Patents

Literature

43results about How to "Accelerate incineration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

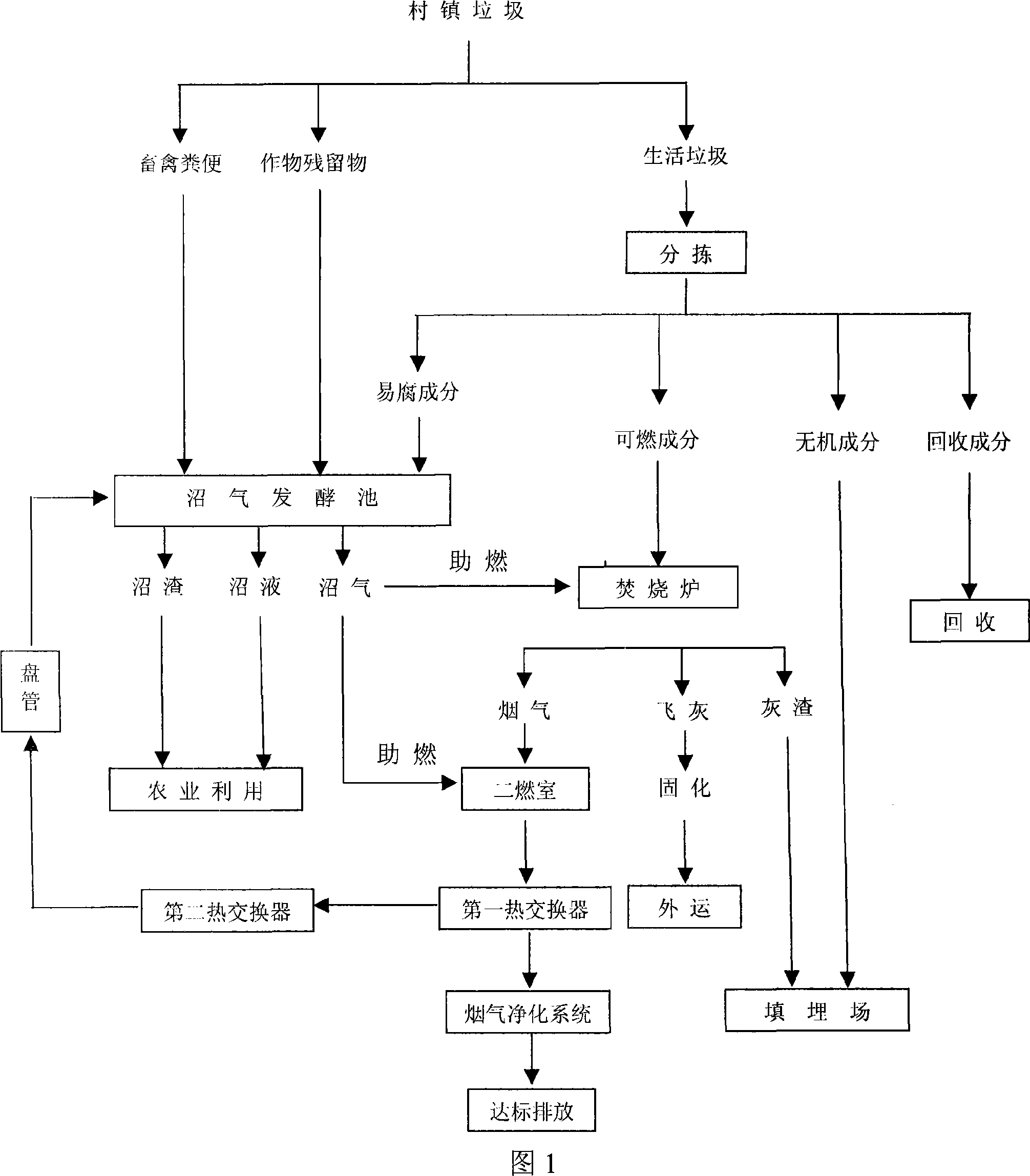

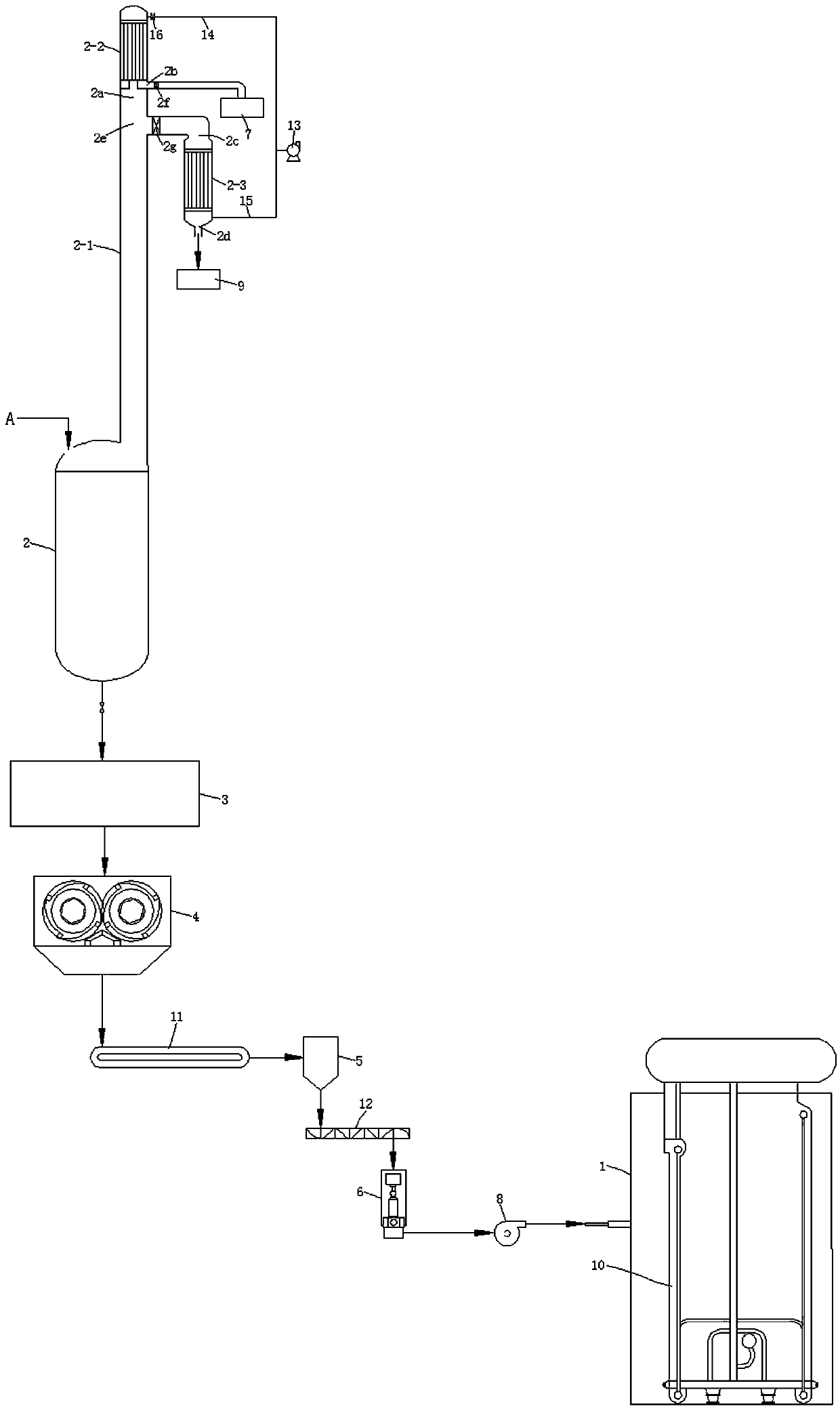

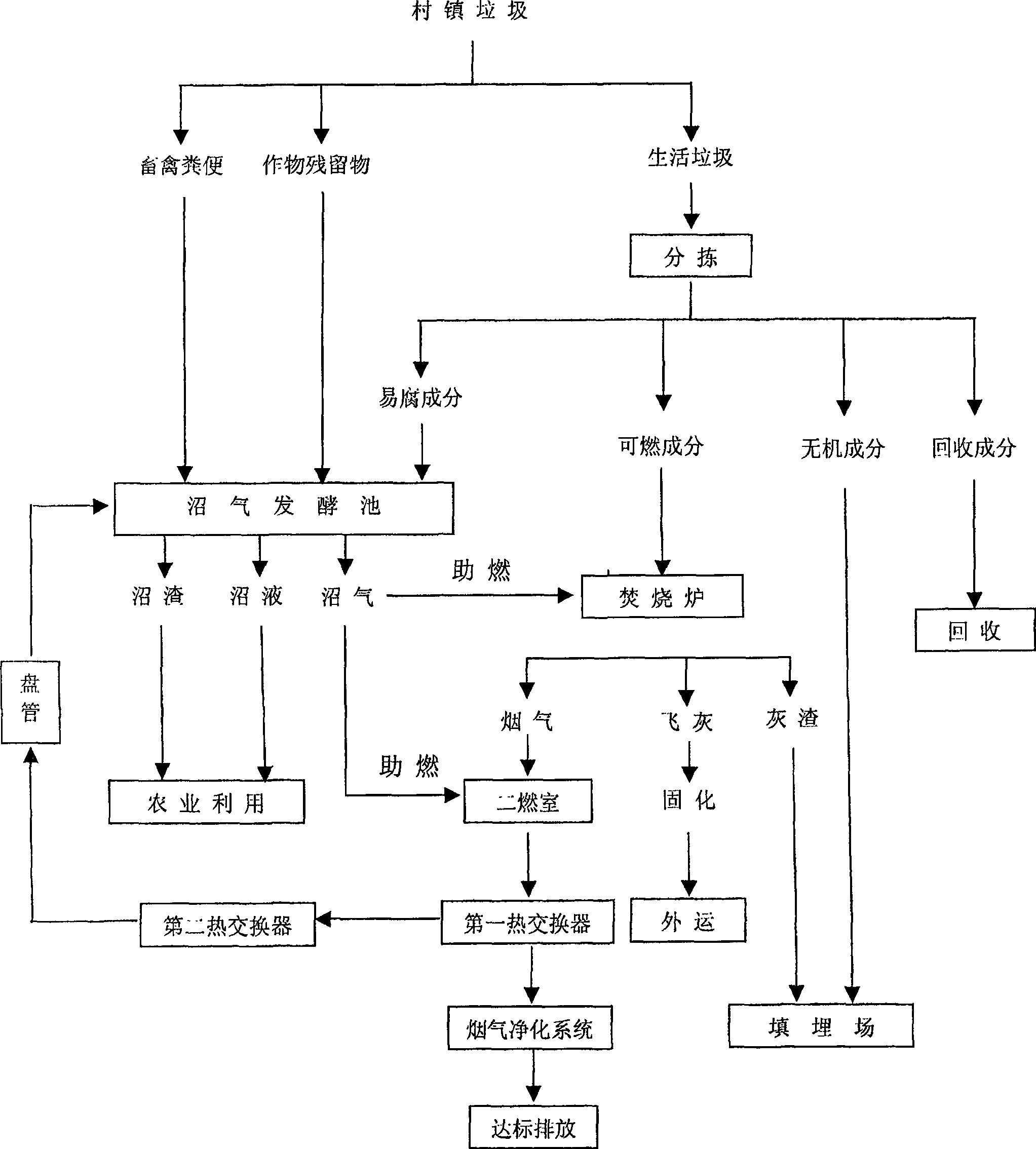

Rubbish comprehensive processing method adapted for village and small town

InactiveCN101062825AIncineration harmlessIncineration reductionBio-organic fraction processingChemical industryThermal energyResource utilization

The invention discloses a garbage comprehensive treatment method for village, which comprises the following steps: sorting life garbage of village to perishable element, combustible constituent, reclaiming element; inorganic element; allocating the perishable element, residues of crop, animal and poultry manure and water with mass ratio at 0. 8-1. 2:0. 8-1. 2:8; proceeding anaerobic fermentation under the insulation action of burning lose heat; generating marsh gas; burning the combustible constituent with combustion-supporting marsh gas completely; getting high temperature smoke gas; recovering thermal energy through the first and second heat exchanger; maintaining the temperature of marsh gas fermenting tank; obtaining resource utilization of marsh liquid or slag, marsh gas and reclaiming component; health-filling the inorganic element and burning ash slag. This invention can prevent twice pollution of the burning smoke gas, which can increase the efficiency and output of mash gas.

Owner:ZHEJIANG UNIV

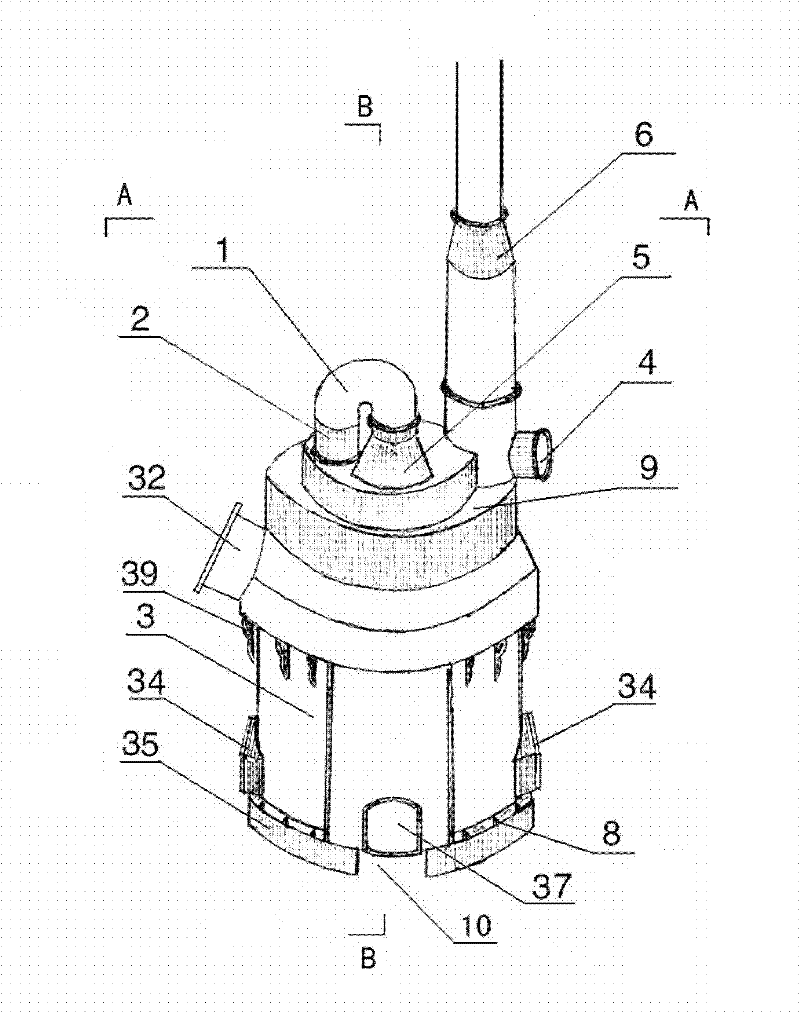

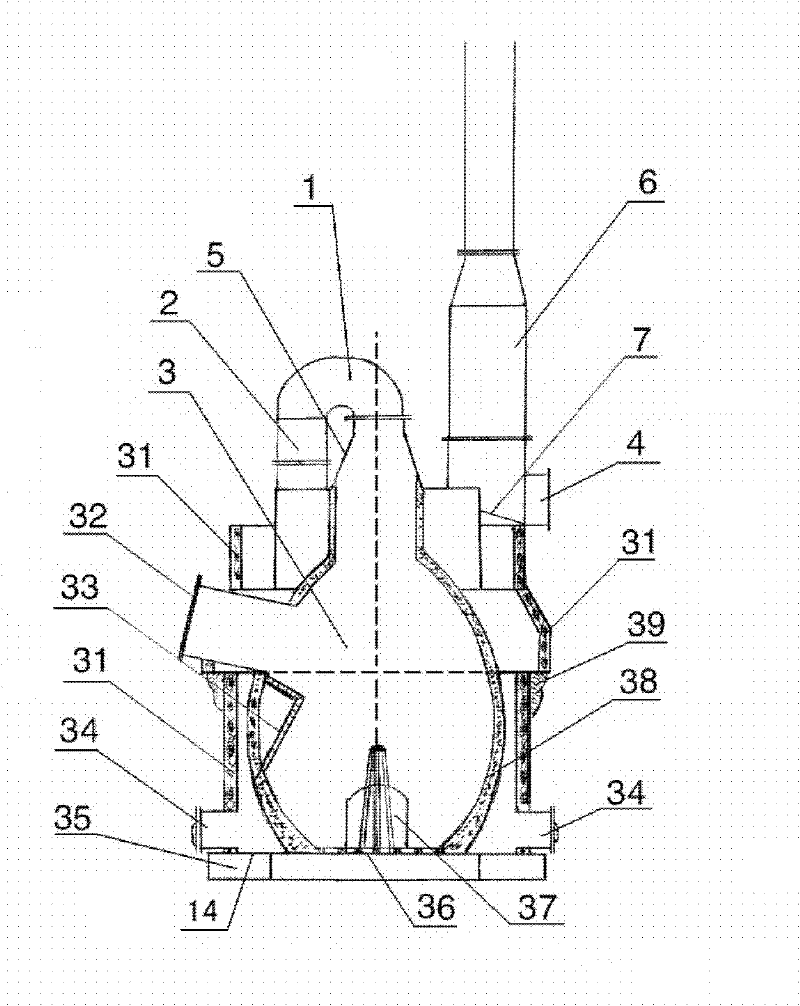

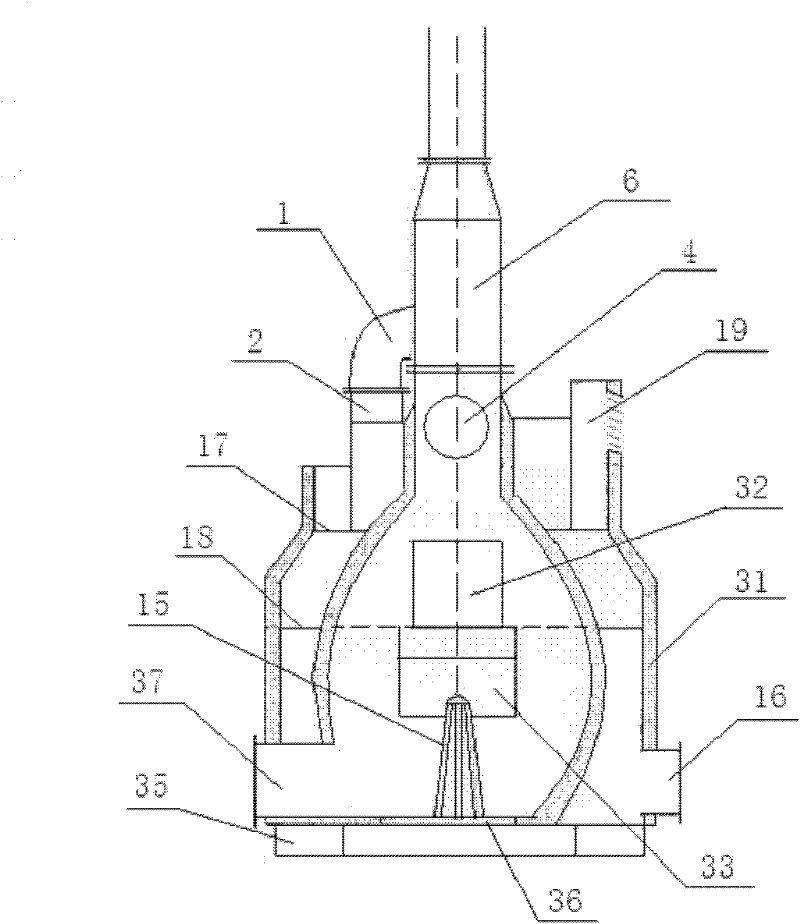

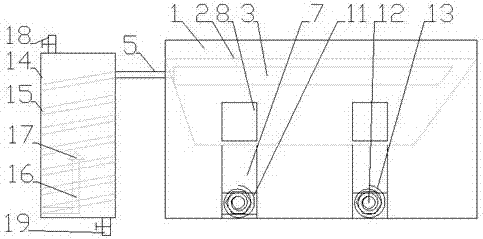

Small refuse incinerator

The invention provides a refuse incinerator which comprises a fume spiral channel device, an incinerator body, a hot air gathering slot, a fume exhaust tube and a chimney, wherein the hot air gathering slot is arranged at the bottom of the incinerator body and is fixedly connected with the bottom surface of the incinerator body; the incinerator body comprises an insulating layer and an inner core layer; a space is reserved between the insulating layer and the inner core layer, thus forming a cold air preheating duct; the side wall at the top of the inner core layer is provided with an air hole; the side wall of the upper part of the incinerator body is provided with a feed port; fire bars are arranged on a bottom plate of the incinerator body; the fume spiral channel device is arranged at the top of the incinerator body; a fume spiral channel outer plate and the incinerator body define a fume spiral channel; the chimney is communicated with the fume spiral channel; and the fume exhaust tube is arranged on the side wall of a bottom end. The refuse incinerator has the advantages that the failure rate is low; the service life is long; the problem of influence of coking on fume flow path and oxygen supply in a hearth can be avoided; the refuse incinerating capacity is increased; and the incineration effect is good.

