Patents

Literature

242results about How to "Easy to incinerate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Respirator that uses a polymeric nose clip

InactiveUS20070068529A1Control flowWithout causing uncomfortable pressure pointsBreathing filtersBreathing masksRespiratorFilter media

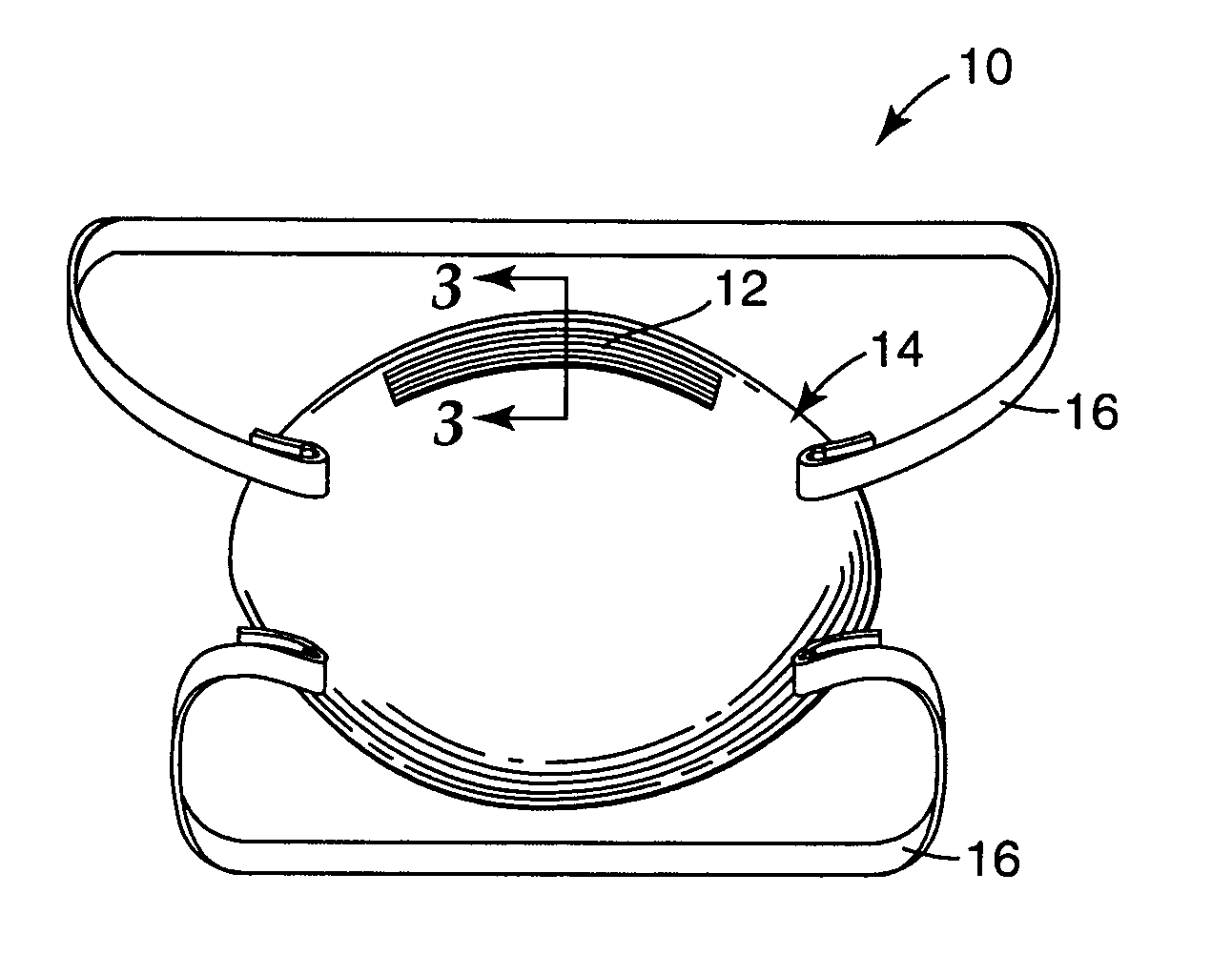

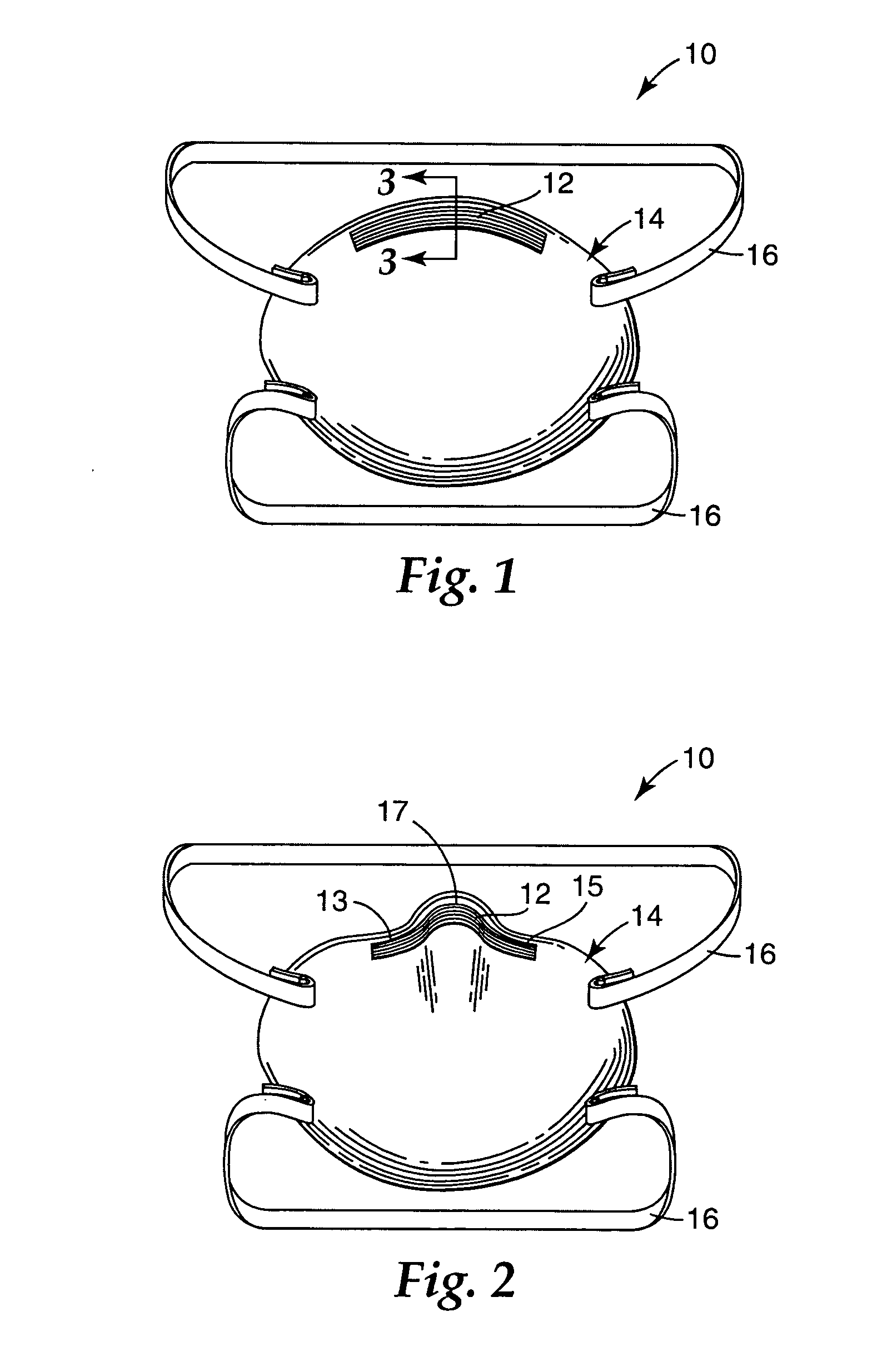

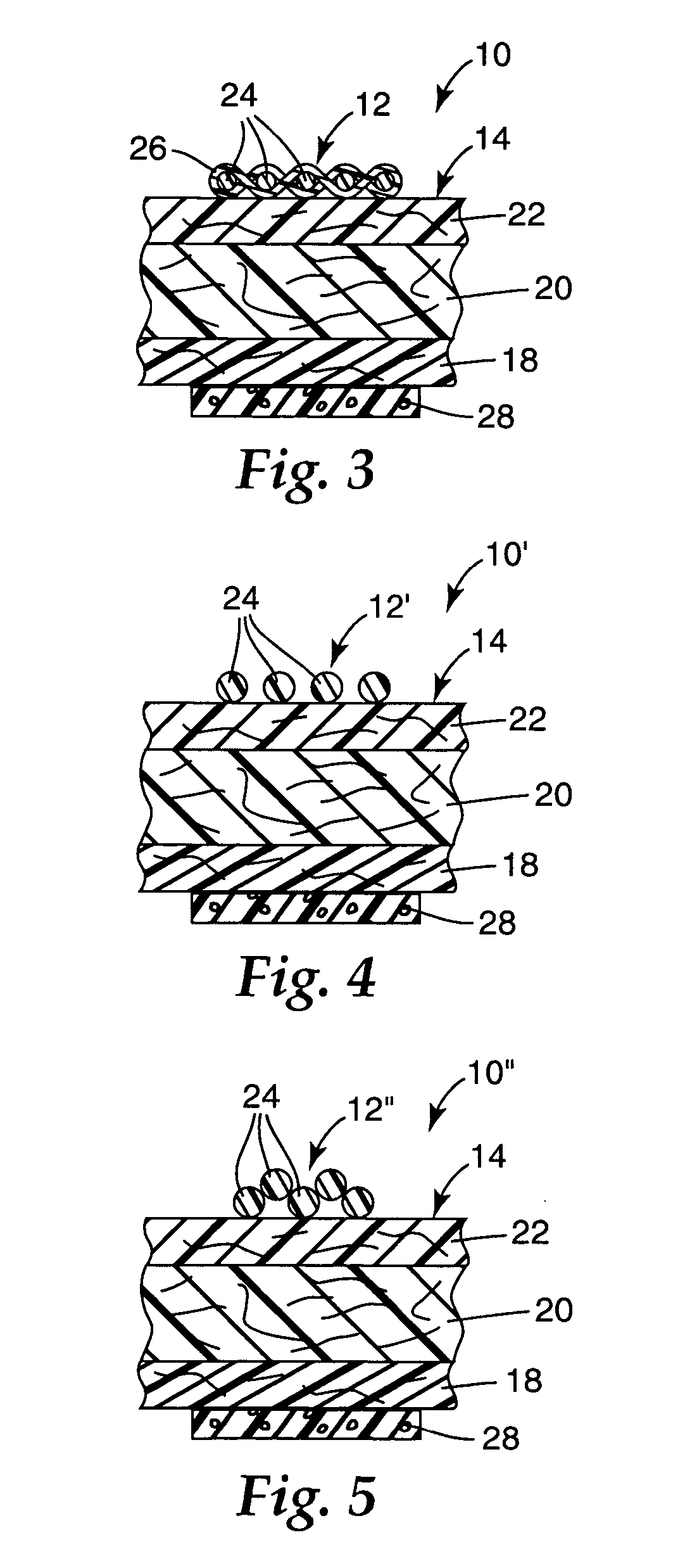

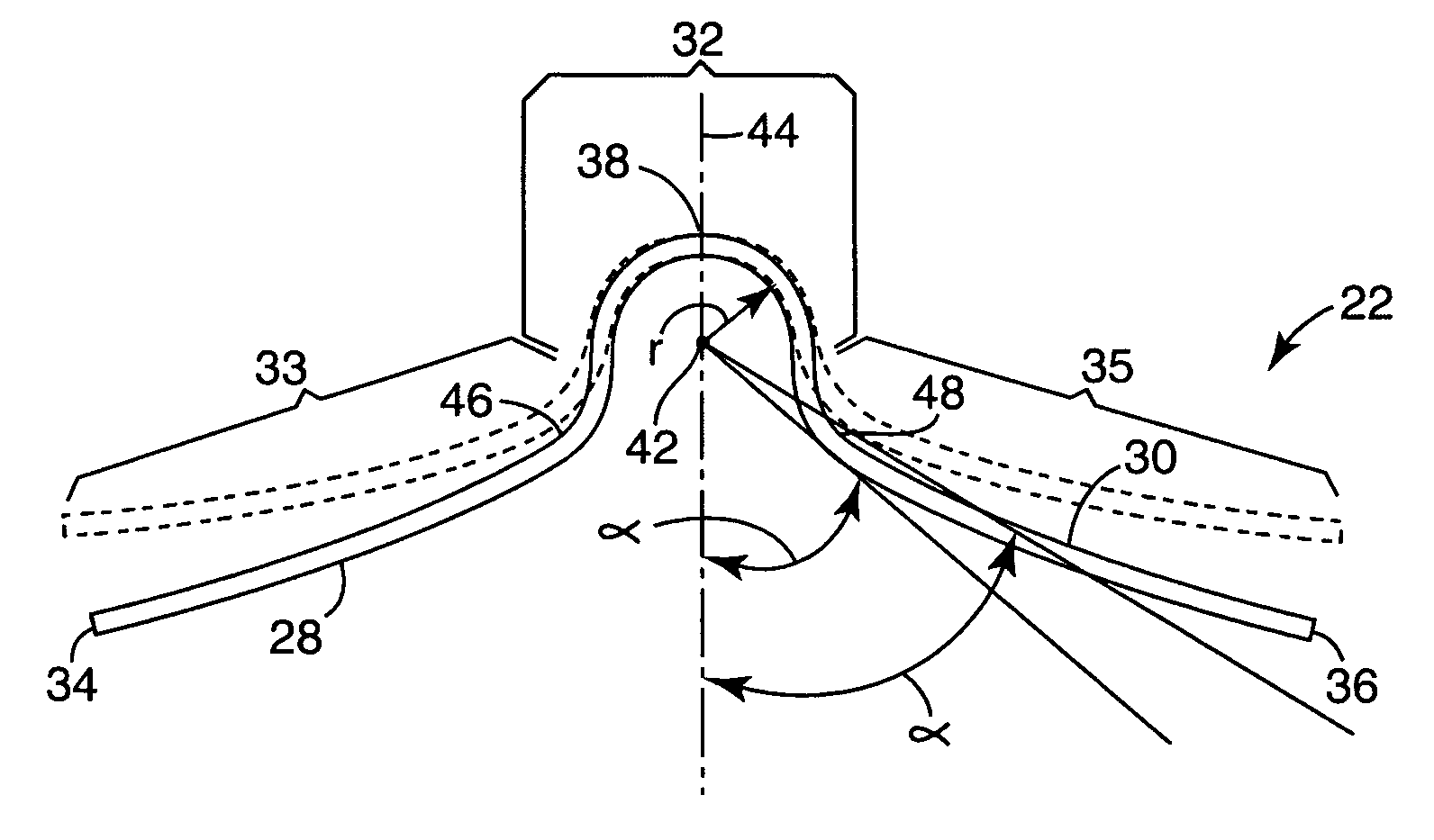

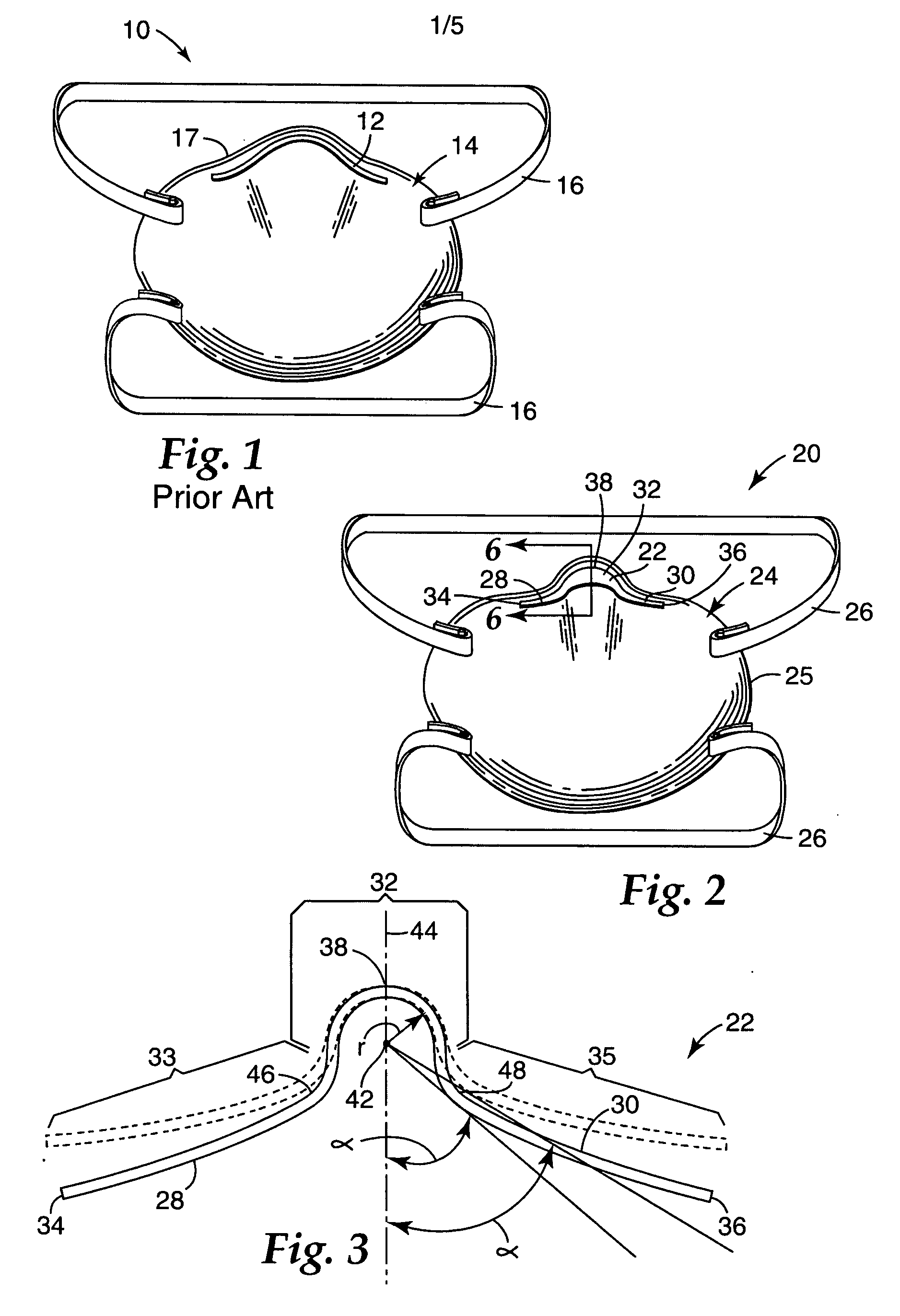

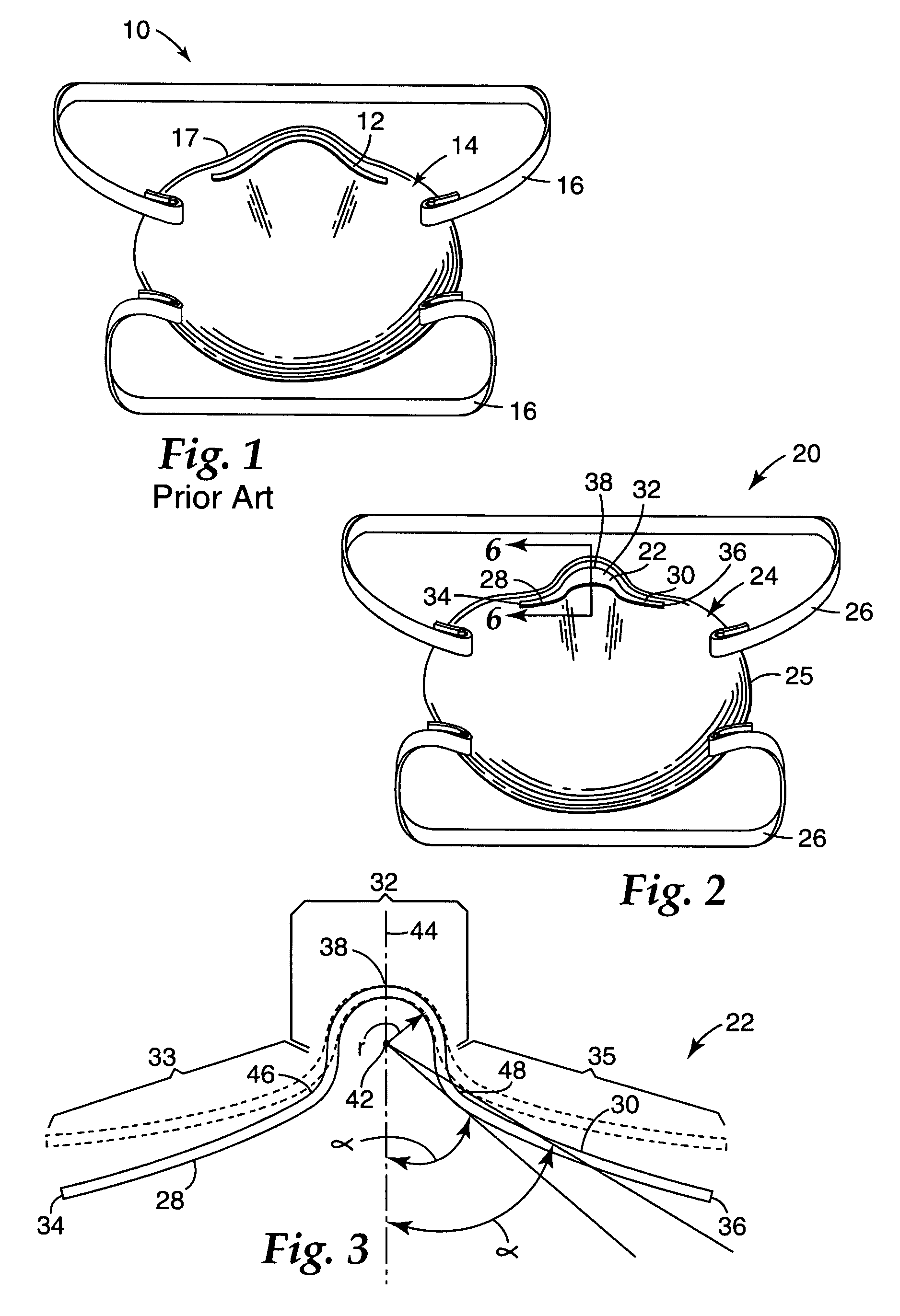

A respirator 10 that has a mask body 14 and a malleable nose clip 12. The mask body 14 is adapted to fit at least over the nose and mouth of a person to define an interior gas space that is separate from the exterior gas space. The mask body 14 has the nose clip 12 secured to it and can include at least one layer of filter media 20. The malleable nose clip 12 comprises a semi-crystalline polymeric material that has an integrated diffraction intensity ratio of at least about 2.0. The nose clip 12 can be deformed into a desired configuration that enables the mask body 14 to maintain a snug fit over a person's nose when the respirator is worn for extended time periods. Because the nose clip 12 does not need to contain metal, the whole respirator 10 can be easily processed as waste in an incinerator when its service has ended.

