin, a filter screen plate B, an exhaust pipe and the incineration bin, harmful smoke generated during incineration can be filtered, so that the situation that the smoke is directly discharged to the outside and harms the surrounding environment or the body health of people is prevented; and meanwhile, the purified smoke can be discharged into the incineration bin again, so that the oxygen content in the incineration bin is increased, the incineration speed is increased again, and the waiting time of operators is shortened.

Owner:宋丹

Environment-friendly and efficient waste incineration device

ActiveCN110397928AEfficient crushingIncrease incineration speedIncinerator apparatusEngineeringWaste treatment

The invention discloses an environment-friendly and efficient waste incineration device, and relates to the technical field of environmental protection treatment. The device comprises an incinerationbox, wherein a feeding hopper is fixedly connected to the top end of the incineration box, a first incineration mechanism and a second incineration mechanism are arranged in the incineration box, thefirst incineration mechanism comprises a screening cover, a discharging opening is formed in the bottom end of the screening cover, the screening cover is internally and rotationally connected with afirst crushing shaft, the first crushing shaft is fixedly connected with a plurality of first crushing blades, a flaming ring is fixedly connected to the top end in the incineration box, the second incineration mechanism comprises a second crushing shaft, a plurality of second crushing blades are fixedly connected to the second crushing shaft, and a bottom separation device is arranged below the second incineration mechanism. According to the device, by arranging the first incineration mechanism and the second incineration mechanism, waste can be crushed and combusted twice, so that the incineration speed of the waste can be accelerated, products obtained after waste incineration can be crushed so as to be conveniently treated and transported, the waste treatment is efficient and rapid, and the environmental protection property is good.

Owner:江苏冰溶重型机械有限公司

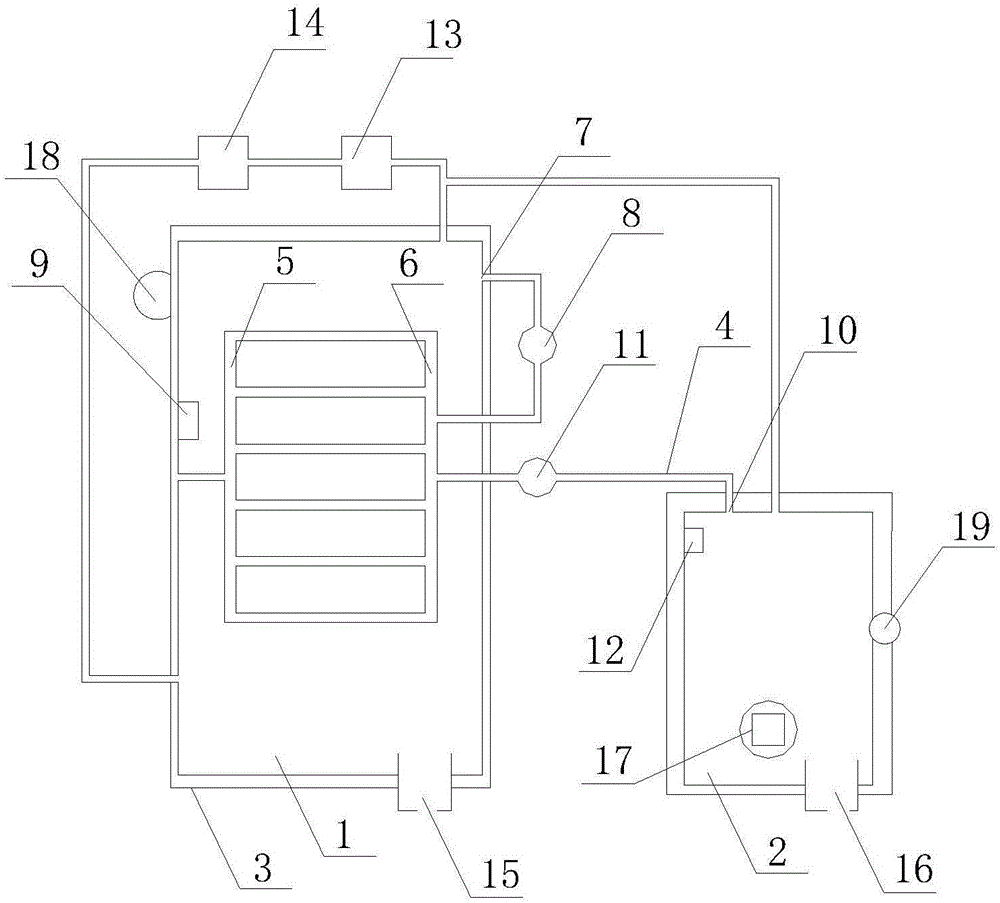

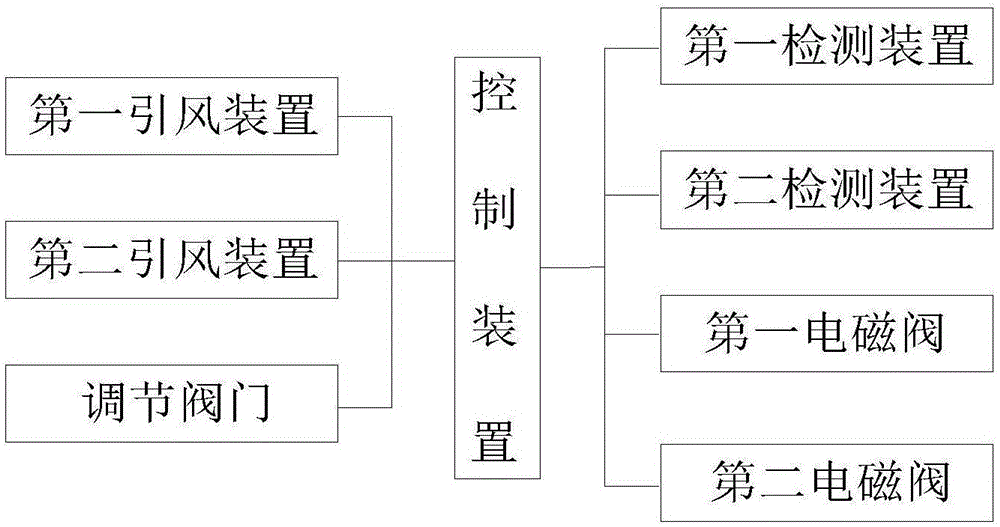

Garbage incinerator gas circulating control system based on temperature detection

InactiveCN106813248AIncrease temperatureGuaranteed incineration effectIncinerator apparatusExhaust gasGas pipeline

The invention discloses a garbage incinerator gas circulating control system based on temperature detection. The system comprises a first cavity, a second cavity, a shell, a first detection device, a second detection device and a control device; a first air induction device is arranged on the outer wall of the shell, a first tail gas outlet is communicated with a second pipeline through a first tail gas pipeline, a first electromagnetic valve is arranged on the first tail gas pipeline, the first detection device is used for detecting the temperature value T of the first position in the first cavity, a second tail gas outlet is communicated with a second pipeline through a second tail gas pipeline, a second electromagnetic valve is arranged on the second tail gas pipeline, a second air induction device is arranged in the second cavity, and the second detection device is used for detecting the temperature value T0 on a tail gas outlet; the control device obtains the detection value T of the first detection device and the detection value T0 of the second detection device and controls the first air induction device, the second air induction device, the first electromagnetic valve and the second electromagnetic valve to act according to size instructions of T and T0.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com