Owner:和田县绿海环保设备有限公司

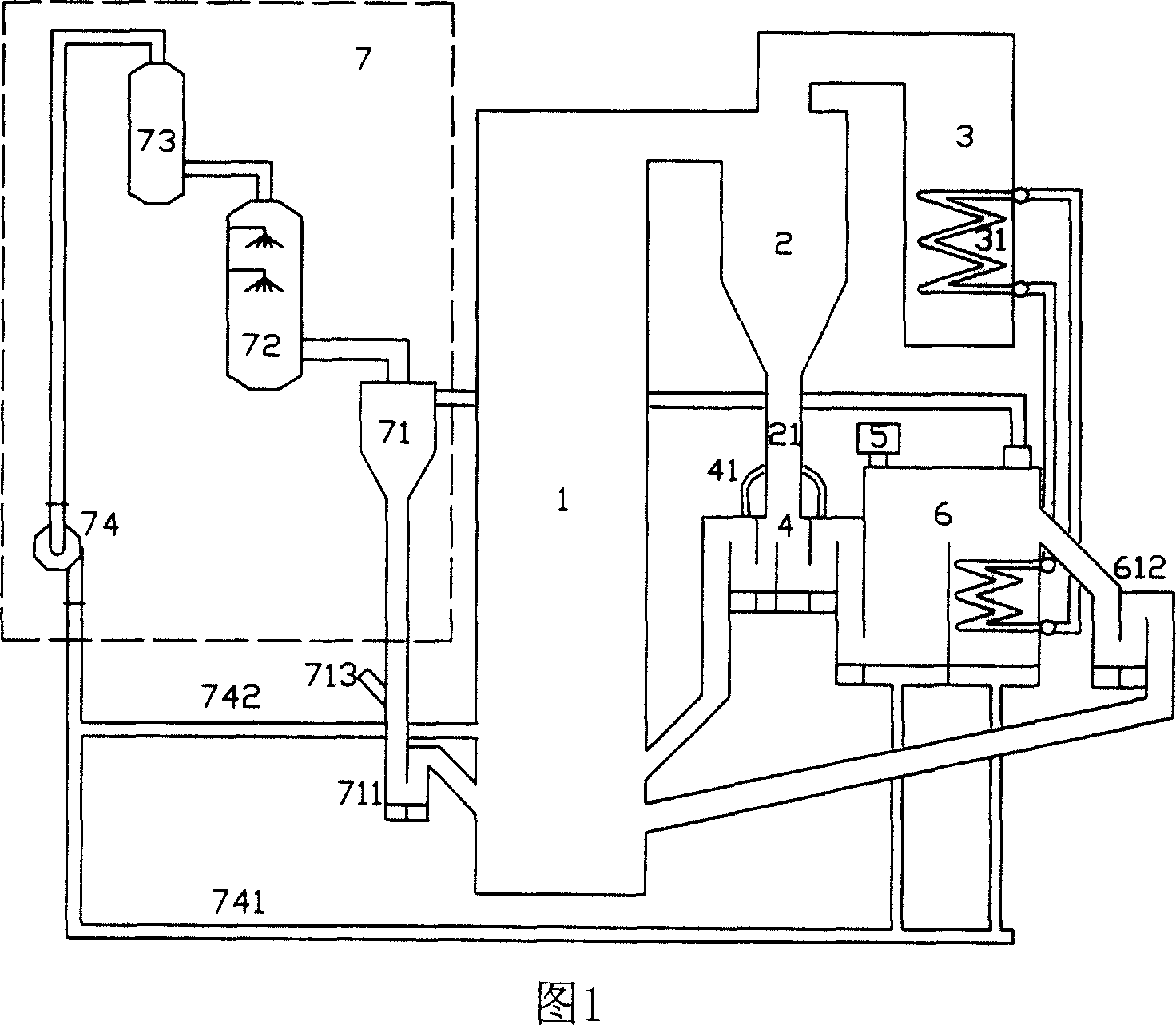

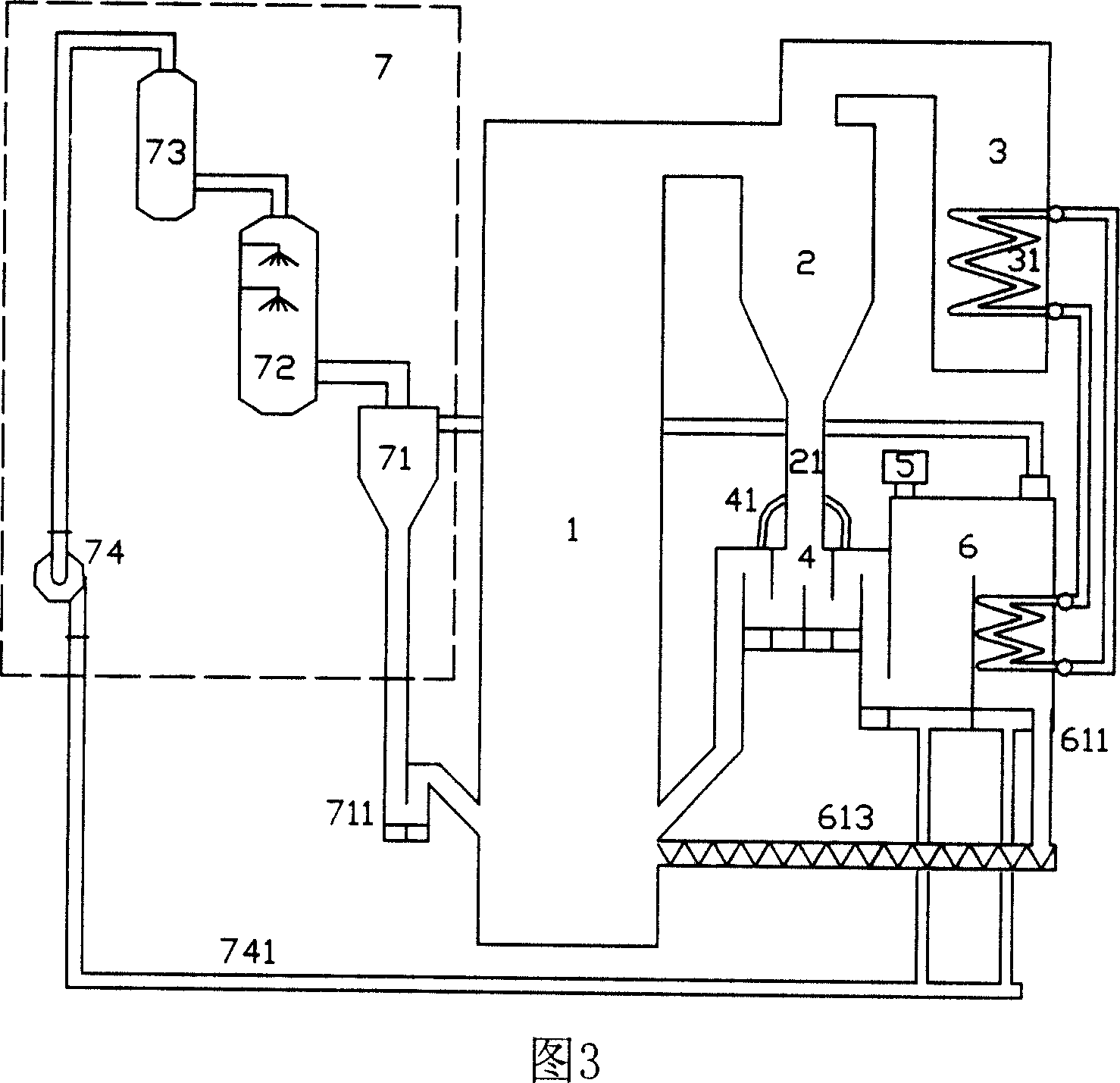

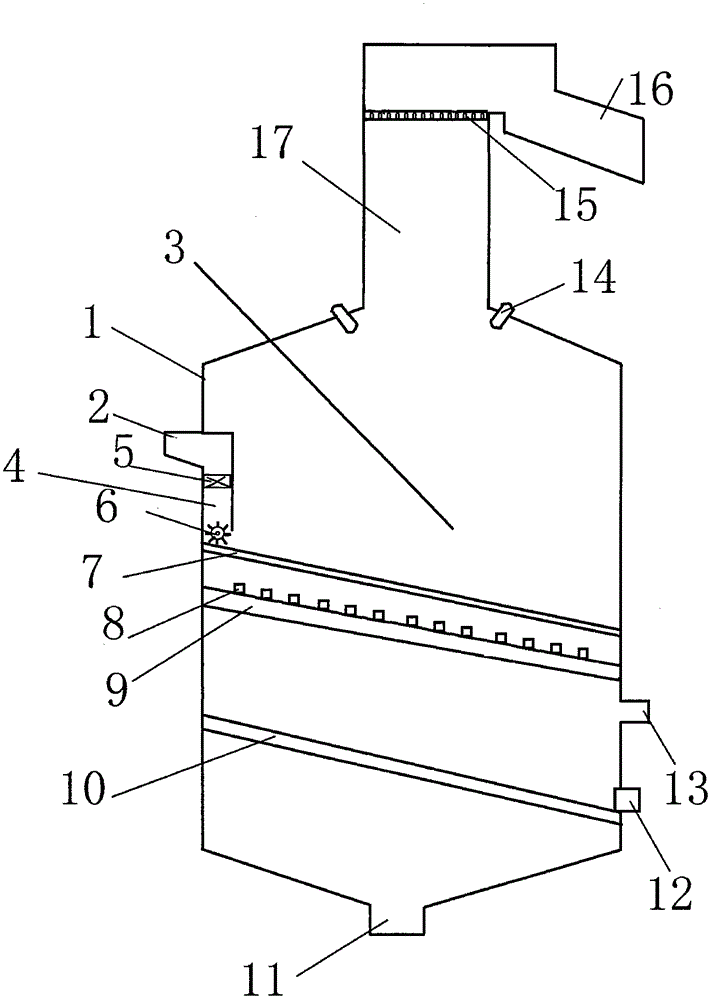

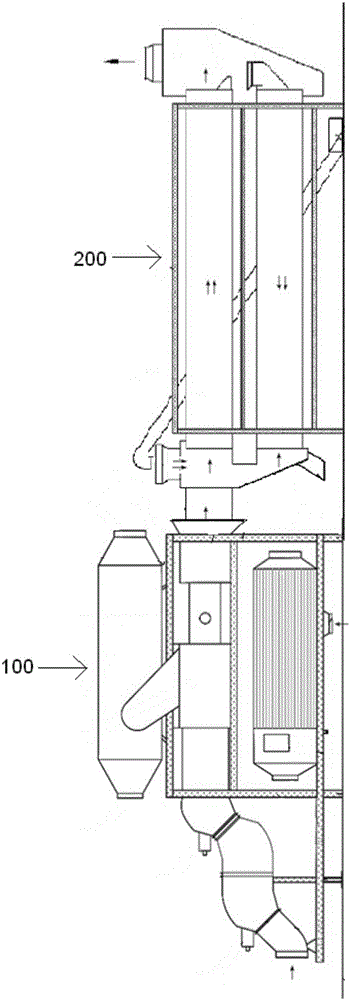

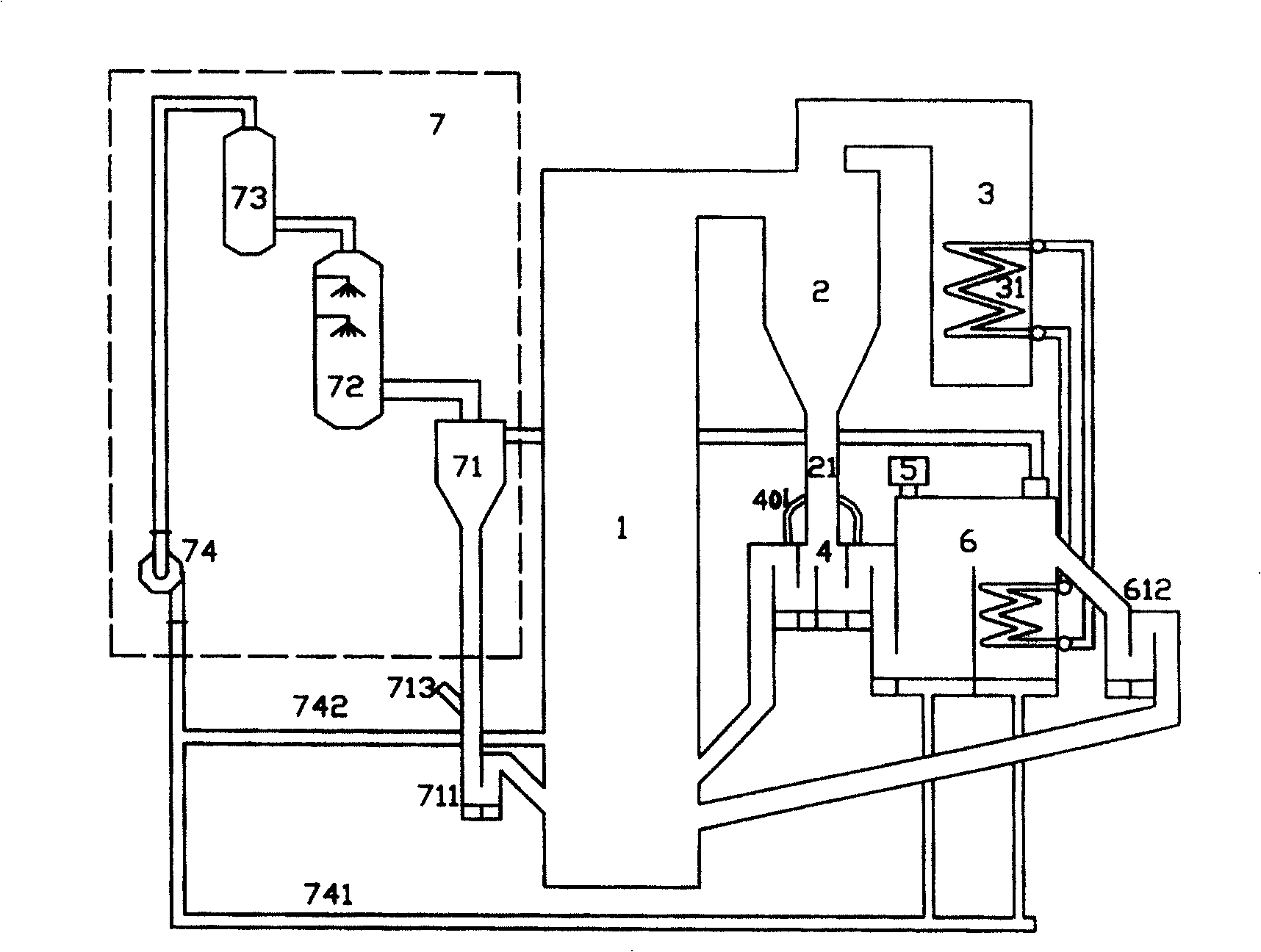

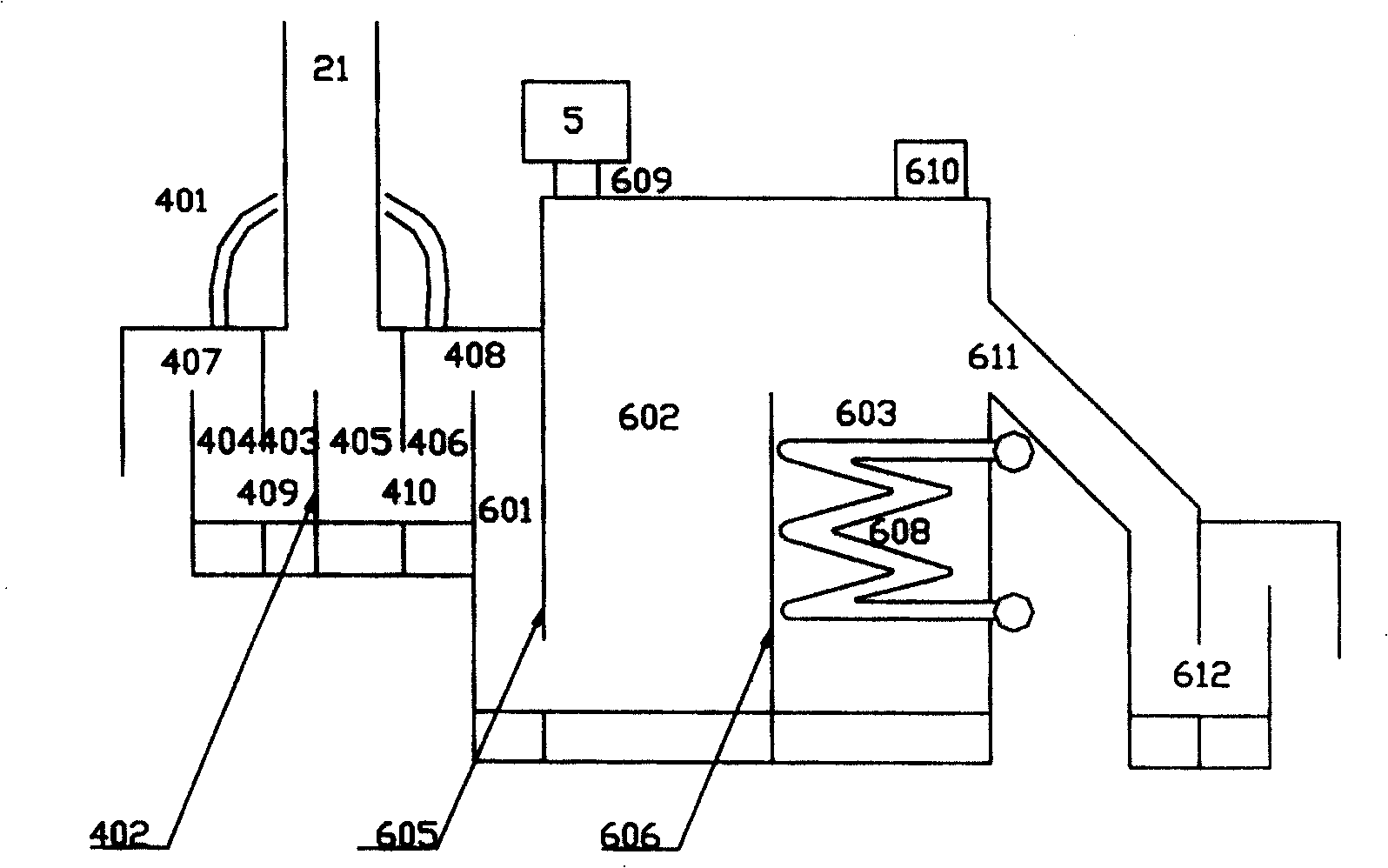

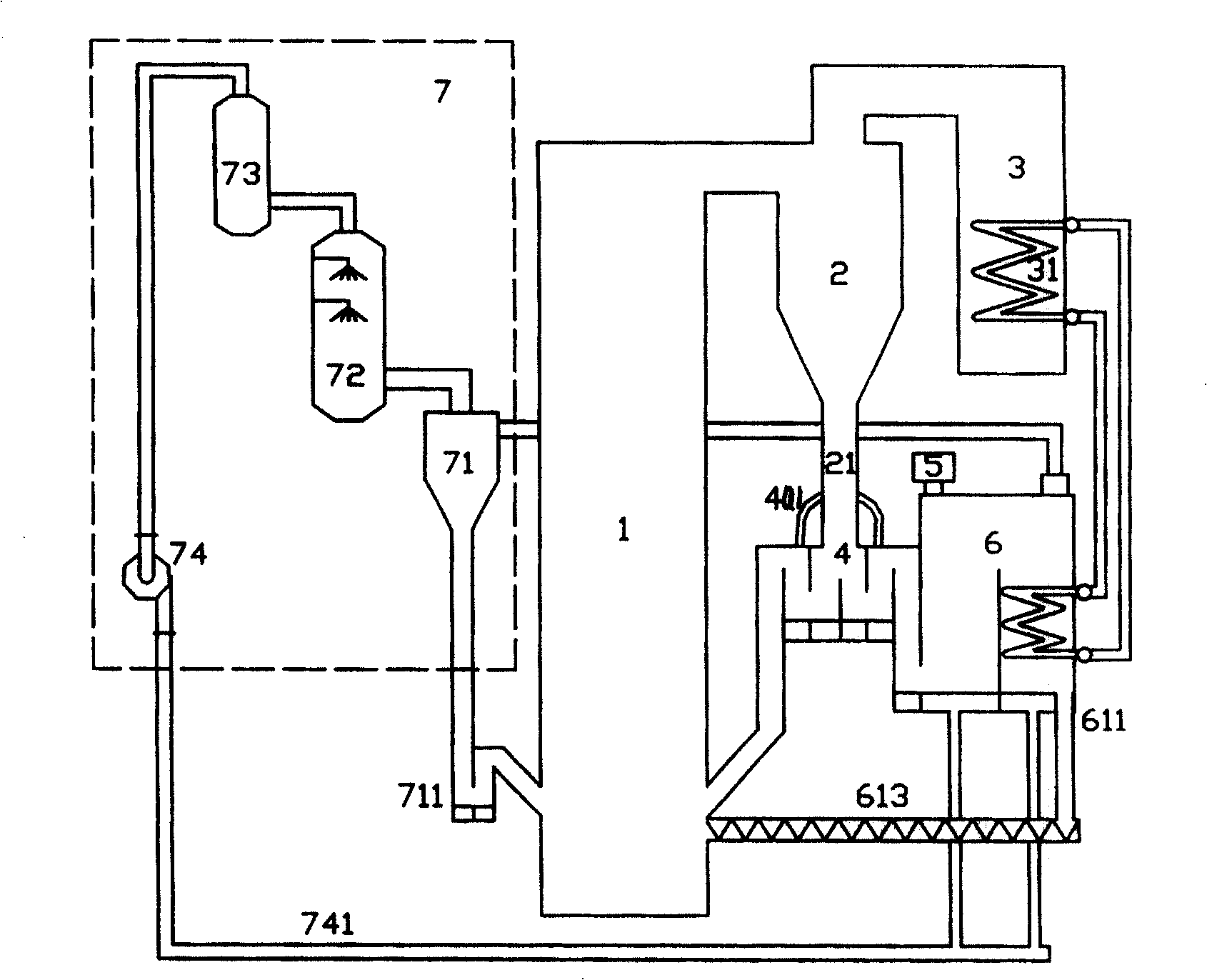

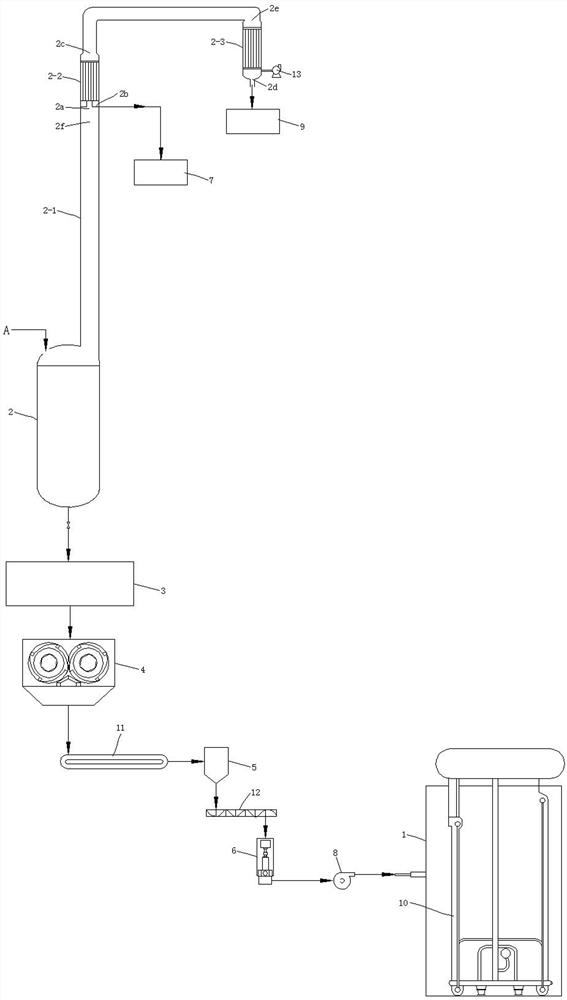

Wet mud burning treatment apparatus with compound dryer

ActiveCN1932384ASave heat loss and power consumptionSimplify the dry incineration processSludge treatment by oxidationByproduct vaporizationFlueFluidized bed

The present invention relates to a wet sludge incineration treatment equipment with composite dryer. It is composed of circulating fluidized-bed incinerator furnace cavity, high-temperature gas-solid separator, tail portion flue duct, hot ash distribution valve, sludge pulverizing device, composite dryer and dryer exhaust treatment system. Said invention also provides its working principle and concrete operation method.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

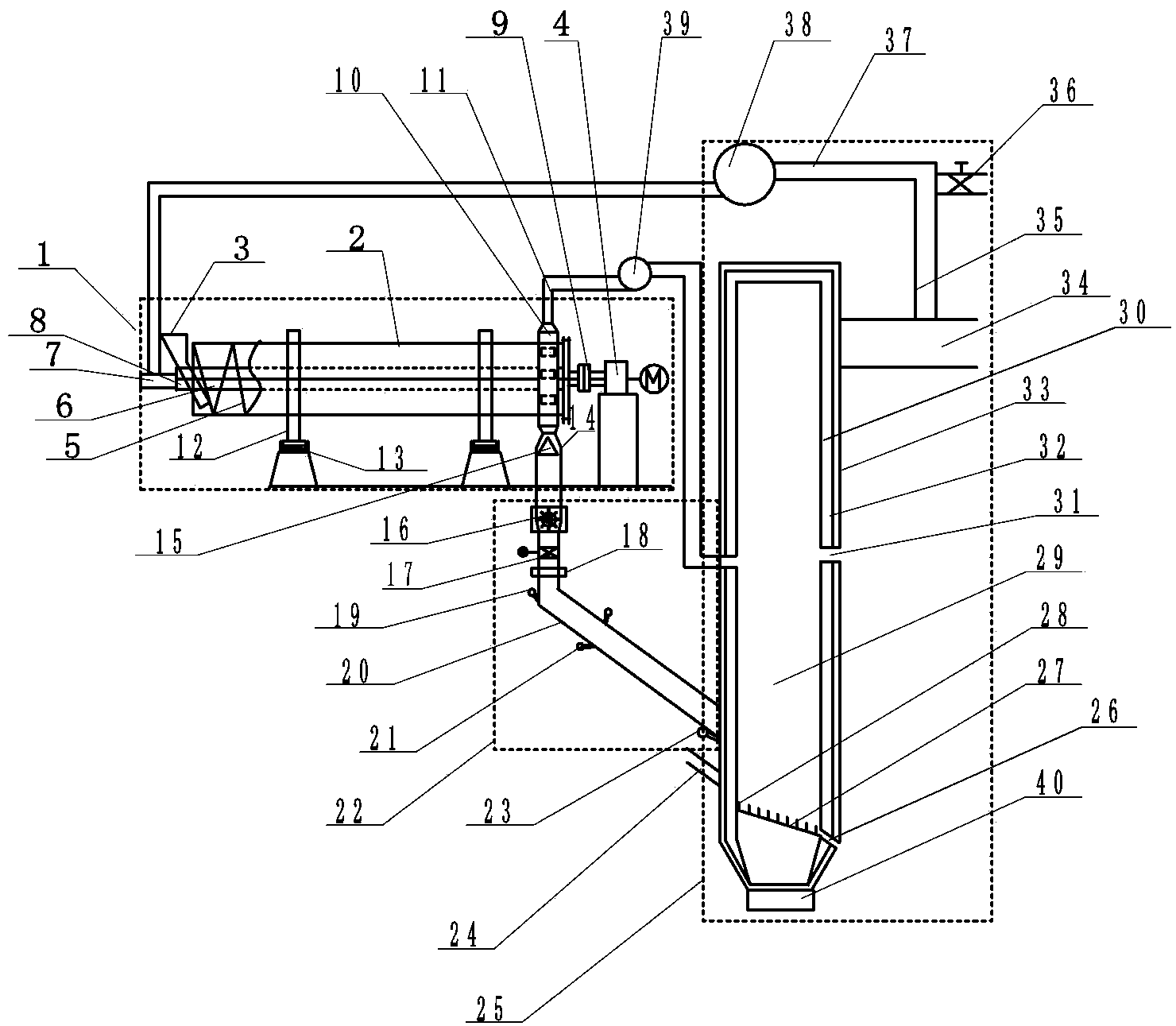

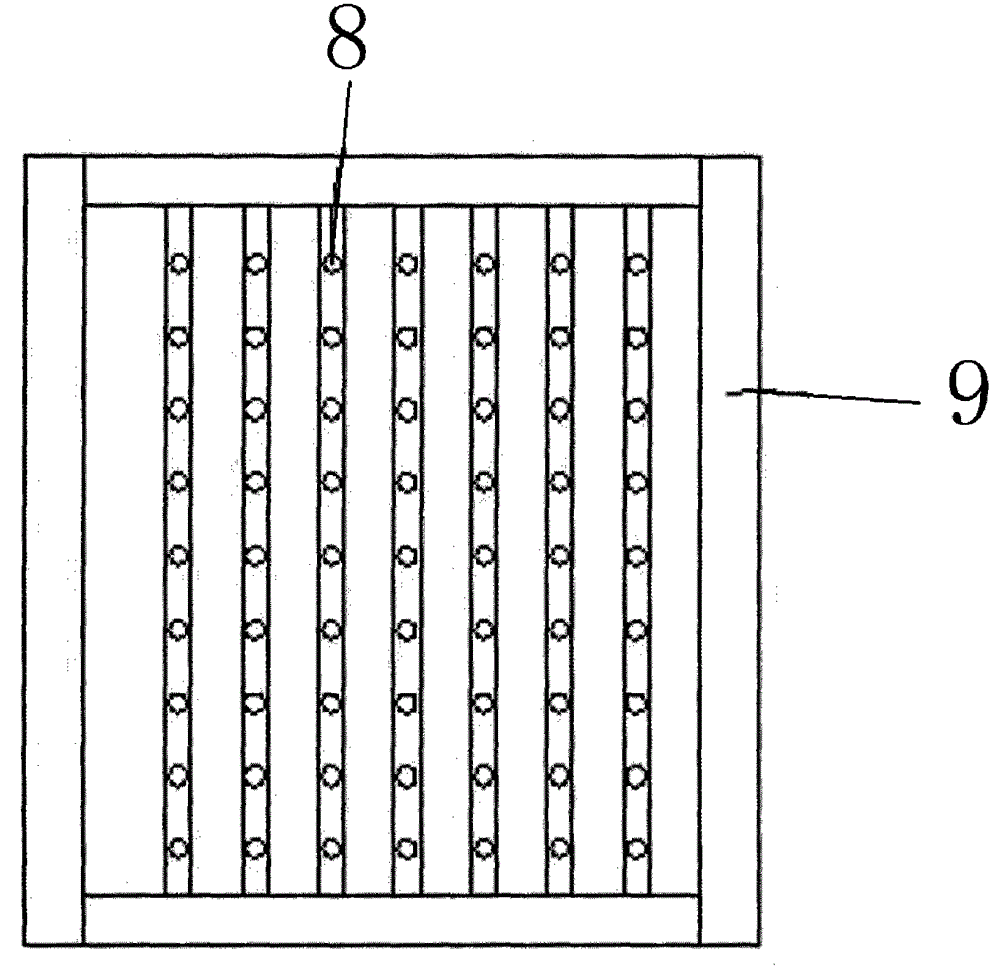

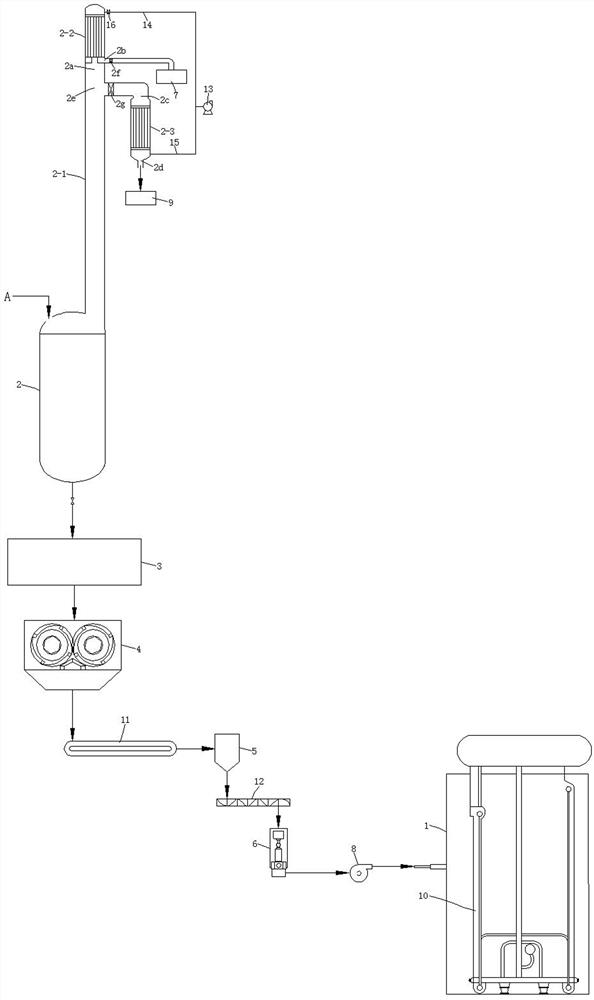

Fluidized bed furnace device utilizing smoke circulation to dry kitchen garbage

InactiveCN103438462AContinuous even entryReduce transportationIncinerator apparatusFluidized bedProcess engineering

The invention discloses a fluidized bed furnace device utilizing smoke circulation to dry kitchen garbage. The fluidized bed furnace device utilizing the smoke circulation to dry the kitchen garbage comprises a drier, a fluidized bed furnace and a feeding device, wherein the fluidized bed furnace is connected with the drier through the feeding device. A kitchen garbage drying device and a kitchen garbage incineration device which are independently arranged are combined into a whole by the smoke circulation, residual heat in the incinerating process is effectively utilized, and the kitchen garbage is ensured to be continuously and uniformly fed into a hearth through the feeding device, so the transshipment storage and the transportation of the kitchen garbage are reduced, and the investment is saved. By adopting the feeding device, the incinerating