Owner:3M INNOVATIVE PROPERTIES CO

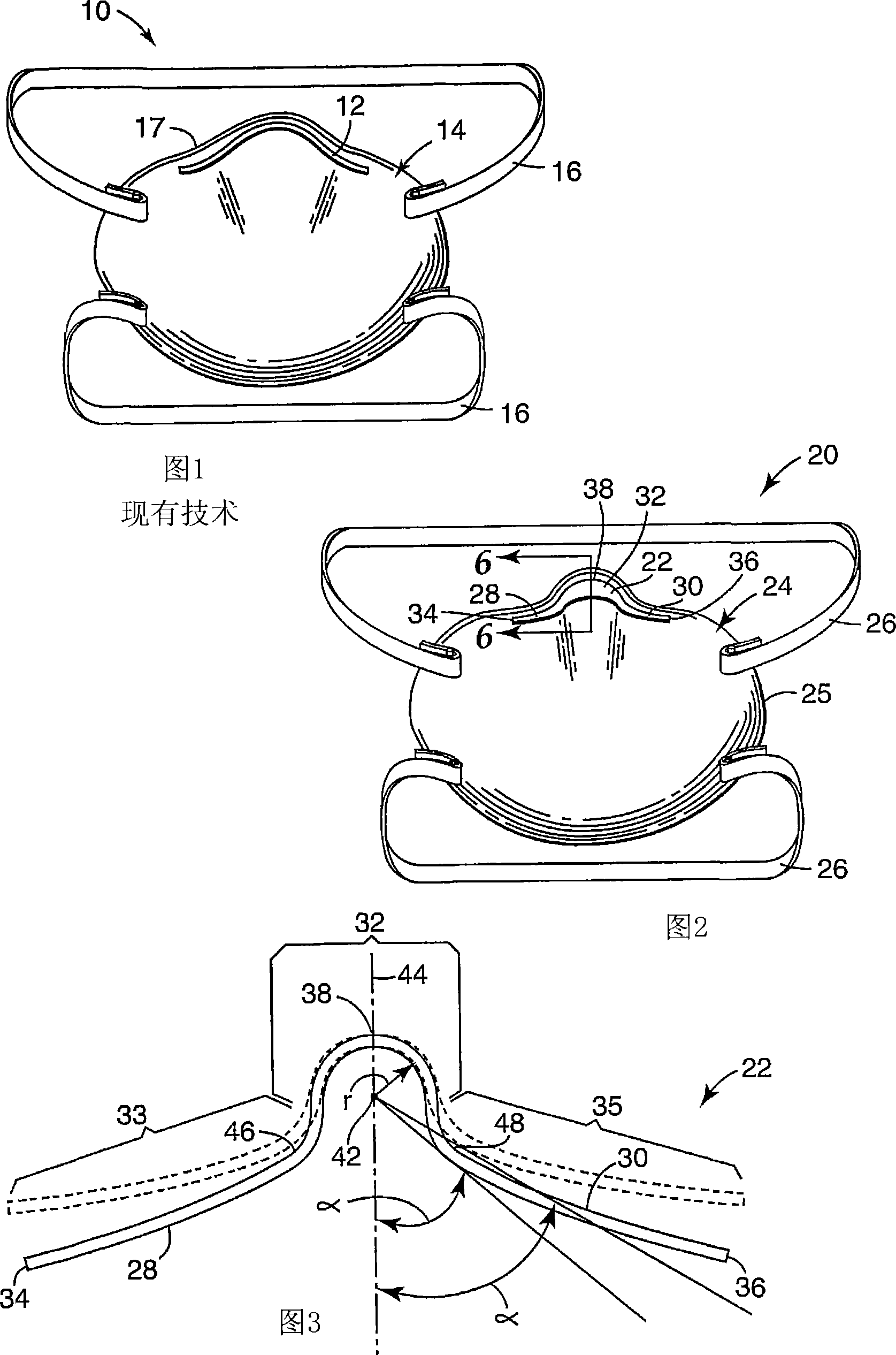

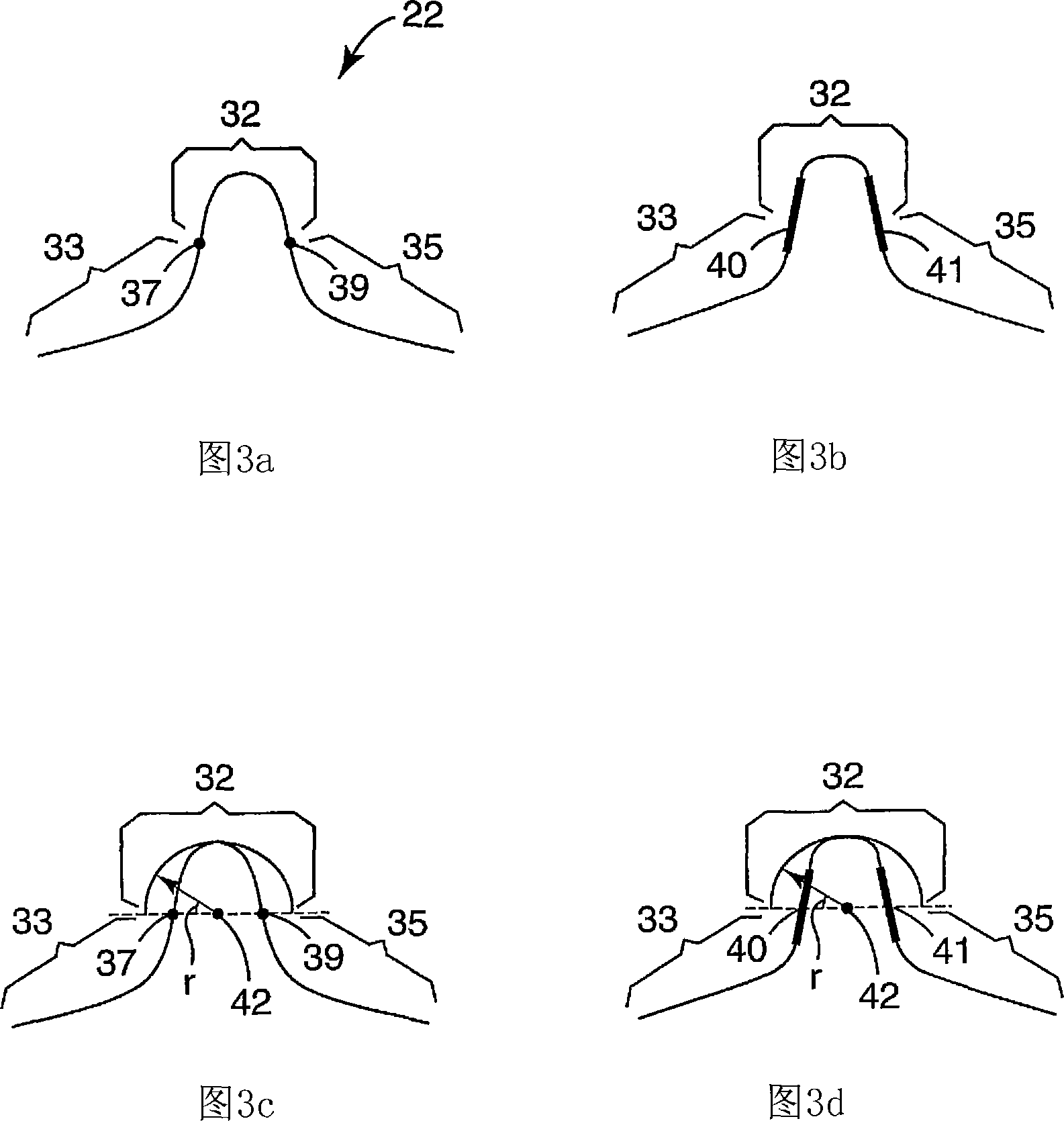

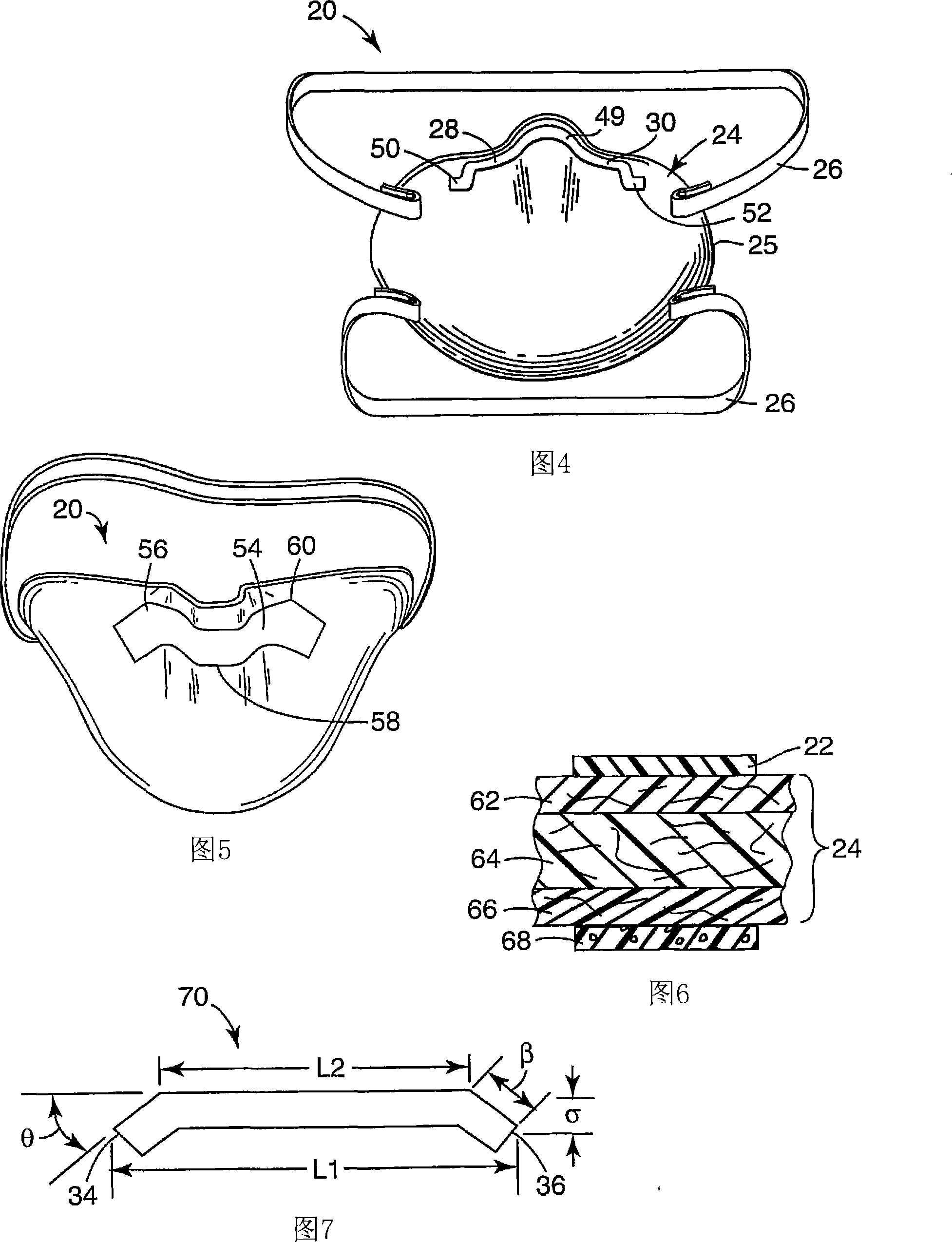

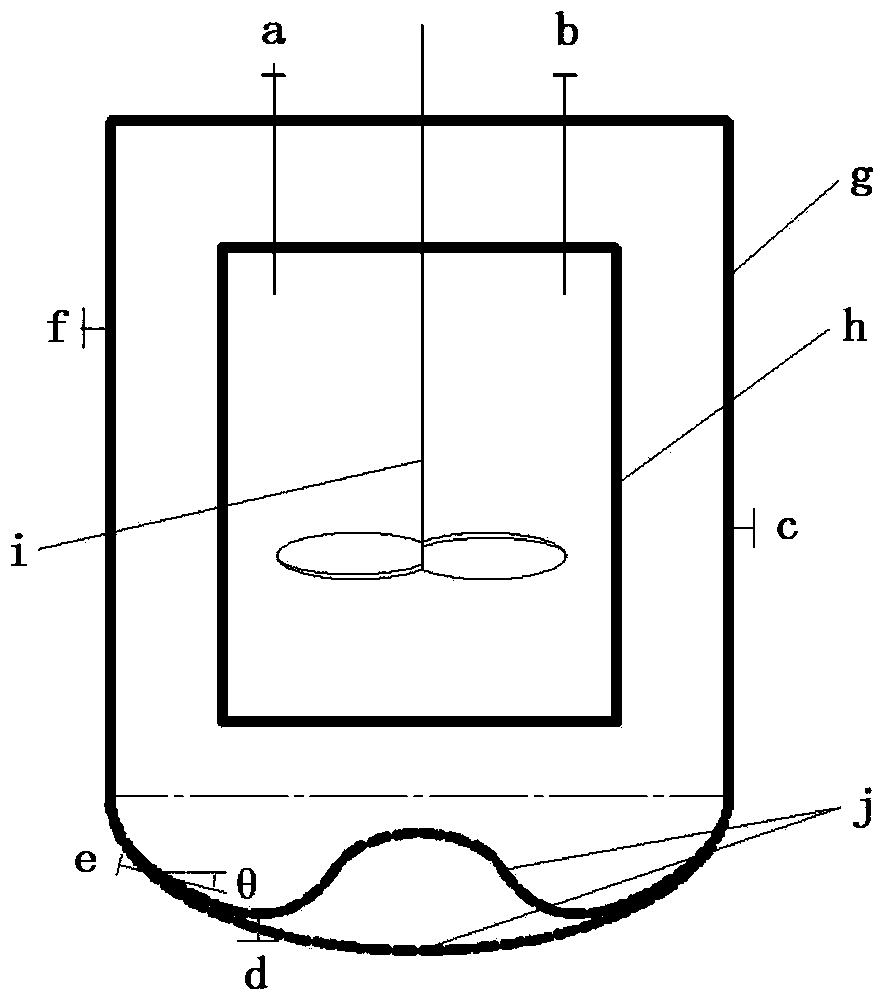

Respirator having preloaded nose clip

InactiveUS20070044803A1Simple processEasy to incinerateRespiratorsBreathing filtersNose clipsRespirator

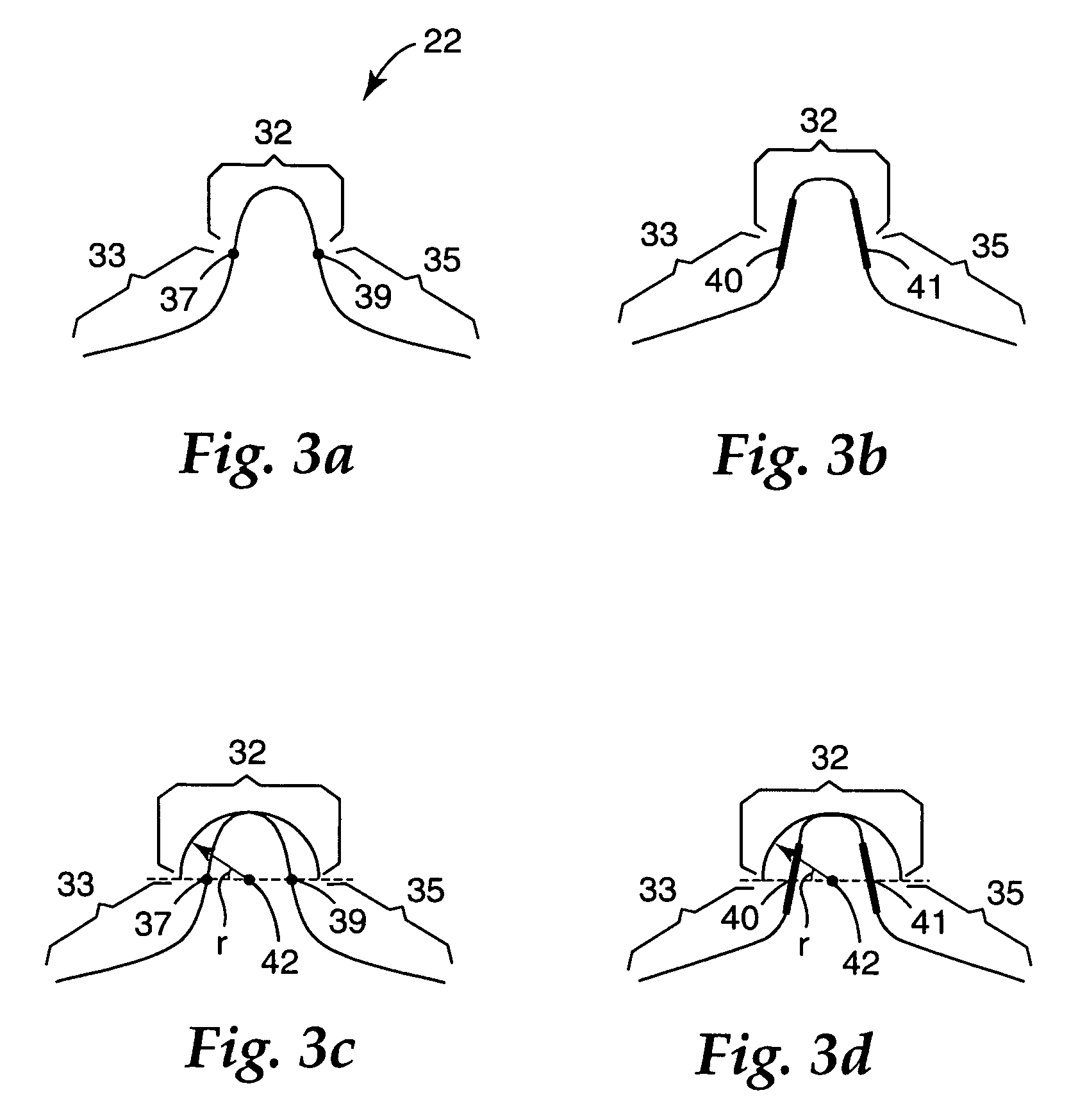

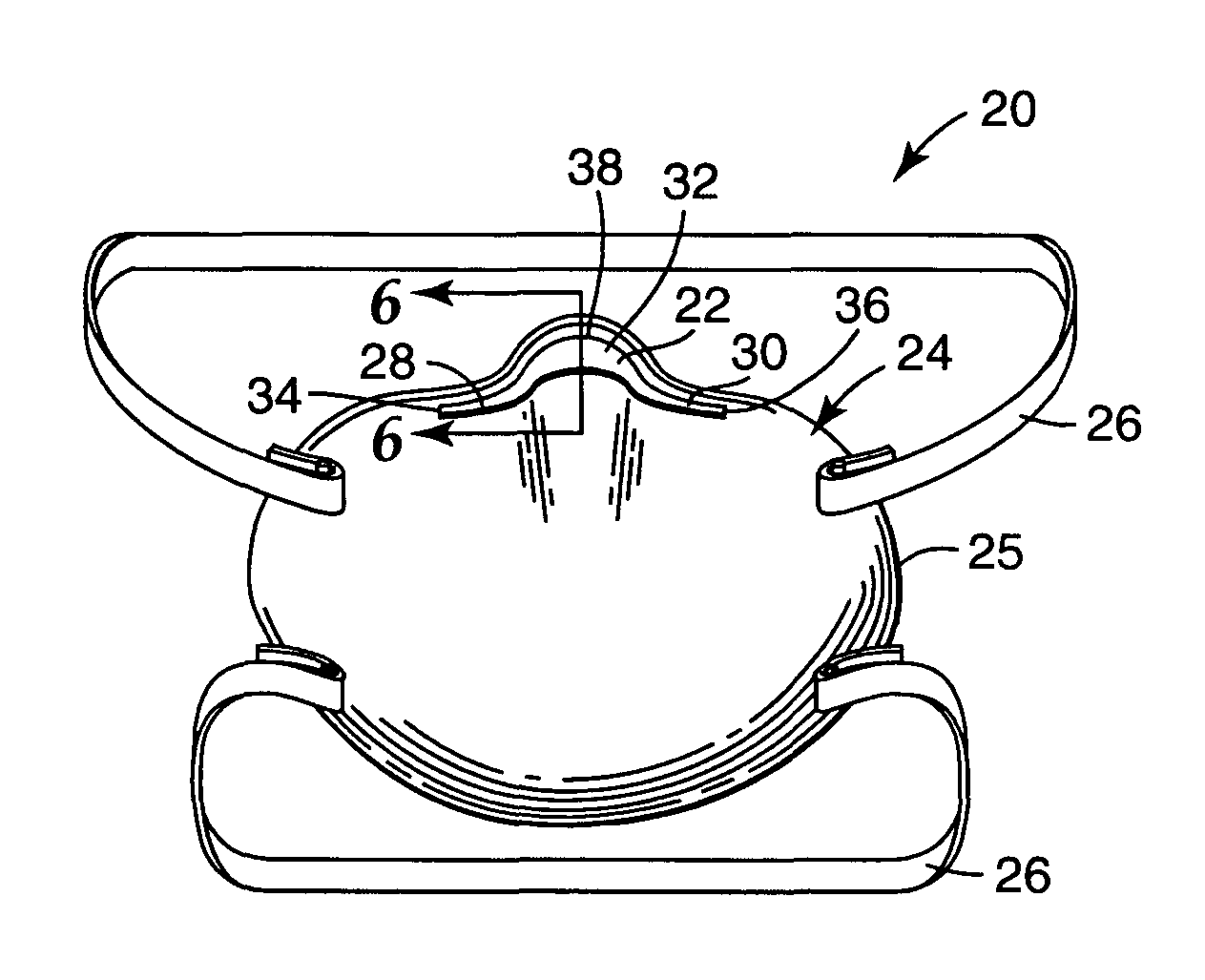

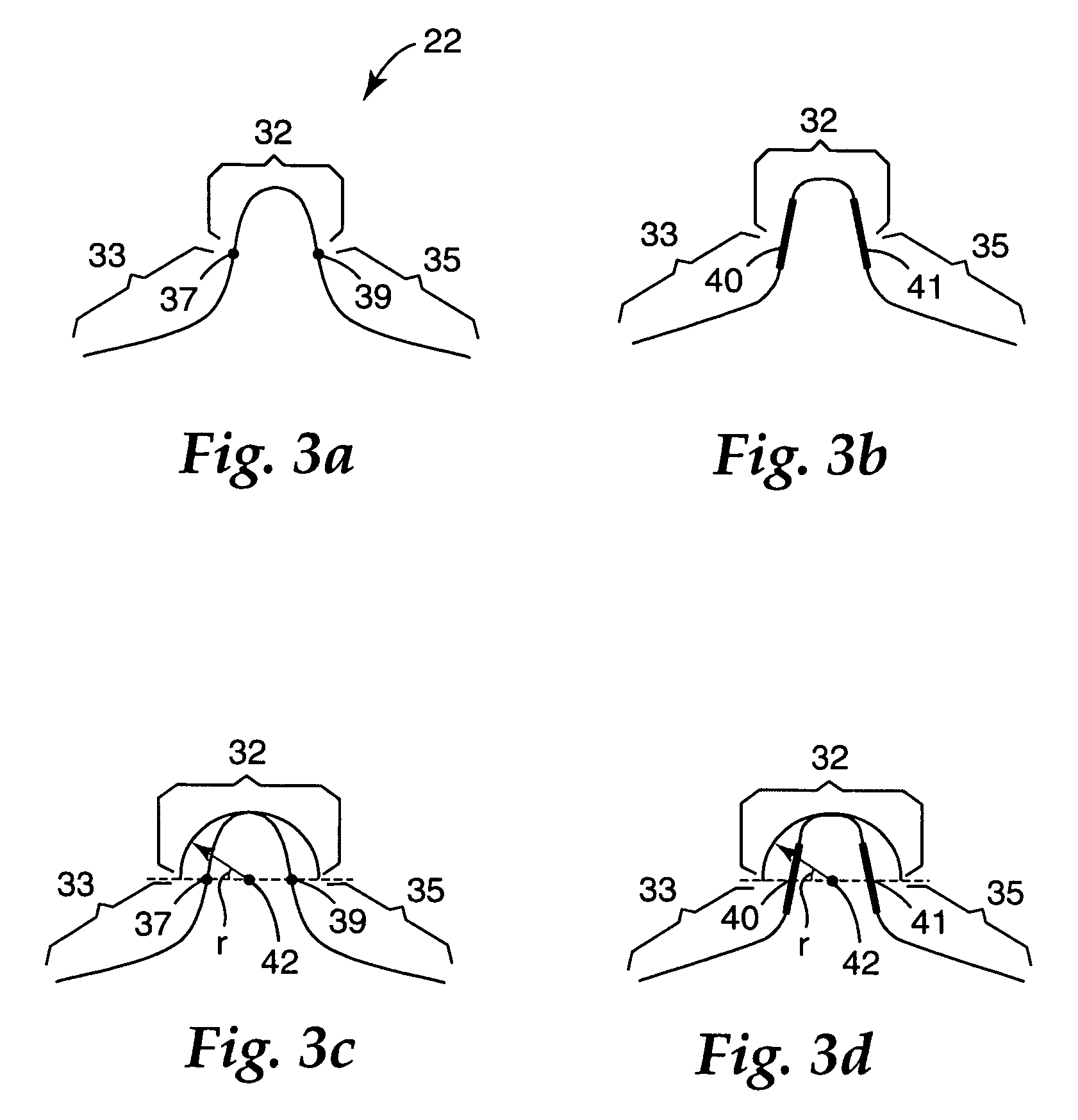

A respirator that includes a mask body and a nose clip. The mask body is adapted to fit over the nose and mouth of a person, and the nose clip is placed on the mask body to extend over the bridge of the wearer's nose when the mask is worn. The nose clip has a predefined shape that comprises first and second wings. These wings exert a force resiliently inward on each side of the wearer's nose when the mask is worn. The invention eliminates the need for the wearer to individually shape the nose clip to the wearer's nose.

Owner:3M INNOVATIVE PROPERTIES CO

Respirator having preloaded nose clip

A respirator that includes a mask body and a nose clip. The mask body is adapted to fit over the nose and mouth of a person, and the nose clip is placed on the mask body to extend over the bridge of the wearer's nose when the mask is worn. The nose clip has a predefined shape that comprises first and second wings. These wings exert a force resiliently inward on each side of the wearer's nose when the mask is worn. The invention eliminates the need for the wearer to individually shape the nose clip to the wearer's nose.

Owner:3M INNOVATIVE PROPERTIES CO

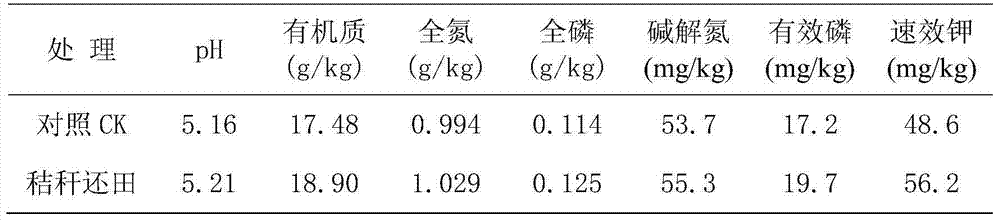

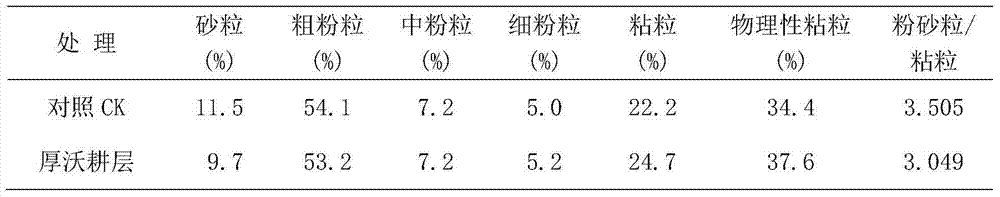

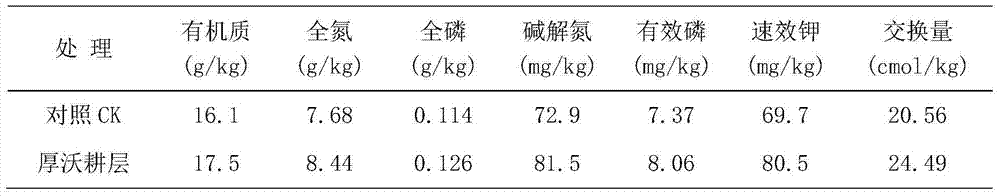

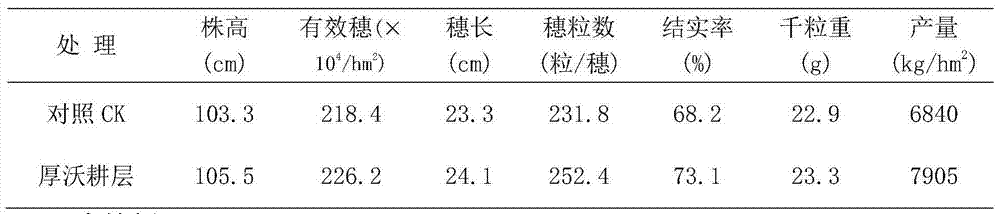

Simplified straw-returning-to-field method applicable to clay paddy fields

InactiveCN104488397AIncrease fertilizer and water retention performanceRapid decay degradationFertilising methodsSoil-working methodsField methodsDecomposition

The invention discloses a simplified straw-returning-to-field method applicable to clay paddy fields. The technique of wheat harvesting, straw smashing and directly returning to field, the technique of more nitrogen application for regulating carbon nitrogen ratio of straw, the technique of applying straw decomposition additives for quickening straw decomposition and degradation, the cultivation technique of subsoiling, burying and pressing the straw and improving the poor soil profile pattern of clay, the technique of field steeping, waterlogged compost and soil acidity regulation, the technique of soil preparation and optimum balanced rice fertilization and the like are integrated.

