Large-size hazardous waste rotary kiln type incinerator device taking sludge as main target

A technology of rotary kiln and incinerator, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of difficult incineration process, achieve the effects of reducing oxygen content, promoting complete combustion, and inhibiting volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

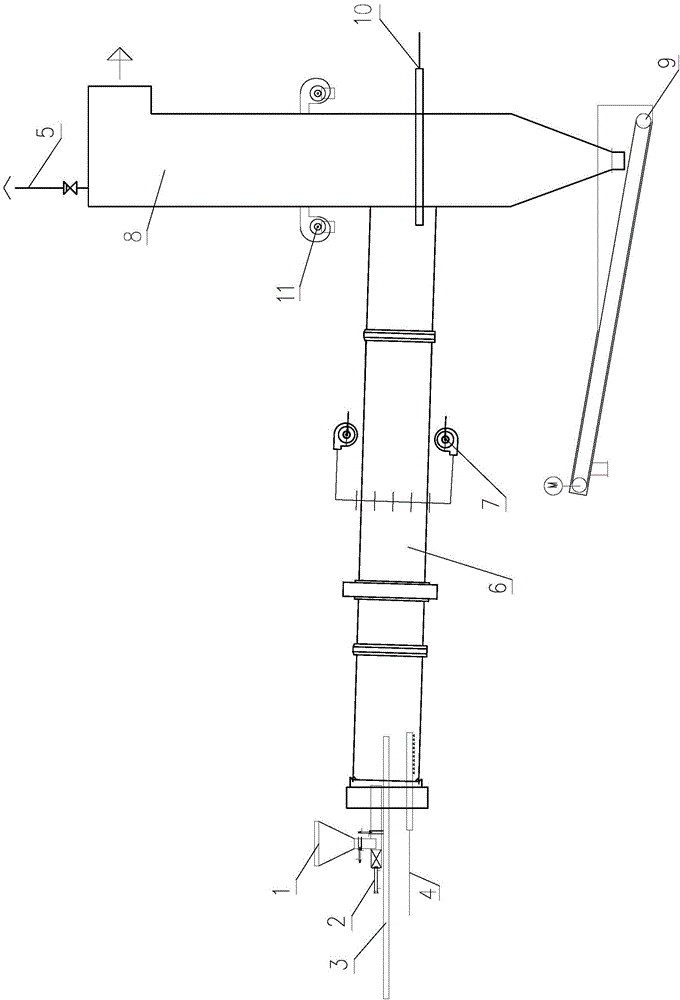

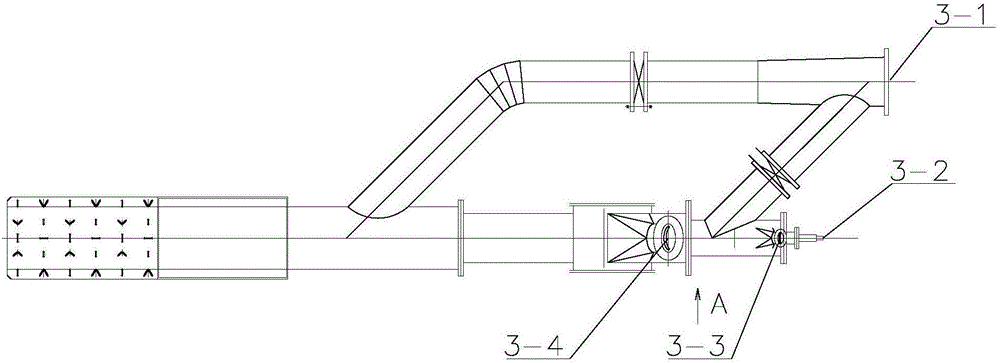

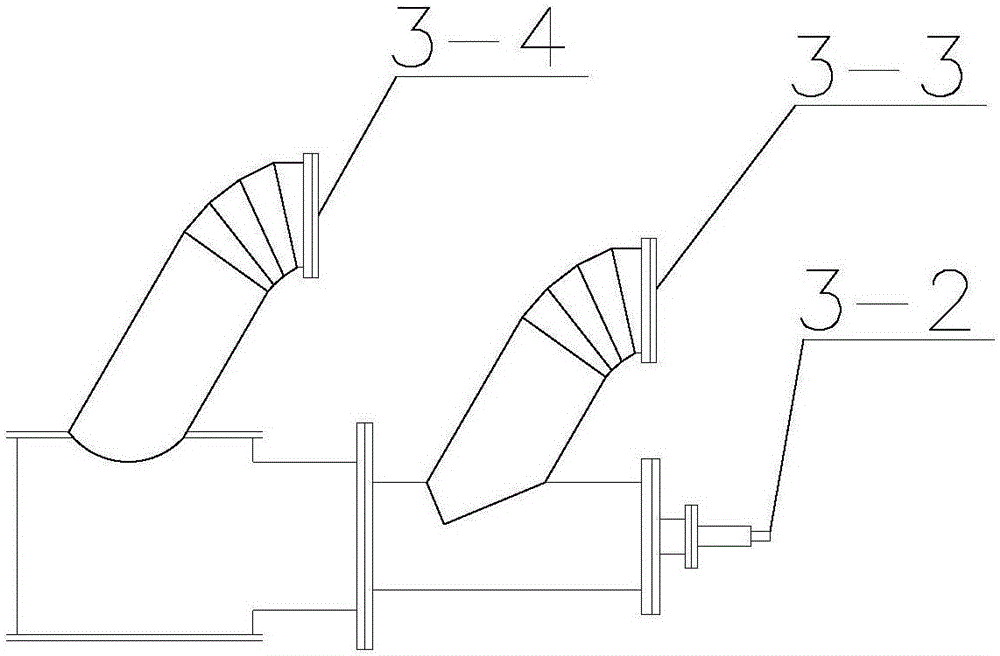

[0027] like Figure 1-Figure 6 As shown in the figure, a large-scale hazardous waste rotary kiln incinerator device mainly composed of sludge includes a receiving bin 1, a feeder 2, a multi-functional fuel nozzle 3, a hot air injection device 4 in the kiln, a rotary kiln 6, powder The material suspension device 7, the second combustion chamber 8, the scraper slag discharger 9, the feeder 2, the multifunctional fuel nozzle 3 and the hot air injection device 4 in the kiln are respectively installed at the entrance of the rotary kiln 6, and the receiving bin 1 is installed Above the feeder 2, a powder suspending device 7 is arranged in the middle of the rotary kiln 6, and the air supply branch pipe 7-1 in the powder suspending device 7 communicates with the inside of the rotary kiln 6, and two The combustion chamber 8 and the scraper slag discharger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com