amount of the kitchen garbage is effectively increased, the overhauling cost and the manual cost are reduced, the running cost is low, the odor generated by the drying of the kitchen garbage enters the hearth to be burnt, and the pollution to the environment is avoided. The fluidized bed furnace device utilizing the smoke circulation to dry the kitchen garbage has the advantages that the structure is simple, the operation is convenient, and the performance is good.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Efficient garbage combustion furnace

InactiveCN104930519AAvoid direct influxAvoid direct influx situationsIncinerator apparatusCombustion chamberSlag

The invention discloses an efficient garbage combustion furnace. The efficient garbage combustion furnace comprises a furnace body, a garbage feeding port, a conveying pipe, a combustion net, a fire grate, a vibration screen mesh, an ash discharging port, a slag discharging port, a blower nozzle, secondary air supply nozzles and an exhaust chimney. The garbage feeding port is formed in one side of the furnace body, a primary combustion chamber is arranged above the combustion net, the fire grate is arranged below the combustion net in parallel with the combustion net, a plurality of combustion nozzles are arranged on the fire grate, the blower nozzle is formed below the fire grate, the ash discharging port is formed in the bottom end of the furnace body, the vibration screen mesh is obliquely formed above the ash discharging port, the slag discharging port is formed in the lowermost portion of the vibration screen mesh, the secondary combustion chamber is arranged above the primary combustion chamber, the secondary air supply nozzles are arranged on the two sides of the bottom of the secondary combustion chamber, and a filter screen is arranged on the top of the secondary combustion chamber which is communicated with the exhaust chimney. The efficient garbage combustion furnace is high in work efficiency, combustion is thorough, harmful gas and particles entering atmosphere are reduced, environmental pollution is avoided, ash collected by the ash discharging port can serve as fertilizer, and cyclic utilization of resources is achieved.