Owner:INST OF SOIL & FERTILIZER ANHUI ACAD OF AGRI SCI

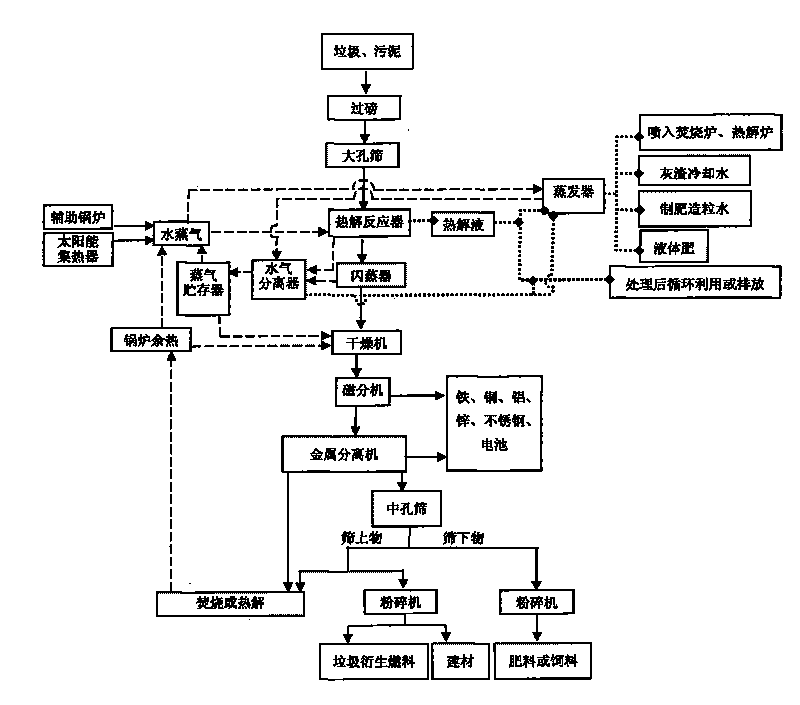

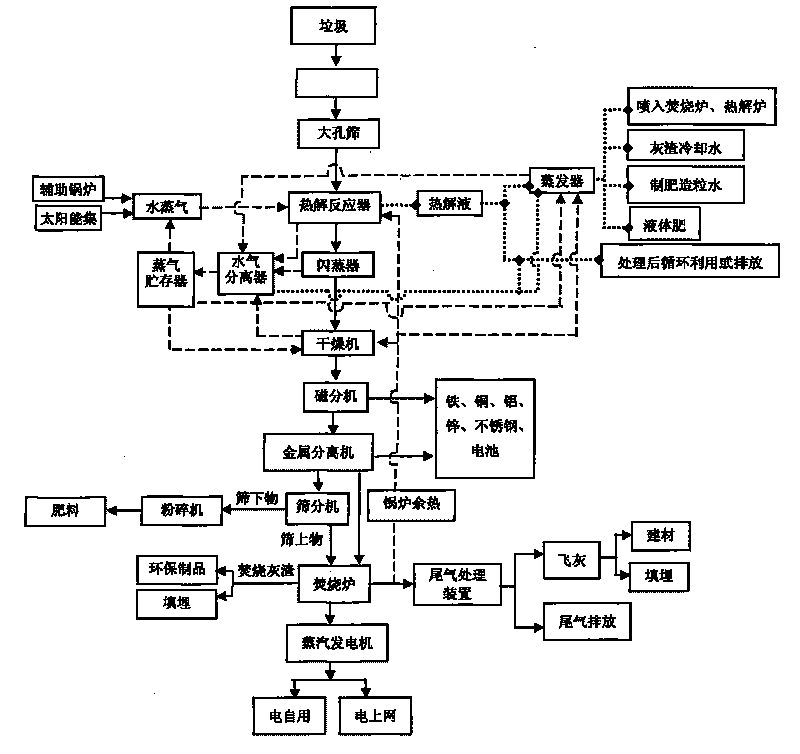

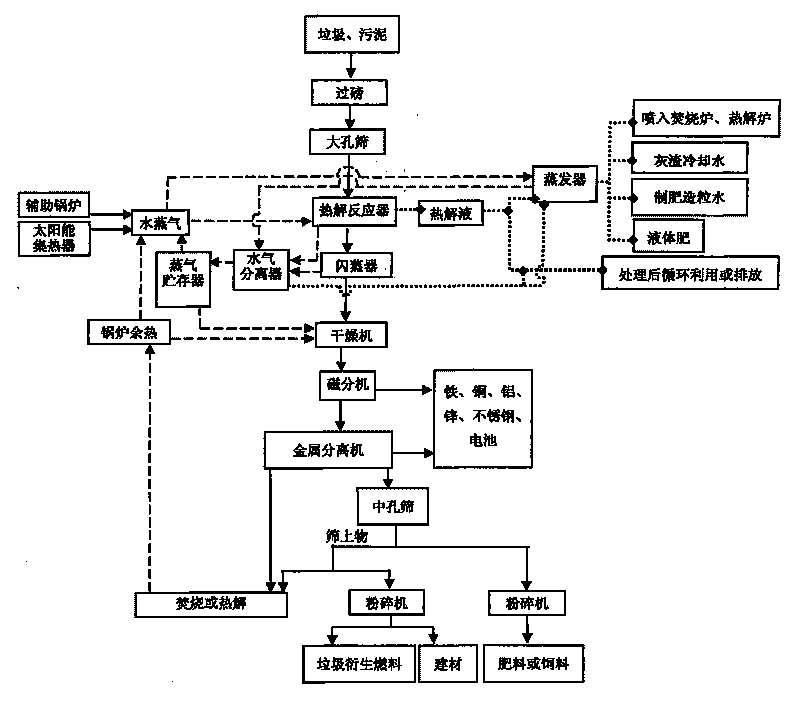

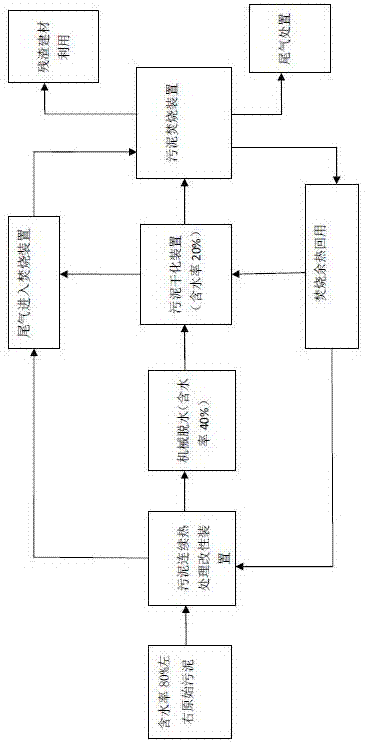

Garbage and sludge high pressure themolysis processing method, system and application thereof

ActiveCN101758059AReduce moisture contentReduce the chance of occurrenceSolid waste disposalSludge treatment by pyrolysisDecompositionSludge

The invention discloses a garbage and sludge high pressure themolysis processing method, system and application thereof. The invention carries out themolysis reaction for 5min-1.5h under the conditions of 8-80atm and 150-320 DEG C and three times of dehydration drying, not only heat value of garbage and sludge is greatly improved, dehydration, benzene removing, dechloridation, deodorization, disinfection, sterilization, volume reduction, bag breaking and degradation decomposition are carried out on garbage and / or sludge and percolation liquid is treated, and clean energy and recycled self-circulation heat are taken as heat supply energy source, energy consumption is reduced; but also method in material is rejected, so as to reduce the production probability of dioxin in garbage incineration smoke. The invention realizes garbage and sludge comprehensive reclamation, including power supply, heat supply, production of multiple organic compound fertilizers and environmentally friendly building materials and direct recovery of metal, battery and plastic. The invention can realize preparation of garbage and sludge organic compound fertilizer and feed, pre-treatment of garbage incineration generating and pre-treatment of garbage themolysis generating and has the characteristics of environmental protection, energy conservation and wide application range.

Owner:SOUTH CHINA AGRI UNIV

Waste removal method for dry toilets

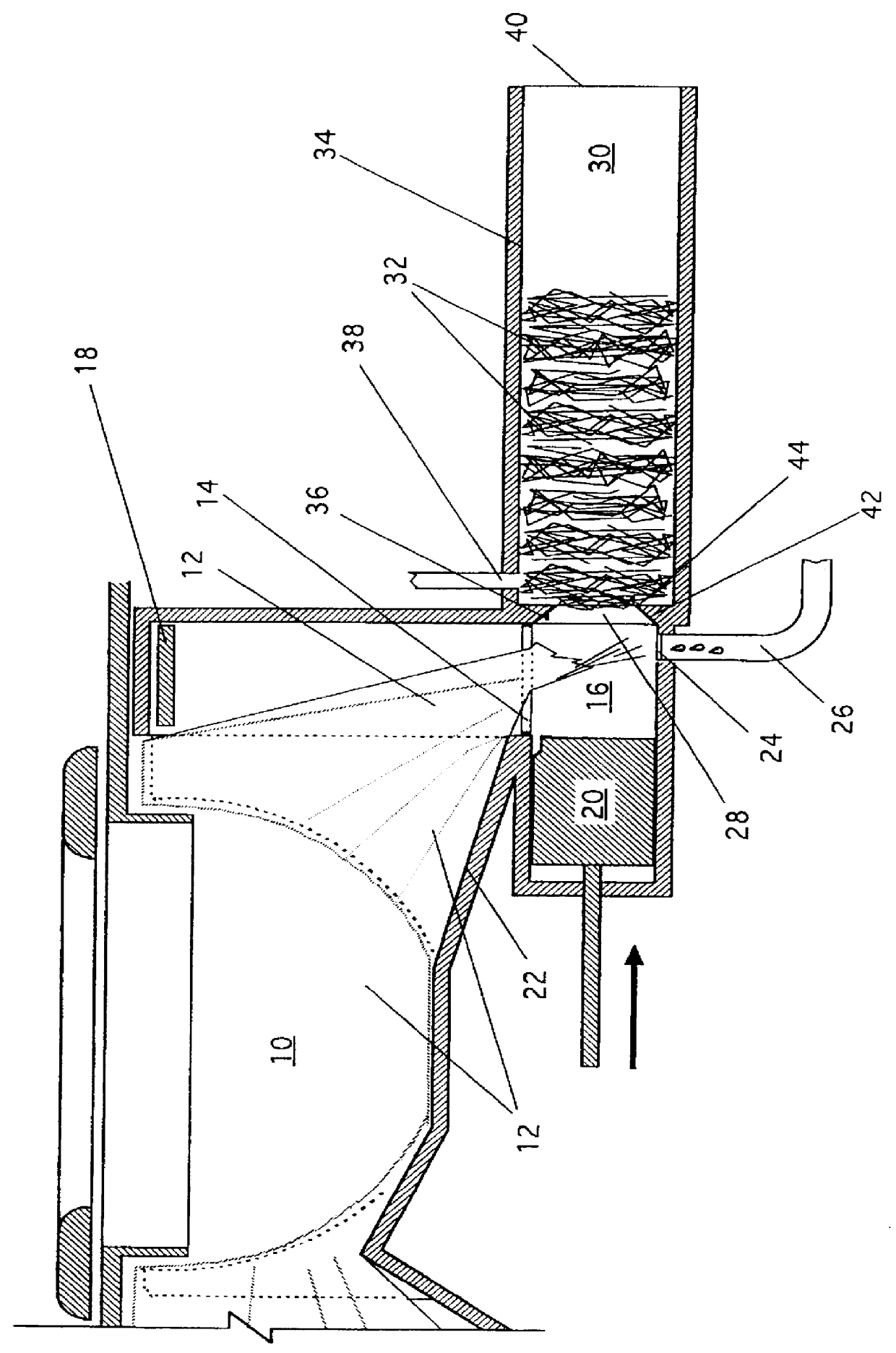

InactiveUS6101641ATransmission easilyWithout usingBathroom accessoriesAgainst vector-borne diseasesFlush toiletWaste management

PCT No. PCT / US97 / 16787 Sec. 371 Date Mar. 26, 1999 Sec. 102(e) Date Mar. 26, 1999 PCT Filed Sep. 22, 1997 PCT Pub. No. WO98 / 14106 PCT Pub. Date Apr. 9, 1998A system for the removal of waste from dry toilet bowls (10) and other containers adapted to have a disposable liner sheet (12) comprising an apparatus (16, 18, 20, 36) for forming elastic wads (32) from lengths of liner sheet (12) containing waste and for inserting the wads through a port (28) into a pipe (34), and an arrangement (38) for introducing air pressure into the pipe near the port to propel the wads along the pipe toward the exit (40).

Owner:HAWKINS ROBERT D +1

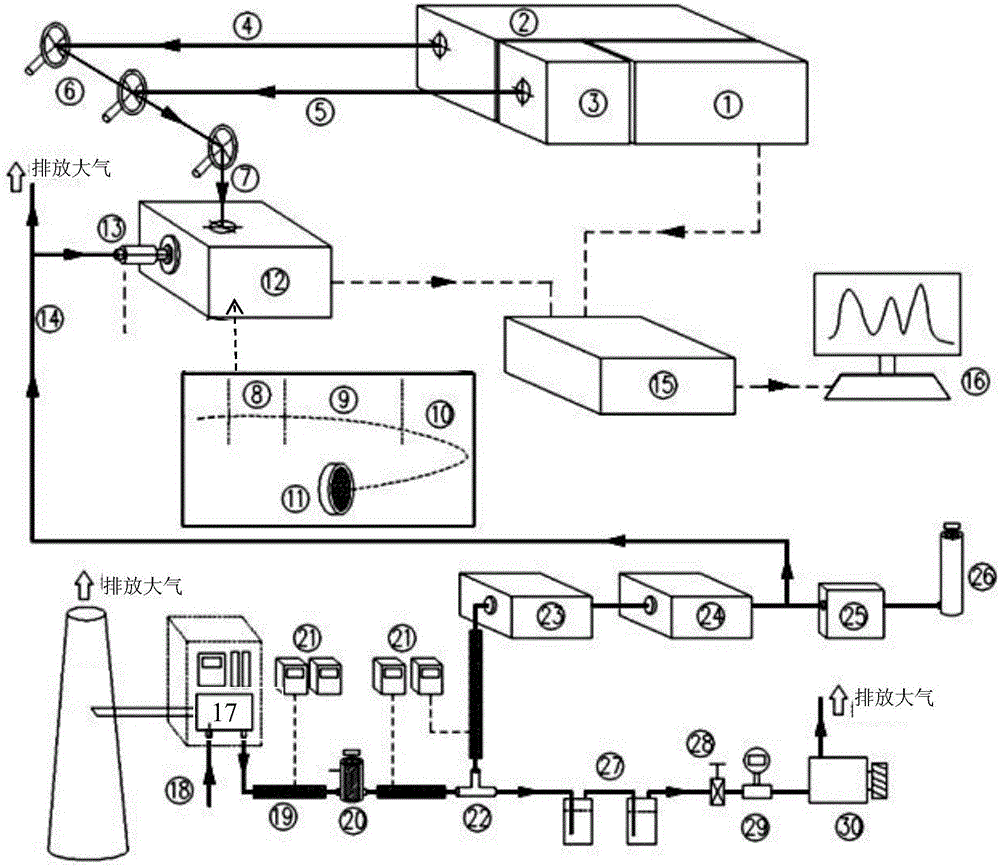

System for on-line detection of dioxin type trace organic pollutants in actual smoke

ActiveCN105954441ARespond quicklyRapid and timely discharge concentrationComponent separationBottleMass spectrometric

The invention relates to a trace organic pollutant detection technology and aims at providing a system for on-line detection of dioxin type trace organic pollutants in actual smoke. A sampling device of the system is connected with a thermal desorption instrument and a sampling pump module respectively through a pipeline, and a heat tracing pipeline is arranged on the pipeline. A laser device can simultaneously output two types light beams of deep ultraviolet wavelength and tunable ultraviolet visible waveband, an optical lens set is arranged between a flight time mass spectrometer and the laser device, two beams of laser are combined and then enter a laser window of the flight time mass spectrometer. A sample inlet pipeline of the flight time mass spectrometer is connected with a calibration gas storage bottle and the thermal desorption instrument respectively. The system integrates a thermal desorption technology and flight time mass-spectrometric technique, overcomes the shortcomings of a sample detection technology, can rapidly reflect the dioxin discharge concentration of smoke in time and is high in precision and large in information amount. The system composition can be adjusted according to actual demands, the adaptation can be improved. Detection results can represent the combustion conditions in a furnace, and the incineration process control can be optimized.

Owner:浙江富春江环保科技研究有限公司

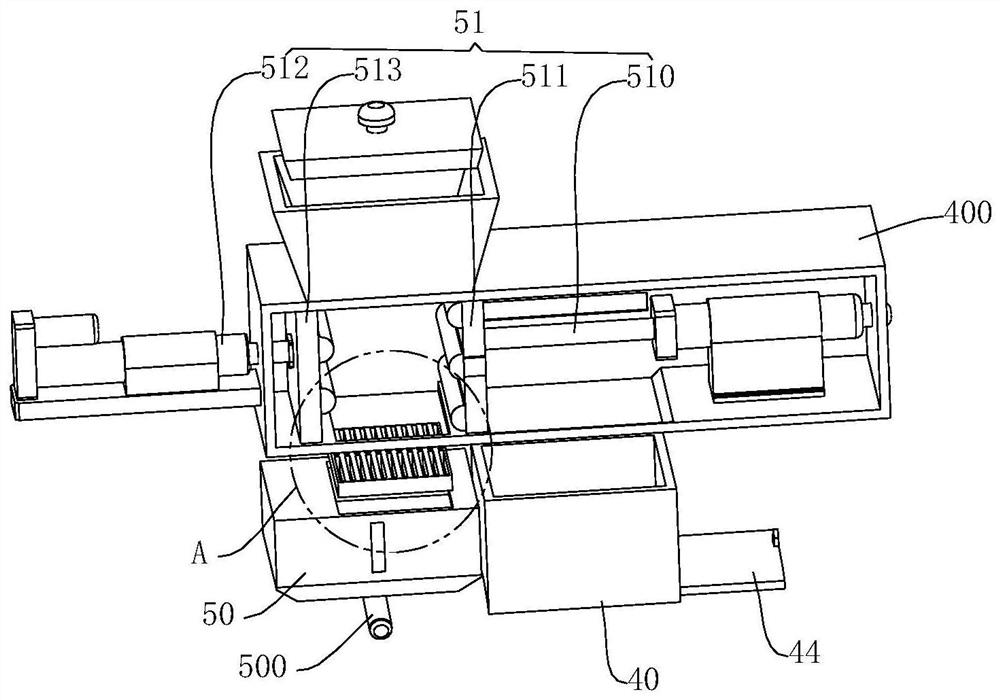

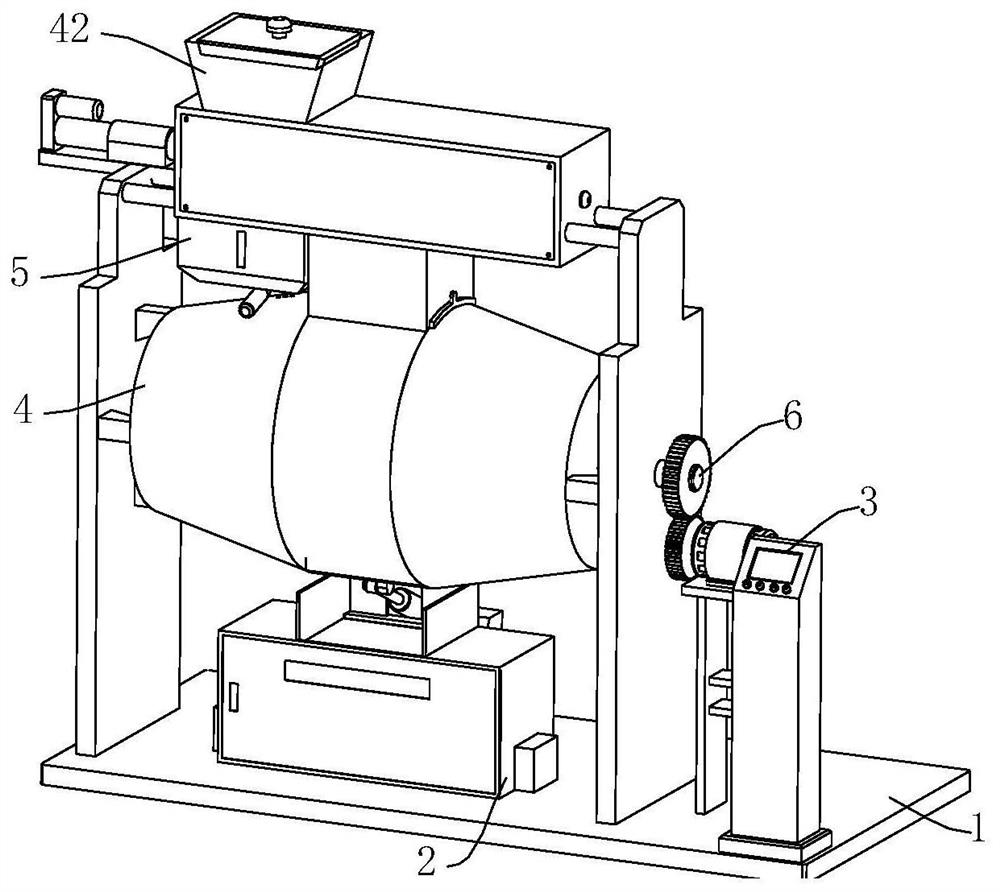

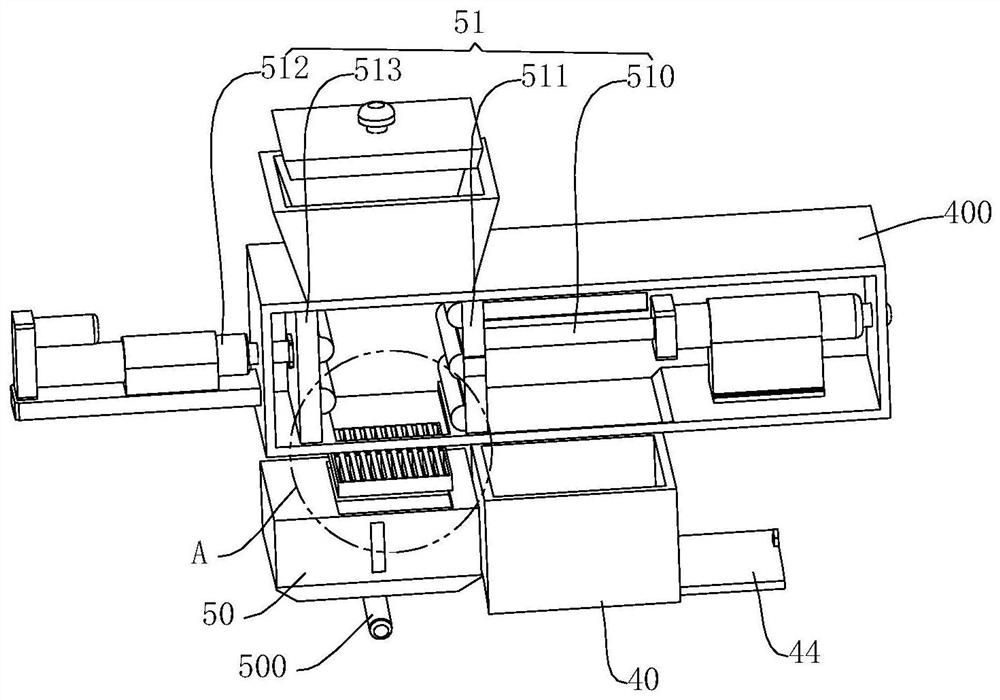

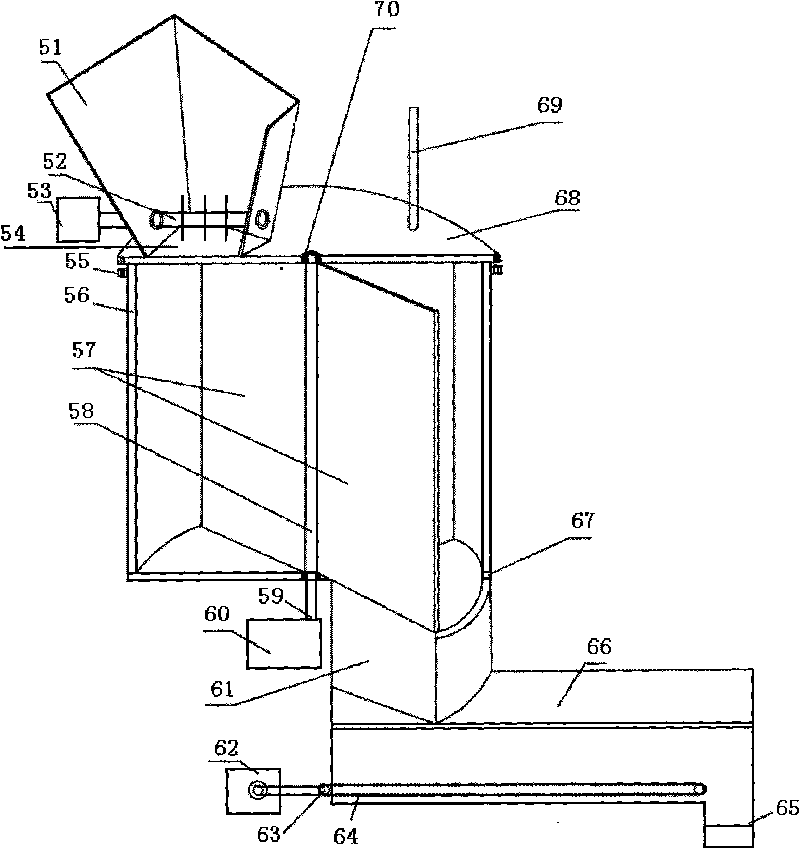

Use method of environment-friendly wet garbage treatment and recovery device

InactiveCN111623605AAvoid missingImprove the efficiency of entering the processing bucketDrying solid materials with heatDrying solid materials without heatProcess engineeringSewage

The invention relates to the field of organic garbage treatment devices, in particular to a use method of an environment-friendly wet garbage treatment and recovery device. The environment-friendly wet garbage treatment and recovery device comprises a base, a collection box, a controller, a processing barrel, a dehydration mechanism and a drying mechanism. A blanking channel is formed in the top of the processing barrel. The top of the blanking channel is fixedly connected with a rectangular box. The dehydration mechanism comprises a sewage tank and an extrusion component. The drying mechanismis arranged inside the processing barrel to dry crushed wet garbage. The drying mechanism comprises a rotating shaft, a crushing component, and two heating components. The extrusion component, the crushing component and the heating components are electrically connected to the controller. According to the use method of the environment-friendly wet garbage treatment and recovery device, water in the garbage is extruded and does not remain inside the device, so as to facilitate subsequent crushing and fully dry the garbage.

