Rotary cement kiln burning method as novel dry method of household garbage

A dry-process cement and domestic waste technology, applied in the combustion method, incinerator, combustion type, etc., can solve the problems of incomplete combustion and the effect of incinerator furnace temperature, so as to achieve no secondary pollution, optimized incineration, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

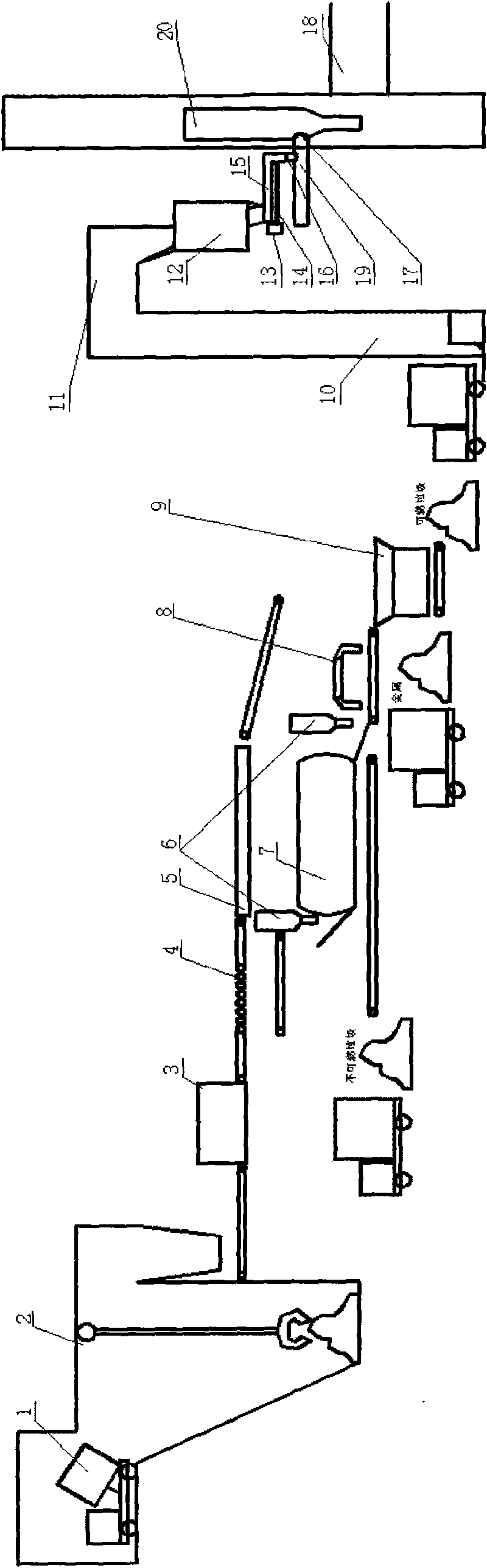

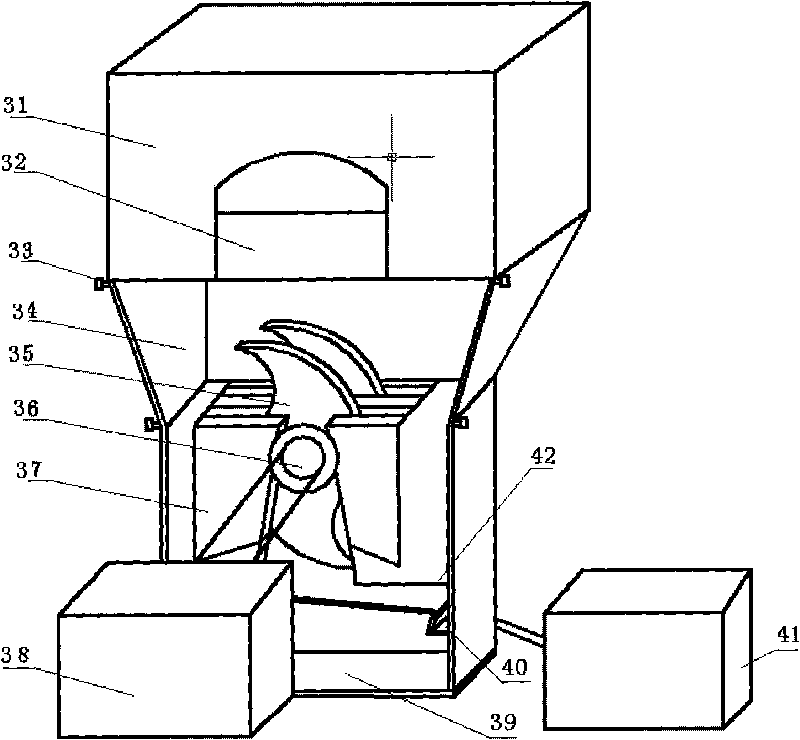

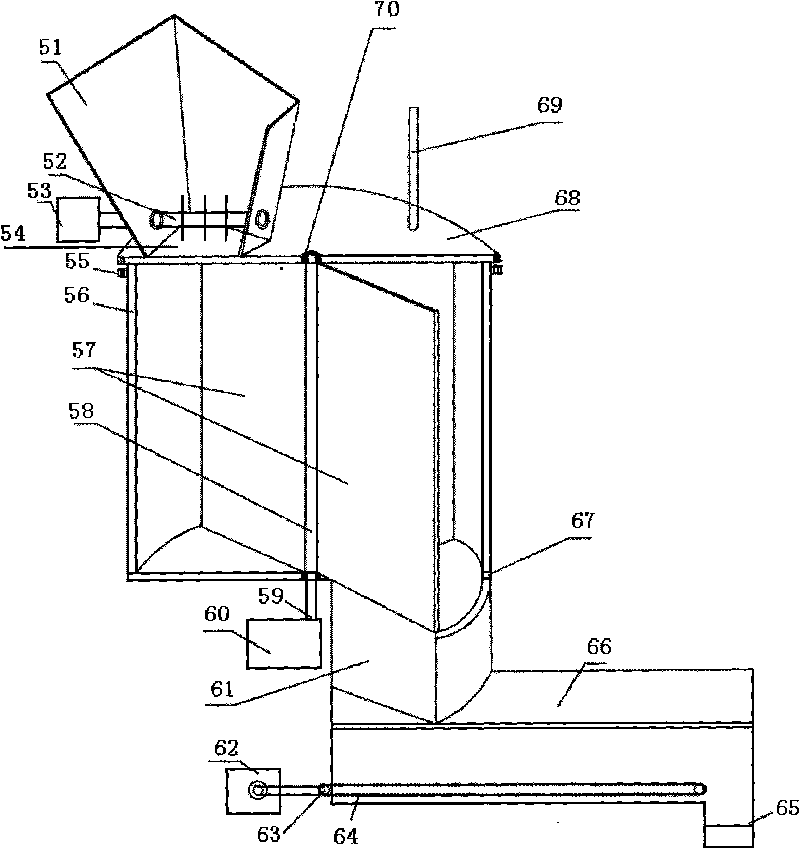

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Garbage is poured into the storage pool from the container 1, grabbed onto the conveyor belt by the driving grab 2, and is processed by the bag breaking machine 3. Garbage passes through the roller sieve 4, and bulky garbage is sieved out, and is transported to the cutting platform 5 for cutting. The remaining small pieces of garbage are conveyed by the conveyor belt, and are sprayed with deodorant by the deodorizing sprayer 6 and enter the drum screen 7 for screening, and the non-combustible garbage is screened out and transported by the conveyor belt into the container 1 for transportation to the designated The platform is treated as cement raw material. The combustible garbage is sprayed with a deodorant by a deodorizing sprayer 6, and the metals therein are selected by a magnetic separator 8 for recycling. The combustible garbage sieved by the trommel 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com