Owner:施婷婷

Method for achieving deep sludge dehydration and energy utilization on plate-and-frame filter press

InactiveCN104445863ASimple processEasy to operateSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCombustionSludge

The invention discloses a method for achieving deep sludge dehydration and energy utilization on a plate-and-frame filter press. The method includes the following steps that firstly, filter aid suspension liquid is prepared, a filter aid and water are mixed in proportion, and the filter aid suspension liquid is prepared; secondly, the filter aid suspension liquid prepared in the first step is conveyed to a filter medium of the plate-and-frame filter press, and a precoat is formed; thirdly, sludge on which dehydration needs to be conducted is doped with the filter aid in the first step, and the use amount of the filter aid is larger than the weight of absolutely-dry sludge in the sludge on which dehydration needs to be conducted by 20 percent; fourthly, the sludge doped with the filter aid is conveyed into the plate-and-frame filter press, filter-pressing dehydrating is conducted on the sludge, and pressing dehydrating is conducted on the sludge after filter-pressing dehydrating. According to the method for achieving deep sludge dehydration and energy utilization, deep dehydrating of the sludge is achieved, automatic discharging can be achieved, efficiency is obviously improved, the operation cost is obviously reduced, conditions are created for energy utilization of the sludge, and an obtained filter cake can be used as the raw materials for combustion of plants or other incinerators to be incinerated or used as the raw material of cement plants to be co-processed.

Owner:梁毅 +2

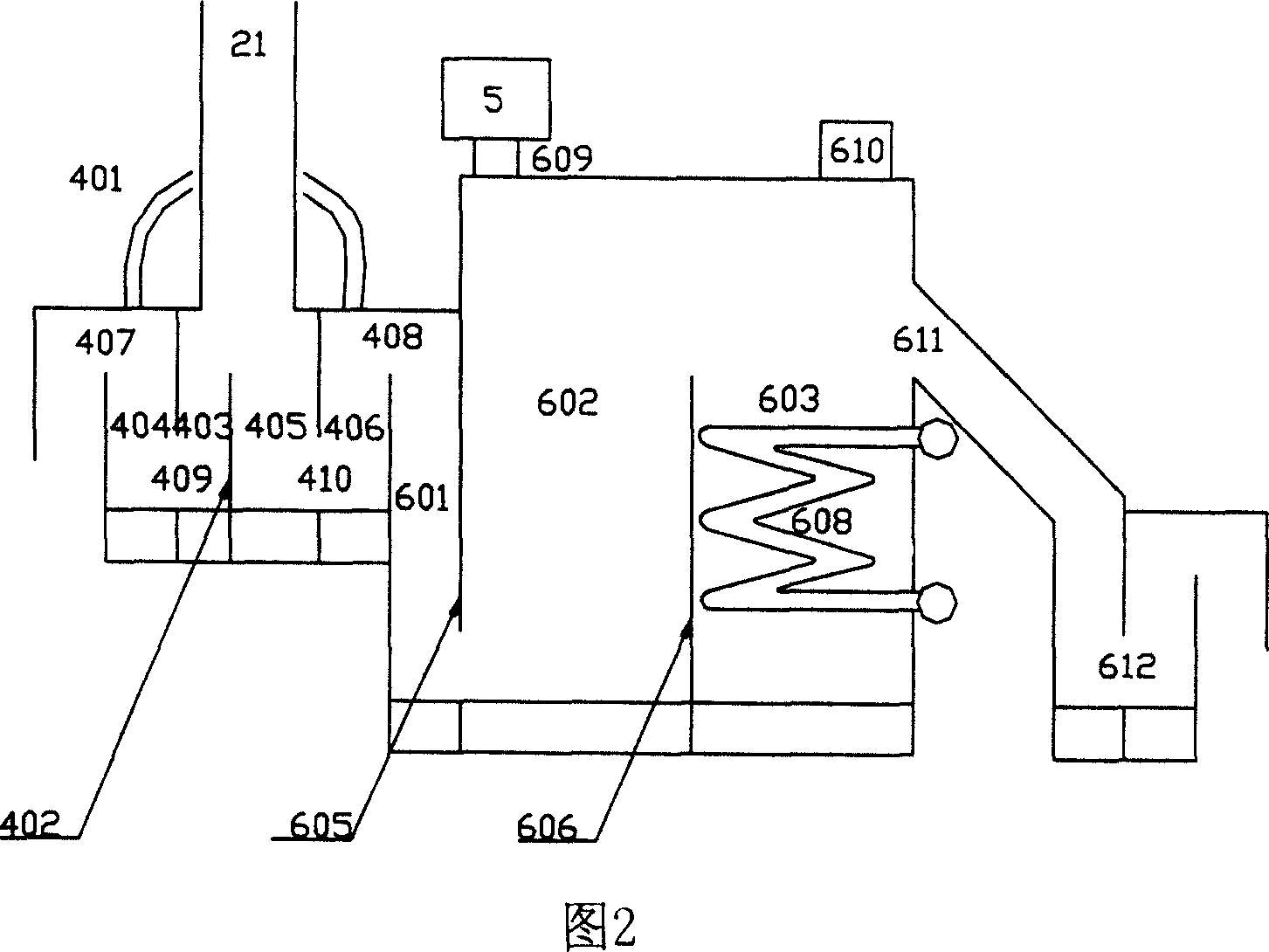

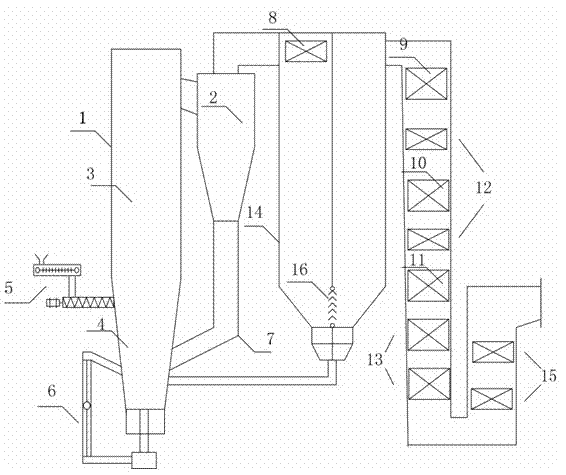

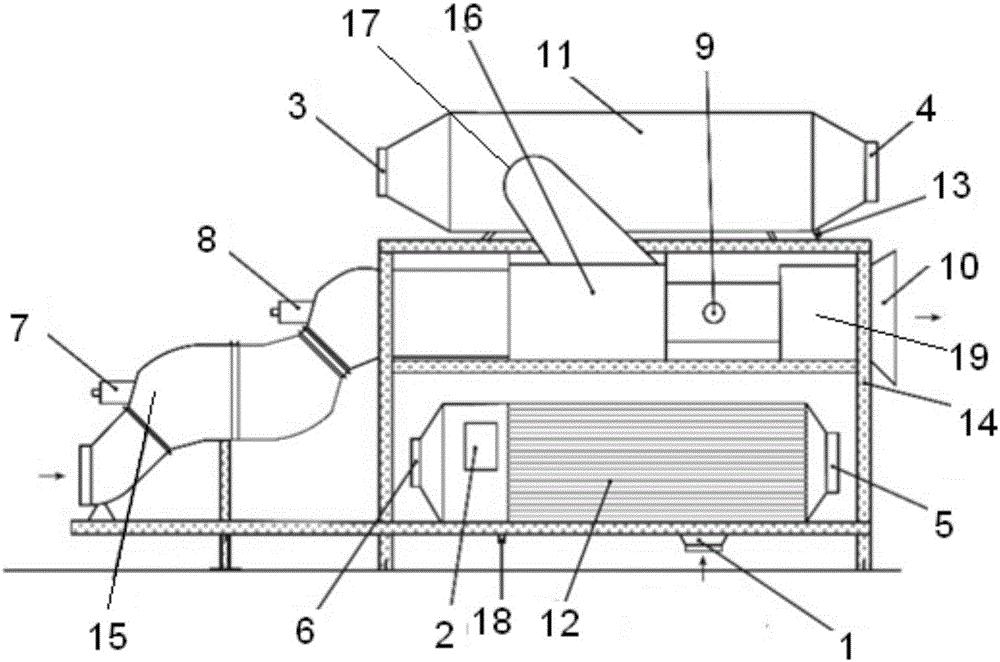

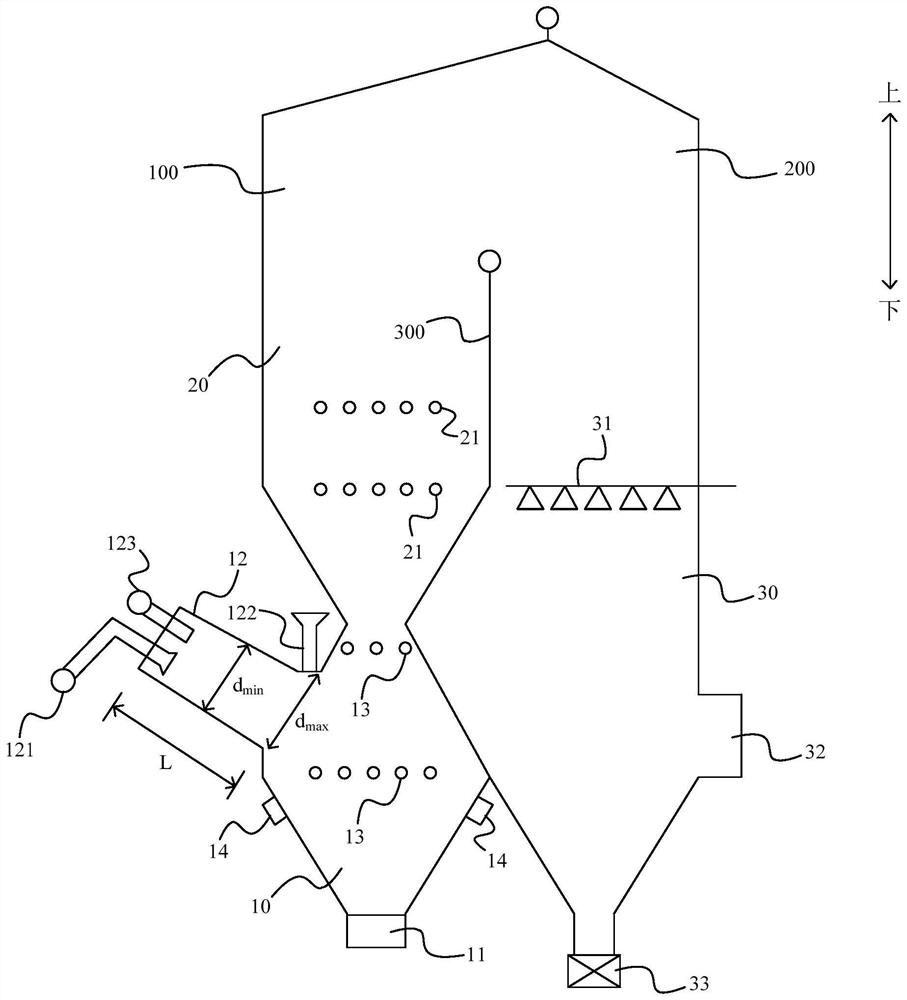

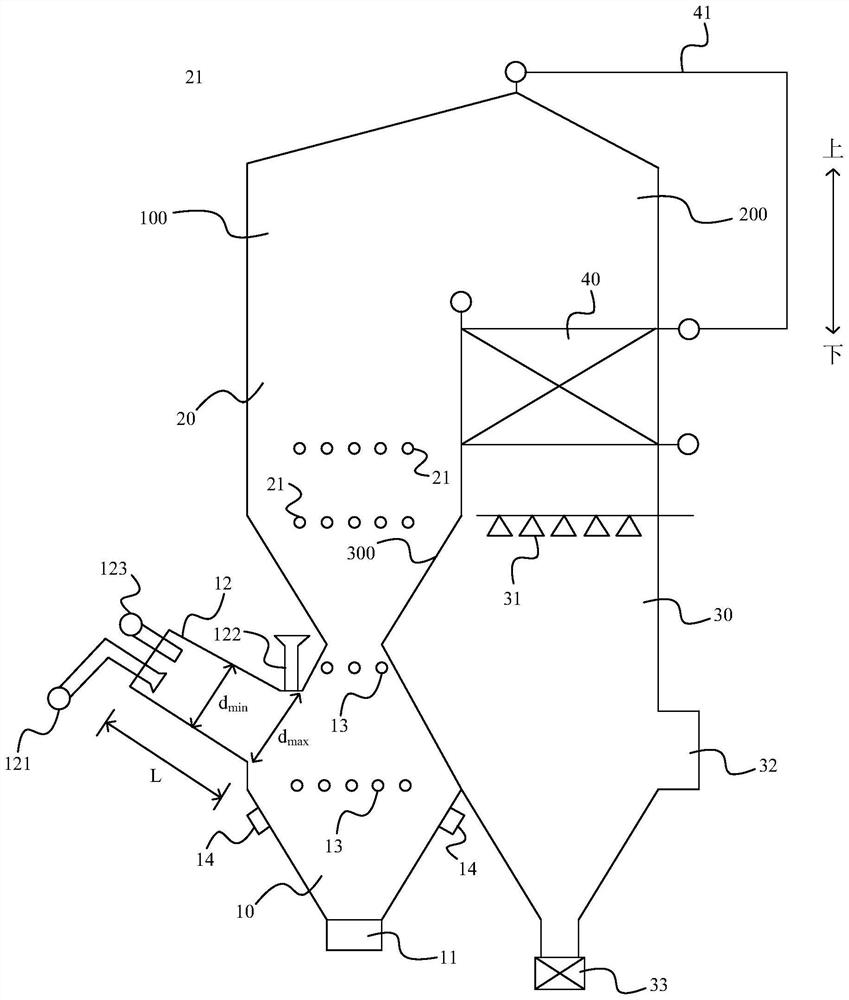

High-temperature air combustion intensifying device and method applicable to low heating value mixed garbage

ActiveCN102878569AIncineration is stable enoughFully stable combustionIncinerator apparatusCombustion chamberSlag

The invention discloses a high-temperature air combustion intensifying device and method applicable to low heating value mixed garbage, wherein a low-temperature preheater is arranged on the rear side of a U-shaped tail part flue; a garbage feeding opening is arranged on the side wall of the lower part of a furnace chamber; the side wall of the upper part of the furnace chamber is connected with the upper part of a cyclone separator; the bottom part of the cyclone separator is connected with the upper end of a back feeder; the lower end of the back feeder is connected with the side wall of the lower part of the furnace chamber; the upper end of the cyclone separator is connected with the upper part of the front side of a U-shaped combustion chamber; the lower end of the U-shaped combustion chamber is connected with the side wall of the lower part of the furnace chamber; the lower end of the furnace chamber is connected with the side wall of the lower part of the furnace chamber through a water-cooled cold slag sorting and back feeding device; and the upper part of the rear side of the U-shaped combustion chamber is connected with the upper part of the front side of the U-shaped tail part flue. The method utilizing the high-temperature air to intensify the low heating value garbage mixed combustion is more suitable for the domestic characteristics that the garbage has complicated components, high moisture and low heating value, has wider fuel application range, and is more sufficient and stable in combustion, the garbage can be purely combusted without the need of coal, the energy consumption is reduced, and the operating economy is improved.