Owner:郭弘

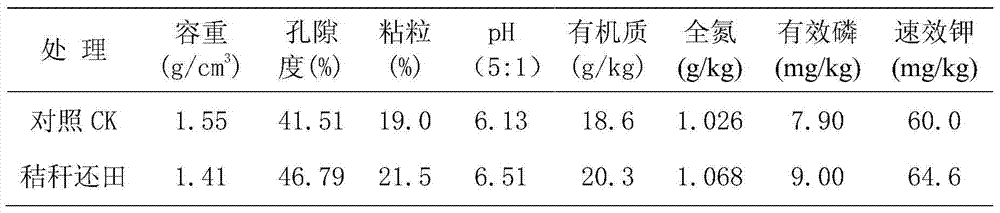

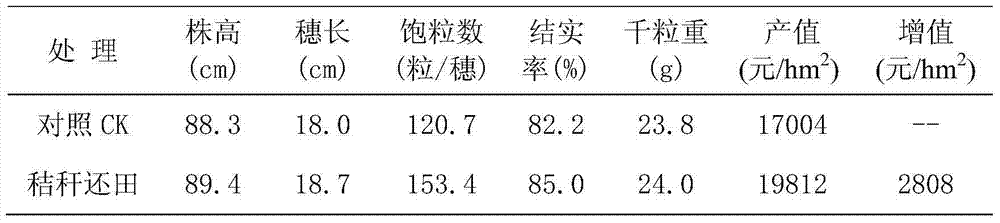

Method for deepening and fertilizing middle-low yield argil rice field plough layer

InactiveCN104718837AImprove fertilityDeepen the thicknessSoil-working methodsHazardous substancePhysics

The invention discloses a method for deepening and fertilizing a middle-low yield argil rice field plough layer in the hilly areas of south China. The technology for direct wheat straw field return for soil improvement, the technology for applying organic fertilizer, curing the plough layer and improving soil fertility, the technology for deeply ploughing soil to transform the bad soil structure of middle-low yield argil, the technology for applying a soil conditioner to neutralizing hazardous substances, the technology for rice optimization fertilizer application and nitrogenous fertilizer operation management for soil nutrient balance, the technology for improving the soil nutrient deficiency condition and recovering soil fertility through scientific crop rotation and the like are integrated.

Owner:INST OF SOIL & FERTILIZER ANHUI ACAD OF AGRI SCI

Conditioner for sludge dehydration and conditioning method

ActiveCN102001814ALow costEasy accessSludge treatment by de-watering/drying/thickeningCoal gangueIron salts

The invention discloses a conditioner for sludge dehydration. Based on the dry weight of the sludge to be treated, the formula of the conditioner contains 10 to 20 percent of iron salt, 10 to 20 percent of burnt lime, 10 to 20 percent of coal gangue and 0.01 to 0.05 percent of potassium permanganate bactericide. The invention also discloses a conditioning method for the conditioner for the sludge dehydration, which comprises the following steps of: adding the potassium permanganate bactericide into the sludge to be treated at normal temperature under normal pressure, treating the sludge for at least 2 minutes with stirring, and then adding the iron salt to react for at least 2 minutes; and then adding the burnt lime to adjust the pH value to be neutral, reacting the mixture for at least 2 minutes, adding the coal gangue to react for at least 2 minutes, and finally performing pressure filtration. The invention has the advantages of low cost, wide raw material source, no toxicity, environmental friendliness, short treatment time, high sludge dehydration degree and the like.

Owner:湖南多普生环境能源有限公司

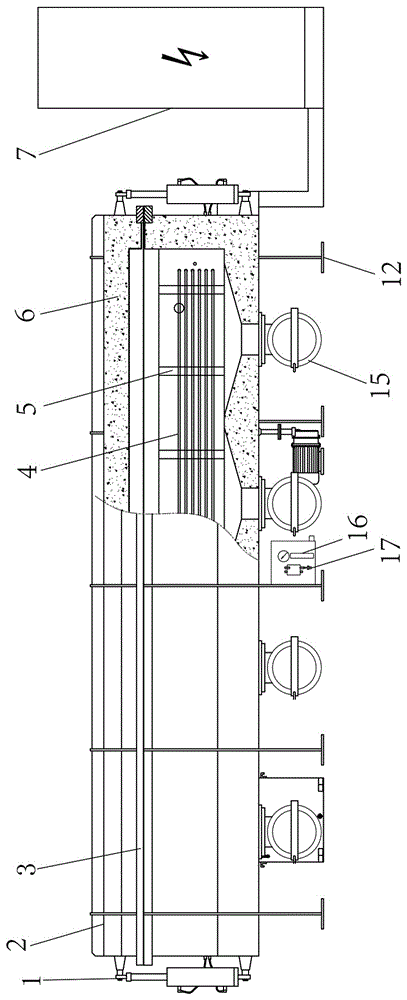

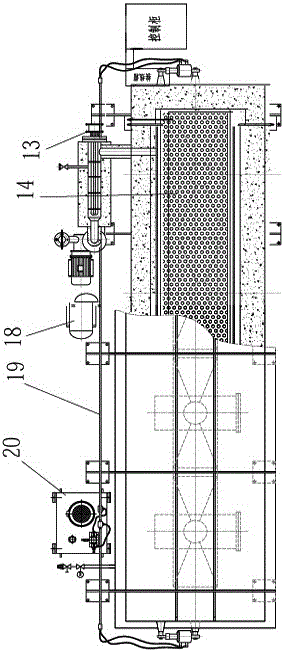

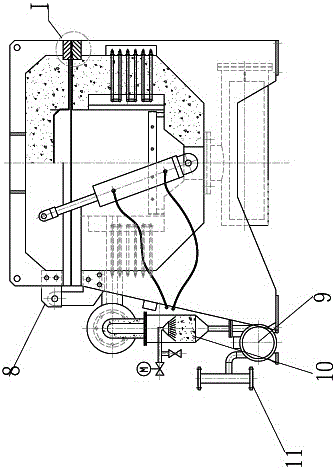

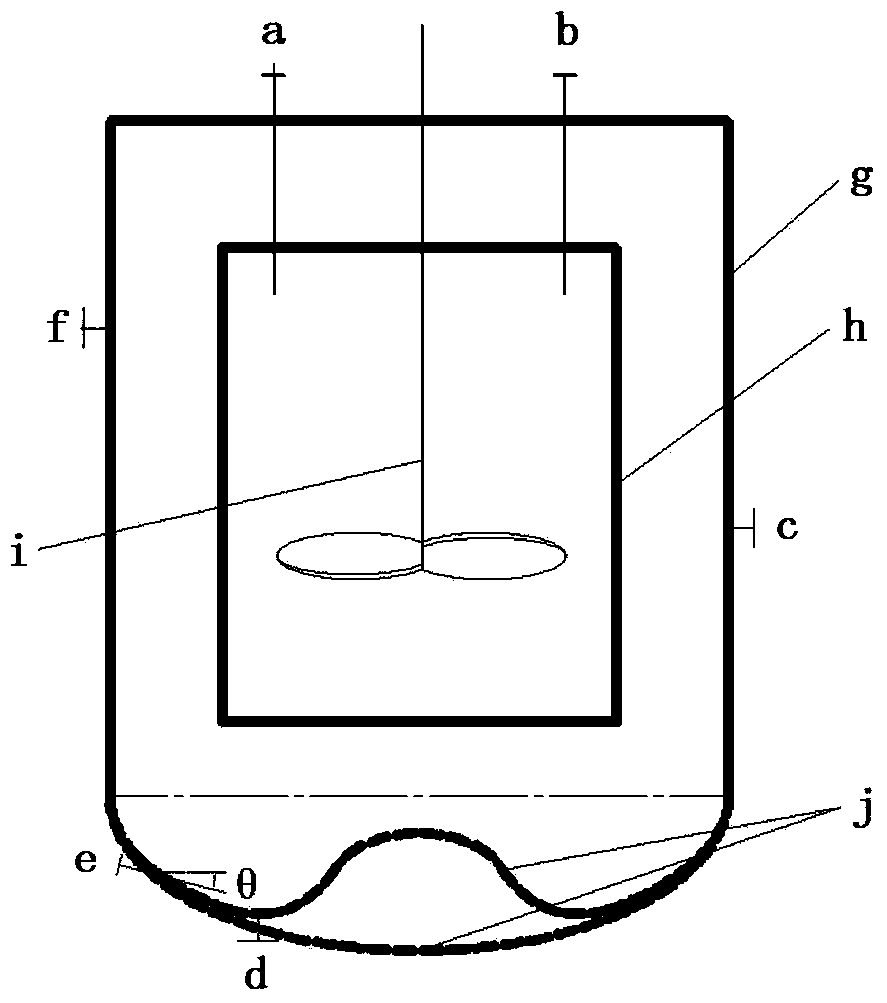

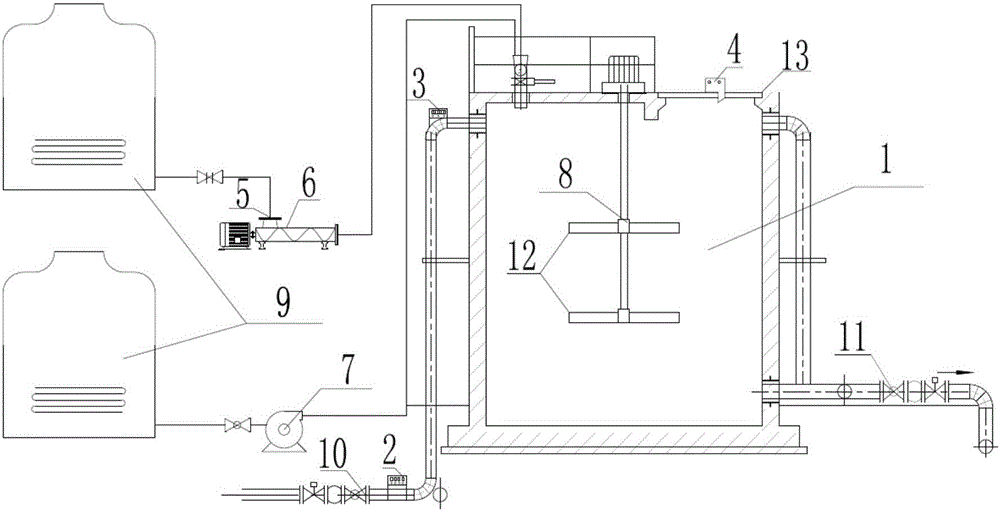

Vacuum incinerator device and operating method thereof

ActiveCN106091689AGuaranteed stabilityEasy to collectRemovable covers for furnacesSpinnerette packsTemperature controlControl system

The invention discloses a vacuum incinerator. The vacuum incinerator is a JZK-C well type vacuum incinerator and comprises a vacuum hearth, an incinerator cover opening and closing device, electric heating pipes, a waste collecting system, a vacuum pipeline anti-blocking device, a water spraying device, a water ring vacuum pump, a water backflow preventing device, a gas-water separator, a control system, a water circuit, an air circuit and the like, wherein the vacuum hearth is horizontally placed with an incinerator opening facing upwards and composed of an incinerator cover and a work room used for storing cleaned parts. The waste collecting system mainly comprises a waste collecting tank which is installed on the lower portion of the hearth. A hopper-shaped tray is arranged at the bottom of an inner cavity of the vacuum hearth. A discharging port of the tray is located over the waste collecting tank. Compared with the prior art, the vacuum incinerator is compact in structure, good in sealing performance and large in work space; the incinerator cover is opened and closed through two oil cylinders, the cover opening angle is larger than 90 degrees, and the opening and closing stability of the incinerator cover is guaranteed; waste can be collected conveniently, incineration and cleaning are conducted efficiently, and the situation of water backflow can be effectively prevented; and the automation level is high, temperature control is accurate, the working efficiency is improved, and the labor intensity is relieved.

Owner:JIANGSU XINLONG CHEM FIBER MACHINERY

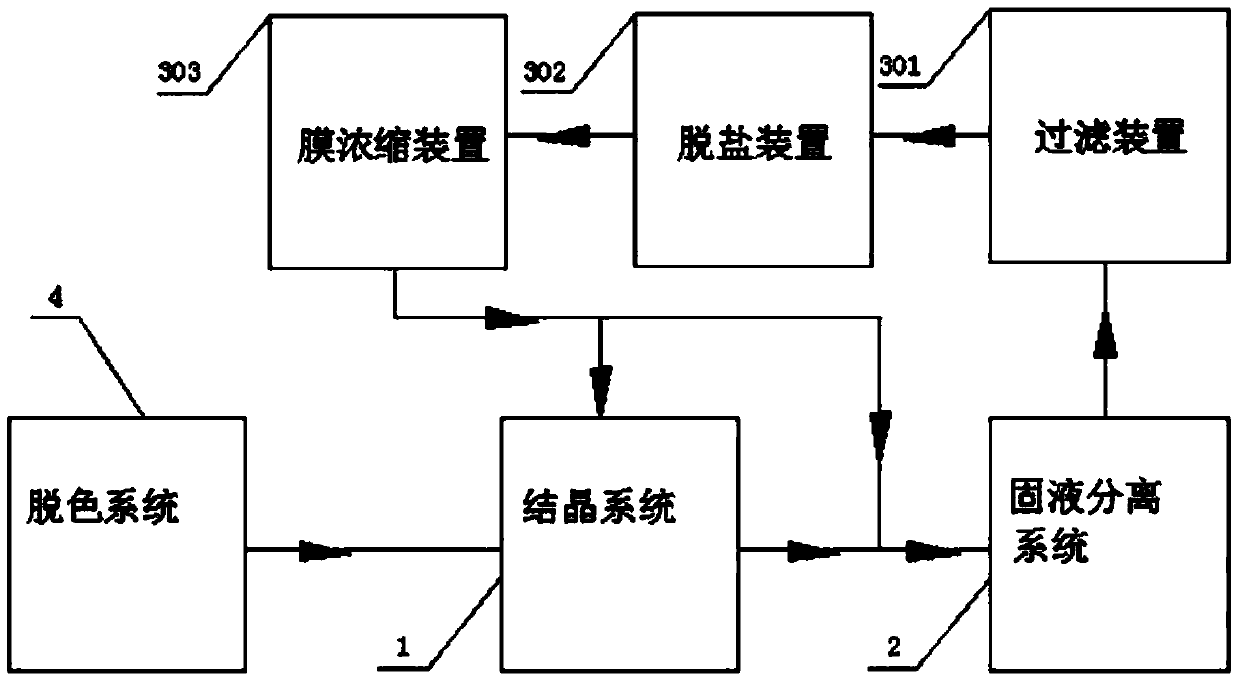

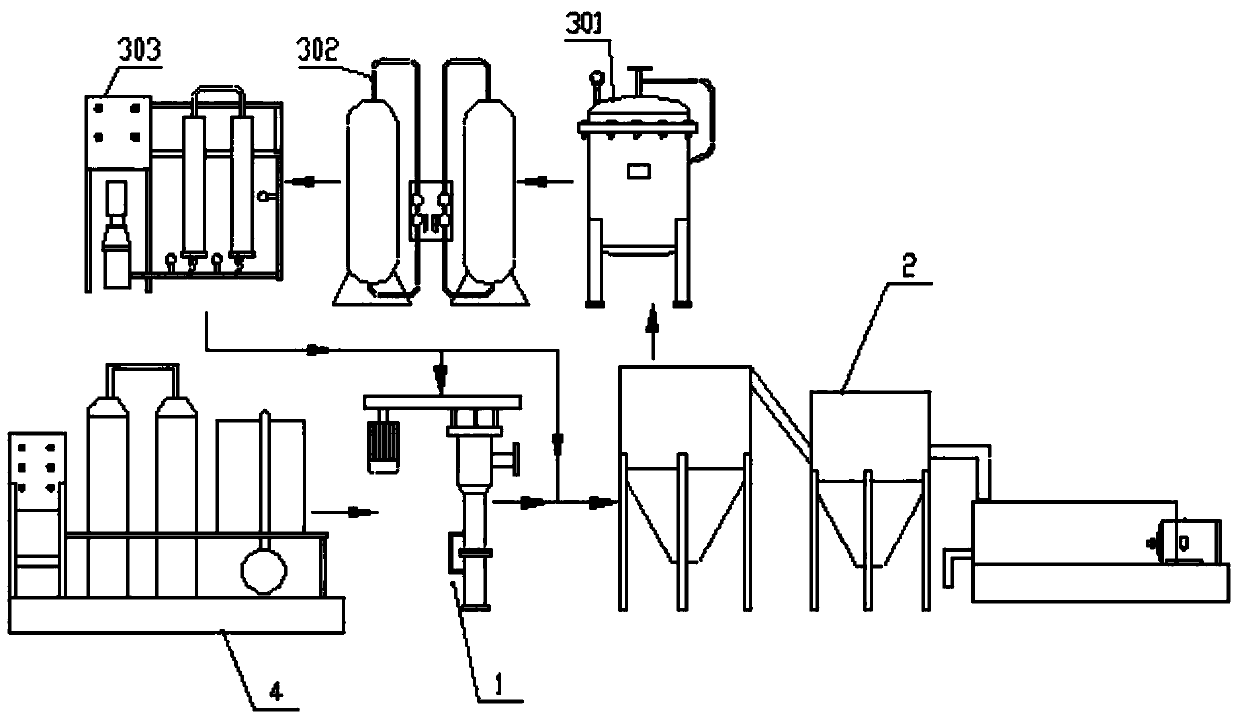

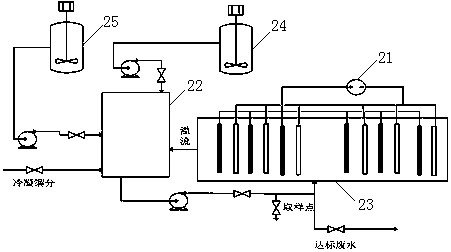

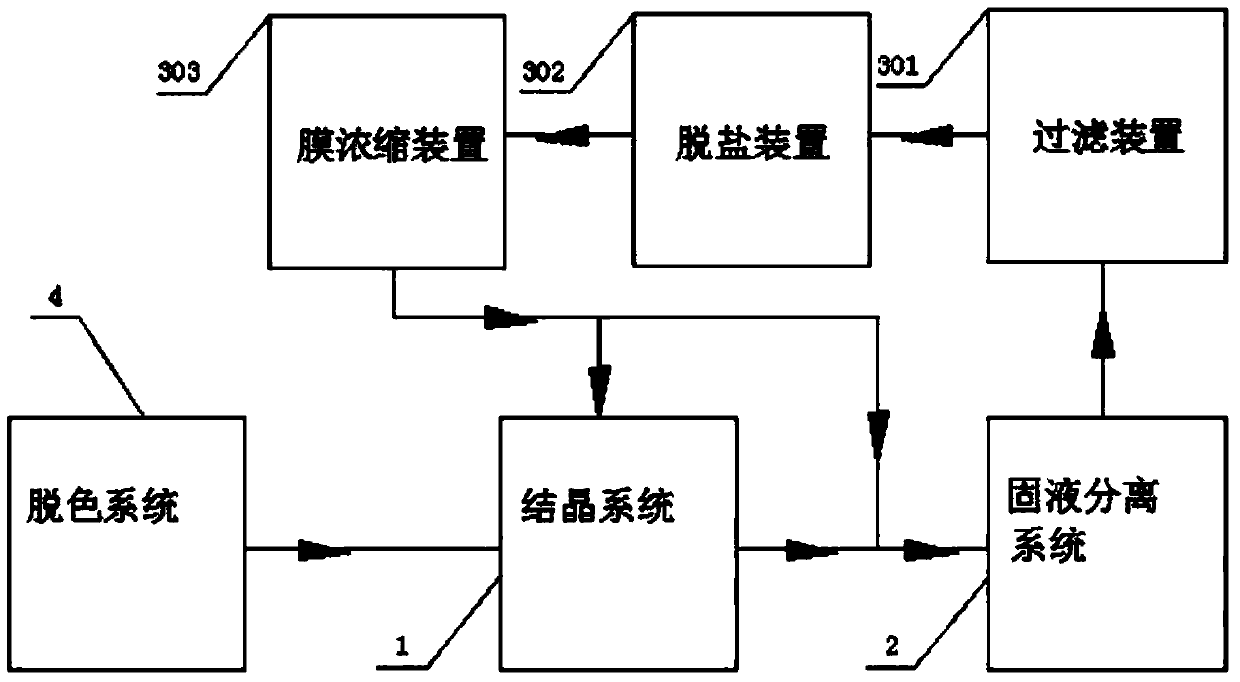

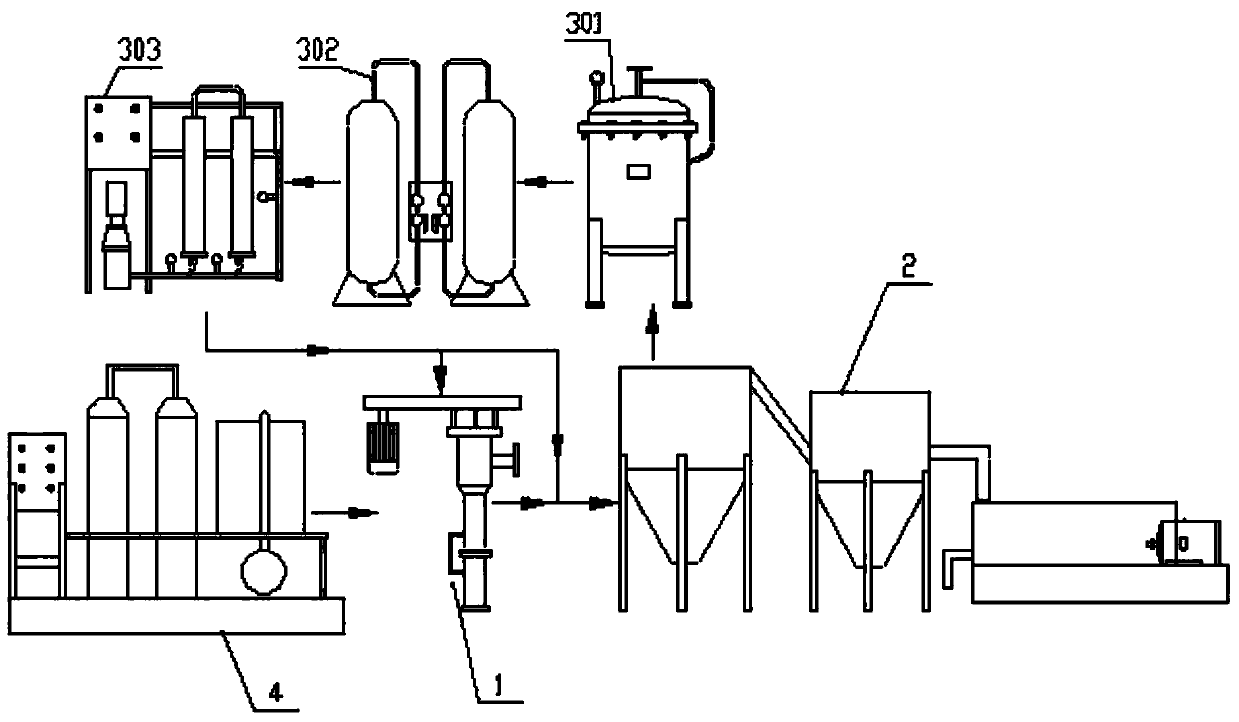

Separation and purification system of organic synthesis feed liquid and separation and purification method thereof

InactiveCN104174181AFull recoveryTake advantage ofGeneral water supply conservationMultistage water/sewage treatmentChemical industryPurification methods

The invention aims at the field of chemical industry and relates to a separation and purification system of organic synthesis feed liquid and a separation and purification method of the organic synthesis feed liquid. The separation and purification system comprises a crystallization system and a solid-liquid separation system which are sequentially arranged from front to back, wherein the crystallization system comprises a mixed suspension-mixed product-removal (MSMPR) crystallizer and a draft-tube-baffled (DTB) crystallizer which are connected with each other in series; the separation and purification system also comprises a liquid processing system used for processing waste liquid produced by the solid-liquid separation system; the liquid processing system comprises a desalting device and a membrane concentration device which are sequentially arranged from front to back. By virtue of the separation and purification system of the organic synthesis feed liquid and the separation and purification method thereof, the organic synthesis feed liquid is separated and purified by using a continuous crystallization technology, an electrodialysis technology and a membrane separation and concentration technology; the produced waste liquid is fully recycled and used, so that the separation and purification efficiency is improved, the purity and the yield of products are improved and the discharge of the waste liquid is reduced; the separation and purification system of the organic synthesis feed liquid and the separation and purification method thereof are strong in production industrialization and low in costs, and are especially suitable for producing iminodiacetonitrile.

