Small refuse incinerator

A waste incinerator, small-scale technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of increasing the amount of waste incineration and incineration effect, displacement of waste burning layer, short service life, etc., to increase the amount of waste incineration, Eliminate easy damage and reduce failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better illustrate the present invention and its implementation, the present invention will be further described in detail below in conjunction with the accompanying drawings.

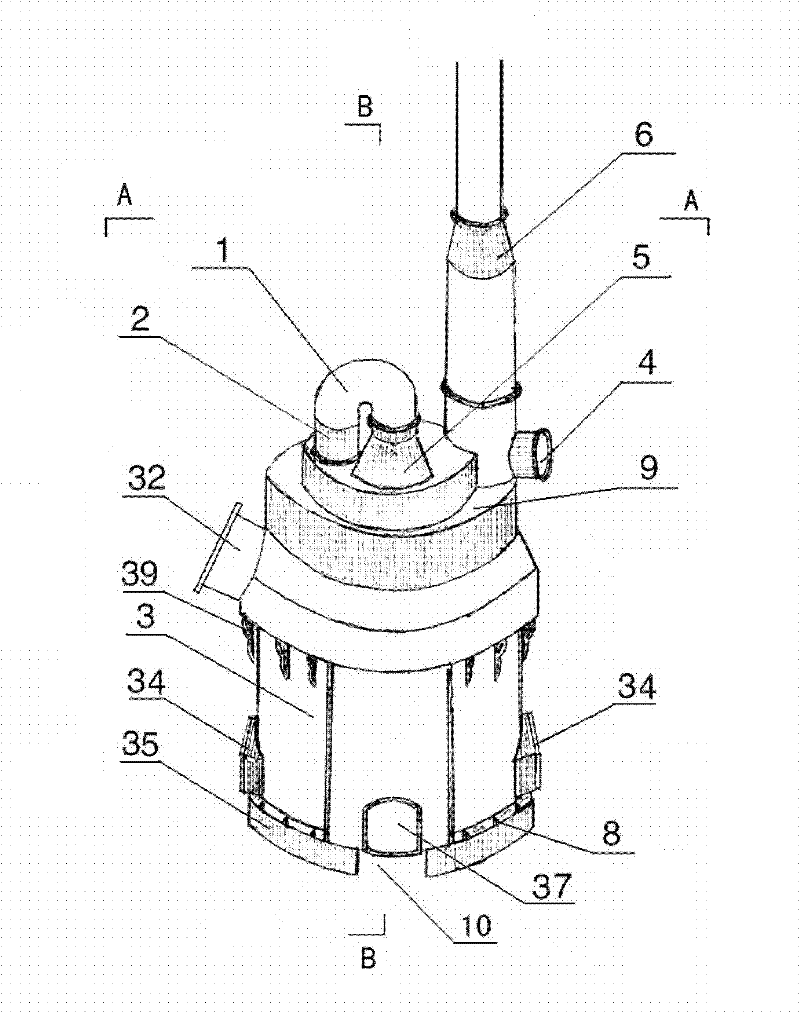

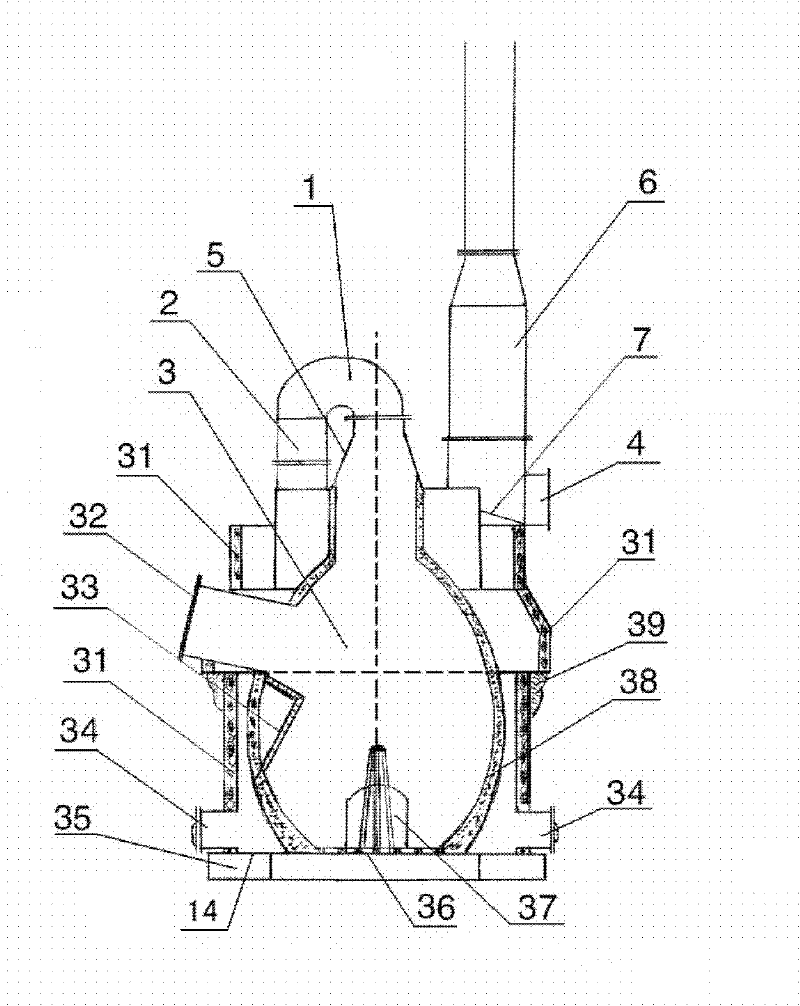

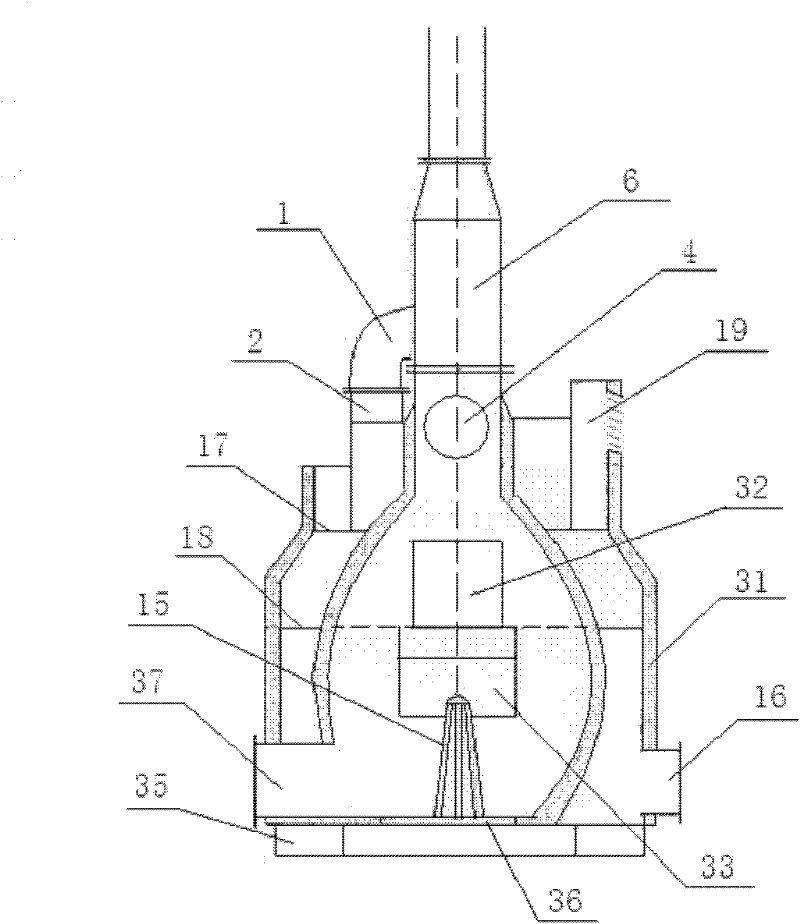

[0026] Such as figure 1 , 2 , 3, and 4, the small-scale garbage incinerator provided by the present invention includes: a flue gas spiral path composed of a smoke port connecting elbow 1, a lower delivery butt joint smoke port 2, a chimney diversion pipe 5 and a flue gas spiral path outer plate 9 device, air inlet member 19, furnace body 3, heat-gathering air groove 13, flue gas discharge pipe 4, chimney 6, cooling water deflector 7, and described heat-gathering air groove 13 is composed of the bottom surface and two equal-height and center-coinciding two The inner cylinder side wall has an opening, the two sides of the opening of the inner side wall are respectively provided with an air inlet 11, and the air inlet 11 is provided with an air inlet spacer 12, Two openings are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com