Owner:ZHEJIANG UNIV

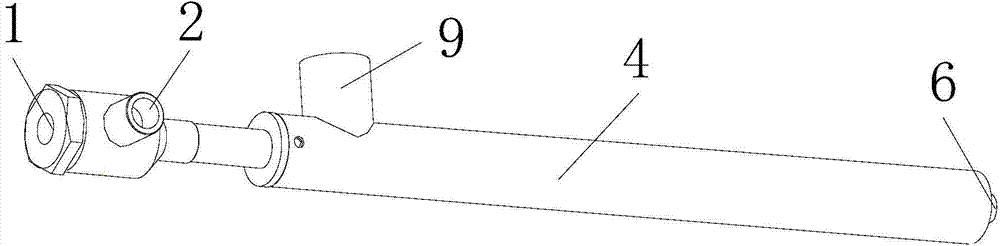

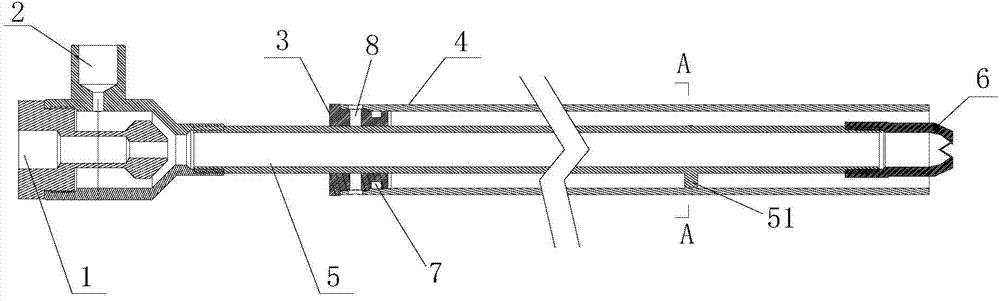

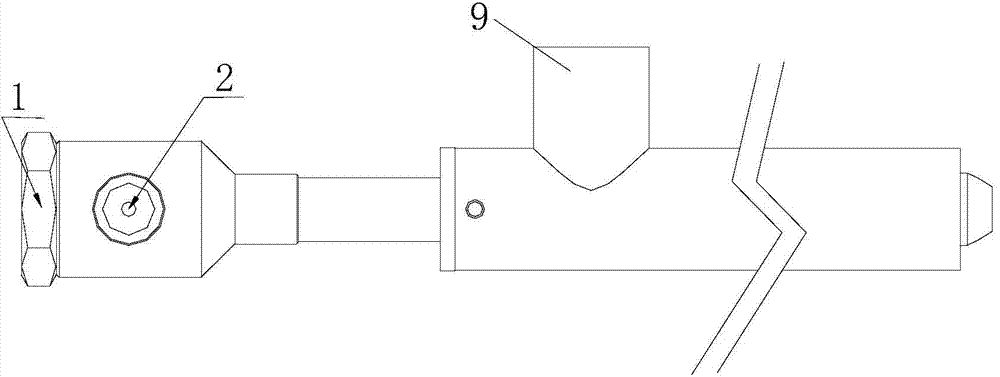

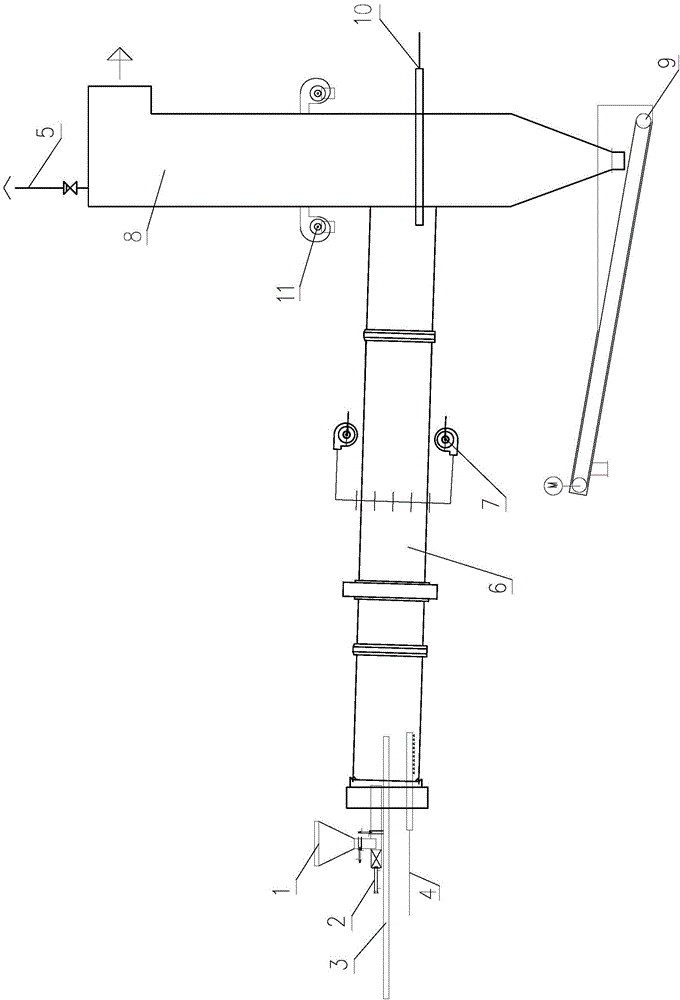

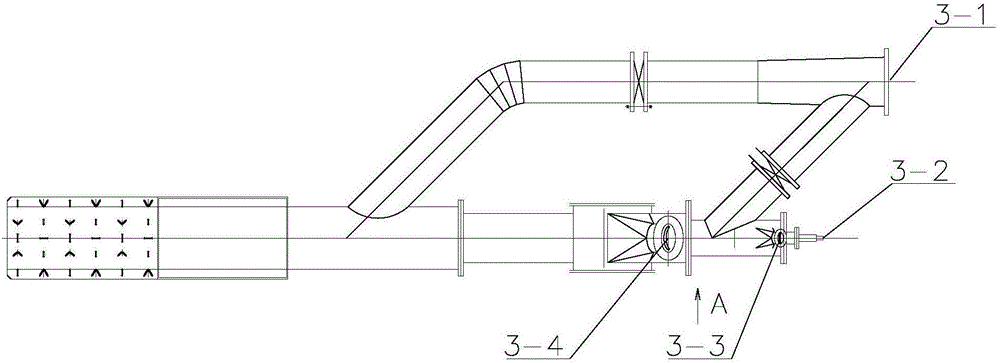

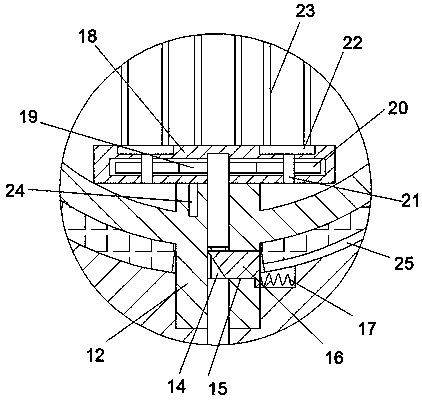

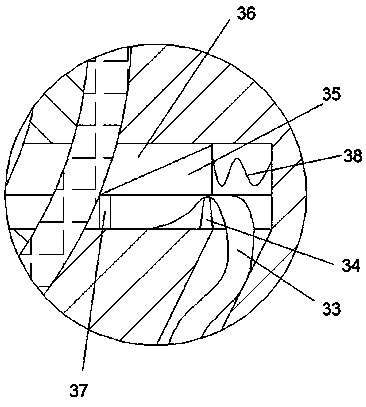

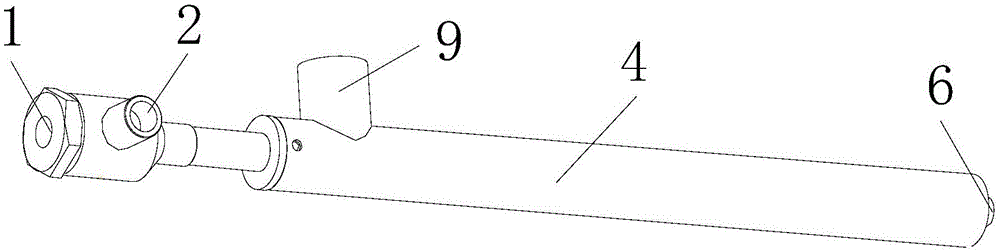

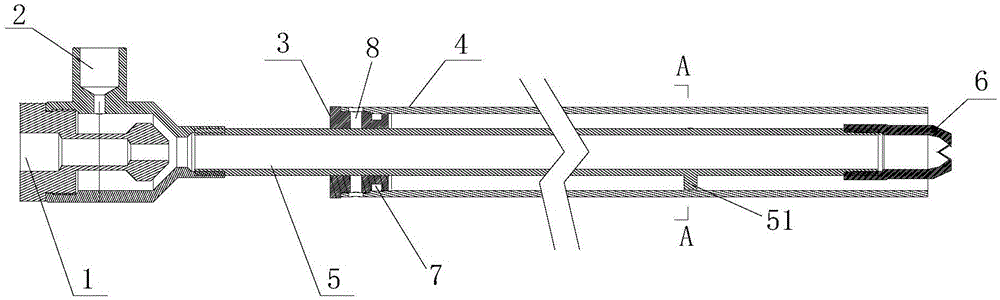

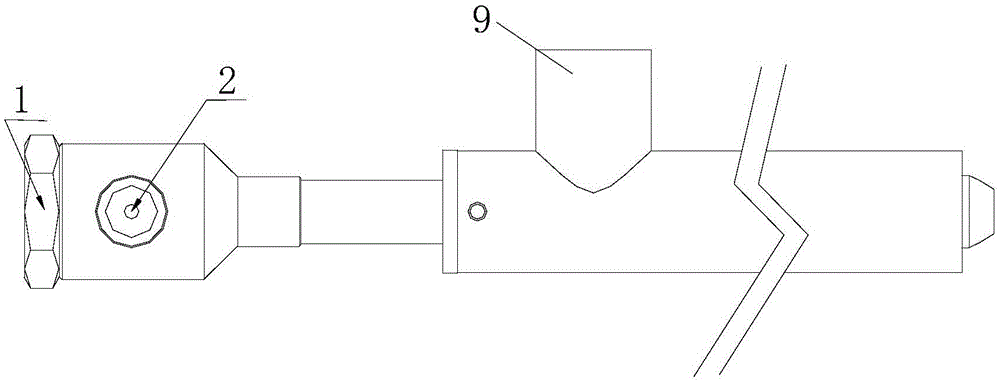

Atomizing spray gun

ActiveCN103759260APower Generation Efficiency ImpactAvoid damageBurnersIncinerator apparatusEngineeringScrew thread

The invention relates to an atomizing spray gun. Four leachate return and spray nozzles are arranged on two sides of the outlet sidewall of a burning hearth furnace and are parallel to a secondary air inlet. The atomizing spray gun comprises a compressed air nozzle, a leachate nozzle, a flange, a protective sleeve, a gun rod and an atomizing nozzle. The compressed air nozzle is screwed to the larger end of the leachate nozzle in a threaded manner, the gun rod is screwed to the smaller end of the leachate nozzle in a threaded manner, and one end of the atomizing nozzle provided with a thread is screwed to the outer thread of one end of the gun rod. The gun rod is fixed to the flange in a welded manner, and the flange is sleeved with a seal ring. One end of the protective sleeve with a mounting hole sleeves the flange and is fixed through a screw to prevent from dropping. The atomizing spray gun has the advantages that dual-fluid design is adopted, the leachate and the compressed air are mixed in the nozzle under certain pressure, fine atomized particles are produced, and service life is super long.

Owner:无锡卓能环境科技有限公司

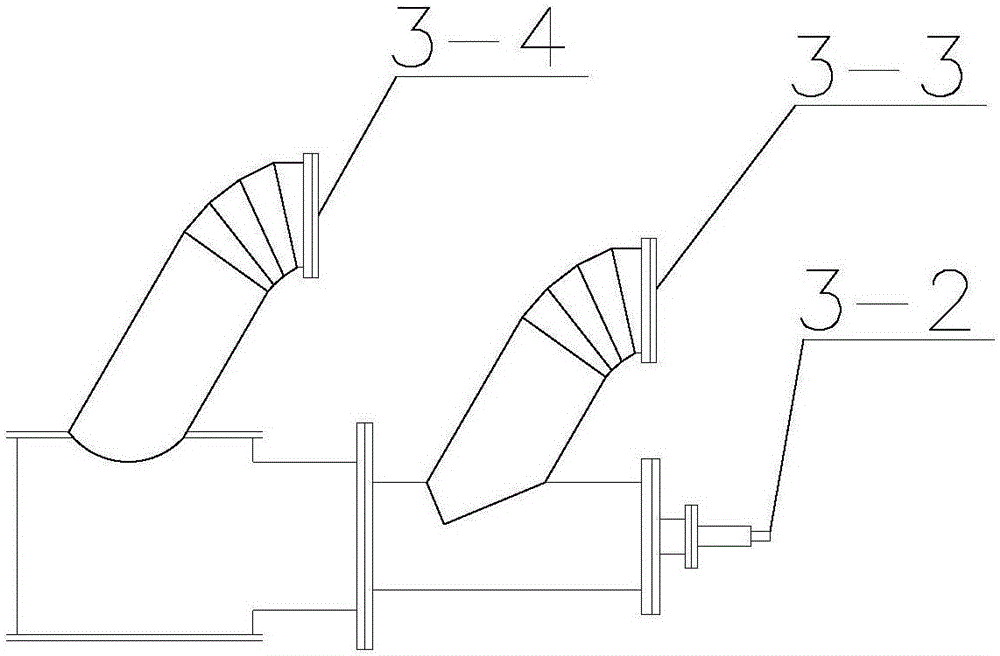

Large-size hazardous waste rotary kiln type incinerator device taking sludge as main target

InactiveCN106402894APromote complete combustionLow oxygenIncinerator apparatusHot blastCombustion chamber

The invention discloses a large-size hazardous waste rotary kiln type incinerator device taking sludge as a main target. The device comprises a receiver bin, a feeder, a multifunctional fuel nozzle, a kiln internal hot blast blowing unit, a rotary kiln, a power suspension unit, a secondary combustion chamber and a scraper slag discharging machine. The feeder, the multifunctional fuel nozzle and the kiln internal hot blast blowing unit are arranged at an inlet of the rotary kiln. The receiver bin is arranged above the feeder. The power suspension unit is arranged in the middle of the rotary kiln. The secondary combustion chamber is arranged at the tail of the rotary kiln. The scraper slag discharging machine is arranged at the lower end of the secondary combustion chamber. Three fuels, namely the solid fuel, the gas fuel, and the liquid fuel can be simultaneously or independently used for providing heat for the incinerator, and steam or nitrogen or water can be used for cooling the fiery furnace under the emergent incinerator shutdown condition. The power suspension unit and the kiln internal hot blast blowing unit are used for increasing the contact area of materials and the gas, so that the heat transferring, drying and combusting effects are improved, and the disposal capacity and efficiency of the kiln type incinerator device are improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

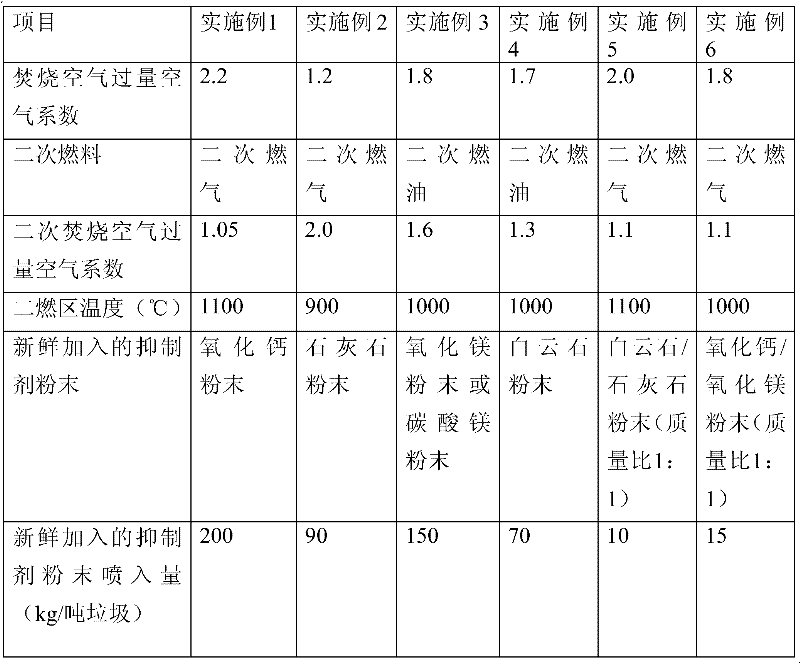

A method for removing dioxins in waste incinerator flue gas

InactiveCN102297433AAccelerate incinerationGuaranteed complete incinerationIncinerator apparatusFlue gasFuel oil

The invention relates to a garbage incineration treatment technology, in particular to a method for removing dioxin from fume of a garbage incinerator, wherein an incineration process for removing the dioxin from the fume of the garbage incinerator and a method for injecting an inhibitor into the garbage incinerator are combined; the incineration process for removing the dioxin from the fume of the garbage incinerator comprises the following steps of: placing garbage on a fire grate at the bottom of a hearth of the garbage incinerator to burn, feeding excess incineration gas from the bottom of the fire grate, and injecting secondary fuel and secondary excess incineration gas into a secondary combustion region above the fire grate; and while implementing the incineration process, injectingan inhibitor powder into the secondary combustion region in the garbage incinerator, wherein the secondary fuel is fuel gas or fuel oil, and the inhibitor in the inhibitor powder is any one or more of calcium oxide, magnesium oxide, magnesium carbonate, lime stone or dolomite. Through the method disclosed by the invention, the formation of the dioxin in the garbage incinerator can be effectively controlled, and the wide application prospect is provided.

Owner:福建省丰泉环保控股有限公司 +1

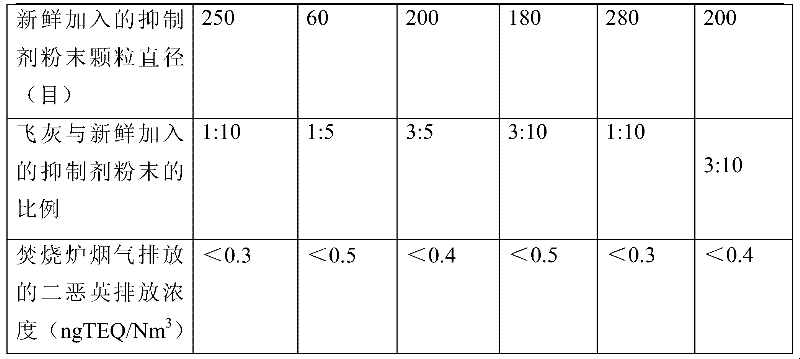

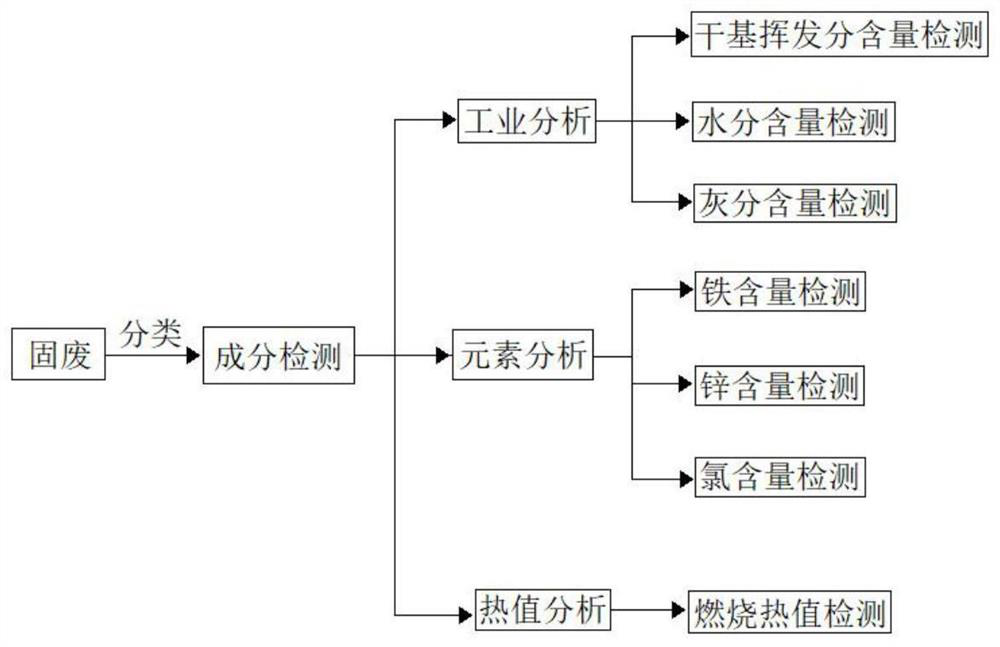

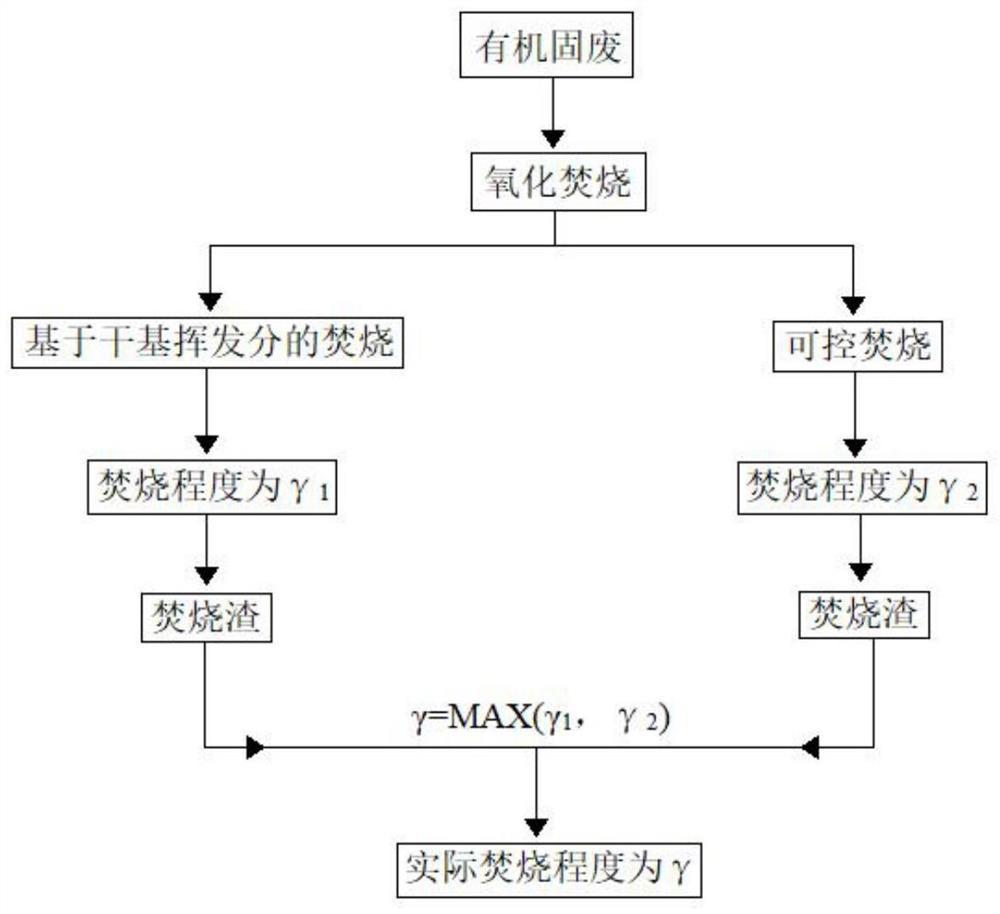

Solid waste, sintering and pelletizing co-treatment process capable of guaranteeing iron grade