Owner:CHONGQING UNISPLENDOUR CHEM

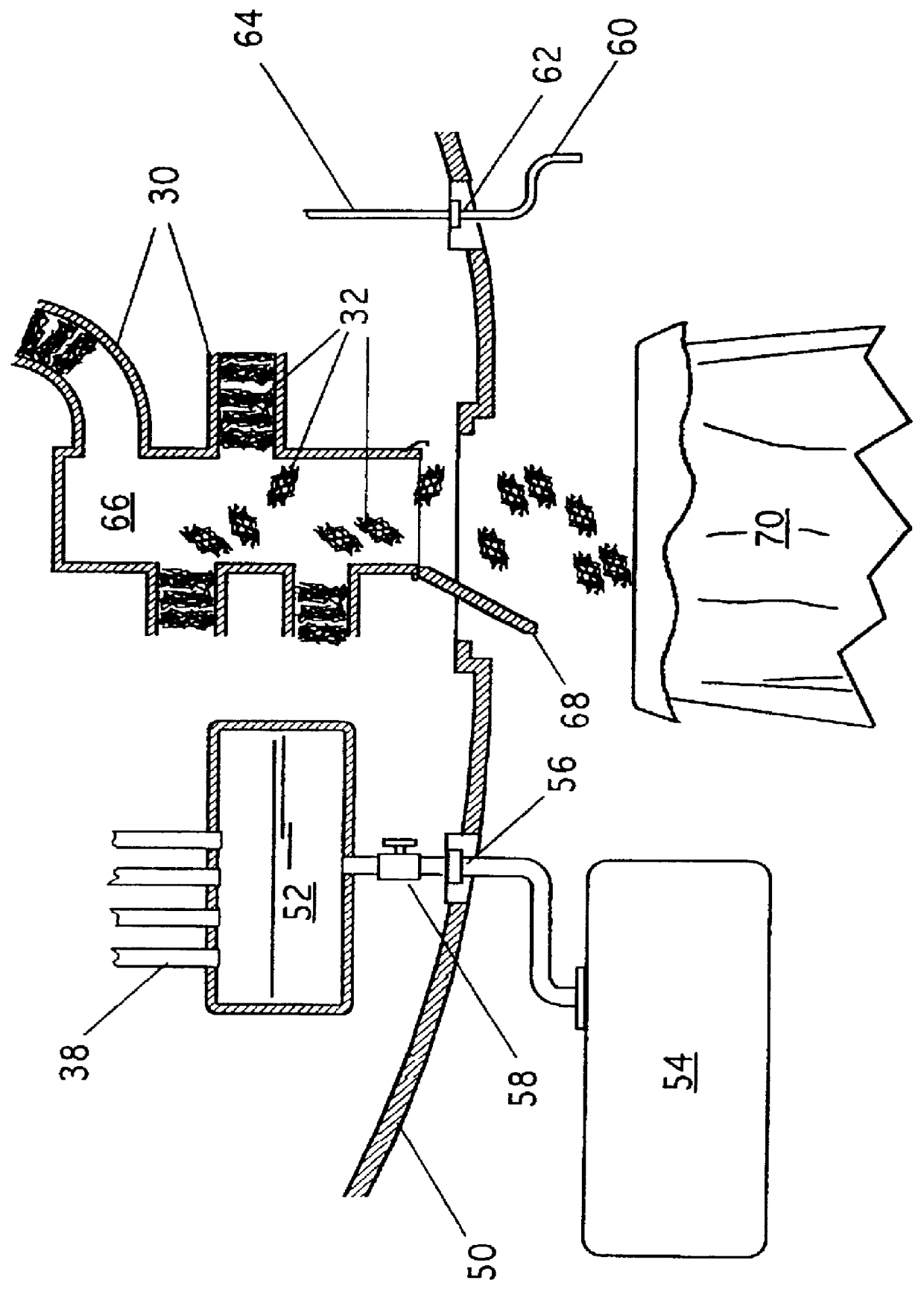

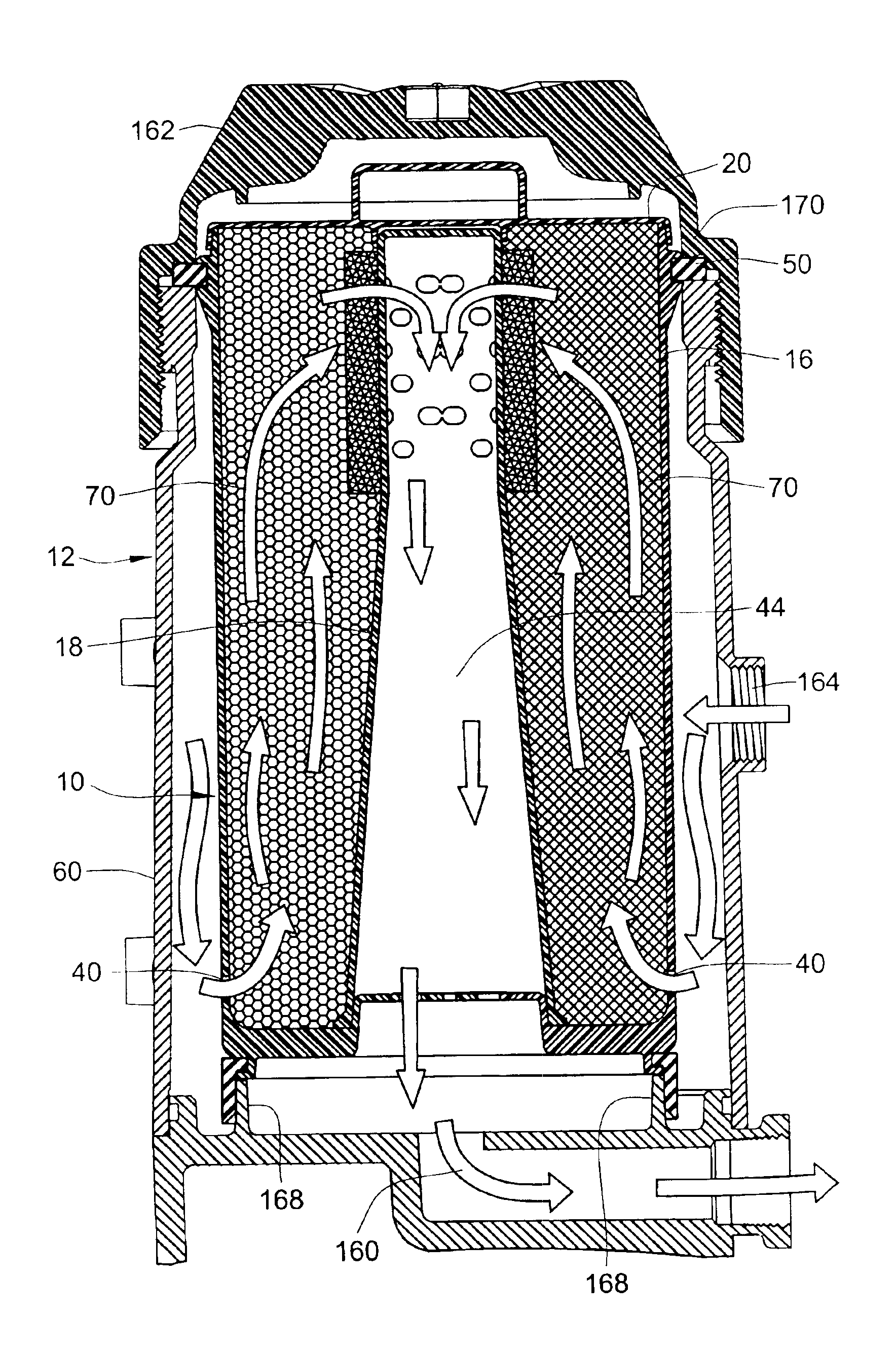

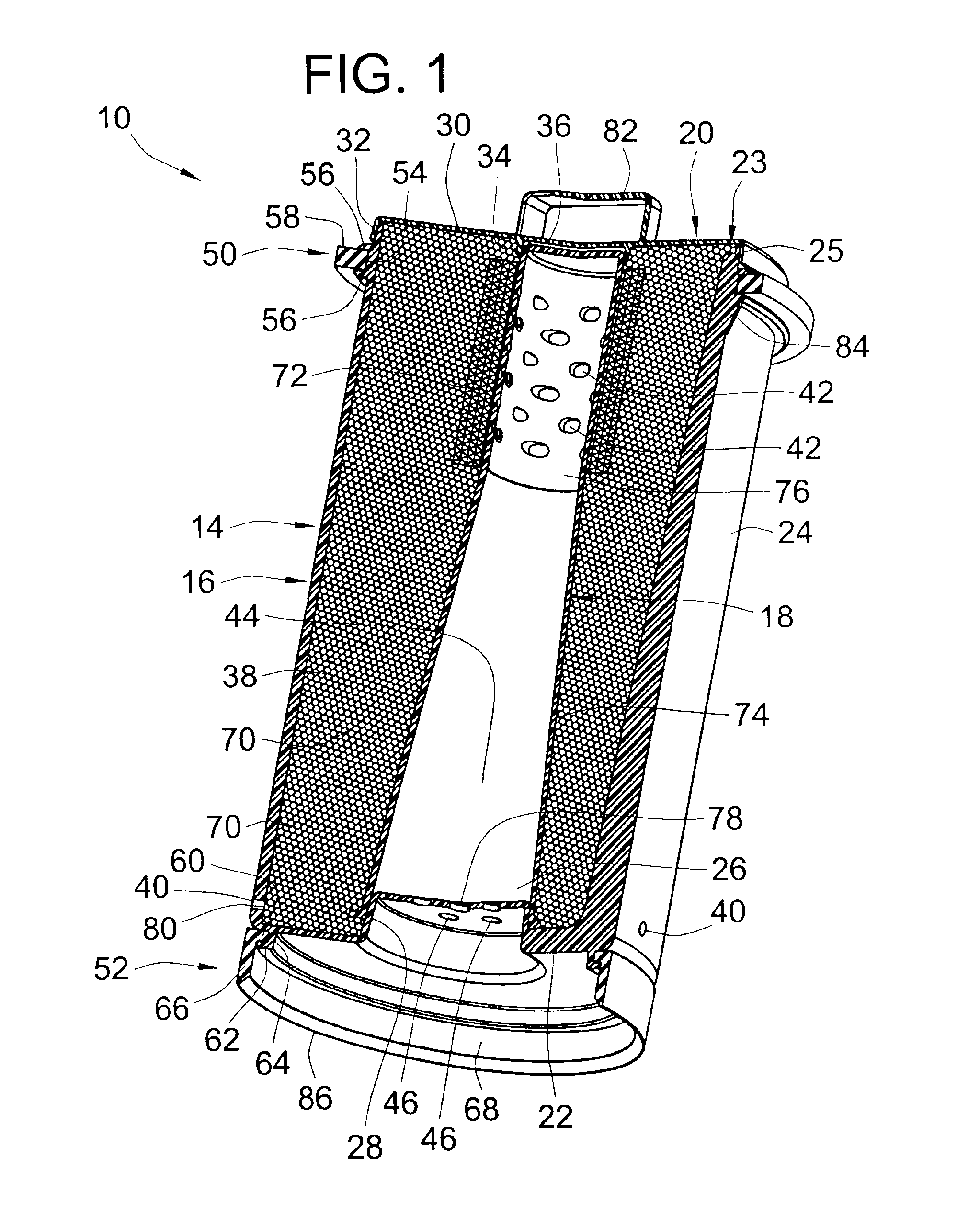

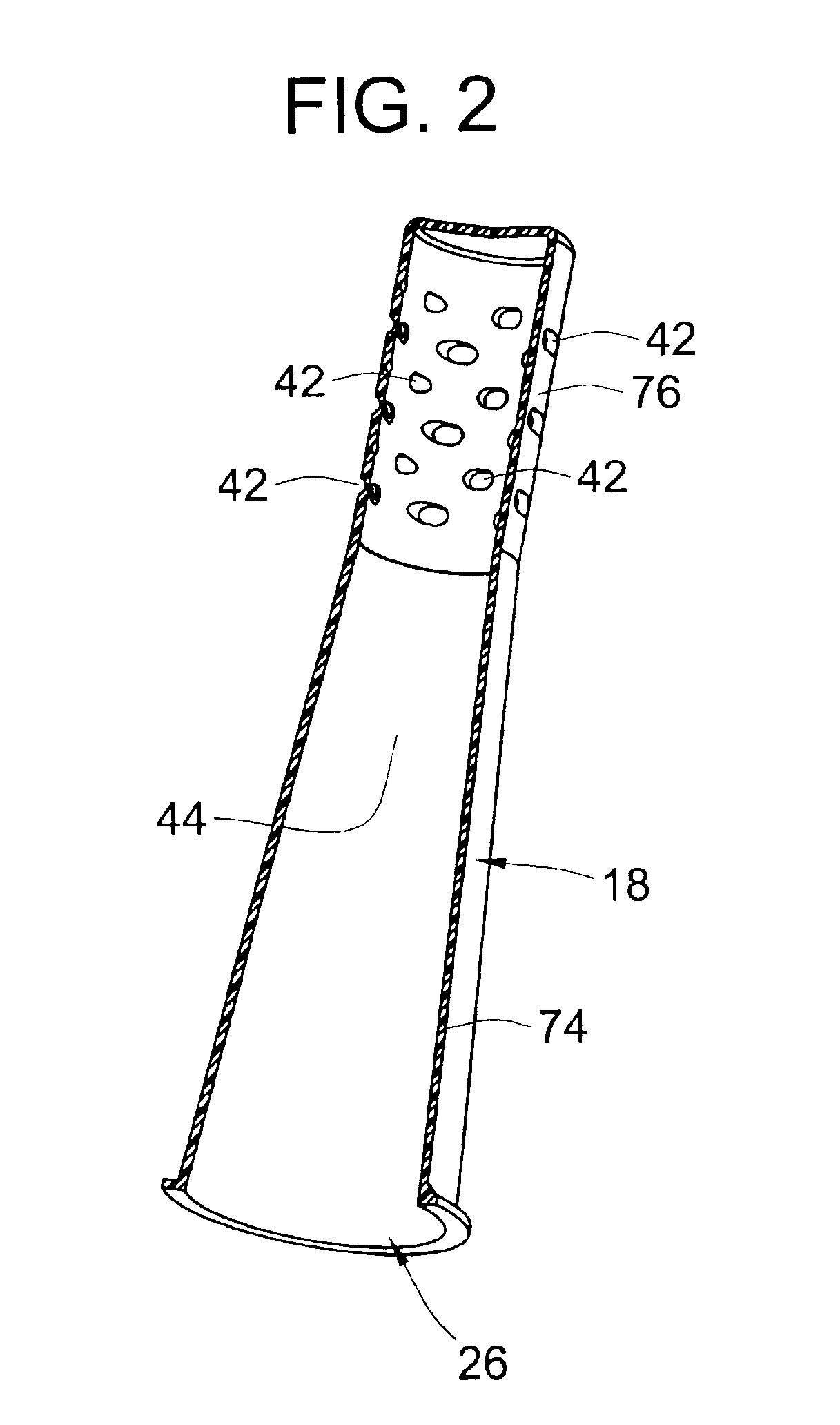

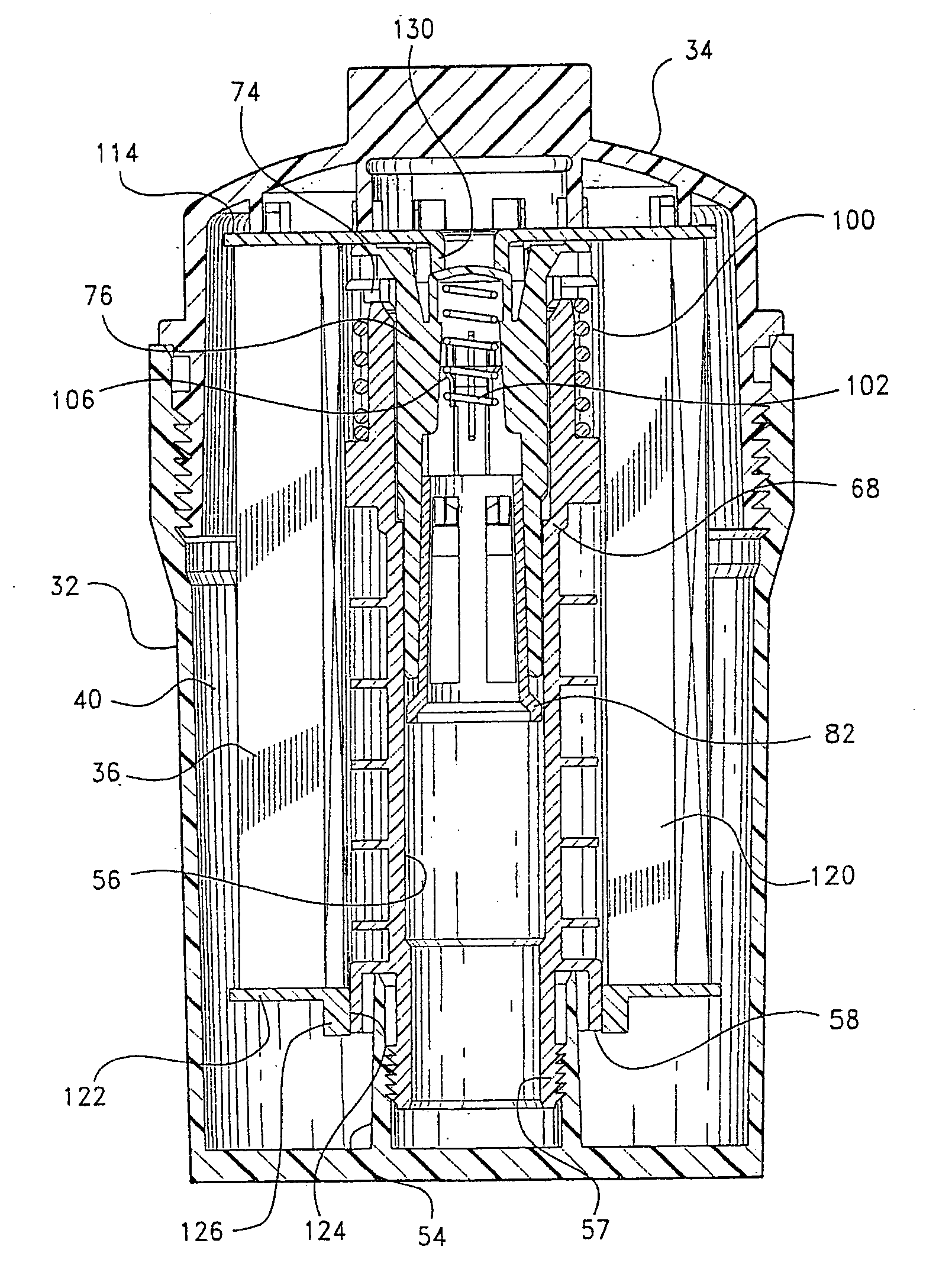

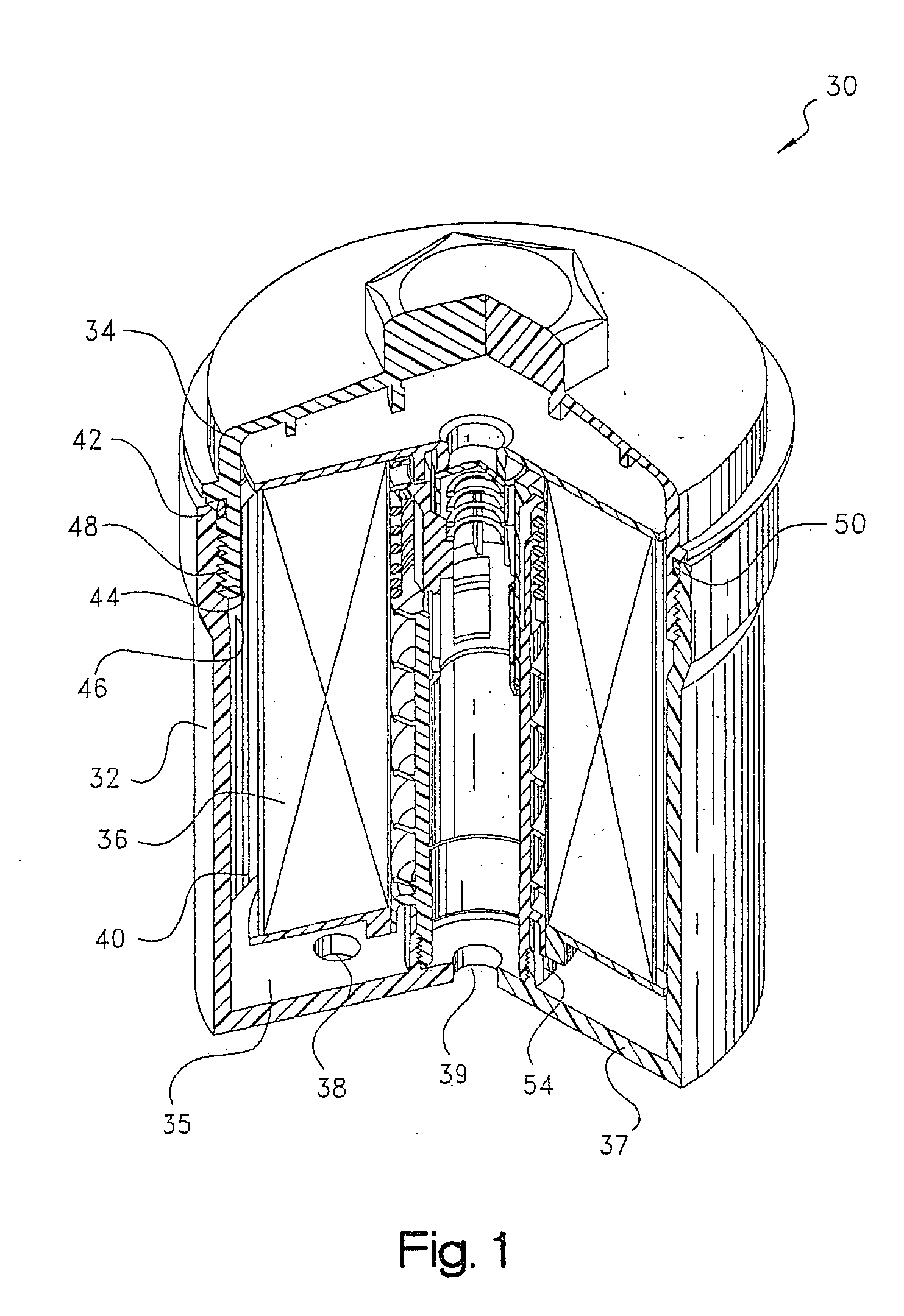

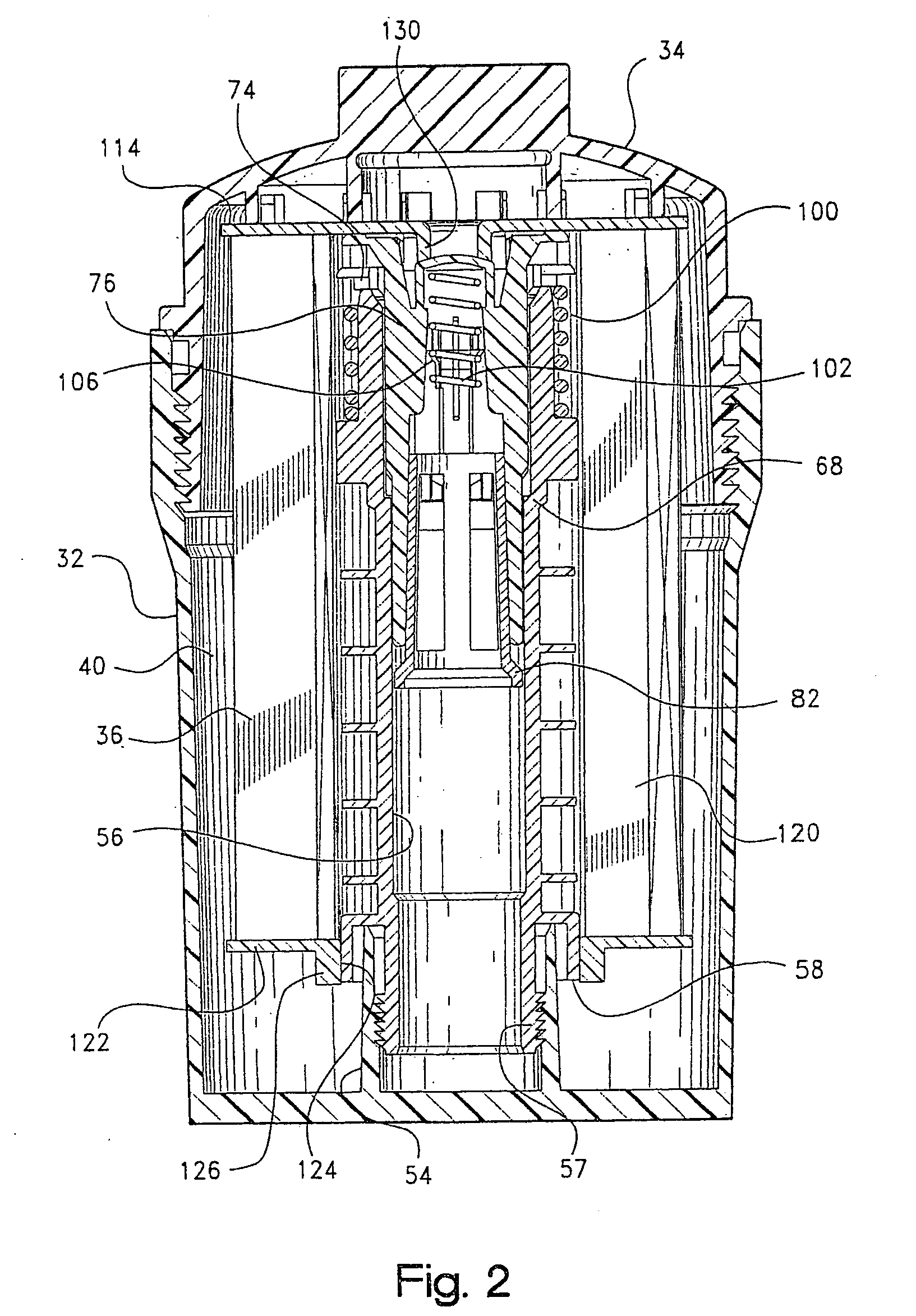

Environmentally friendly acid neutralizing cartridge

An environmentally friendly acid neutralizing filter cartridge for mounting into a chamber of a cartridge mounting body for neutralizing acid in engine oil in an oil circulation circuit of an engine. The environmentally friendly acid neutralizing filter cartridge comprises a support housing comprising substantially no metal parts such that the environmentally friendly acid neutralizing filter cartridge can be readily incinerated. The support housing comprises at least one inlet port and at least one outlet port. A bed of acid neutralizing particles is contained in the support housing between the inlet port and the outlet port. Means is provided for preventing acid neutralizing particles from flowing through the at least one outlet port. An annular seal is arranged externally on the support housing and separates the at least one inlet port and the at least one outlet port to prevent oil from short circuiting the bed of acid neutralizing particles.