ActiveCN113122709AEliminate the effects ofEliminate the risk of secondary pollutionProcess efficiency improvementSlagMixed materials

The invention discloses a solid waste, sintering and pelletizing co-treatment process capable of guaranteeing the iron grade. The process comprises the following steps that the adding amount of incineration slag, pyrolysis slag, reducing slag, filter residues, sintering raw materials and pelletizing raw materials is controlled according to the respective iron content in the incineration slag, pyrolysis slag, reducing slag and filter residues obtained after solid waste pretreatment, the sintering raw materials and the pelletizing raw materials. Therefore, the mass content of iron in the mixed material is controlled to meet the production requirement of actual working conditions on the mass content of iron, cooperative treatment of various solid wastes is achieved, finally, full-process treatment of the various solid wastes is achieved, and the influence of the solid wastes on the environment and the risk of secondary pollution are thoroughly eliminated. Besides, the quality of sintered and / or pellet products is ensured.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Garbage air drying treatment system and method

ActiveCN106642146ARemarkable drying efficiencyEasy to storeDrying gas arrangementsDrying machines with non-progressive movementsDehydrationTreatment system

The invention discloses a garbage air drying treatment system. The garbage air drying treatment system comprises a low-temperature air drying production device and a connected garbage air drying treatment device. The garbage air drying treatment device includes a first garbage air drying cylinder provided with a first spiral turning plate on the inner wall; the first spiral turning plate is overturned under rotation of the first garbage air drying cylinder to push garbage to move; an intake port of the first garbage air drying cylinder is connected with the low-temperature air drying production device; low-temperature dry air is blown out in the axial direction of the first garbage air drying cylinder; and the operation direction of the low-temperature dry air is the same with the pushing direction of the garbage. The garbage air drying treatment device further includes a second garbage air drying cylinder; and the operation direction of the low-temperature dry air in the second garbage air drying cylinder is opposite to the pushing direction of the garbage. The invention further discloses a treatment method of the garbage air drying treatment system. The garbage air drying treatment system uses high-temperature tail gas as a hot air source and natural wind and fed wind to produce the low-temperature dry air; and the low-temperature dry air performs dehydration and air drying for garbage raw materials, so that the storage and the transportation are facilitated, the garbage pyrolysis efficiency is improved, and the effects of environmental protection and feasibility are achieved.

Owner:BEIJING ZHONGJI TORCH ENVIRONMENTAL PROTECTION TECH CO LTD

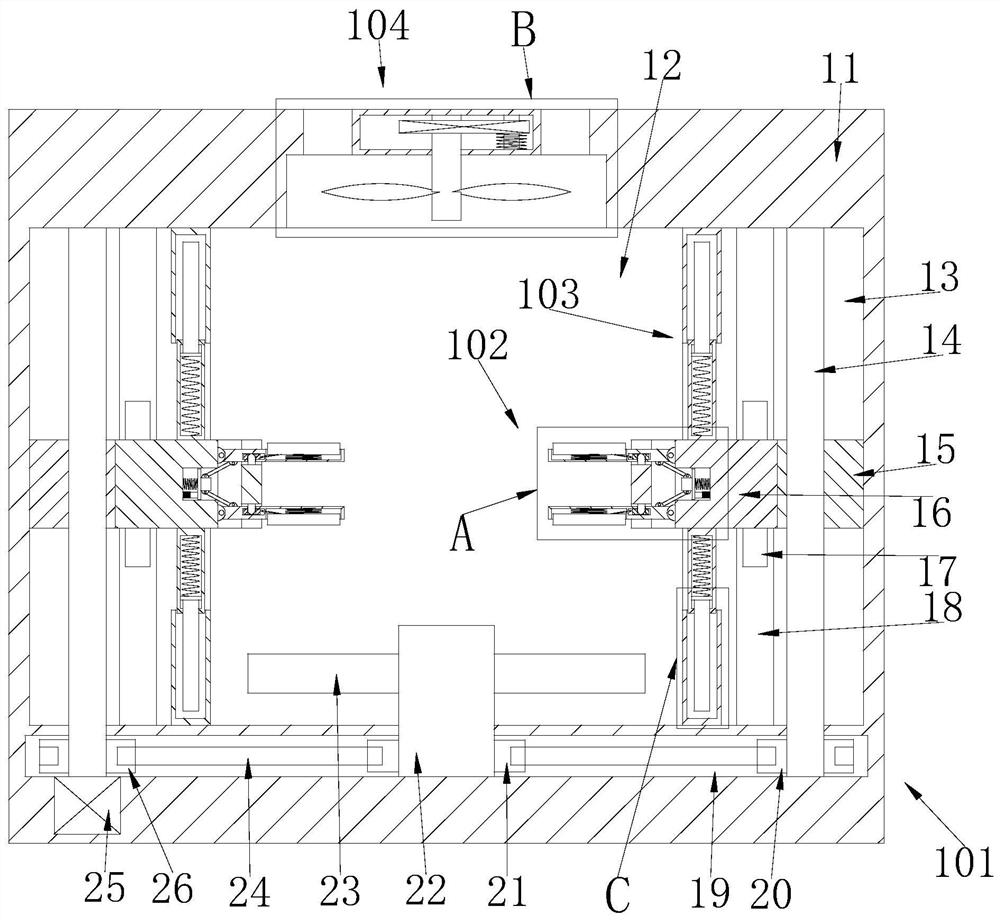

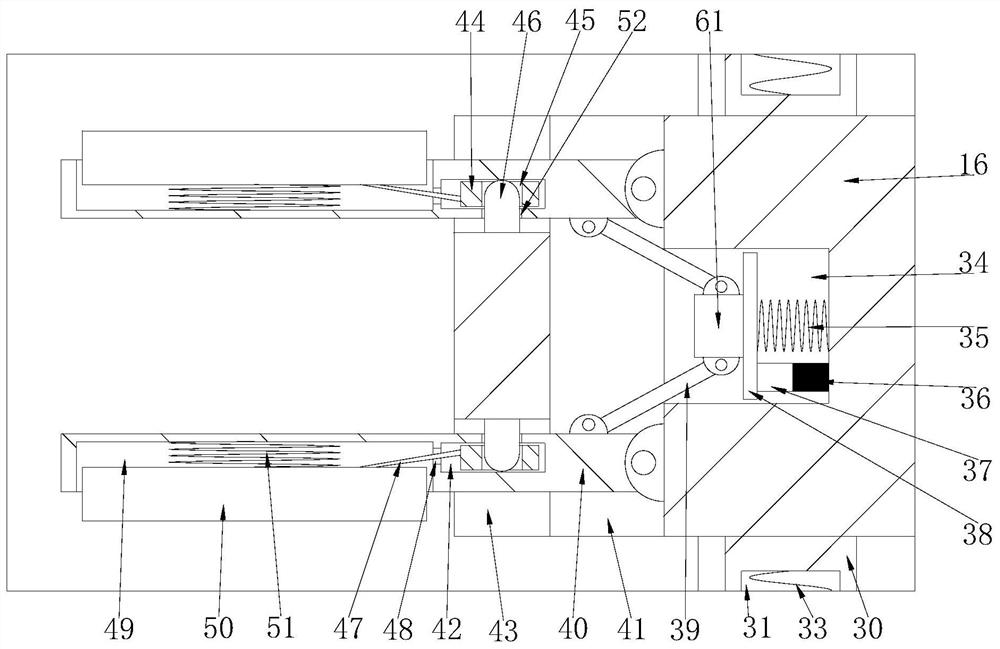

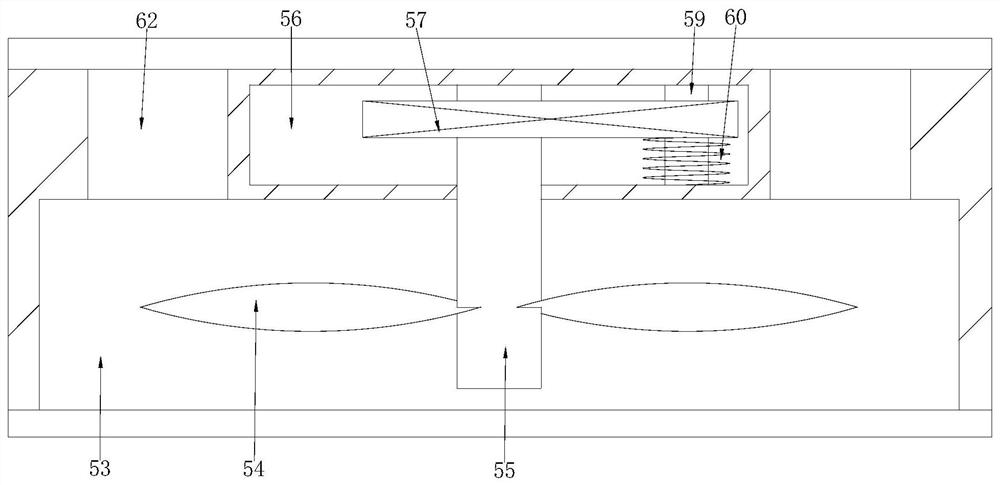

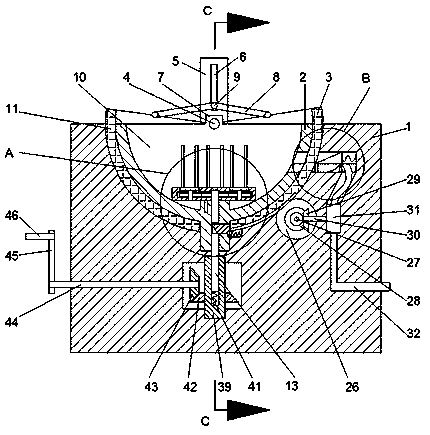

Incineration treatment equipment with cleaning function

InactiveCN112577055AAccelerate incinerationImprove sealingIncinerator apparatusGear wheelConveyor belt

The invention relates to the technical field of incineration equipment, and discloses incineration treatment equipment with a cleaning function. The incineration treatment equipment comprises an incineration box, an incineration cavity is formed in the incineration box, symmetrical screw cavities are formed in the left wall and the right wall of the incineration cavity in a communicating mode, a belt cavity is formed in the lower side of the incineration cavity, the upper walls of the screw rod cavities are rotationally connected with main screw rods extending downwards to be rotationally connected with the lower wall of the belt cavity, the lower wall of the belt cavity is rotationally connected with a stirring shaft extending upwards into the incineration cavity, the outer circle face ofthe side, located in the incineration cavity, of the stirring shaft is fixedly connected with stirring blades, a power transmission mechanism is arranged in the belt cavity, and the outer circle faceof the main screw rod is in threaded connection with threaded connection blocks which are in vertical sliding connection with the side wall, away from the incineration cavity, of the screw rod cavities. According to the incineration treatment equipment, the rotation and the up-down movement of a shifting rod are driven by the transmission of a screw rod and a gear rack, and therefore, the waste can be shifted when being incinerated.

Owner:QUZHOU UNIV

Purified terephthalic acid residue recycling and incineration treatment method

ActiveCN110836378AAchieve reductionReduce processing costsIncinerator apparatusFractional distillationBenzoic acidProcess engineering

The invention discloses a purified terephthalic acid residue recycling and incineration treatment method. An incinerator serves as an incineration treatment device, a reaction kettle is adopted as a resource recycling treatment device, the reaction kettle is provided with a rectifying tower, a first condenser and a second condenser, the first condenser is provided with a gas inlet and a liquid outlet, the second condenser is provided with a gas inlet and a liquid outlet, and the gas inlet of the first condenser and the gas inlet of the second condenser communicate with a gas outlet of the rectifying tower. The method comprises the following steps of feeding, dewatering, benzoic acid recycling, waste residue crushing, waste residue grinding and waste residue incineration. According to the method, useful resources in residues can be effectively extracted, resource recycling is achieved, and waste recycling is carried out on the residues. Besides, compared with the prior art, the incineration amount is improved by more than three times, the incineration amount is greatly improved, combustion of the residues is more sufficient, harmless treatment is more thorough and more environmentally friendly, the energy consumption during treatment is low, the process is simple and feasible, and the residue treatment cost is lower.

Owner:沈福昌

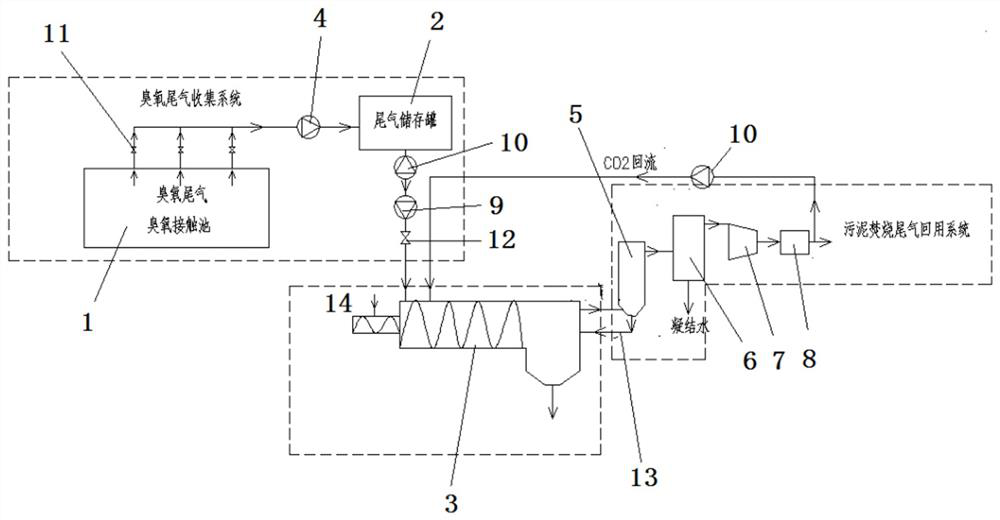

Method for recycling ozone tail gas for sludge incineration

PendingCN112161277AImprove incineration efficiencyAccelerate incinerationGas treatmentCarbon compoundsExhaust gasZero emission

The invention discloses a method for recycling ozone tail gas for sludge incineration, which is characterized in that a tail gas collecting pipe is arranged at the top of an ozone contact tank and isused for collecting tail gas generated after ozone contact oxidation, and a tail gas collecting system is used for introducing the collected ozone tail gas into a sludge incineration system; CO2 in incineration tail gas is collected through a sludge incineration tail gas recycling system, then purified CO2 is captured and stored through a CO2 capturing and sealing device, and near-zero emission ofthe ozone tail gas and the sludge incineration tail gas is achieved; and a part of the recycled CO2 flows back to the front end of the sludge incineration system. According to the method, ozone tailgas destruction treatment cost and pure oxygen preparation cost are reduced; and meanwhile, the sludge incineration tail gas is CO2 and can be recycled, so that the problem of high treatment cost caused by complex components and high sludge treatment difficulty of the sludge incineration tail gas is solved. Near-zero emission of the ozone tail gas and the sludge incineration tail gas of a sewage plant is realized, waste is turned into wealth, and low-carbon operation of the sewage plant is facilitated.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

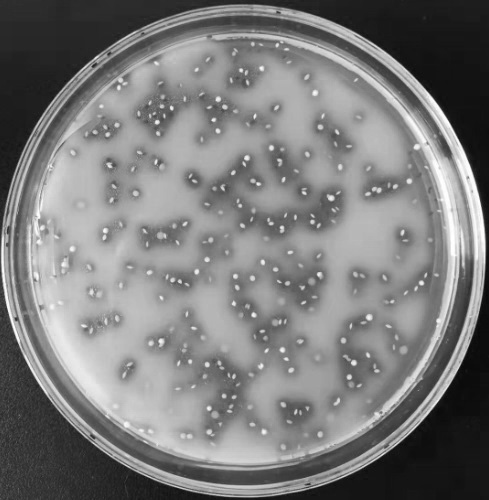

Microorganism-enhanced microbial agent capable of remarkably promoting composting effect before household garbage incineration, and application thereof

ActiveCN111004748AEasy growth metabolismGrow fastBacteriaSolid waste disposalBiotechnologyMicroorganism

The invention discloses a microorganism-enhanced microbial agent capable of remarkably promoting the composting effect before household garbage incineration, and an application thereof. The enhanced microbial agent is prepared by mixing a plurality of composite microbial agents or mixing the composite microbial agents with a carrier, and the composite microbial agents comprise Lactobacillus pasteurii with the preservation number of CGMCC No.18391, Clostridium butyricum with the preservation number of CGMCC No.14499, Bacillus lentus with the preservation number of CGMCC No.18392, and Bacillus psychrophilus with the preservation number of CGMCC No. 18393. The microorganism-enhanced microbial agent can obviously promote the composting effect before household garbage incineration, increase thelow calorific value during garbage incineration and promote garbage dehydration, also can increase the abundance and content of functional microorganisms in garbage composting and accelerate the garbage fermentation process, and can rapidly start the composting process in cold regions to remarkably reduce the use of a combustion improver.