Owner:BALDWIN FILTERS

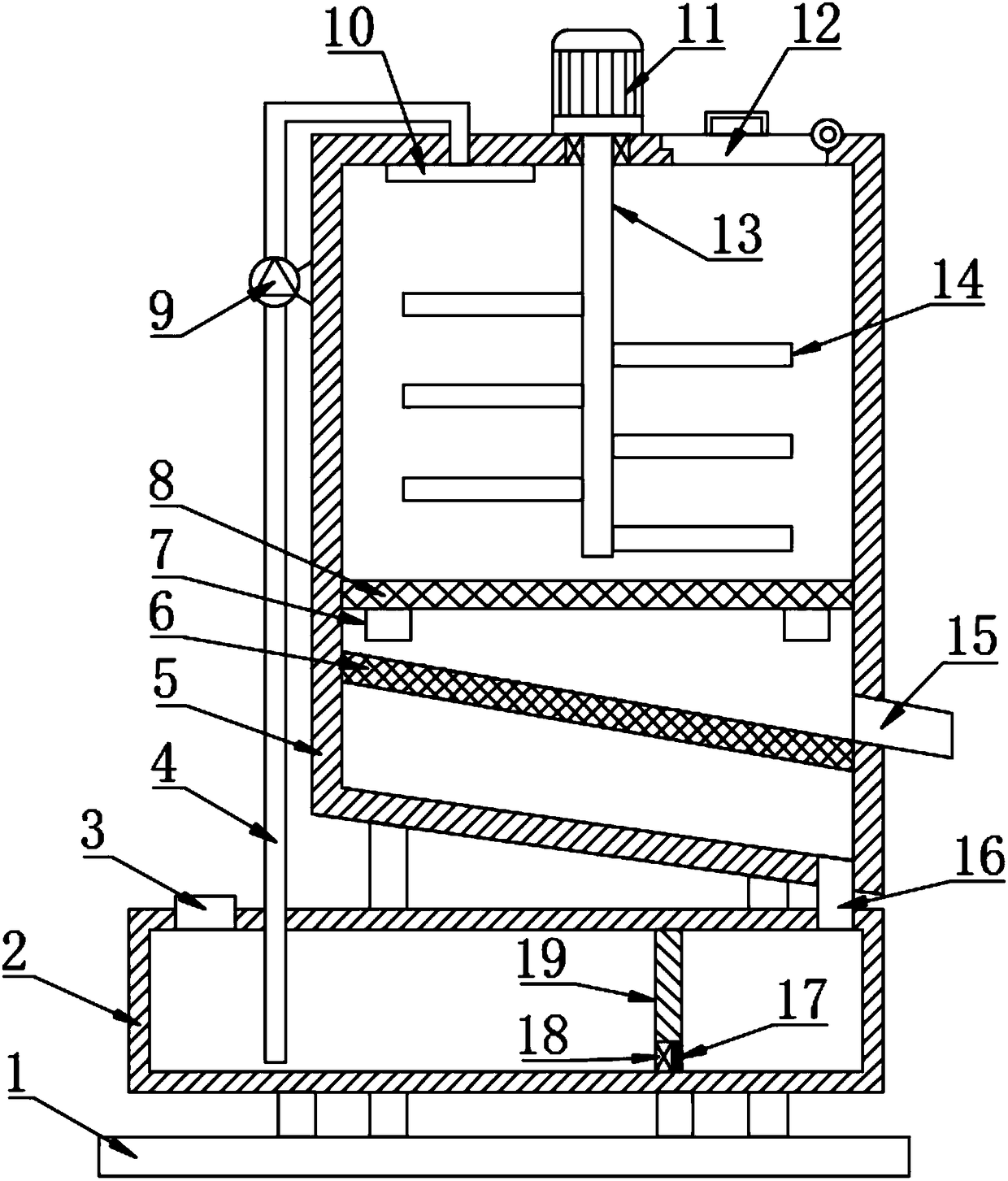

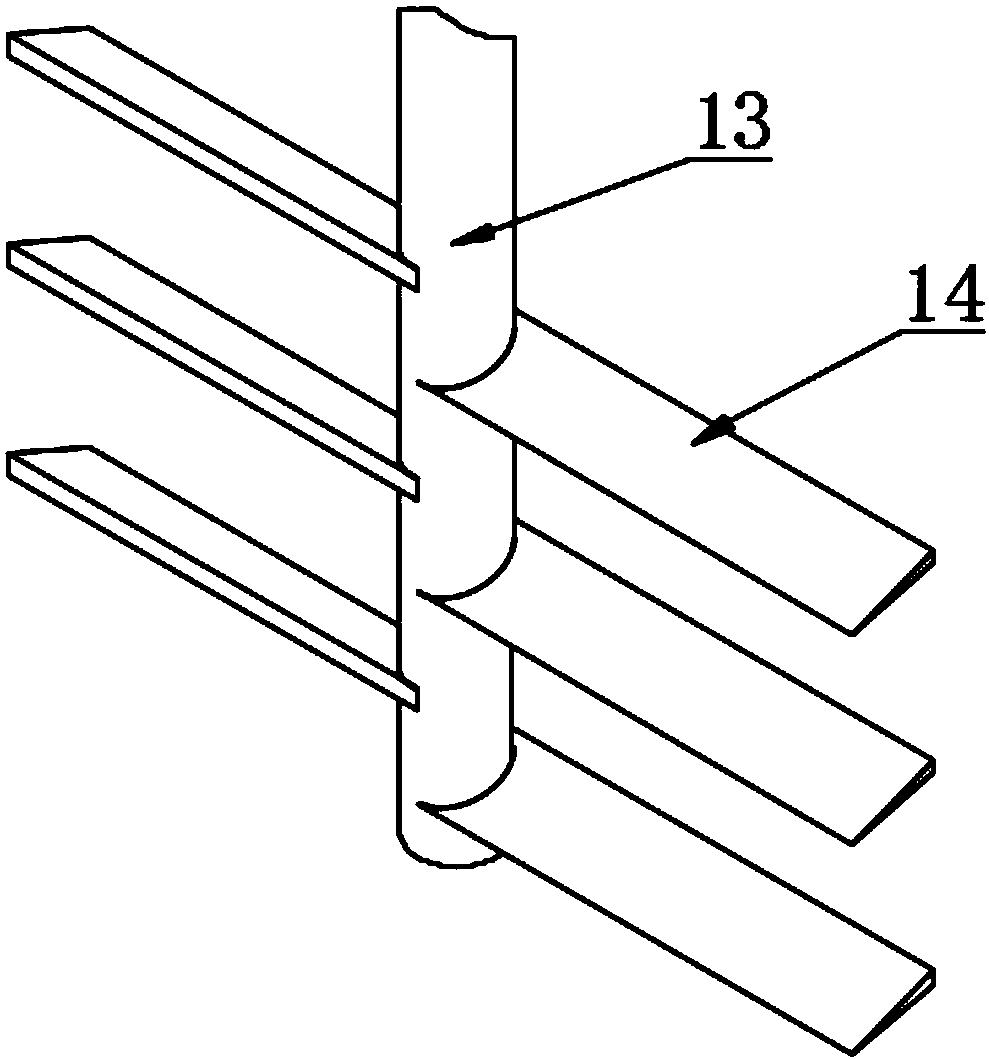

Medical waste processing device with circulatory function

The invention discloses a medical waste processing device with a circulatory function. The medical waste processing device comprises a base, the top of the base is separately and fixedly provided witha disinfection fluid box and a working box through a support, wherein the working box is located above the disinfection fluid box, the lower right corner of the working box communicates with the topright corner of the disinfection fluid box through a liquid feeding pipe. A shower nozzle is fixedly arranged on the left side of the inner top wall in the working box, the water inlet end of the shower nozzle is connected with a liquid inlet pipe, the water inlet end of the liquid inlet pipe passes through the top wall of the working box and the top wall of the disinfection fluid box to be connected with the inner bottom of the disinfection fluid box, and the liquid inlet pipe is further connected with a water pump. A motor is fixedly arranged at the center of the top of the working box, a motor shaft at the bottom end of the motor passes through the top of the working box and is fixedly connected with a rotating shaft, and the rotating shaft is fixedly connected with a plurality of smashing blades. According to the medical waste processing device with the circulatory function, the medical waste is disinfected by spaying disinfection fluid, and germs are effectively prevented from being spread; and the medical waste is smashed by the smashing blades, the medical waste and the disinfection fluid are mixed completely, and the disinfection effect is ensured.

Owner:HUNAN HUIXUN ENTERPRISE MANAGEMENT CO LTD

Chlorine fixing agent suitable for waste derived fuel, and preparation method and application thereof

The invention aims to provide a chlorine fixing agent suitable for reducing chloride emission in combustion gas of tail gas waste derived fuel. The chlorine fixing agent comprises the following components of acetylene sludge, fly ash and exciting agent in percentage of (60-80): (15-30): (3-10) by weight. With the adoption of the chlorine fixing agent, the purpose of treatment of wastes with processes of wastes against one another is realized; the waste is extruded into waste gas waste derived fuel at normal temperature under normal pressure, and the energy consumption is low; the volatilization rate of S-element and Cl-element are reduced greatly, so the chlorine fixing agent is beneficial for the waste combustion treatment; and the inflaming property of the waste is reduced. The waste derived fuel prepared by the preparation method has high compressive strength, and is suitable for the subsequent use of the waste derived fuel in combustion furnace and gasification furnace.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Respirator having preloaded nose clip

InactiveCN101247858APrevent deviationEasy to manufactureBreathing filtersProtective garmentNasal bridgePhysical medicine and rehabilitation

The invention discloses a respirator including a mask body and a nose clip. The mask body is adapted to fit over a person's nose and mouth, and the nose clip is positioned on the mask body such that the nose clip extends over the bridge of the wearer's nose when the mask is worn. The nose clip has a predetermined shape including first and second wings. When the mask is worn, these wings elastically exert forces on each side of the inner wearer's nose. The present invention eliminates the need for the wearer to individually adjust the shape of the nose clip to fit the wearer's nose.

Owner:3M INNOVATIVE PROPERTIES CO

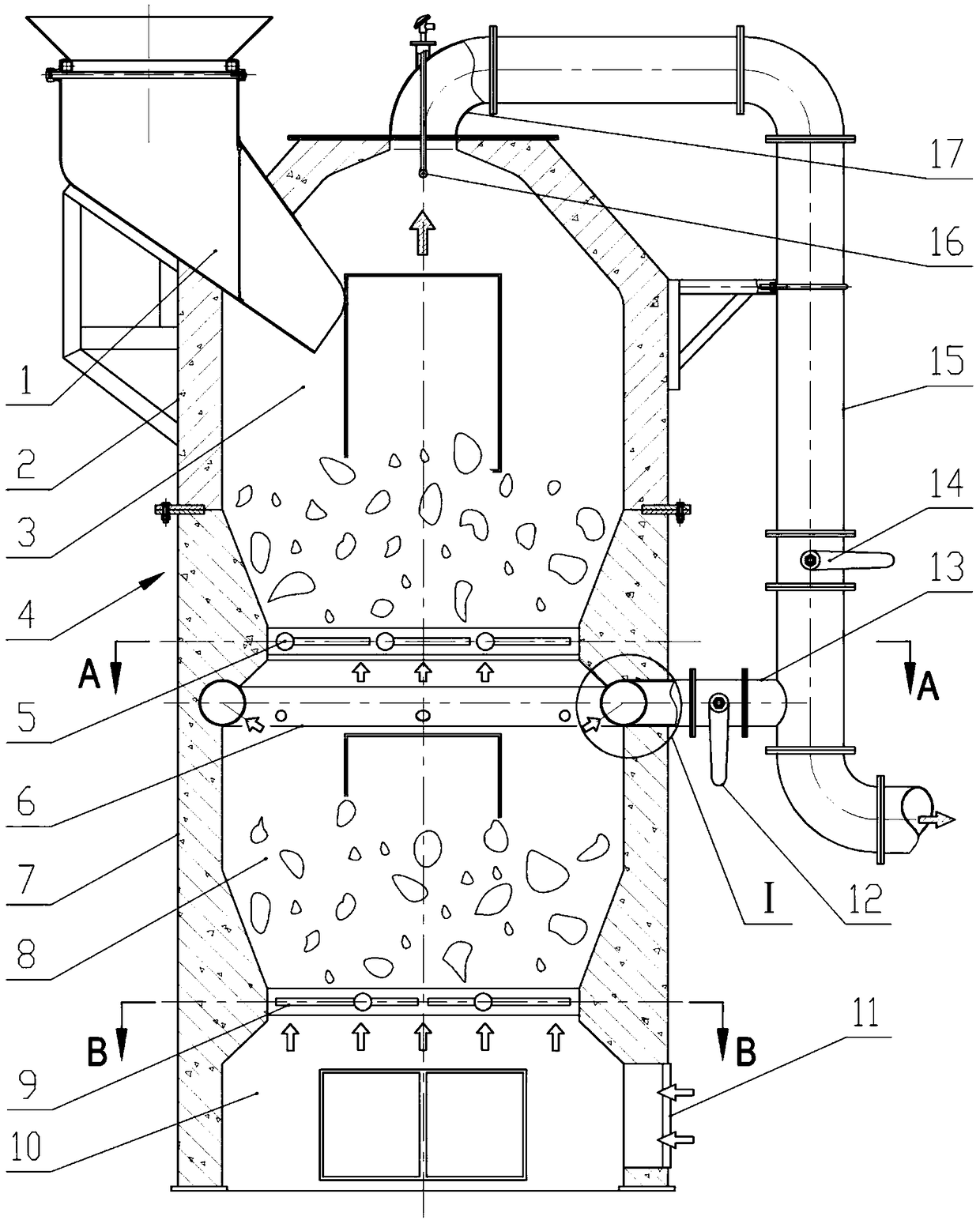

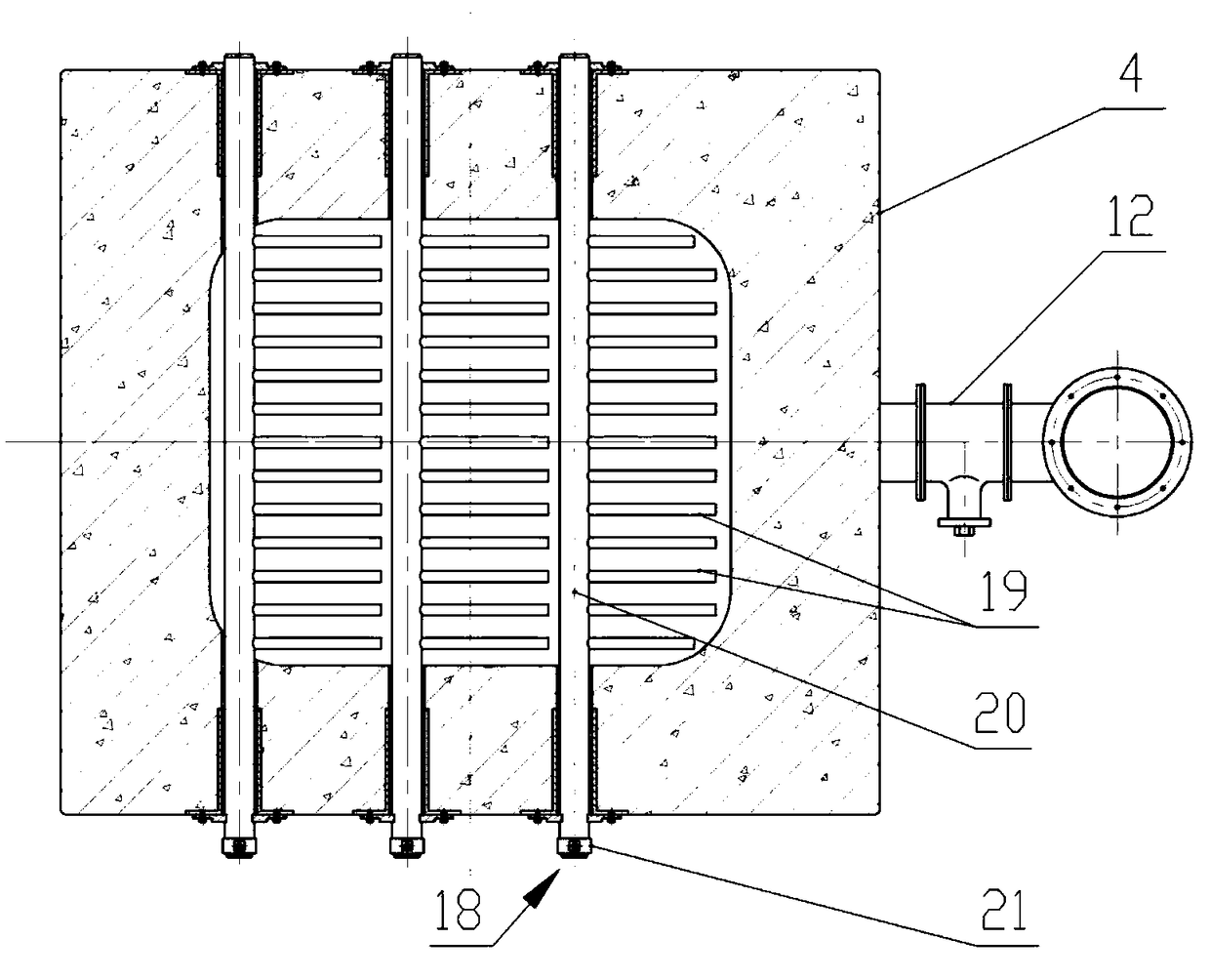

Sectional type small-sized garbage incinerator

The invention relates to a sectional type small-sized garbage incinerator which comprises an incinerator body. An upper fire grate assembly and a lower fire grate assembly are arranged inside the incinerator body and divide an inner cavity of the incinerator body into three parts including an upper hearth, a lower hearth and an ash pit in sequence from top to bottom. A circular air guide pipe is arranged on the inner side wall of the portion, above the lower hearth, of the incinerator body. Garbage enters the upper hearth, is dried through high-temperature smoke generated by the lower hearth and then enters the lower hearth for combustion. By controlling the smoke flow of the upper hearth and controlling the garbage drying process accordingly, uncontrollable combustion of the garbage in the drying process is avoided. According to the incinerator, garbage is dried at first and then incinerated, so that the garbage combustion process is improved, and the incinerator has better adaptability to garbage with high moisture content and low heat value.

Owner:株洲中车南方环保科技有限公司

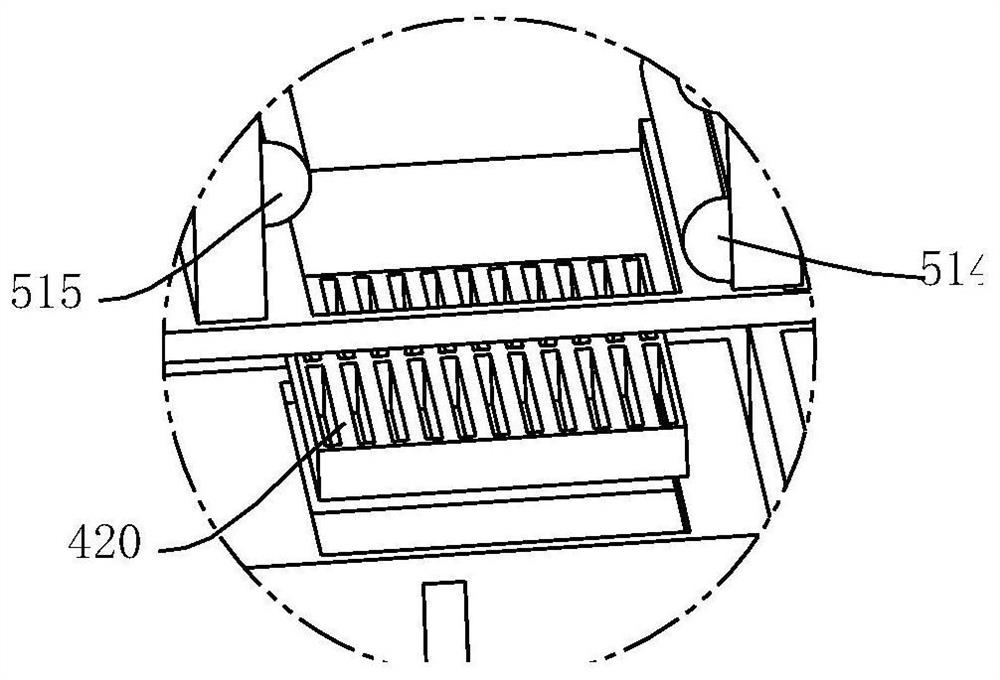

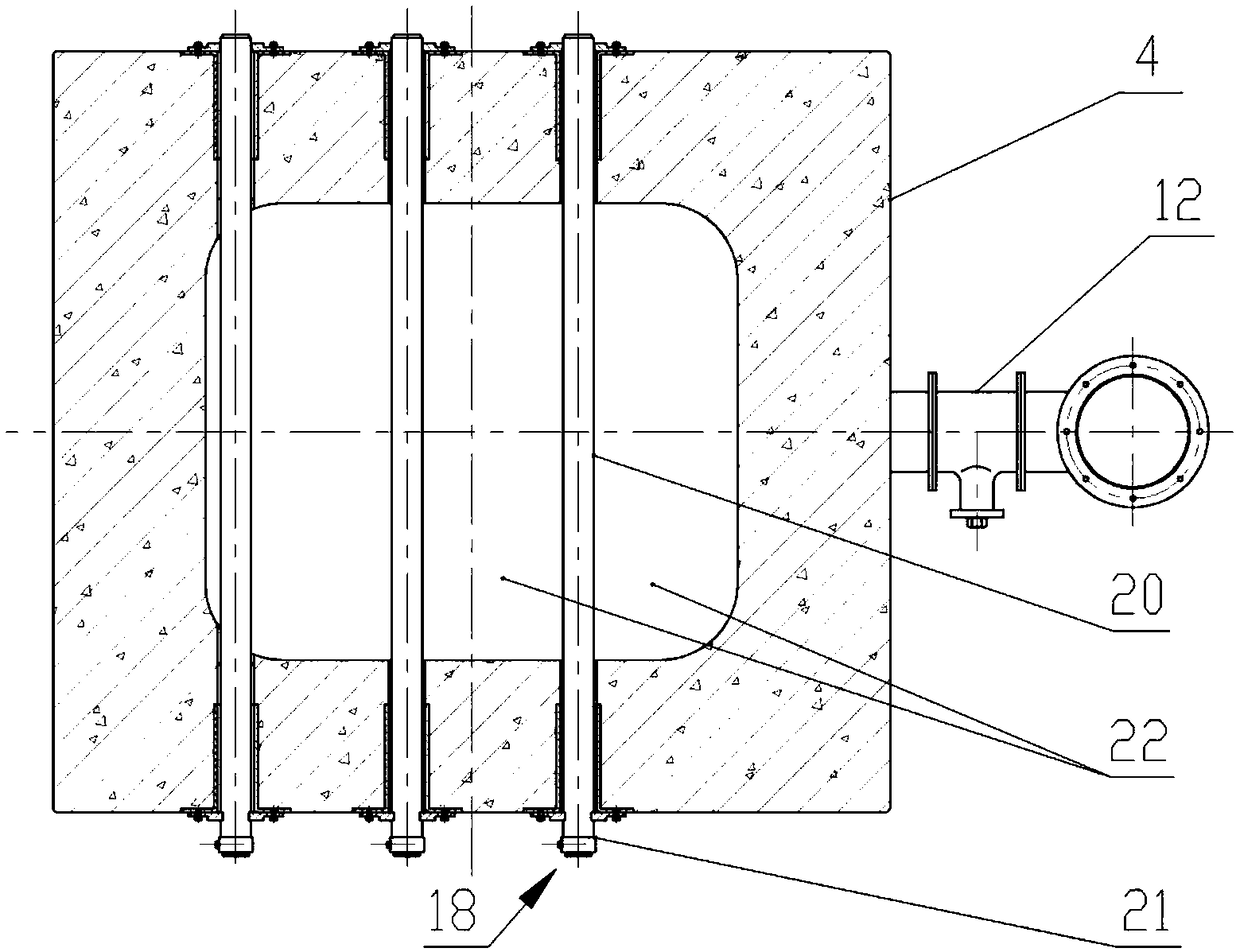

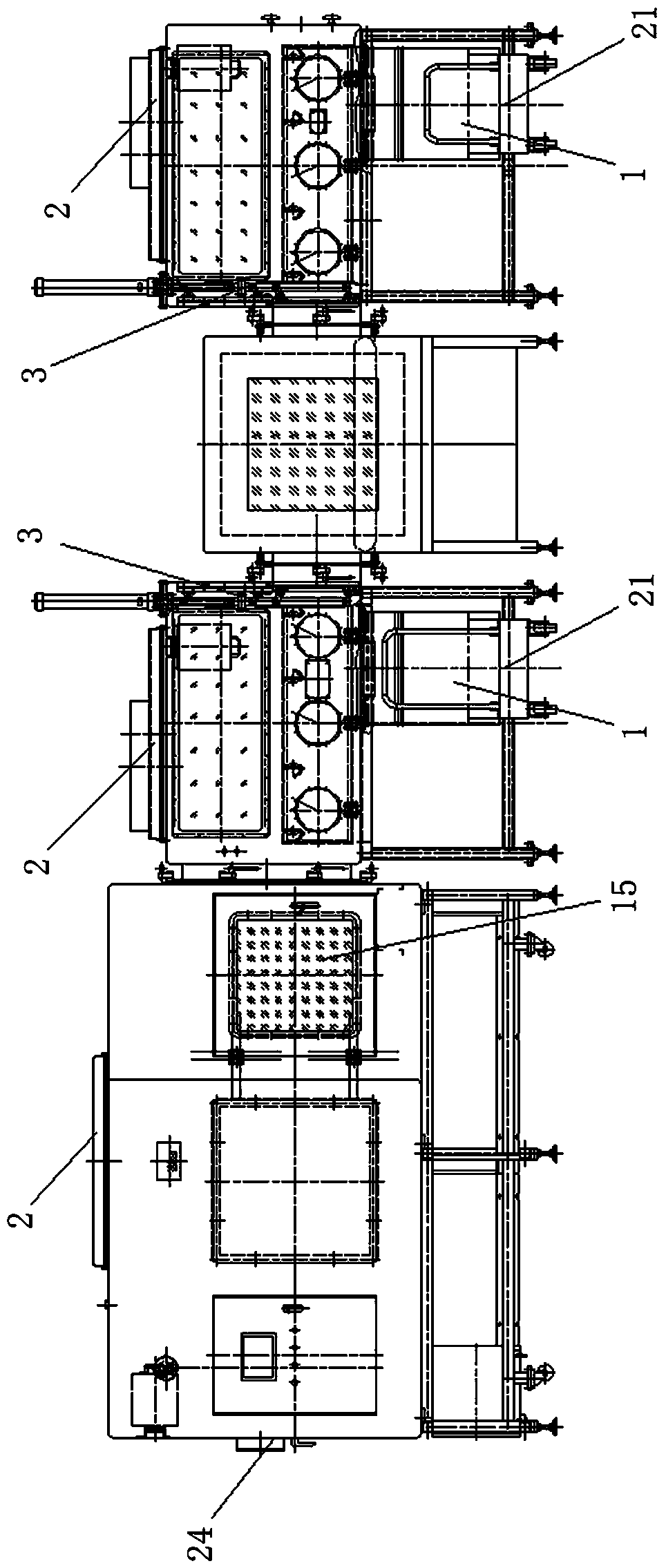

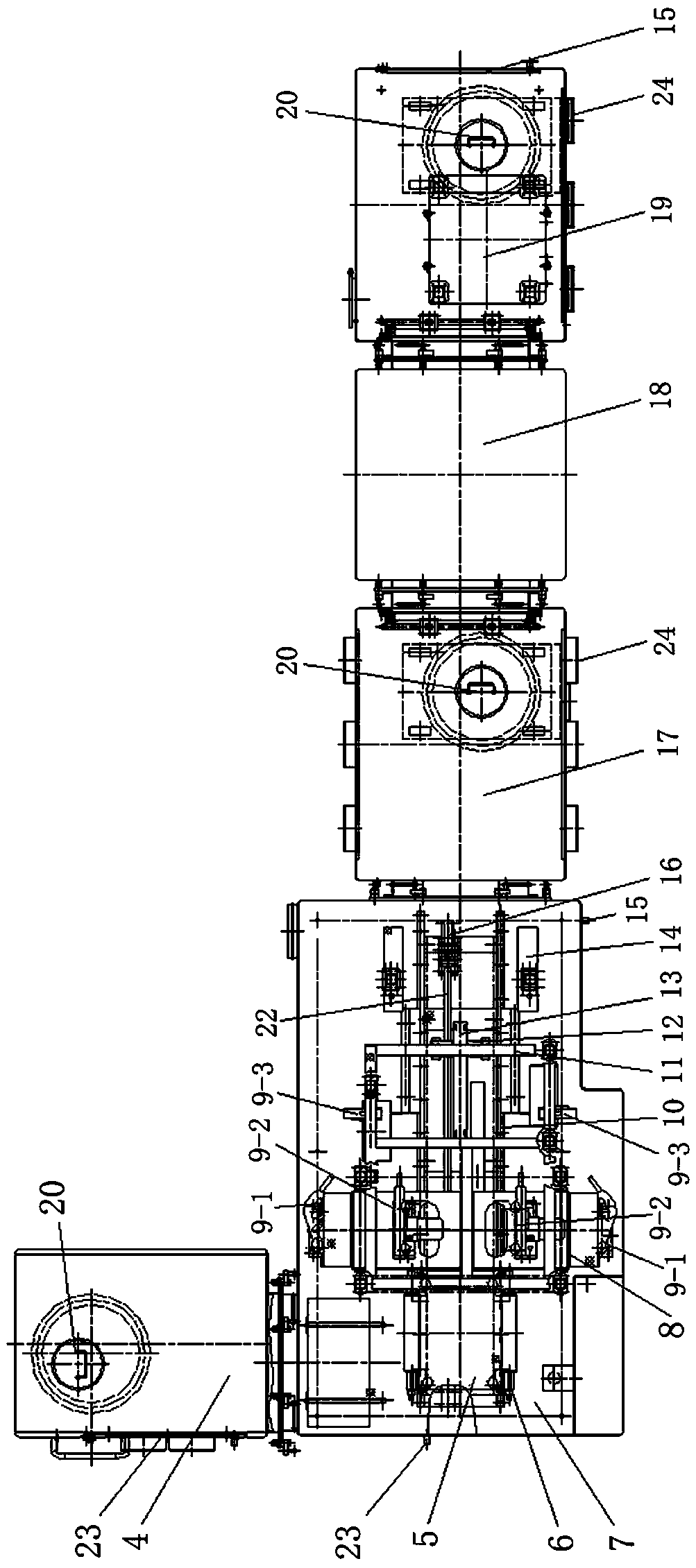

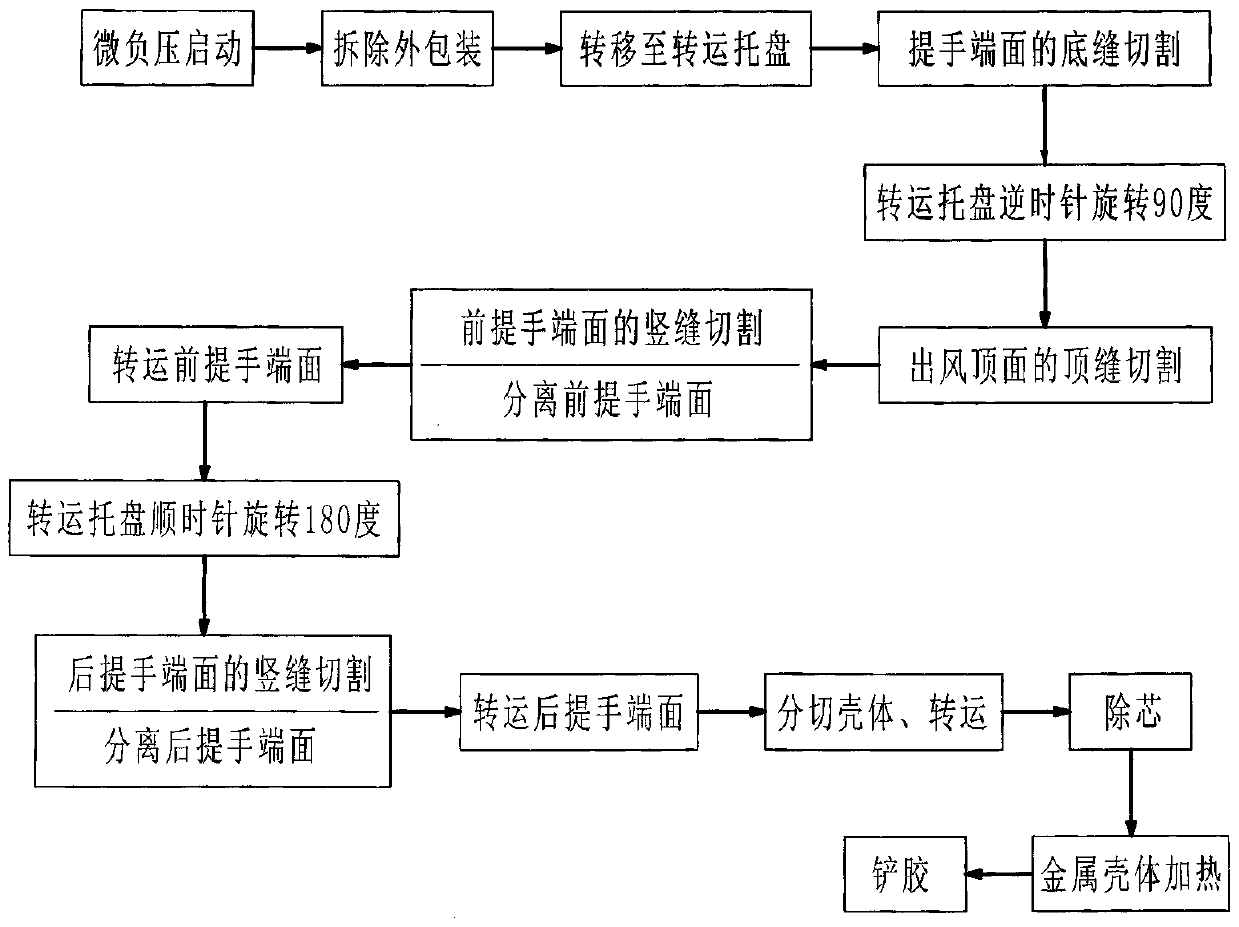

Device and method for disassembling low-radioactivity gather type waste filter

PendingCN107812781AGuaranteed safe collectionCause secondary pollutionSolid waste disposalPlastic recyclingAgricultural engineeringWaste treatment

The invention discloses a device and method for disassembling a low-radioactivity gather type waste filter. The low-radioactivity gather type waste filter to be disassembled is placed into a disassembling system, after an outer package is removed, a bottom seam cutting machine, a top seam cutting machine, a vertical seam cutting machine and a transfer tray are cooperated for carrying out bottom seam cutting on the front handle end face, top seam cutting on the air exhaust top face, vertical seam cutting on the front handle face and vertical seam cutting on the rear handle face of a metal shellof the low-radioactivity gather type waste filter, the front handle face and the rear handle face are separated in first batch, a core is recycled after cut, and the metal shell and glue attached tothe metal shell are heated in a tunnel type drying oven and subjected to glue shoveling treatment through a glue shoveling negative pressure ventilation cabinet to be classified and recycled. The gather type waste filter can be disassembled before waste treatment, meal materials and nonmetal materials are classified, and the device and method have the advantages of being high in automation degree,high in efficiency, safe and environmentally friendly, saving energy and the like.

Owner:HENAN HEJING CLEANING TECH

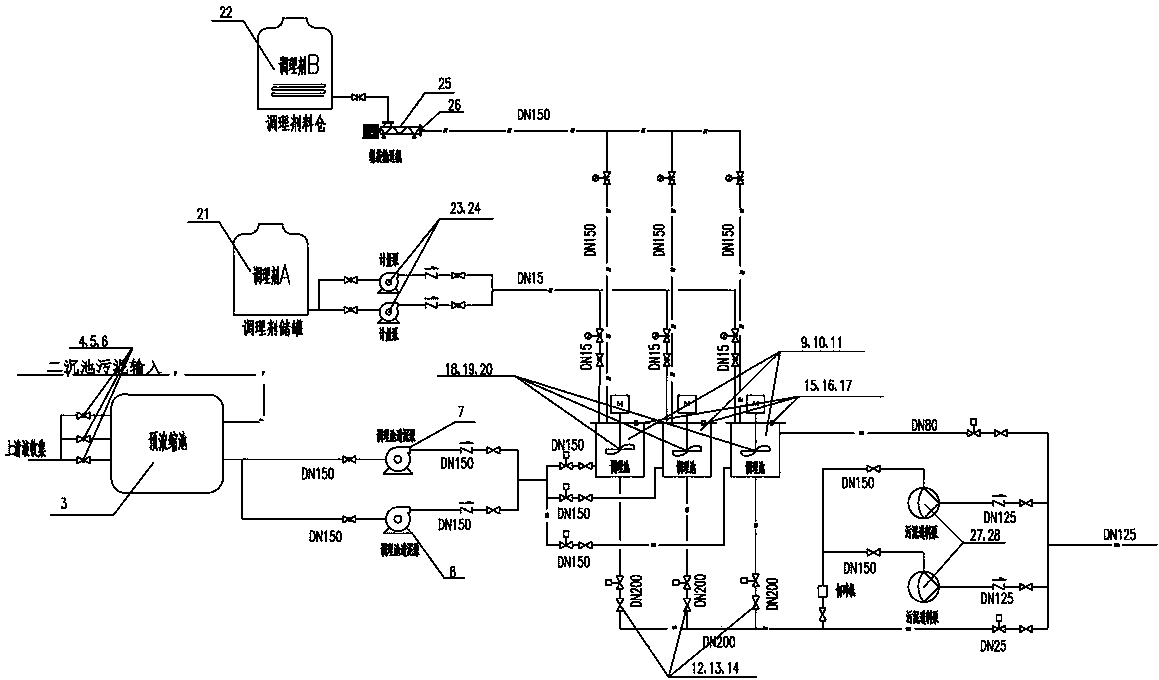

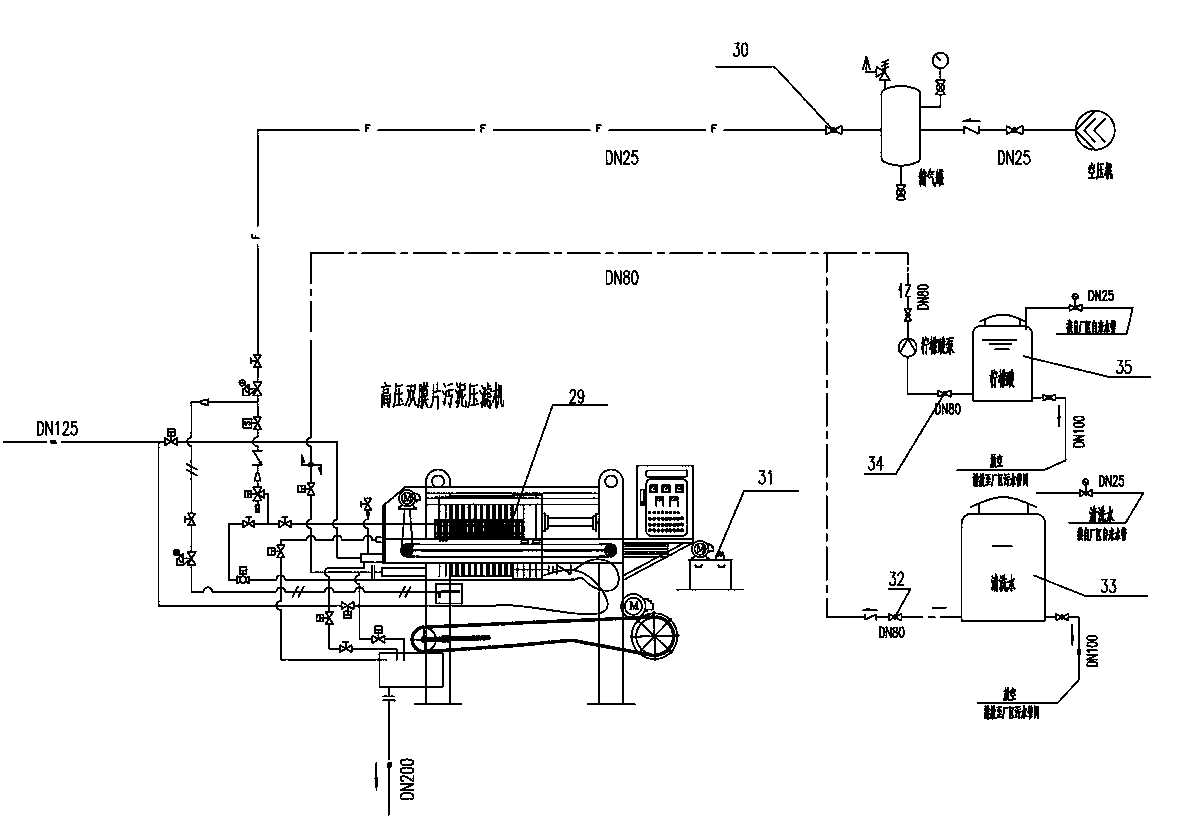

Efficient automatic control method for sludge deep dehydration

ActiveCN104386899AImprove processing efficiencyGuaranteed uptimeSludge treatment by de-watering/drying/thickeningProgramme control in sequence/logic controllersAutomatic controlSludge

The invention discloses an efficient automatic control method for sludge deep dehydration. The method comprises the following steps: a sludge preconcentration control step, a sludge hardening and tempering control step, a filter press control step and a mud cake transmission control step. The system is provided with two modes, namely automatic control and manual control. Under automatic control, the system operates automatically according to preset parameters. Under manual control, various links can be controlled and adjusted. Dehydrated sludge processed by the system is shaped as solidified clumps, has no percolate, has no obvious foul smell and is beneficial to further disposal such as landfill, burning, land utilization and the like. According to the invention, treatment efficiency and safety of the sludge dehydration system are enhanced, and manpower is saved.

Owner:江苏道科环境科技有限公司

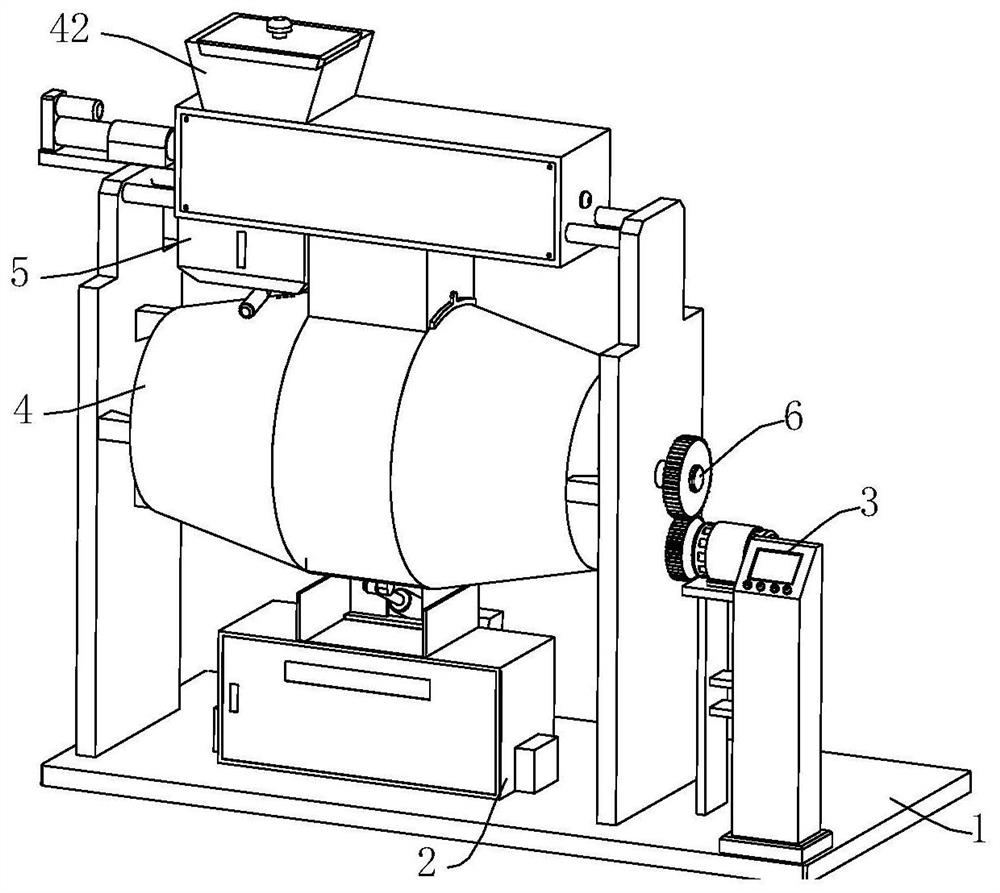

Environment-friendly wet waste disposal and recovery device

PendingCN111623604AAvoid missingImprove the efficiency of entering the processing bucketDrying solid materials with heatDrying solid materials without heatSewageRefuse Disposals

The invention relates to the field of organic waste disposal devices, in particular to an environment-friendly wet waste disposal and recovery device and working method. The environment-friendly wet waste disposal and recovery device comprises a base and a collection box, as well as a controller, a disposal barrel, a dewatering mechanism and a drying mechanism; the top of the disposal barrel is provided with a material falling channel, and the top of the material falling channel is fixedly connected with a rectangular box body; the dewatering mechanism comprises a sewage tank and an extrusionassembly, and the drying mechanism is arranged in the disposal barrel, and used for drying crushed wet waste; and the drying mechanism comprises a rotating shaft, a crushing assembly and two heating assemblies, and the extrusion assembly, the crushing assembly and the heating assemblies are connected with the controller electrically. According to the environment-friendly wet waste disposal and recovery device and the working method, during extrusion of water in waste, the water does not remain in the device, thereby benefiting subsequent crushing; and meanwhile, the waste can be dried fully.

Owner:郭弘

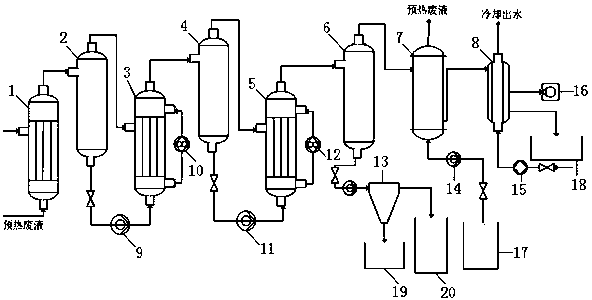

Treatment system for high-salt high-concentration organic wastewater and method

ActiveCN107601742AAvoid melting and cokingAvoid cloggingDispersed particle filtrationWater contaminantsHigh concentrationEvaporation

The invention relates to a treatment system for high-salt high-concentration organic wastewater and a method. The system comprises an evaporation concentration unit, an electrocatalytic oxidation unitand a burning unit, wherein the evaporation concentration unit comprises an evaporation concentrator, a separator, a preheater, a condenser, a vacuum pump and a conveying pump; the electrocatalytic oxidation unit comprises a direct current power supply, a circulating cylinder, an electrocatalytic oxidation tank and a drug dosing system; the burning unit comprises a low-temperature burning chamber, a high-temperature burning chamber, a waste heat recovering device and a tail gas purifying device. The invention also provides a treatment method for the high-salt high-concentration organic wastewater. According to the invention, the characteristics of evaporation concentration method, electrocatalytic oxidation method and burning method are combined, the treatment efficiency for the high-salthigh-concentration organic wastewater is high, the adaptability to the concentration change of the wastewater is high, the treatment cost is low and the requirement of wastewater emission after reaching standard is met.

Owner:湖南绿网环保科技有限责任公司

Sludge dehydration and conditioning system and method

PendingCN106746480AWon't wasteEfficient use ofWater treatment parameter controlSludge treatment by de-watering/drying/thickeningFailure rateSludge

The invention discloses a sludge dehydration and conditioning system. The system comprises a conditioning pool, a sludge entering module, a conditioner adding module and a sludge output module; the conditioning pool is connected to the sludge entering module, the conditioner adding module and the sludge output module; the upper portion of the conditioning pool is provided with a sludge inlet and a conditioner adding opening, the lower portion of the conditioning pool is provided with a sludge outlet, the interior of the conditioning pool is provided with a stirrer, and the conditioning pool comprises a closed conditioning pool top; the sludge entering module comprises a flowmeter, and the conditioner adding module comprises an agent storage tank and a weight calculation unit. The invention further discloses a sludge conditioning method. The method comprises the steps of firstly conveying sludge to the conditioning pool, then calculating an average moisture content of the entered sludge, and calculating absolutely dry mud quantity in the conditioning pool, and setting conditioner adding quantity; secondly completing sludge conditioning ; finally conveying the sludge. According to the sludge dehydration and conditioning system and method, the sludge outlet effect is good, meanwhile the agent cannot be wasted, the obtain dehydration sludge through treatment facilitates disposition of backfilling, incineration, land utilization and the like, and equipment in all links operates efficiently and stably, is low in failure rate and high in safety, and greatly saves manpower and material resources.

Owner:江苏道科环境科技有限公司

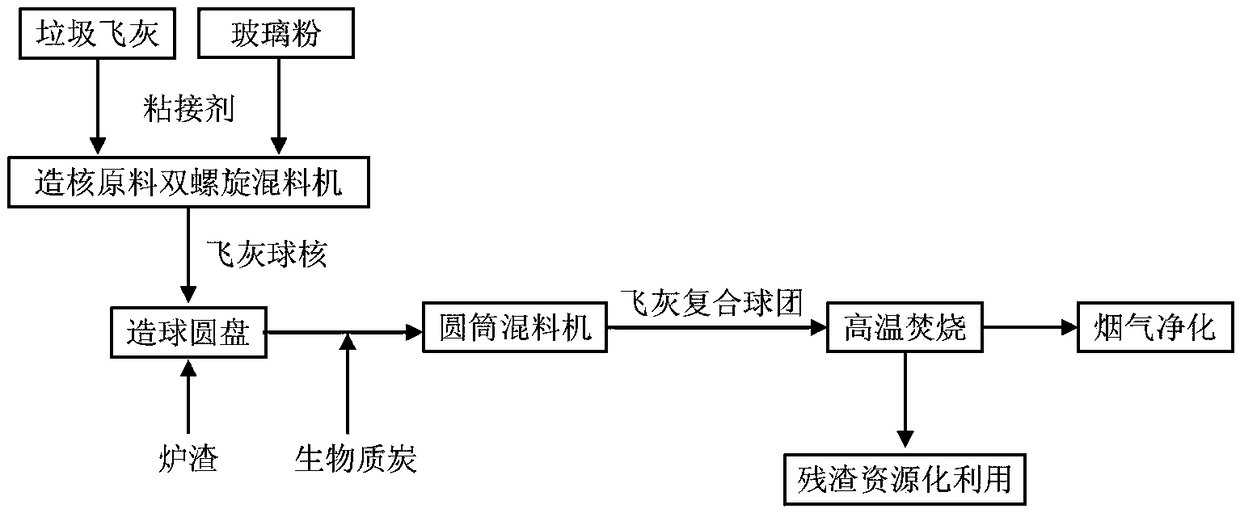

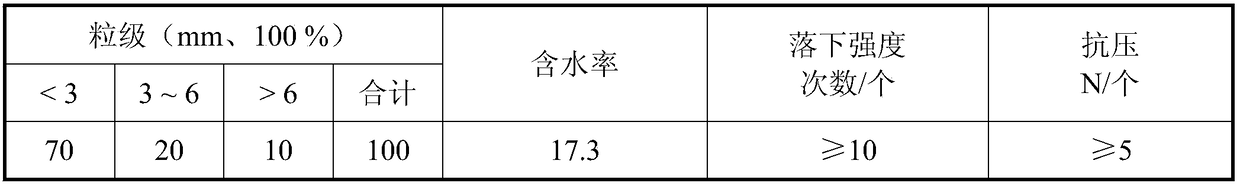

Garbage incineration fly ash high-temperature melting innocuous treatment process

ActiveCN109404916AShorten and simplify the balling processRealize nearby processingIncinerator apparatusBiomass carbonSlag

The invention relates to a garbage incineration fly ash high-temperature melting innocuous treatment process. The garbage incineration fly ash high-temperature melting innocuous treatment process comprises the steps that (1) garbage fly ash and glass powder are mixed to prepare fly ash ball cores; (2) fly ash composite pellets are obtained by adding slag to coat the surfaces of the ball cores; (3)the fly ash composite pellets are mixed with biomass carbon to obtain mixtures; and (4) the mixtures are directly accessed into an incineration device of an existing garbage incineration plant for high-temperature incineration, flue gas generated by incineration is purified by flue gas purification equipment of the garbage incineration plant, and incineration residue is subjected to residue treatment. According to the garbage incineration fly ash high-temperature melting innocuous treatment process, only the garbage fly ash and the glass powder are adopted to prepare the ball cores, the ballcores are coated with slag substances, and the obtained composite pellets are mixed with biomass carbon particles to form the mixtures, so that the ball forming process of the garbage fly ash is shortened and simplified, solid melting of heavy metals in the fly ash is facilitated, glass melts are formed, and leaching toxicity requirements are met; and meanwhile, the required equipment is less, andthe process is matched with the existing garbage incineration plant for implementation, so that nearby treatment of the garbage fly ash can be realized.