Owner:QINGDAO SHANGDE BIOTECH

Wet mud burning treatment apparatus with compound dryer

ActiveCN100447489CSimplify the dry incineration processMoisture limit increasedSludge treatment by oxidationByproduct vaporizationBurn treatmentFluidized bed

The invention relates to a wet sludge incineration treatment device with a composite dryer. The exhaust gas treatment system is composed of dryer and dryer. The drying and incineration of wet sludge are concentrated in a single device. After the wet sludge is dried in the composite dryer, it returns to the furnace for incineration together with the circulating ash, so that the wet sludge The large amount of moisture contained does not enter the tail flue together with the high-temperature flue gas of the furnace, but is drawn out with the fluidized gas of the composite dryer, which reduces the heat loss of the system; The tube heat exchanger is connected, and the heat brought out of the furnace by the introduction of flue gas, together with the high-temperature circulating ash, is used as a heat source for wet sludge drying, making full use of the residual heat of the incinerator.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

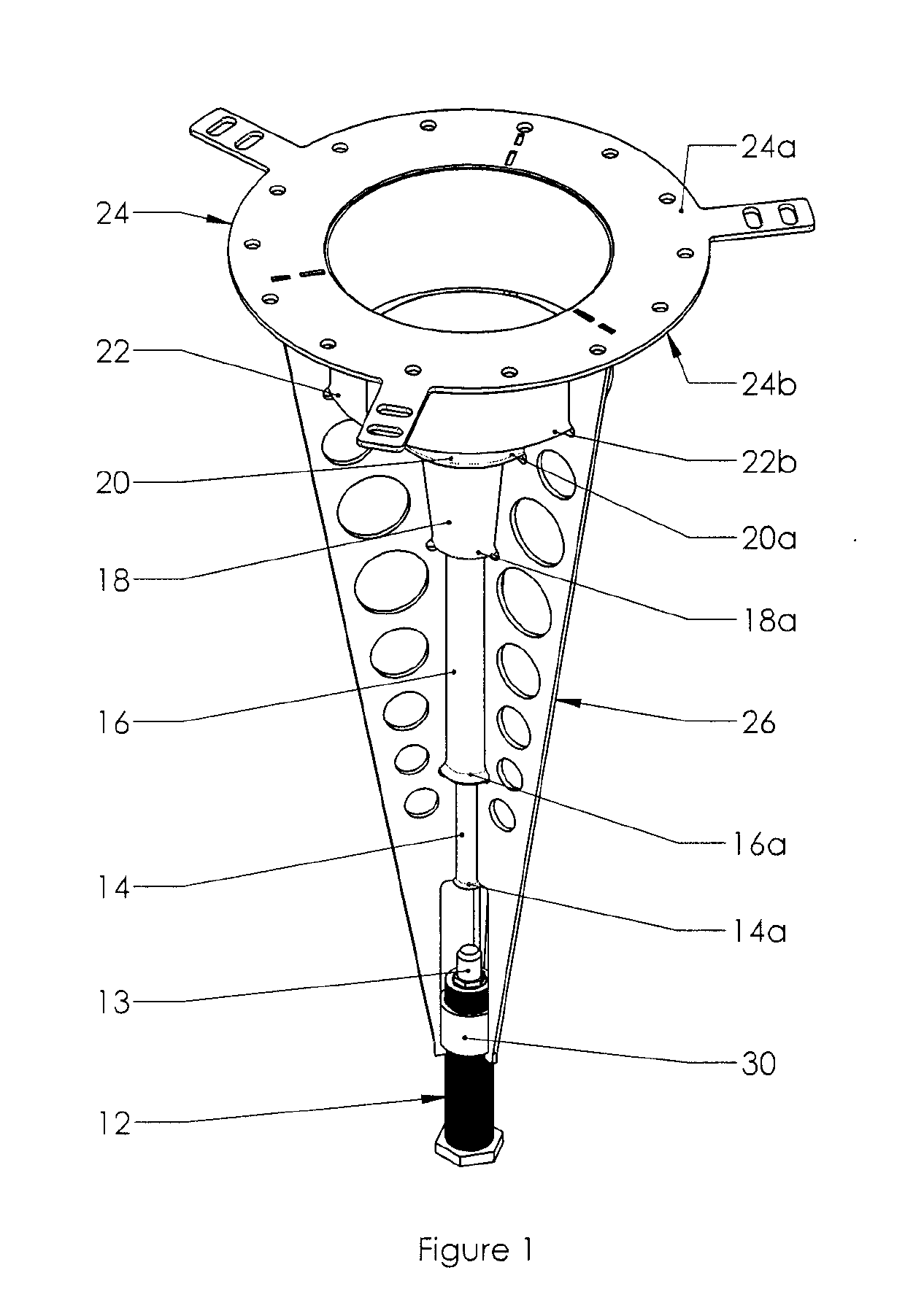

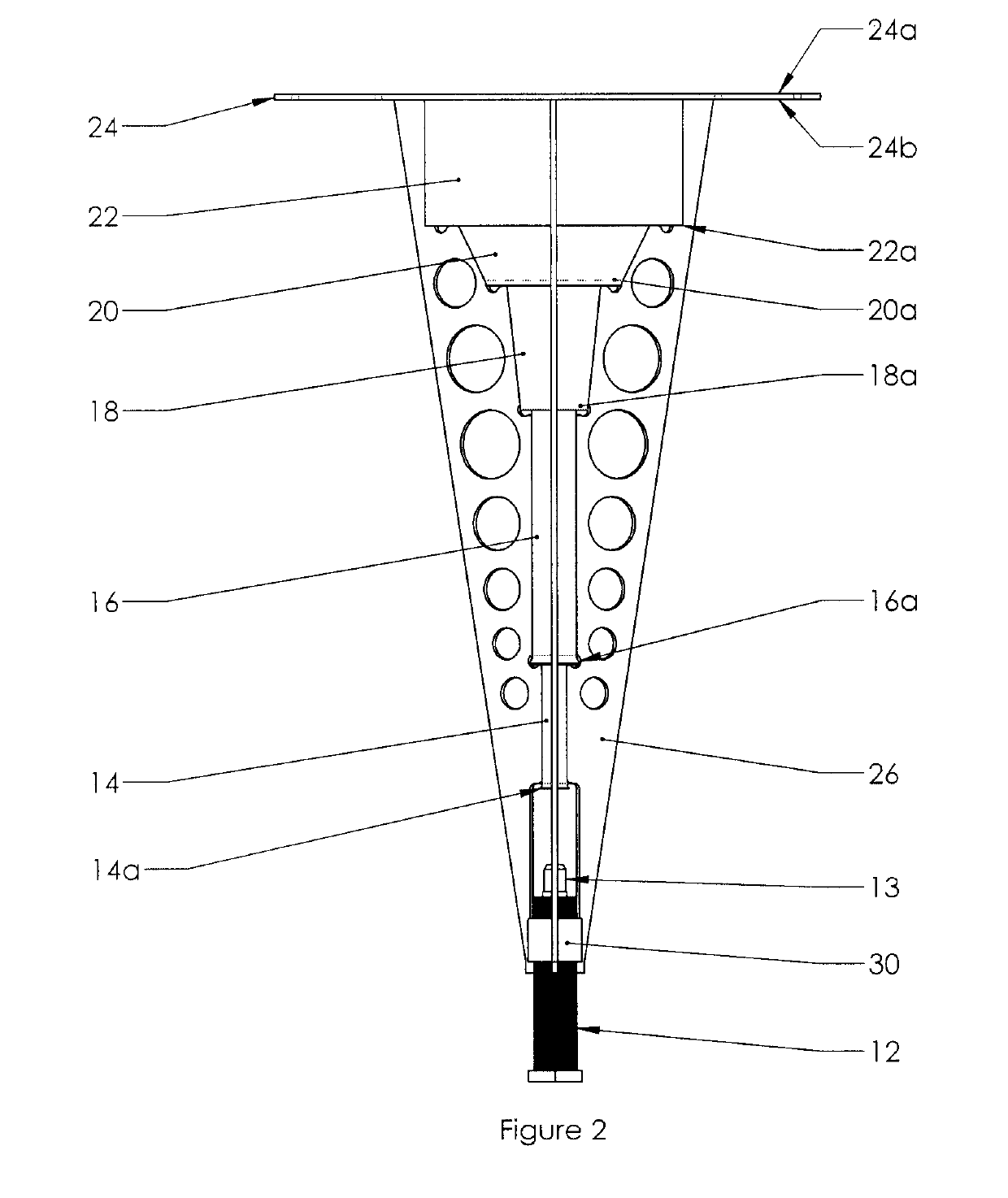

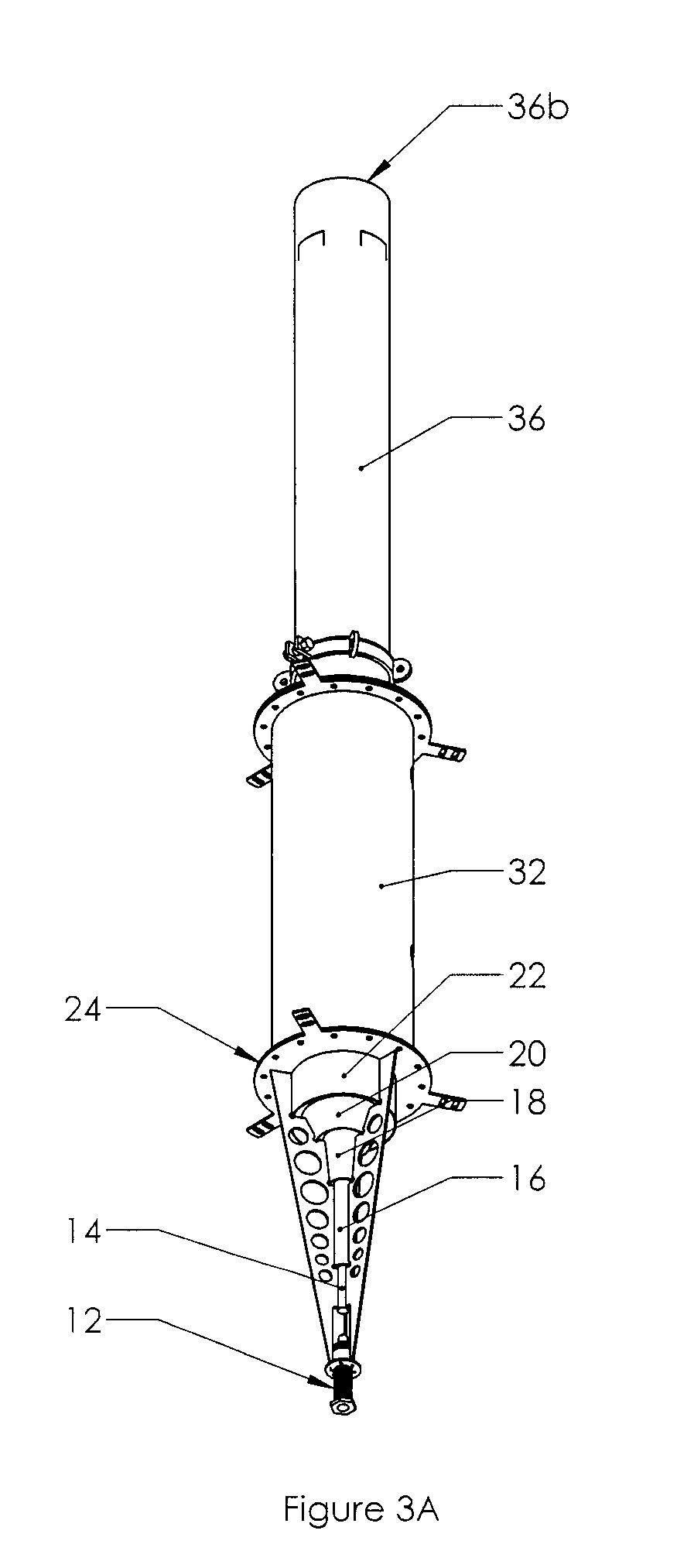

Incinerating system

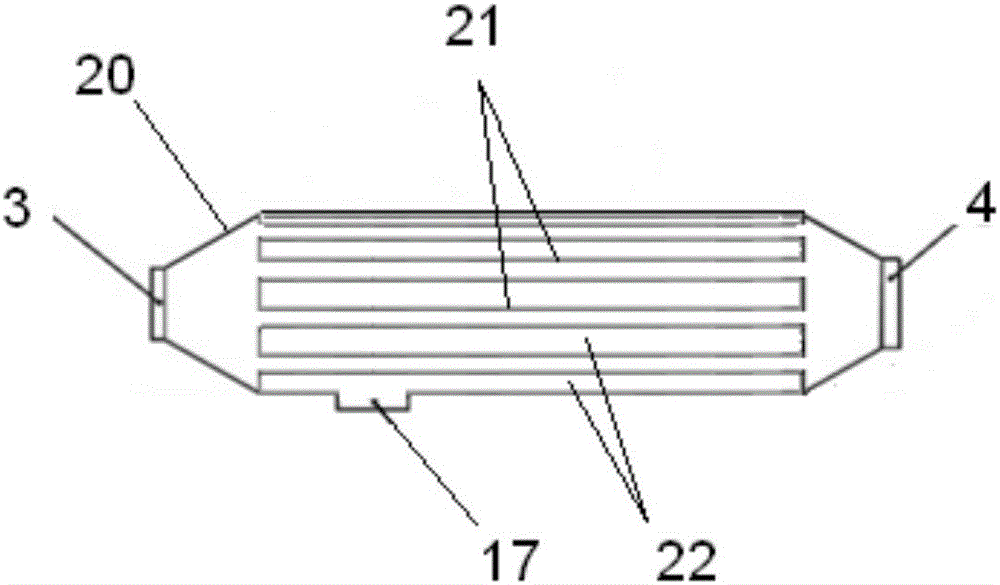

ActiveUS20190101280A1Accelerate incinerationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

The present invention provides a fuel incinerating system comprising a fuel injector, a multi-stage fuel-air mixing device comprising a plurality of fuel intake tubes stacked vertically and configured to provide annular gaps between one or more of the vertically stacked fuel intake tubes to entrain ambient air to form a fuel-air mixture; and a combustor in communication with the fuel-air mixing device and defining a combustion chamber and in communication with an ignition source. The combustor is configured to impede flow of the fuel-air mixture through the combustion chamber to achieve a desired retention time of the fuel-air mixture within the combustion chamber to achieve substantially complete combustions of the fuel.

Owner:ATLANTIS RES LABS INC

Recycling and incineration treatment method of purified terephthalic acid residue

ActiveCN110836378BAchieve reductionReduce processing costsIncinerator apparatusFractional distillationBenzoic acidResource recovery

Owner:沈福昌

Fire pan capable of accelerating combustion and having fire extinguishing function for sacrifice

InactiveCN111150288AComprehensive contactAccelerate incinerationFire rescueReligious equipmentThermodynamicsCombustion

The invention discloses a fire pan capable of accelerating combustion and having a fire extinguishing function for sacrifice, which comprises a base, a combustion basin is arranged in the middle of the base; a combustion cavity is formed in the combustion basin; a supporting column is arranged at the lower part of the combustion basin; the supporting column is installed in the base, two mounting plates are arranged at the upper part of the combustion basin; a first rotating shaft is mounted in the mounting plate; the other end of the first rotating shaft is rotationally mounted at the upper part of the base; two mounting rings are further rotationally mounted on each of the two first rotating shafts; the installation rings on the two sides are installed at the two ends of a first ball cover and the two ends of a second ball cover respectively, and the first ball cover and the second ball cover are both installed between the base and the combustion basin in a sliding mode. When incineration is carried out in the product, a handle can be rotated according to the situation to scatter comburent in the equipment, the comburent makes contact with more air, combustion is accelerated, after combustion is finished, the cover on the device is closed, the valve can be opened to spray out water flow to extinguish residual ash, and sewage can be collected.

Owner:WUYI YILAN METAL HOUSEHOLD PROD CO LTD

Rubbish comprehensive processing method adapted for village and small town

InactiveCN100462315CIncineration harmlessIncineration reductionBio-organic fraction processingChemical industryThermal energyResource utilization

The invention discloses a garbage comprehensive treatment method for village, which comprises the following steps: sorting life garbage of village to perishable element, combustible constituent, reclaiming element; inorganic element; allocating the perishable element, residues of crop, animal and poultry manure and water with mass ratio at 0. 8-1. 2:0. 8-1. 2:8; proceeding anaerobic fermentation under the insulation action of burning lose heat; generating marsh gas; burning the combustible constituent with combustion-supporting marsh gas completely; getting high temperature smoke gas; recovering thermal energy through the first and second heat exchanger; maintaining the temperature of marsh gas fermenting tank; obtaining resource utilization of marsh liquid or slag, marsh gas and reclaiming component; health-filling the inorganic element and burning ash slag. This invention can prevent twice pollution of the burning smoke gas, which can increase the efficiency and output of mash gas.

Owner:ZHEJIANG UNIV

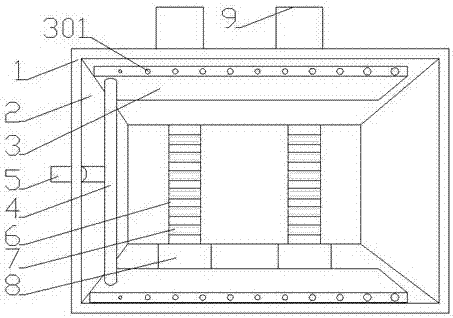

Environment-friendly incinerator for incinerating straw

The invention discloses an environment-friendly incinerator for burning straw, which comprises a furnace body, the furnace body is arranged in a furnace, the upper parts of the front and rear inner walls of the furnace are connected with a flue, the left end of the flue is connected to a main smoke pipe, and the main smoke pipe is connected to an outlet. The smoke pipe, the smoke outlet pipe runs through the furnace body and connects the smoke removal tank through the joint. The upper end of the spiral pipe is arranged in the smoke removal tank, and the lower end of the spiral pipe is vertically connected to the smoke removal pipe. There is an ash discharge channel at the bottom, a number of evenly arranged furnace bridges are installed on the upper end, a stirring cage is provided at the lower part of the ash discharge channel, and a furnace door is set through the front wall of the furnace; it has a compact structure and a reasonable design. After the dust is purified by the smoke removal tank, it is harmless to the air quality. At the same time, the amount of incineration is large, the ignition point is high, and the heat generated can be used. It is also beneficial to environmental protection and has a wide application prospect.

Owner:赵敬武

Harmless recovery and incineration treatment method of purified terephthalic acid residue

ActiveCN110864308BAchieve reductionReduce processing costsOrganic chemistryVapor condensationBenzoic acidFiber

The invention discloses a method for the harmless recovery and incineration of purified terephthalic acid residues. An incinerator is used as the incineration treatment equipment, and a reaction kettle is used as the harmless recovery treatment equipment. The reaction kettle has a rectification tower, a first A condenser and a second condenser, the gas inlet of the first condenser is connected with the gas outlet of the rectification tower, the second condenser is connected in series with the first condenser, the gas inlet of the second condenser is connected with the gas outlet of the first condenser The gas outlet is connected, and the method includes the following steps: feeding, dehydrating, recovering benzoic acid, crushing waste residues, grinding waste residues, and incinerating waste residues. The present invention not only realizes waste recycling, extracts useful benzoic acid to be used as raw material for producing polyester fiber and PET resin, but also increases the amount of incineration by more than three times compared with the prior art, greatly improving the amount of incineration, and The residue is burned more fully, the harmless treatment is more thorough, more environmentally friendly, the energy consumption is low during treatment, and the process is simple and easy.

Owner:沈福昌

Gasification incinerator and waste gasification incineration method

PendingCN114440223ATemperature controlKeep warmIncinerator apparatusCombustionEnvironmental engineering

The invention discloses a gasification incinerator and a waste gasification incineration method. The gasification incinerator comprises a first incinerator body and a second incinerator body. The first furnace body comprises a gasification section and a combustion section, and the second furnace body comprises a quenching section. And the tops of the first furnace body and the second furnace body are communicated and share a wall surface. A primary air distribution device is arranged at the bottom of the gasification section, a pre-combustion section and a secondary air distribution device are arranged at the side part of the gasification section, the pre-combustion section comprises a liquid feeding device, a solid feeding device and a combustion device, an outlet of the pre-combustion section is communicated to the upper section of the gasification section, and a steam inlet is formed in the lower section of the gasification section. The bottom of the combustion section is communicated with the top of the gasification section, and a tertiary air distribution device is arranged on the side portion of the combustion section. The top of the quenching section communicates with the top of the combustion section, and the quenching section is provided with a cooling water inlet, a smoke outlet and a fly ash outlet. When the gasification incinerator is used for treating waste materials, the waste material incineration and tail gas treatment effects can be remarkably improved, and the operation energy and labor cost can be remarkably reduced.