Owner:CHONGQING ANGRUIYUE SCI & TECH +1

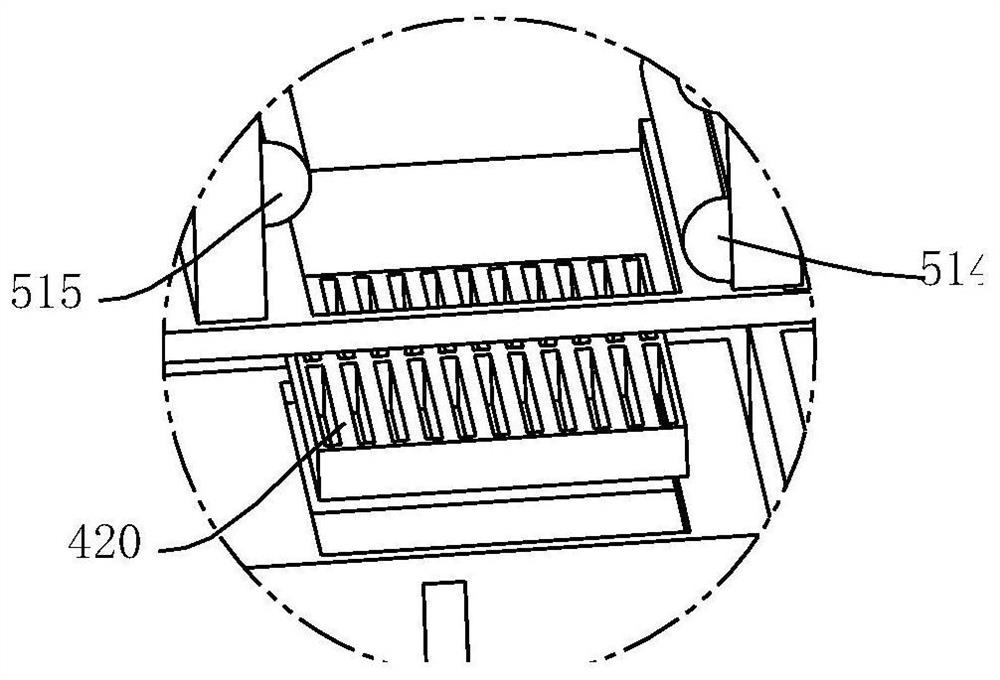

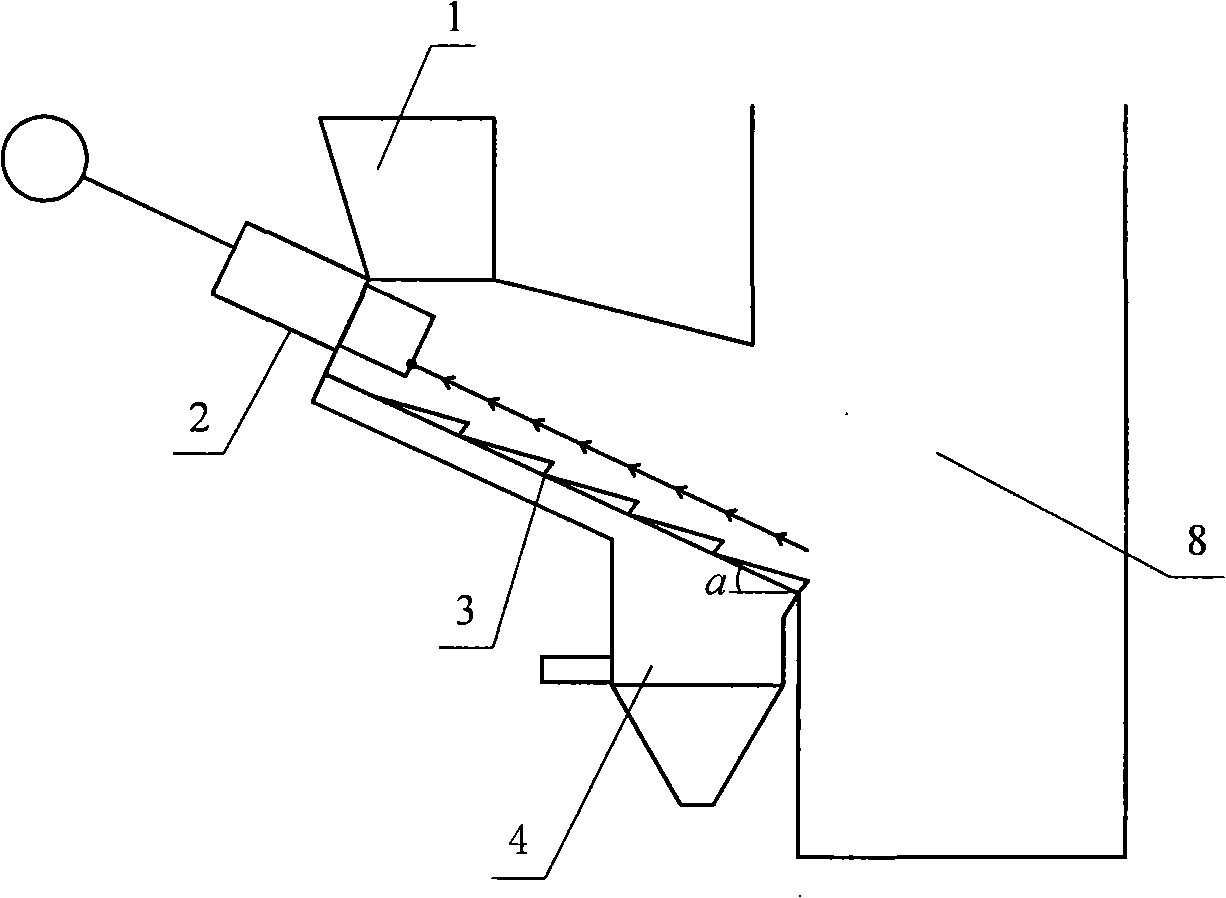

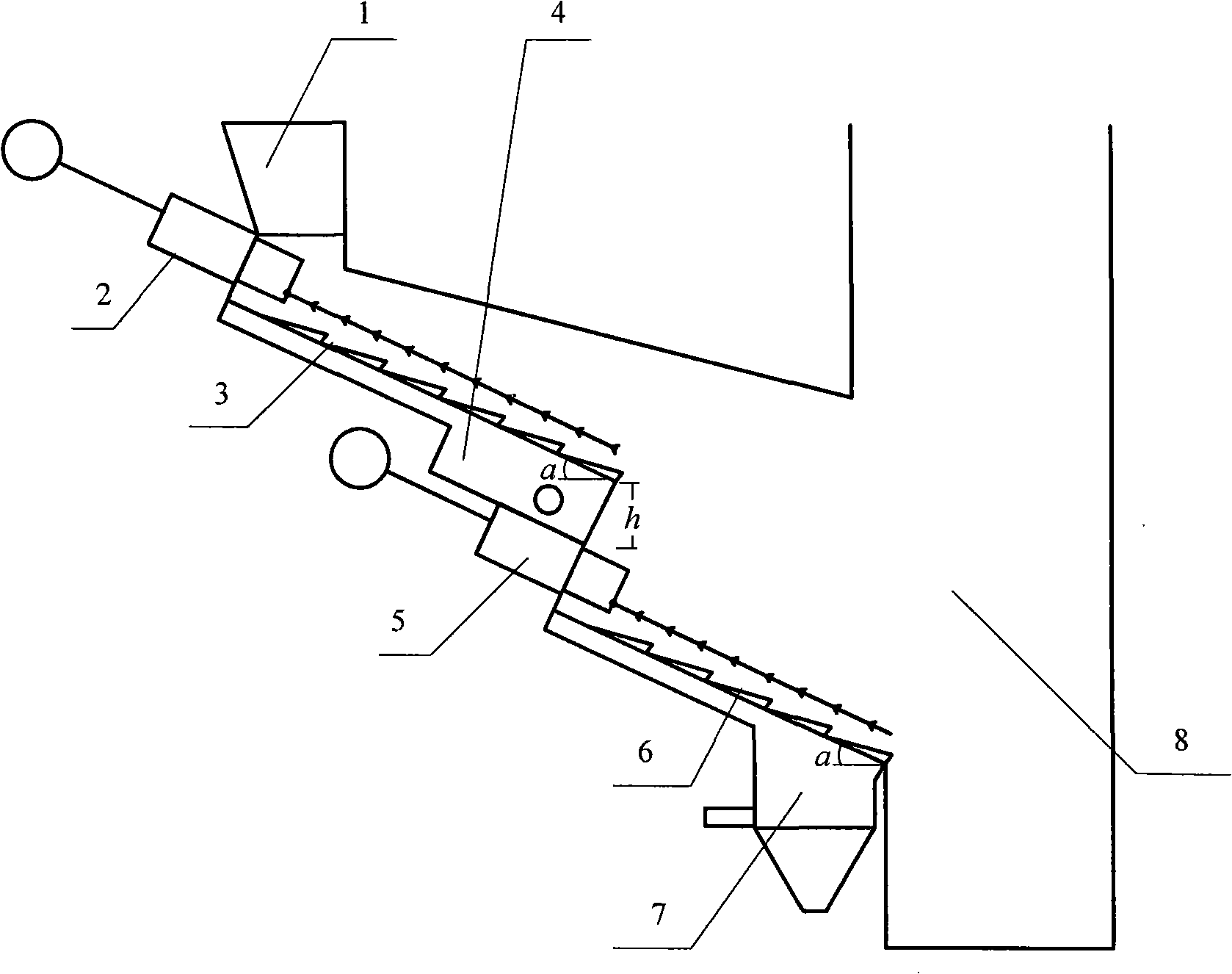

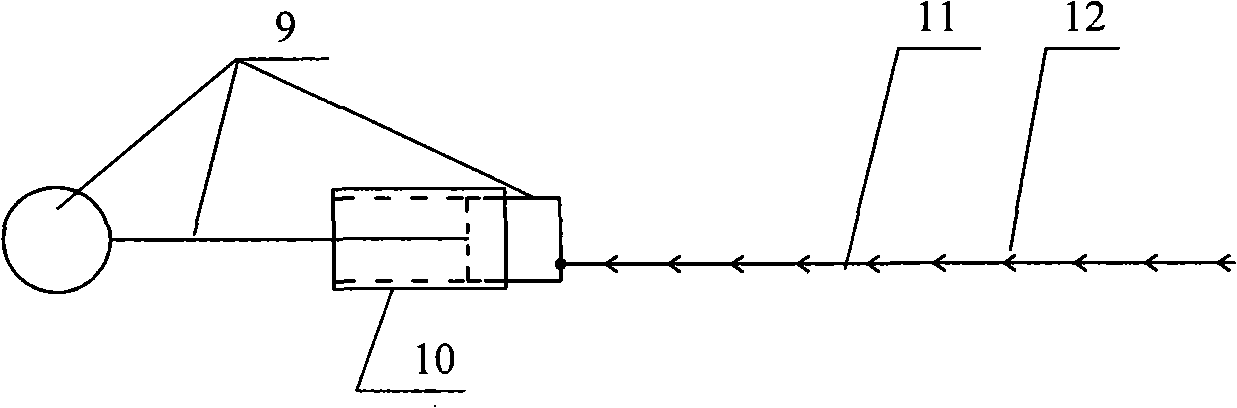

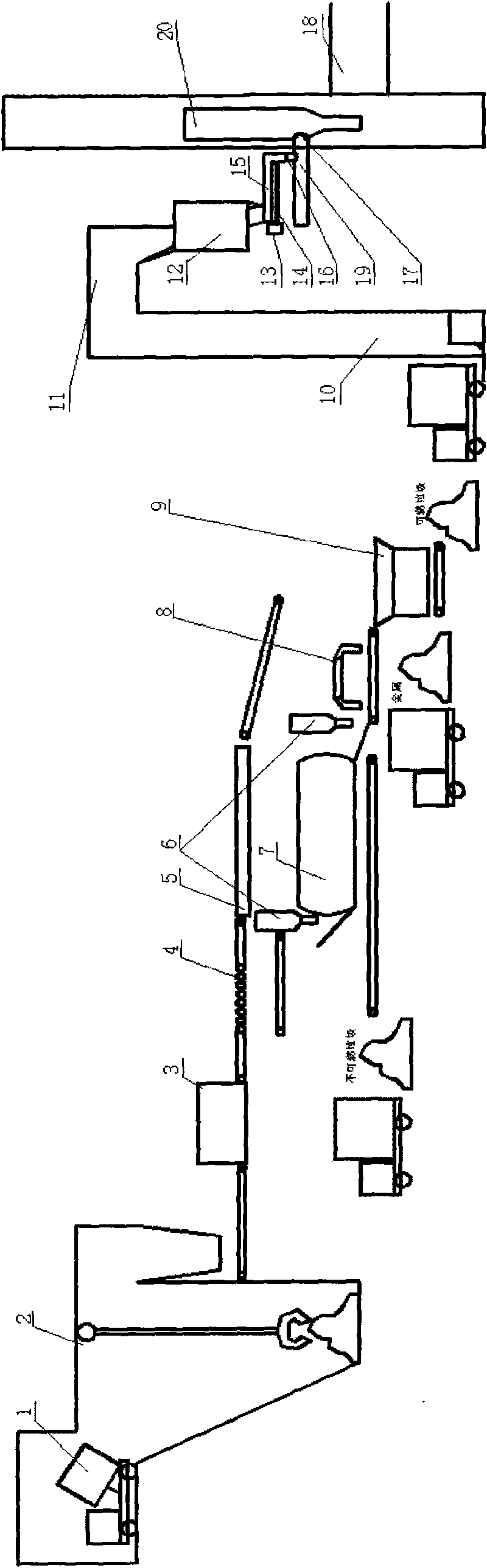

Garbage feeding, prewarming and drying arrangement

InactiveCN101358732ADry evenlyAdvance smoothlyIncinerator apparatusEngineeringMechanical engineering

The present invention relates to a garbage feeding and pre-heating drying device, and belongs to the field of the biomass and renewable energy utilization devices, and comprises a garbage funnel, a material pushing device and a drying bed; wherein, the material pushing device is arranged above the drying bed. The garbage feeding and pre-heating drying device is distributed in one level or two levels; when the device is distributed in two levels, a stage-typed arrangement is formed between the front level and the back level; each level of the device comprises a material pushing device and a drying bed, and the drying bed is of a fixed type; each level of the material pushing device consists of a sliding-block guide-rail reciprocating mechanism, a connection box and a material pushing rod; the material pushing rod is hinged with the sliding block, and the material pushing rod is provided with a reversed-triangle fin. When the flat size of the drying bed is too large, two or more material pushing material devices can be arranged in parallelism. The drying device of the present invention has the advantages that with the material pushing rod, the garbage can be smoothly proceeded on the drying bed, thereby being uneasy to cause the squeezing; the height different exists between the drying bed and the material pushing device, so that the garbage falls down during the proceeding process, thereby realizing the effect of loosening the garbage, therefore, the garbage is dried more uniformly.

Owner:TSINGHUA UNIV

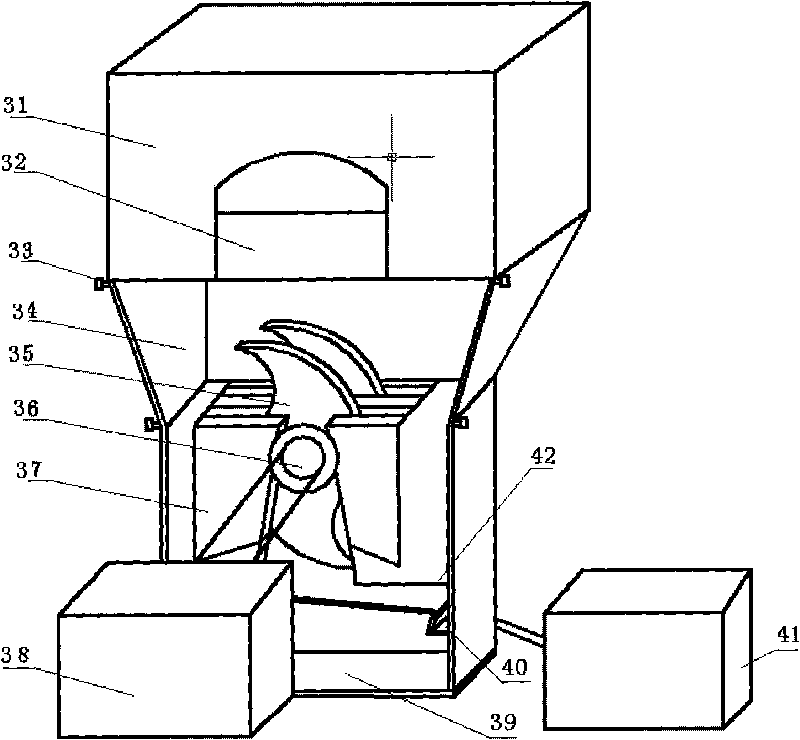

Solid garbage crusher

InactiveCN101502841AReduce pollutionNo manual collectionSolid waste disposalGrain treatmentsPulp and paper industrySolid particle

The invention relates to a solid waste disintegrator, comprising a disintegrator and a squeezer, the case body of the disintegrator is mounted on a mounting frame at both ends of the squeezer so that a discharge hole of the disintegrator can be aligned with a feed hopper of the squeezer, one end of a spiral shaft of the squeezer is connected with a decelerator and the other end thereof is sleeved outside with a dewatering screen drum, one end of the dewatering screen drum is connected with a squeezing pipe via a flange, and a water collecting tank, which is equipped with a water outlet pipe at one side thereof, is arranged below the dewatering screen drum. The invention integrates the disintegrator with the squeezer, the combination is reasonable, the cost is saved and the occupied area is reduced; solid particles disintegrated by the disintegrator are squeezed, dewatered or de-oiled by the spiral squeezer and then subjected to post-treatments such as transporting, incinerating and land-filling of the waste, thus reducing treatment expense, improving working efficiency and reducing labor intensity with the integrated automatic operations,, therefore, the invention is worthy of being popularized and used.

Owner:丁永芝

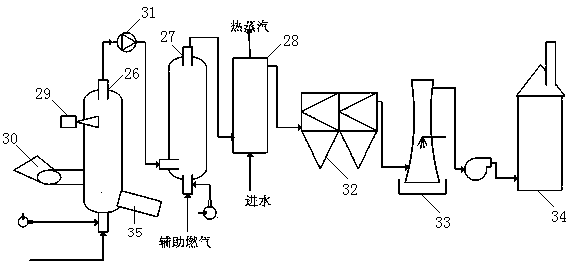

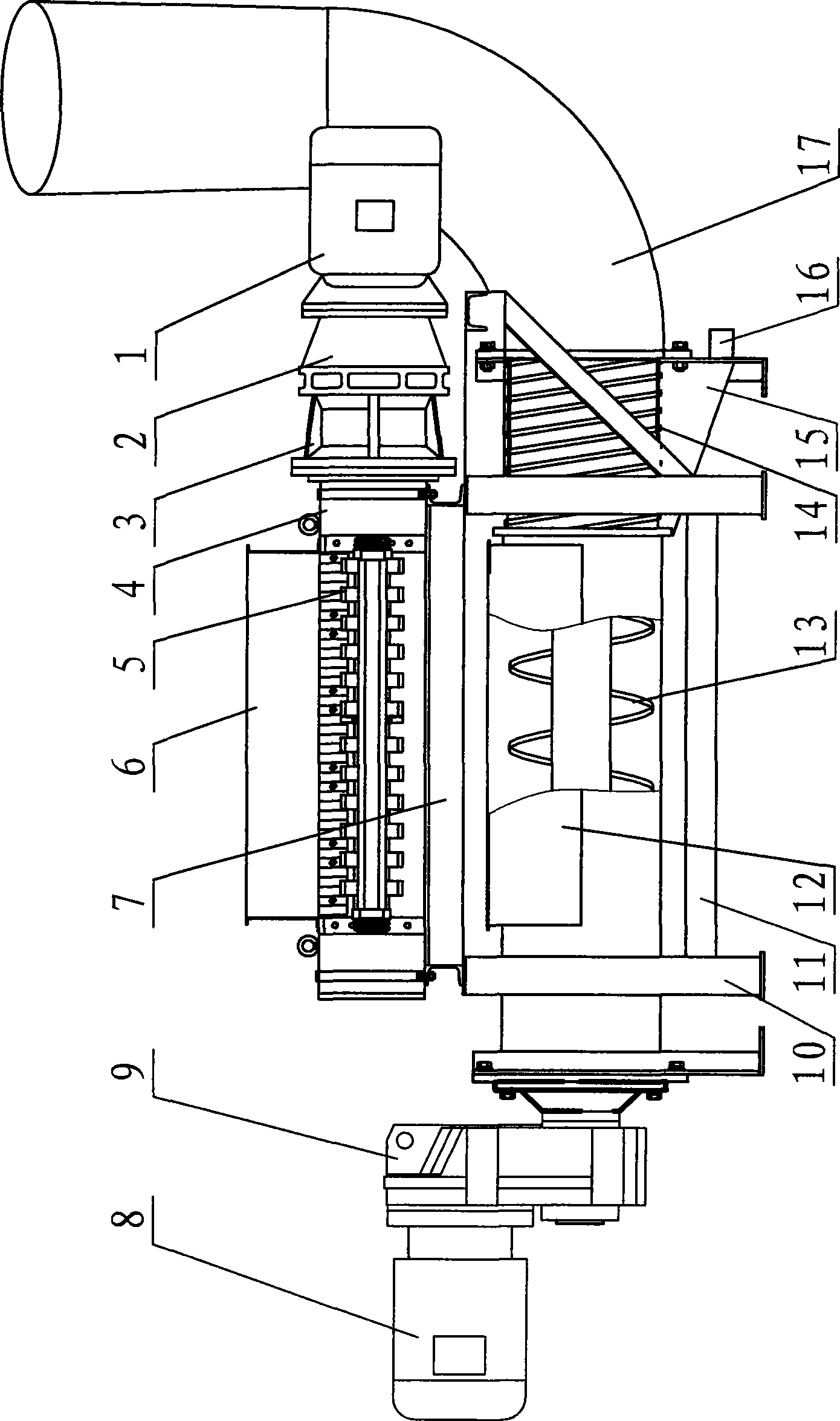

Sludge continuous-heat-treatment modification device and technology of deep dehydrating, drying and incineration

ActiveCN107265821ARealize resource utilizationAvoid it happening againSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningEngineeringTreatment modification

The invention relates to a sludge continuous-heat-treatment modification device and a technology of deep dehydrating, drying and incineration. The sludge continuous-heat-treatment modification device comprises sludge conveying tubes and heat medium spacing casing tubes, wherein the sludge conveying tubes comprises a preheating section, a reacting section and a cooling section, and the sludge conveying tubes of all the preheating section, the reacting section and the cooling section are sleeved by the heat medium spacing casing tubes; the heat medium spacing casing tube of the reacting section communicates with a heat medium heating converter to form a first heat medium circulating loop; the heat medium spacing casing tube of the preheating section communicates with the heat medium spacing casing tube of the cooling section to form a second heat medium circulating loop; and a heat medium heat recovery circulating pump is arranged in the second heat medium circulating loop. The sludge continuous-heat-treatment modification device uses a heat medium to perform indirect heat treatment on sludge and improves the dehydrating property of the sludge, therefore the sludge continuous heat treatment is realized and the recycling use of the heat medium saves more energy and is more friendly to environment at the same time.

Owner:浙江绿治环保技术有限公司 +1

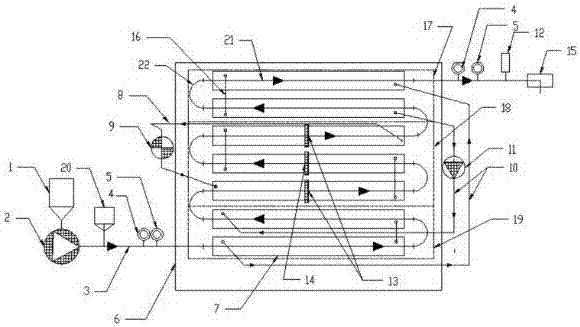

Rotary cement kiln burning method as novel dry method of household garbage

InactiveCN101696807AZero emissionReduce processing costsIncinerator apparatusGrain treatmentsFurnace temperatureCombustion

The invention discloses a rotary cement kiln burning method as a novel dry method of household garbage, which adopts a uniform garbage crusher, a uniform rotary wind-locking feeding machine and garbage container equipment to design a closed garbage sieving workshop. The invention improves the quality effect of garbage classification, packaging, crushing and feed processing, and solves the technical problems of influence on the furnace temperature of a combustion furnace during garbage feeding and insufficient burning caused by garbage accumulation. Clinkers of non-combustible garbage and combustible garbage are used as mixed materials of cement raw materials, and therefore, household garbage is totally treated reasonably. The whole treatment process has zero release and no harmful material, does not cause secondary pollution, and realizes the resourceful and harmless treatment of household garbage.

Owner:席凯帆

Extension and locking assembly for dripless element, and container therefore

InactiveUS20050126983A1Reduce environmental problemsEasy to incinerateMachines/enginesMembrane filtersFiltrationEngineering

A filter assembly includes housing enclosing a replaceable filter element. A support core is provided in the housing, and includes an extension and locking assembly. The element includes a ring of filtration media with a pair of end caps. The first end cap includes a central opening to receive the support core. The extension and locking assembly prevents the cover of the housing from being attached to the housing body without a proper filter element installed. The extension and locking assembly includes a bypass member and a locking member, which are in locking engagement when an element is absent in the housing. The second end cap includes internal protrusions which engage the locking member when the filter element is installed to disengage the bypass member from the support core, and allow the element to be inserted and the cover to be installed.

Owner:PARKER INTANGIBLES LLC

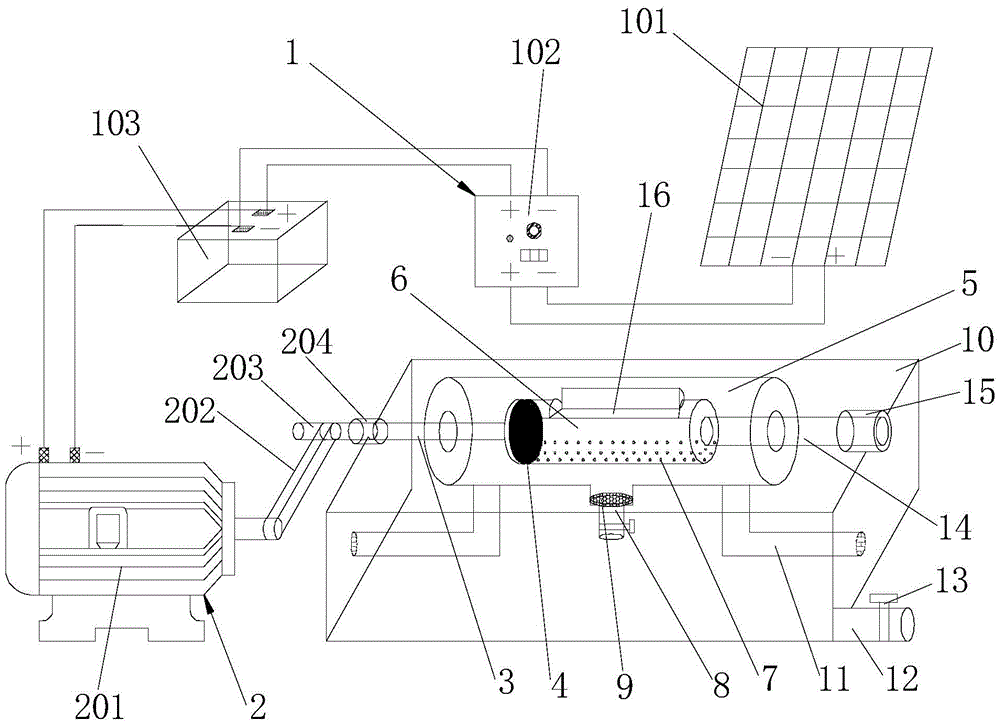

Traditional Chinese medicine residue treatment device based on solar energy

InactiveCN105479796AEasy to incineratePromote fermentationBatteries circuit arrangementsElectric powerEngineeringChinese herbology

The invention discloses a traditional Chinese medicine residue treatment device based on solar energy. The device comprises a power mechanism, a driving mechanism, a push rod, a pressing disc, an outer barrel and an inner barrel; the power mechanism is connected with the driving mechanism, the driving mechanism is connected with one end of the push rod, the other end of the push rod is connected with the pressing disc, and the pressing disc is located in a squeezing chamber in the inner barrel; multiple through holes are formed in the lower side of the inner barrel, and a drainage hole is formed in the lower side of the outer barrel; the power mechanism comprises a solar panel, a pressure regulating module and an accumulator, the solar panel is connected with the accumulator through the pressure regulating module, and the accumulator is connected with the driving mechanism. According to the traditional Chinese medicine residue treatment device, clean solar energy is adopted as energy, traditional Chinese medicine residues placed in the squeezing chamber are squeezed, liquid medicine which is squeezed out is drained through the through holes, flows into the outer barrel and then is drained through the drainage hole for recycling, and the medicine residues dried through squeezing can be incinerated or fermented for utilization conveniently.

Owner:SOUTH CHINA UNIV OF TECH

Recycling system and recycling method for waste liquor produced in separation and purification of organically synthesized feed liquid

InactiveCN104176844AFull recoveryTake advantage ofGeneral water supply conservationMultistage water/sewage treatmentElectricityOrganic synthesis

The invention relates to a recycling system and a recycling method for waste liquor produced in separation and purification of an organically synthesized feed liquid, and belongs to the field of chemical engineering. The recycling system for the waste liquor comprises a filter device, a desalting device and a membrane concentrating device which are arranged from the front to the rear in sequence, or the filter device is replaced with a filtrate collecting slot, wherein the filter device is used for filtering and collecting the waste liquor; the filtrate collecting slot is used for stewing and collecting the waste liquor; the desalting device is used for desalting the collected waste liquor; the membrane concentrating device is used for concentrating a liquid which is desalted by virtue of the desalting device; and the desalting device is preferably an electrodialysis device. According to the recycling system and the recycling method, a membrane separating and concentrating technology, an electrodialysis technology and the like are comprehensively utilized to separate and purify the organically synthesized feed liquid, and the produced waste liquor is sufficiently recycled, the separating and purifying efficiency and the purity and the yield of products are improved, discharge of the waste liquor is reduced, the production industrialization is strong and the cost is low, and thus, the recycling system and the recycling method are especially suitable for being applied in production of iminodiacetonitrile.

Owner:CHONGQING UNISPLENDOUR CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com