Owner:BEIJING SIWEI TIANTUO TECH CO LTD

A kind of microbe-enhanced bacterial agent and its application that can significantly promote the composting effect before domestic waste incineration

ActiveCN111004748BEasy growth metabolismGrow fastBacteriaSolid waste disposalBiotechnologyBacillus lentus

The invention discloses a microorganism-enhanced bacterial agent for significantly promoting the composting effect before incineration of domestic garbage and an application thereof. The enhanced bacterial agent is made by mixing a variety of composite bacterial agents or composite bacterial agents with a carrier, and the composite bacterial agent includes Lactobacillus parreni with a preservation number of CGMCC No.18391, and a preservation number of CGMCC No.14499. Clostridium butyricum, Bacillus lentus with preservation number CGMCC No.18392 and Psyrophilic Bacillus with preservation number CGMCC No.18393. The microbial enhanced bacterial agent of the present invention can significantly promote the effect of composting fermentation before domestic waste incineration, increase the low calorific value during waste incineration, promote the dehydration of garbage, and can also increase the abundance and content of functional microorganisms in garbage composting fermentation, and accelerate the efficiency of garbage fermentation process, and in cold regions, the bacterial agent can also quickly start the composting process, significantly reducing the use of combustion aids.

Owner:QINGDAO SHANGDE BIOTECH

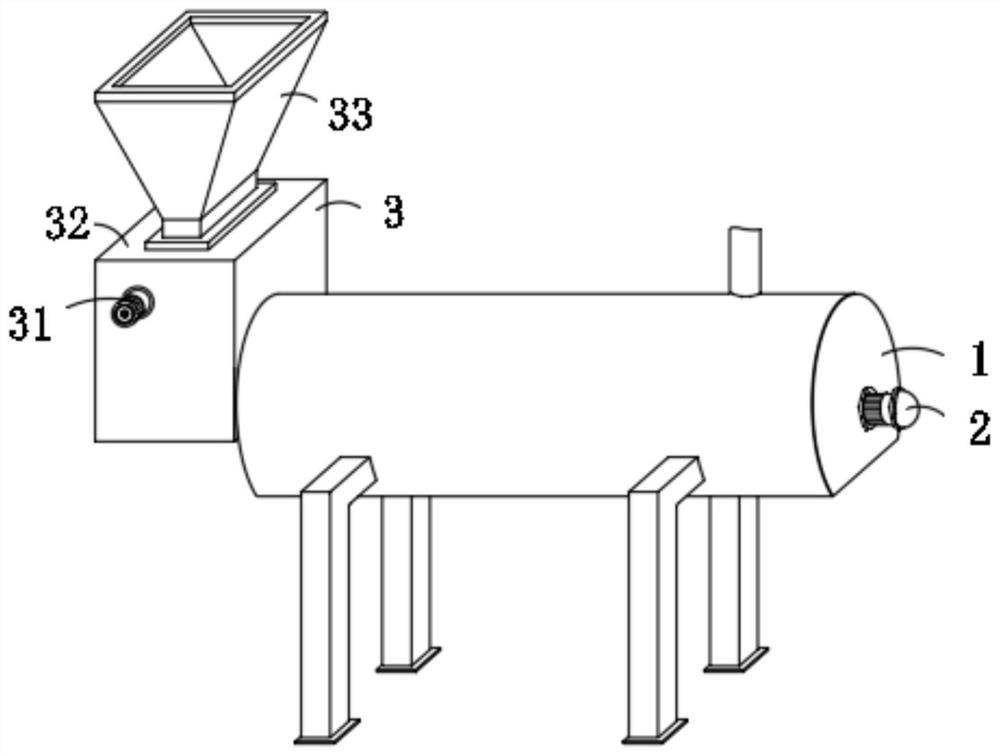

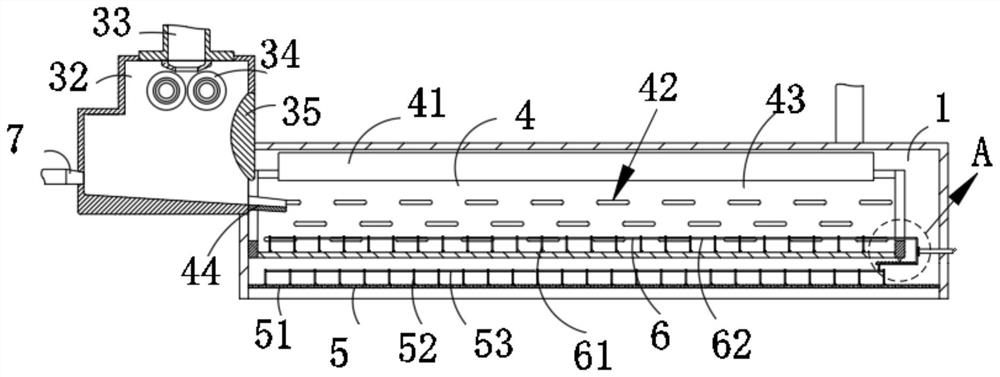

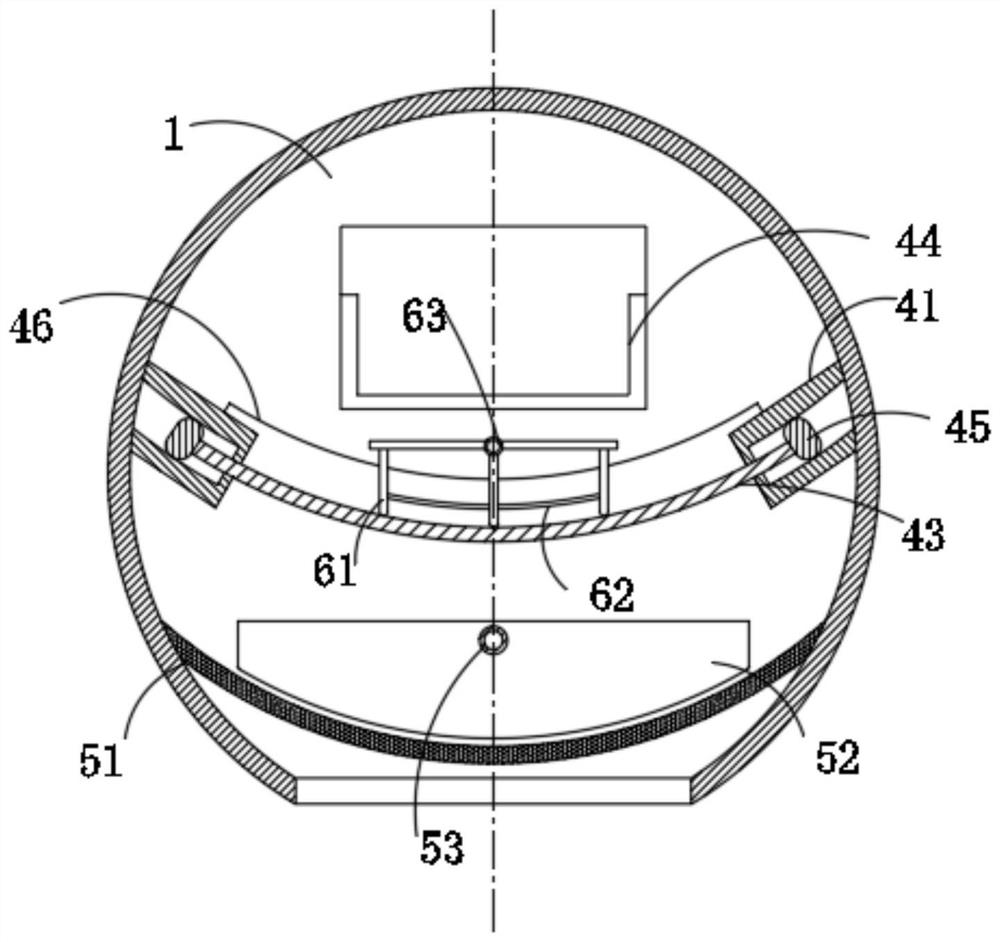

Incineration device for wastewater sludge reduction

PendingCN112797420AAccelerate incinerationEasy to incinerateSludge treatment by de-watering/drying/thickeningIncinerator apparatusMechanical engineeringSludge

The invention provides an incineration device for wastewater sludge reduction. The incineration device for wastewater sludge reduction comprises a fixed barrel, a crushing mechanism, a supporting mechanism, a flattening mechanism, a collecting mechanism and a driving mechanism, wherein the supporting mechanism comprises fixed plates, filter screens, a supporting plate, a second funnel, connecting strips and protective plates; the fixed plates are symmetrically mounted in the fixed barrel; the connecting strips and the supporting plate are slidably connected to the interiors of the fixed plates; the connecting strips are mounted at the two ends of the supporting plate with arc-shaped side walls respectively; the protective plates are mounted on the side walls of the supporting plate respectively; the filter screens are mounted in the supporting plate at equal intervals; the second funnel is mounted on the side wall of the crushing mechanism; the flattening mechanism is in sliding connection with the interior of the supporting plate; the collecting mechanism is mounted at the bottom end of the fixed barrel. The incineration device for wastewater sludge reduction provided by the invention has the advantage of facilitating rapid combustion of sludge.

Owner:NANJING JINNI RESOURCES & ENVIRONMENT CO LTD

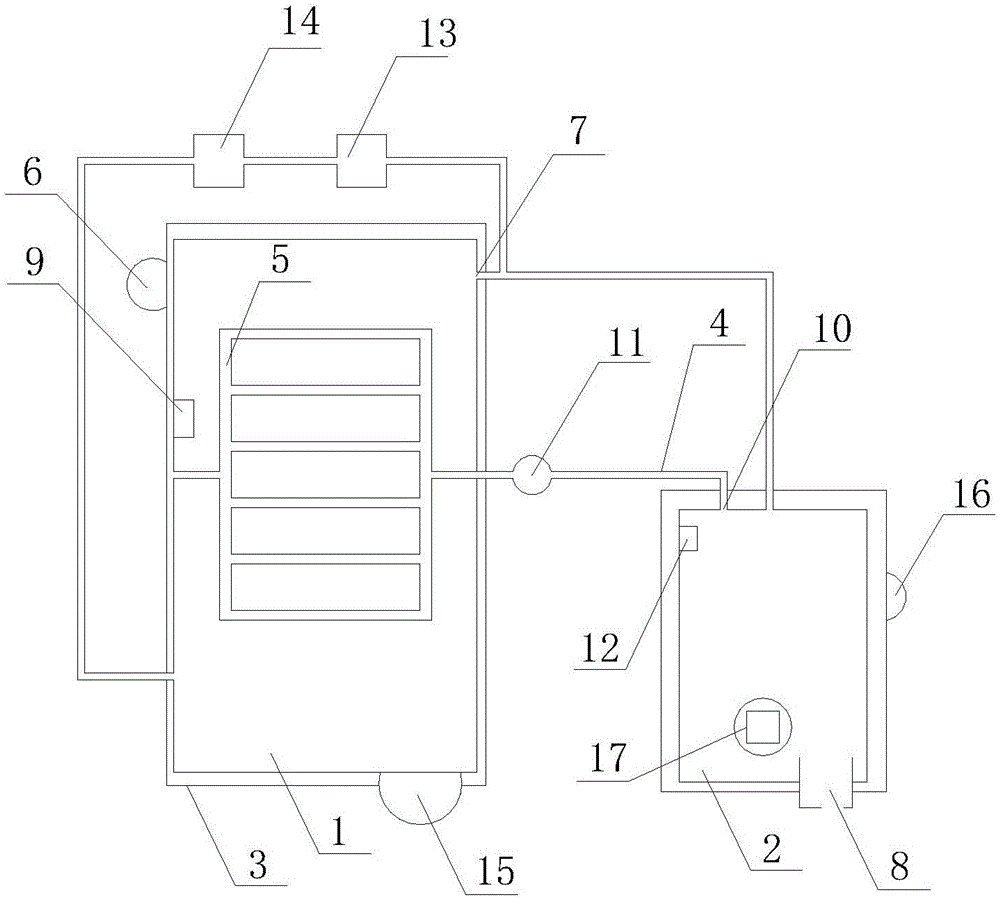

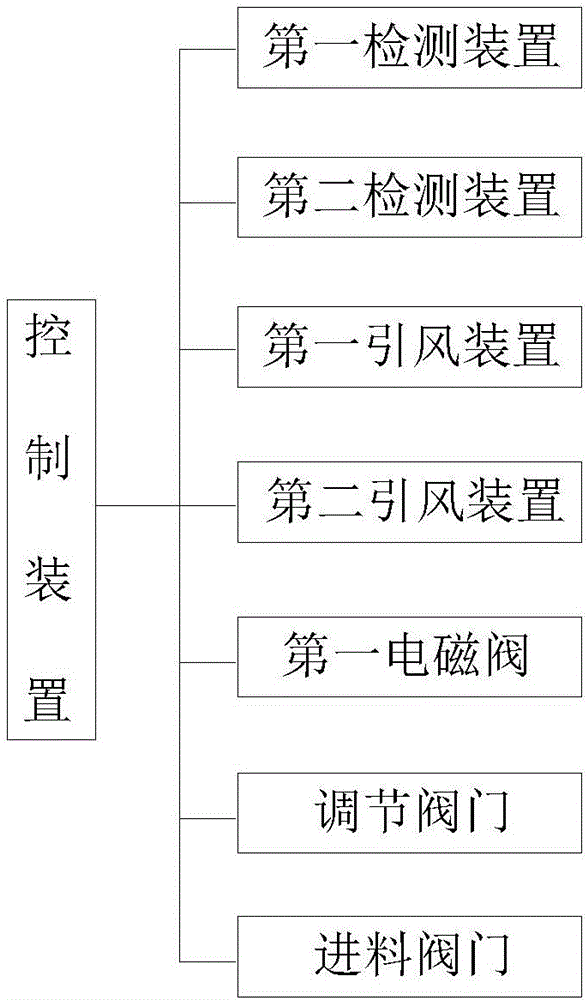

Garbage incinerator circulation control system

InactiveCN106765197AImprove incineration effectKeep dryIncinerator apparatusControl systemEngineering

The invention discloses a garbage incinerator circulation control system. A first cavity is formed in a shell and is internally provided with a multi-pipe channel; the multi-pipe channel communicates with an air channel pipeline; a first air-induced device is arranged on the outer wall of the shell; a material falling hole is formed in the bottom of the first cavity and is provided with a regulation valve; a first detection device is used for detecting a temperature value T of a first position in the first cavity; a first electromagnetic valve is arranged on a tail gas pipeline; a second air-induced device is arranged in a second cavity; a feeding hole is formed in the second cavity and is provided with a feeding valve; a second detection device is used for detecting a temperature value T0 of a tail gas outlet; a control device acquires the temperature value T of the first position in the first cavity through the first detection device, acquires the temperature value T0 of the tail gas outlet through the second detection device and controls the first air-induced device, the second air-induced device, the first electromagnetic valve, the regulation valve and the feeding valve to act according to a T size and T0 size command.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

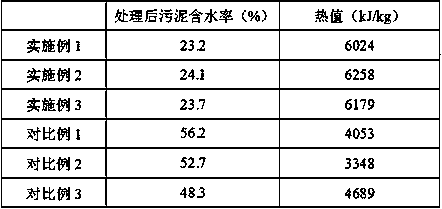

Method for reducing water content of sludge

ActiveCN109608019AOptimizing the Group Distribution RatioOvercoming inefficienciesSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSodium acetatePollution

The invention discloses a method for reducing the water content of sludge. Cationic polyacrylamide I is sequentially added into the sludge, then sodium acetate and cationic polyacrylamide II are addedinto the sludge, candida utilis is added, and then cationic polyacrylamide III and rhodopseudomonas palustris are added into the sludge; finally, sepiolite powder is added under the stirring condition, activated carbon is spread on the surface of the sludge, the mixture stands for several hours, and liquid is filtered out, so that the sludge is treated. According to the method, the addition timeof each component is strictly limited, the treatment time of each stage is strictly limited, and the water content can be reduced to 25% or below; the low-grade heat value is increased, the sludge incineration capacity per unit time can be improved when the incineration treatment is carried out at the later stage, no pollution is caused to the environment in the whole treatment process, and no odor is released. The treatment method has the advantages of being simple in raw material, easy to operate and control, low in cost, high in treatment efficiency and the like.

Owner:GUANGXI NANNING WATERWORKS CO LTD

A method for reducing the moisture content of sludge

ActiveCN109608019BOptimizing the Group Distribution RatioOvercoming inefficienciesSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSodium acetateActivated carbon

The invention discloses a method for reducing the moisture content of sludge. Adding cationic polyacrylamide I to the sludge successively, then adding sodium acetate and cationic polyacrylamide II, adding Candida utilis, and then adding cationic polyacrylamide to the sludge Polyacrylamide III, Rhodopseudomonas palustris, and finally add sepiolite powder under stirring conditions, spread activated carbon on the surface of the sludge, let it stand for several hours, filter out the liquid, and complete the sludge treatment. The present invention specifically limits the timing of adding each component, and strictly limits the treatment time of each stage, the moisture content can be reduced to below 25%, and the lower calorific value is increased, which is convenient for the amount of sludge incinerated per unit time in the later incineration treatment It has been improved, and the whole treatment process has no pollution to the environment and no odor release. The treatment method of the invention has the advantages of simple raw materials, easy operation control, low cost, high treatment efficiency and the like.

Owner:GUANGXI NANNING WATERWORKS CO LTD

an atomizing spray gun

ActiveCN103759260BPower Generation Efficiency ImpactAvoid damageBurnersIncinerator apparatusSpray nozzleEngineering

The invention relates to an atomizing spray gun. Four leachate return and spray nozzles are arranged on two sides of the outlet sidewall of a burning hearth furnace and are parallel to a secondary air inlet. The atomizing spray gun comprises a compressed air nozzle, a leachate nozzle, a flange, a protective sleeve, a gun rod and an atomizing nozzle. The compressed air nozzle is screwed to the larger end of the leachate nozzle in a threaded manner, the gun rod is screwed to the smaller end of the leachate nozzle in a threaded manner, and one end of the atomizing nozzle provided with a thread is screwed to the outer thread of one end of the gun rod. The gun rod is fixed to the flange in a welded manner, and the flange is sleeved with a seal ring. One end of the protective sleeve with a mounting hole sleeves the flange and is fixed through a screw to prevent from dropping. The atomizing spray gun has the advantages that dual-fluid design is adopted, the leachate and the compressed air are mixed in the nozzle under certain pressure, fine atomized particles are produced, and service life is super long.

Owner:无锡卓能环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com